Patents

Literature

379 results about "Nitroxide radical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

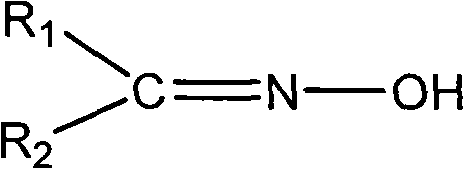

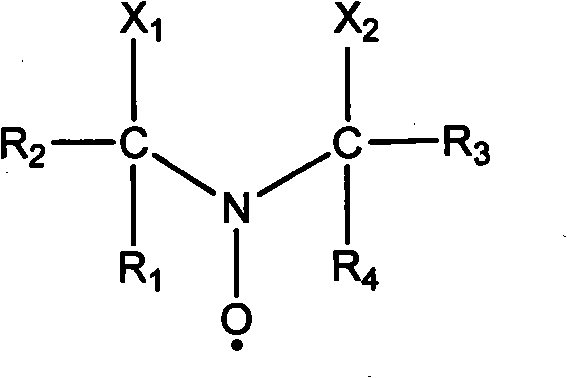

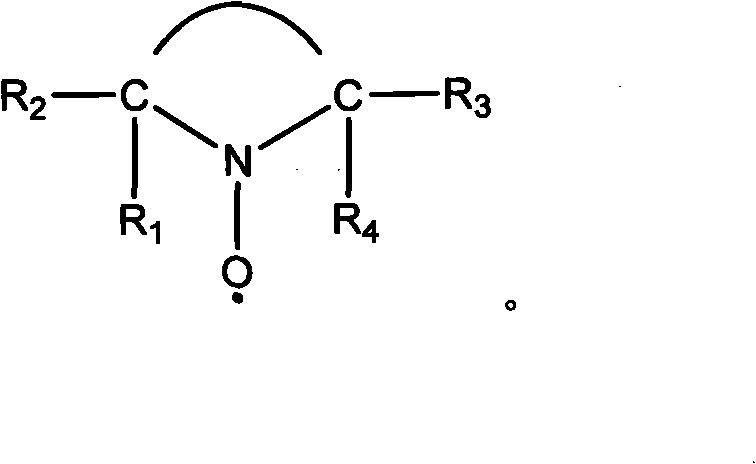

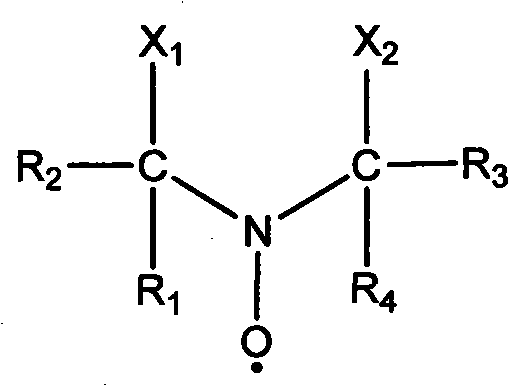

Polymerization in the presence of a beta-substituted nitroxide radical

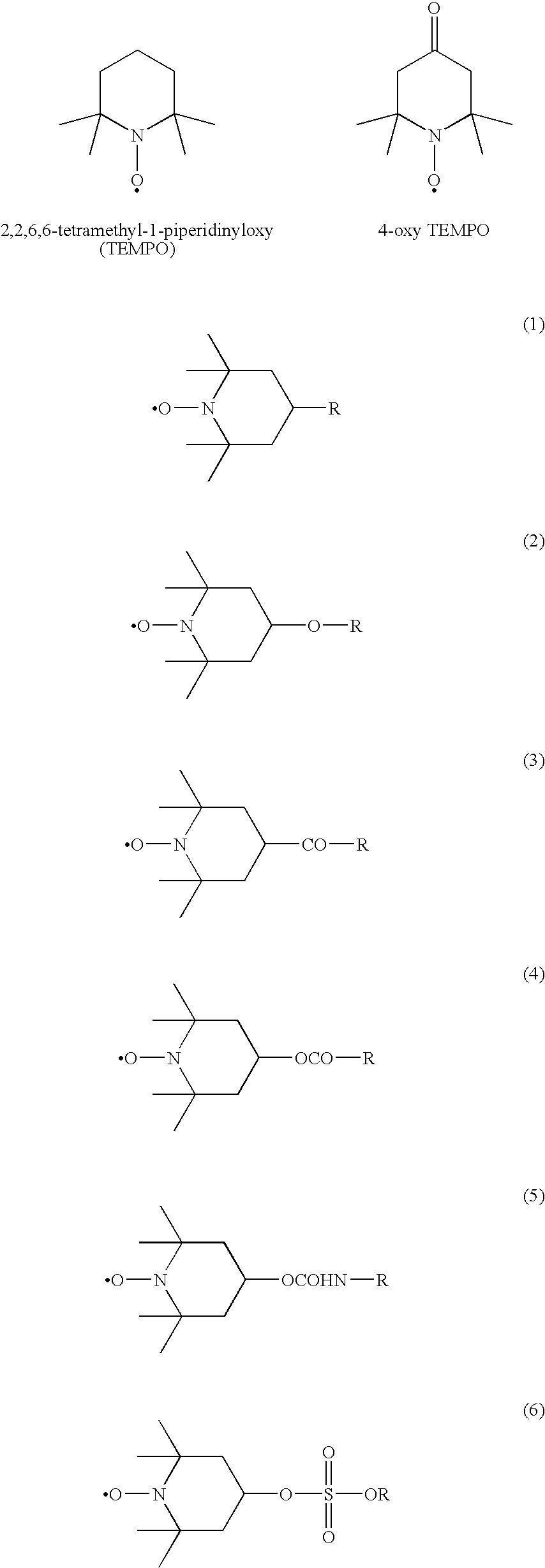

The invention relates to a process for the polymerization or copolymerization of at least one monomer which is polymerizable by the radical route in the presence of a stable free radical from the nitroxide family. The stable free radical is beta-substituted and provides excellent control of polydispersity while ensuring a better rate of polymerization or copolymerization, if they are compared with the stable free radicals used in the prior art.

Owner:ELF ATOCHEM SA

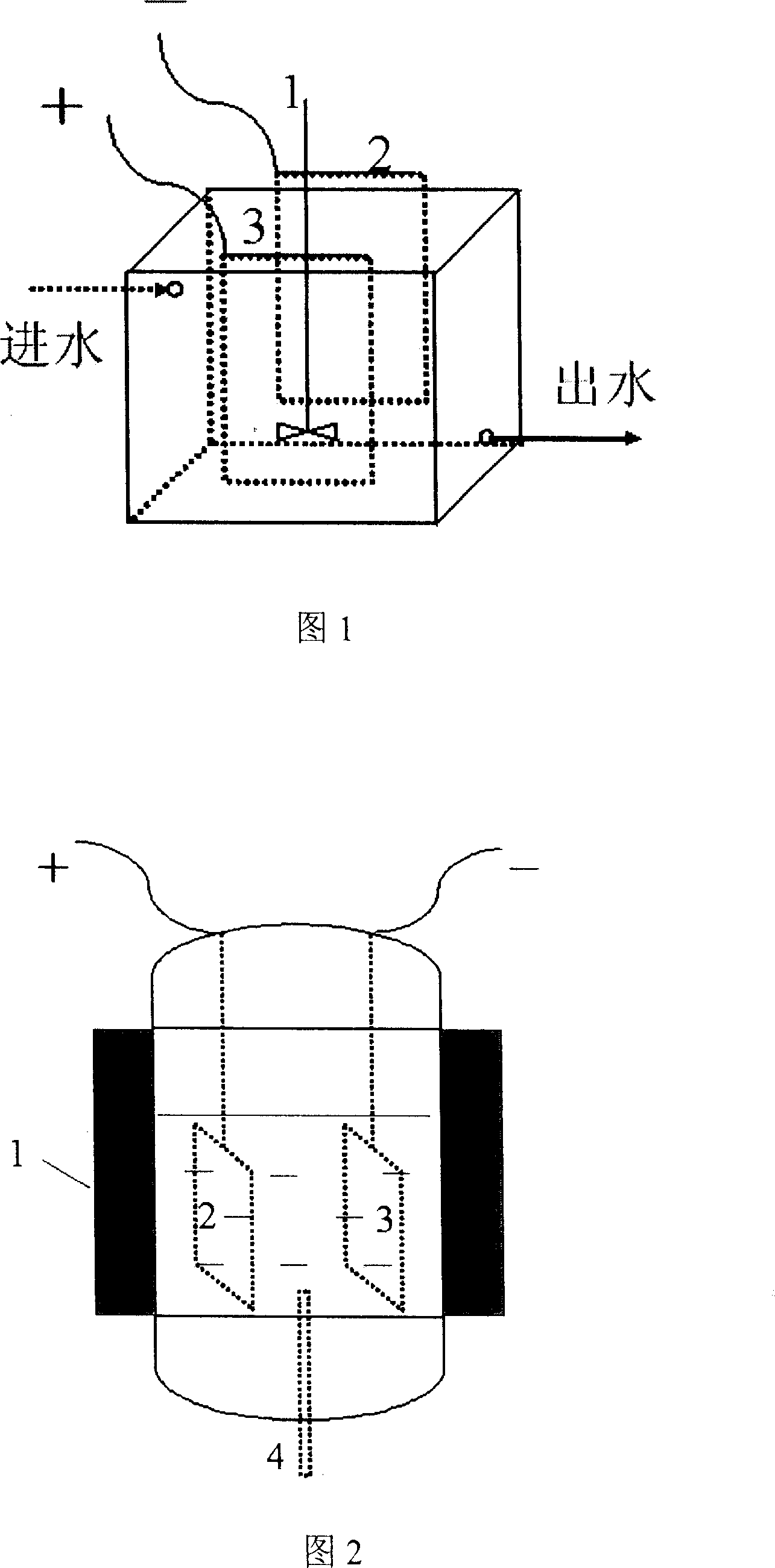

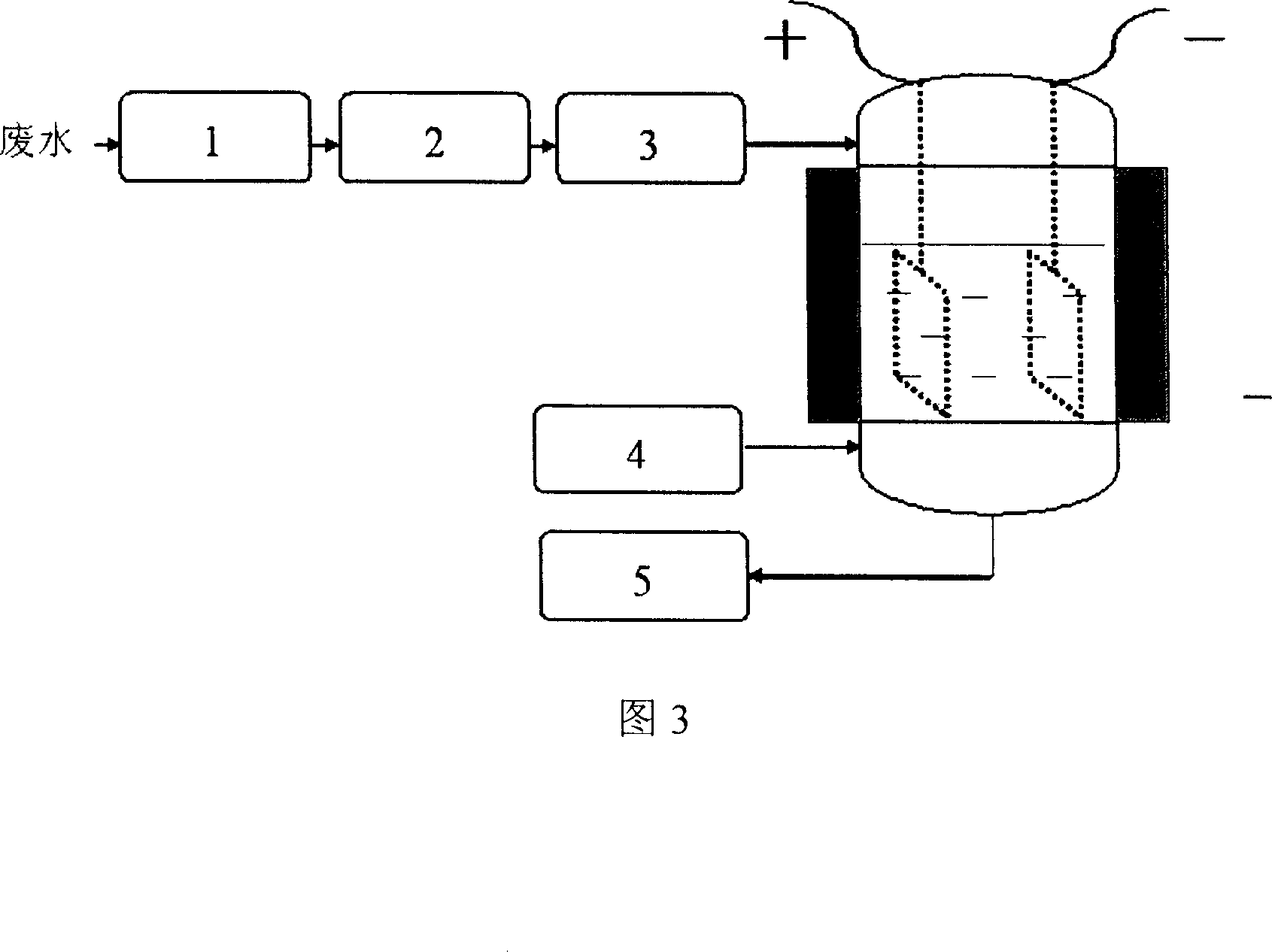

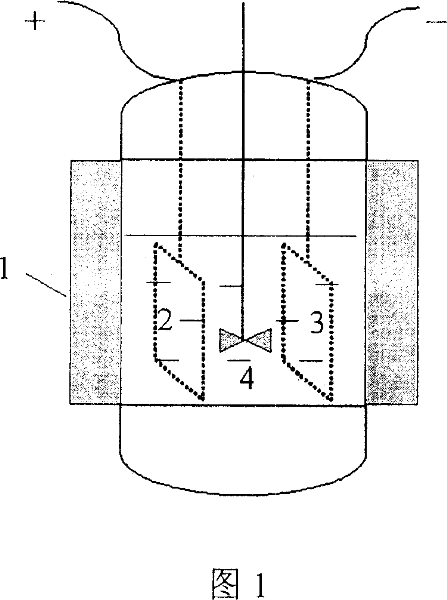

Process of treating refractory organic effluent with free radical and electrically catalyzed reactor therewith

InactiveCN101020590AImprove processing efficiencyEfficient use ofWater contaminantsWater/sewage treatment by electrochemical methodsHigh concentrationDecomposition

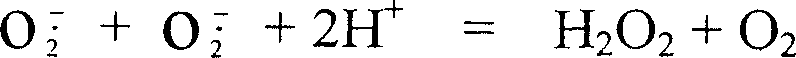

The present invention is process of treating refractory organic effluent with free radical and the electrically catalyzed reactor therewith. The present invention features that in an electrochemically hydrating proton reaction kettle and in the presence of initiator, free hydroxyl radical, superoxide anion free radical, free nitrogen radical, active free oxygen radical, etc are generated circularly and reacted in an electrically catalyzing high pressure reaction kettle with various kinds of refractory organic compounds for efficient decomposition. The present invention has high organic waste water degrading rate and low cost, and is suitable for high concentration organic waste water treatment in papermaking, petrochemical and other industry.

