Patents

Literature

44results about How to "Avoid self-polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

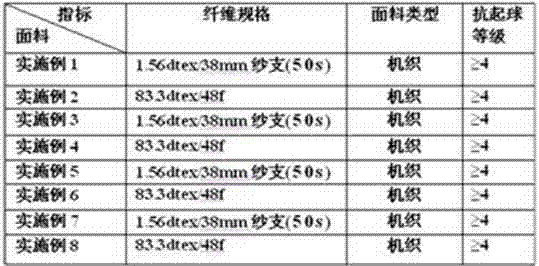

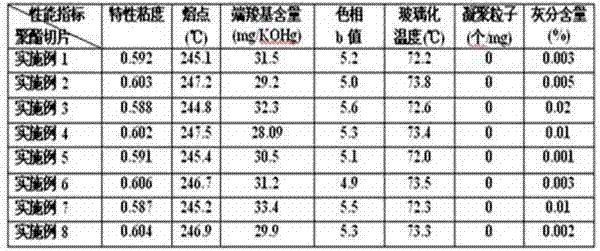

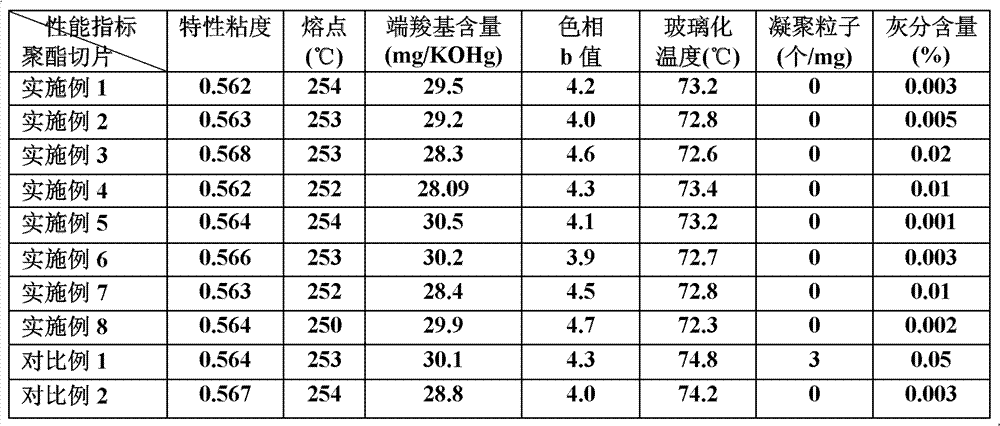

Preparation method for anti-pilling, anti-ageing and normal-pressure cation dyeable polyester chips

InactiveCN102391487AAvoid stickingAvoid self-polymerizationMonocomponent polyesters artificial filamentPolyesterTrans esterification

The invention relates to a preparation method for anti-pilling, anti-ageing and normal-pressure cation dyeable polyester chips. The preparation method comprises procedures of primary esterification, transesterification, secondary esterification and polymerization, wherein three monomers are added in the transesterification procedure; a hindered amine light stabilizer, a hindered phenol antioxidant and hydroxyl silicon oil are added after the secondary esterification and before prepolymerization; and the polyester slices are precrystallized and dried before the spinning procedure. A fabric prepared from fibers spun by the polyester chips has a high anti-pilling property and high light fastness; the polyester fibers can be dyed with various bright colors due to the normal-pressure cation dyeable property; the unified requirement of high-grade spring and summer clothing at present on functionality and color is met; and the polyester fibers and wool can be dyed in the same bath and a good clothing effect of the fibers blended with the wool is achieved. The polyester fibers spun by the polyester chips are important supplement for the cation dyeable polyester fiber market at present and have wide market prospect.

Owner:WUJIANG GANGYANG CHEM FIBER +1

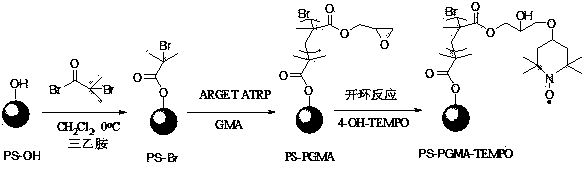

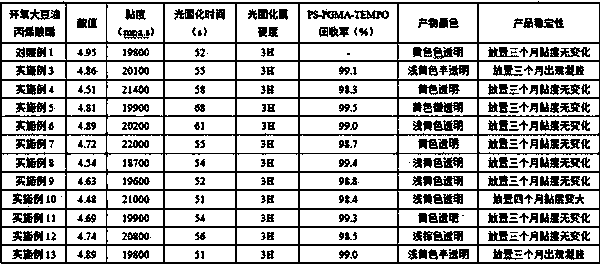

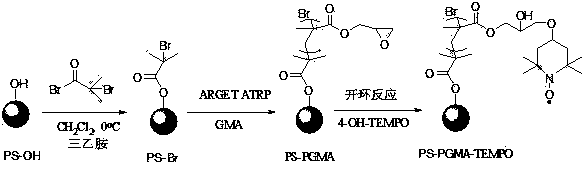

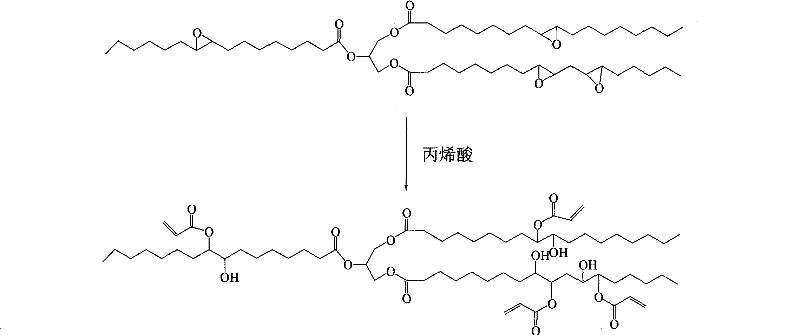

Preparation method and application of free nitroxide radical polymer brush polymerization inhibitor

ActiveCN104211863APerformance is not affectedAvoid self-polymerizationOrganic chemistryFatty acid esterificationEpoxyPolymer science

The invention relates to a preparation method of a free nitroxide radical polymer brush polymerization inhibitor, and application of the free nitroxide radical polymer brush polymerization inhibitor in synthesis of epoxy soybean oil acrylic ester. The preparation method comprises the following steps: firstly, grafting a polyglycidyl methacrylate polymer brush on the surfaces of cross-linked polystyrene microspheres by using an electron transfer regenerated catalyst atom transfer free radical polymerization technique, and secondly, bonding tetramethyl piperidine free nitroxide radical onto the polyglycidyl methacrylate polymer brush, thereby obtaining the free nitroxide radical polymer brush. The application comprises: taking the free nitroxide radical polymer brush as a main polymerization inhibitor and a small molecule polymerization inhibitor as a polymerization inhibitor aid, thereby forming a composite polymerization inhibition system for preparing epoxy soybean oil acrylic ester. The composite polymerization inhibition system not only has a high-efficiency polymerization inhibition function in the epoxy soybean oil acrylic ester preparation, but also is easy in recycling the main polymerization inhibitor, namely the free nitroxide radical polymer brush, so that the free nitroxide radical polymer brush can be recycled, and a product can be prevented from self-polymerization when being preserved when a small amount of the polymerization inhibitor is retained in the system.

Owner:廊坊市安次区调河头振达生物技术推广中心

Method of preparing esterified substance by rosin and hydroxyl acrylate

InactiveCN101016437AIncrease added valueAvoid self-polymerizationNatural resin chemical modificationResistAromatic solvent

The invention discloses a preparing method of esterified matter with rosin and acroleic acid hydroxy ester, which comprises the following steps: (1) heating 100 wt rosin; melting; adding into 0.1-2 wt esterification catalysts and 0.01-2 wt hydroquinone inhibitor; (2) adding into 1-50 wt acroleic acid hydroxy ester; reacting under 200-250 deg.c at 1-8 h; cooling; adding into 10-150 wt aromatic solvent; dissolving the product; filtering; vacuum-distilling; removing dissolvent; getting thick rosin and acroleic acid hydroxy ester. This invention possesses simple method and high conversion rate, which can be used to paint, ink, adhesives and photo resist.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

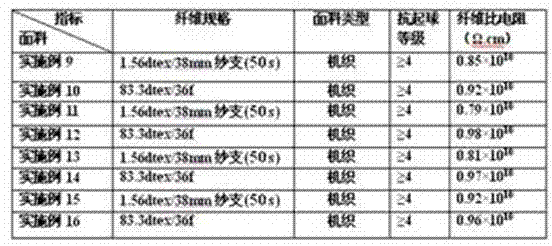

Preparation method for polyester fibers with anti-static, anti-pilling and normal-pressure cation dyeable compound functions

InactiveCN102391486AAvoid self-polymerizationEasy-to-stain function guaranteeMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a preparation method for polyester fibers with anti-static, anti-pilling and normal-pressure cationic dyeable compound functions. The preparation method comprises procedures of primary esterification, transesterification, secondary esterification and polymerization, wherein three monomers are added in the transesterification procedure; a hindered amine light stabilizer, a hindered phenol antioxidant and hydroxyl silicon oil are added after the secondary esterification and before prepolymerization; and an antistatic agent is added after the prepolymerization and before final polymerization. Fabric spun by the polyester fibers has high anti-static and anti-pilling properties; the polyester fibers can be dyed with various bright colors due to the normal-pressure cation dyeable property; the unified requirement of high-grade spring and summer clothing at present on functionality and color is met; and the fibers and wool can be dyed in the same bath and a good clothing effect of the fibers blended with the wool is achieved. The polyester fibers are important supplement for the cation dyeable polyester fiber market at present and have wide market prospect.

