Patents

Literature

77 results about "Methyl radical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methyl (also systematically named trihydridocarbon) is an organic compound with the chemical formula CH•₃ (also written as [CH₃]•). It is a metastable colourless gas, which is mainly produced in situ as a precursor to other hydrocarbons in the petroleum cracking industry. It can act as either a strong oxidant or a strong reductant, and is quite corrosive to metals.

Organic working fluids

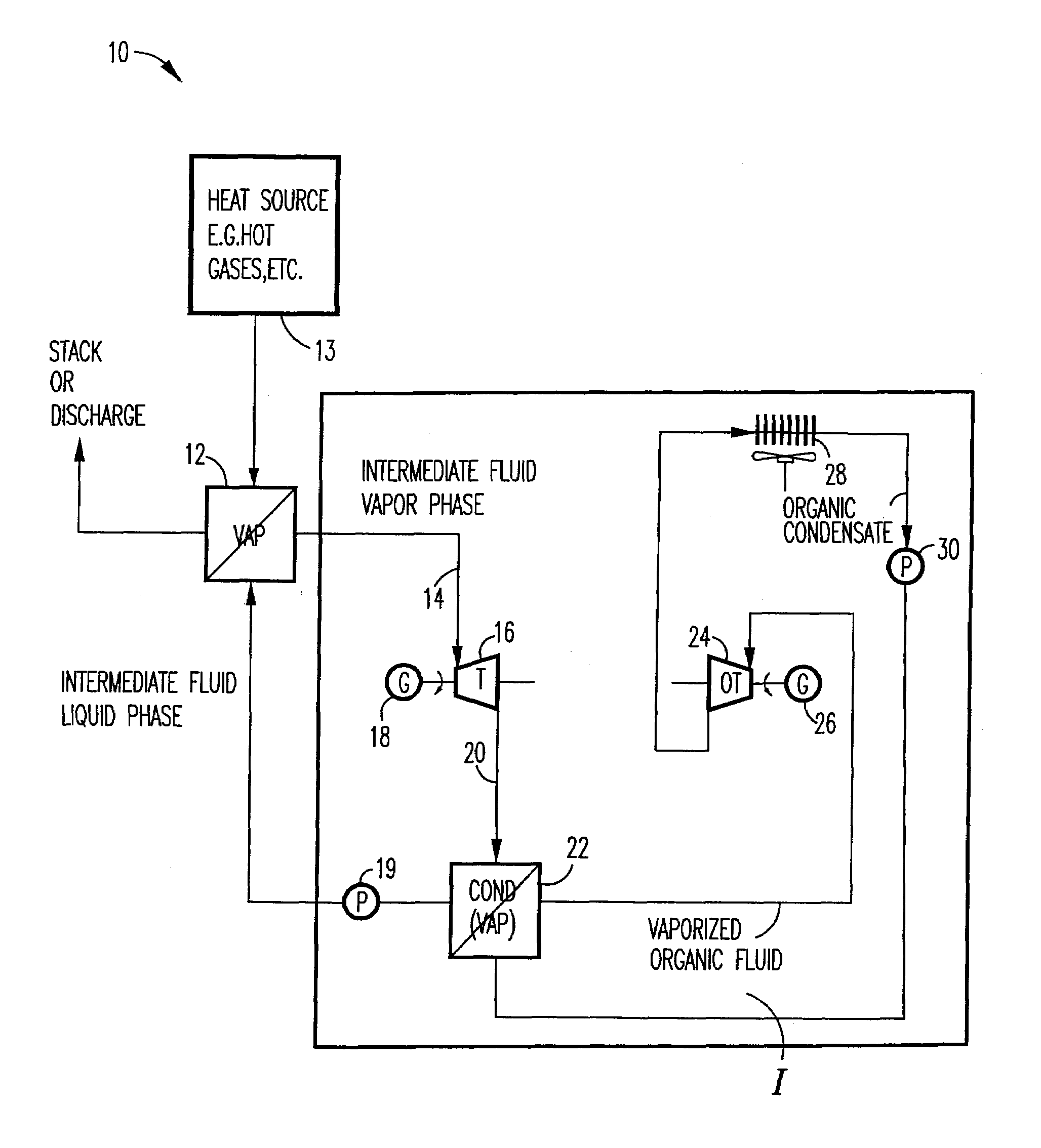

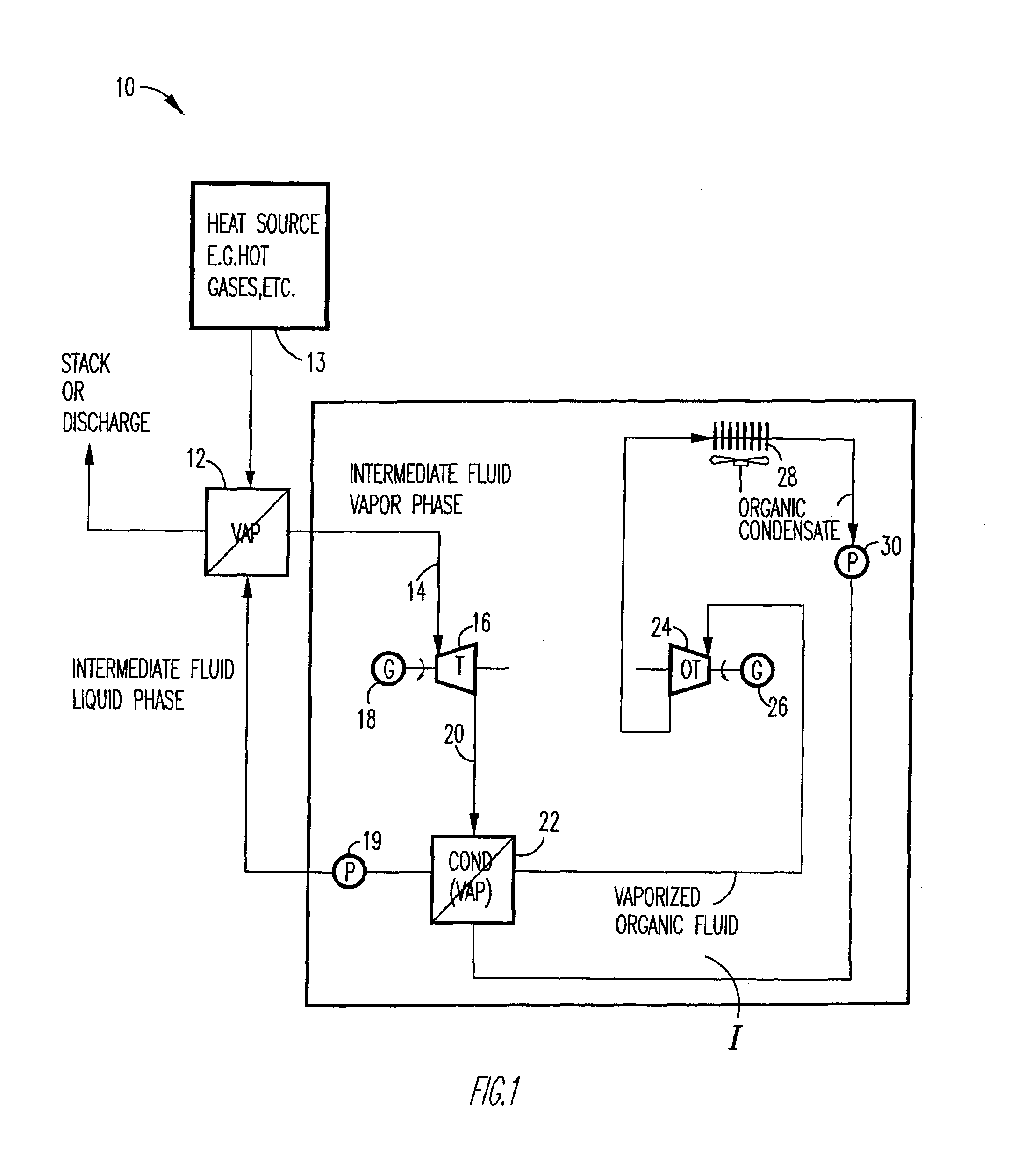

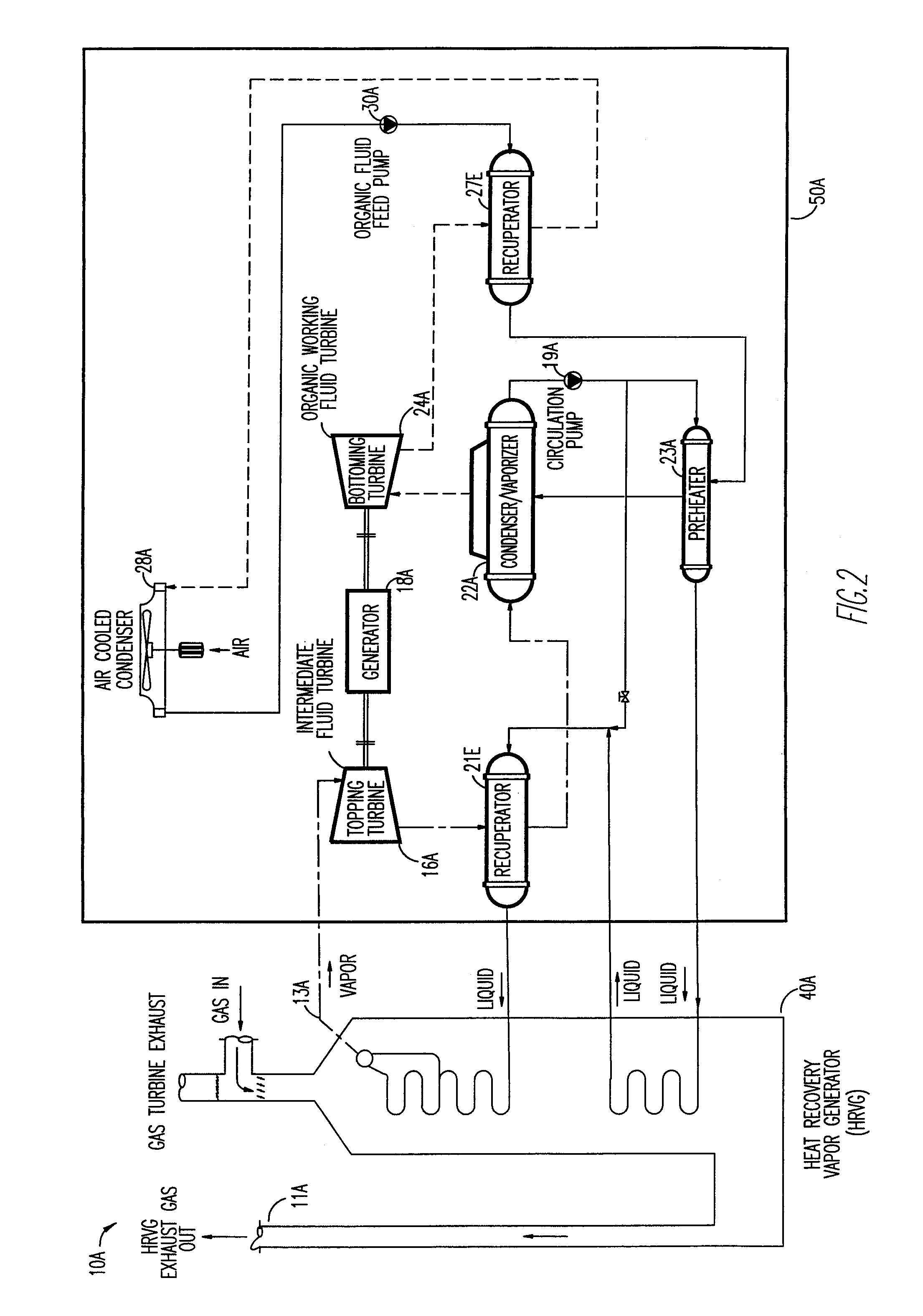

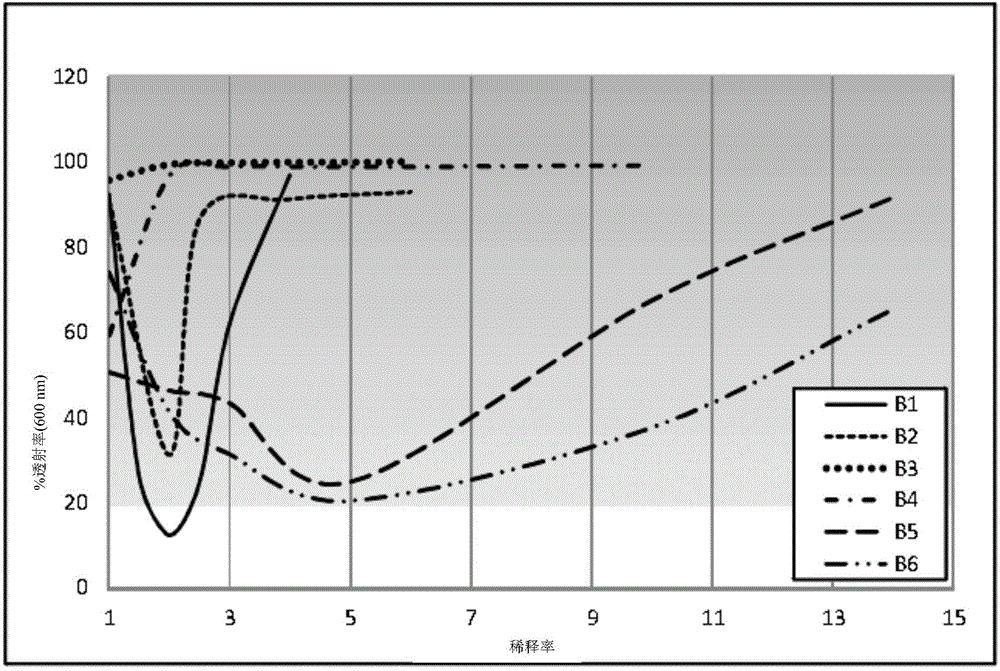

ActiveUS7225621B2Improve thermal stabilityStable compoundAuxillary drivesFrom solar energyHuman useAlkane

The present invention provides an improved, commercially available organic working fluid, which is operable under a broad range of temperatures, is thermally stable, has a high auto-ignition temperature, low freezing point and high critical temperature and is benign to the environment, and safe for human use. Such an organic working fluid is useful in organic Rankine cycle (ORC) power plants or units and other systems of the like; as an intermediate fluid for heat-recovery wherein heat from various heat sources is transferred using the intermediate fluid to a further working fluid and converted into work, and the intermediate fluid is also exploited to produce electricity. Such organic working fluids are also operable as heat transfer fluids either in ORC power plants or units or in other heat transfer systems. For this purpose the present invention presents a working fluid comprising at least one highly branched, heavy iso-paraffin hydrocarbons, or a mixture of two or more of such hydrocarbons. Preferably, at least one highly branched iso-paraffin hydrocarbon is present as the major component (i.e. at least 50% by volume) in the working fluid. A preferred sub-class of the class of the branched iso-paraffins which are suitable to be incorporated in organic working fluids of the present invention includes 8 to 20 carbon atom-containing hydrocarbons having at least one methyl radical (CH3) arranged to achieve a highly stable compound.

Owner:ORMAT TECH INC

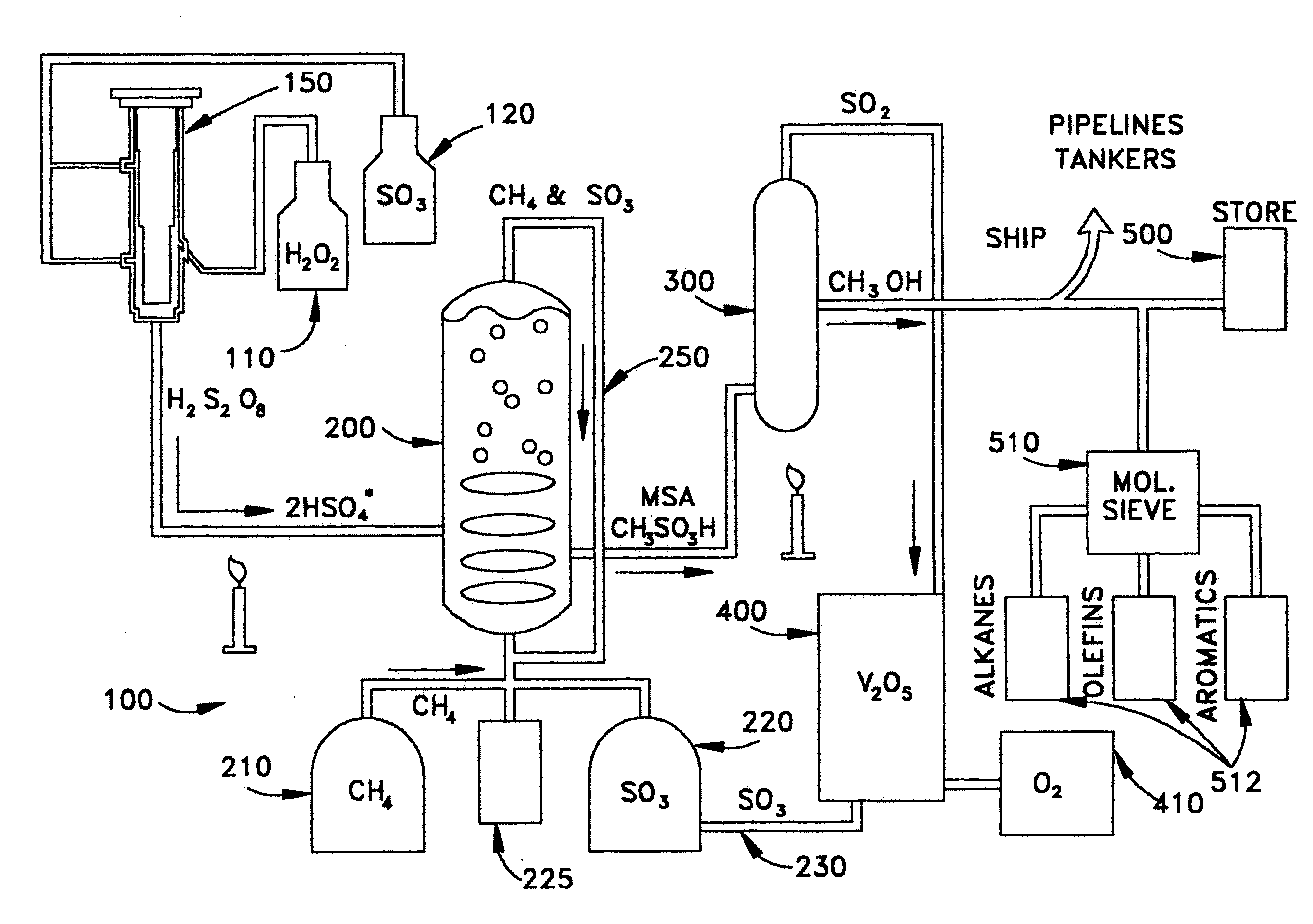

Anhydrous processing of methane into methane-sulfonic acid, methanol, and other compounds

ActiveUS20050070614A1Increases solubility and reaction rateEfficient removalHydrogenOrganic compound preparationLiquid fuelOxygen compound

