Patents

Literature

102results about How to "Promote reaction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogenation dechlorinating catalyst for synthesizing trifluoroethylene and novel preprocessing process of carrier of catalyst

ActiveCN102211028AHigh selectivityImprove stabilityPreparation by dehalogenationCatalyst activation/preparationChemistryActivated carbon

The invention discloses a catalyst used for preparing trifluoroethylene by hydrogenating and dechlorinating trifluorochlor oethylene, comprising a first catalyst, a second catalyst and an assistant, wherein the first catalyst is one or combination of more than two of palladium, ruthenium and platinum, the second catalyst is Fe and / or Cu, and the assistant is selected from one or combination of more than two of V, Bi and K. The invention also discloses an activated carbon carrier preprocessing method of the catalyst for preparing the trifluoroethylene by hydrogenating and dechlorinating the trifluorochlor oethylene and an application of the prepared catalyst in trifluoroethylene preparation. The catalyst prepared by the method disclosed by the invention has the advantages of high catalytic activity and catalyst efficiency, good trifluoroethylene selectivity, strong reaction stability, mild reaction condition, simple catalyst preparation and processing process and the like.

Owner:SINOCHEM LANTIAN

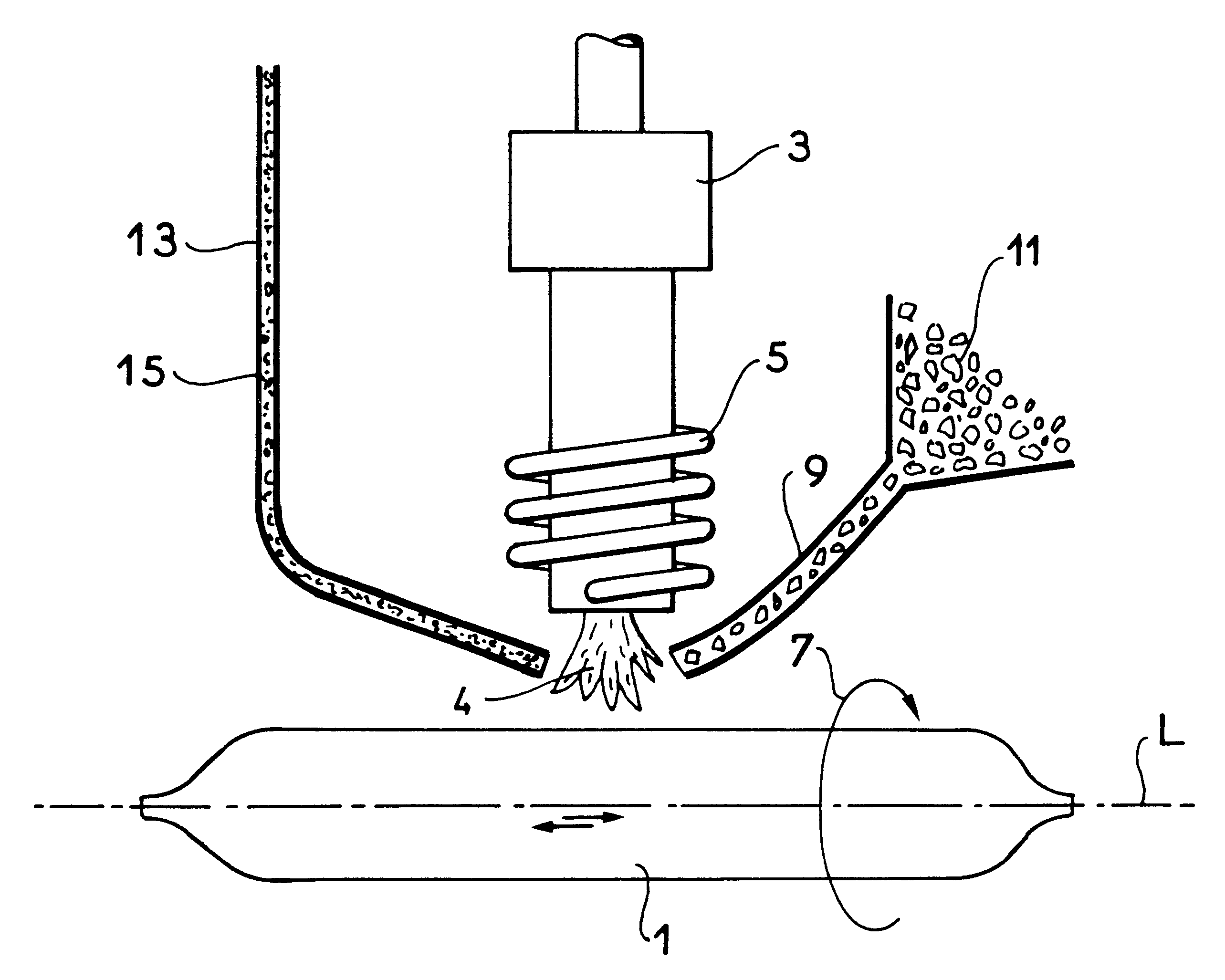

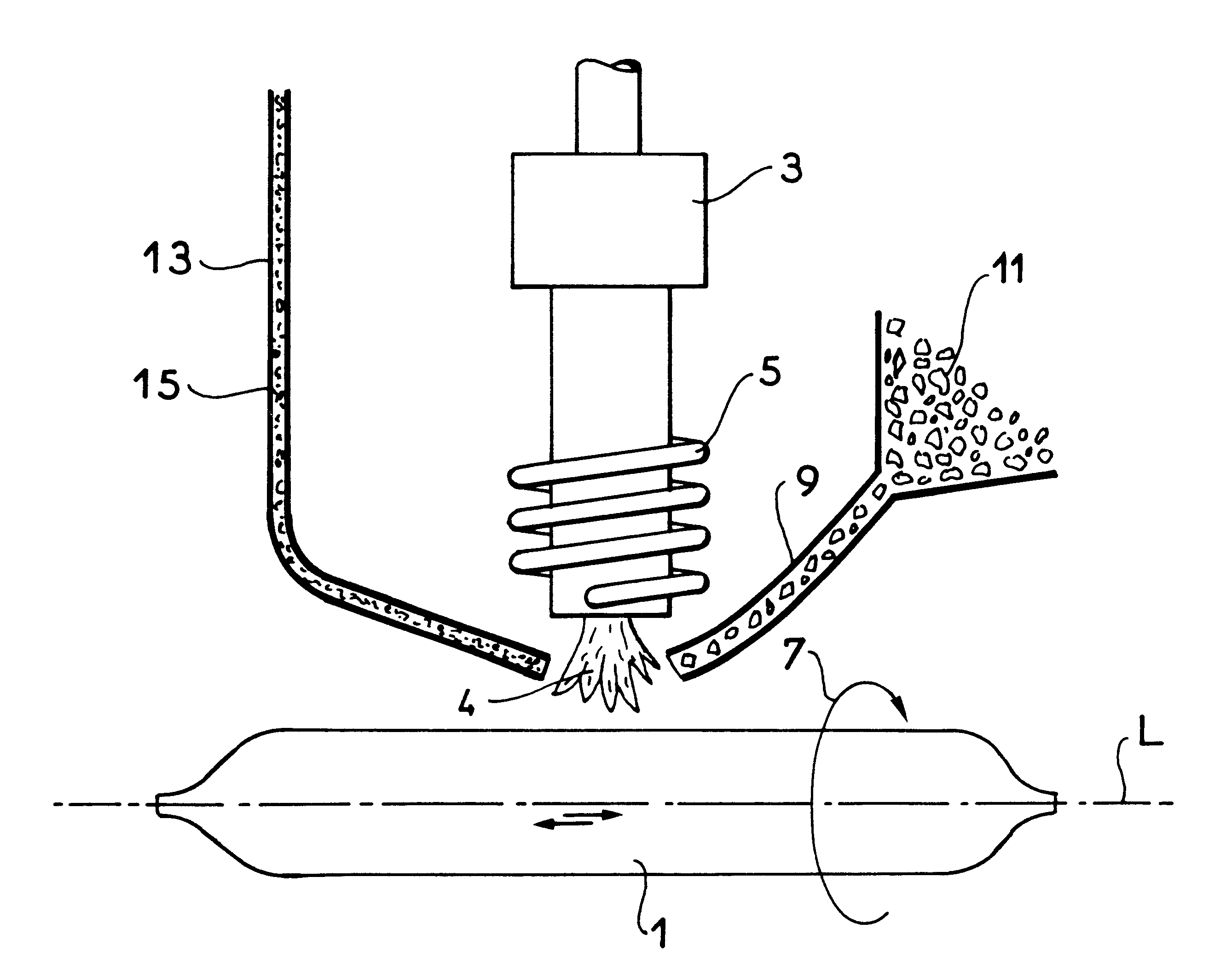

Method of purifying natural or synthetic silica, and application thereof to depositing purified natural or synthetic silica on an optical fiber preform

InactiveUS6477864B2Improve efficiencyIncrease feed rateLiquid surface applicatorsMolten spray coatingSilica particleLithium

Natural or synthetic silica is deposited on a preform set into rotation in front of a plasma torch which moves back and forth substantially parallel to a longitudinal direction of the preform, a first feed duct feeds the plasma with grains of natural or synthetic silica while a second feed duct feeds the plasma with a fluorine or chlorine compound, preferably a fluorine compound, mixed with a carrier gas. Any sodium or lithium contained in the grains of natural or synthetic silica react with the fluorine or chlorine of the fluorine or chlorine compound, thereby making it possible to improve the optical quality of fibers drawn from a preform built up with natural or synthetic silica, and to do so at reduced cost.

