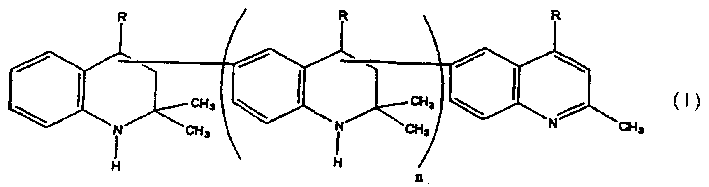

Lubricating compositions containing aromatized 1,2-dihydro-2,2,4-trimethylquinoline polymers

A lubricating composition and composition technology, applied in a lubricating composition, ethyl, n-propyl or isopropyl, in which R is one of the following groups: the field of methyl, which can solve the problem of reduced lubricating performance and insufficient Problems with protecting equipment or machinery, falls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] To evaluate thermal stability, several lubricating compositions were prepared and evaluated. Sample A contained a formulated diester base oil (XR No. 2437-RT, manufactured by Quaker USA) and was used as a control. Sample B contained a formulated diester base oil and 2% by weight of AGERITE MA (arylated 1,2-dihydro-2,2,4-trimethylquinoline polymer containing mainly 2-6 monomer units) . Sample C contained a formulated diester base oil and 2 wt% of VANLUBE RD (a non-aromatic 1,2-dihydro-2,2,4-trimethylquinoline consisting of dimer and trimer units) and Also used as a comparative sample.

[0089] Thermal stability was evaluated by a modified ASTM D2070-91 test for thermal stability of oil-based compositions. The test is commonly known as the Cincinnati Milacron method. Copper and steel rods in contact with oil were evaluated for appearance and weight loss after exposure at 135°C for 168 hours. Sludge was determined by filtering the oil through No. 41 Whatman packing and...

Embodiment 2

[0093] The high temperature stability of base oils comprising arylated and non-arylated TMDQ polymers was evaluated. Lubricating compositions were prepared using different concentrations of the TMDQ polymer described in Example 1. The thermal stability of the composition was evaluated using the standard ICI thermal stability test, ie, requiring heating of a sample of the lubricating composition in a 150 ml beaker with a steel coupon at 200°C for 24 hours. The composition and thermal stability test results of the samples are listed in Table 4.

[0094] mass percentage

[0095] As can be seen from Table 4, lubricating compositions comprising arylated TMDQ polymers are clearly superior to lubricating compositions comprising non-aromatic TMDQ polymers. For example, at 1.0 wt% of the additive, the weight loss of the composition containing the arylated polymer was 59.2, while the weight loss of the composition containing the non-aromatic polymer was 63.5. At 2.0 wt% ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com