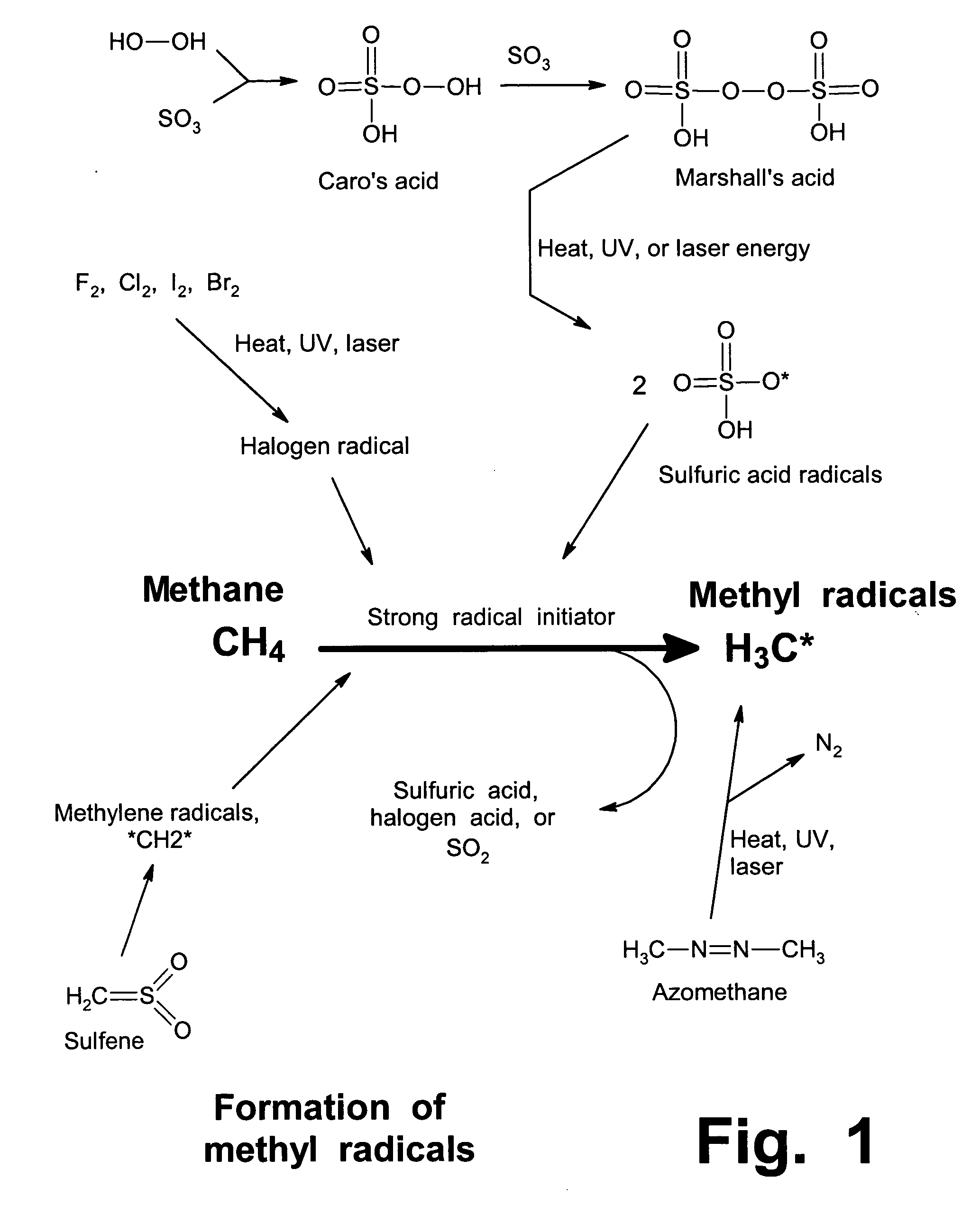

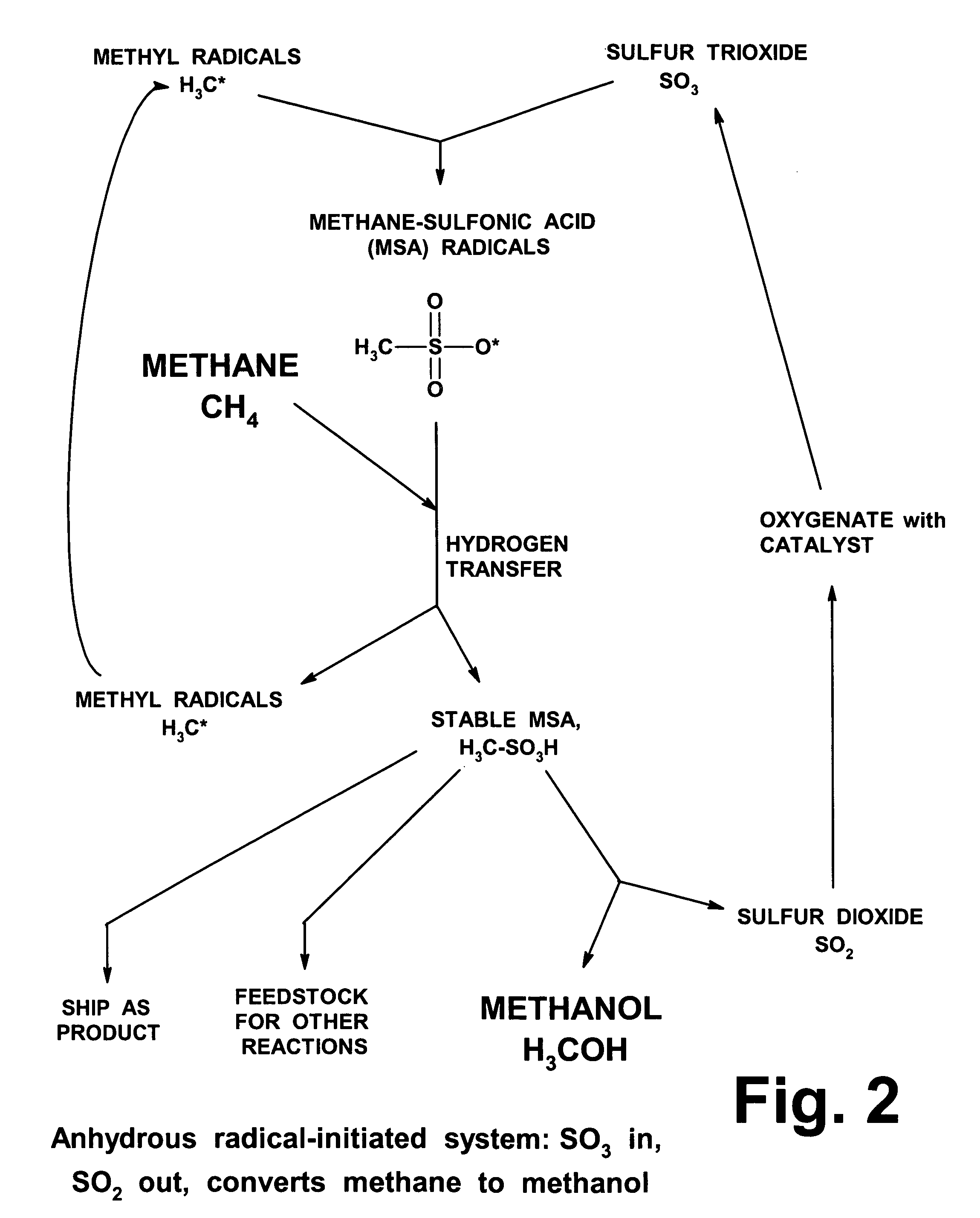

Anhydrous processing to convert methane into oxygenates (such as methanol), liquid fuels, or olefins uses an initiator to create methyl radicals. These radicals combine with sulfur trioxide to form methyl-sulfonate radicals. These radicals attack fresh methane, forming stable methane-sulfonic acid (MSA) while creating new methyl radicals to sustain a chain reaction. This system avoids the use or creation of water, and liquid MSA is an amphoteric solvent that increasing the solubility and reactivity of methane and SO3. MSA from this process can be sold or used as a valuable chemical with no mercaptan or halogen impurities, or it can be heated and cracked to release methanol (a clean fuel, gasoline additive, and chemical feedstock) and sulfur dioxide (which can be oxidized to SO3 and recycled back into the reactor). MSA also can be converted into gasoline, olefins, or other valuable chemicals.

Owner:VEOLIA NORTH AMERICA REGENERATION SERVICES LLC

Implantable prostheses with improved mechanical and chemical properties

InactiveUS7083644B1Improved mechanical and chemical propertyImproved mechanical and thermal propertyBlood vesselsBiopolymerMechanical property

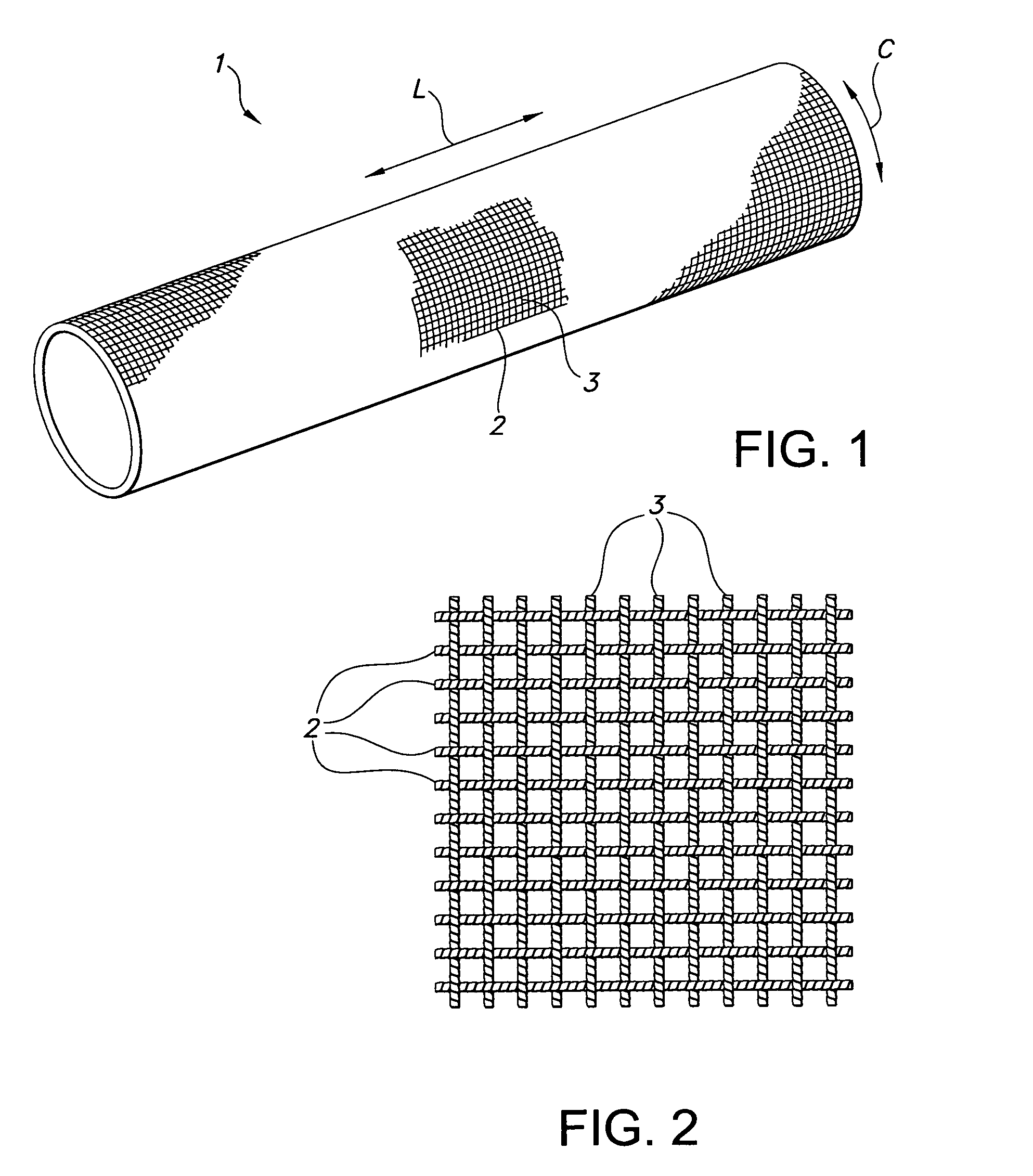

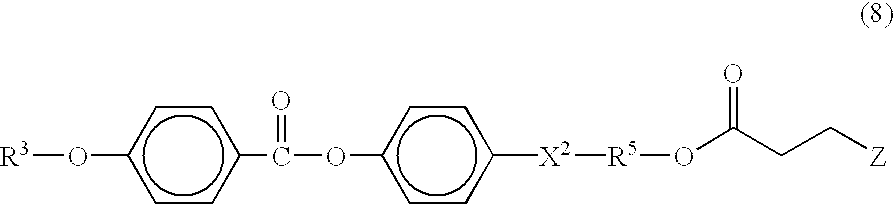

Prostheses with improved chemical and mechanical properties manufactured that includes a radiation resistant and hydrolytically stable biocompatible fabric having outer and first and second ends with a textile fabric that includes a naphthalene dicarboxylate derivative polymer having the general formula:wherein R1 and R3 are the same or different groups and are independently selected from the naphthalene dicarboxylate derivative repeating unit (I), a hydrogen radical and a methyl radical. R2 is an alkylene radical having 1 to 6 carbon atoms; n is from 10 to 200. Also contemplated are implantable prostheses that are flat constructions useful as patches and filters or tubular constructions useful as vascular grafts. A further aspect of this invention provides a method for making a radiation and thermal resistant and hydrolytically stable, steam sterilizable biocompatible prosthesis.

Owner:SCI MED LIFE SYST +1

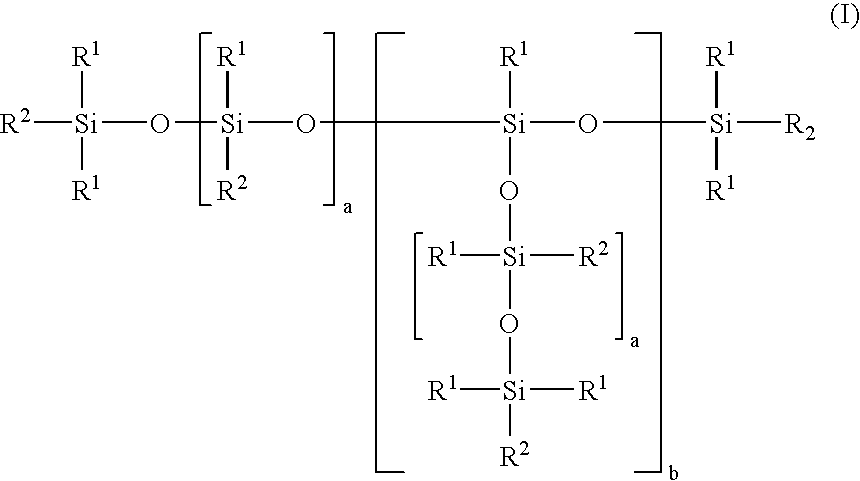

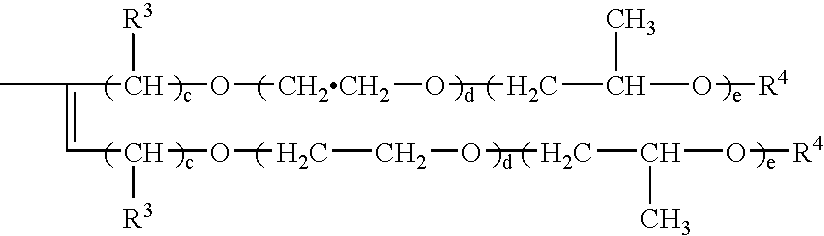

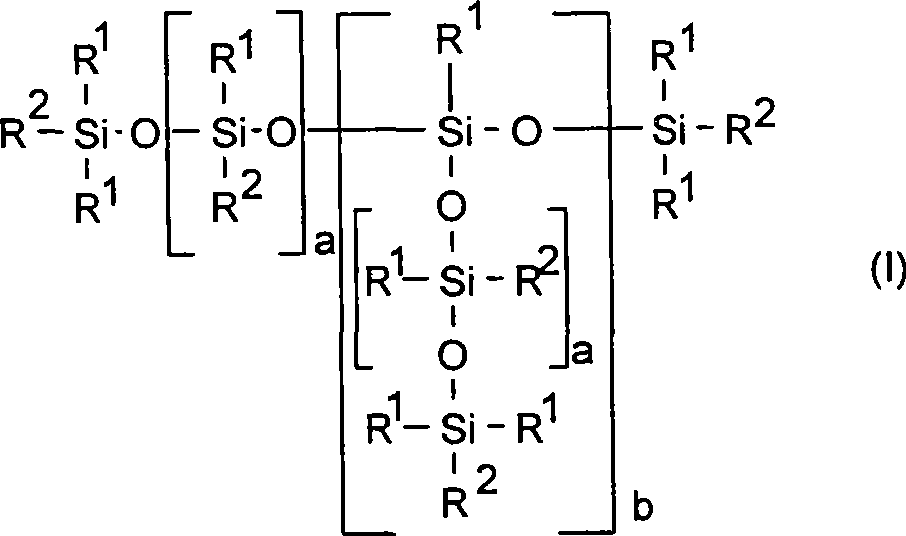

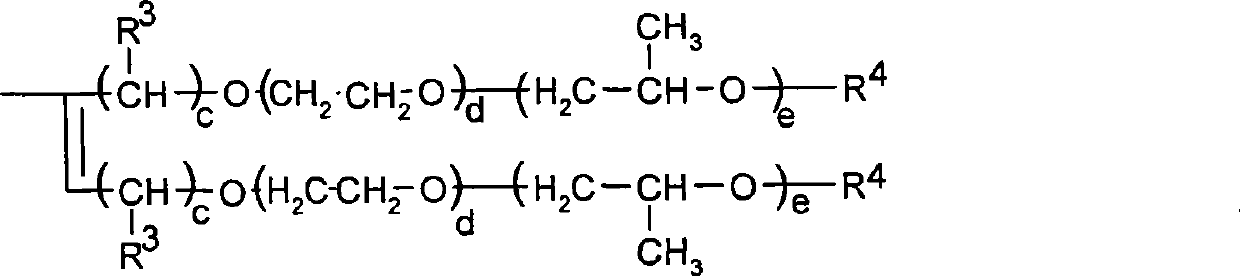

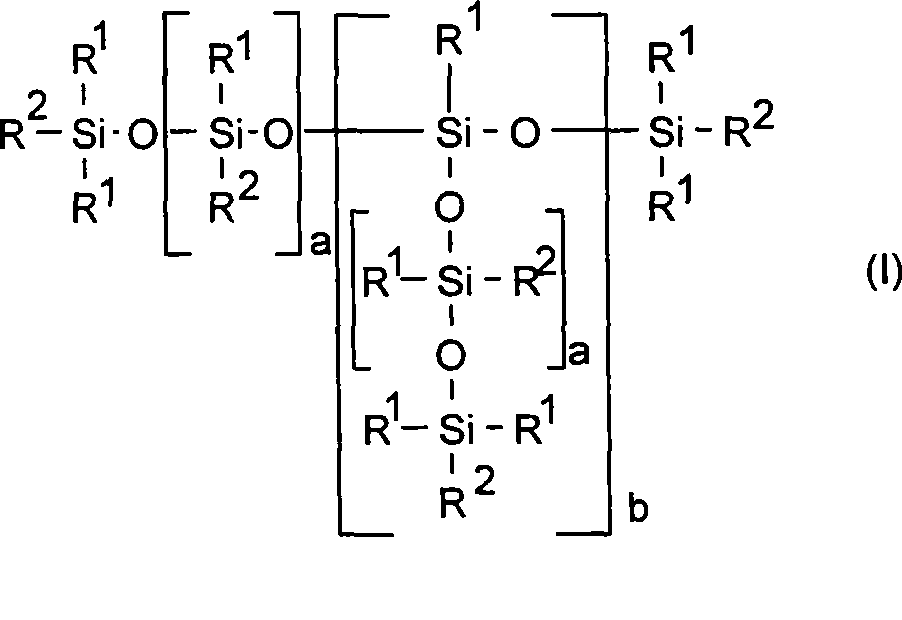

Agrochemical compositions comprising alkylenediol-modified polysiloxanes

InactiveUS20070213226A1Good curative effectImprove performanceBiocideAnimal repellantsCarboxyl radicalHydrogen

Described are agrochemical compositions which comprise of one or more one agrochemical active ingredient(s) and alkylenediol-modified polysiloxanes of the general formula (I): wherein R1 are alkyl radicals having 1 to 4 carbon atoms or aryl radicals, wherein at least 80% of the radicals R1 are methyl radicals , R2 in the molecule are identical or different and can have the following definitions: a) in which R3 is a hydrogen or alkyl radical, R4 is a hydrogen, alkyl or carboxyl radical, c is a number from 1 to 20, d is a number from 0 to 50, e is a number from 0 to 50 or b) correspond to R1, with the provisio that in the average molecule at least one radical R2 has the definition (a), a is a number from 1 to 200; b is a number from 0 to 10; and optionally one or more other agrochemically acceptable ingredients. The agrochemical compositions of the invention have enhanced efficacy, enhanced hydrolytic stability and / or decreased foaming properties.