Owner:BEIJING GUOLIYUAN POLYMER SCI & TECH R & D CENT

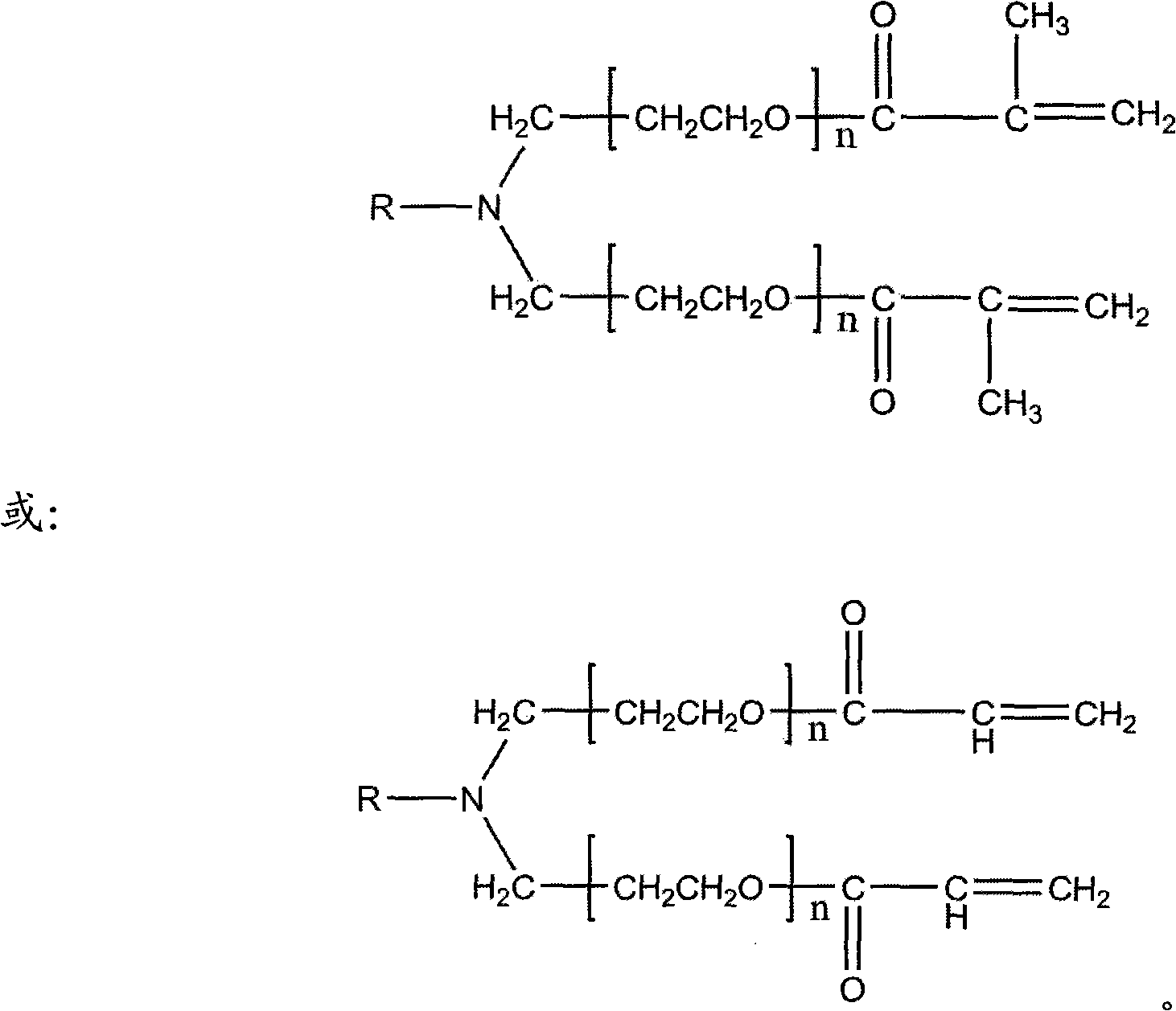

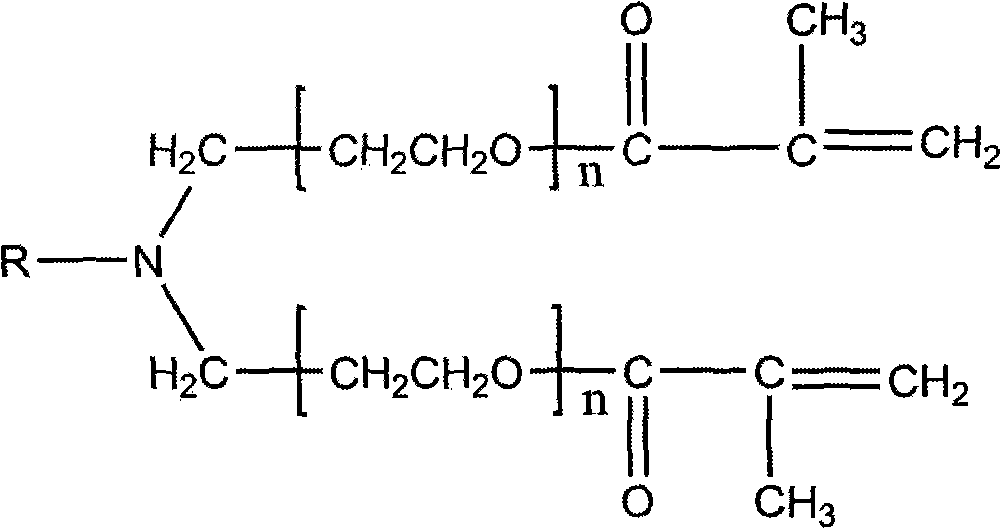

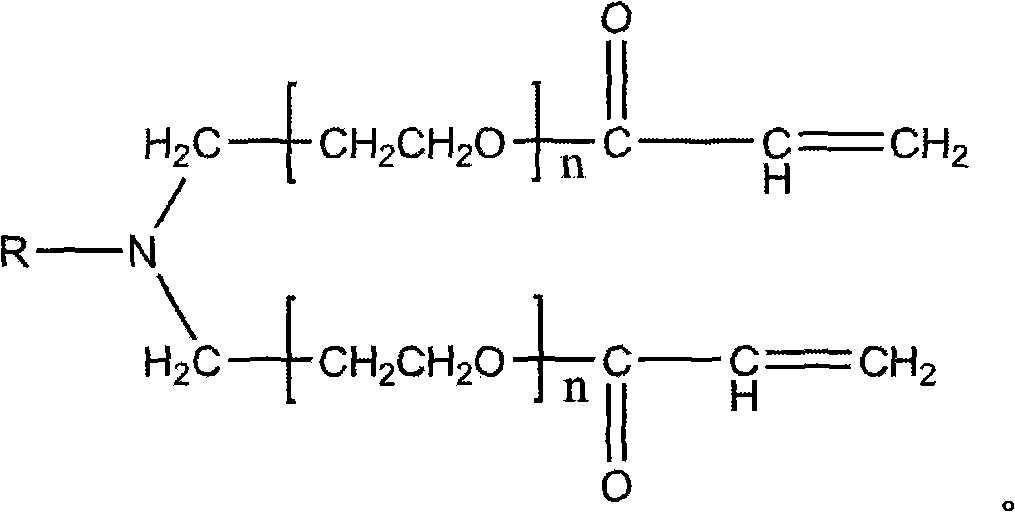

Thickening agent synthesized by acrylic ester and preparation method thereof

InactiveCN101619543AGood thickening effectStrong electrolyte resistanceOrganic compound preparationDyeing processTextile printerSodium methoxide

The invention discloses a preparation method for synthesizing a thickening agent by acrylic ester. The thickening agent synthesized by acrylic ester comprises crylic acid, acrylamide, 25 percent of ammonia water, a functional monomer, EDTA, deionized water, tasteless kerosene, 3<#> white oil, diallyl phthalate, ammonium persulphate, Span 80 and isomeric hexadecanol polyethenoxy ether, wherein the functional monomer is prepared from alicyclic amine polyethenoxy ether, methyl methacrylate, nitroxide free radical pipradrol and sodium methoxide. The preparation method synthesizes a special weak cation type (methyl) acrylic ester functional monomer by adopting an ester exchange method, and the functional monomer and vinyl monomers of the acrylic acid, the acrylamide, and the like are adopted to synthesize a textile printing thickening agent by adopting inverse emulsion polymerization. The thickening agent has the characteristics of high thickening capacity, strong electrolyte resistant capacity and good water-retaining property.

Owner:成都德美精英化工有限公司

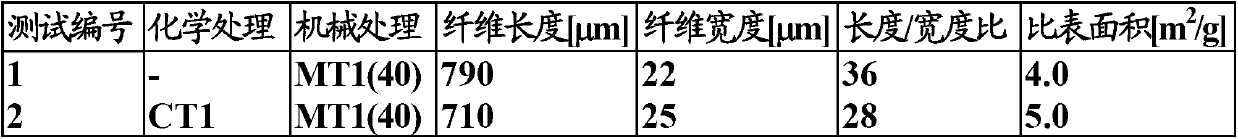

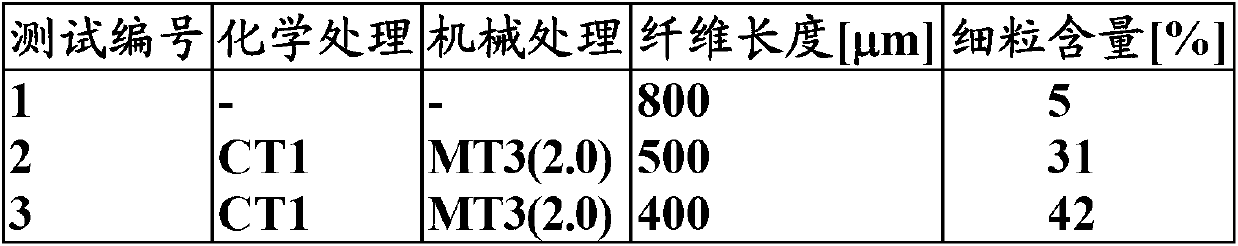

Cellulosic fibre composition

InactiveCN102971462AEasy to prepareWithout significant loss of qualityWood working apparatusPaper/cardboardChemical treatmentNitroxyl radicals

The invention relates to a composition comprising cellulosic fibres having an average degree of substitution of anionic groups of from 0.001 to 0.25, and DEG a length weighted mean fibre length up to 1,100 [mu]m and a length weighted mean fibre width over 10 [mu]m, or DEG a length weighted mean fibre length up to 1,100 [mu]m, and wherein at least 50 % by weight of the cellulosic material is insoluble in water, or DEG a length weighted mean fibre length / width ratio up to 30, or DEG a length weighted mean fibre width over 35 [mu]m. The invention also relates to a composition comprising cellulosic fibres having a specific surface area of at least 1.5 m2 / g, a length weighted mean fibre length / width ratio up to 30, and a dry solids content of at least 5 % by weight, based on the weight of the composition, or up to 30 % by weight, based on the total weight of the cellulosic fibres, of cellulosic fibres with a length weighted mean fibre length up to 100 [mu]m. Method of producing a composition comprising cellulosic fibres which comprises subjecting cellulosic fibres to chemical treatment and mechanical treatment, wherein the chemical treatment comprises treating cellulosic fibres with (i) at least one agent containing a carboxyl group, optionally substituted, (ii) at least one oxidant and at least one transition metal, or (iii) at least one nitroxyl radical, and the mechanical treatment comprises subjecting cellulosic fibres to extrusion with a twin-screw extruder or a planetary roller extruder. The invention also relates to a method of producing a composition comprising cellulosic fibres which comprises subjecting cellulosic fibres having an average degree of substitution of anionic groups of from 0.001 to 0.25 to extrusion. The invention also relates to a composition comprising cellulosic fibres obtainable by the methods, a process for producing a cellulosic pulp mixture which comprises mixing the composition with cellulosic pulp, a cellulosic pulp mixture obtainable by the process, and the use of the composition and cellulosic pulp mixture as an additive in the production of paper and board, processes for producing paper and board in which the composition or cellulosic pulp mixture is used, paper and board obtainable by the processes, and various uses of the paper and board.

Owner:AKZO NOBEL CHEM INT BV

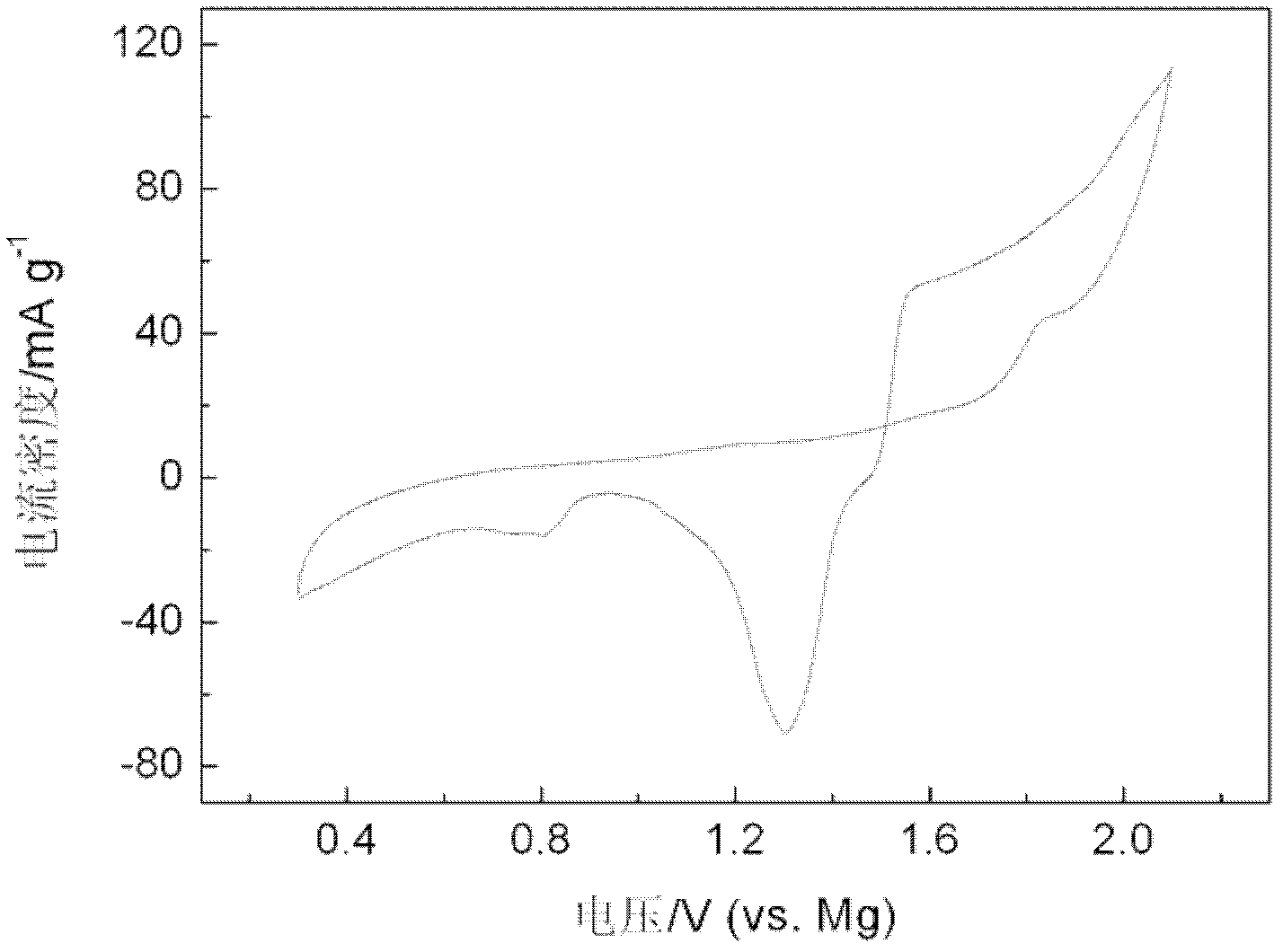

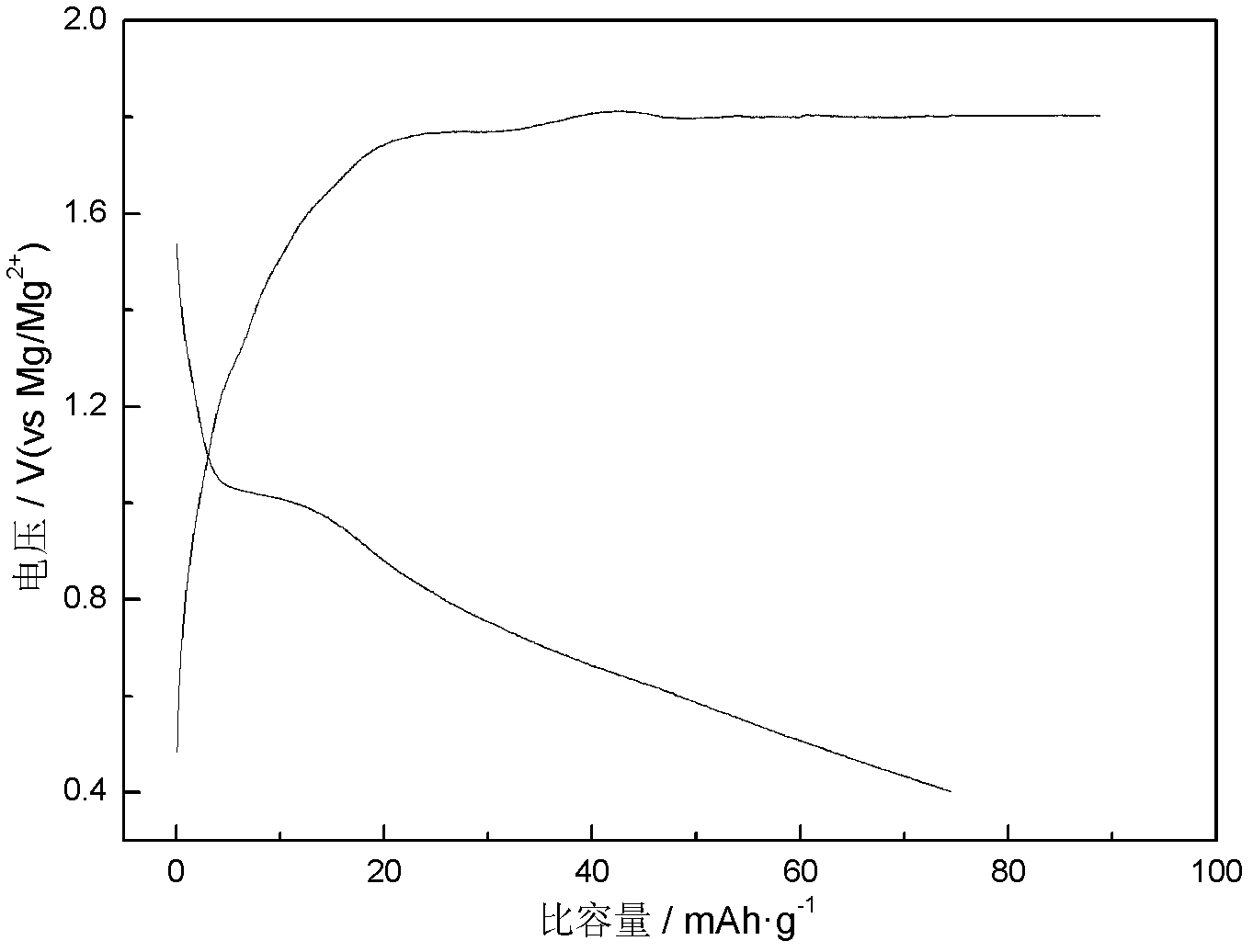

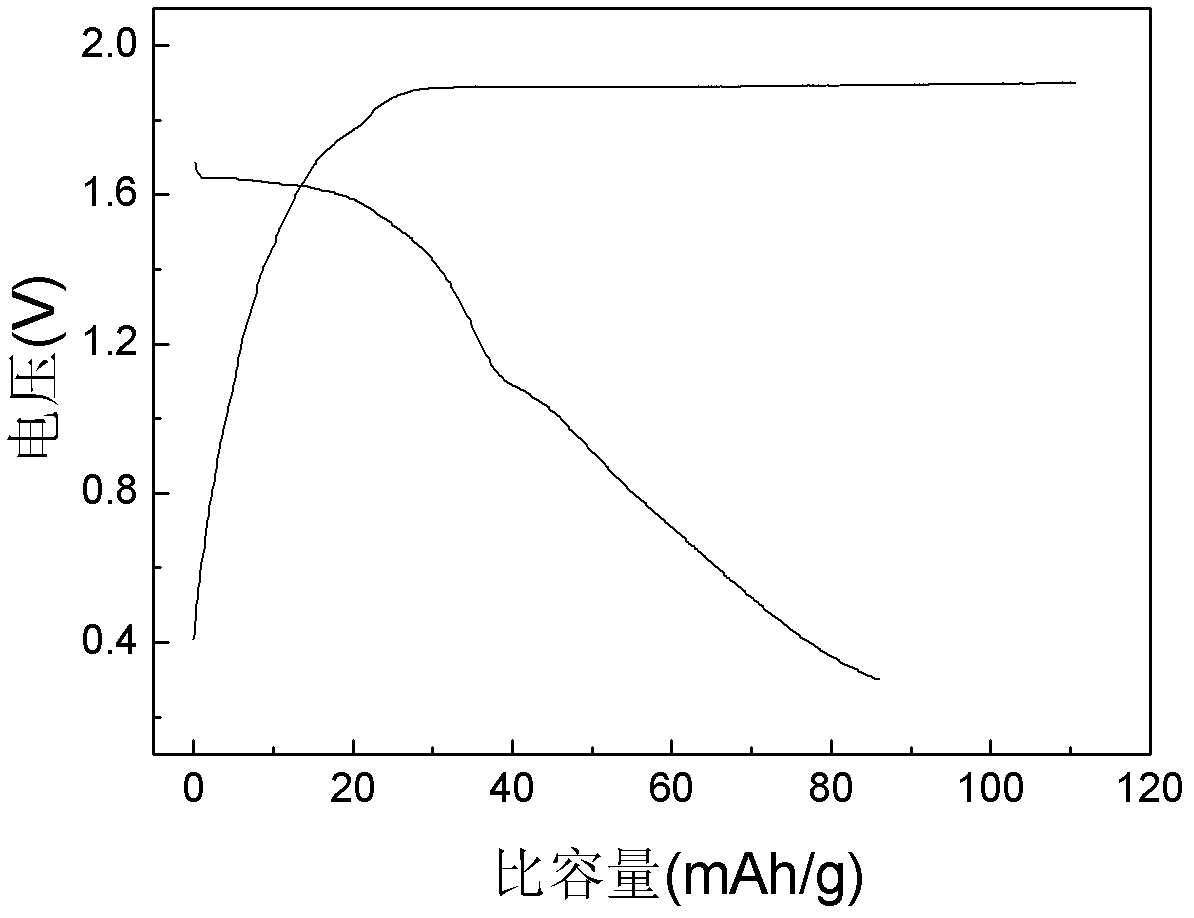

Rechargeable magnesium battery taking oxygen-containing organic matter as cathode material, and preparation method thereof

InactiveCN102683744AEasy to manufactureIncrease discharge voltage platformCell electrodesSecondary cellsQuinoneOrganic matter

The invention discloses a rechargeable magnesium battery taking oxygen-containing organic matter as a cathode material, and a preparation method of the rechargeable magnesium battery, wherein the oxygen-containing organic matter comprises the components of quinones, phenols, anhydrides derivatives and a compound containing nitro and oxygen radical. The battery and the method have the advantages of being simple in preparation technology, easy to process, environment-friendly and high in regeneration. The rechargeable magnesium battery prepared by the invention has the advantages of being relatively good in structural stability and circulation stability, rich in raw materials, safe in system and the like.