Owner:WUJIANG GANGYANG CHEM FIBER +1

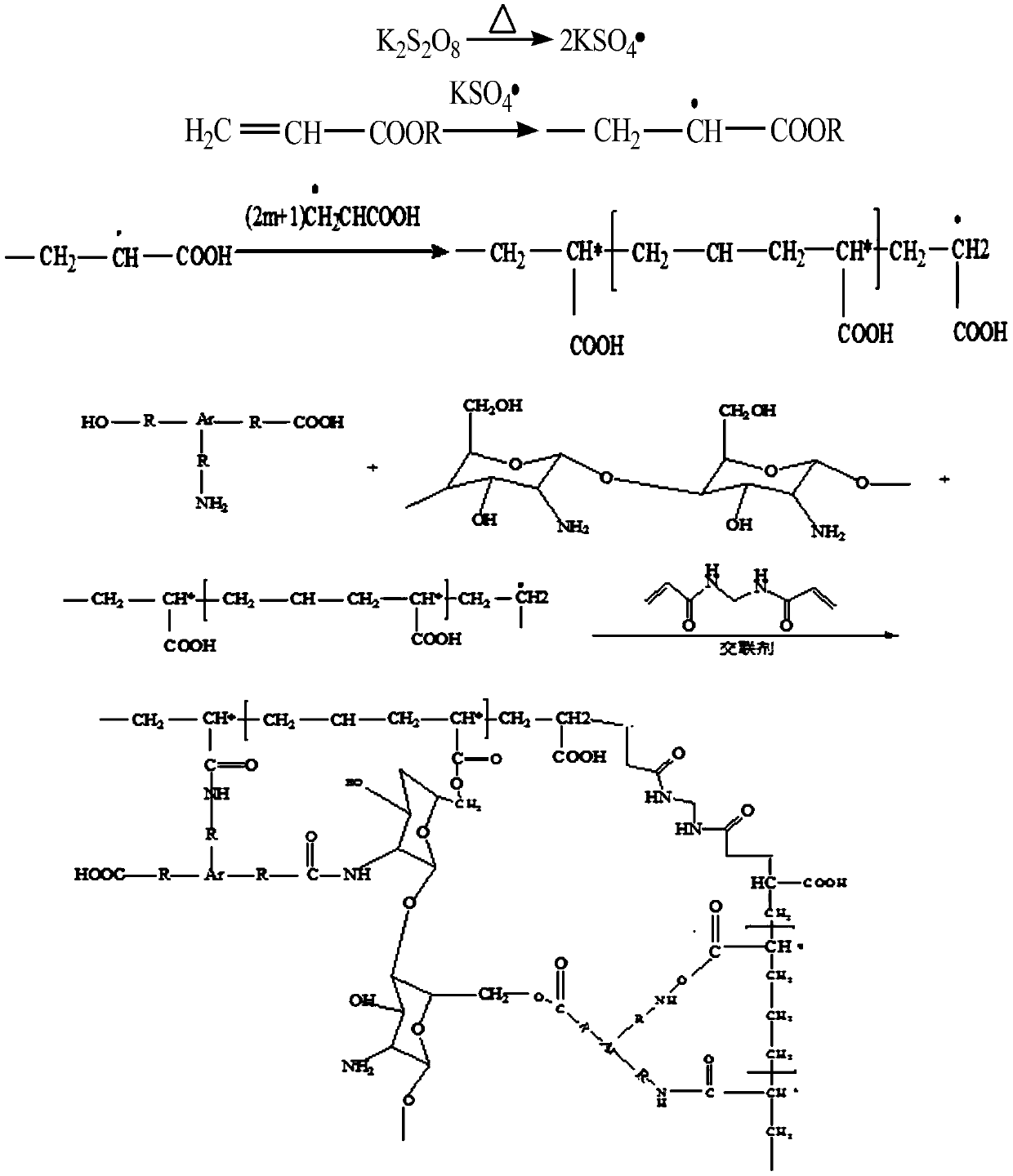

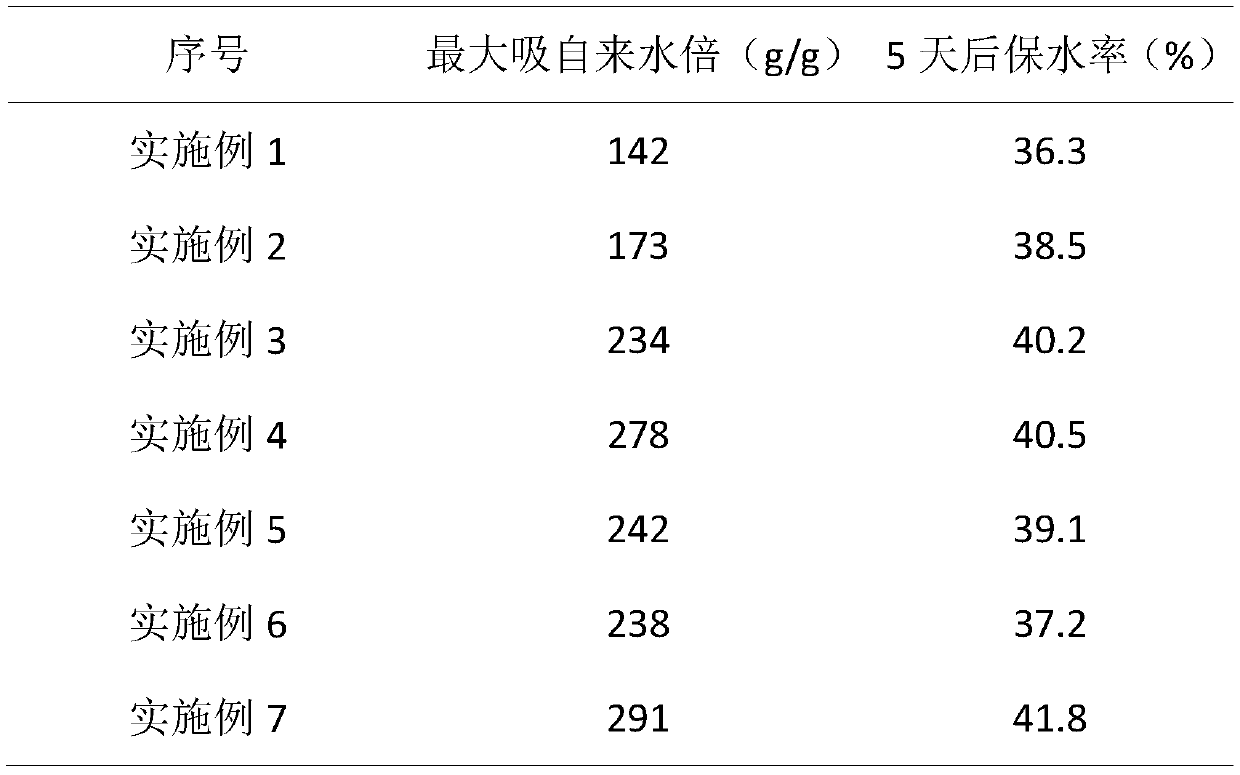

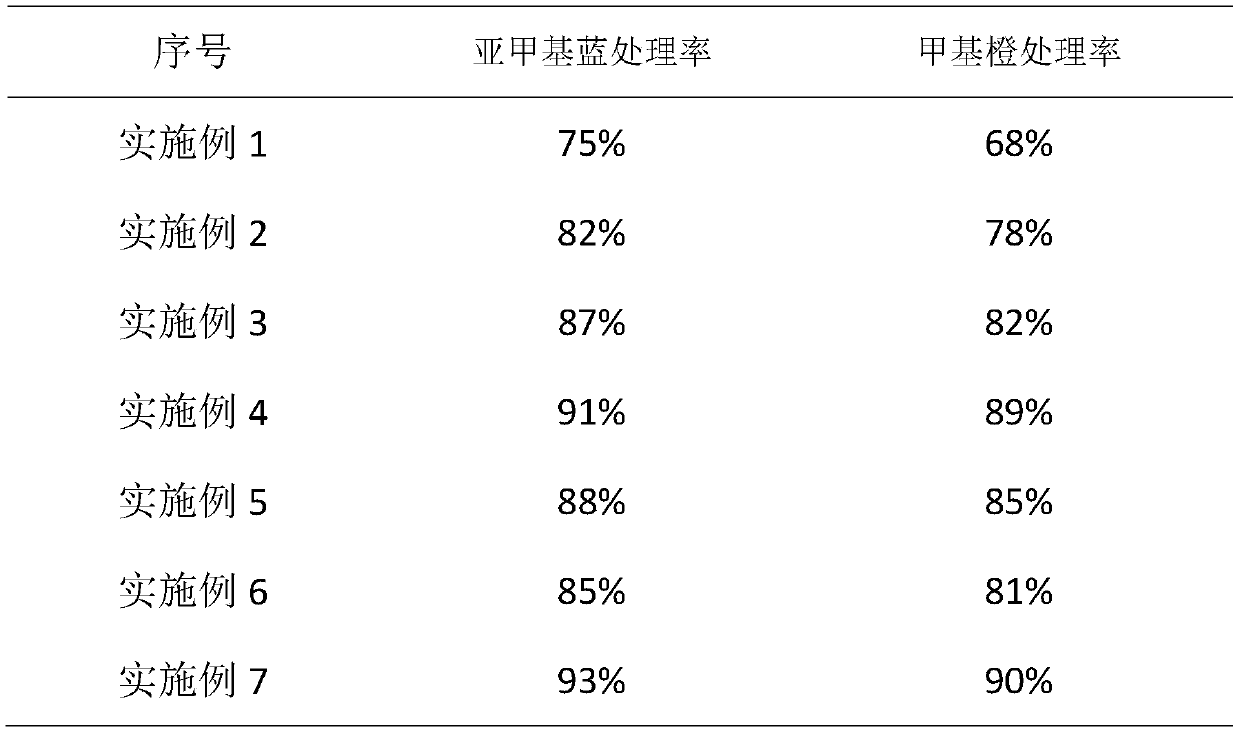

Fulvic acid type three-dimensional network composite material, and preparation method and application thereof

The invention discloses a fulvic acid type three-dimensional network composite material, and a preparation method and application thereof, and belongs to the technical field of material preparation and environment treatment. The fulvic acid type three-dimensional network composite material is prepared by dissolving fulvic acid and natural macromolecules, adding a cross-linking agent and an initiating agent, adding polyethylene glycol dropwise under the condition of heating, and stirring and drying. The fulvic acid is a high molecular organic acid which consists of aromatic groups and various functional groups thereof, is natural and degradable, and has good physiological activity and the functions of adsorbing, absorbing, complexing, exchanging and the like. The formed porous structure canenhance the adsorbing or complexing actions on heavy metal ion particulate matters. When the composite material is used for pollution treatment and ecological remediation, heavy metals in a water body and land can be adsorbed; after the adsorption is completed, the composite material can also be used as soil fertilizer to improve soil structure, restore ecological balance and reduce chemical pollution.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of modified polylactic acid

The invention provides a preparation method of modified polylactic acid. The method comprises the following steps: irradiating polylactic acid at the air atmosphere; and carrying out grafting reaction on the irradiated polylactic acid with an auxiliary and a monomer containing a double bond in a solvent so as to obtain the modified polylactic acid, wherein the temperature of the grafting reaction is above 30 DEG C. After the polylactic acid is irradiated at the air atmosphere, stable peroxide is formed on the molecular chain of the polylactic acid; when the irradiated polylactic acid is heated, the peroxide forms the macromolecule radial of the polylactic acid to be used as an initiator for initiating the monomer containing the double bond to be subjected to the grafting polymerization on the macromolecule of the polylactic acid, so that the modified polylactic acid is obtained. The polylactic acid is directly irradiated at the air atmosphere, thus the process requirement is low, and the cost is also reduced; and the irradiated polylactic acid and the monomer containing the double bond are subjected to the grafting reaction in the solvent, and the auxiliary can be used for preventing the monomer containing the double bond from being subjected to self-polymerization reaction and further generating a homopolymer.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Waterborne binder and food-contact waterborne printing ink prepared by using waterborne binder

The invention relates to the technical field of printing ink, and particularly relates to a waterborne binder and food-contact waterborne printing ink prepared by using the waterborne binder. The waterborne binder comprises the following raw materials in parts by weight: 15-20 parts of modified rosin, 5-15 parts of starch, 0.5-5 parts of emulsifying monomers, 0.5-5 parts of an initiator, 0.1-2 parts of a pH regulator and 40-60 parts of water, wherein each part of the emulsifying monomers is prepared by the following method: stirring 70-90 parts of acrylic monomers and / or styrene monomers, 0.5-5 parts of an emulsifier and 20-30 parts of water at a temperature of 30-45 DEG C to obtain the emulsifying monomers. According to the waterborne binder, the harm of the use of organic solvents to thehealth of human bodies is avoided, and compared with the existing waterborne acrylic resin, the waterborne binder is more environmentally friendly and is harmless to the human bodies.

Owner:GUANGDONG YINGKE GRP CO LTD

Preparation method of antistatic, anti-balling, and ordinary pressure cation dyeable polyester chip

InactiveCN102433605AAvoid self-polymerizationEasy-to-stain function guaranteeElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a preparation method of an antistatic, anti-balling, and ordinary pressure cation dyeable polyester chip, comprising the following steps: a primary esterification reaction step, an ester exchange reaction step, a secondary esterification reaction step, and a polymerization reaction step, wherein, a ternary-monomer is added in the ester exchange reaction step, hindered anime light stabilizers, hindered phenol antioxygens and hydroxyl silicone oil are added after the ester exchange reaction and before a prepolymerization reaction, and an antistatic agent is added after the prepolymerization of the polymerization reaction step and before a final polymerization. Fabrics prepared from polyester fibers produced by using the polyester chips disclosed herein have good antistatic behavior and good anti-balling behavior, and have unlimited dyeing possibilities by using the ordinary pressure cation dyeability, thus the uniform requirements of present high-grade spring and summer clothes for functionality and colors can be satisfied. The obtained fibers can be dyed with wool together, and the blending of the fibers with wool has good dress effect. The polyester chips and fibers disclosed herein are an important supplement of present cation dyeable polyester fiber market, and have a wide market prospect.

Owner:WUJIANG GANGYANG CHEM FIBER +1

Depolymerization process of dicyclopentadiene

ActiveCN109704905AControl concentrationReduce the rate of depolymerizationChemical industryHydrocarbon purification/separationRefluxDepolymerization

The present invention provides a depolymerization process of dicyclopentadiene. With dicyclopentadiene as a raw material, a diluent and a polymerization inhibitor are added to the raw material and mixed uniformly, and then subjected to depolymerization rectification separation in a reactive distillation tower after still standing for 30-60 minutes, under controlled conditions as follows: a tower bottom temperature of 240-270 DEG C, a tower top temperature of 40-45 DEG C, a tower top pressure of 12-17 KPaG, a reflux ratio of 6-10, and a feed rate of 8-15 mL / min; and cyclopentadiene is collectedat the top of the tower. The depolymerization process provided by the present invention, by adding a diluent and a polymerization inhibitor which are scientifically proportioned and controlling reaction conditions, realizes effective inhibition of the occurrence of self-polymerization and side reactions during pyrolysis, and inhibits the occurrence of coking simultaneously, thus improving the yield and purity of cyclopentadiene.