Owner:EVONIK GOLDSCHMIDT GMBH

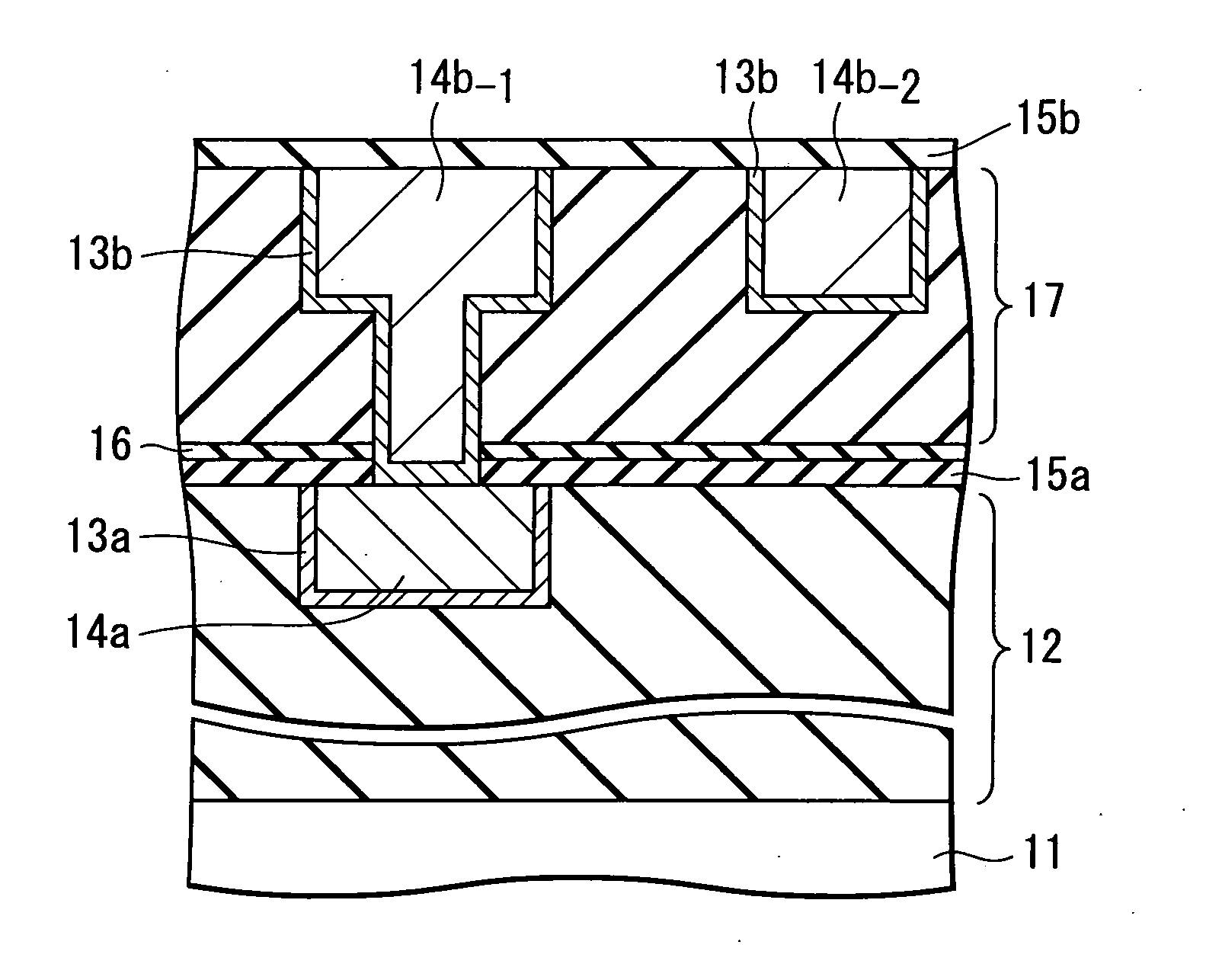

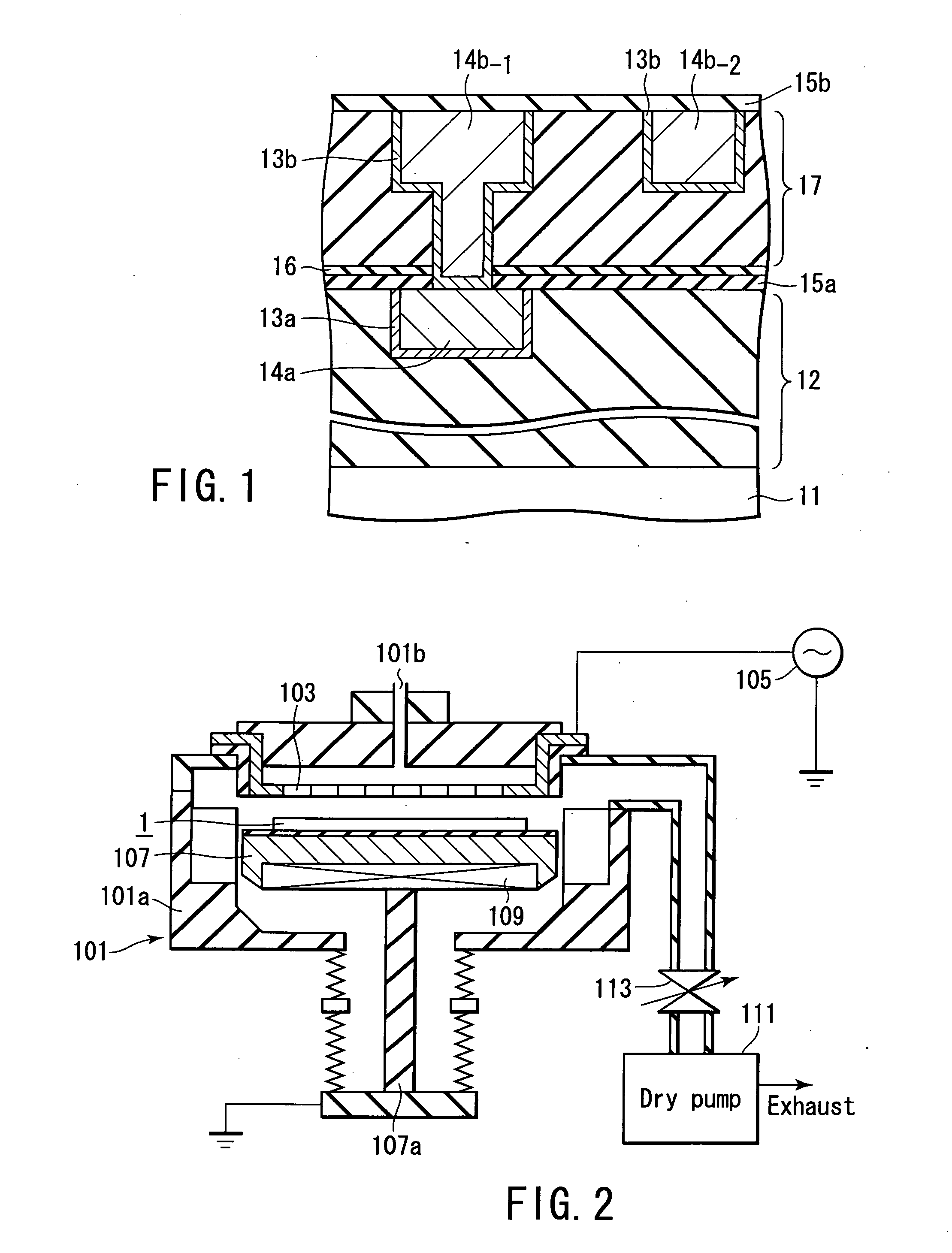

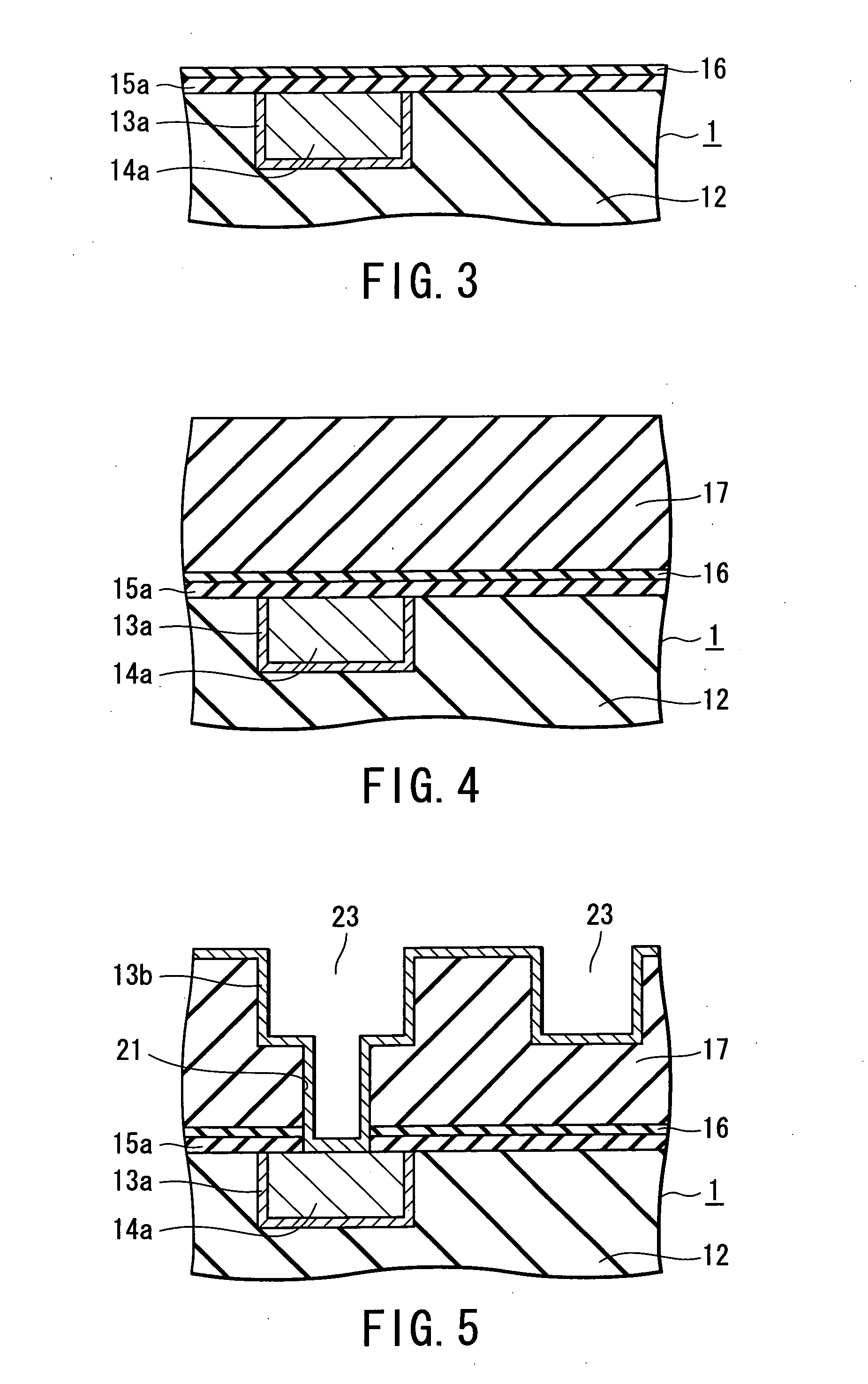

Semiconductor device and manufacturing method thereof

InactiveUS20050023691A1Semiconductor/solid-state device detailsSolid-state devicesDevice materialSilicon oxygen

A semiconductor device includes a metal wiring provided on a semiconductor substrate. The device further includes an anti-metal diffusion film formed on the metal wiring, a buffer layer which is formed on the anti-metal diffusion film and includes at least a silicon-methyl radical bond and a silicon-oxygen bond, and a low-dielectric constant film layer which is formed on the buffer layer and includes at least the silicon-methyl radical bond and the silicon-oxygen bond, wherein the silicon-methyl radical bonding density of the buffer layer is less than the silicon-methyl radical bonding density of the low-dielectric constant film layer.

Owner:KK TOSHIBA

Organopolysilozane compositions crosslinkable with elimination of alcohols to give elastomer

InactiveUS6254811B1Easy to useLow modulusSilicon organic compoundsBuilding repairsPhosphoric Acid EstersElastomer

Alkoxy RTV-1 compositions comprise the product of the reaction of(A) an HO-terminated organopolysiloxane,(B1) an alkoxysilane which has at least three alkoxy groups and / or its partial hydrolysates, and(B2) an alkoxysilane which has two alkoxy groups and / or its partial hydrolysates, in the presence of(C) an acid phosphoric ester of the general formula (I)wherea is 1 or 2,R1 and R2 are a hydrogen radical, methyl radical or hydroxyl radical,b and d are 2 or 3,c is an integer from 2 to 15,e is 0 or 1L comprises a radical -O-, -COO-, -OOC-, -CONR3-, -NR4CO- or -CO-,R3 and R4 are a hydrogen radical or C1-C10-alkyl radical, andM is a monovalent, unsubstituted or hydroxyl-, fluorine-, chlorine-, bromine-,C1-C10-alkoxyalkyl- or cyano-substituted C1-C20-hydrocarbon radical, with the proviso that on any given carbon atom not more than one radical R1 and R2 may be a hydroxyl radical.

Owner:WACKER CHEM GMBH

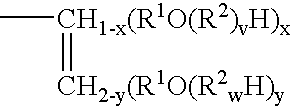

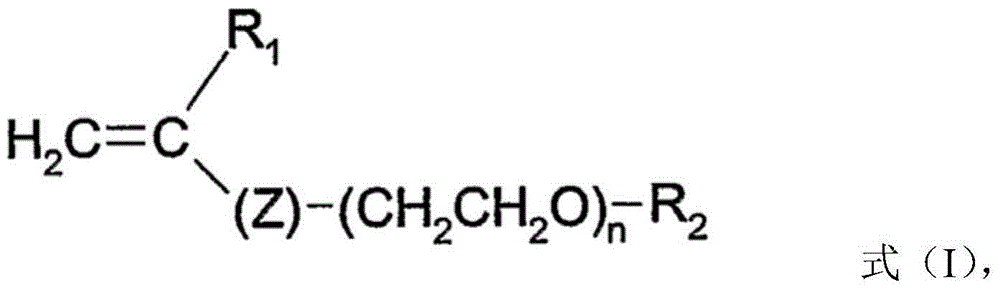

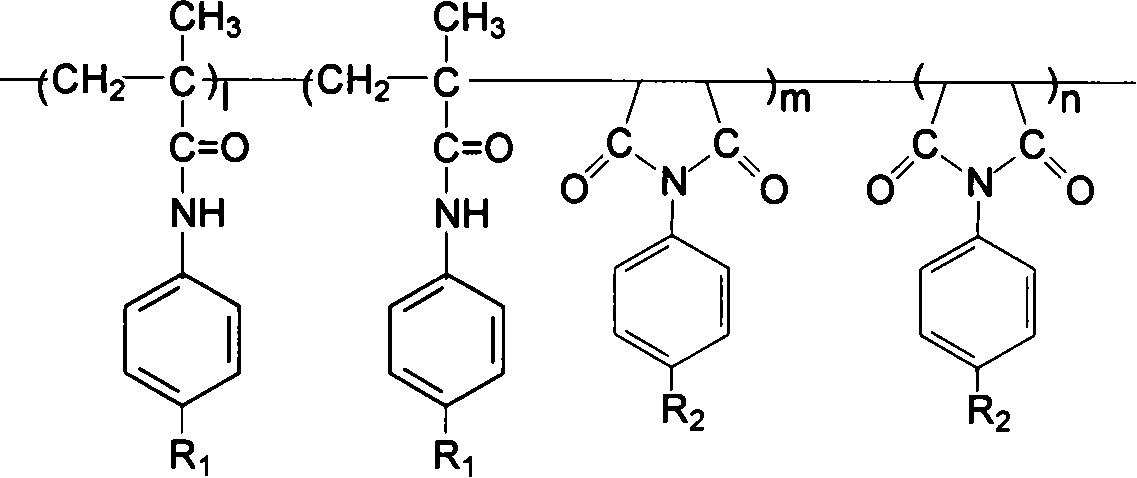

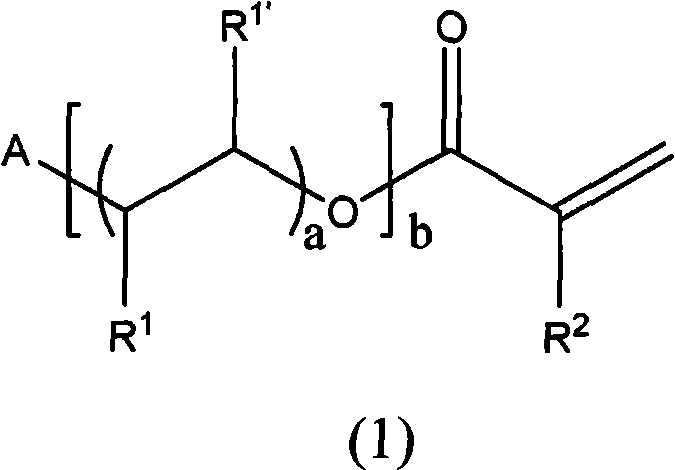

Novel comb polymers which can be used in cosmetics and detergents

A water-soluble copolymer comprising, by mass relative to the total mass of the copolymer: 1 to 40% of at least one cationic monomer; 59.99 to 98% of at least one nonionic monomer; 0.01 to 10% of at least one monomer of formula (I); in which: R1 is a hydrogen atom or a methyl radical; Z is a divalent group —C(═O)—O—, or —(═O)—NH—; n is an integer between 2 and 200; R2 is a hydrogen atom or a carbon-containing radical which is saturated or unsaturated, optionally aromatic, linear, branched or cyclic, comprising 1 to 30 carbon atoms, and from 0 to 4 heteroatoms chosen from the group comprising O, N and S; the copolymer having a cationic charge density between 0.05 and 3 meq / g.