Owner:ALCATEL LUCENT SAS

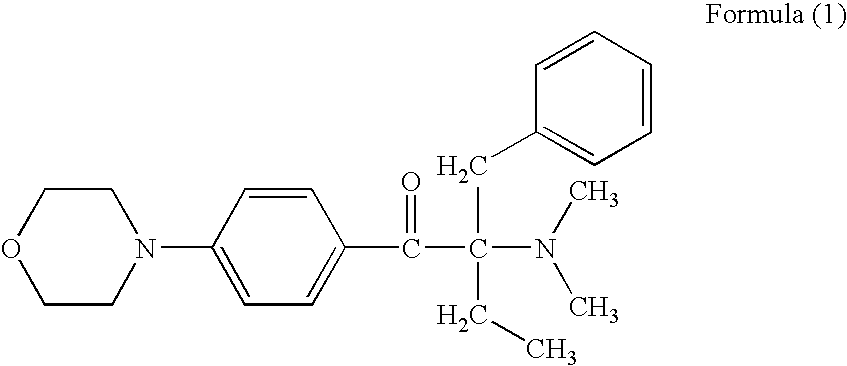

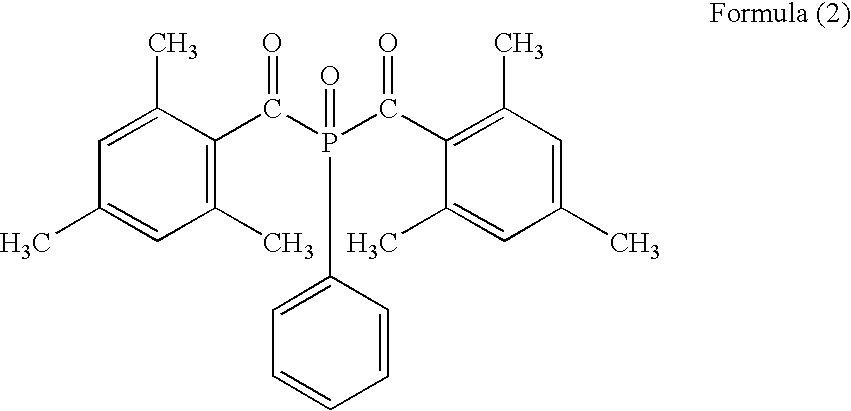

UV-curable pressure-sensitive adhesive composition and its pressure-sensitive adhesive sheet

InactiveUS6841587B2Promote reaction efficiencySufficient curing performanceNon-macromolecular adhesive additivesFilm/foil adhesivesProduction rateUV curing

Provided are a UV-curable pressure-sensitive adhesive composition comprising a photoinitiator which has a molar absorptivity at 365 nm of at least 1,000 mol−1·cm−1 and the maximum absorption wavelength of at least 420 nm on a long wavelength side; and an adhesive sheet having a layer of the composition disposed over a photo-transmitting base film. The pressure-sensitive adhesive sheet according to the invention can be cured even by exposure to ultraviolet rays at a low intensity or for short time so that it can contribute to energy saving and productivity improvement as a sheet for processing, fixation or surface protection of a semiconductor wafer.