Owner:YANGPU AOLI PETROCHEM

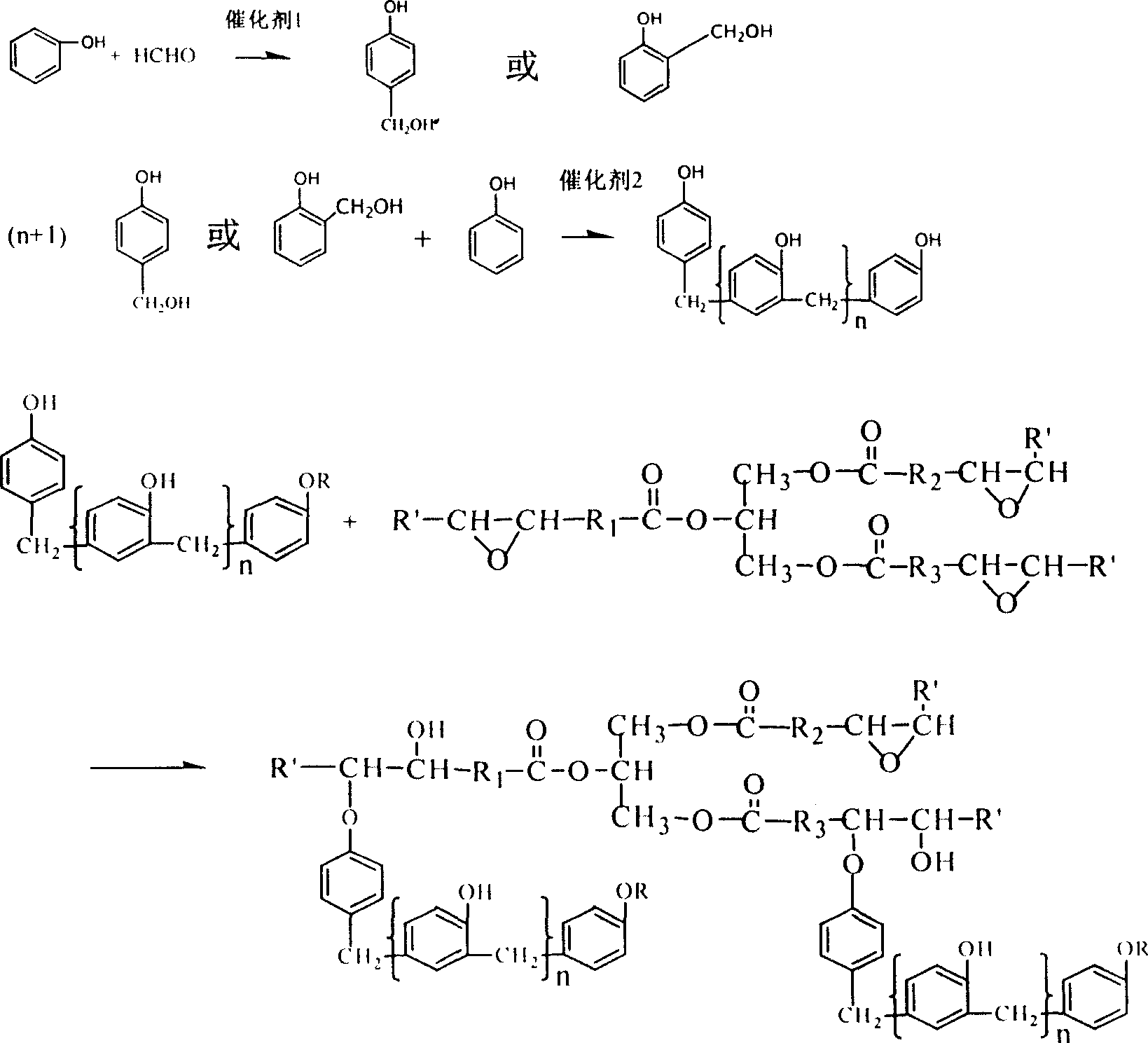

Epoxy plant oil modified phenol-formaldehyde resin, its preparation method and application

InactiveCN100347213CImprove punching effectImprove electrical performanceCircuit susbtrate materialsEpoxyVegetable oil

The preparation method for phenolic resin modified by epoxy vegetable oil comprises: putting thephenol, formaldehyde and nontoxic acid catalyst into a reactor; controlling temperature and holding for 1-8h; cooling to room temperature to obtain the coarse phenolic resin; transferring the coarse product into vacuum distillation kettle to dewater for refine; adding the epoxy vegetable oil, phenolic resin and faintly-alkaline catalyst into the reactor; heating and holding; reacting till the specified range of gelling time; cooling and adding solvent and additive to obtain the target with wide application. This invention has well security and quality with low cost and high efficiency.

Owner:SOUTH CHINA UNIV OF TECH

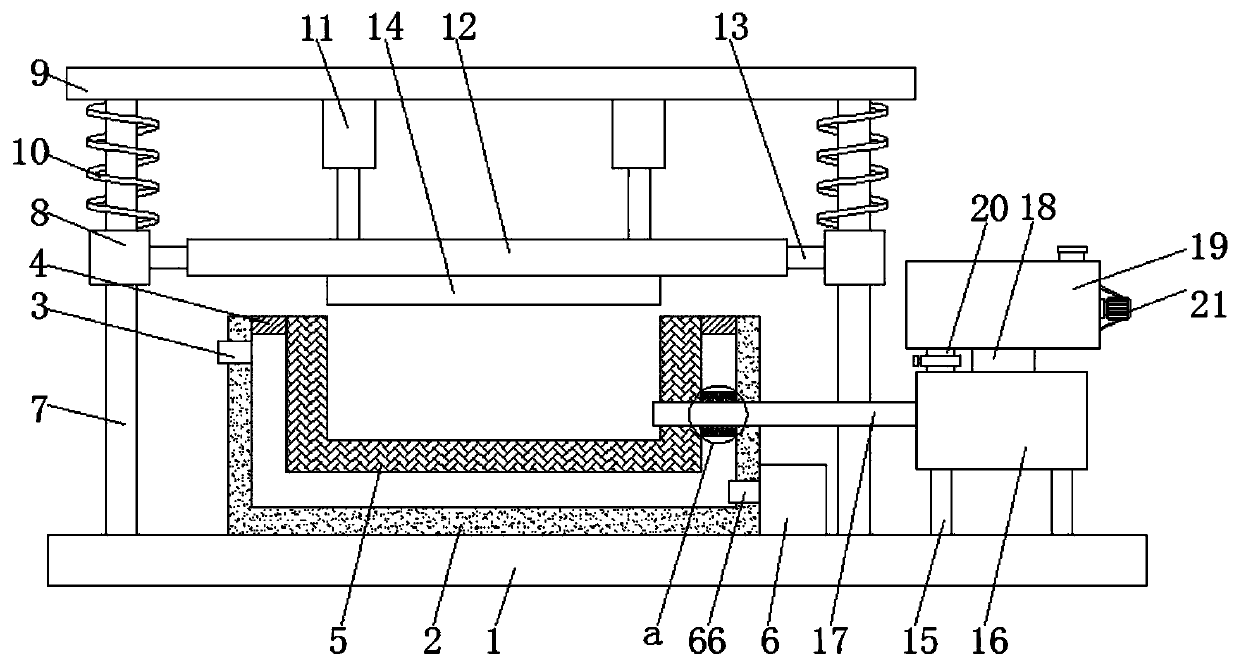

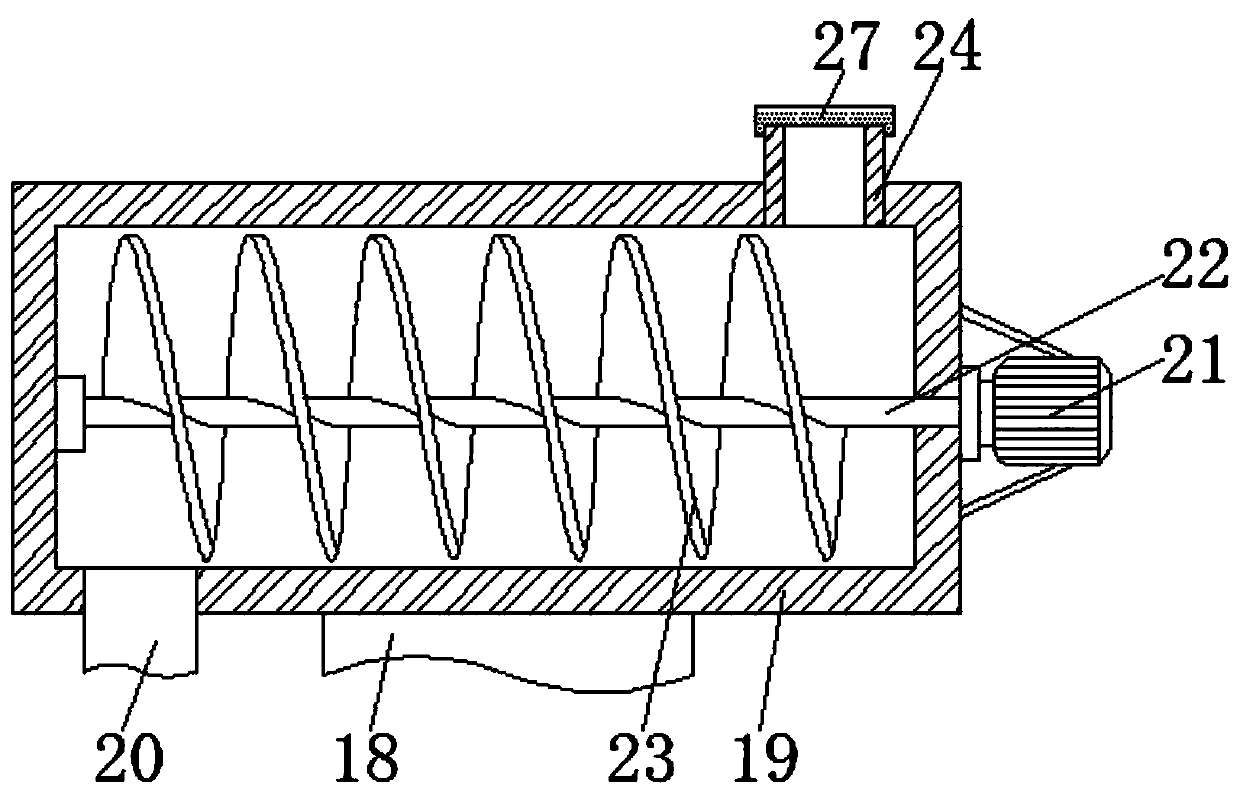

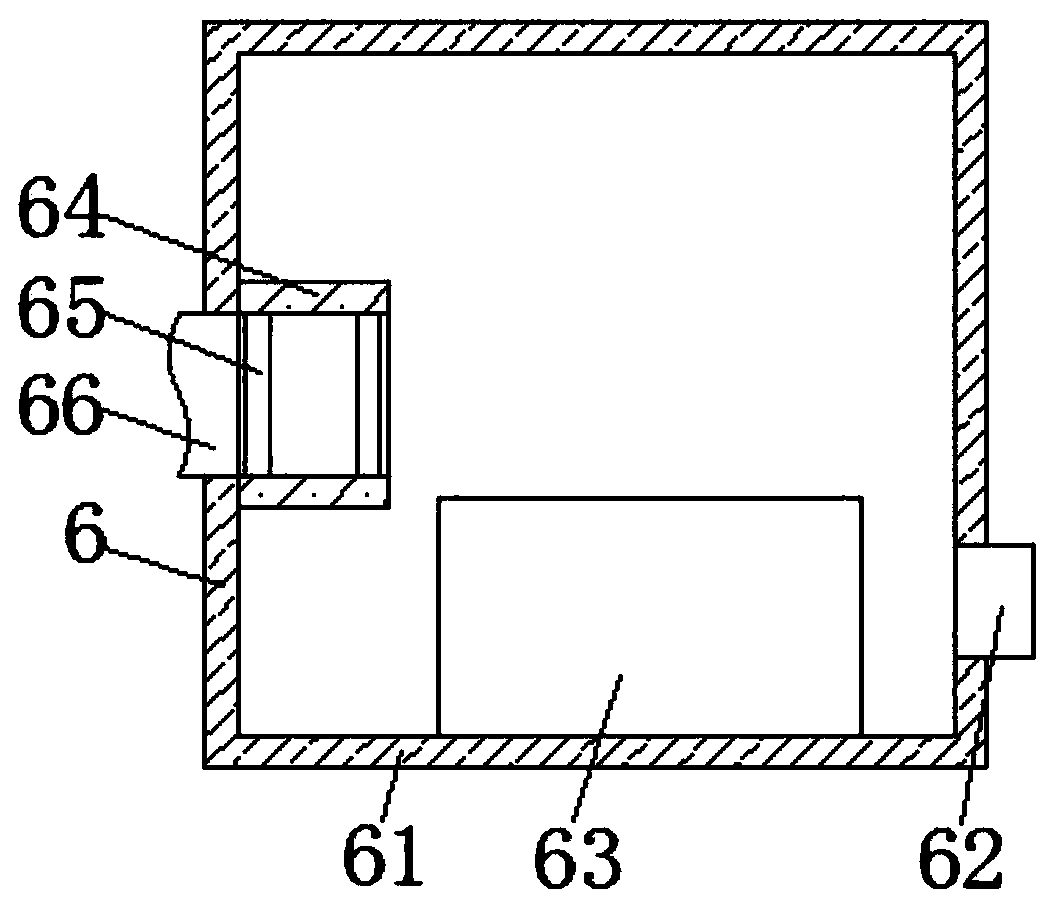

Refrigerator freezing box foaming mould

InactiveCN109968587APlay the role of heat insulationAvoid self-polymerizationDomestic articlesEngineeringRefrigerated temperature