Owner:S P C M SA

Preparation and application of coating catalyst using ionic liquid as binder

ActiveCN106040314AIncrease profitHigh mechanical strengthOrganic compound preparationHeterogenous catalyst chemical elementsSilicon oxideIonic liquid

The invention relates to a method of producing a coating catalyst and application thereof. The method of producing the coating catalyst comprises: applying catalyst powder with an active component to an inertial support under the action of ionic liquid, wherein the outer active component of the coating catalyst contains molybdenum oxide, bismuth oxide and other oxides, the inner active component is an inertial support such as aluminum oxide and silicon oxide. During preparation of the catalyst, it is possible to disperse the catalyst powder and ionic liquid jointly (or separately) in ethanol and is sprayed (simultaneously) to an inertial spherical support so as to obtain the coating catalyst. The catalyst forms pores of special distribution after being treated via drying and calcining and the like, has high mechanical strength, and has good reacting performance during acrolein production by propylene oxidation, (methyl) acrylic acid by (methyl) acrolein oxidation and methacrylaldehyde production by isobutylene.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Agrochemical compositions comprising alkylenediol-modified polysiloxanes

Described are agrochemical compositions which comprise of one or more one agrochemical active ingredient(s) and alkylenediol -modified polysiloxanes of the general formula (I), wherein R<1> are alkyl radicals having 1 to 4 carbon atoms or aryl radicals, wherein at least 80% of the radicals R<1> are methyl radicals, R<2> in the molecule are identical or different and can have the following definitions (a), in which R<3> is a hydrogen or alkyl radical, R<4> is a hydrogen, alkyl or carboxyl radical, c is a number from 1 to 20, d is a number from 0 to 50, e is a number from 0 to 50 or b) correspond to the radical R<1>, with the proviso that in the average molecule at least one radical R<2> has the definition (a), a is a number from 1 to 200; b is a number from 0 to 10; and optionally one or more other agrochemically acceptable ingredients. The agrochemical compositions of the invention have enhanced efficacy, enhanced hydrolytic stability and / or decreased foaming properties.

Owner:TH GOLDSCHMIDT AG

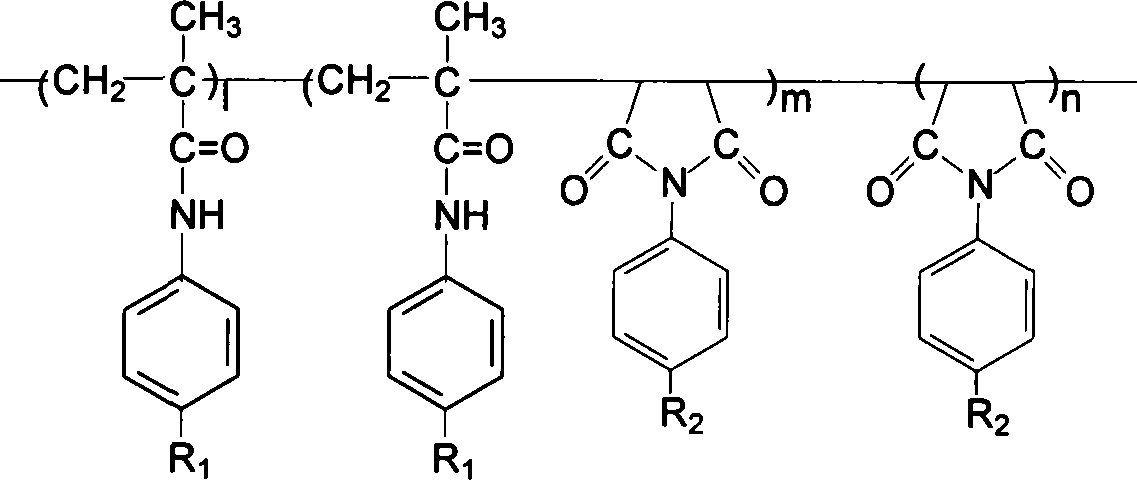

Main body film forming resin for photoresist and its preparation method and uses

InactiveCN101149561AHigh resolutionImprove adhesionPhotosensitive materials for photomechanical apparatusFiltration membraneLacquer

There is a sort of principal phragmoid colophony that it is used for the light-sensitive lacquer, and its manufacturing method is that 1. Make the monomer N-substitution methyl radical acrylamide and the monomer N-substitution maleimide to be dissolved to the solvent in order to execute the homogeneous liquor. 2. Affiliate the free-radical polymerization initiator in this liquor, and aggregate them in the definite temperature, and then drop it to the precipitator in order to separate out the polymer deposition, at last filtrate it, and then get the coarse production. 3. Dissolve this coarse production in the solvent anew, and then drop it to the precipitator in order to deposition, at last filtrate it, and then get the copolymer colophony of this invention. Its applied method is that: Dissolve the copolymer colophony and the sensitizer and the additive and the solvent, and filtrate it by the hyper-filtration membrane, at last get the light-sensitive lacquer of this invention. This light-sensitive lacquer has the character in that the high resolution factor, the good adhesive power with the bulk material, and the strong anti-dry-etching ability. In addition it has the good high-temperature capability.

Owner:HUAZHONG UNIV OF SCI & TECH

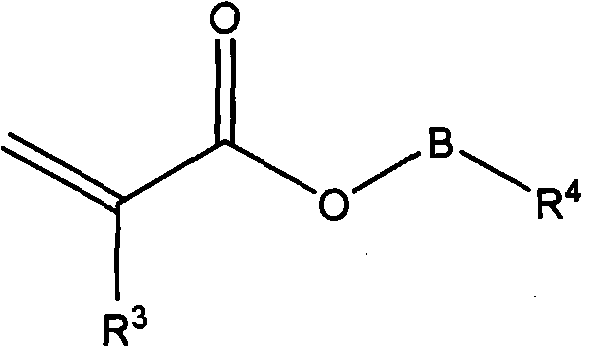

Preparation of organosilicon compounds containing alpha, beta-unsaturated carboxylic acids

InactiveUS6486338B1High selectivityEasy to readLiquid crystal compositionsSilicon organic compoundsHydrogenOrganic group

Organosilicon compounds (P) containing alpha,beta-unsaturated carboxylic acid radicals, of the general formula (1)are prepared by a process in which, in a first step, organosilicon compounds (H) containing hydrogen atoms bonded directly to silicon are reacted with olefinically unsaturated compounds (U) containing a terminal double or triple bond, of the general formula (2)in the presence of metals or compounds from the platinum group as catalyst, to give organosilicon compounds (E) containing radicals of the general formula (3)and, in a second step, H-Z compounds are eliminated from organosilicon compounds (E), whereA is a divalent organic radical,OMEGA is a monovalent organic radical containing a terminal double or triple bond,R is an H atom or a methyl radical, andZ is Cl, I, Br or 4-methyltoluenesulfonyl.

Owner:WACKER CHEM GMBH

Optically active aliphatic alcohols and their use as perfuming ingredients

InactiveUS6054426ACosmetic preparationsOrganic detergent compounding agentsAliphatic alcoholOptically active

The optically active compounds of formula wherein R1 represents a hydrogen atom or a methyl radical, or of formula are useful as perfuming ingredients for the preparation of perfuming compositions and perfumed articles to which they impart woody-amber notes.

Owner:FIRMENICH SA

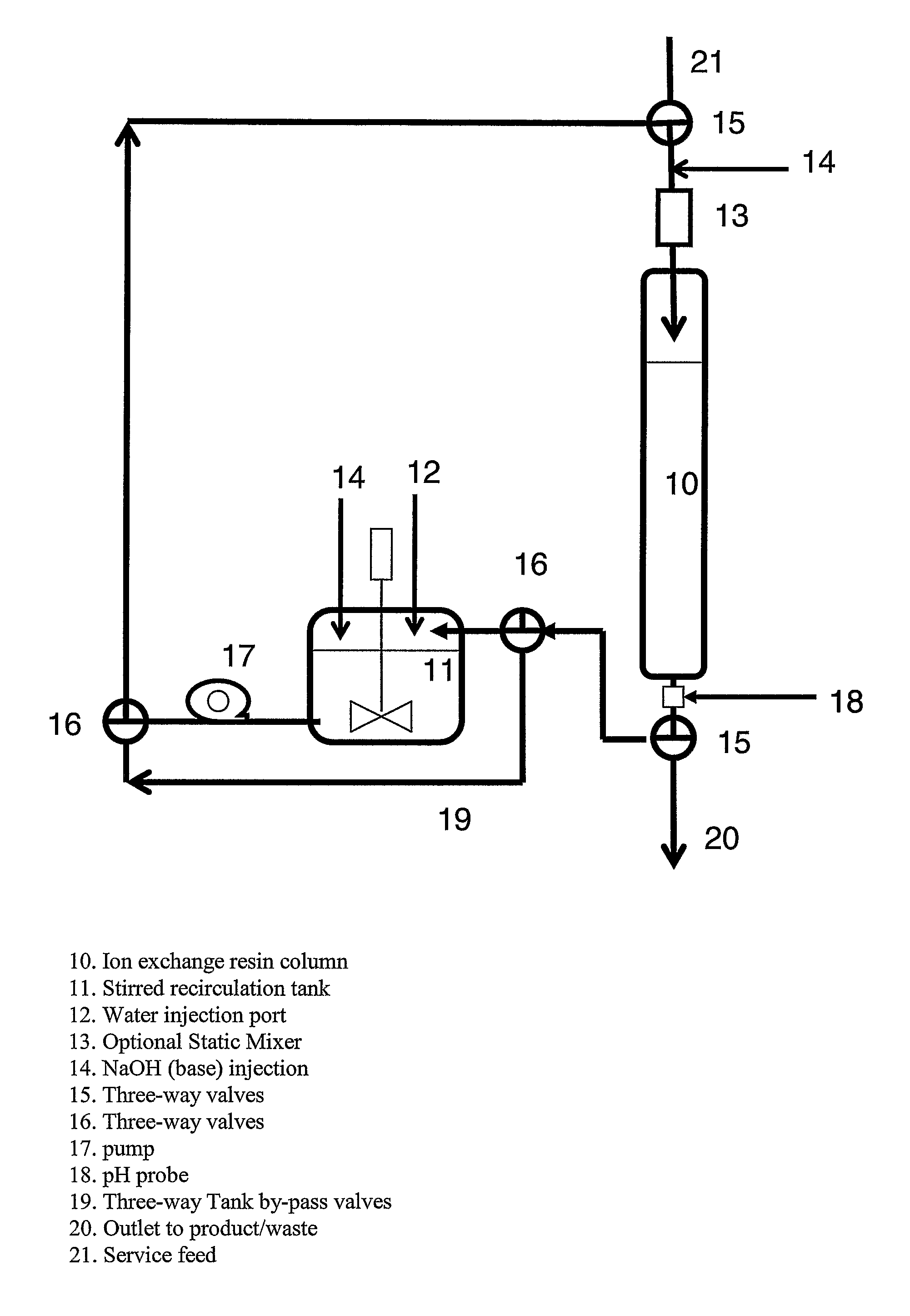

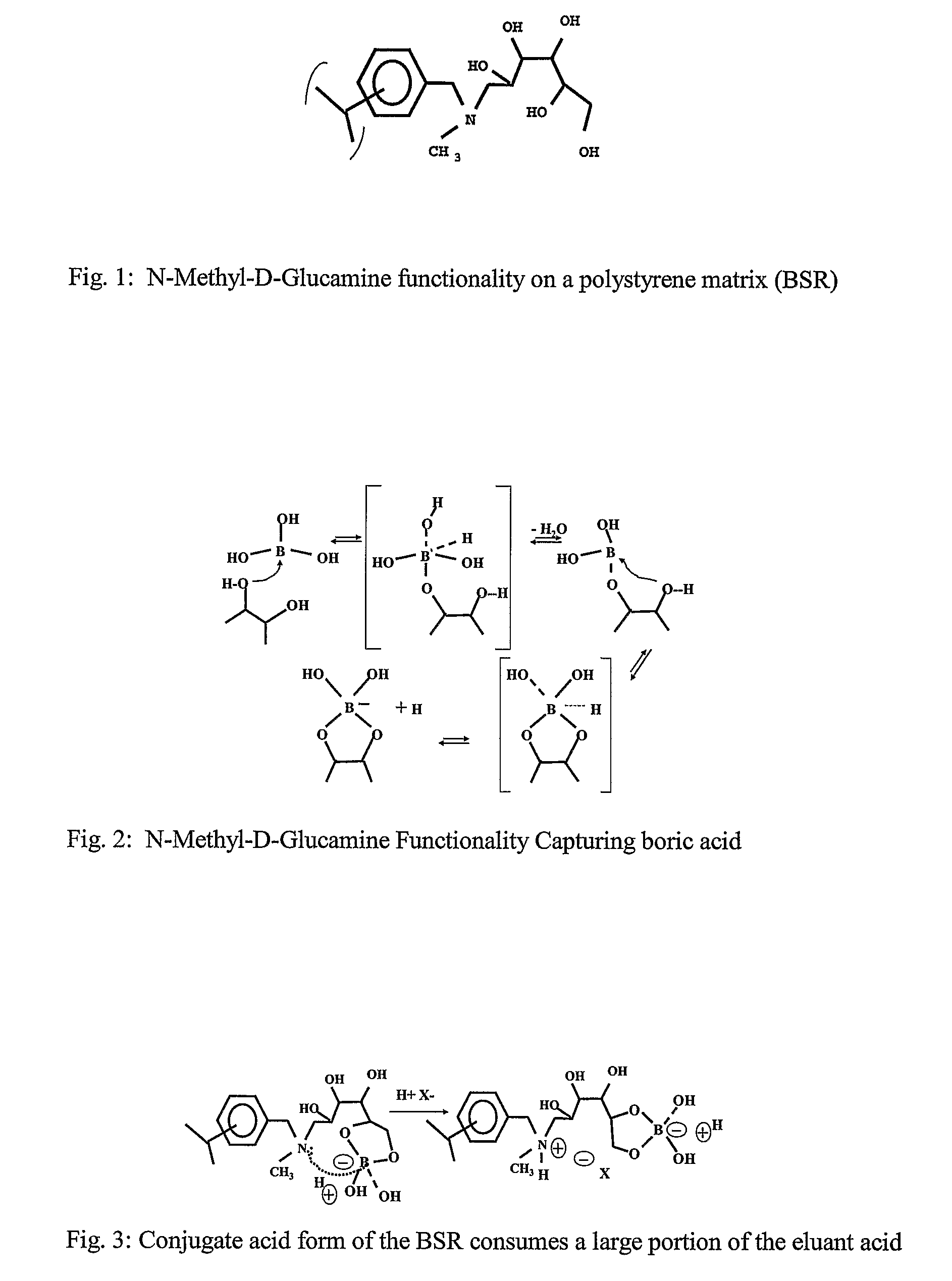

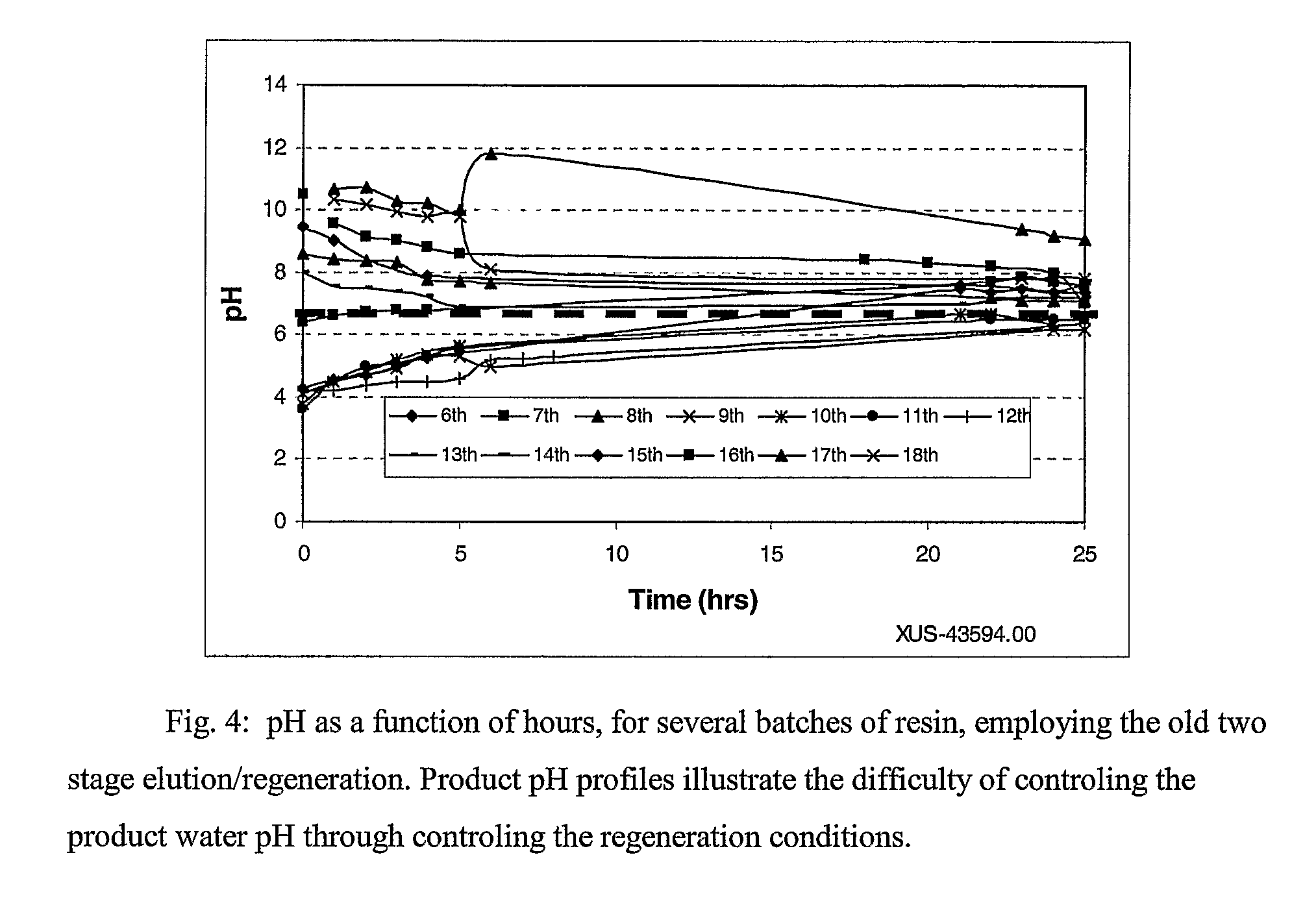

Alkaline regeneration of N-methyl-D-glucamine functional resins

InactiveUS7811457B2Minimize amount of waterEasy to controlIon-exchange process apparatusGeneral water supply conservationPh controlHydrometallurgy