Owner:NITTO DENKO CORP

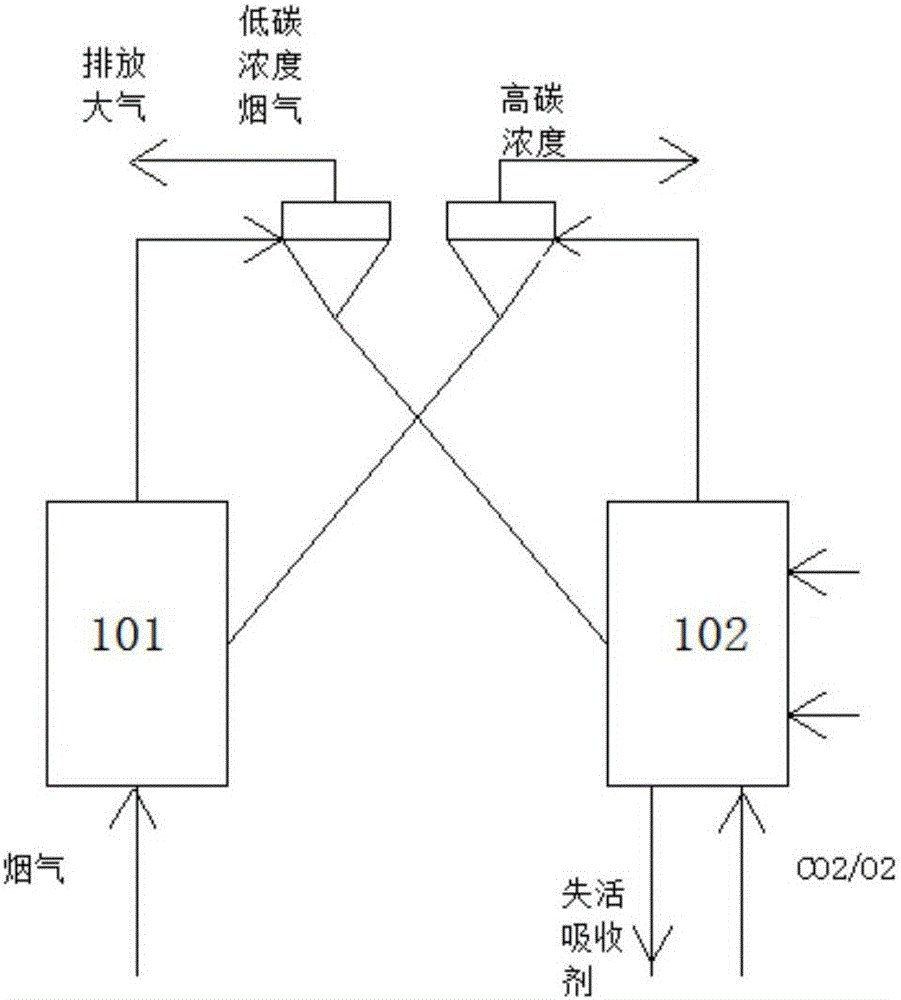

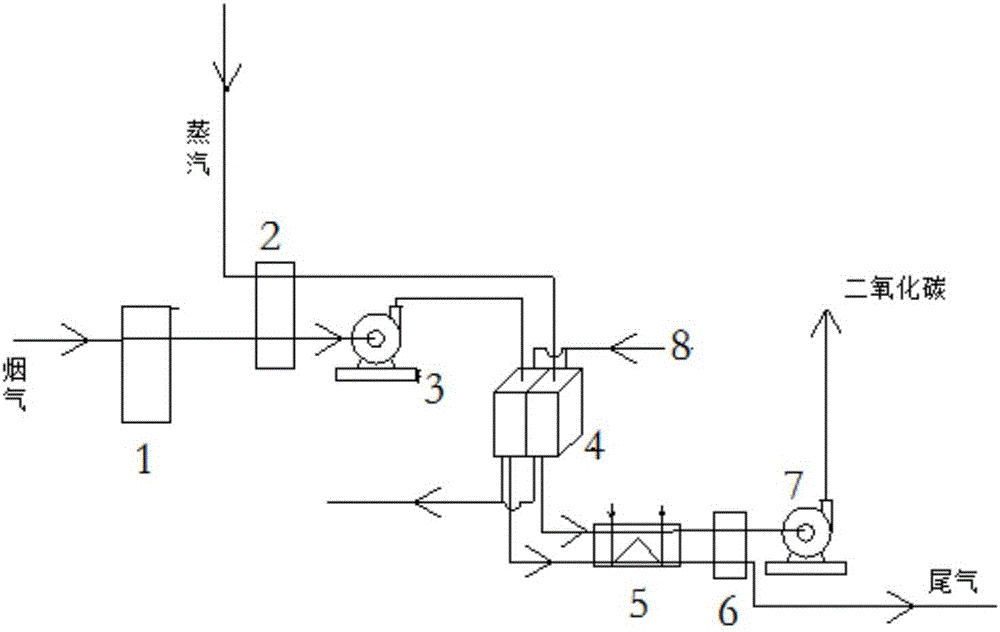

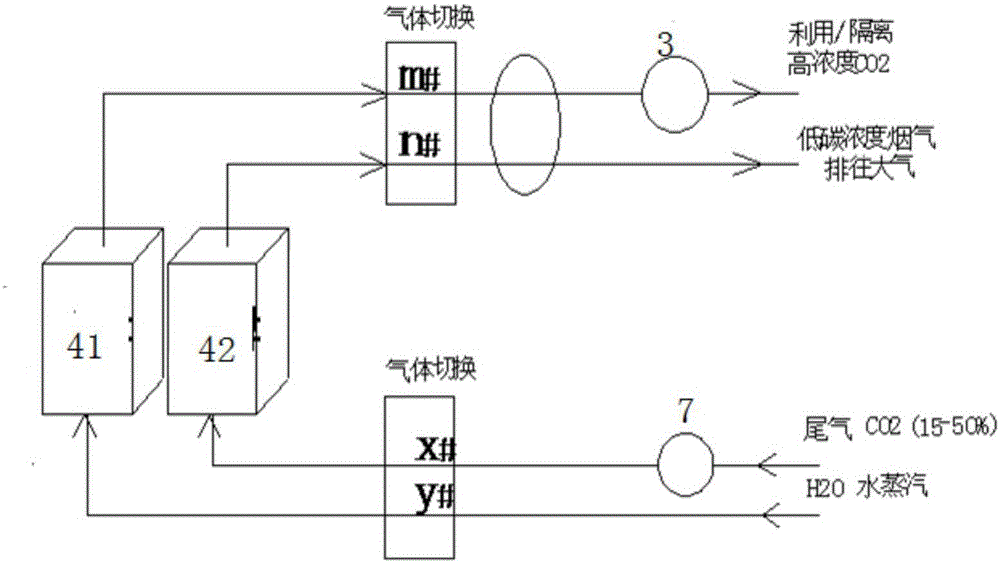

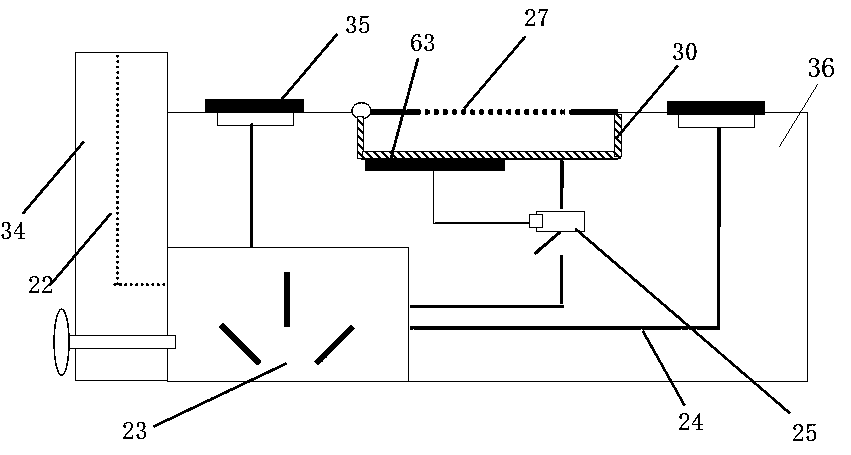

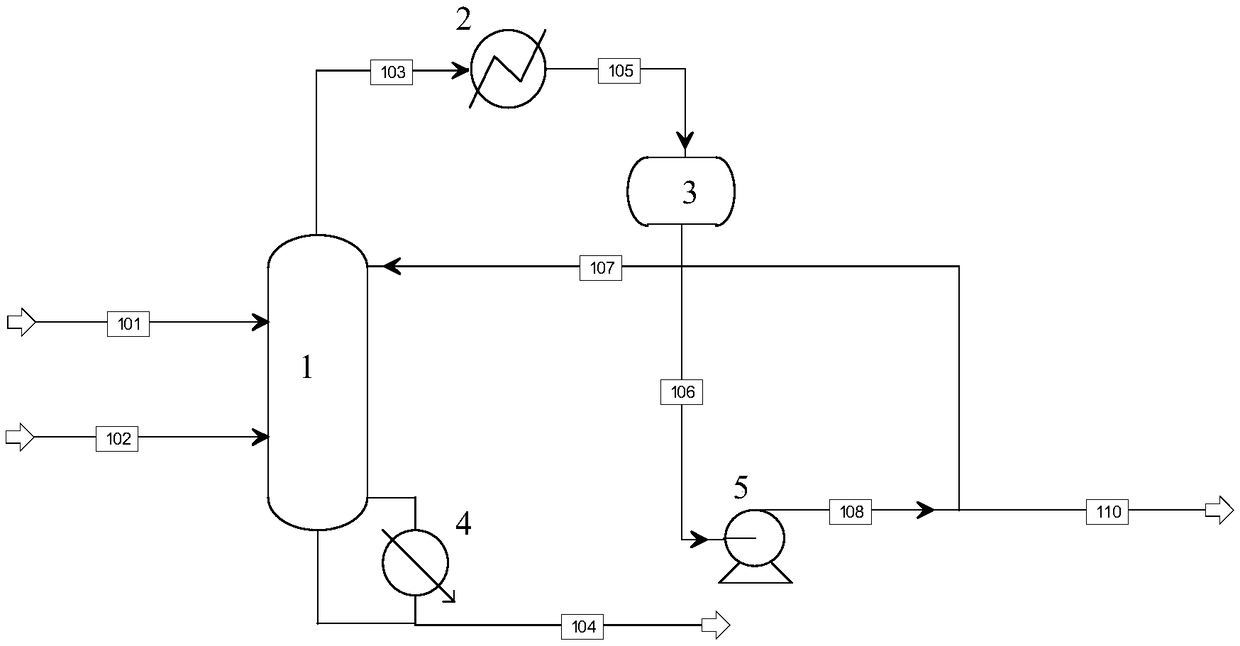

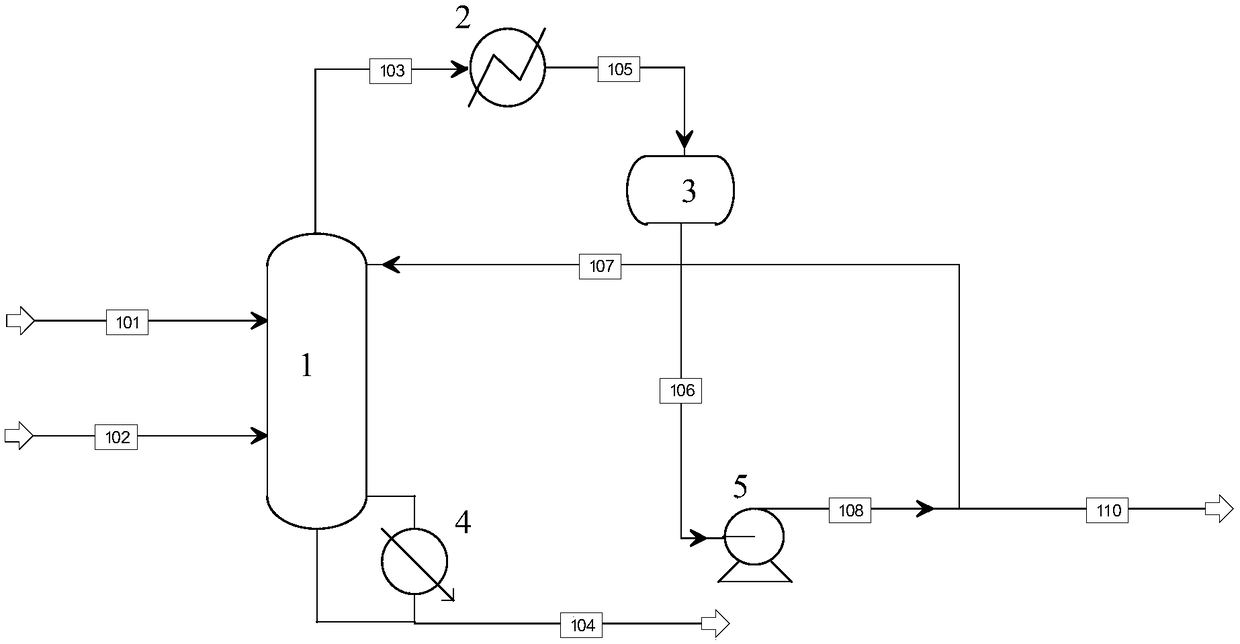

Continuous circulation carbon dioxide capture system on basis of in-situ adsorption/desorption modes

ActiveCN105727729AExtend your lifeEliminate wear and tearGas treatmentDispersed particle separationWater vaporDesorption