Owner:SHANGHAI JIAO TONG UNIV

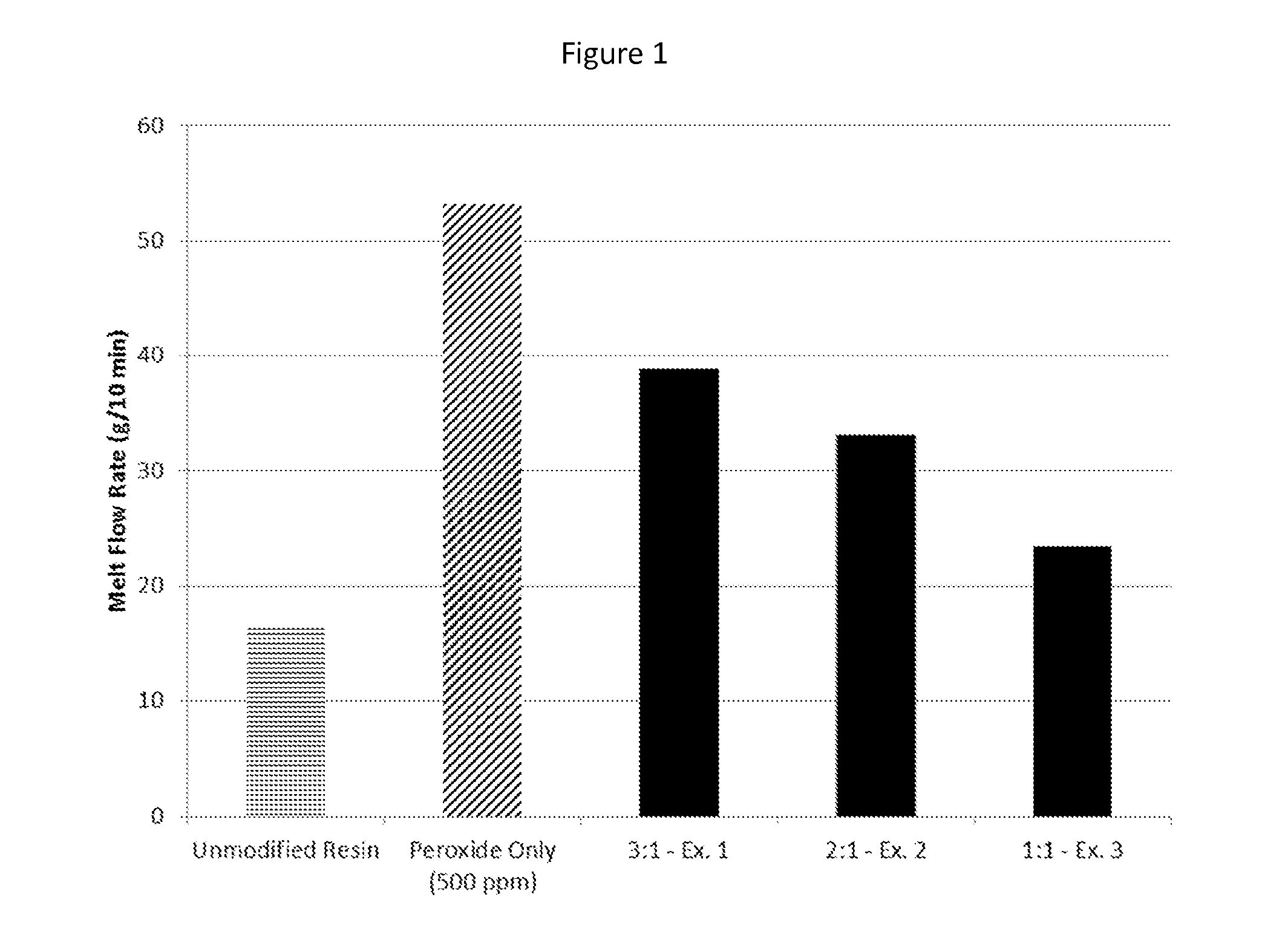

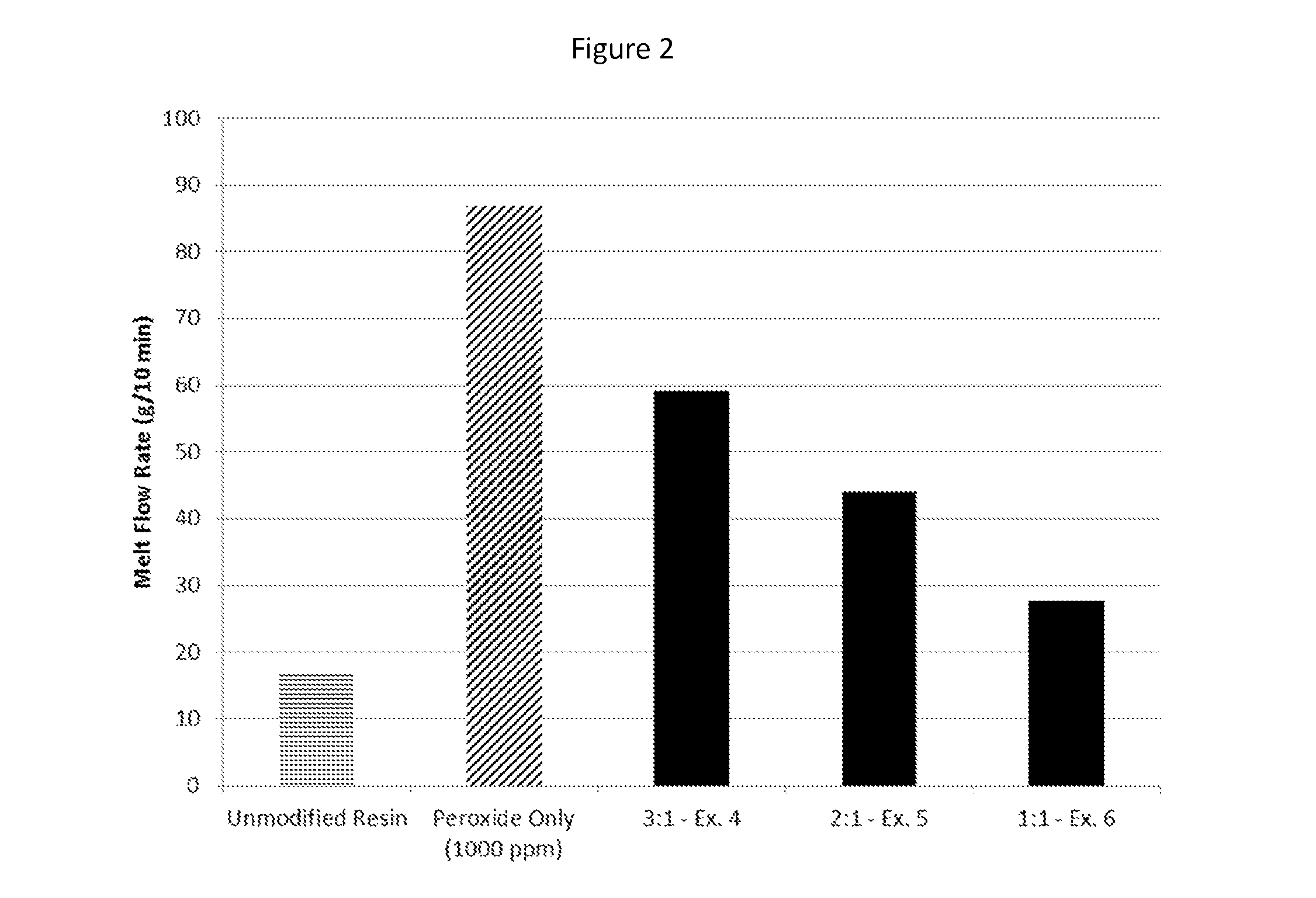

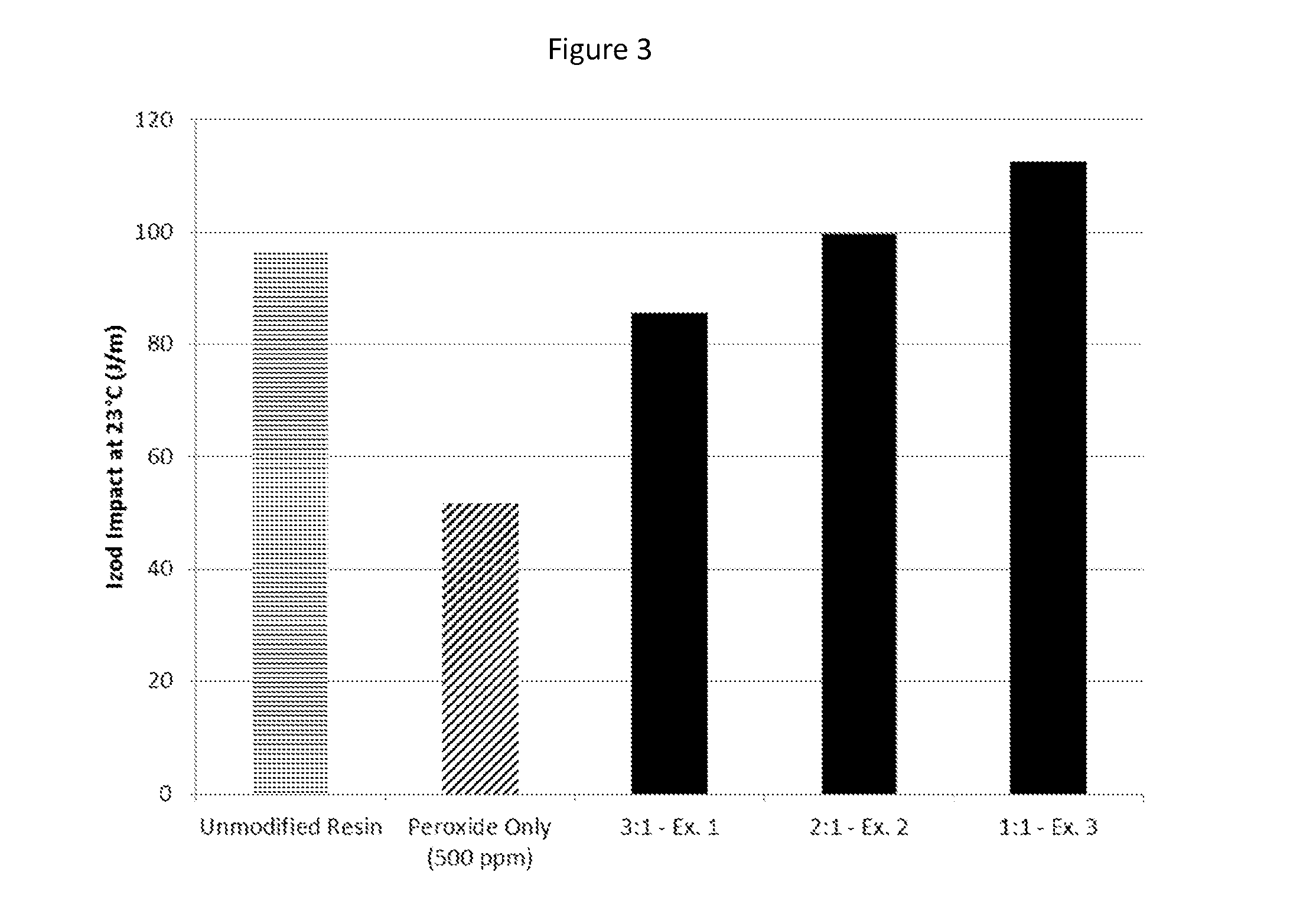

Modified heterophasic polyolefin composition

A method of creating a modified heterophasic polyolefin composition is provided, whereby a polyolefin composition having at least two phases is melt mixed with a free radical generator, such as a peroxide, and a compatibilizing agent characterized by at least one nitroxide radical and at least one unsaturated bond capable of undergoing a radical addition reaction. Modified heterophasic polyolefin compositions with increased melt flow rates, impact strength, and clarity, which incorporate the compatibilizing agent, are also included within the scope of the invention.

Owner:MILLIKEN & CO

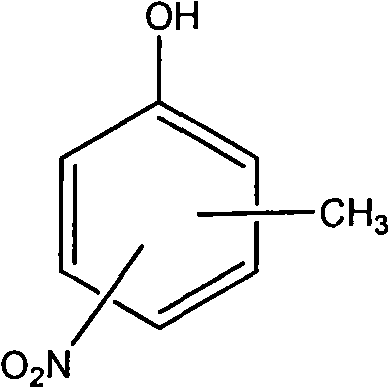

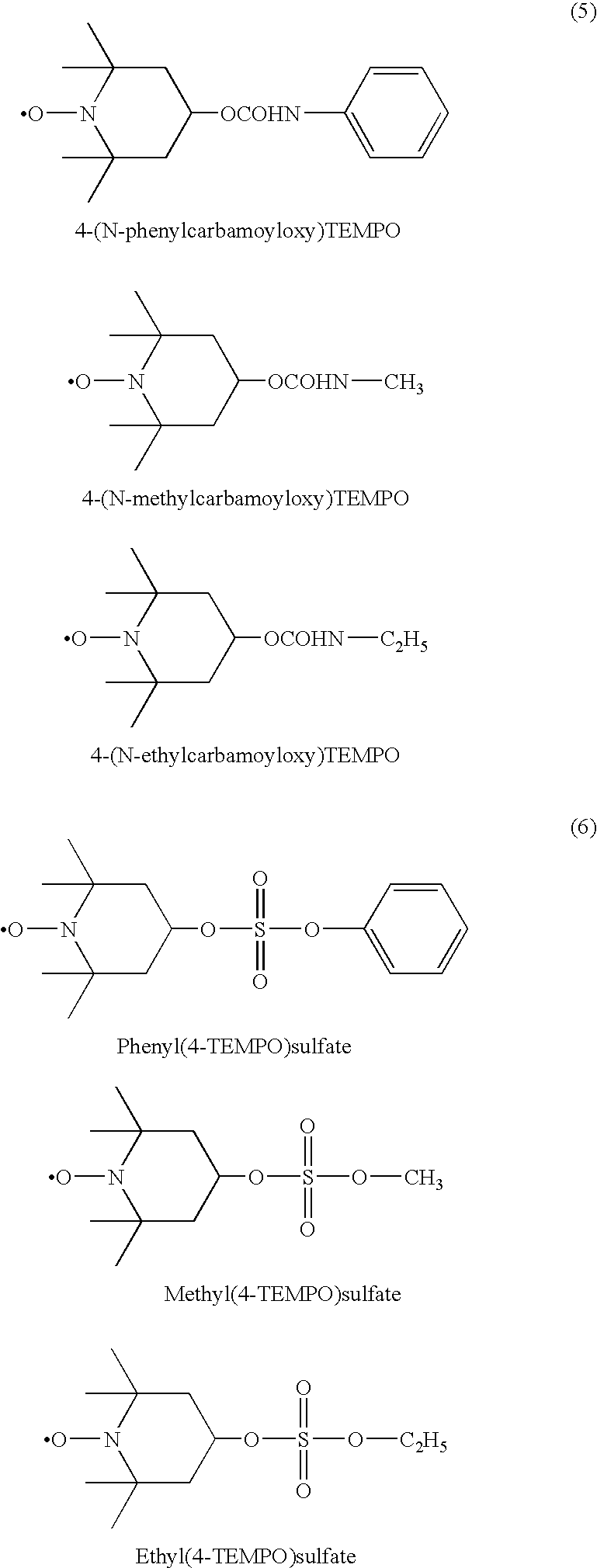

Polymerization inhibitor suitable for vinyl aromatic compound

ActiveCN101857519AHigh inhibition efficiencyLow costDistillation purification/separationHydrocarbonsSolubilityOrganic solvent

The invention discloses a polymerization inhibitor suitable for a vinyl aromatic compound, which can be applied in the processes of production, treatment, transportation and utilization of vinyl aromatic compounds. The compounded polymerization inhibitor is composed of an oxime compound, a nitrophenol compound and a nitroxide free radical compound and skilfully utilizes the respective advantages of a true polymerization inhibitor and a retarder; the synergy of components obviously improves inhibition effect, reduces use amount of highly toxic substances, lowers toxicity, improves solubility in the organic solvent and obtains good economic benefit.