The invention relates to the technical field of refrigerator production equipment and discloses a refrigerator freezing box foaming mould. The mould comprises a base. A mounting groove is fixedly mounted in the top of the base. Fixing rings are fixedly mounted between the inner walls of the top of the mounting groove. A lower mould body is fixedly mounted between the inner walls of the fixing rings. A heating mechanism is arranged on the lateral side of the mounting groove. Two symmetric air cylinders are fixedly mounted on the bottom surface of a top cover. An upper mould base is fixedly mounted between the output ends of the two air cylinders. An upper mould body is fixedly mounted on the bottom surface of the upper mould base. Two symmetrically-connected connecting frames are fixedly mounted on the top surface of the base. An injection mechanism is arranged between the tops of the two connecting frames. A communicating pipe is fixedly connected between the left side wall of the injection mechanism and the right side wall of the lower mould body in a communicating mode. A connecting block is fixedly mounted at the top of the injection mechanism. A stirring box is fixedly mountedat the top of the connecting block. A connecting pipe is fixedly connected between the inner bottom wall of the stirring box and the inner top wall of the injection mechanism in a communicating mode.By means of the refrigerator freezing box foaming mould, the lower mould body can be heated and subjected to heat preservation before foaming, and foaming layering is avoided.

Owner:滁州益佳模具设备制造有限公司

A kind of preparation method and application of nitroxide free radical polymer brush inhibitor

ActiveCN104211863BPerformance is not affectedAvoid self-polymerizationOrganic chemistryFatty acid esterificationGlycidyl methacrylatePolymer science

The invention relates to a preparation method of a nitroxide free radical polymer brush inhibitor and its application in the synthesis of epoxy soybean oil acrylate. The preparation method is to first adopt electron transfer regeneration catalyst atom transfer radical polymerization technology on the surface of cross-linked polystyrene microspheres, graft polyglycidyl methacrylate polymer brushes; Bonded thereon, a nitroxide radical polymer brush is obtained. Said application is to use nitroxide free radical polymer brush as the main polymerization inhibitor, and the small molecular polymerization inhibitor as auxiliary polymerization inhibitor to form a composite polymerization inhibition system to prepare epoxy soybean oil acrylate. The composite inhibitory system can not only have high-efficiency polymerization inhibitory effect in the preparation of epoxy soybean oil acrylate, but also is easy to recycle the main inhibitory agent nitroxide free radical polymer brush, so that it can be recycled, and a small amount of auxiliary inhibitory agent remains In the system, it can also prevent the self-aggregation of the product during storage.