The invention belongs to the field of equipment related to carbon capture technologies, and discloses a continuous circulation carbon dioxide capture system on the basis of in-situ adsorption / desorption modes.The continuous circulation carbon dioxide capture system comprises a flue gas purification module, a pressurization module, an isothermal circulation carbon capture reactor group, a gas outlet condensation device, a negative-pressure module and the like which are sequentially connected with one another.The designed isothermal circulation carbon capture reactor group comprises a carbonization reactor and a regeneration reactor which cling to each other to transfer heat, and functions of the carbonization reactor and the regeneration reactor can be switched over after reaction is carried out for a certain time; the carbonization reactor is provided with the pressurization module, the regeneration reactor (42) is provided with the negative-pressure module, and an appropriate quantity of water vapor can be continuously supplied for the regeneration reactor (42).The continuous circulation carbon dioxide capture system has the advantages that the integral reaction efficiency can be obviously improved as compared with existing continuous carbon capture modes, abrasion of solid adsorbent particles due to collision can be eliminated, temperature difference between adsorption and desorption can be reduced to a great extent, the continuous circulation carbon dioxide capture system is economical and environmentally friendly, and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

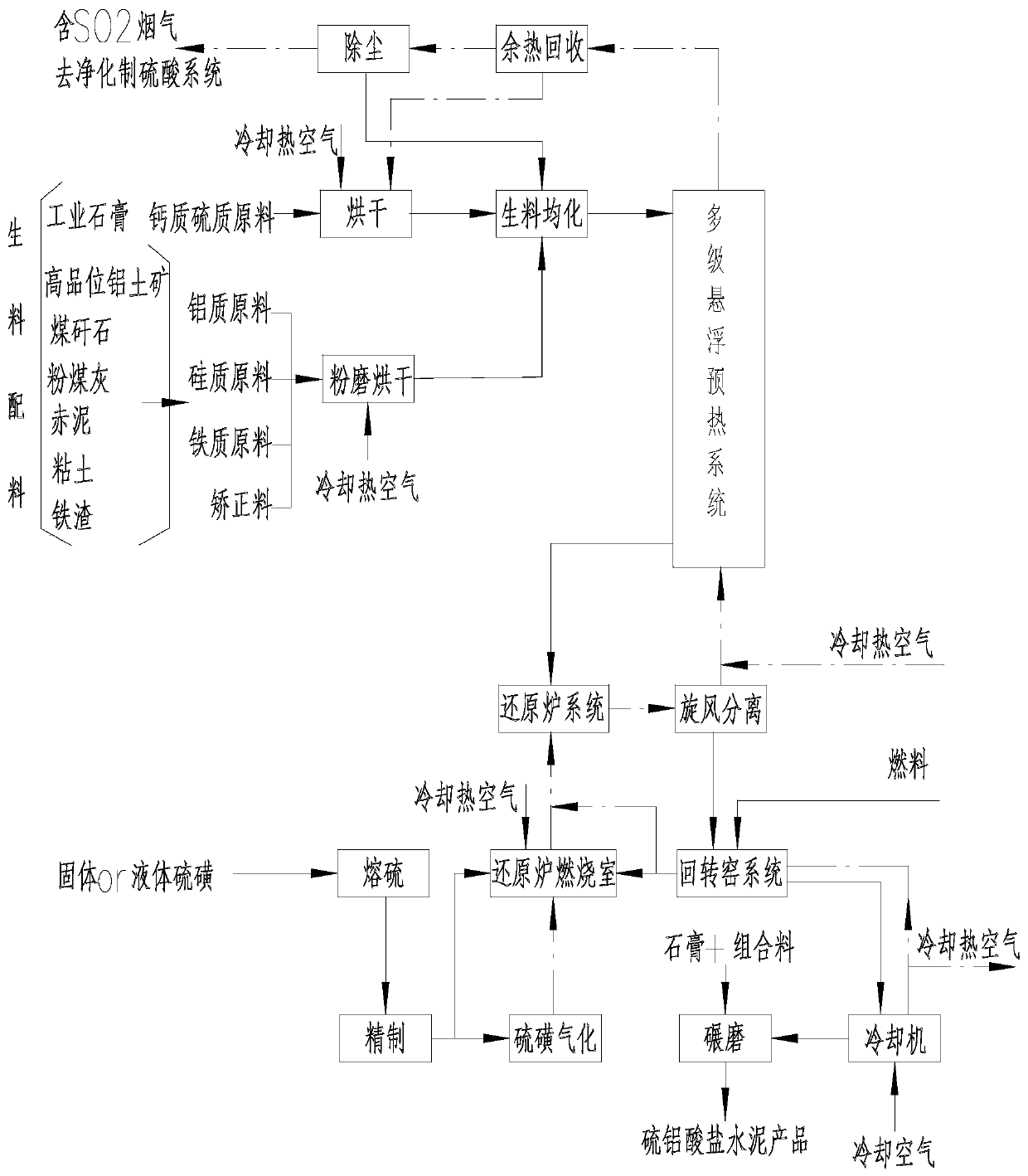

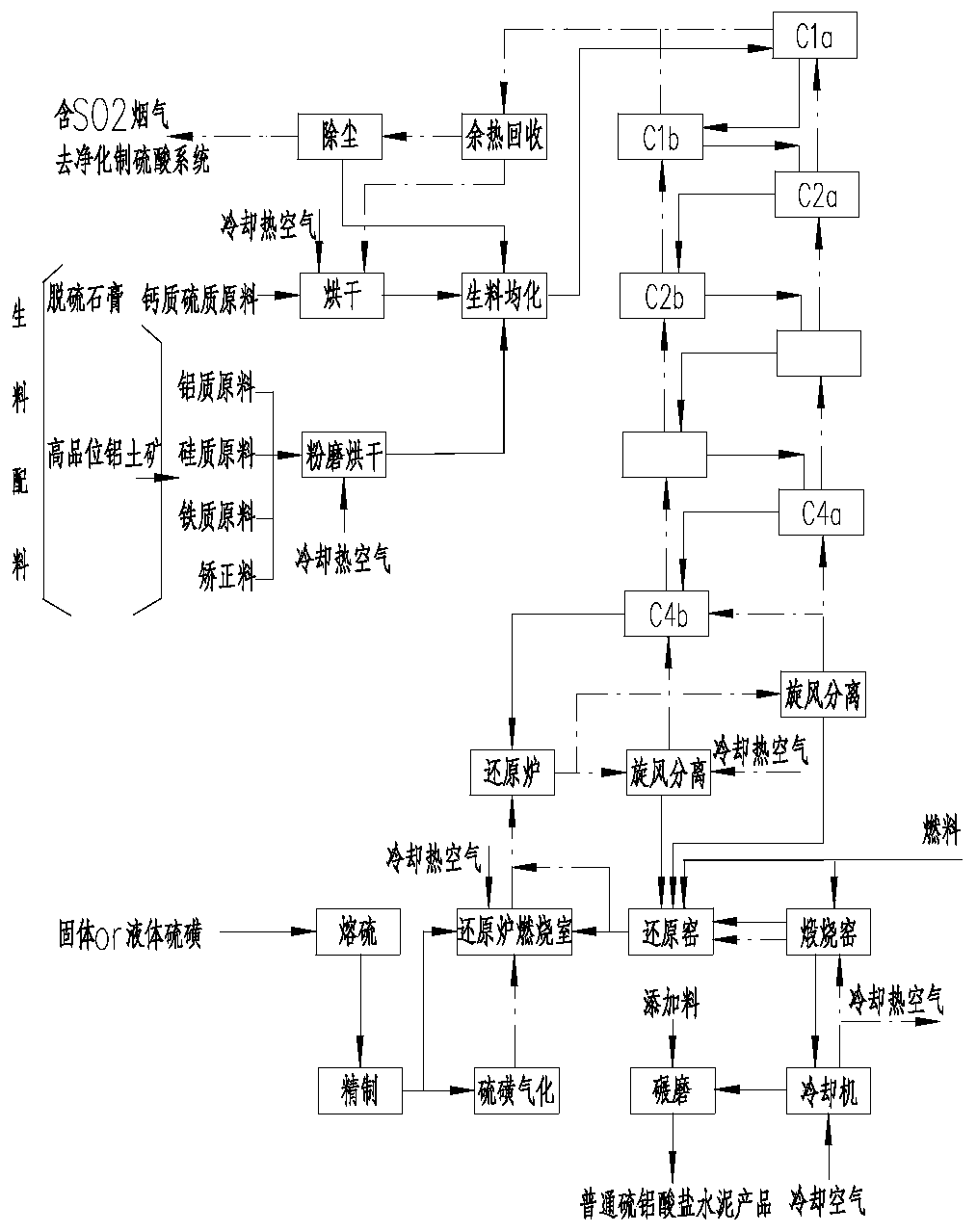

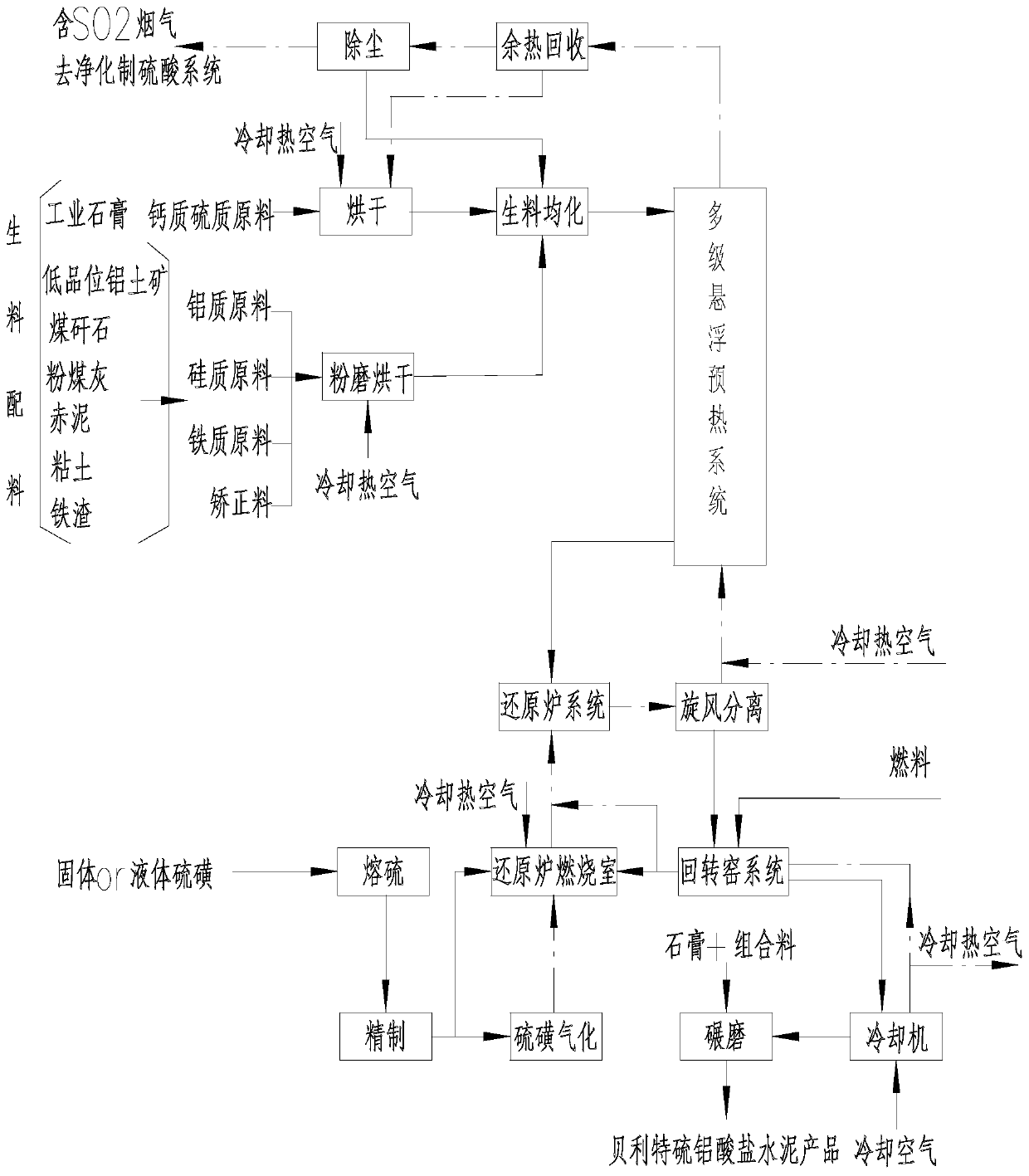

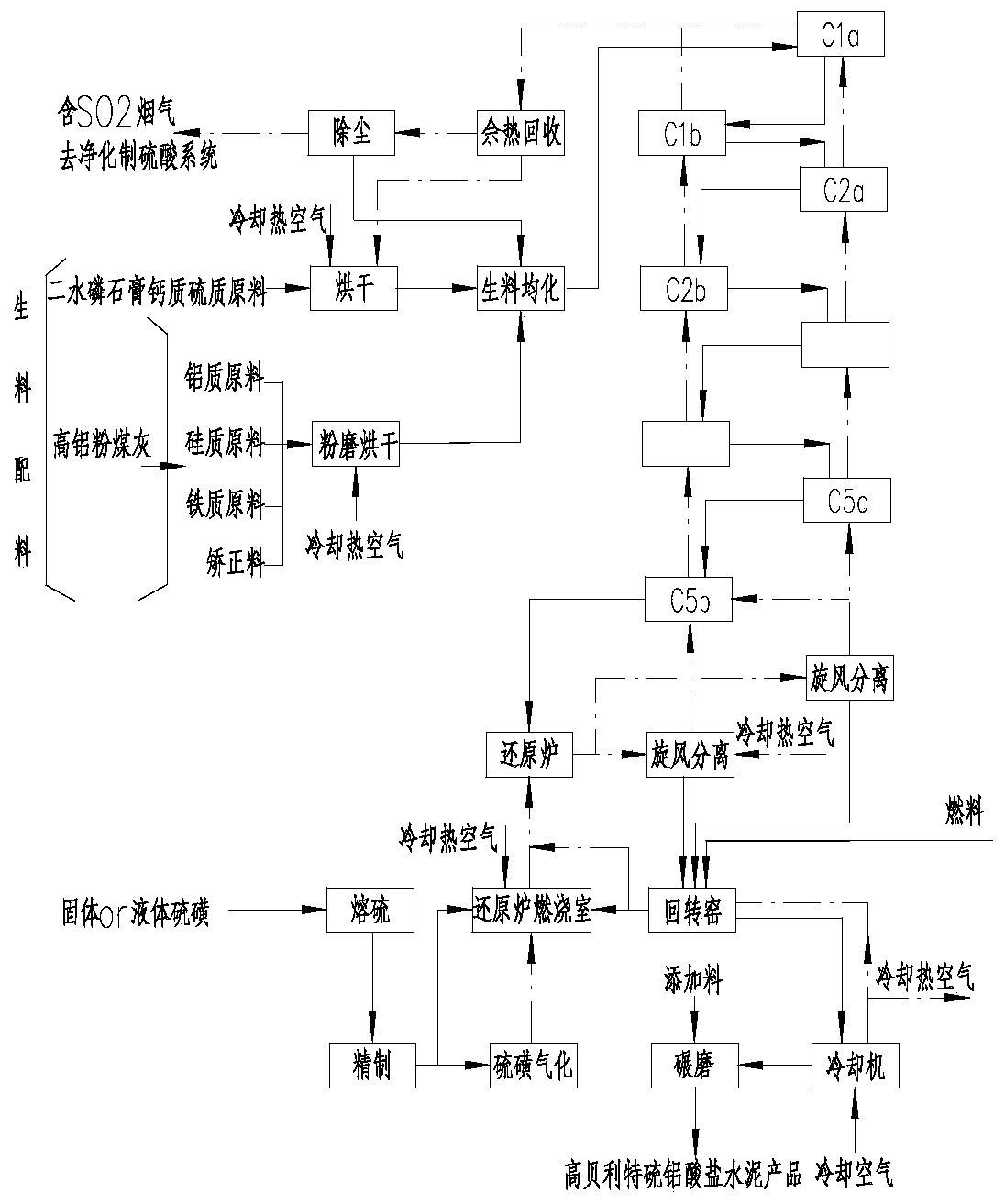