Owner:ZHEJIANG UNIV

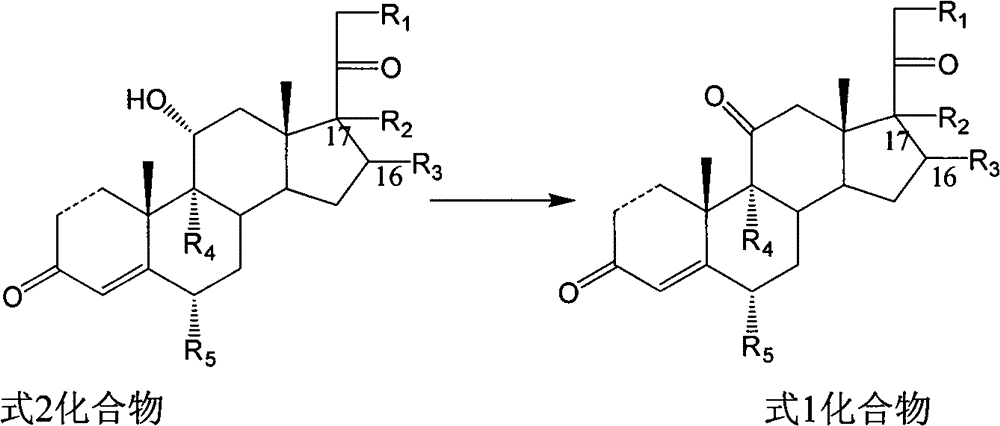

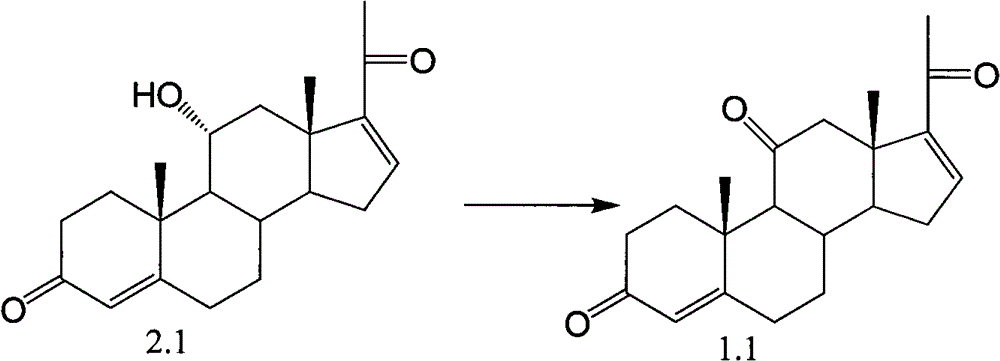

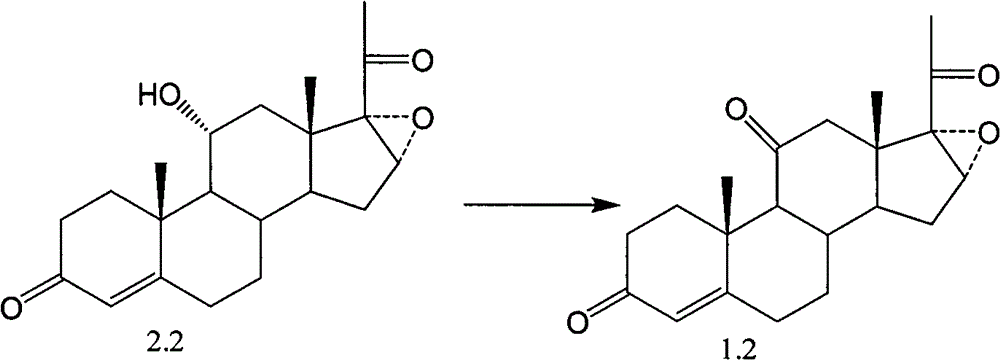

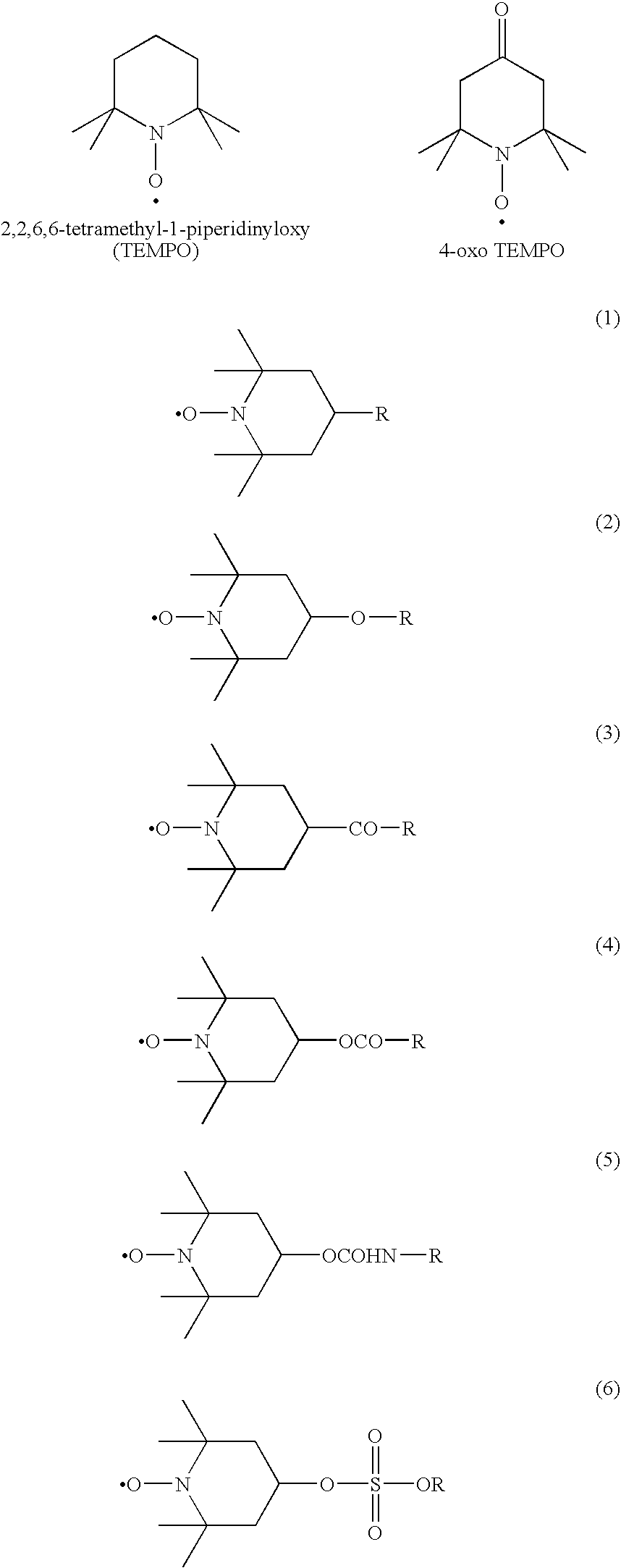

Novel technology for oxosynthesis of pregnane 11-bit ketonic group

The invention relates to a novel technology for oxosynthesis of pregnane 11-bit ketonic group, which is characterized in that a compound in a formula 2 uses piperidine nitroxide free-radical as an oxidation catalyst under the condition of an organic solvent, and uses positive valence halide as an oxidant to react to generate a compound in a formula 1.

Owner:TIANJIN JINYAO GRP

Modified diene-based rubber and rubber composition containing the same

To modify a diene-based rubber whereby the dispersibility of silica and the abrasion resistance or heat buildup resistance are improved.A modified diene-based rubber obtained by adding and reacting, to a diene-based rubber (A), a compound (B) having, in the molecule thereof, a nitroxide free radical stable at an ordinary temperature and in the presence of oxygen, a radical initiator (C) and a radical polymerizable monomer (D) having a functional group in the molecule thereof and a rubber composition and pneumatic tire containing the same.

Owner:YOKOHAMA RUBBER CO LTD

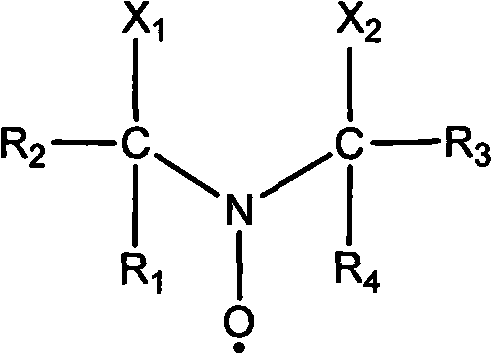

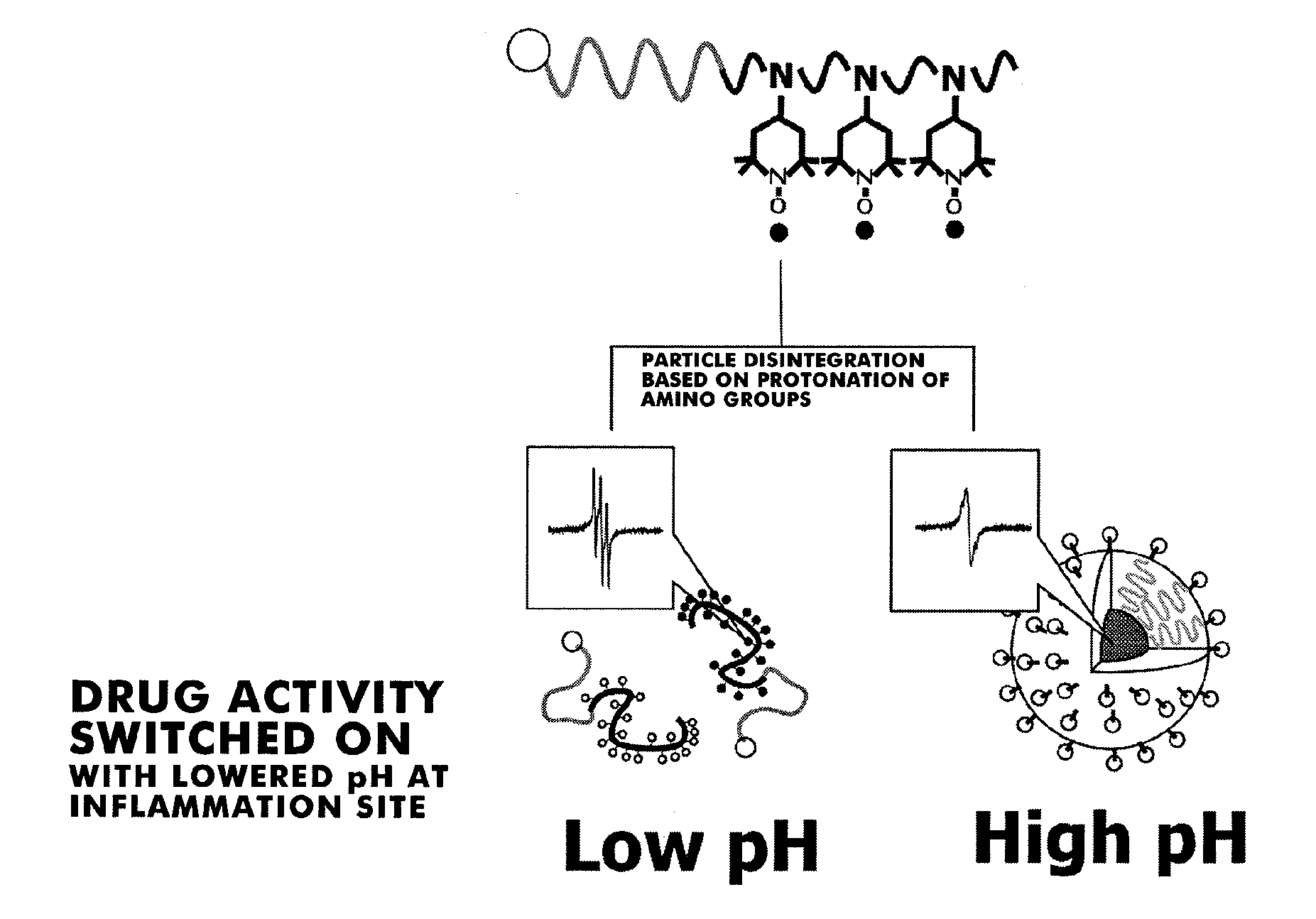

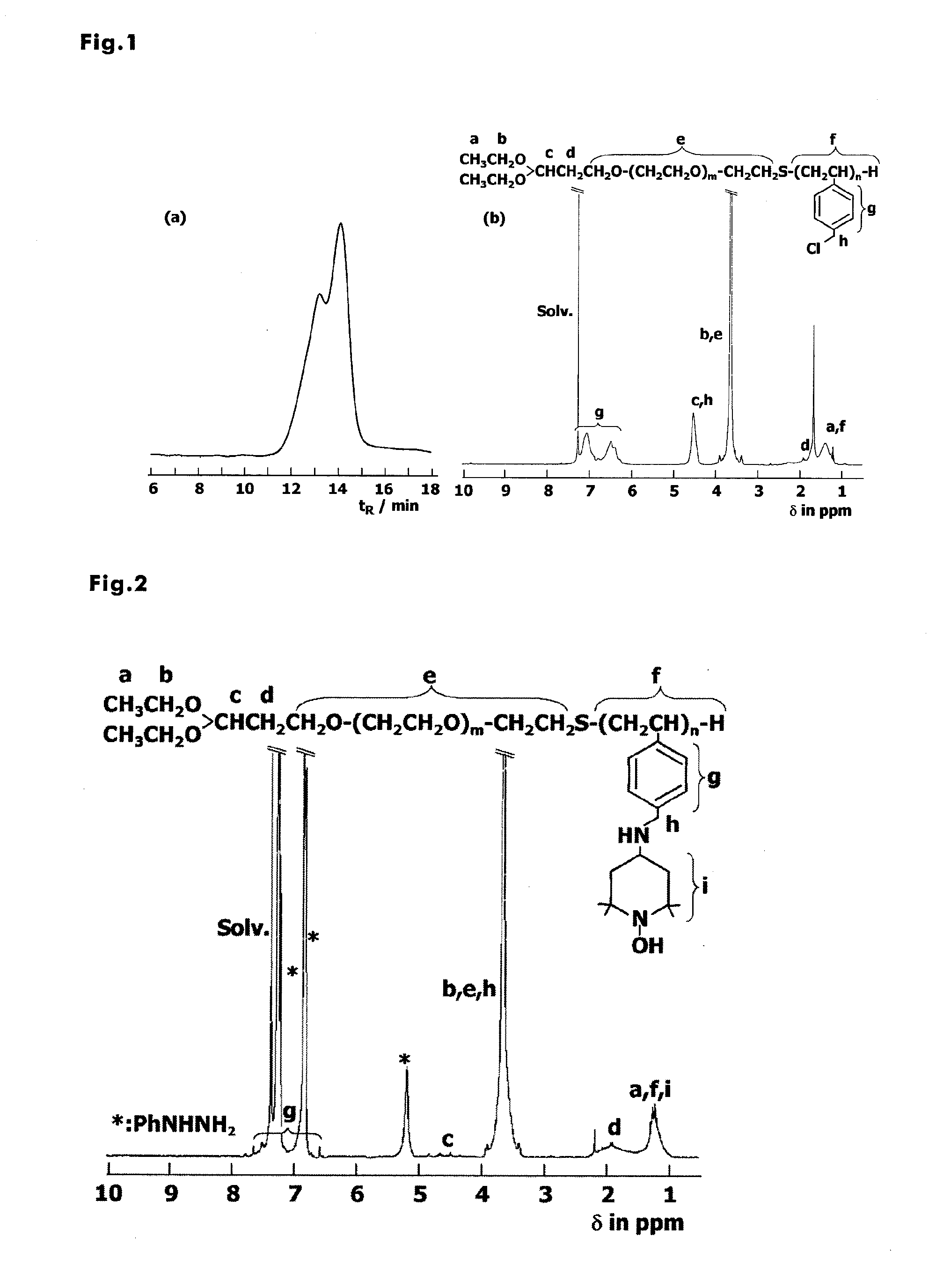

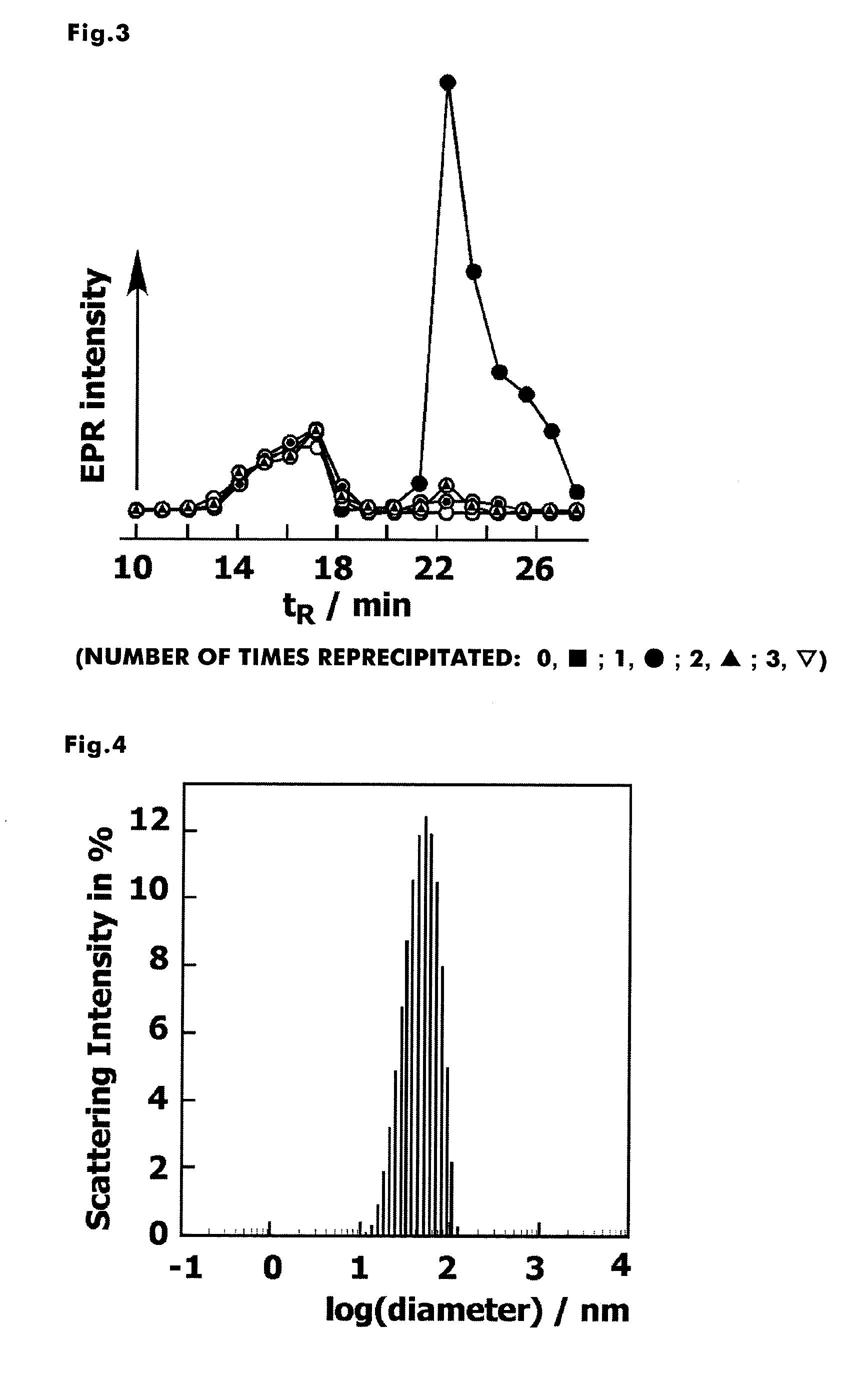

Polymerized cyclic nitroxide radical compound and use thereof

ActiveUS20110142787A1Short timePrevent and treat damageNervous disorderDispersion deliveryChemical compoundIn vivo

A method of covalently bonding a cyclic nitroxide radical compound to a hydrophobic block of a specific hydrophylic-phobic block copolymer, and polymerized cyclic nitroxide radical compound copolymerized in this manner, as well as use of such a compound, for instance, in the medical field are provided. The compound demonstrates long term stability in vivo under reductive environment.

Owner:UNIV OF TSUKUBA

Composite polymerzation inhibitor for producing methyl propenoic acid and its ester

ActiveCN1821207AEffect of long-term prevention of polymerizationThe effect of aggregation is remarkableOrganic compound preparationCarboxylic acid esters preparationNitrogenOxygen content

The present invention relates to a kind of composite polymerization inhibitor for the production process of methylacrylic acid and its ester. The composite polymerization inhibitor is re-compounded with nitrogen and oxygen free radical type compound and copper salt type polymerization inhibitor. The composite polymerization inhibitor has high polymerization inhibiting effect and no requirement on oxygen content in the material system.