Owner:廊坊市安次区调河头振达生物技术推广中心

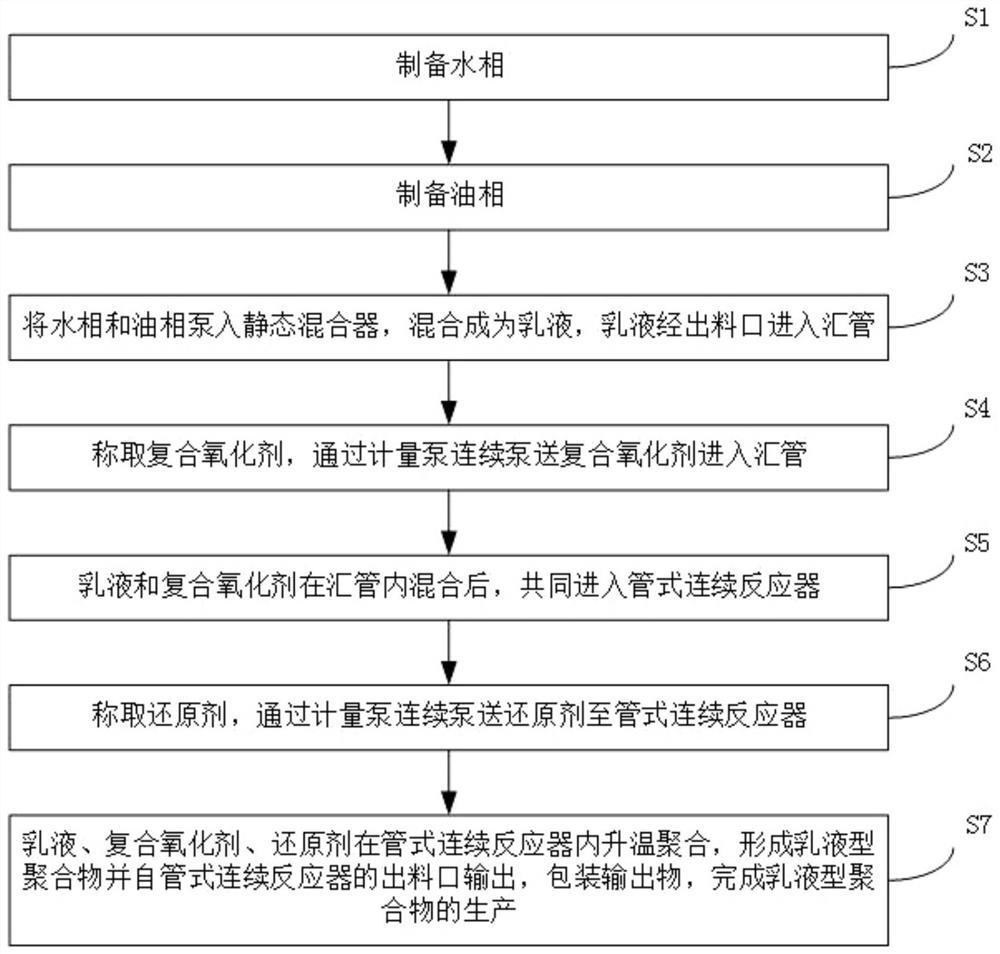

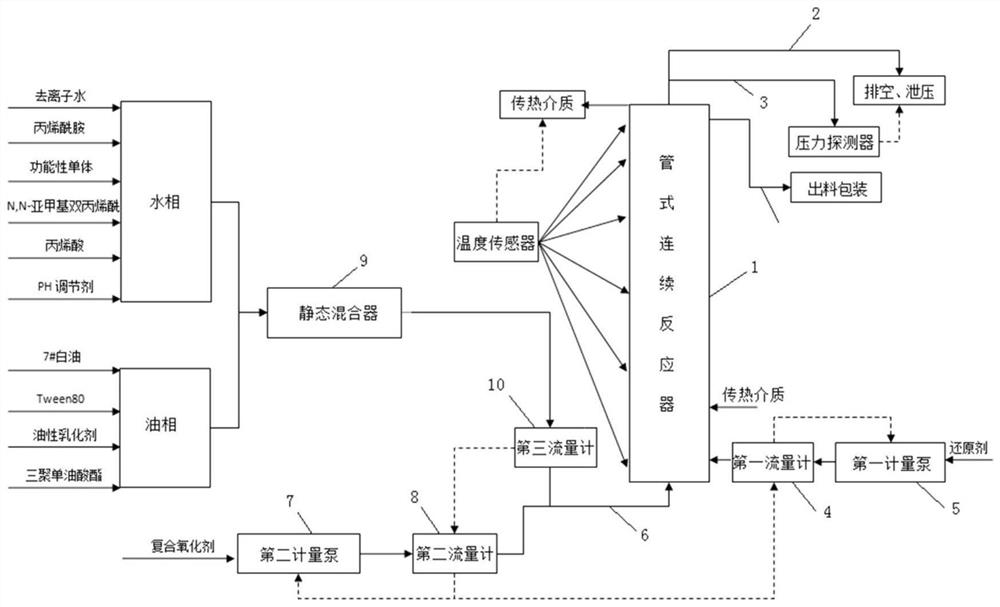

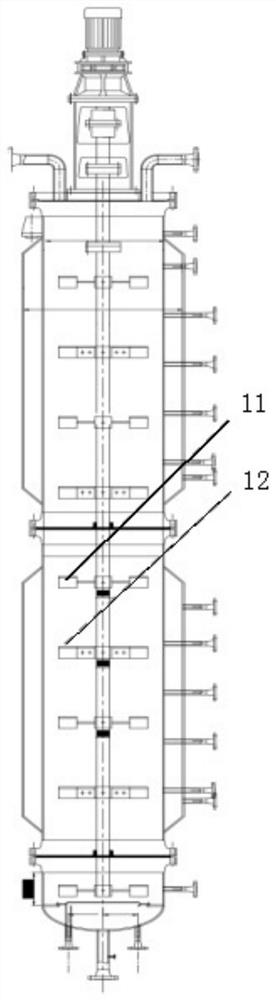

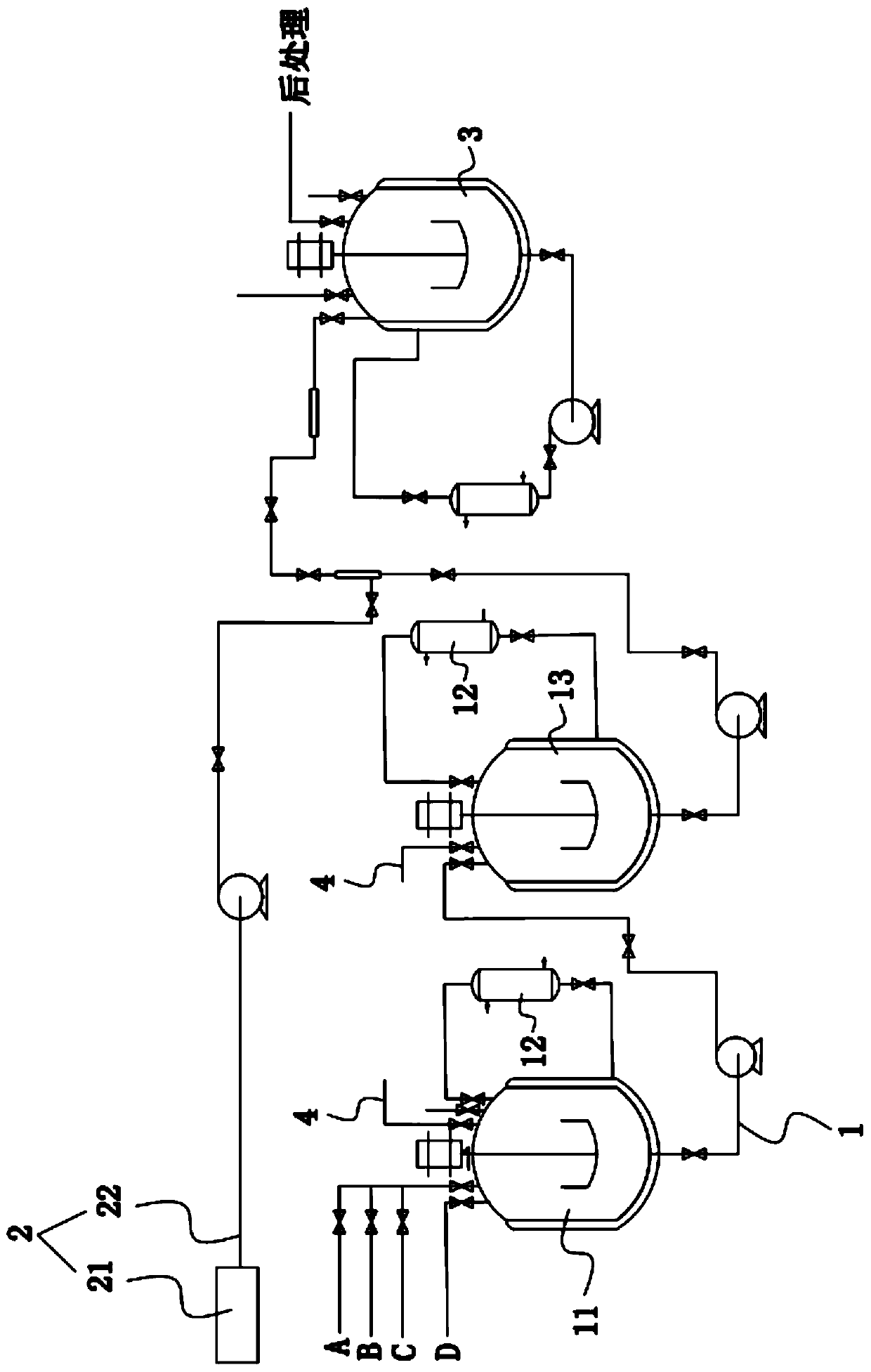

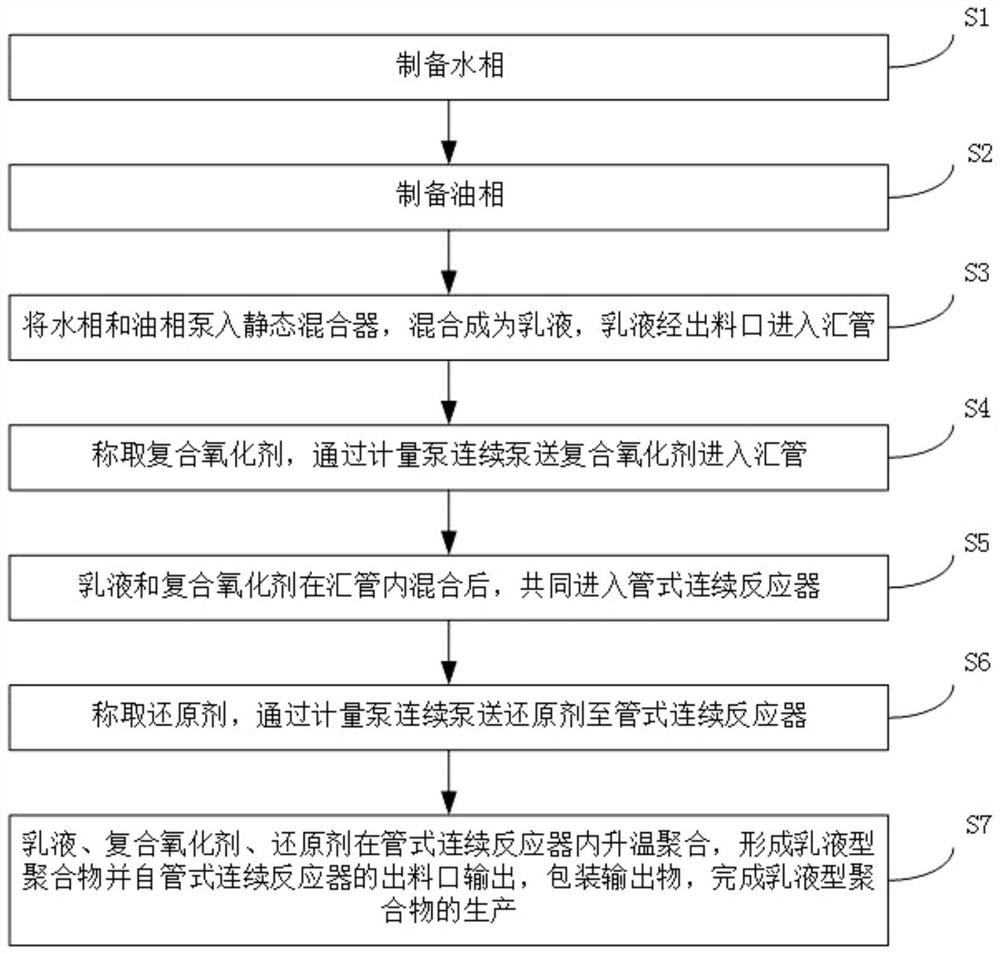

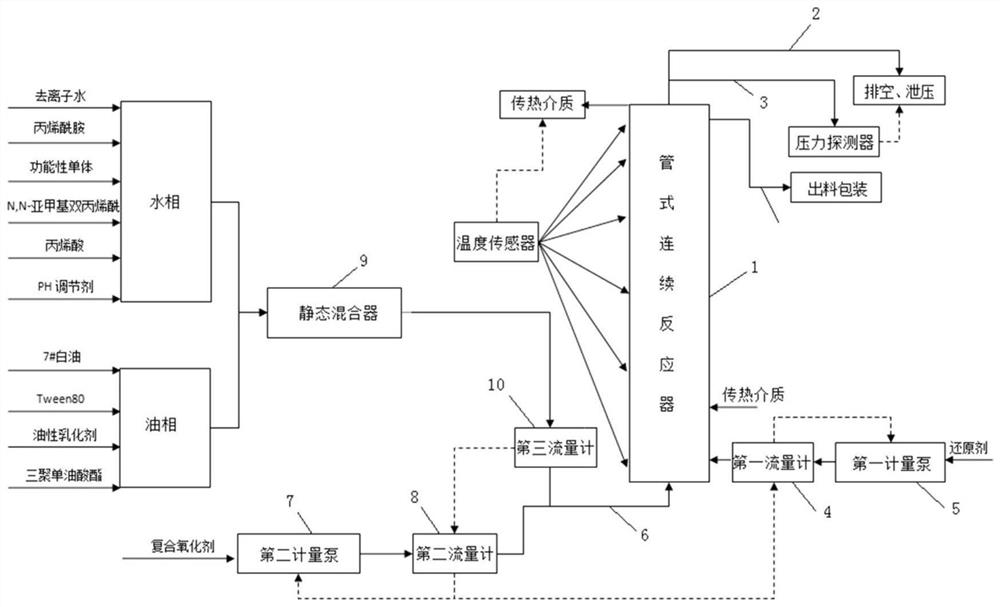

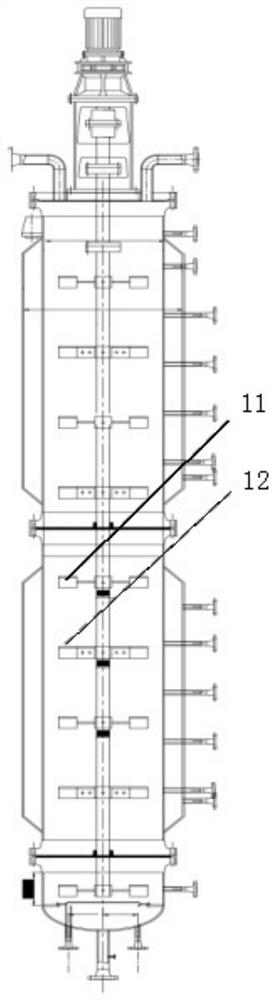

Continuous production process and continuous production device of emulsion polymer and application thereof

ActiveCN111704694AAchieving Continuous AggregationStrong thrustProcess control/regulationChemical/physical/physico-chemical stationary reactorsContinuous reactorProcess engineering

The invention provides a continuous production process and a continuous production device of an emulsion polymer and application of the continuous production process and the continuous production device. An emulsion is prepared firstly, then the emulsion and an oxidant are mixed and conveyed to a tubular continuous reactor, and simultaneously a reductant is separately input, so that early polymerization can be prevented. The tubular continuous reactor disclosed by the invention has stirring and back-mixing effects inside, and is suitable for a continuous production process of a high-viscosityemulsion system; according to the process, the emulsion is conveyed into the reactor from the bottom of the tubular continuous reactor through a pump, the composite oxidant is added to a feeding pipeline, the reductant is added to the bottom of the reactor, then a liquid is gradually pumped to the reactor pipeline and discharged out of the top of the reactor through the pump, early polymerizationis avoided, continuous polymerization is ensured, and the stability of products is improved.