Method for preparing sulphoaluminate cement and coproducing sulfuric acid by reducing gypsum with sulfur gas

ActiveCN111559879AImprove decomposition rateFast and efficient decomposition reactionSulfur compoundsEnergy inputGypsumAluminate

The invention relates to a method for preparing sulphoaluminate cement and coproducing sulfuric acid by reducing gypsum with sulfur gas. The method comprises the following steps: A, preparing gaseoussulfur; B, burdening: preparing dehydrated gypsum, bauxite, a siliceous correction material and an iron correction material into a raw material with uniform components; C, preheating and pre-reducing:preheating the raw material, feeding the preheated raw material into a reduction furnace, performing reduction reaction on the preheated raw material and the gaseous sulfur, performing gas-solid separation, feeding flue gas into a multistage suspension preheating system, and feeding the pre-reduced raw material into a rotary kiln; D, carrying out deep reduction and clinker sintering: performing adeep reduction reaction on the reduced raw material in the rotary kiln, and then performing high-temperature sintering to form sulphoaluminate cement clinker; and E, cooling the clinker, recycling heat, purifying to prepare sulfuric acid, adding gypsum and a combined material into the cement clinker, and processing to obtain sulphoaluminate cement products with different performance requirements.Compared with the prior art, the method has the following advantages: a large amount of industrial waste residues such as industrial gypsum can be consumed, limestone and natural gypsum resources canbe saved, and meanwhile, high-quality sulphoaluminate cement and industrial sulfuric acid products can be obtained.