Owner:SHANGHAI HUAYI NEW MATERIAL

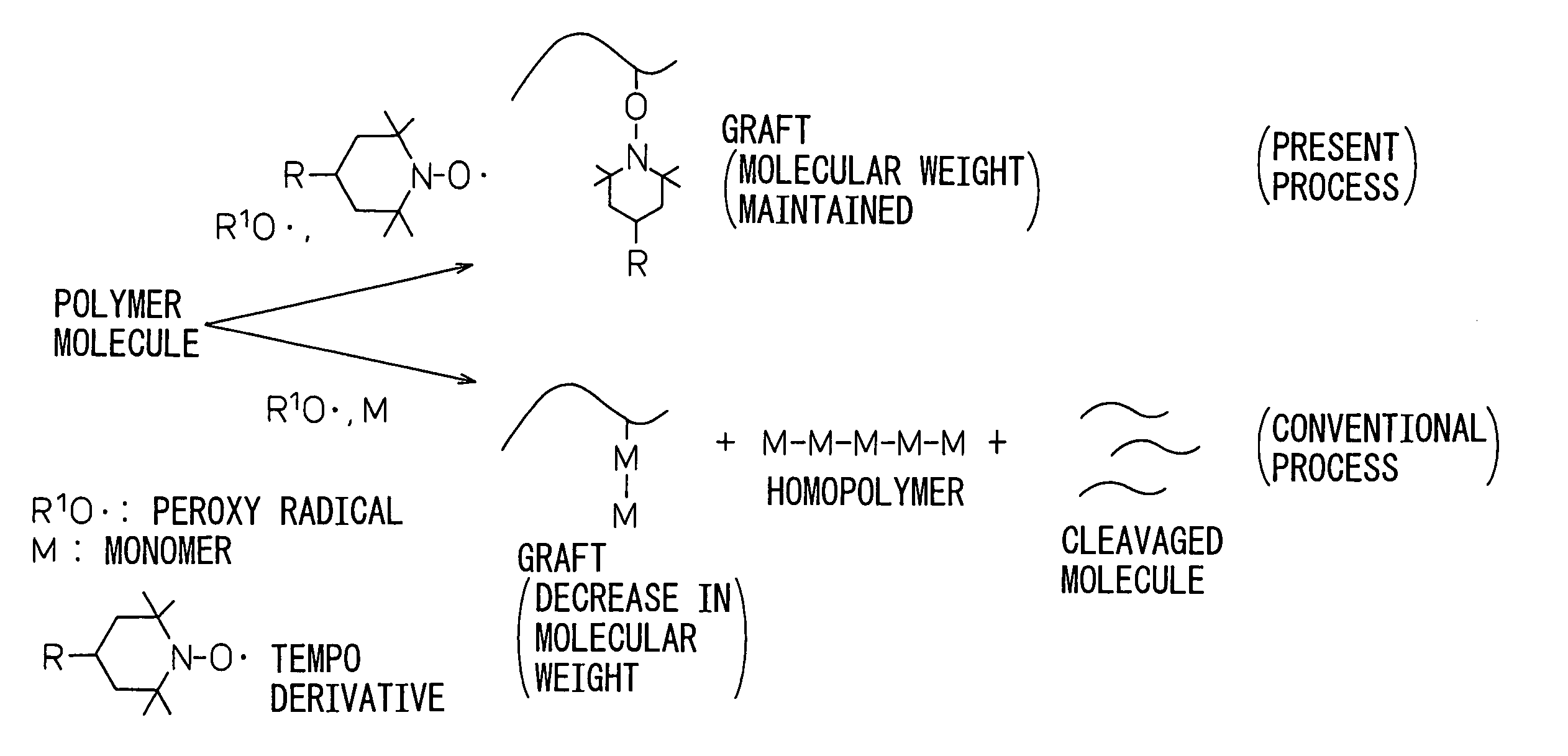

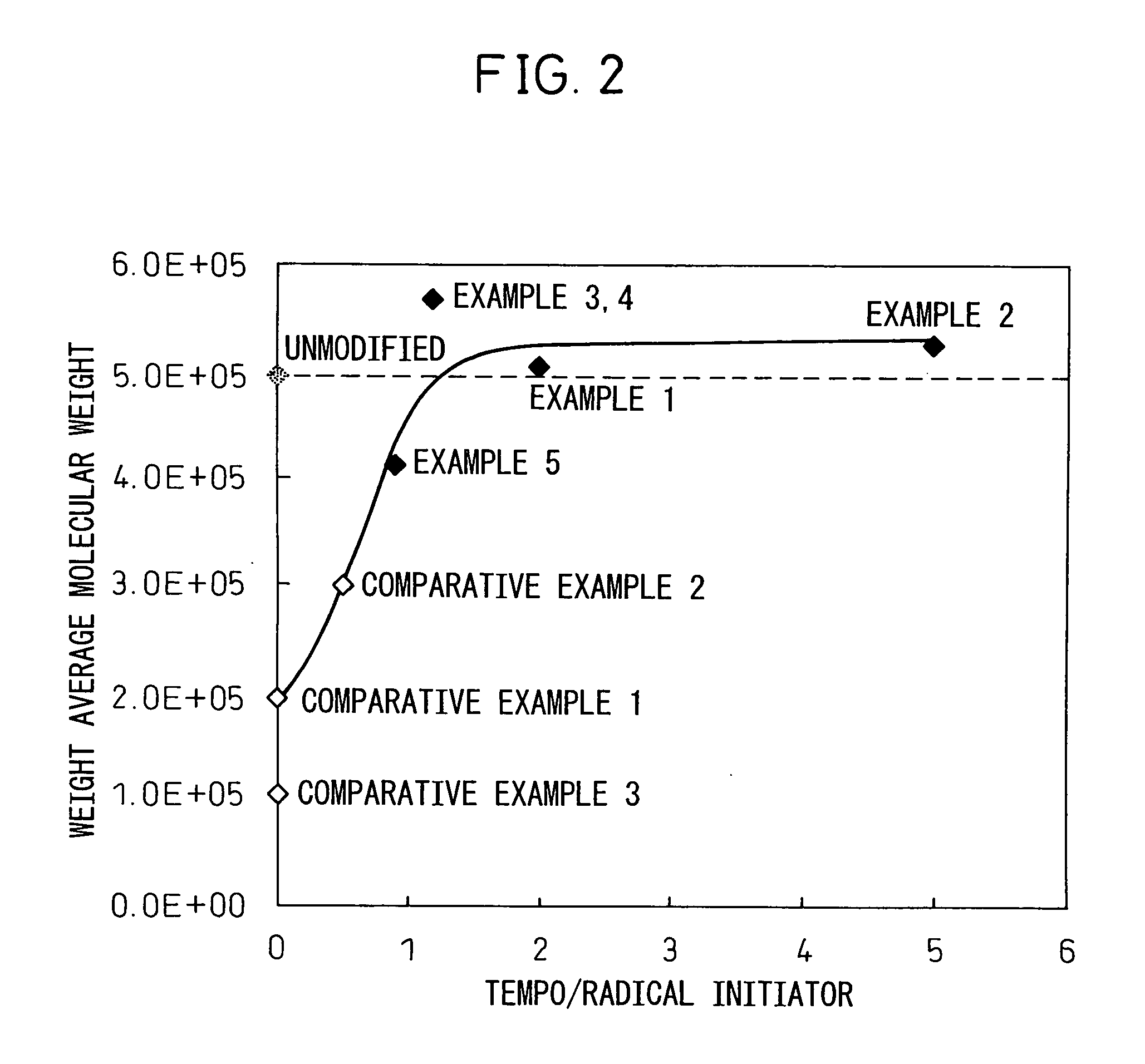

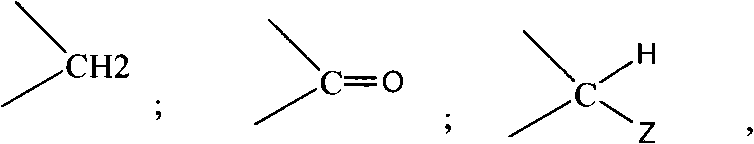

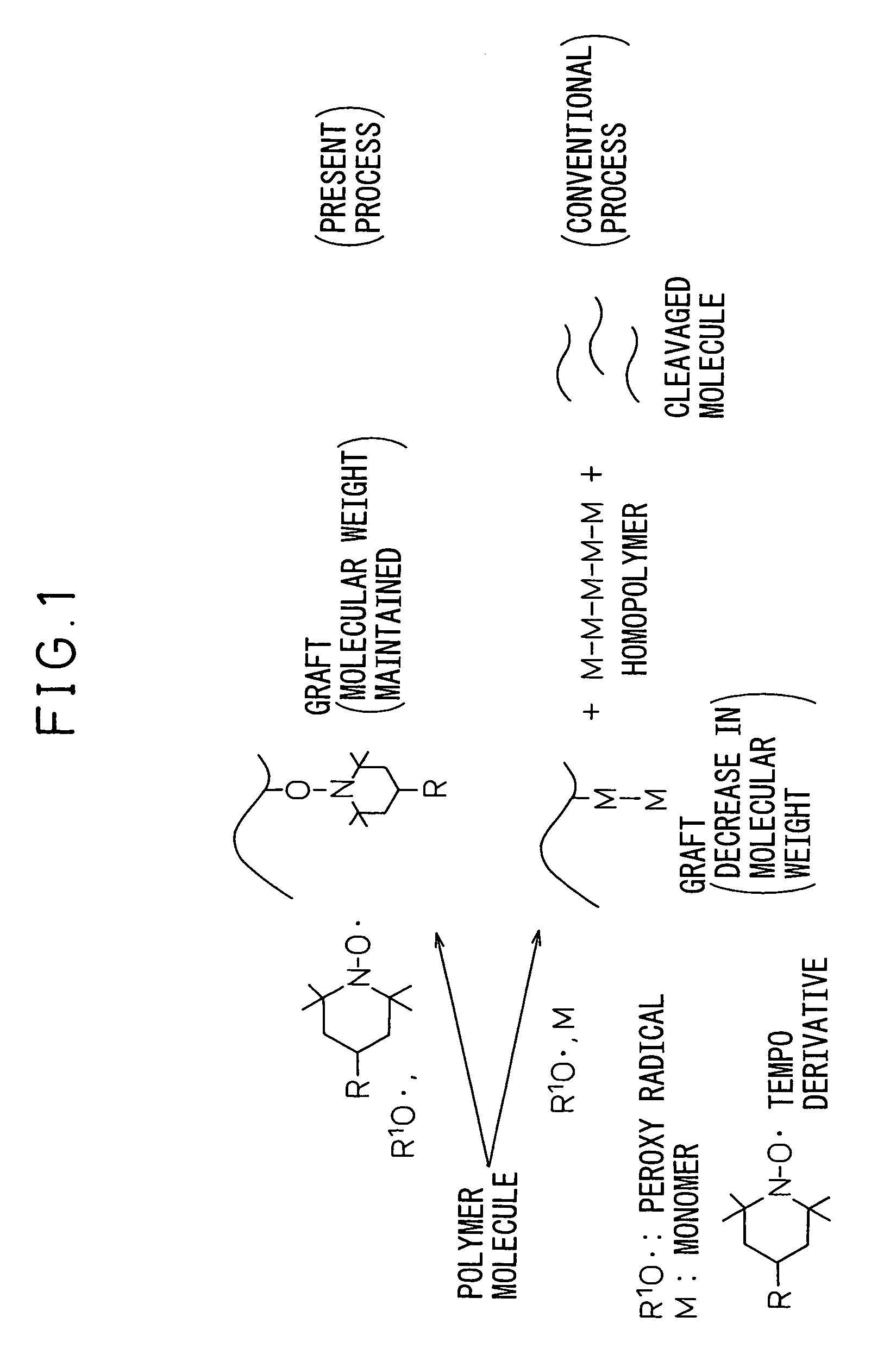

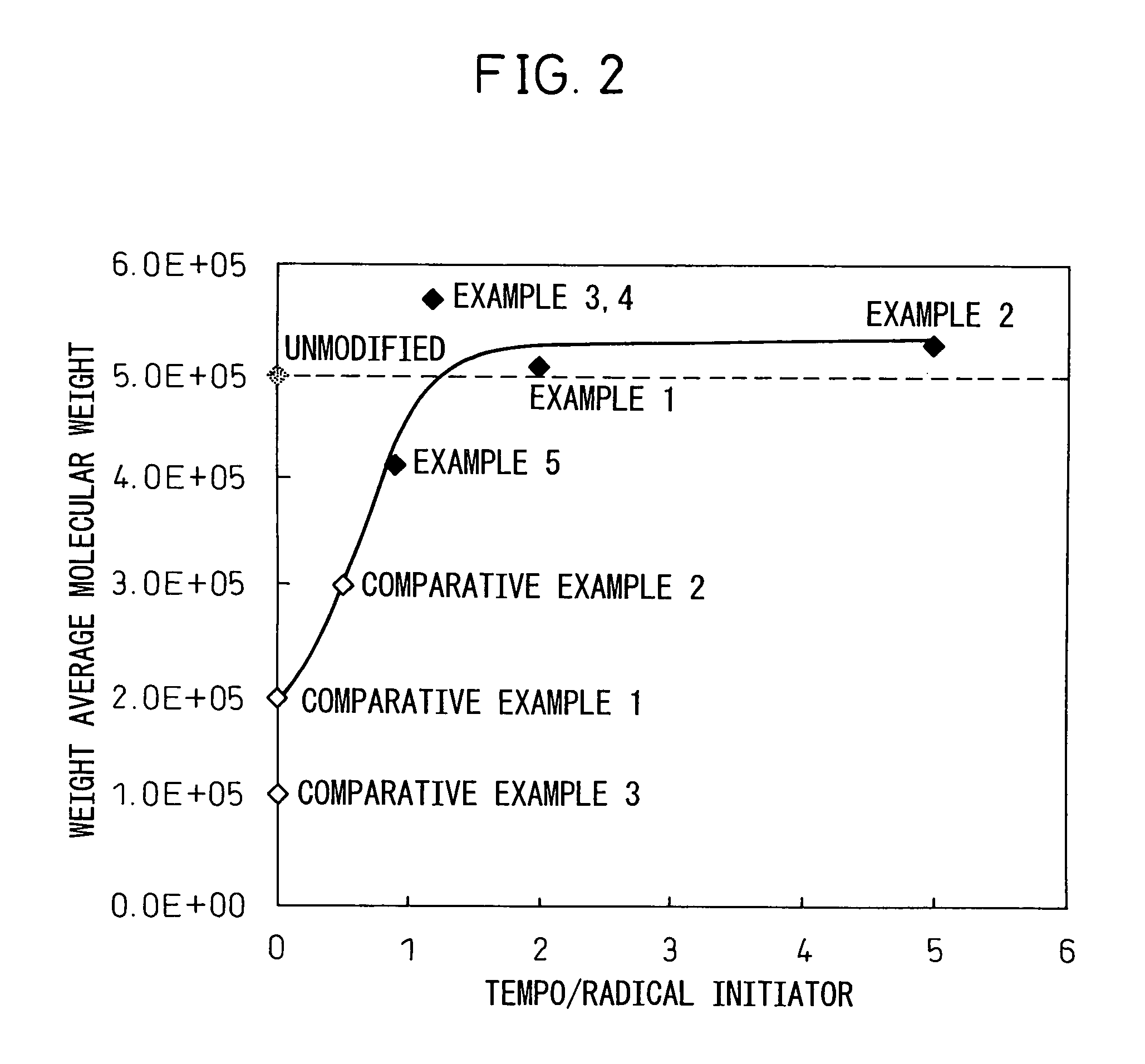

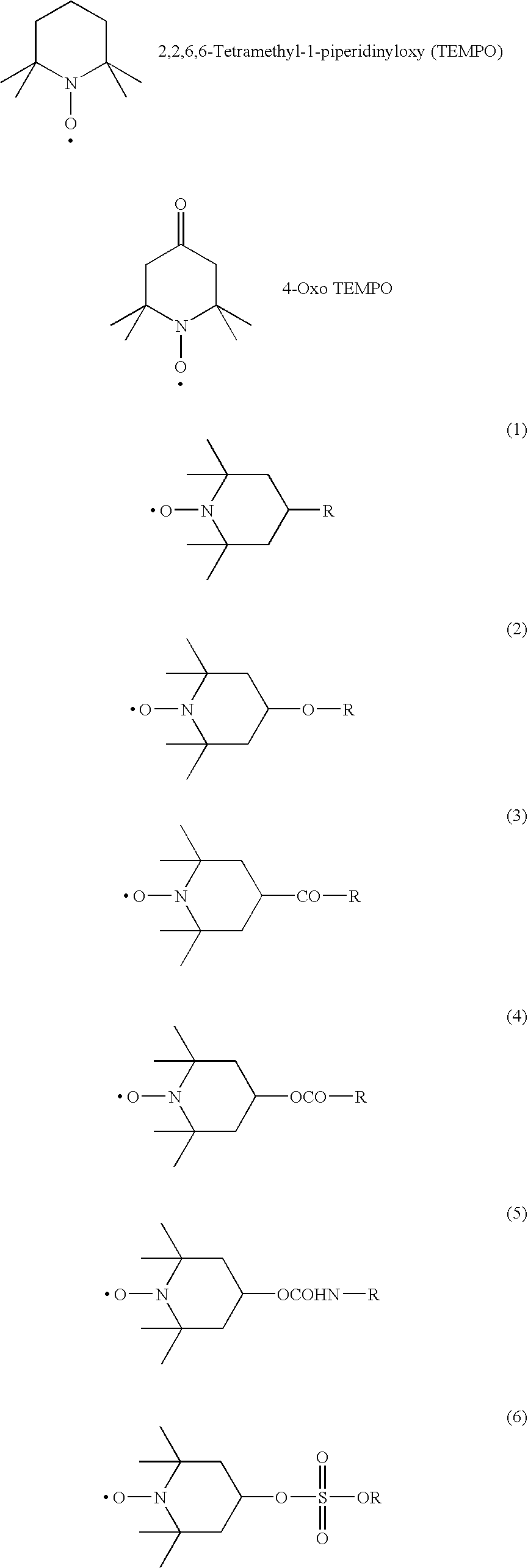

Process for modification of polymer

InactiveUS20050222343A1Suppressing drop in molecular weightDrop in molecular weightPolymer sciencePolymer modified

A process for modification of a polymer comprising modifying a polymer (A) capable of decomposing by carbon radicals present in the molecule thereof using a compound (B) having a nitroxide radical in the molecule thereof and a radical initiator (C) in a ratio of (B) / (C) (molar ratio) of at least 0.7, whereby organic groups derived from the nitroxide radicals are introduced into the polymer and a modified unhalogenated butyl rubber obtained therefrom.