Owner:DOW GLOBAL TECH LLC

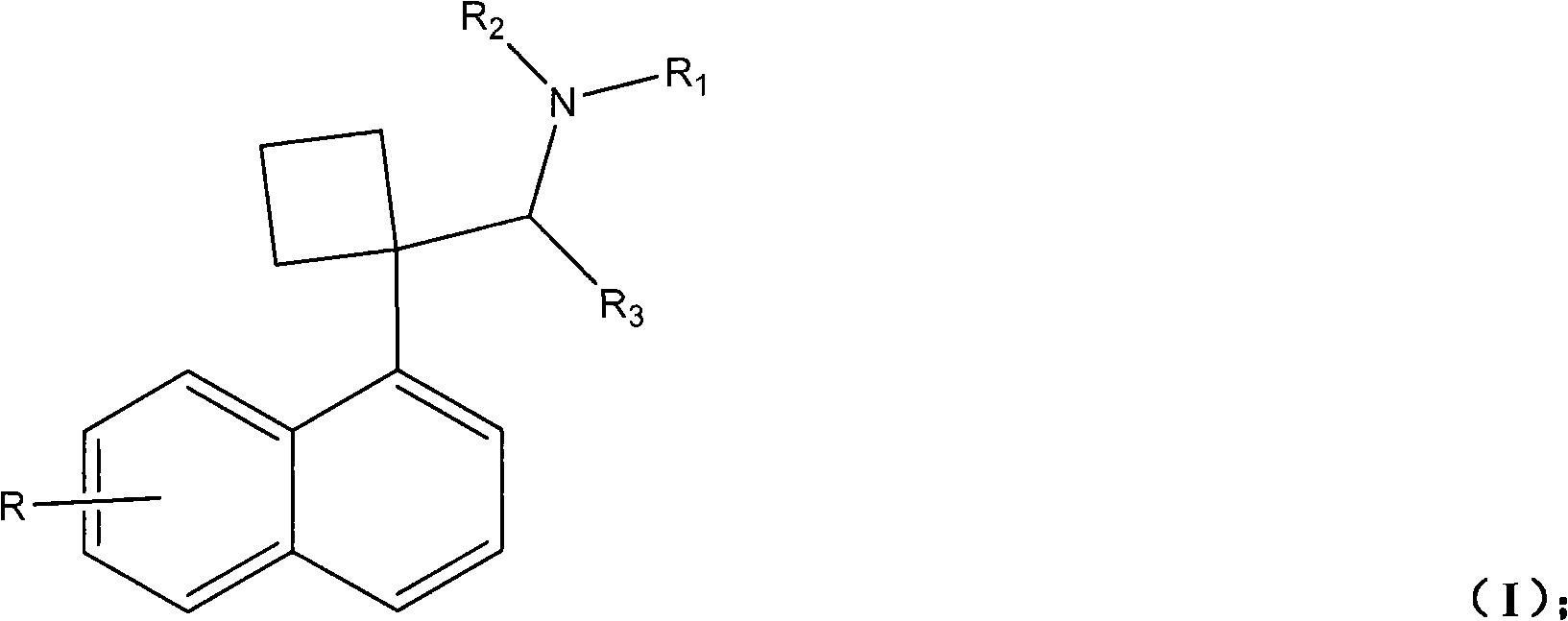

Naphthyl ethylamine derivative and preparation method thereof and application of naphthyl ethylamine derivative in preparing weight-reducing medicament

ActiveCN101602680AGood weight loss and lipid lowering effectOrganic active ingredientsOrganic compound preparationArylStructural formula

The invention discloses a naphthyl ethylamine derivative and a preparation method thereof and application of the naphthyl ethylamine derivative in preparing medicaments for treating obesity. The naphthyl ethylamine derivative is characterized in that the composition exists in a form of alkali or pharmaceutical salt, and has the general structural formula shown in the formula (I), wherein R is halogen, halogenated methyl radical, nitryl or optionally-substituted C1 to C3 alkoxy; R1 and R2 are H, optionally-substituted C1 to C6 alkyl or a substituent group of which the structure is shown in general formula (II); in the formula (II), R4 is the H, aryl, or optional C1 to C6 alkyl or C1 to C3 alkoxy; and the R3 is the optionally-substituted C1 to C6 alkyl. Pharmacological tests prove that the composition has good function of treating the obesity.

Owner:苏州凯达生物医药技术有限公司

Method for synthesizing famciclovir

InactiveCN101550137AFew reaction stepsRaw materials are cheap and easy to getOrganic chemistryAntiviralsEthyl groupAcetic oxide

The invention relates to a method for synthesizing famciclovir, which includes preparing sodium salt of diethyl malonate at the acting of sodium ethylate by taking diethyl malonate as raw charge and ethyl hydrate as dissolvent, preparing bromo ethyl group diethyl malonate by carrying out nucleophilic substitution reaction with 1, 2-dibromoethane and sodium salt of diethyl malonate, preparing bromo ethyl group propanediol by deoxidizing bromo ethyl group diethyl malonate at the acting of sodium borohydride, preparing 2-acetyl oxygen radicel methyl radicel -4-bromo butyl acetic ester by carrying out reaction with bromo ethyl group propanediol and acylating agent acetic oxide, preparing 2-(2-acetyl oxygen radicel-4-bromo butyl acetic ester)-6-chloropurine by carrying out condensation with 2-acetyl oxygen radicel methyl radical-4-bromo butyl acetic ester and 2-amidocyanogen-6-chloropurine, and then preparing famciclovir by carrying out dechlorination with 2-(2-acetyl oxygen radicel methyl radical -4-bromo butyl acetic ester)-6-chloropurine. This method is suitable for the industrial production with short production line, high yield and low cost.

Owner:彭洋

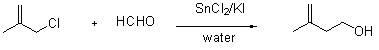

Method for synthesizing 3-methyl-3-butene-1-ol

InactiveCN102432434ARaw materials are easy to getEasy to storeOrganic compound preparationHydroxy compound preparationIodised saltButene

The invention belongs to the field of synthesis of fine chemical water reducing agent intermediates, and in particular relates to a method for synthesizing 3-methyl-3-butene-1-ol. The 3-methyl-3-butene-1-ol is generated by reacting isocrotylchloride with paraformaldehyde or formaldehyde in a water-containing medium under the action of a catalyst, wherein the catalyst is a mixture of a divalent tin compound and iodized salt. The raw materials are readily available and easy to store in the synthesis process, reaction conditions are simple, reaction yield is high, and production cost is low; the reaction conditions are normal temperature and normal pressure, the requirement on environment is low, and the process is easy to operate; and the using amount of an organic solvent is small, environmental pollution is light, the requirement on production equipment is simple, and industrial production is easy to implement.

Owner:LUOYANG NORMAL UNIV

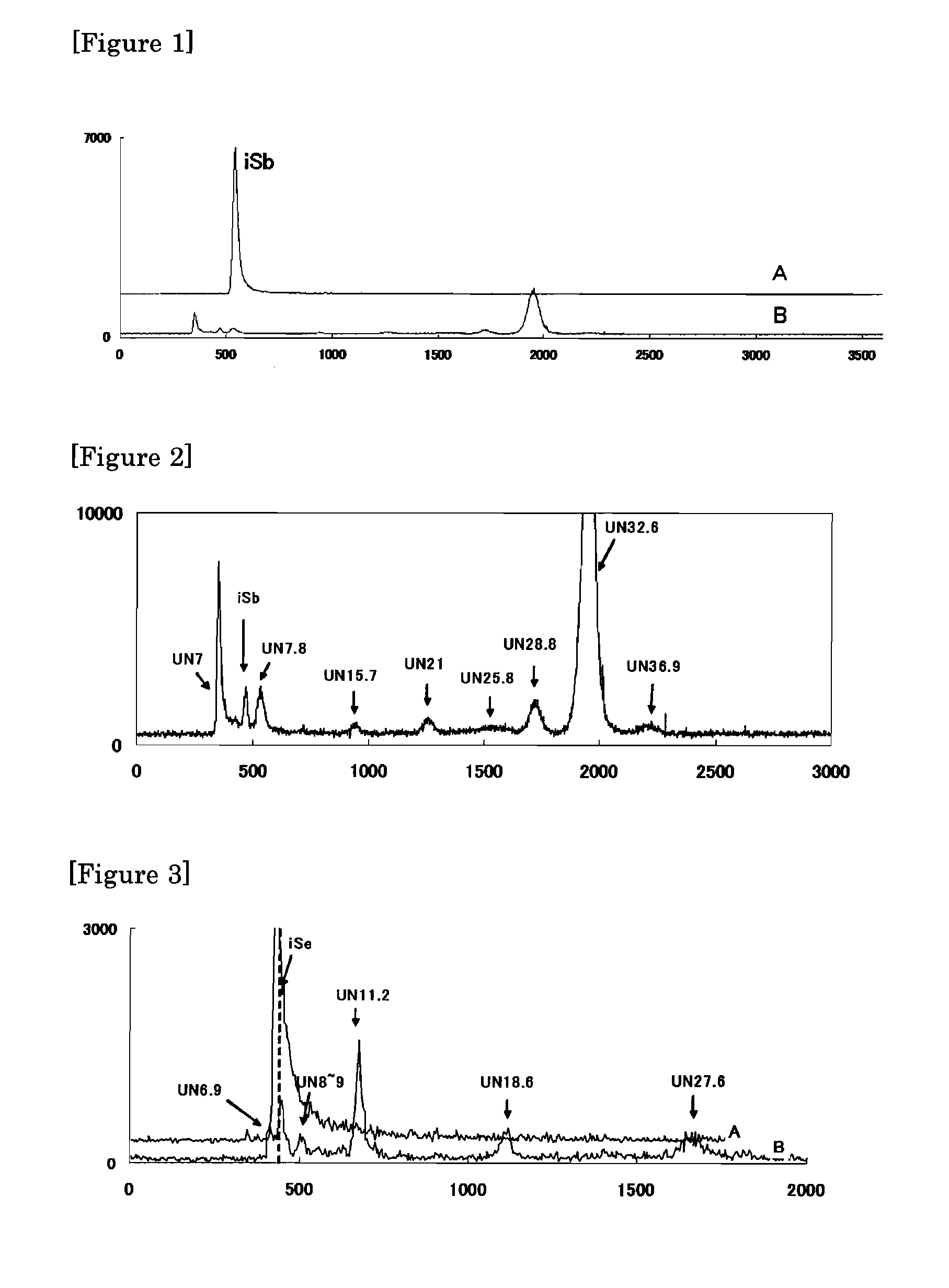

Method of detoxifying a harmful compound

InactiveUS20100305386A1Reduce decreaseCompound damageMetal/metal-oxides/metal-hydroxide catalystsAcetic acidAcetic anhydride

It is an object of the present invention to provide a beneficial method for detoxifying a harmful compound to detoxify the harmful compound containing arsenic etc., effectively.The method of detoxifying a harmful compound according to the present invention is characterized in that a methyl radical and / or a carboxymethyl radical is (are) contacted with a harmful compound comprising at least one element selected from the group comprising arsenic, antimony and selenium to detoxify the harmful compound. Furthermore, in a preferred embodiment of the method of detoxifying a harmful compound according to the present invention, the method is characterized in that the radical is generated by the exposure to light. Furthermore, in a preferred embodiment of the method of detoxifying a harmful compound according to the present invention, the method is characterized in that the resource of the radical is at least one selected from the group comprising acetic acid, methanol, ethanol, acetic anhydride, propionic acid, butanoic acid or formic acid.