Owner:西安长庆化工集团有限公司 +1

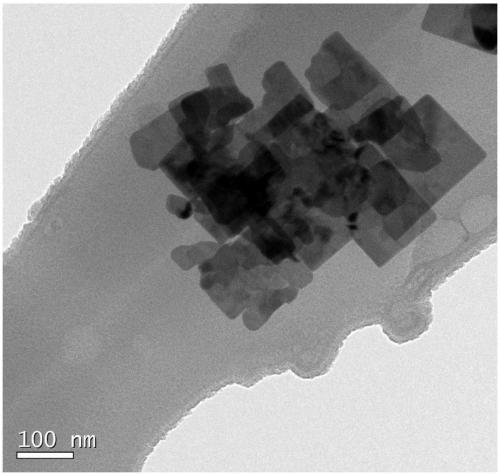

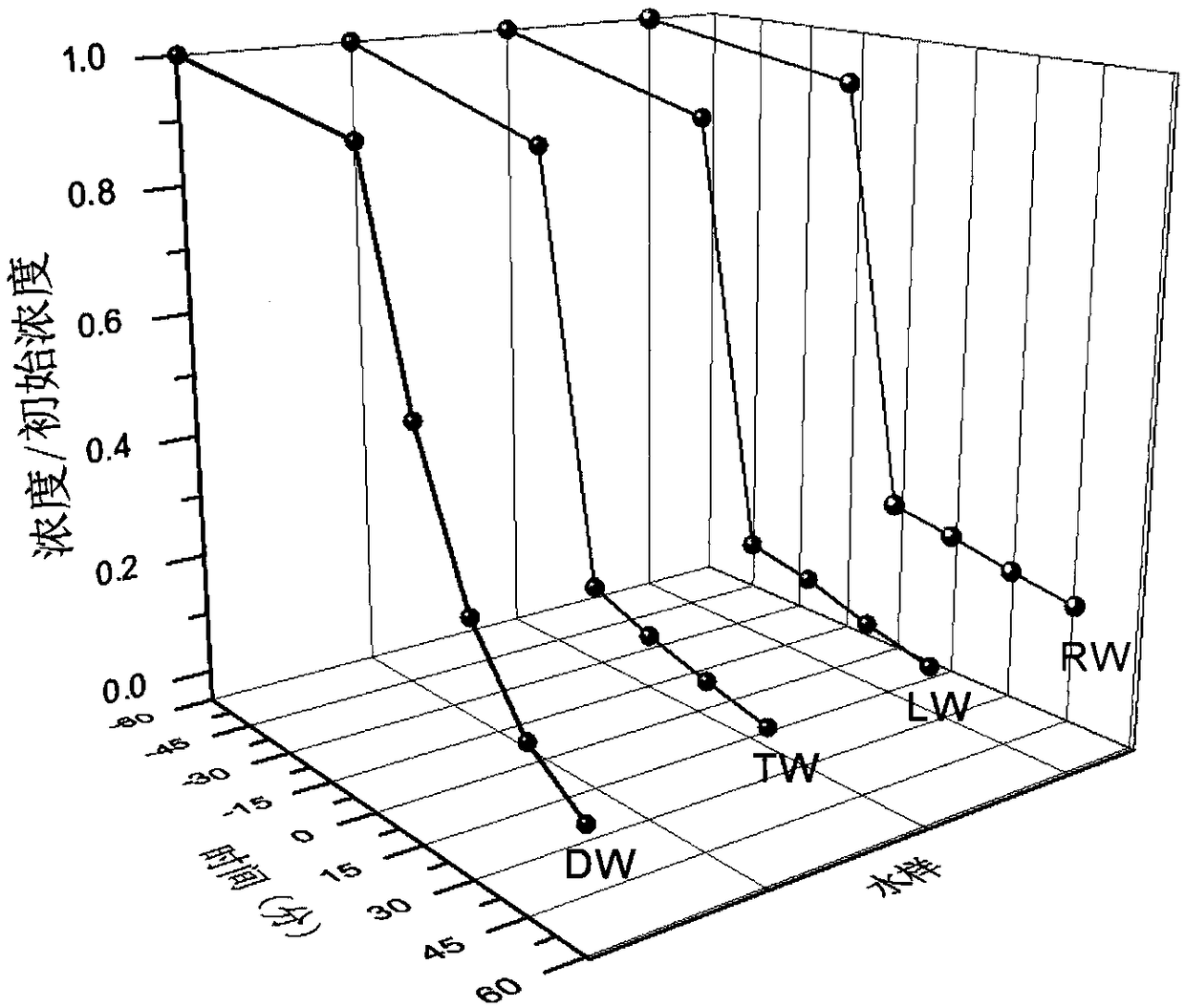

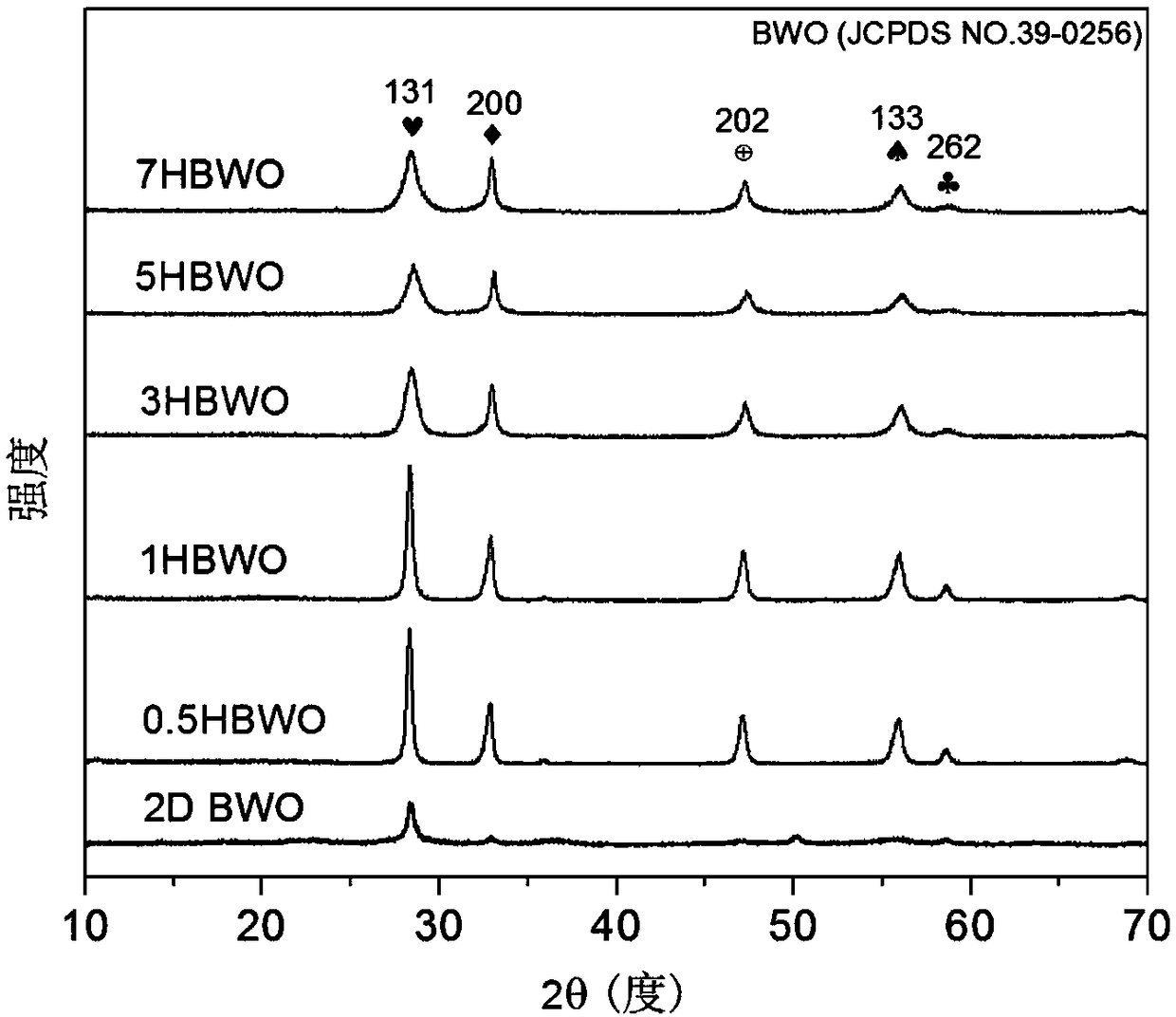

Iron porphyrin-flaky bismuth tungstate two-dimensional composite material and preparation method thereof

ActiveCN109289929AImprove electronic conductivityAvoid self-polymerizationWater/sewage treatment by irradiationWater treatment compoundsTungstatePorphyrin

The invention discloses an iron porphyrin-flaky bismuth tungstate two-dimensional composite material and a preparation method thereof, wherein the iron porphyrin-flaky bismuth tungstate two-dimensional composite material comprises iron porphyrin and flaky bismuth tungstate, and the iron porphyrin is immobilized on the surface of the flaky bismuth tungstate. The preparation method comprises: preparing a mixed solution of bismuth nitrate and sodium tungstate; preparing a precursor mixed solution; and carrying out a hydrothermal reaction on the precursor mixed solution. According to the present invention, the iron porphyrin-flaky bismuth tungstate two-dimensional composite material has advantages of good dispersibility, strong stability, easy recovery and reuse, excellent photocatalytic performance, environmental friendliness and the like, can efficiently degrade pollutants (such as antibiotics) in environment without the adding of H2O2, has good photocatalytic degradation effect, can significantly reduce the treatment cost, and has good application prospects and application range in the field of photocatalysis; and the preparation method has advantages of mild reaction conditions, simple process flow and environmental protection.

Owner:HUNAN UNIV

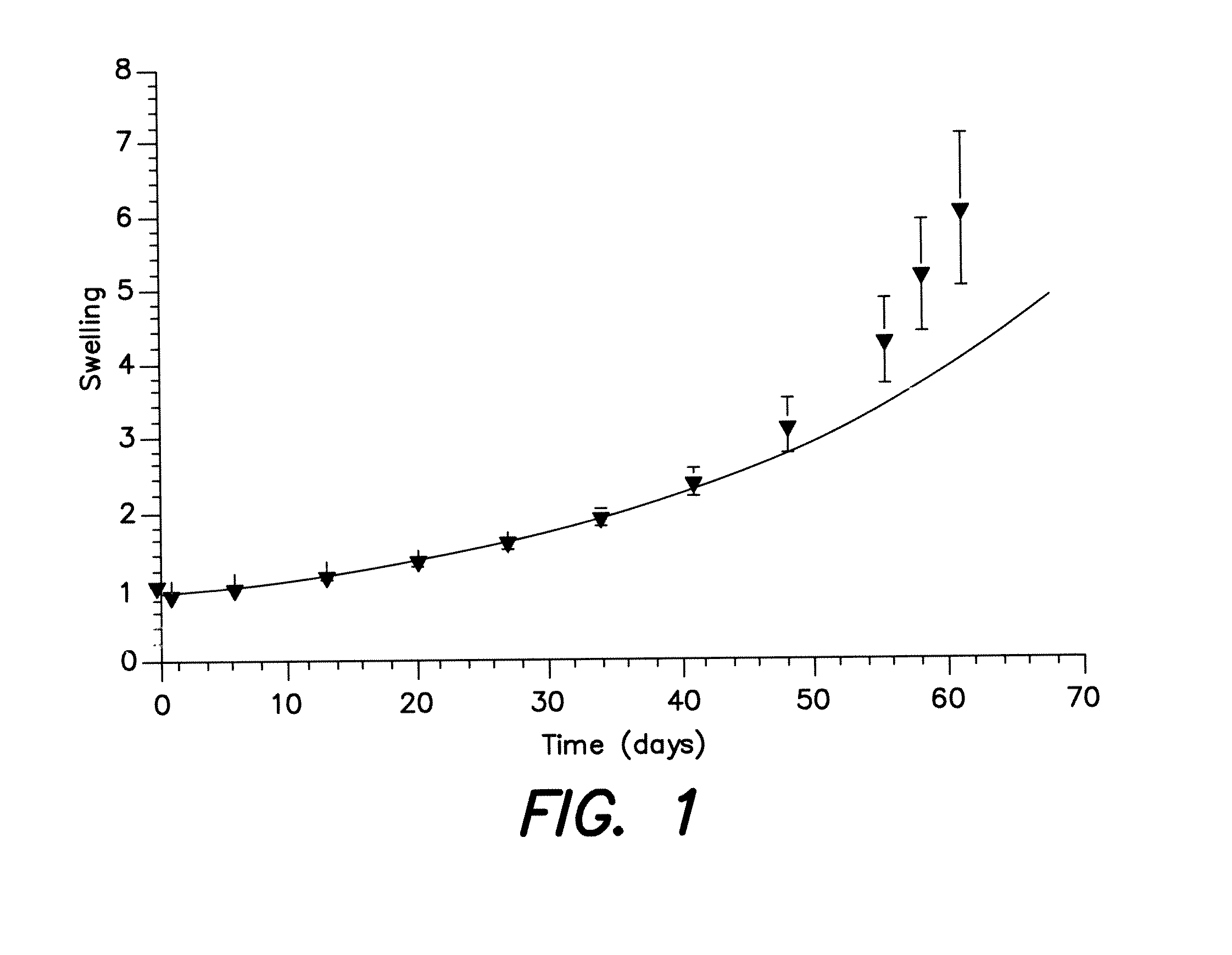

Barrier membrane

ActiveUS20100105800A1Improve stabilityPrevent self-aggregationOrganic chemistrySurgical adhesivesBarrier membranePolymer chemistry