Owner:YOKOHAMA RUBBER CO LTD

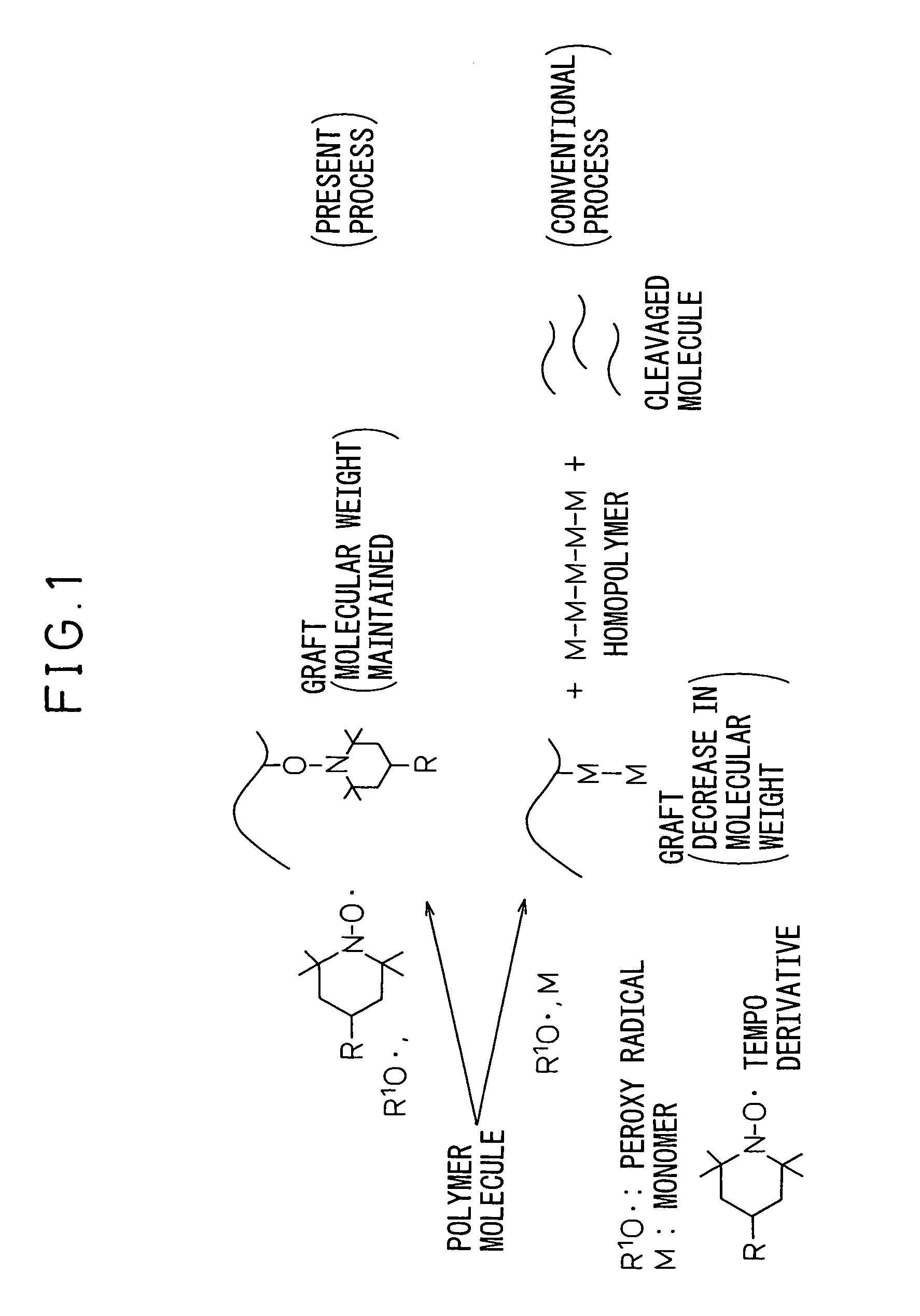

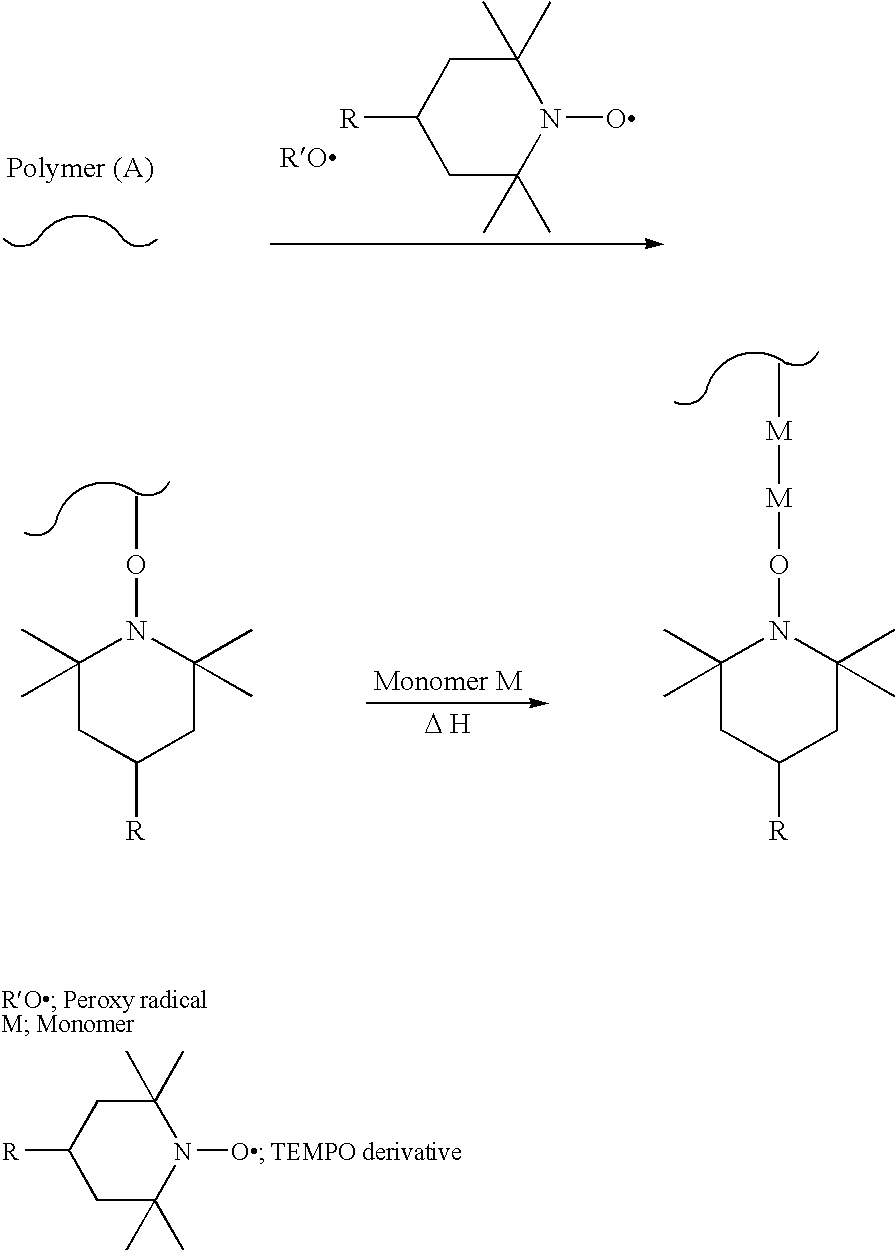

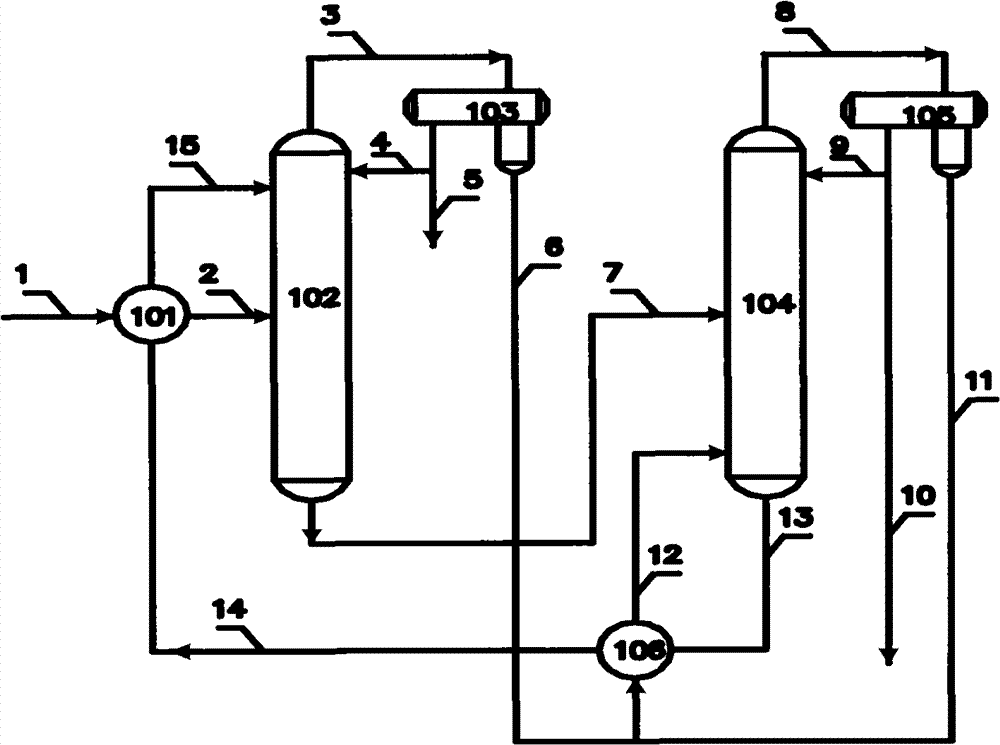

Modification method of polymer

A method for modifying a polymer by mixing and reacting a polymer (A), a compound (B) having a nitroxide radical in the molecule thereof, a radical initiator (C), and a radical polymerizable monomer (D) in a non-solvent system in a mixed to thereby graft a monomer (D) to the polymer (A), whereby a desired functional group is introduced to the polymer, without a causing decrease in the molecular weight, gelation, or formation of a homopolymer.

Owner:YOKOHAMA RUBBER CO LTD

Method for synthesizing 3-methyl-2-butene aldehyde

InactiveCN101709026AReduce pollutionHigh reaction yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic oxidation2-Butene

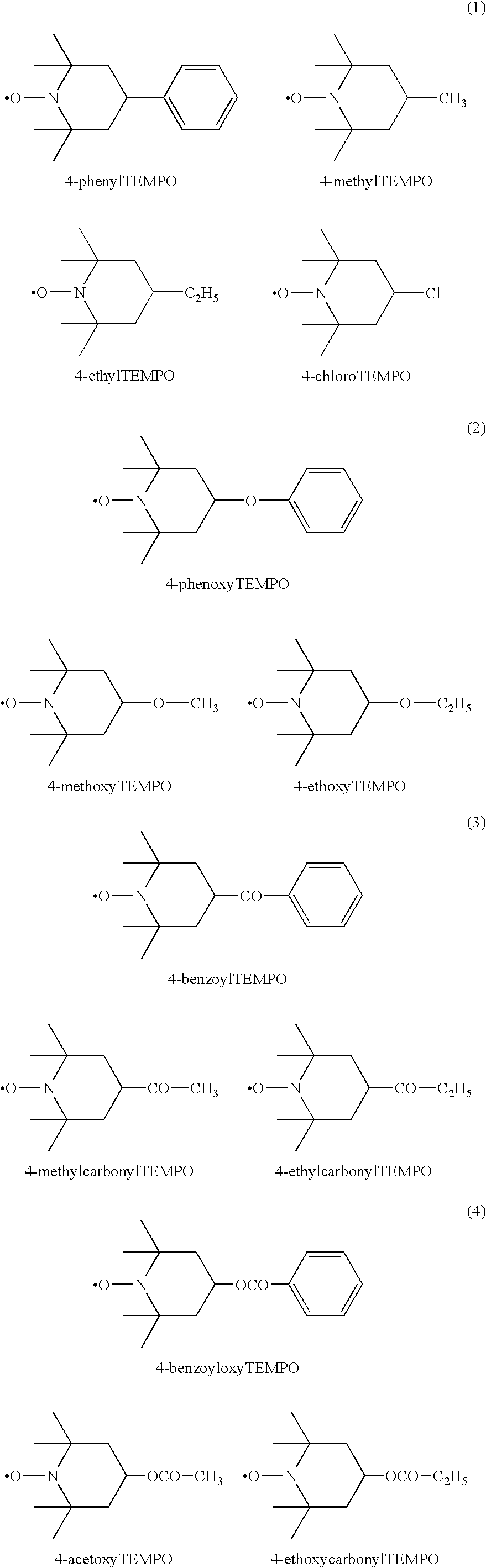

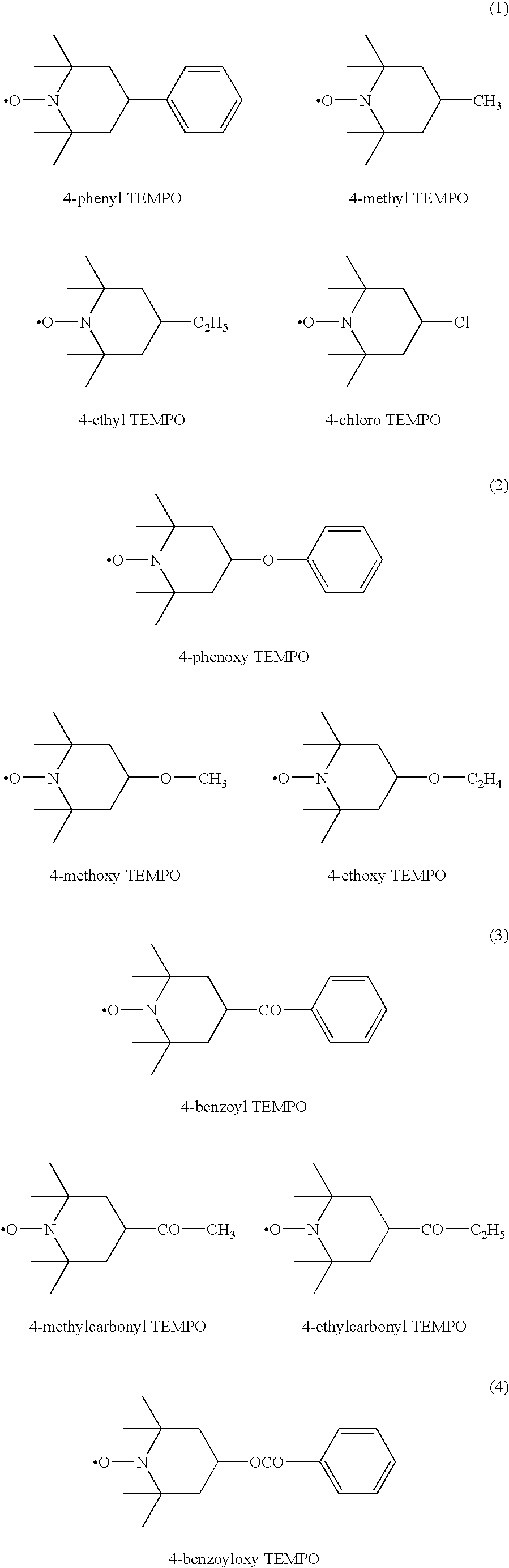

The invention discloses a method for synthesizing intermediate of 3-methyl-2-butene aldehyde which is used for synthesizing the medicine and the spice, aiming at solving the problems of low conversion rate, many by-products from some reaction and poor selectivity in the prior method for synthesizing the intermediate of 3-methyl-2-butene aldehyde. The 3-methyl-2-butene aldehyde is prepared by catalyzing and oxidizing 3-methyl-2-butenol which is used as raw material with the oxygen-containing gas which is used as oxidant at room temperature or heating condition. The method for synthesizing the 3-methyl-2-butene aldehyde is characterized in that the catalyst used in the reaction is 2, 2, 6, 6-tetramethyl piperidine nitroxide radical compound, and the additive used in the reaction is iron nitrate, cobalt nitrate or manganese nitrate. The catalyst can be used for high selectively synthesizing the 3-methyl-2-butene aldehyde, is environmental friendly and can be recycled. The method for synthesizing the 3-methyl-2-butene aldehyde ensures the mild reaction condition, the little side reaction and the high reaction yield.

Owner:ZHEJIANG MEDICINE CO LTD

Epoxy polymer microsphere immobilized tetramethyl-piperidyl-nitroxide free radical catalyst, as well as preparation method and application method thereof

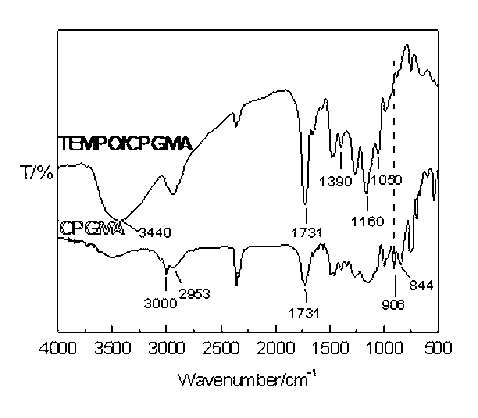

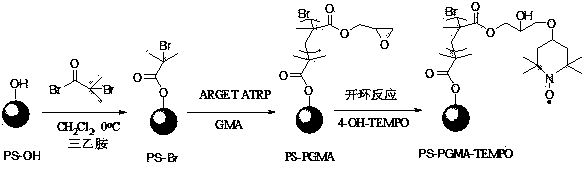

InactiveCN103285922ARealize immobilizationImprove thermal stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyGlycidyl methacrylate

The invention belongs to the field of nitroxide free radical catalysts, aims at solving the problem that the existing homogeneous catalyst TEMPO (tetramethyl-piperidyl-nitroxide free radical) is difficult to separate and recover after reaction and can not be reused to seriously restrict development of a catalytic system, and provides an epoxy polymer microsphere immobilized (tetramethyl-piperidyl-nitroxide free radical) TEMPO catalyst, as well as a preparation method and an application method thereof. According to the preparation method, 4-OH-TEMPO (4-hydroxy-2,3,6,6-tetramethyl-piperidyl-nitroxide free radical) is bonded on a (crosslinked poly glycidyl methacrylate microsphere) CPGMA to prepare the solid catalyst TEMPO / CPGMA shown in the general formula I immobilized by TEMPO. According to the preparation method, the TEMPO is subjected to chemical bonding on a solid carrier, immobilization of TEMPO is realized, homogeneous catalysis oxidation is changed to heterogeneous catalysis oxidation, and therefore, the heat stability of the catalyst is improved, separation of the catalyst from a reaction medium is convenient, the catalyst is reused, and high activity can be generated.

Owner:ZHONGBEI UNIV

High efficiency composite polymerization inhibitor for refining styrene and its application

InactiveCN1974503AGood inhibition effectLow costHydrocarbon purification/separationHydrocarbonsSolubilityOrganic solvent

The present invention relates to one kind of high efficiency composite polymerization inhibitor for refining styrene. The composite polymerization inhibitor is re-compounded with aromatic amine compound, nitrogen-oxygen free radical or phenothiazine, and nitrophenol compound in certain proportion, and through dissolving in organic solvent. The composite polymerization inhibitor has the synergistic effect of the polymerization retarder and polymerization inhibitor, obviously polymerization inhibiting effect higher than single polymerization inhibitor, lowered toxicity and raised solubility, and can meet the requirement for styrene rectifier to run stably for long term.

Owner:DALIAN UNIV OF TECH

Preparation method and application of free nitroxide radical polymer brush polymerization inhibitor

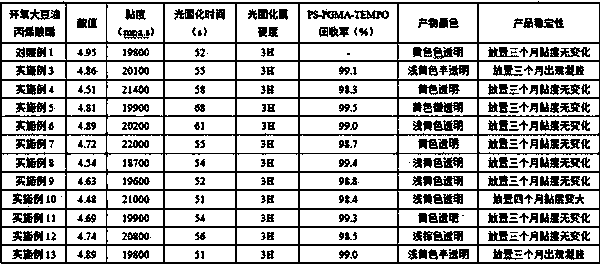

ActiveCN104211863APerformance is not affectedAvoid self-polymerizationOrganic chemistryFatty acid esterificationEpoxyPolymer science

The invention relates to a preparation method of a free nitroxide radical polymer brush polymerization inhibitor, and application of the free nitroxide radical polymer brush polymerization inhibitor in synthesis of epoxy soybean oil acrylic ester. The preparation method comprises the following steps: firstly, grafting a polyglycidyl methacrylate polymer brush on the surfaces of cross-linked polystyrene microspheres by using an electron transfer regenerated catalyst atom transfer free radical polymerization technique, and secondly, bonding tetramethyl piperidine free nitroxide radical onto the polyglycidyl methacrylate polymer brush, thereby obtaining the free nitroxide radical polymer brush. The application comprises: taking the free nitroxide radical polymer brush as a main polymerization inhibitor and a small molecule polymerization inhibitor as a polymerization inhibitor aid, thereby forming a composite polymerization inhibition system for preparing epoxy soybean oil acrylic ester. The composite polymerization inhibition system not only has a high-efficiency polymerization inhibition function in the epoxy soybean oil acrylic ester preparation, but also is easy in recycling the main polymerization inhibitor, namely the free nitroxide radical polymer brush, so that the free nitroxide radical polymer brush can be recycled, and a product can be prevented from self-polymerization when being preserved when a small amount of the polymerization inhibitor is retained in the system.