Owner:NIPPON SHEET GLASS CO LTD

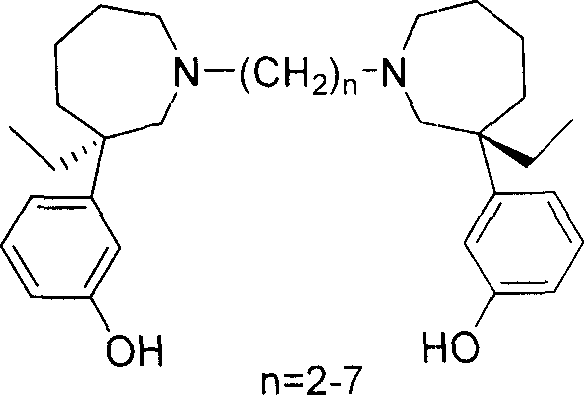

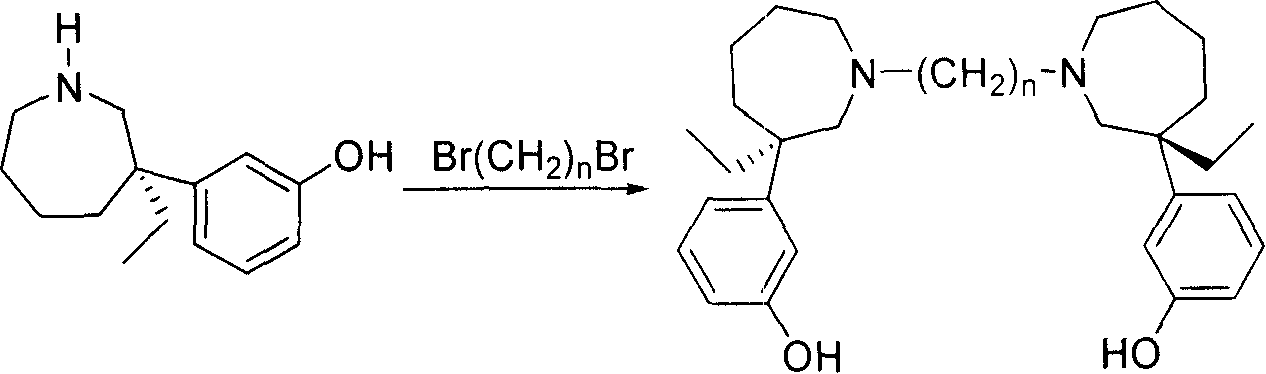

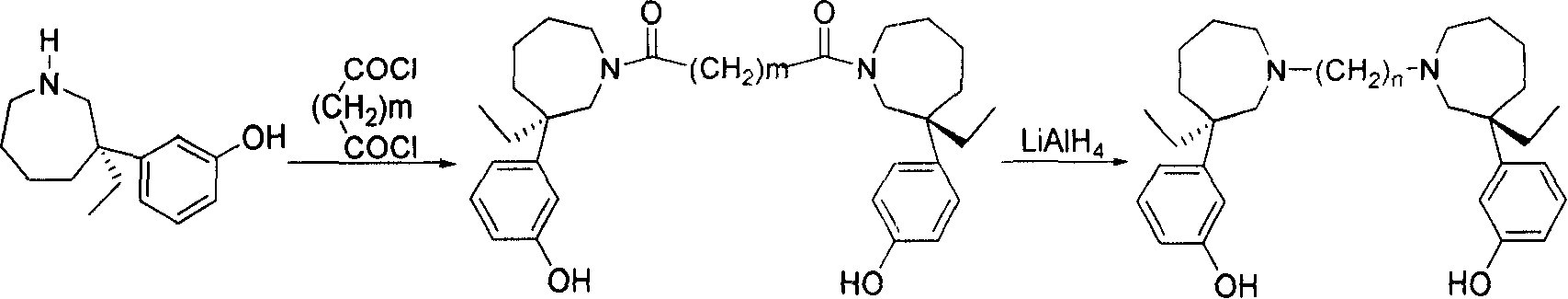

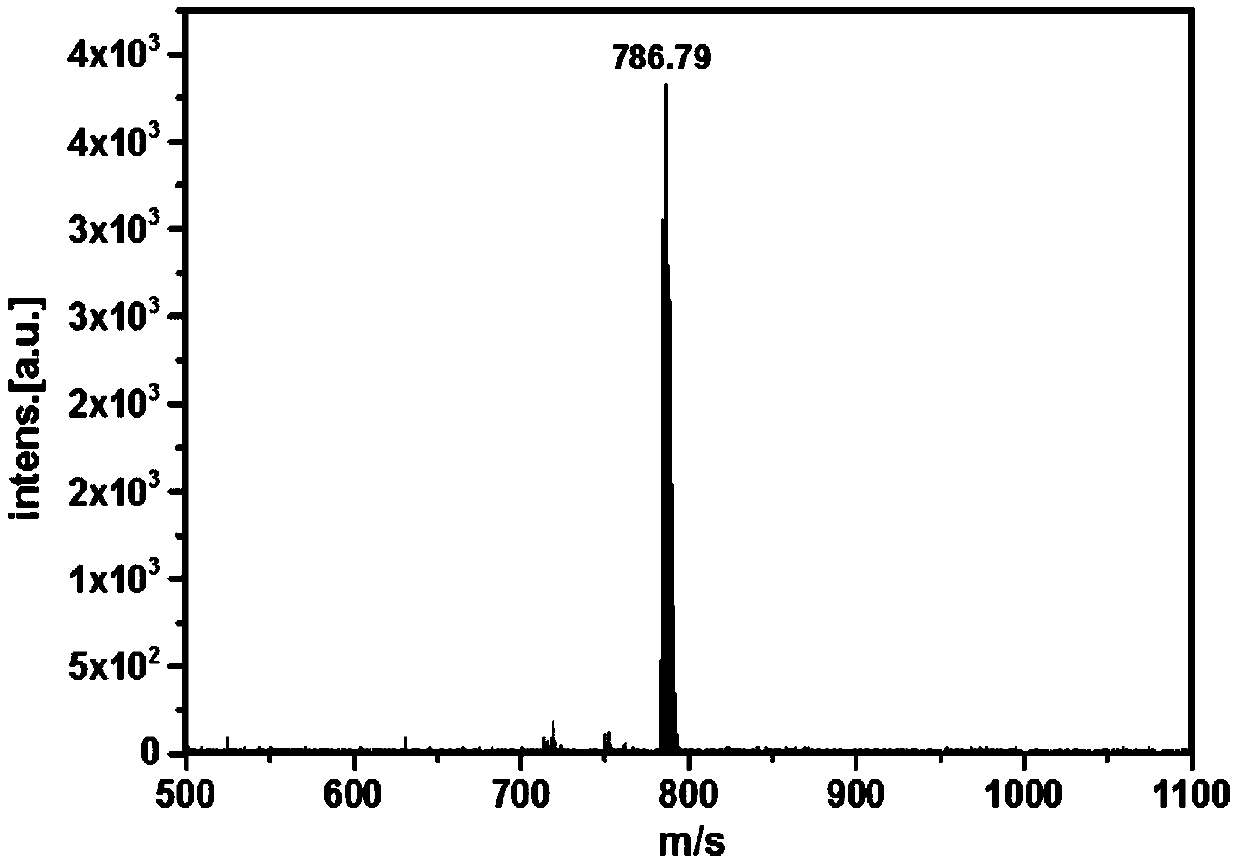

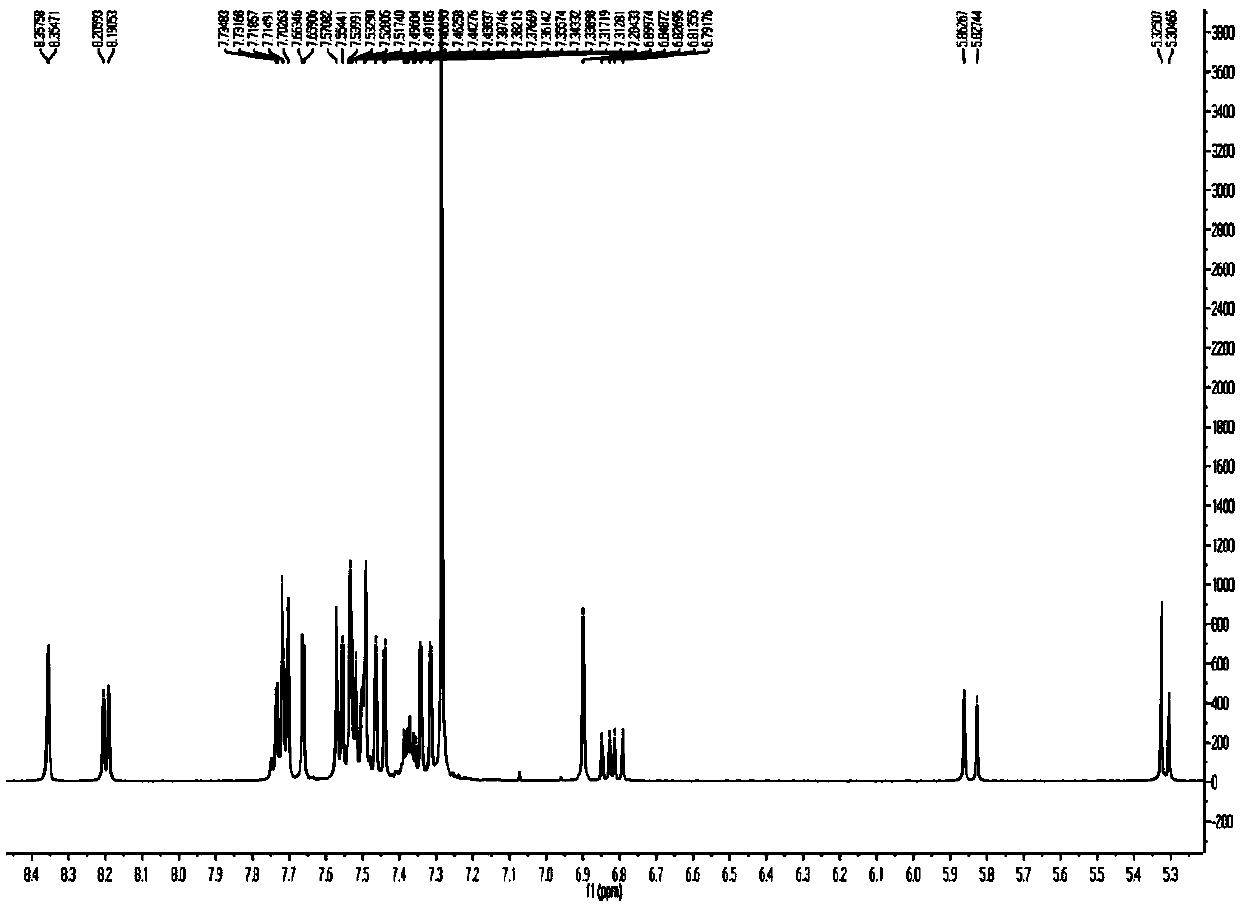

(+)-Meptazinol diligand derivative and/or its salt and the prepn process

The present invention relates to pharmaceutical technology, and is especially (+)-Meptazinol diligand derivative as shown in the structural general expression and / or its salt and the preparation process. The present invention modifies the structure of (+)-Meptazinol through eliminating its N-methyl radical and connecting two N's on the seven-membered rings of two (+)-N-nor Meptazinol with hydrocarbon chains in different lengths to obtain the (+)-Meptazinol diligand derivative. The pharmacological experiment shows that the (+)-Meptazinol diligand derivative possesses analgesic activity of different degree.

Owner:FUDAN UNIV

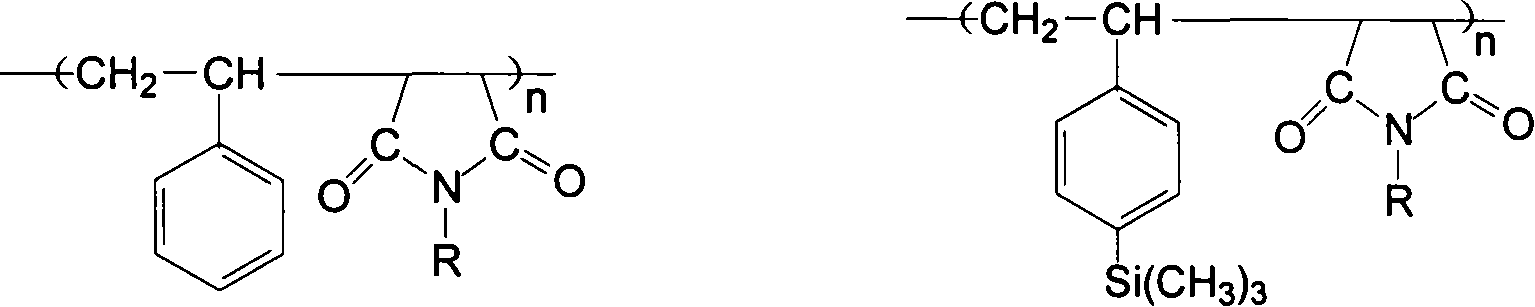

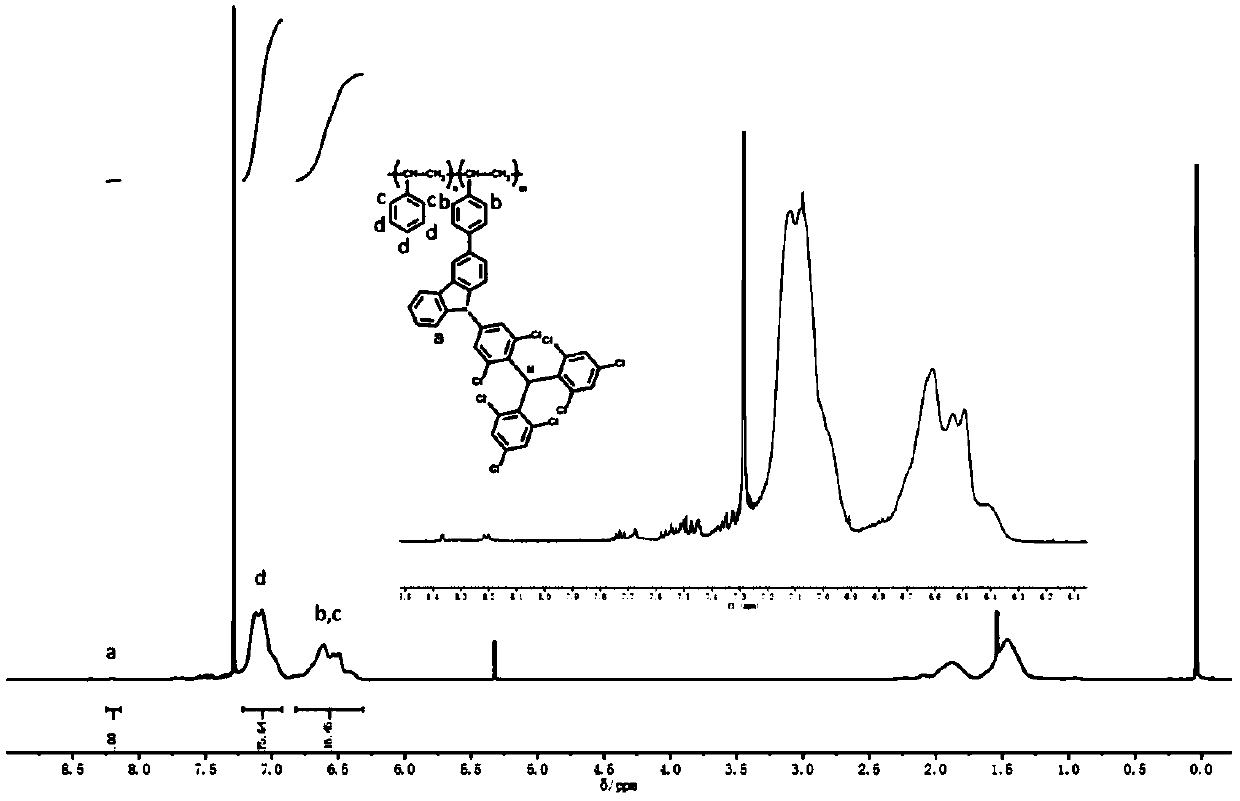

Stable organic luminescent radical polymer and OLED device based on same

ActiveCN109535397ASolid-state devicesSemiconductor/solid-state device manufacturingSolubilityPolymer science

A stable organic luminescent radical polymer material and an organic light-emitting device produced from the same belong to the technical field of organic luminescence. The radical polymer material which can emit lights in a solid form is successfully obtained by a design strategy of suspending a luminescent radical monomer on a polymer main chain, the polymer main chain can be selected from polyethylene and other non-conjugated main chains and polycarbazole and other conjugated main chains, and the suspended luminescent free radical can be selected from a tris(2,4,6-trichlorophenyl)methyl radical, a perchlorobenzyl radical and a bis(2,4,6-trichlorophenyl)methyl radical and derivatives thereof. The free radical polymer material has good magnetic properties, the polymer skeleton improves the solubility and the photostability of the radical material, and the spectral wavelength of the light-emitting device produced through a spin coating process of the material is 684 nm.

Owner:JILIN UNIV

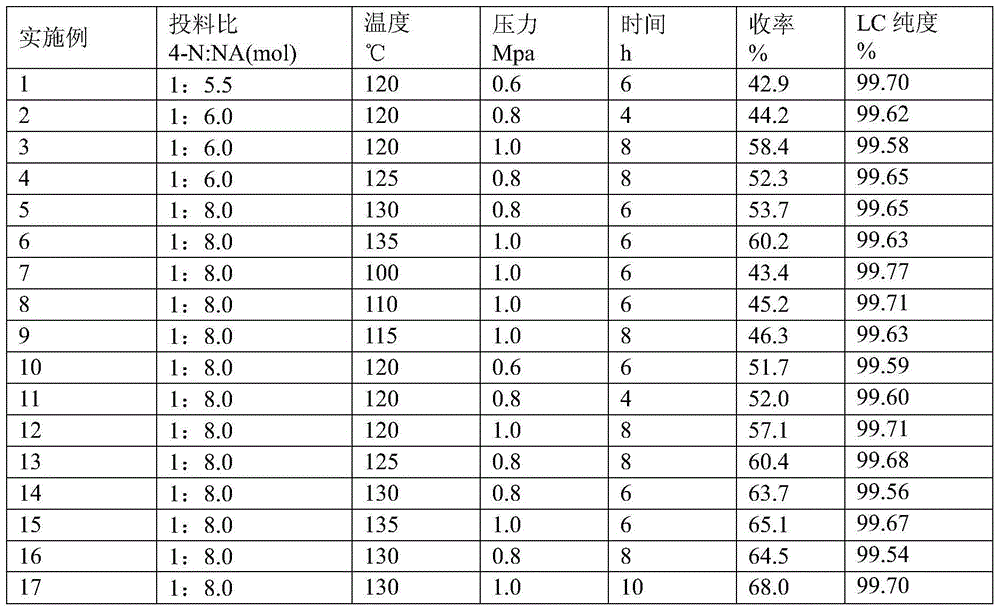

Method for preparing 3-methyl-4-nitrobenzoic acid by oxidizing with nitric acid

InactiveCN104447348AReasonable control of reaction temperatureReasonable control of reaction pressureOrganic chemistryOrganic compound preparationChromium trioxideReaction temperature

The invention relates to a method for preparing 3-methyl-4-nitrobenzoic acid by oxidizing with nitric acid. The method comprises the steps of carrying out oxidation reaction, neutralizing, extracting, decolorizing and acidifying, wherein diluted nitric acid serves as an oxidant, and 2,4-dimethyl-nitrobenzene serves as a basic raw material. The feed ratio, the reaction temperature, the reaction pressure and the reaction time are controlled reasonably, thus the problems of low reaction conversion rate and generation of many by-products are solved. Because the diluted nitric acid serves as the oxidizing agent and replaces potassium permanganate, potassium dichromate, chromium trioxide and other strong oxidizing agents which are high in cost and are difficult to recover, and the generated waste acid can be recycled, the cleanness of industrial synthesis reaction can be improved, and the pollution to environment can be reduced. The method provided by the invention has the advantages that the reaction yield is improved to over 50% from the initial 27%, the reaction condition is mild, the production and operation safety is high, the reaction equipment is simple, and the raw materials including nitric acid and 2,4-dimethyl-nitrobenzene are wide in supply and low in cost and are suitable for large-scale industrial production.

Owner:GANSU YINGUANG CHEM IND GRP CO LTD

Photosensitive composition, photosensitive film, photosensitive layered body, permanent pattern forming method and printed circuit board

InactiveCN101587298AExcellent plating resistanceConducive to preservationPhotomechanical exposure apparatusPrinted circuit manufactureAdhesivePrinted circuit board

The photosensitive composition provided in the invention characterized by composing (methyl radical) acrylic ester series adhesive, polymerized compound, neutral photopolymerization initiator, thermalcross-linking agent and compound indicated in following general formula (1) in which X means hydrogen atom or substitute with SigmaMu value higher than -0.22.

Owner:FUJIFILM CORP

Negative fluorine-contained photoresist composition and its application in polymer optical waveguide device