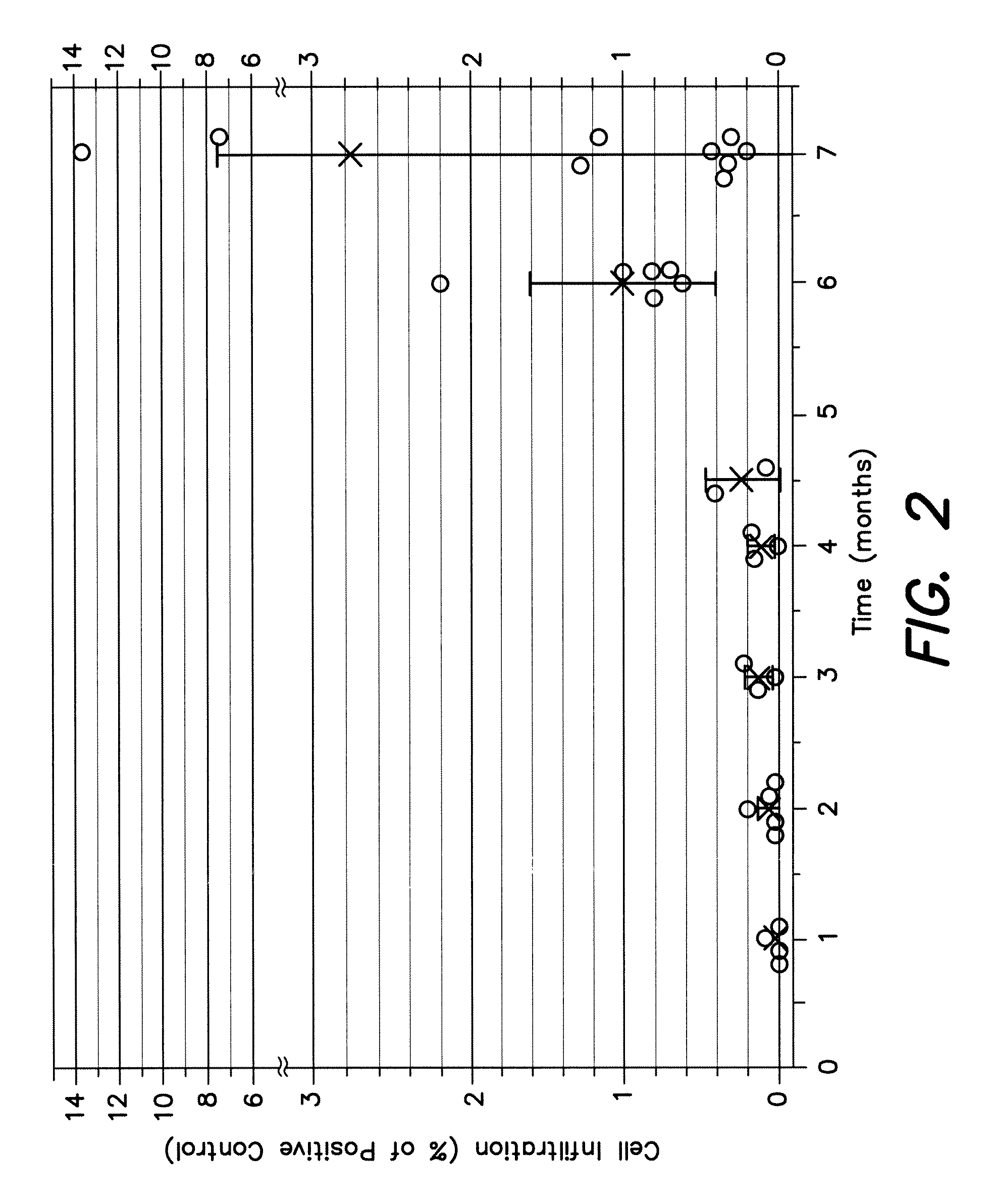

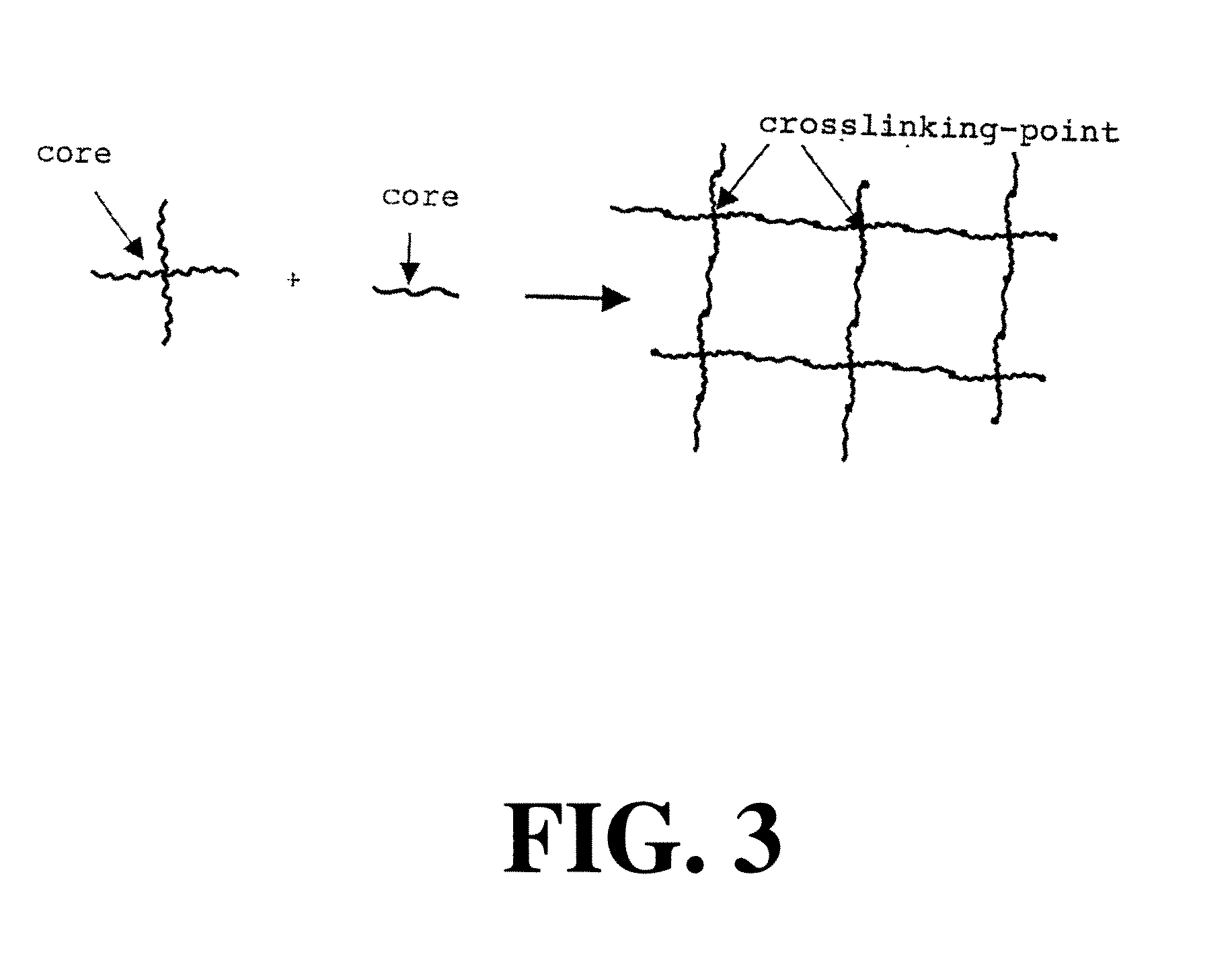

Cell-occlusive membrane, obtainable by reaction of at least two precursors in the presence of water. The first precursor A comprises a core and n chains each having a conjugated unsaturated group or a conjugated unsaturated bond, and the second precursor B comprises a core and m chains each having a thiol group, wherein m is greater than or equal to 2, n is greater than or equal to 2, and m+n is greater than or equal to 5. The reaction forms a three dimensional network with crosslinking-points. The adjacent crosslinking-points are connected by a chain having less than 600 atoms.

Owner:STRAUMANN HLDG AG

Method and system for preparing polymer polyol

PendingCN111499810ALess impuritiesImprove qualityTransportation and packagingMixer accessoriesPolymer sciencePolyol

The invention relates to the technical field of chemical production, in particular to a method and a system for preparing polymer polyol. The method for preparing the polymer polyol comprises the following steps: uniformly mixing the raw materials except the basic polyether, and then mixing with the basic polyether to carry out polymerization reaction. The raw materials except the basic polyetherare uniformly mixed and then mixed with the basic polyether, so that on one hand, the material cooling time can be shortened, the production period is shortened, the production efficiency is improved,and on the other hand, the batching frequency and the labor intensity of workers can be reduced; and the self-polymerization reaction of the raw materials except the basic polyether can be prevented,so that impurities in the polymer polyol can be reduced, the quality of the polymer polyol can be improved, a pipeline can be prevented from being blocked by a product produced by a self-polymerization reaction, and meanwhile, the situation that a part of raw materials volatilize due to the fact that the temperature of the basic polyether is higher than the boiling point of the raw materials except the basic polyether can be avoided.

Owner:上海抚佳精细化工有限公司 +1

Preparation method and application of bifunctional catalyst for high-selectivity preparation of isobutyraldehyde by propylene hydroformylation

ActiveCN112169829AAvoid self-polymerizationPrevent sinteringMolecular sieve catalystsOrganic compound preparationCarbon layerPtru catalyst

The invention belongs to the technical field of catalysis, and particularly relates to a preparation method and application of a bifunctional catalyst for high-selectivity preparation of isobutyraldehyde by propylene hydroformylation. According to the characteristics of an isobutyraldehyde product, propylene is firstly adsorbed on a rare earth modified acidic carrier to generate secondary positivecarbon ions, then the secondary positive carbon ions are subjected to addition with CO on active center cobalt carbide, and finally the product is generated through addition with active hydrogen. Thebifunctional catalyst is prepared by the steps of dipping cobalt salt and a nitrogen-containing compound precursor into acidic molecular sieve pores, carbonizing at a relatively high temperature, generating active center cobalt carbide highly dispersed in the molecular sieve pores in situ, and generating an N-modified carbon layer on the surface of the cobalt carbide. The carrier in the catalystplays an acidic role, and cobalt carbide activates CO and H2 at the same time. The prepared catalyst enables the yield of isobutyraldehyde to be as high as 79%. The catalyst prepared by the method islow in cost, high in activity, good in catalyst stability and high in isobutyraldehyde selectivity, and has a good industrial prospect.

Owner:RUNTAI CHEM TAIXING CO LTD

Industrial production process for preparing high-purity cyclopentadiene

ActiveCN111499487AReduce the rate of depolymerizationAvoid self-polymerizationChemical industryDistillation purification/separationDepolymerizationReactive distillation

The invention provides an industrial production process for preparing high-purity cyclopentadiene by depolymerizing dicyclopentadiene. Dicyclopentadiene is used as a raw material; adding the diluent 1and the polymerization inhibitor 1 into dicyclopentadiene and uniformly mixing; then carrying out depolymerization, rectification and separation in a reactive distillation tower 1; collecting crude cyclopentadiene at the top of a tower, then adding the crude cyclopentadiene, a diluent 2 and a polymerization inhibitor 2 into an evaporation kettle, carrying out heating vaporization, feeding steam through a cracking tube, carrying out tubular cracking, carrying out secondary depolymerization distillation separation in a reaction distillation tower 2 after cracking, and collecting high-purity cyclopentadiene at the top of the tower. The process solves the problems of coking, blasting boiling and low purity in the existing process, obtains high-purity cyclopentadiene, has higher yield and hashigher industrial application value.

Owner:山东省阳信科瑞实业有限公司

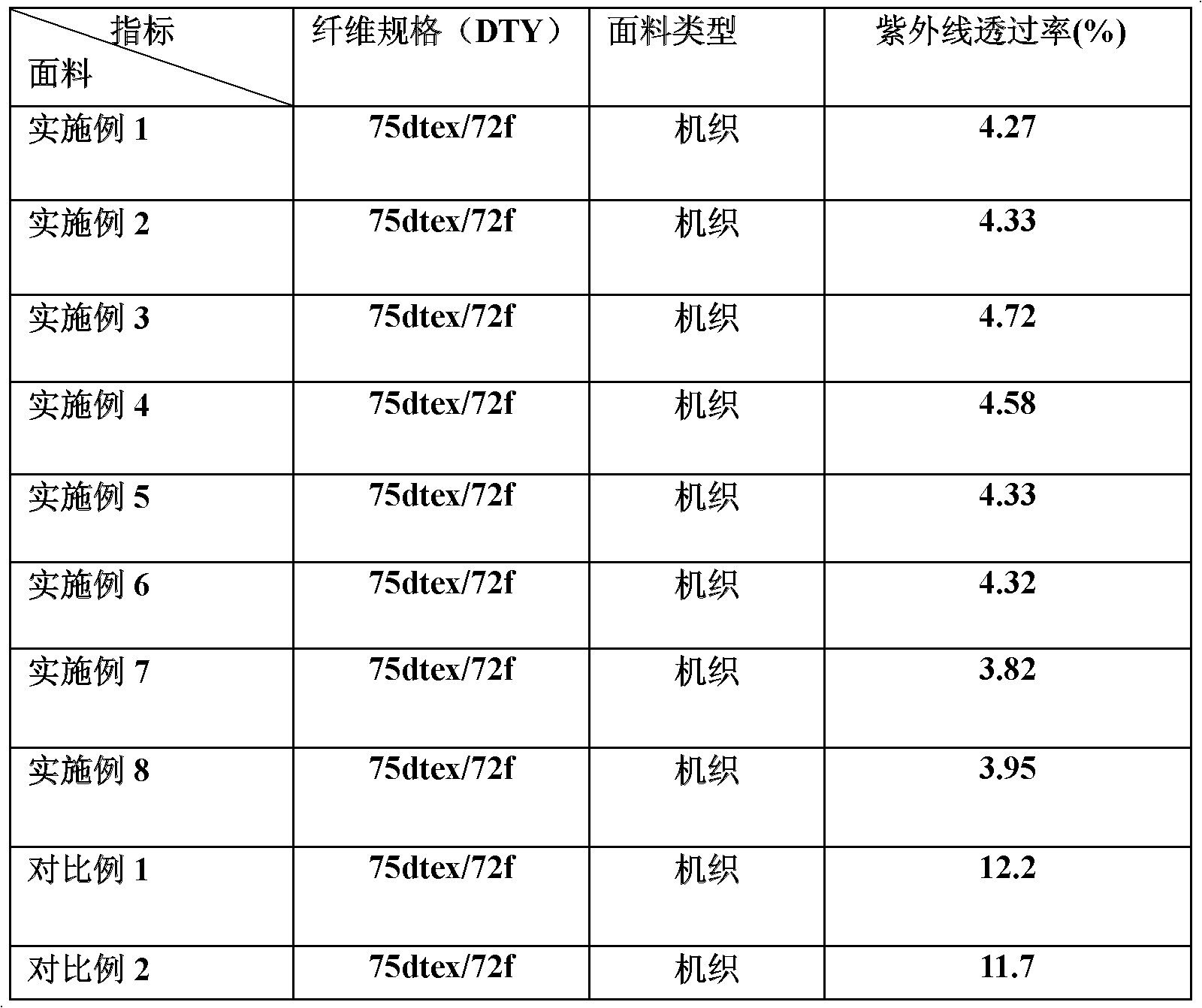

Preparation method for polyester fiber with composite ultraviolet resisting and cationic dyeing functions

ActiveCN102409428BImprove spinnabilityHigh strengthMonocomponent polyesters artificial filamentArtifical filament manufactureFiberPolyester

The invention relates to a preparation method for a polyester fiber with composite ultraviolet resisting and cationic dyeing functions. The preparation method comprises an esterification reaction procedure, an interesterification reaction procedure, a polymerization reaction procedure and a spinning procedure, wherein three monomers are added in the interesterification reaction procedure; after esterification reaction and before pre-polymerization reaction, a hindered amine light stabilizer and a hindered phenol anti-oxidant are added; in the polymerization reaction procedure, after the pre-polymerization and before final polymerization, an ultraviolet absorbent is added; and before the spinning procedure, polyester obtained by the polymerization reaction procedure is sliced for pre-crystallization and drying. Fabrics prepared from the polyester fibers have good ultraviolet resisting effects, and can be dyed into various colors by cationic dyes of the polyester fiber at the same time,so the polyester fiber meets the requirements of conventional high-end spring and summer clothing on uniformity between functions and colors, has vast market prospect and is an important supplement to the conventional cationic-dyeable polyester fiber market in China.