Owner:廊坊市安次区调河头振达生物技术推广中心

An additive cigarette production technology

InactiveCN1543884AImprove stabilityNo effect on tasteTobacco treatmentCigar manufactureNitrosoNitroso Compounds

The invention relates to an addition agent for lowering the content of N-nitroso compound in cigarette and the cigarette production process, wherein the addition agent is a plant polyphenol microcapsule with plant polyphenol as the core, and alpha-cyclodextrin or beta-cyclodextrin or hydroxypropyl beta-cyclodextrin is used as molecular embedding agent for charging plant polyphenol microcapsule into the molecular embedding agent, forming stabilized colloid, by dissolving the colloidal solution and adding into the shredded tobacco, the content of N-nitroso compound in cigarette can be substantially reduced.

Owner:李波

Process for modification of polymer

A process for modification of a polymer comprising modifying a polymer (A) capable of decomposing by carbon radicals present in the molecule thereof using a compound (B) having a nitroxide radical in the molecule thereof and a radical initiator (C) in a ratio of (B) / (C) (molar ratio) of at least 0.7, whereby organic groups derived from the nitroxide radicals are introduced into the polymer and a modified unhalogenated butyl rubber obtained therefrom.

Owner:THE YOKOHAMA RUBBER CO LTD

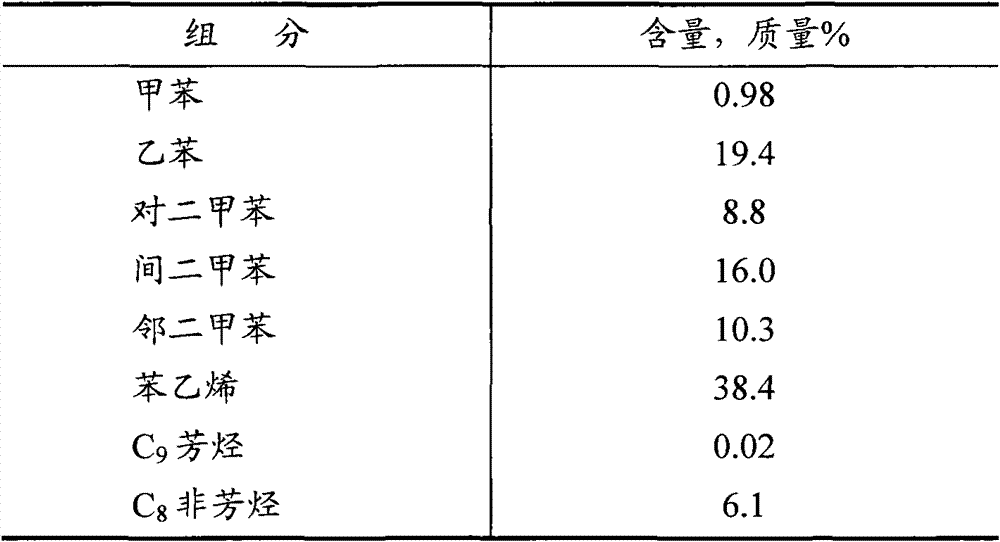

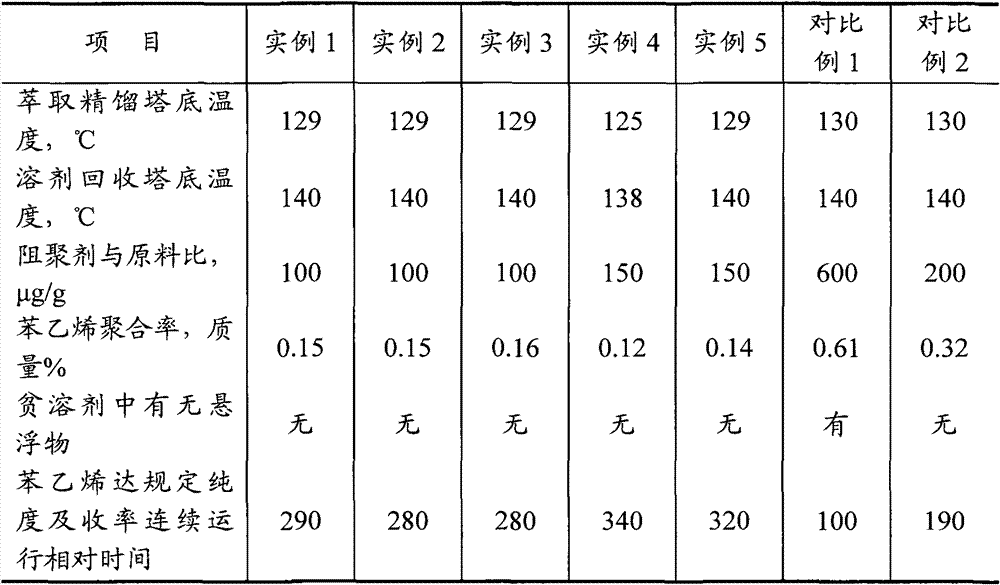

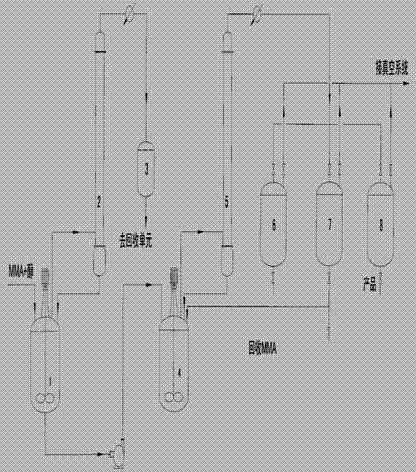

Method for extracting, distilling and recovering styrene from hydrocarbon mixture

ActiveCN103360201APrevent precipitationGood inhibition effectDistillation purification/separationHydroxylamineHydrocarbon mixtures

The invention relates to a method for extracting, distilling and recovering styrene from a hydrocarbon mixture. The method comprises the following steps of: extracting, distilling and recovering the styrene from the hydrocarbon mixture by using a composite solvent in the presence of a polymerization inhibitor. The composite solvent comprises 80-99% by mass of a main solvent, 0.01-19% by mass of an auxiliary solvent and 0.1-2.0% by mass of water, wherein the main solvent is a sulfone compound, and the auxiliary solvent is metoxyphenol or the mixture of the metoxyphenol and the glycol monomethyl ether. The polymerization inhibitor comprises 40-80% by mass of free radicals of nitrogen and oxygen, 15-50% by mass of nitro-phenol and derivatives thereof and 5-30% by mass of N, N-diethyl hydroxylamine. The use amount of the polymerization inhibitor is 10-500mug / g of the amount of the hydrocarbon raw material. Because the composite solvent is used together with the polymerization inhibitor, the use amount of the polymerization inhibitor can be decreased, and the rate of polymerization of the styrene can be reduced significantly.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of neopentyl glycol dimethacrylate

ActiveCN103755565AReduce contentShort reaction timeOrganic compound preparationPreparation by ester-hydroxy reactionTrans esterificationPolymer science

The invention discloses a preparation method of neopentyl glycol dimethacrylate. The preparation method comprises the following steps: reacting methyl methacrylate and neopentyl glycol used as raw materials by adopting a reaction rectification ester exchange technology in the presence of a catalyst and a polymerization inhibitor so as to obtain a reaction product containing neopentyl glycol dimethacrylate; distilling the reaction product under the condition of reduced pressure to remove excess methyl methacrylate, and then remove the catalyst and the polymerization inhibitor, thus obtaining the neopentyl glycol dimethacrylate product. The preparation method has the advantages that the carbonate and thiocyanate compound catalyst is adopted, can be recycled and has a good catalytic effect, the reaction time is shortened, the reaction efficiency is improved, and the production amount of polymers is reduced; the nitroxide free radical polymerization inhibitor is adopted, the using amount of the polymerization inhibitor is reduced, and the polymerization inhibition effect is improved.

Owner:抚顺东联安信化学有限公司

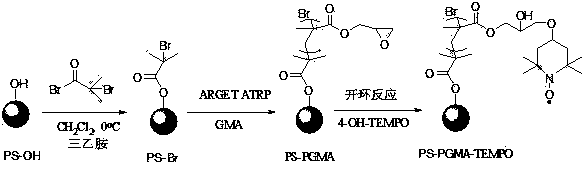

Preparation method for polymer brush supported TEMPO catalyst system

ActiveCN104162450AHomogeneous catalysisOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzoic acidPolymer science

The invention relates to a preparation method for a polymer brush supported TEMPO catalyst system. Specifically, the method includes the steps of: 1) conducting soap-free emulsion polymerization to prepare a surface hydroxylated crosslinked polystyrene (PS) microsphere; 2) loading an ATRP initiator to the PS microsphere surface through O-acylation reaction of 2-bromoisobutyryl bromide and hydroxyl; 3) taking the PS microsphere as a macroinitiator, grafting a structure controllable polymer brush containing methacrylic acid-2, 2, 6, 6-tetramethyl-4-piperidyl ester (TMPM) to the microsphere surface through an ARGETATRP technology; and 4) oxidizing the piperidyl of TMPM into free radical of nitroxide by m-chloroperoxybenzoic acid (mCPBA) so as to load the TEMPO to the polymer brush in the form of a covalent bond. The polymer brush supported TEMPO catalyst system can employ O2 as the oxidizing agent to efficiently catalyze the selective oxidation reaction of alcohol, is convenient to recycle, and can maintain catalytic performance basically unchanged after 5 times of recycling.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

High-efficiency environmentally-friendly polymerization inhibitor of styrene

ActiveCN102249842AGood inhibition effectAvoid disadvantagesDistillation purification/separationHydrocarbonsSolubilityPhosphorous acid

The invention relates to a high-efficiency environmentally-friendly polymerization inhibitor of styrene, and a use method thereof. The compound polymerization inhibitor comprises nitroxide free radical compounds, hydroxylamine compounds, nitrophenol compounds and phosphite ester compounds. The compound polymerization inhibitor utilizes ingeniously synergistic effects of the above compounds, thus overcomes respectively defects of a retarder and an actual polymerization inhibitor and improves obviously polymerization inhibiting effects. Simultaneously, the compound polymerization inhibitor realizes that the use of high toxic substances is reduced; toxicity is reduced; the solubility in styrene or ethylbenzene is increased; and good economic benefits are obtained.

Owner:CHINA PETROLEUM & CHEM CORP +2

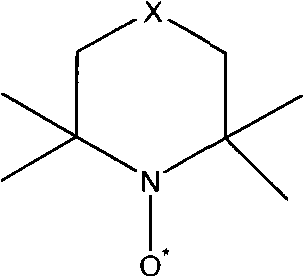

Polymer, process for producing the polymer, and curable composition containing the polymer

A vinyl polymer having, at a molecular chain terminus, a structure represented by the general formula 1: (wherein R3 is a hydroxy, amino, epoxy, carboxylic acid, ester, ether, amide or silyl group, an alkenyl group having low polymerizability, an organic compound having 1 to 20 carbon atoms, X is a halogen atom, a nitroxide or sulfide group or a cobalt porphyrin complex).

Owner:KANEKA CORP

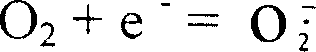

Method for producing green fuel by free radical treatment paper liquor waste slag and electrical catalytic reaction device

InactiveCN101041488ASolve pollutionSimple processWater/sewage treatment by electrochemical methodsWaste water treatment from plant processingHigh concentrationElectrolysis

The invention discloses a preparing method of green fuel by using free radical to deal with high concentration paper liquor waste slag and electrocatalysis reaction, which comprises the following steps: using electrochemical hydrated proton autoclave and initiating agent; cyclical generating hydroxyl group free radical (.OH), superoxide negative ion free radical (O2-), nitrogen-oxygen free radical (NO,NO2) and active oxygen (1O2, H2O2); proceeding free radical chain reaction with lignin, cellulose and hemicellulose and so on high molecular compound in electrocatalysis autoclave; proceeding electrolytic reduction; separating; dewatering; getting the product. This invention possesses simply craft and low cost, which can solve pollution caused by paper company.

Owner:BEIJING GUOLIYUAN POLYMER SCI & TECH R & D CENT

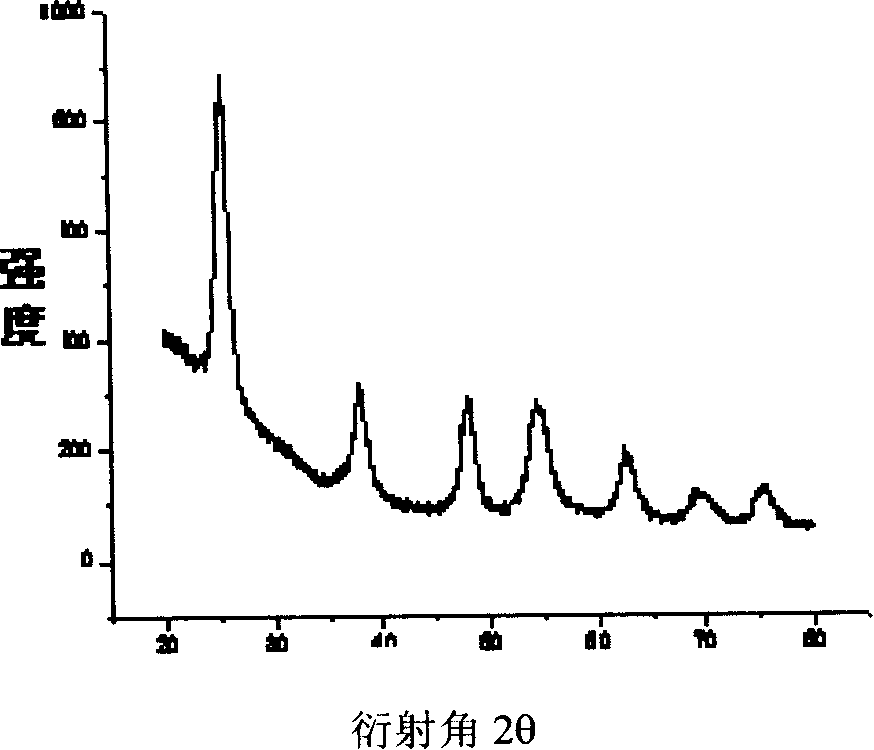

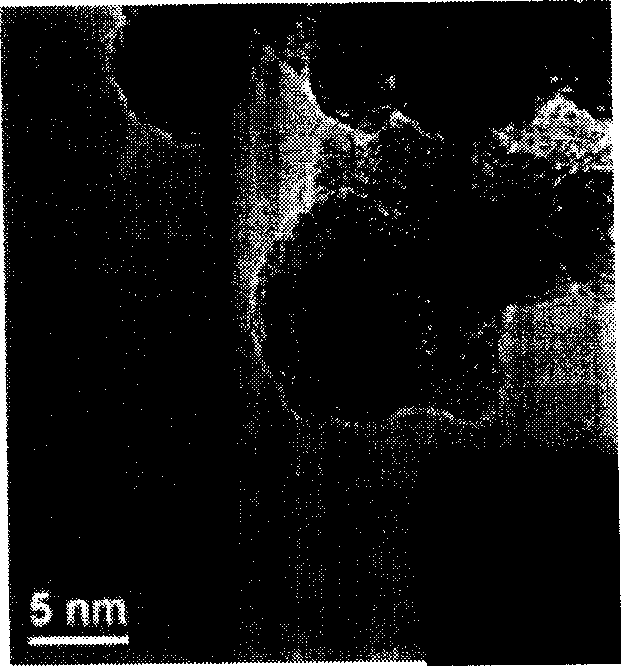

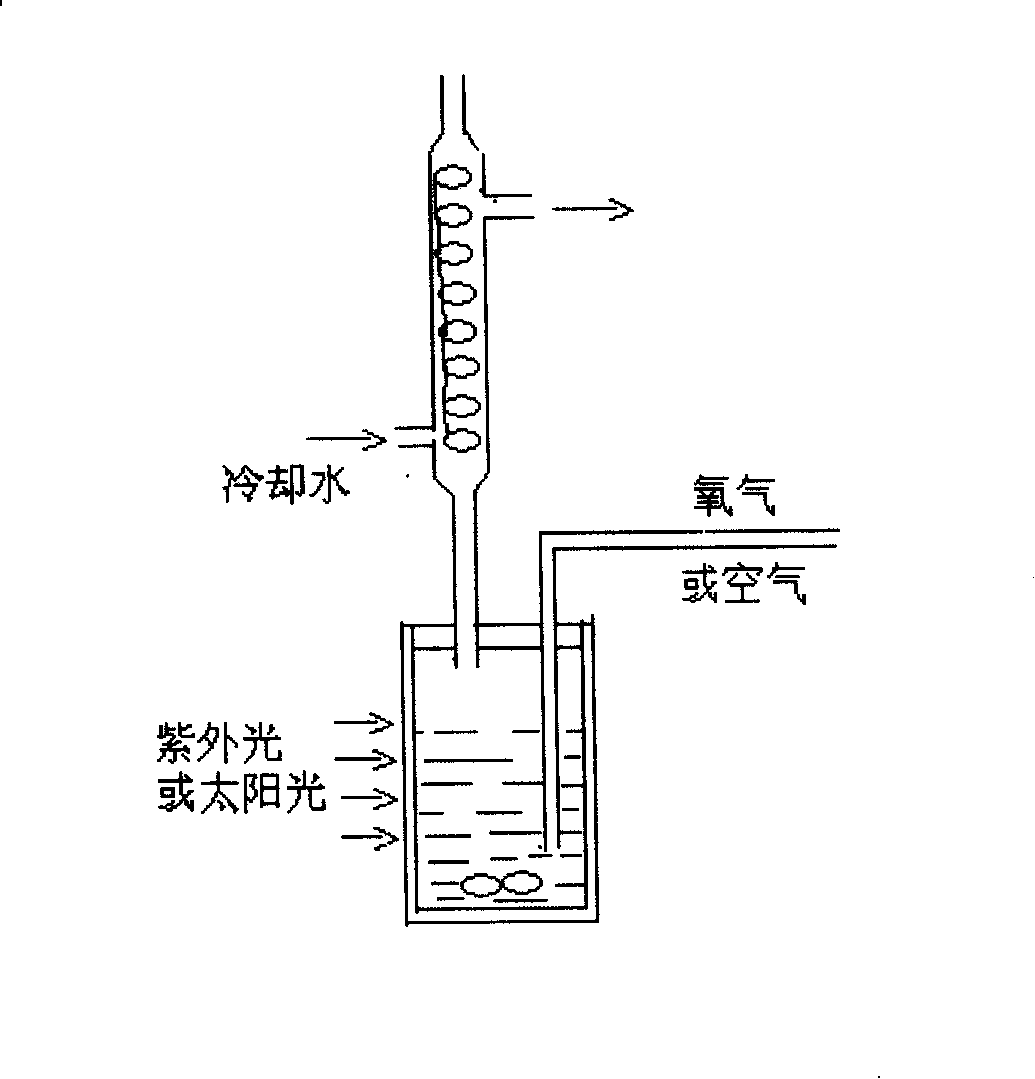

Semiconductor TiO2 photocatalyst of surface modified cocatalyst, preparing method and uses thereof

ActiveCN101224433ASolution to short lifeGentle preparationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical treatmentFiltration

The invention relates to the technical field of selective photocatalytic oxidation synthesis, which more particularly relates to a semiconductor TiO2 photocatalyst modified with promoter on the surface and the corresponding preparation method, as well as the catalyst application on the selective oxidation of primary alcohol or secondary alcohol to Aldehyde or Ketone. The invention is designed to perform chemical treatment on the TiO2 surface to convert the TiO2 into organic nitro-oxy radical which can highly selectively react with the primary or secondary alcohol to obtain the corresponding aldehyde or ketone as for the selectivity of stereo-hindrance, through an in-situ conversion of photo-excited holes. The selective conversion rate to any hydrin by the catalyst in the invention can achieve up to 99%, while commonly the conversion rate is over 90%, particular to the aromatic alcohol e.g. benzyl alcohol of over 99% of selectivity; both the catalyst and promoter can be reused for times through simple filtration, have long life without carbon deposition; the conditions of both preparation and reaction are mild.