Owner:上海三夫工程技术有限公司 +1

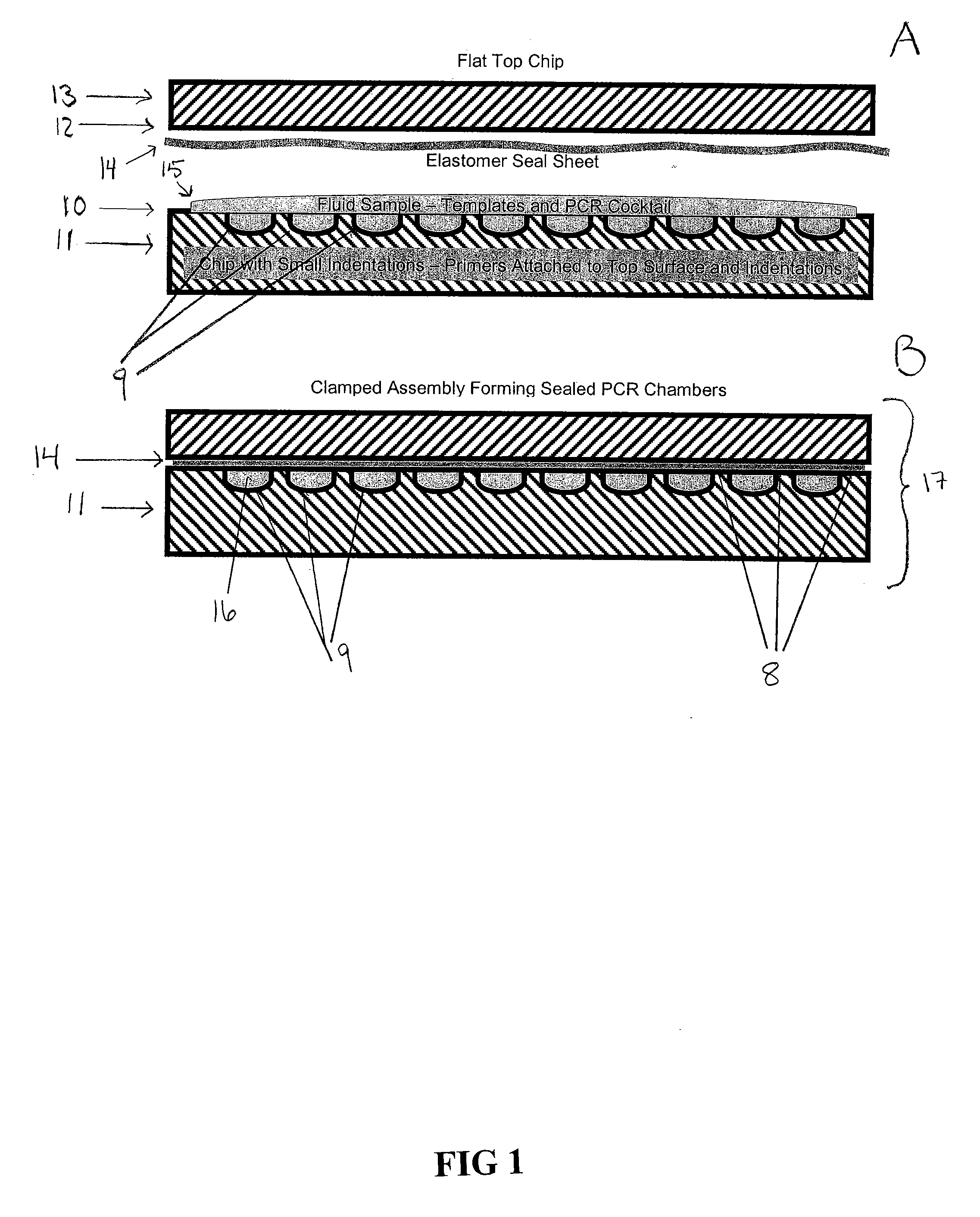

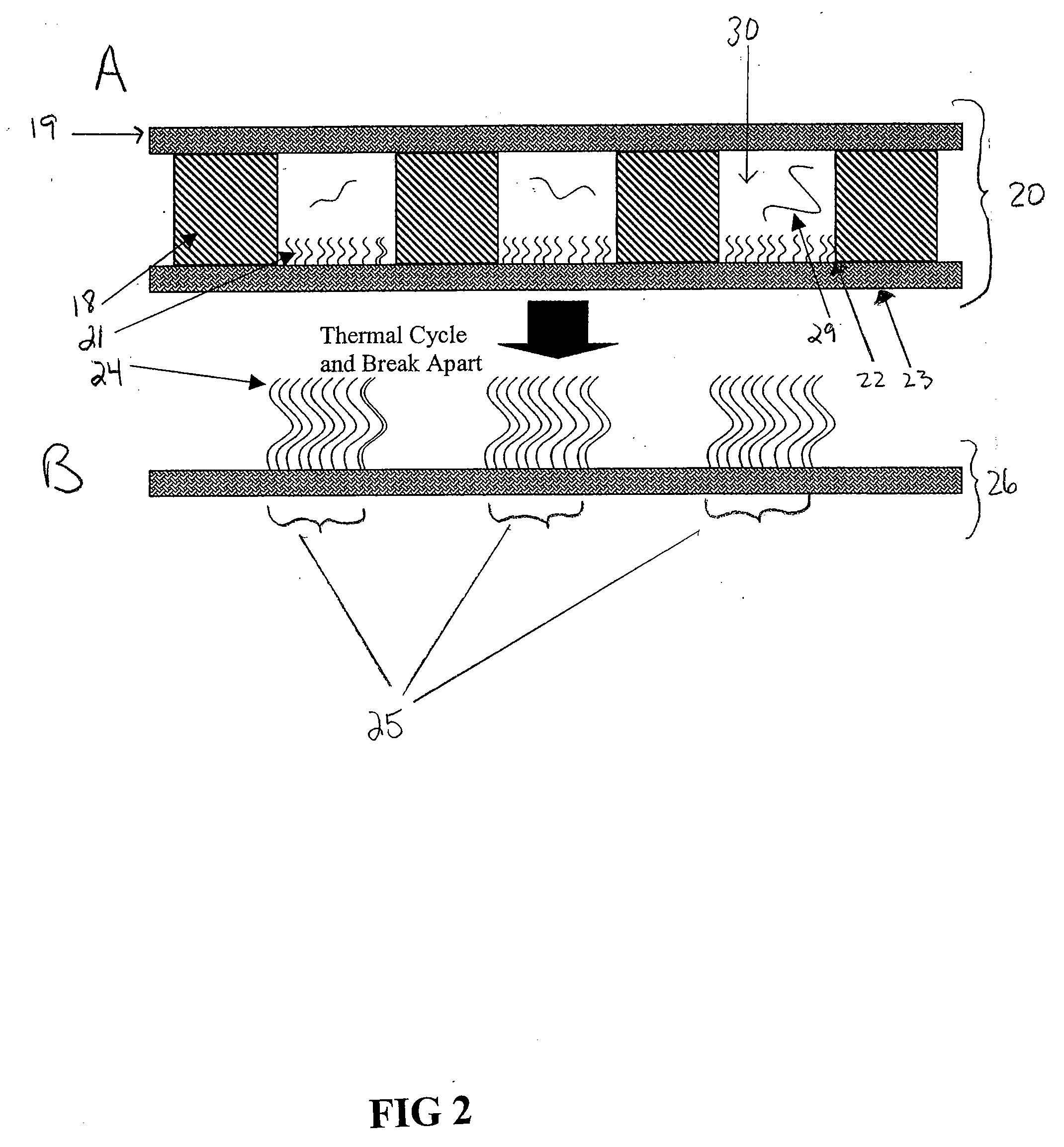

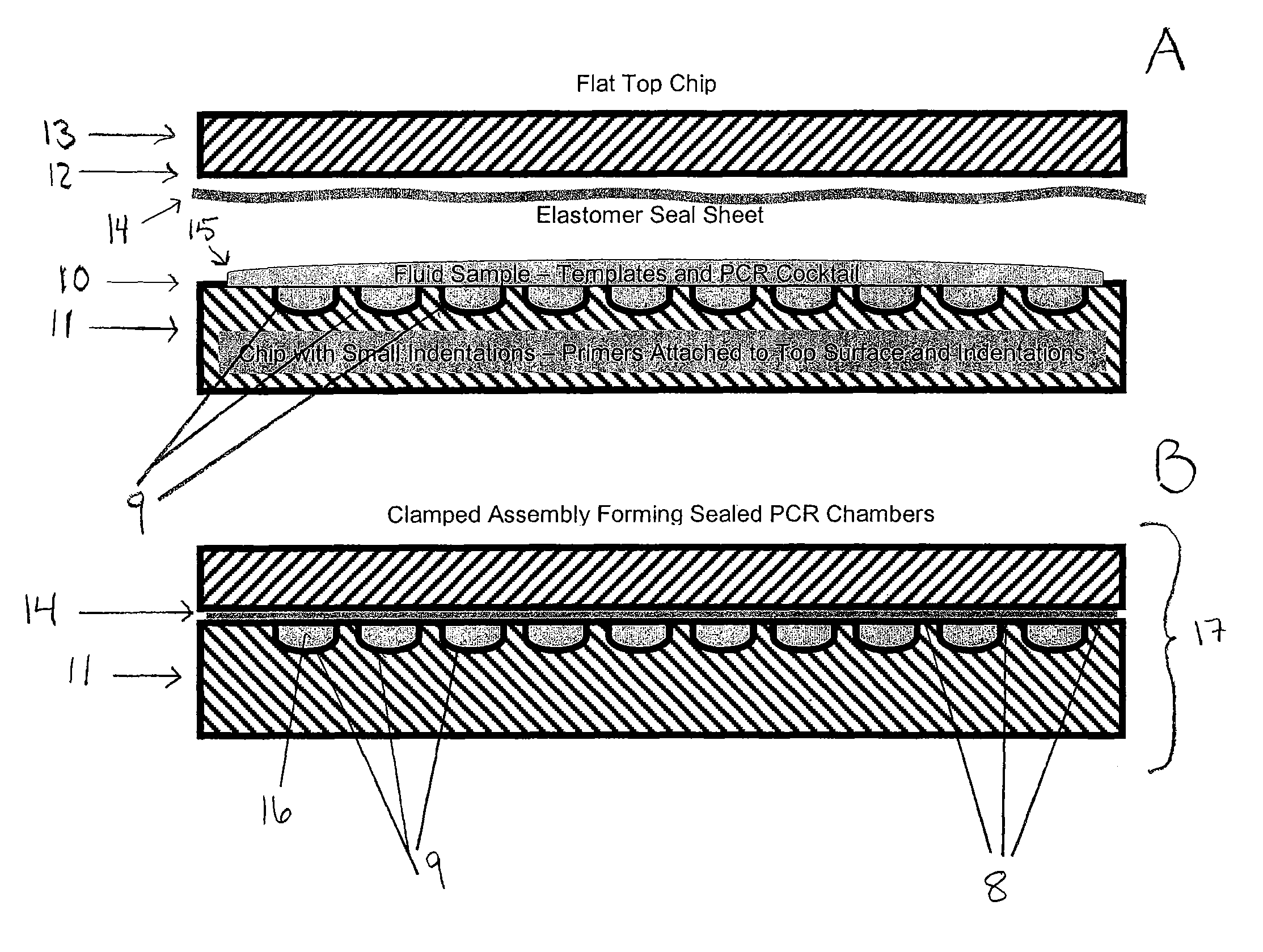

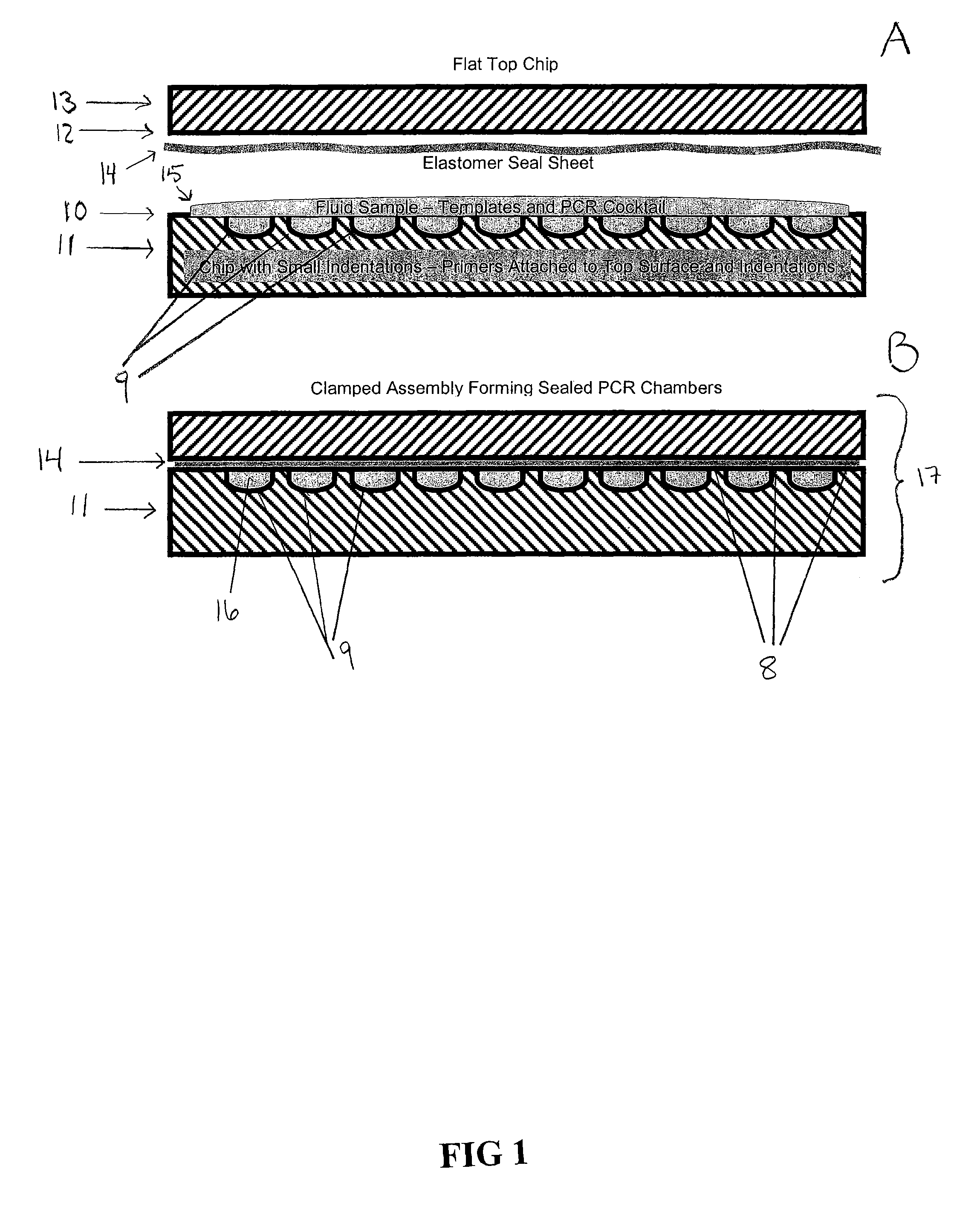

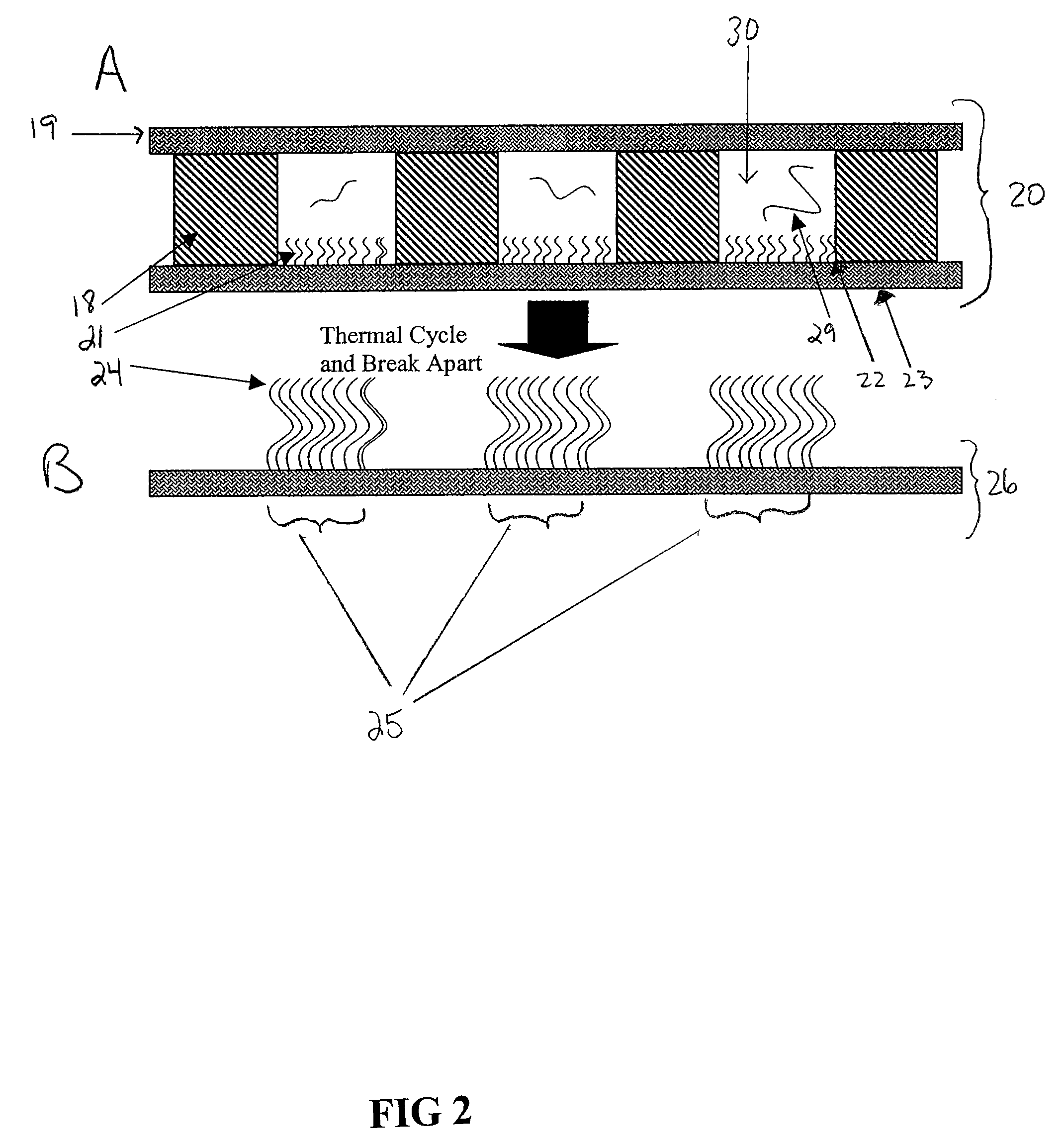

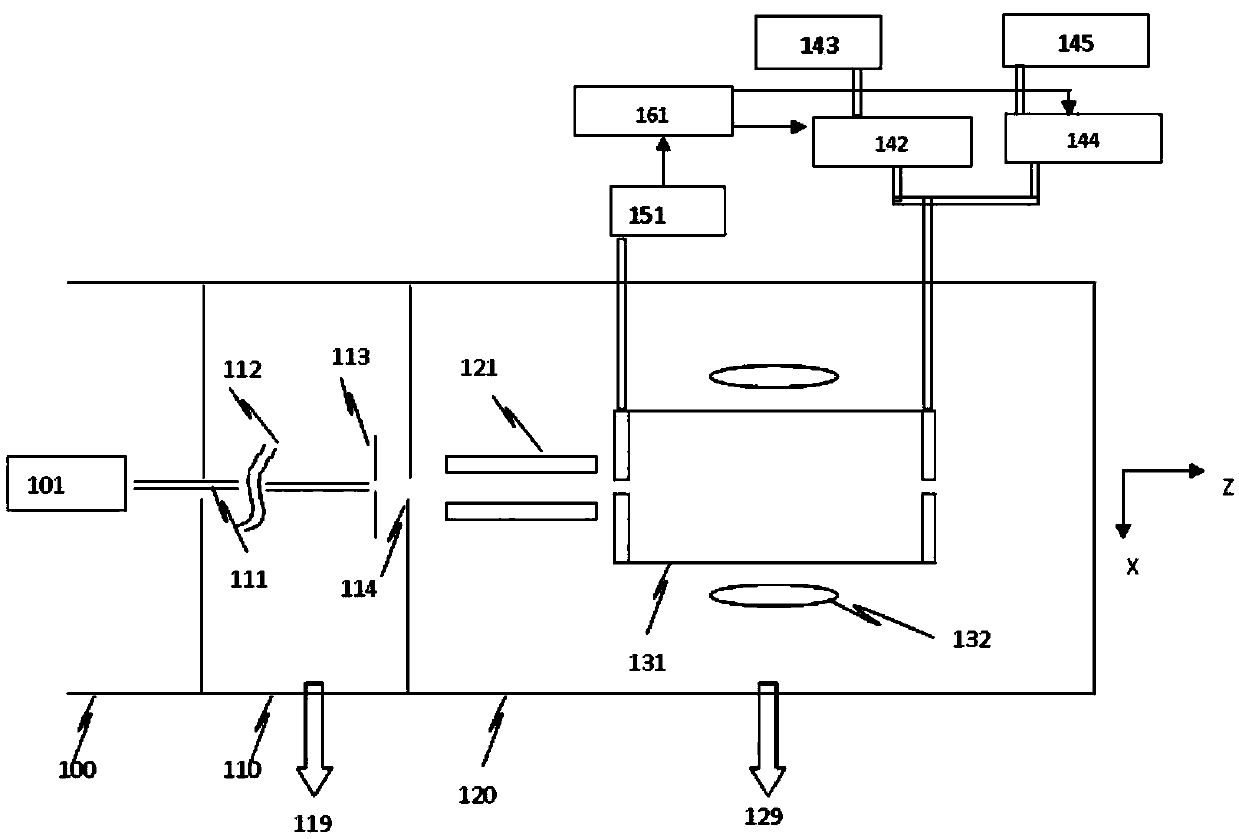

Methods And Devices For Amplification Of Nucleic Acid