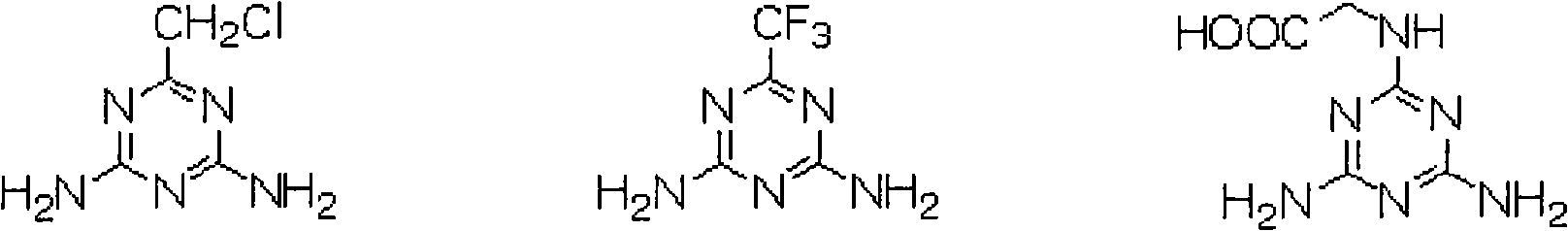

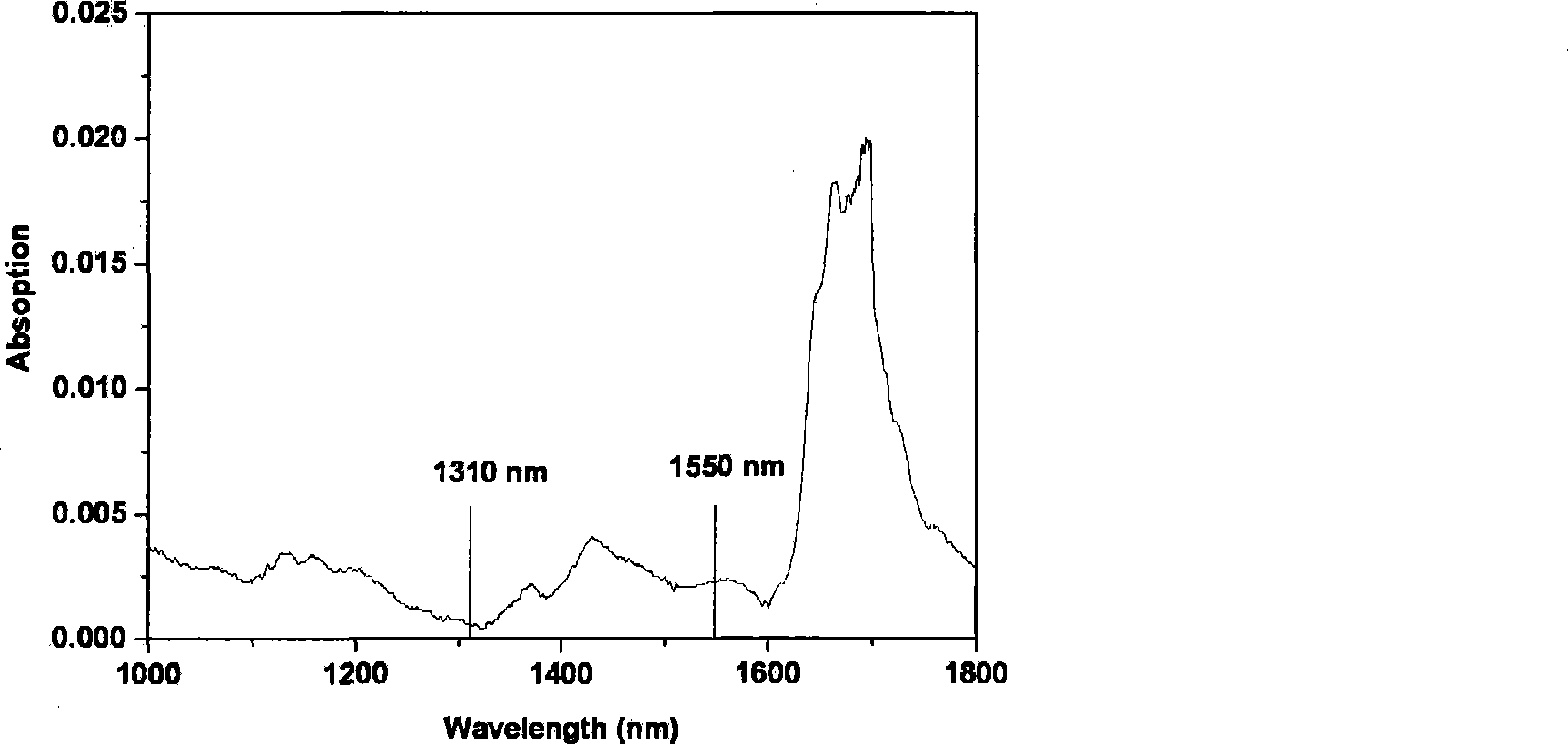

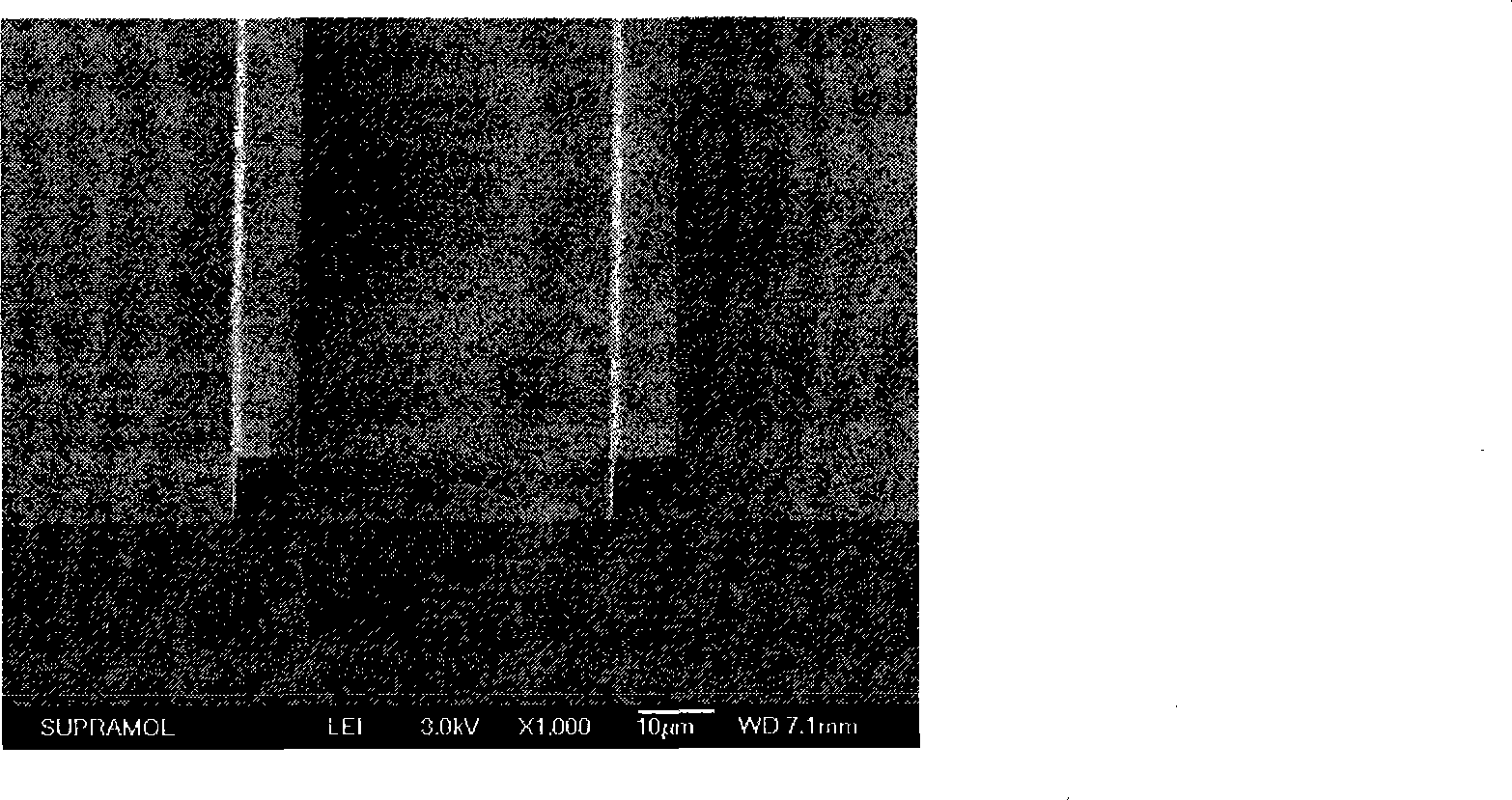

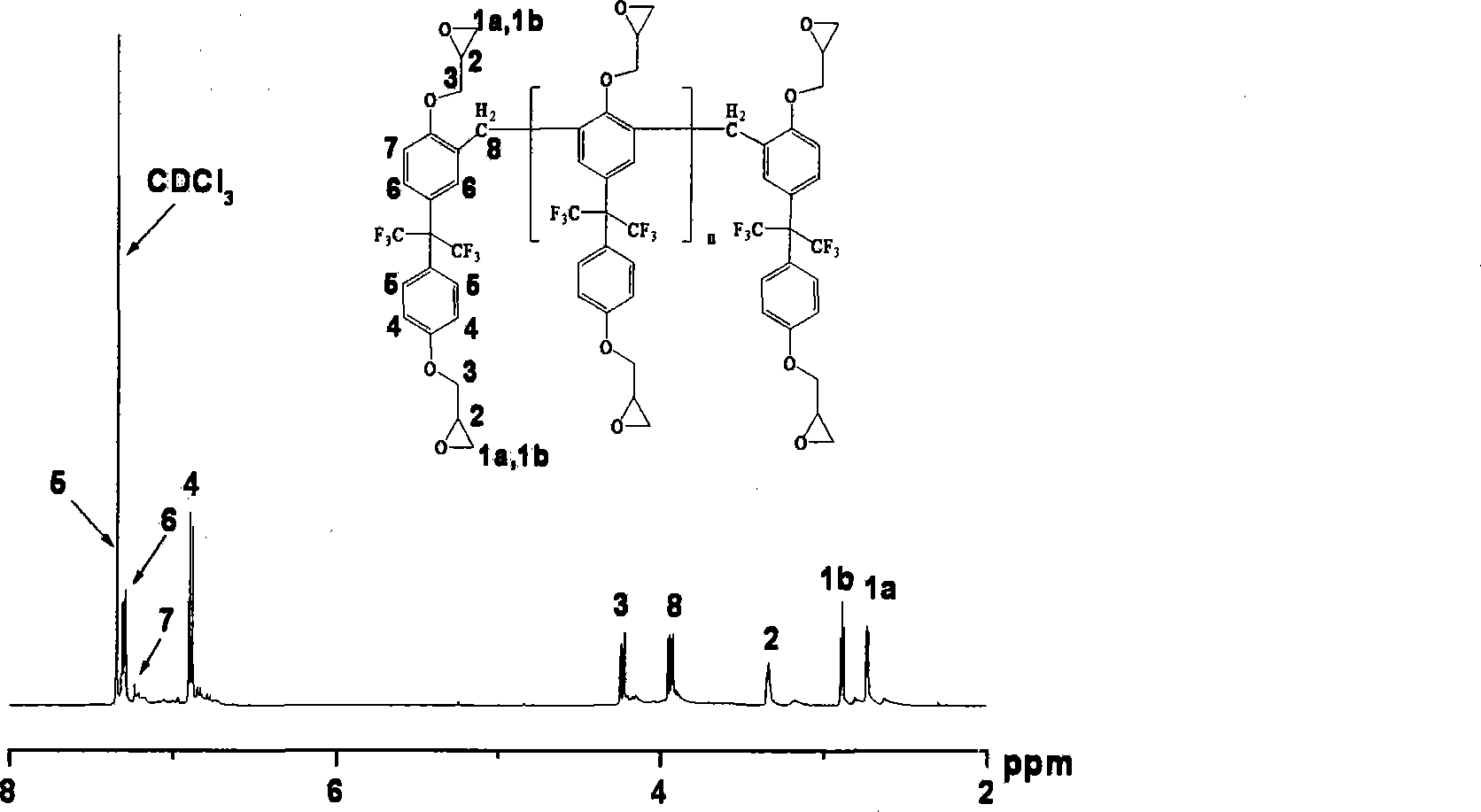

The invention belongs to optical waveguides device field, particularly relates to a negativity photoresist composition containing fluorine capable of using as polymers optical waveguides material and its application in preparing polymers optical waveguides device. The negativity photoresist composition containing fluorine contains 5.0-7.001920598hoto-induced acid-preparing object, 50.0-75.0 2.124886e-314poxy resins containing fluorine shown as formula (1) and 20.0-45.0wtH%wolvent by weight, R is chloridization (CCL2) or no-chloridization (CH2) methyl radical, n is 1-8. Because partly hydrogen atoms are superseded by fluorine atomics in epoxy resins containing fluorine, the absorption in communicating wave range is very small and the epoxy resins containing fluorine can be used as polymers optical waveguides material for preparing optical waveguides device. The photoresist composition can expose and form image to prepare optical waveguides device in ultraviolet wavelength range of 200-400nm and also can adjust exposal wavelength through changing kinds of photo-induced acid-preparing object.

Owner:JILIN UNIV

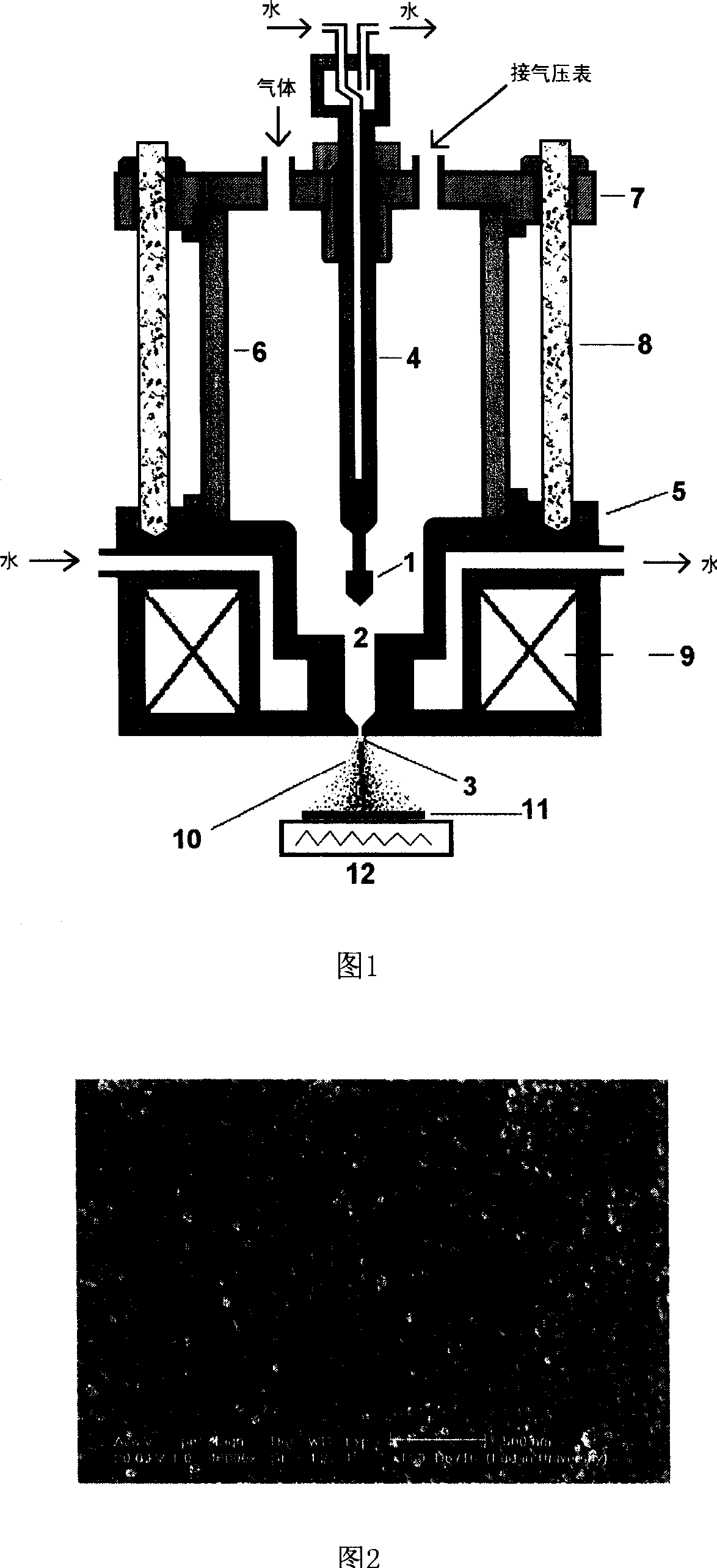

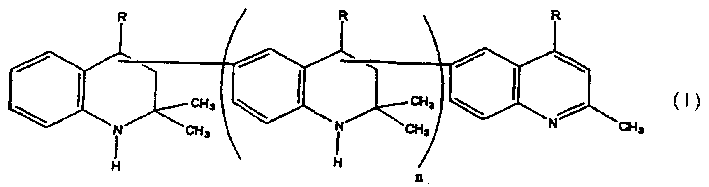

Active atom beam spraying DC discharging process for preparing nano carbon nitride film

The present invention relates to film preparing technology, and is especially one active atom beam spraying DC discharging process for preparing nanometer carbon nitride film. One set of arc heated plasma beam source is utilized to decompose methane and nitrogen to obtain outgoing particle beam comprising neutral nitrogen atoms and methyl radicals in the strength of 1019-1020 atoms / rad.sec. The outgoing particle beam reaches to the substrate to synthesize carbon nitride film at low substrate temperature. The synthesized film consists of compact 21-50 nm size spherical crystal grains of beta-C3N4, graphite phase C3N4 and CNx mainly.

Owner:FUDAN UNIV

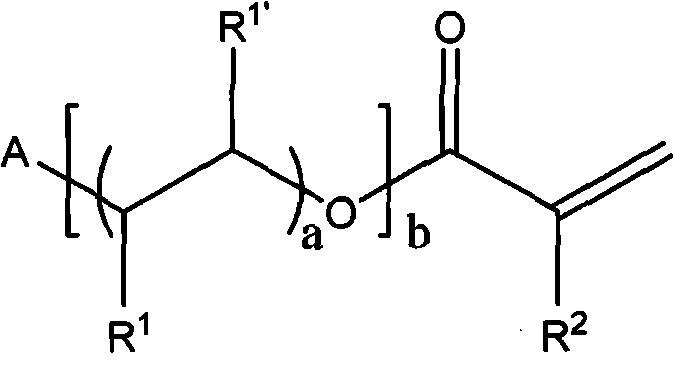

Lubricating compositions containing aromatized 1,2-dihydro-2,2,4-trimethylquinoline polymers

Lubricating compositions containing a major amount of a base oil and an effective amount of an additive component having at least one compound of formula (I):where R is one of the following radicals, methyl, ethyl, n-propyl, i-propyl or a combination thereof, and n=0-8. In a preferred embodiment, R is a methyl radical and n=2-3. The lubricating compositions provide improved lubricating performance, particularly by inhibiting oxidation and improving thermal stability.

Owner:VANDERBILT CHEM LLC

Photosensitive resin composition and a sealant

ActiveCN101713921AExcellent hydrofluoric acid resistanceHydrofluoric acid resistance decreasedPhotomechanical apparatusNon-linear opticsCarbon numberSealant

The invention provides photosensitive resin composition with excellent tolerance and permeability and a sealant. The photosensitive resin composition in the invention comprises the following components: a tail end (methyl radical) acrylic ester oligomer (A), more than one kind of monomer (B) selected from a monomer (b1) represented by the following formula (1) and a monomer (b2) represented by the following formula (2), a photopolymerization initiator (C). [Formula 1] (in the formula, A represents radical with annular amide group or annular imide, and their nitrogen-atoms combine with residuein formula (1); R1, R1' and R2 independently represent hydrogen atom or methyl radical ; a and b independently represent integer from 1 to 3). [Formula 2] (in the formula, R3 represents hydrogen atomor methyl radical; B represents single key, or alkylidene with carbon number from 1 to 5; R4 represents residue formed by removing one hydrogen atom bonded to carbon atom of the single ring or multi ring cyclic lactone compound).

Owner:TOKYO OHKA KOGYO CO LTD

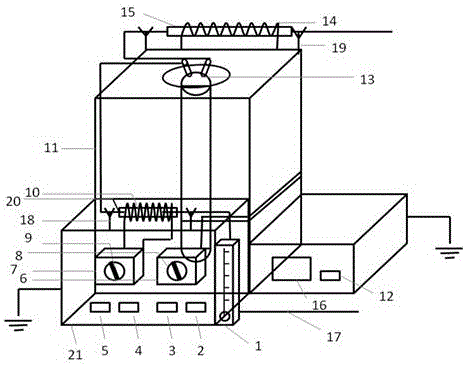

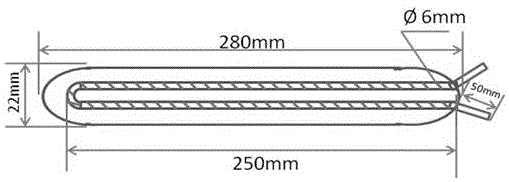

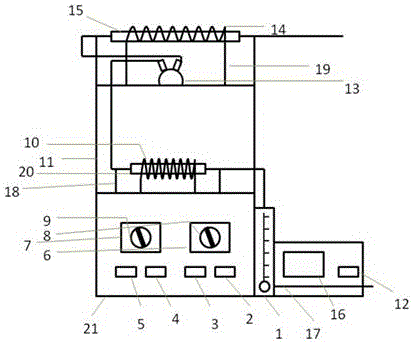

Thermal desorption, gas-phase separation and thermal cracking system based on ethylation derivation of methyl mercury

The invention discloses a thermal desorption, gas-phase separation and thermal cracking system based on ethylation derivation of methyl mercury, comprising a thermal desorption part, a gas-phase separation part, a thermal cracking part, a gas flowmeter, a Teflon FEP pipeline and a pressure regulating and temperature control switch chamber, wherein the thermal desorption part comprises a thermal desorption heater strip switch, a thermal desorption heater strip time control switch, a thermal desorption heater strip pressure regulator, a pressure regulating knob of the thermal desorption heater strip pressure regulator, a thermal desorption heater strip and a Tenax adsorption pipe; the gas-phase separation part comprises a heater jacket, a heater jacket switch, an OV-3 packed column and a heater jacket temperature control plate; and the thermal cracking part comprises a thermal cracking heater strip switch, a thermal cracking heater strip time control switch, a thermal cracking heater strip pressure regulator, a pressure regulating knob of the thermal cracking heater strip pressure regulator, a thermal cracking heater strip and a quartz pipe. The system realizes the aim of integration of thermal desorption, gas-phase separation and thermal cracking devices, and simultaneously, each part can be individually operated, thereby saving the analysis time, having low manufacturing cost and greatly reducing experiment cost.

Owner:OCEAN UNIV OF CHINA

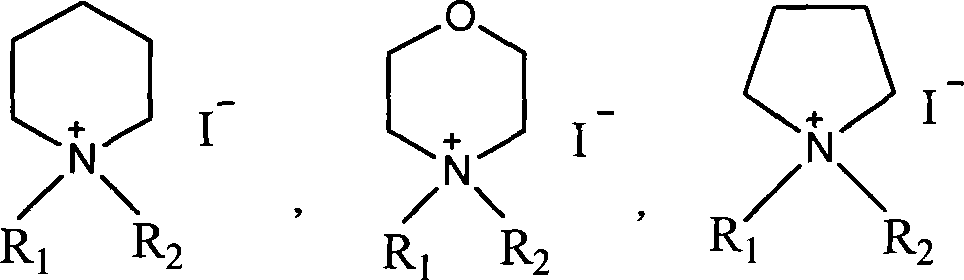

Bi-radical compound composed of triaryl methyl radical and nitroxide radical and salt thereof and preparation method and application of bi-radical compound composed of triaryl methyl radical and nitroxide radical and salt thereof

ActiveCN108794510AExcellent frequency matchingHigh CE efficiencyOrganic chemistryWater resource assessmentMagic angle spinningSolubility

The invention provides a bi-radical compound composed of a triaryl methyl radical and a nitroxide radical and salt thereof and a preparation method and application of the bi-radical compound composedof the triaryl methyl radical and the nitroxide radical and the salt thereof. A structural formula of the bi-radical compound is as shown in the formula 1; the formula is shown in the description; thepreparation method comprises the steps that a compound A1 and a compound A2 are subjected to acid amide condensation reaction to obtain a compound A3; the compound A3 and a compound A4 are subjectedto acid amide condensation reaction to obtain the bi-radical compound and the salt thereof. The portion, provided with both the nitroxide radical and the triaryl methyl radical, of a bi-radical polarization agent has the following advantages that the frequency matching ability is better, and the CE efficiency is higher; under a magic angle spinning condition, a depolarization effect does not exist, and a high field DNP enhancing effect is better; exchange interaction is stronger; the water solubility is good, so that the DNP enhancing multiple is high; by modifying R1, R2, R3, R4, R5 and R6 groups, exchange interaction can be improved moderately, bi-radical relaxation time can be prolonged moderately, and the bi-radical water solubility can be improved moderately, so that the DNP propertyof the polarization agent is improved.