Owner:JIANGSU GANGHONG FIBER CO LTD +1

Preparation method for uvioresistant and cationic dyeable polyester chip

ActiveCN102408554BImprove spinnabilityHigh strengthMonocomponent polyesters artificial filamentPolyesterPolymer science

The invention relates to a preparation method for uvioresistant and cationic dyeable polyester chip, which comprises an esterification reaction procedure, an ester exchange procedure and a polymerization procedure in sequence, wherein three monomers are added in the ester exchange procedure; hindered anime light stabilizer and hindered phenol antioxygen are added after the esterification and before prepolymerization; and ultraviolet absorbent is added after the prepolymerization and before the final polymerization of the polymerization procedure. Fabric prepared by the fiber spun by the polyester chip has good uvioresistant effect. Meanwhile, the fabric can be dyed into various beautiful colors through the cationic dye characteristic of the polyester chip. The unified requirements of top grade spring and summer clothes on function and color are satisfied. The cationic dyeable polyester chip has broad market prospect and is also an important supplementation for the domestic current cationic dyeable polyester fiber market.

Owner:JIANGSU ZHONGLU TECH DEV +1

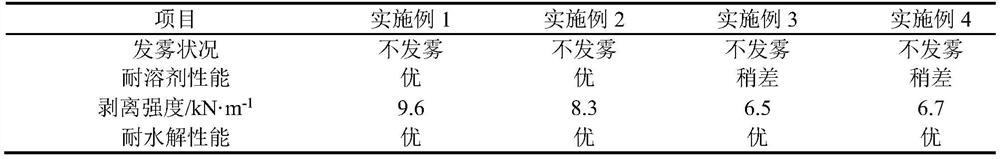

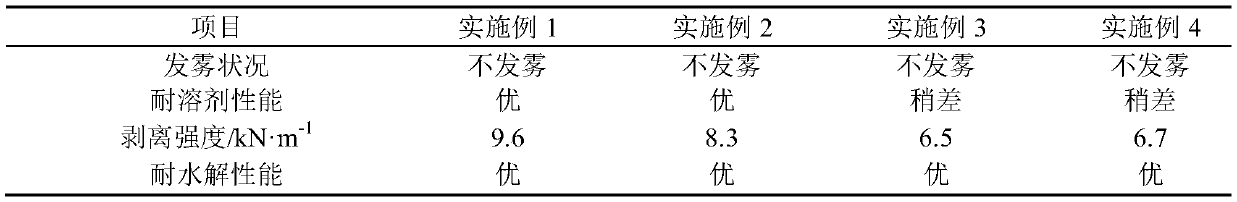

PU adhesive for single-component microfiber leather and preparation method thereof

ActiveCN111394043BPrevents the color from turning redAvoid self-polymerizationNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

Owner:YANGZHOU POLYTECHNIC INST

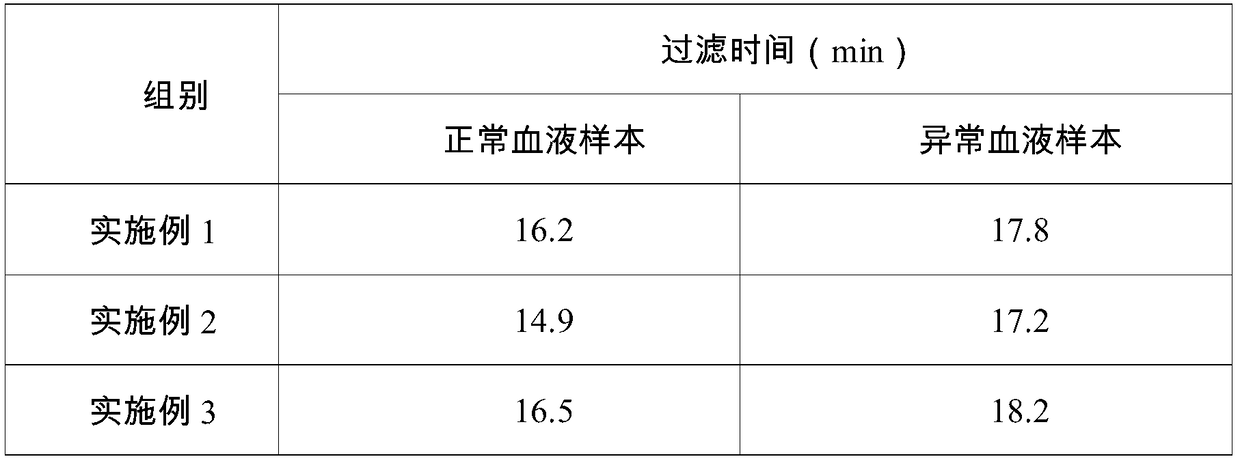

Modification method of leucocyte filtering membrane

ActiveCN109078511AAvoid self-polymerizationReduce processSemi-permeable membranesHaemofiltrationHemolysisWhite blood cell

The invention belongs to the technical field of leucocyte filtering and particularly relates to a modification method of a leucocyte filtering membrane. The modification method includes: completely soaking washed PBT nonwoven fabric into an ethanol solution containing benzophenone and polyalkyl glycol allyl epoxyl ether, then soaking into an ethanol solution containing methacrylic acid-2-hydroxyethyl and polyalkyl glycol allyl epoxyl ether, performing ultraviolet irradiation after the soaking, and allowing the irradiated PBT nonwoven fabric to have reaction with a silane coupling agent to obtain the leucocyte filtering membrane. The leucocyte filtering membrane prepared by the method is high in grafting rate and free of hemolysis, has an evident protecting effect on erythrocytes and has anefficient filtration effect on leukocytes and thrombocytes in whole blood.

Owner:广州达济医学科技有限公司

A kind of depolymerization technique of dicyclopentadiene

ActiveCN109704905BControl concentrationReduce the rate of depolymerizationChemical industryHydrocarbon purification/separationRefluxDepolymerization

The present invention provides a depolymerization process of dicyclopentadiene. With dicyclopentadiene as a raw material, a diluent and a polymerization inhibitor are added to the raw material and mixed uniformly, and then subjected to depolymerization rectification separation in a reactive distillation tower after still standing for 30-60 minutes, under controlled conditions as follows: a tower bottom temperature of 240-270 DEG C, a tower top temperature of 40-45 DEG C, a tower top pressure of 12-17 KPaG, a reflux ratio of 6-10, and a feed rate of 8-15 mL / min; and cyclopentadiene is collectedat the top of the tower. The depolymerization process provided by the present invention, by adding a diluent and a polymerization inhibitor which are scientifically proportioned and controlling reaction conditions, realizes effective inhibition of the occurrence of self-polymerization and side reactions during pyrolysis, and inhibits the occurrence of coking simultaneously, thus improving the yield and purity of cyclopentadiene.

Owner:YANGPU AOLI PETROCHEM

Environment-friendly polyvinyl chloride elasticizer and method of preparing the same

InactiveCN101367958BMeet environmental protection requirementsImprove plasticityContour matchingVegetable oil

Owner:SOUTH CHINA UNIV OF TECH

Fructose-modified furan resin for casting and preparation method thereof

ActiveCN111531119BReduce manufacturing costAvoid self-polymerizationFoundry mouldsFoundry coresTetramethylammonium bromideFuran

Owner:共享新材料(山东)有限公司

Method for preparing polyester fiber having compound functions of pilling resistance, ageing resistance and normal-pressure cationic dyeability

InactiveCN102433604BAvoid self-polymerizationEasy-to-stain function guaranteeMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention relates to a method for preparing a polyester fiber having compound functions of pilling resistance, ageing resistance and normal-pressure cationic dyeability, comprising a primary esterification reaction step, an ester exchange reaction step, a secondary esterification reaction step and a polymerization reaction step, wherein three monomers are added in the ester exchange reaction step; a hindered amine light stabilizer and a hindered phenol antioxidant as well as hydroxyl silicone oil are added after the secondary esterification reaction and a pre-polymerization reaction; and pre-crystallization and drying are performed on polyester slices before a spinning step. Fabrics made of the polyester fibers of the invention are good in pilling resistance and good in light fastness, and can be dyed into various beautiful colors by means of the normal-pressure cationic dyeability of the fibers, thereby meeting the uniform requirements of the present high-grade spring-summer dresses for functionality and colors; the obtained polyester fibers also can be subjected to apposition dyeing with wool; and as being blended with wool, good dressing effect can be obtained. The polyester fiber of the invention is an important supplement for the cationic dyeable polyester market at present in China.

Owner:WUJIANG GANGYANG CHEM FIBER +1

PU adhesive for single-component microfiber leather and preparation method of PU adhesive

ActiveCN111394043AGood bonding performanceSimple processNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesIsocyanatePhosphoric acid

The invention relates to a PU adhesive for single-component microfiber leather and a preparation method of the PU adhesive. The preparation method comprises the following steps: adding polyester polyol into a reaction bottle, heating to melt the polyester polyol, adding an antioxidant BHT and phosphoric acid, uniformly stirring, adding molten isocyanate, reacting at 110 DEG C, adding an organic solvent in the reaction process for dilution, and reacting until the viscosity of the system reaches 80,000-120,000 cps / DEG C; and adding another organic solvent into the reaction bottle so as to adjustthe solid content of the system to 40%, continuously stirring for 1 hour, and packaging. The PU adhesive for the single-component microfiber leather prepared by the scheme has the advantages of simple process, convenience in operation and the like; the prepared PU adhesive is low in softening point, has good hydrolysis resistance, heat resistance and mildew resistance and is suitable for dry sticking, and when the PU adhesive is used for microfiber veneering, the matte phenomenon is avoided.

Owner:YANGZHOU POLYTECHNIC INST

A kind of preparation method of polypropylene foam special material based on sorbitol acetal compound

The invention discloses a preparation technology of a polypropylene foaming special-purpose material of a sorbitol acetal compound. The polypropylene foaming special-purpose material comprises, by weight, 100 parts of polypropylene, 0.1-0.7 parts of an initiator, 0.1-1 part of a sorbitol acetal compound and 0.05-1 part of a benzenoid aromatic hydrocarbon grafted monomer. A volume ratio of the benzenoid aromatic hydrocarbon grafted monomer to a solvent is 1-15. The preparation technology comprises feeding polypropylene into an extruder through a main feed inlet, feeding the initiator and the sorbitol acetal compound into the extruder through an auxiliary feed system, dissolving the benzenoid aromatic hydrocarbon grafted monomer in the solvent, feeding the solution into the extruder through a liquid feed inlet, simultaneously, starting a vacuum pump at the tail of the extruder, pumping the solvent and the unreacted grafted monomer and carrying out reactive extrusion, cooling and granulation to obtain the polypropylene foaming special-purpose material. The preparation technology has simple processes, can be operated flexibly and is suitable for continuous industrial production of the polypropylene foaming special-purpose material with high melt strength and excellent processing fluidity.

Owner:EAST CHINA UNIV OF SCI & TECH

Continuous Production Technology and Continuous Production Equipment of Emulsion Polymer and Its Application

ActiveCN111704694BAvoid self-polymerizationGuarantee stabilityProcess control/regulationChemical/physical/physico-chemical stationary reactorsContinuous reactorProcess engineering

Owner:西安长庆化工集团有限公司 +1

Method for preparing dinonyl substituted diphenylamine antioxidant

ActiveCN108409581AGood reaction selectivityPromote reaction efficiencyAmino preparation from aminesOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveAntioxidant

The invention provides a method for catalytically preparing nonylated diphenylamine. The nonylated diphenylamine product is prepared through carrying out an alkylation reaction on diphenylamine and excessive nonylene in the presence of a composite catalyst system. A composite catalyst is prepared from the following catalyzing components: a catalyzing component A, a catalyzing component B and a flaky nano-alumina cocatalyst, wherein the catalyzing component A is selected from mesoporous silicon dioxide loaded alkyl imidazolium salt and aluminum chloride ionic liquid, the catalyzing component Bis selected from molecular sieve loaded heteropolyacid catalyst, and the content of dinonyl diphenylamine in the nonylated diphenylamine product is higher than 85%. According to the method provided bythe invention, the yield of dinonylated diphenylamine can be effectively increased, a chlorine element is hardly remained, and the quality of the antioxidant product is improved.

Owner:JIANGSU FEIYA CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com