Owner:INST OF CHEM CHINESE ACAD OF SCI

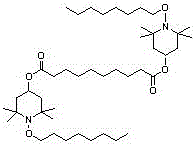

Synthesis method of light stabilizer HS-112

InactiveCN106699639AReduce generationThe reaction steps are simpleOrganic chemistryChemical synthesisCalcium Chloride Hexahydrate

The invention discloses a synthesis method the a light stabilizer bis(1-octyoxy-2,2,6,6-tetramethyl-4-piperidyl) sebacate, belongs to the field of organic chemical synthesis. The bis(1-octyoxy-2,2,6,6-tetramethyl-4-piperidyl) sebacate is the material, ethanol solution is the solvent, and magnesium hydrate or magnesium chloride hexahydrate is the catalyst. Oxidation reaction is conducted with the action of aquae hydrogenii dioxidi which is used as the oxidant to generate bis(2,2,6,6-tetramethyl-1-piperidinyloxy-4-yl)sebacate free radicals. Then molybdenum trioxide is used as the catalyst, normal octane is used as the material and solvent to react with the bis(2,2,6,6-tetramethyl-1-piperidinyloxy-4-yl)sebacate free radicals to obtain the light stabilizer HS-112. The method uses two steps to synthesize the HS-112. The process is simple, the reaction time is short the side effects are few, the pollution is minimal, the production cost is low, the reaction yield rate is high, and therefore the industrial application prospect is good.

Owner:GANSU RES INSTION OF CHEM IND GRICI

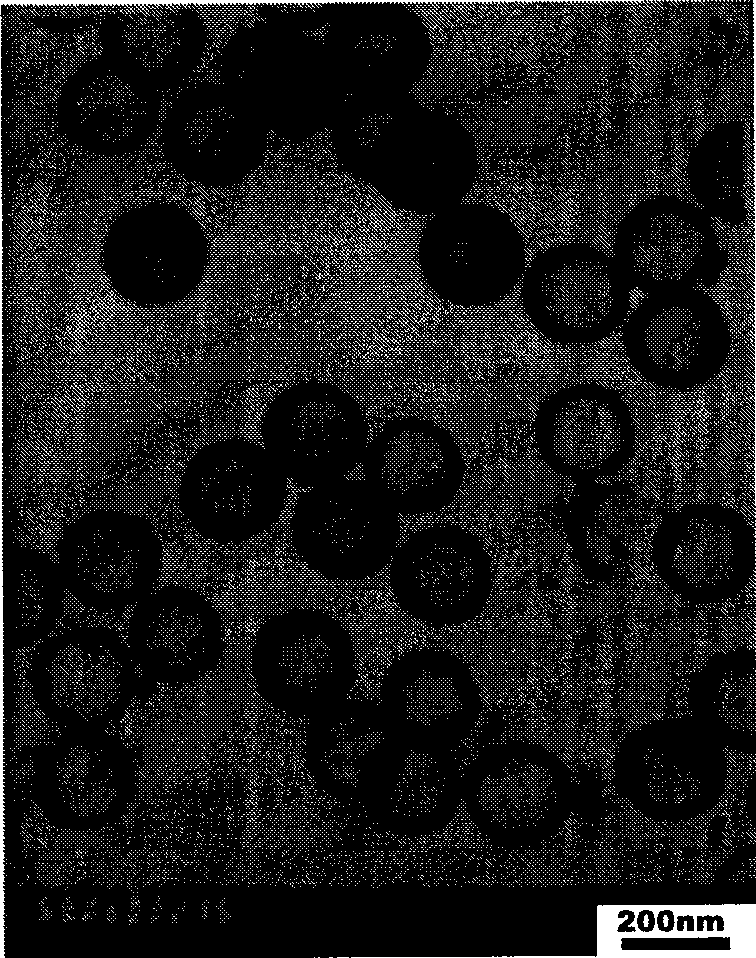

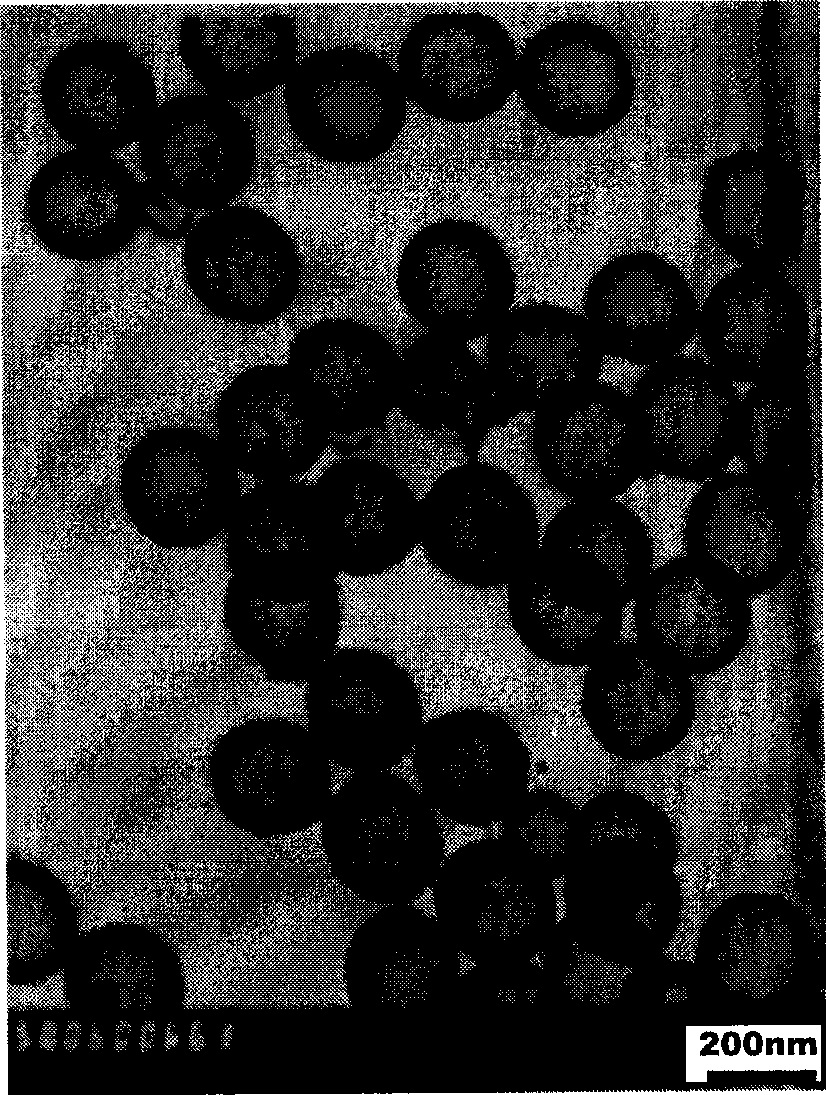

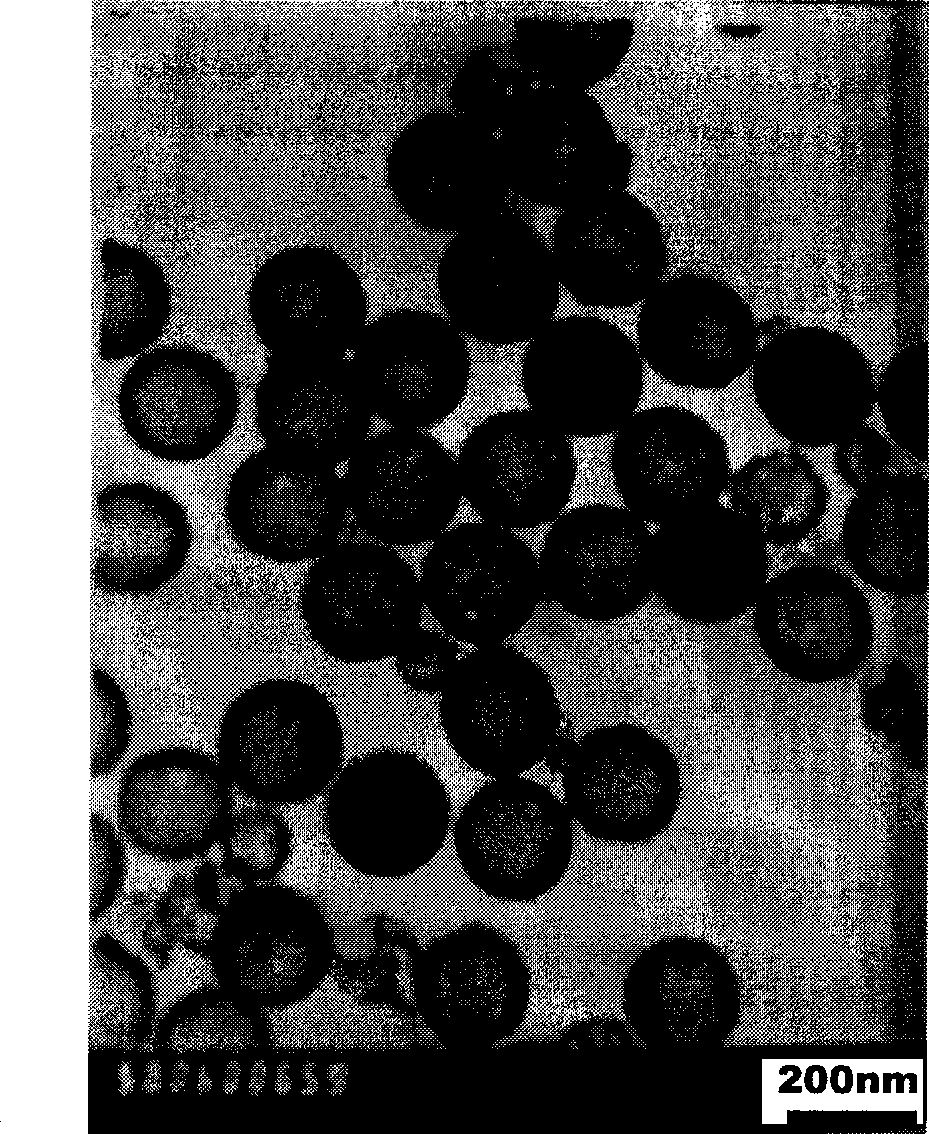

Controlled polymer/inorganic compound hollow microsphere and method for preparing same

InactiveCN101543756AUniform sizeGood dimensional stabilityMicroballoon preparationMicrocapsule preparationPolymer scienceMicrosphere

The invention belongs to the technical fields of compound materials and functional polymer materials, and particularly relates to a controlled polymer / inorganic compound hollow microsphere and a method for preparing the same. The preparation method comprises the following steps that: the surface of a silicon dioxide hollow microsphere is modified by KH-550; and a nitrogen-oxygen free radical is inoculated to the surface of silicon dioxide, and the nitrogen-oxygen free radical is used for triggering the active free radical polymerization on the surface of a monomer to form a controlled polymer layer. The microsphere prepared by the method has the advantages of uniform size, good size stability, big mechanical strength, good compatibility with an organic substrate, difficult falling-off of the polymer layer, controllable thickness of an inorganic layer and the polymer layer, quite strong designability and wide application prospect.

Owner:TONGJI UNIV

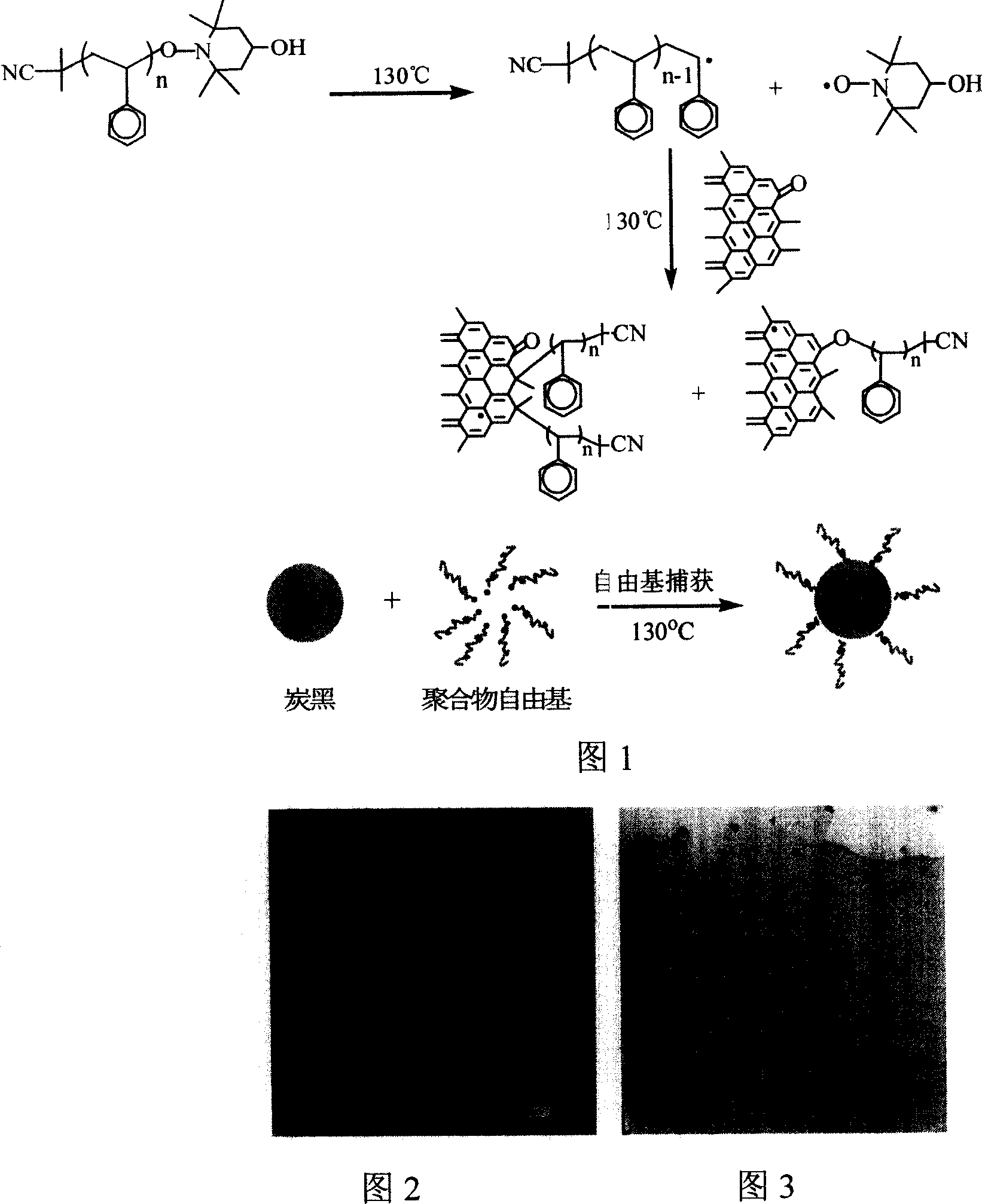

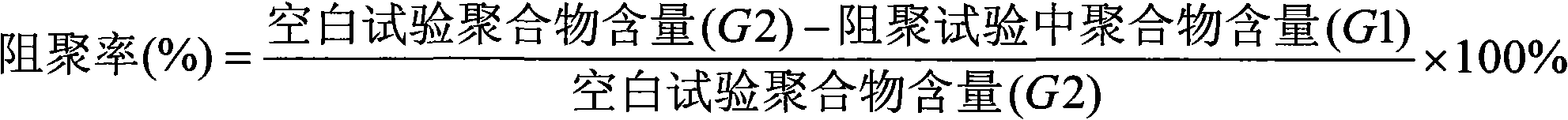

Method for preparing dispersive type carbon black adopting surface graft modification method

InactiveCN1970648AGood dispersionEasy to makePigment treatment with macromolecular organic compoundsOrganic solventPolymer science

The invention discloses a making method of dispersing carbon black through surface grafting modifying method, which is characterized by the following: making a series of polymer with HTEMPO terminal group polymerized by controllable free radiacal; decomposing HTEMPO into polymer free radical under higher temperature; making non-paired electron on the surface of carbon black catch polymer free radical; obtaining the modified carbon black grafted by polymer; dispersing the modified carbon black in multiple organic solvents; applying in the PTC material, air-sensitive material and ink domain.

Owner:ZHEJIANG UNIV

Polymerization inhibitor for inhibiting diolefin polymerization in petroleum cracking C5 fraction

InactiveCN101823932AGood inhibition effectReduce dosageHydrocarbon purification/separationHydrocarbonsHydroxylamineReboiler

The invention relates to a polymerization inhibitor for inhibiting diolefin polymerization in a petroleum cracking C5 fraction, which consists of a component 1, a component 2 and a component 3, wherein the component 1 is o-methyl-hydroquinone; the component 2 is 4-hydroxy-2,2,6,6-tetramethyl piperidine nitronyl nitroxide radical; the component 3 is N-isopropyl hydroxylamine; a solvent is acetonitrile, dimethyl formamide or N-methyl-pyrolidone; the weight ratio of the component 1 to the component 2 to the component 3 is 1:0.2-8:0.3-5; and the content of the component 1, the component 2 and the component 3 in the solvent is between 5 and 20 weight percent. The polymerization inhibitor can effectively inhibit diolefin auto polymerization or polymerization in a separating tower in the petroleum cracking C5 fraction and avoids blockage of a reboiler. The dosage of the polymerization inhibitor is small so as to reduce the production cost. The selected solvent is the same with the solvent used for extractive distillation so as to avoid inducing other impurities. The boiling points of various components of the polymerization inhibitor are very different from that of the petroleum cracking C5 fraction, so the separation is easy.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com