Owner:TIANJIN MEDICAL UNIV

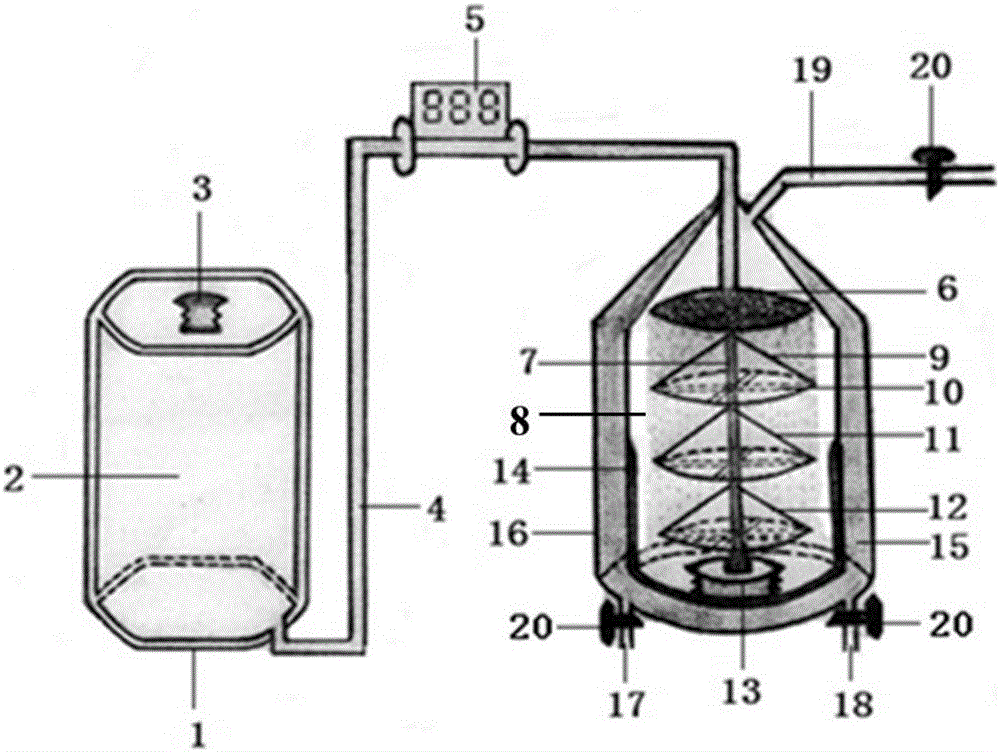

Multi-bed reaction device for preparing hydrogen by sodium borohydride alcoholysis

ActiveCN106744678AAccurate quality controlPrecise control of flow rateHydrogen productionHydrogen/synthetic gas productionHydrogen productionLiquid solid

The invention discloses a multi-bed reaction device for preparing hydrogen by sodium borohydride alcoholysis. The multi-bed reaction device comprises a sodium borohydride storage tank, a flow controller, a sprayer, a catalyst reaction bed, a heat exchanger and a product recovery tank; the sodium borohydride storage tank is used for storing an alkaline sodium borohydride methanol solution; the flow controller is used for adjusting the flow velocity and flow rate of the solution; the sprayer is arranged at the top of the hydrogen production reaction tank; the catalytic reaction bed comprises at least two layers of catalyst reaction beds; the heat exchanger is used for regulating and controlling the temperature of the reaction tank. The product recovery tank is placed at the bottom of the reaction tank to collect the reactants sodium tetramethylborate for following recovery and reuse. The multi-bed reaction device is capable of improving the utilization rate of the reactants and realizing the precise control over hydrogen production quantity. The contact of the reactants with the catalyst is expanded, the liquid-solid separation is more thorough, the influence of concentration difference gradient is eliminated, furthermore the catalyst utilization rate is improved, and the cost of precious metal is reduced.

Owner:XUZHOU NORMAL UNIVERSITY

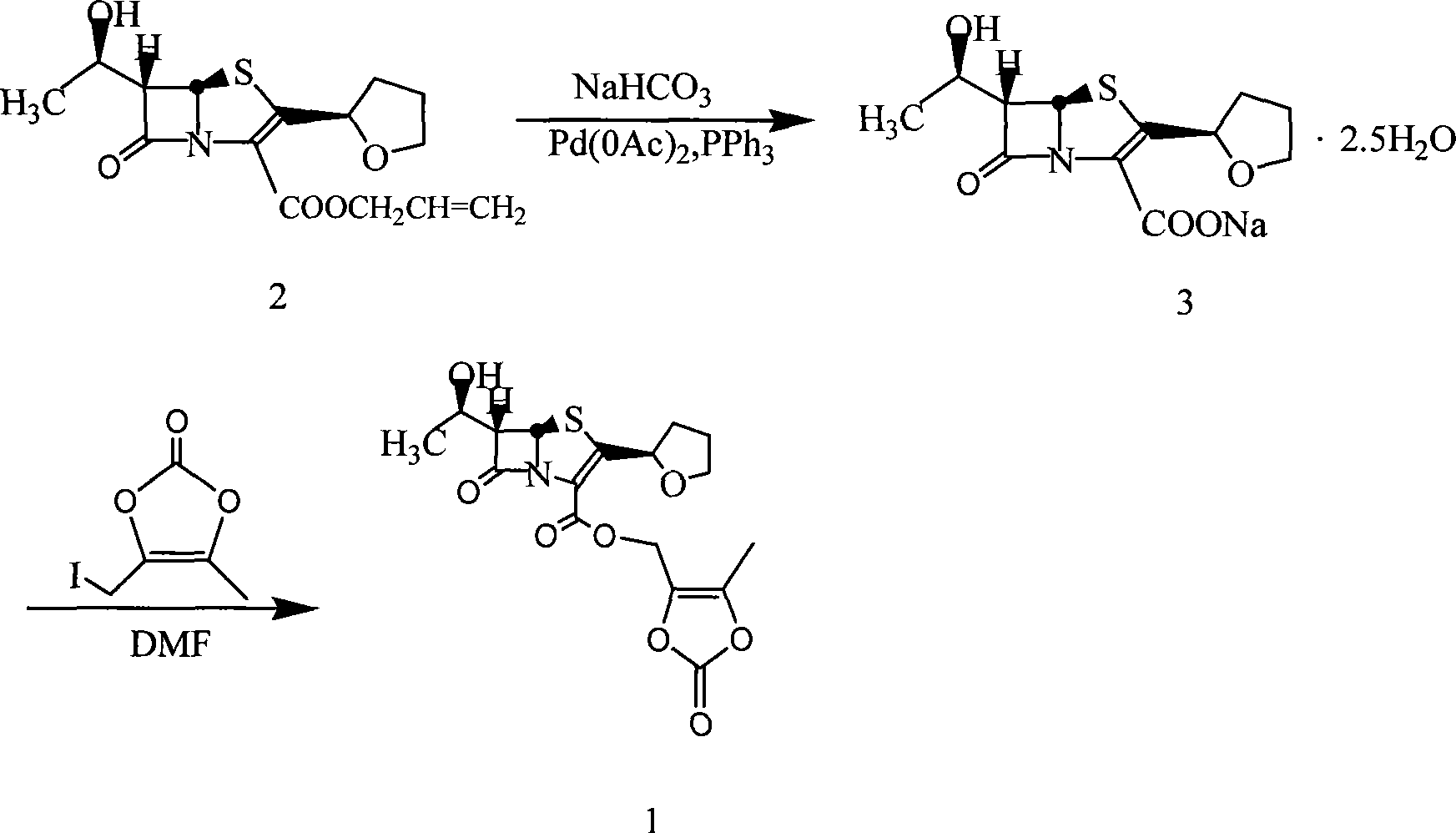

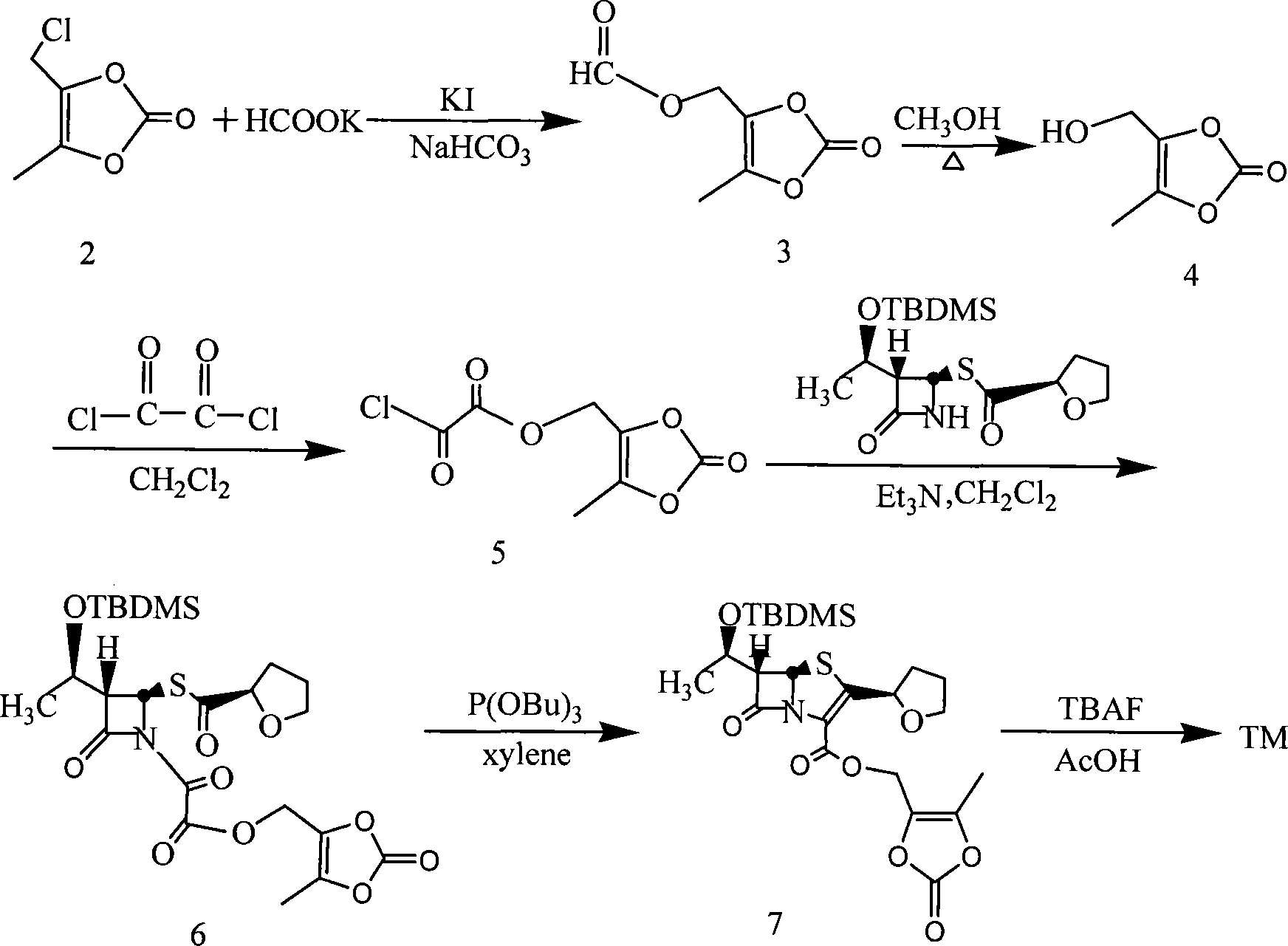

Method for preparing faropenem daloxate

ActiveCN101235044AEasy to operateLow costOrganic chemistryAntiinfectivesCyclopenteneChemical synthesis

The invention relates to a preparation method of faropenem medoxomil, belonging to chemical synthesis technical field, which is characterized in that faropenem and 4-halogenated methyl radical-5-methyl-1, 3-dioxane cyclopentene-2-ketone, in alkali condition and solvent A, via phase transfer catalyst and reaction promoter containing iodine are synthesized to obtain faropenem medoxomil, or the inorganic salt of faropenem medoxomil and 4-halogenated methyl radical-5-methyl-1, 3-dioxane cyclopentene-2-ketone, in solvent B, via phase transfer catalyst and reaction promoter containing iodine are synthesized to obtain faropenem medoxomil. The method has simple operation, mild reaction and saved cost, while the synthesized faropenem medoxomil has high yield and purity.

Owner:NANJING HUAWE MEDICINE TECH DEV +1

Laser soldering flux for Cu-Mg-Sn-Fe composite nanomaterial and preparation method of laser soldering flux

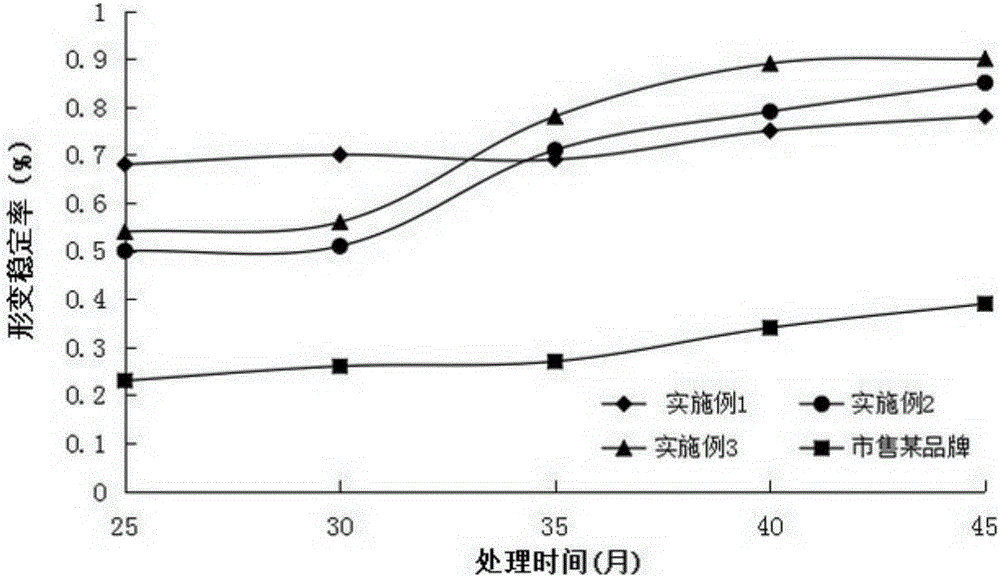

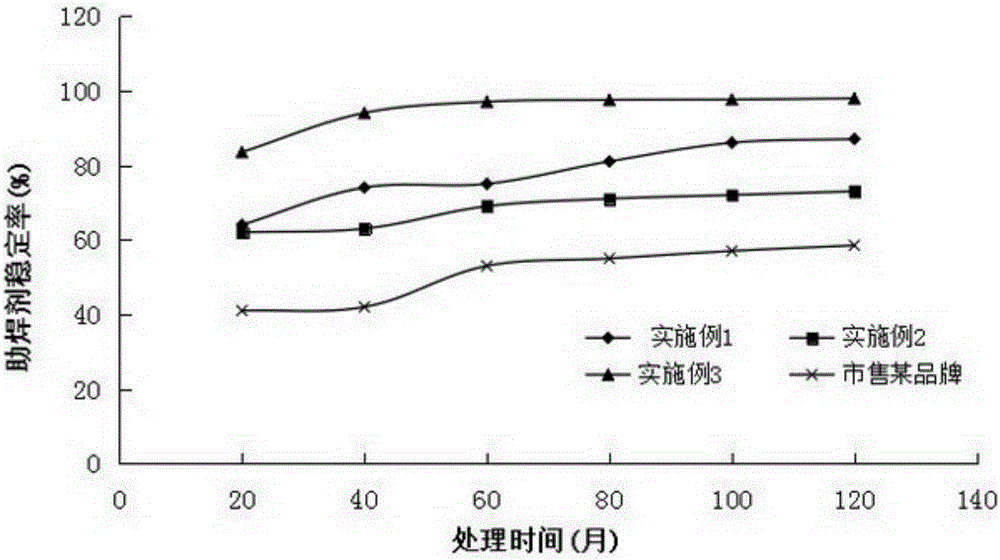

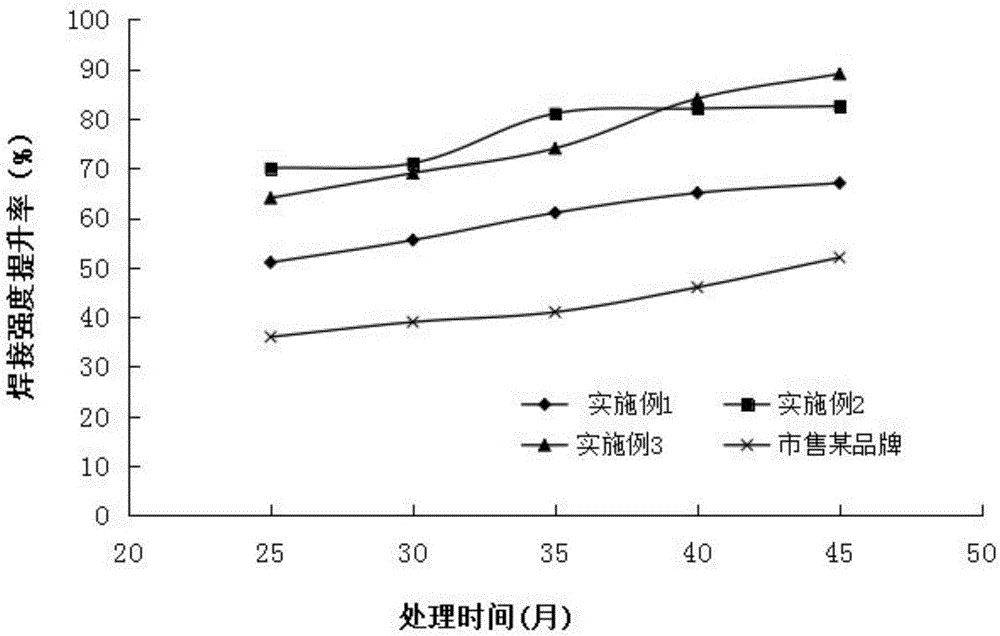

InactiveCN106216883AImprove welding strengthReduce welding stressWelding/cutting media/materialsSoldering mediaNitrosoCarboxylic salt

The invention discloses laser soldering flux for a Cu-Mg-Sn-Fe composite nanomaterial and a preparation method of the laser soldering flux. The laser soldering flux is prepared from, by weight, pure water, polyoxyethylene(4)C8alcohol ether, polyoxyethylene polyoxypropylene ether carboxylate of fatty alcohol, N-methyl(13C)-N-nitroso para toluene sulfonamide, 3-nitrophthalimide, 1-hydroxy-4-(para-toluene amino)anthraquinone, 1-amino-2-[4-[(hexahydro-2-oxo-1H-azepin-1-yl) methyl]phenoxy]-4-hydroxy-9,10-anthraquinone, methoxybenzyl alcohol and mercury nanoparticles. The laser soldering flux has the beneficial effects that according to the method, welding strength can be improved, welding stress and welding deformation are greatly reduced, the process is stable, the application range is wide, cooling is fast, the effect is good, and different welding requirements are met.

Owner:XUZHOU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com