ActiveUS20090227474A1Maximize efficiencyImprove efficiencyHeating or cooling apparatusMicrobiological testing/measurementEmulsionNucleic acid

The present invention relates to methods and devices for amplifying nucleic acid, and, in particular, amplifying so as to generate products on a surface without the use of emulsions. In a preferred embodiment, a plurality of groups of amplified product are generated on the surface, each group positioned in different (typically predetermined) locations on said surface so as to create an array.

Owner:ISOPLEXIS

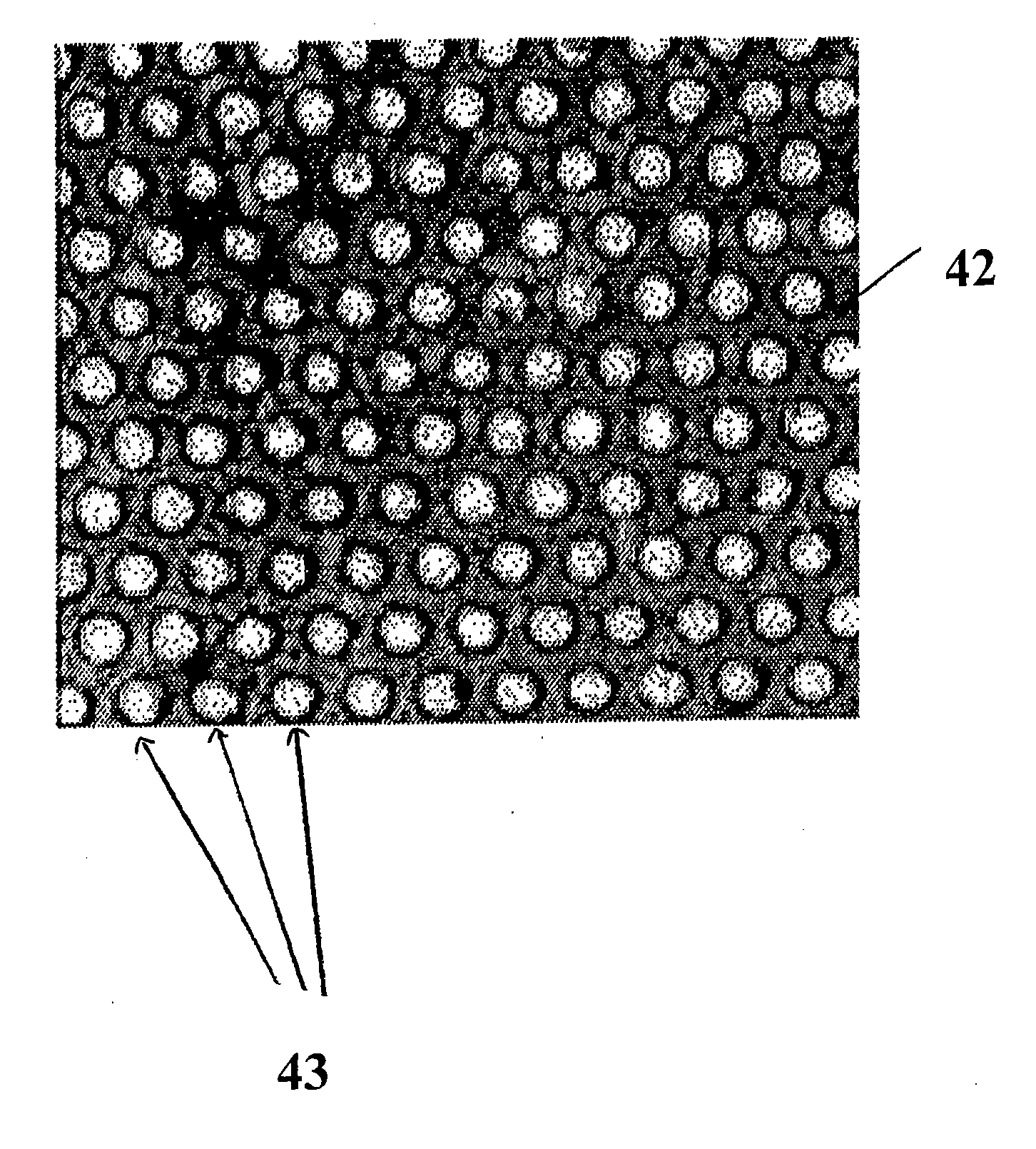

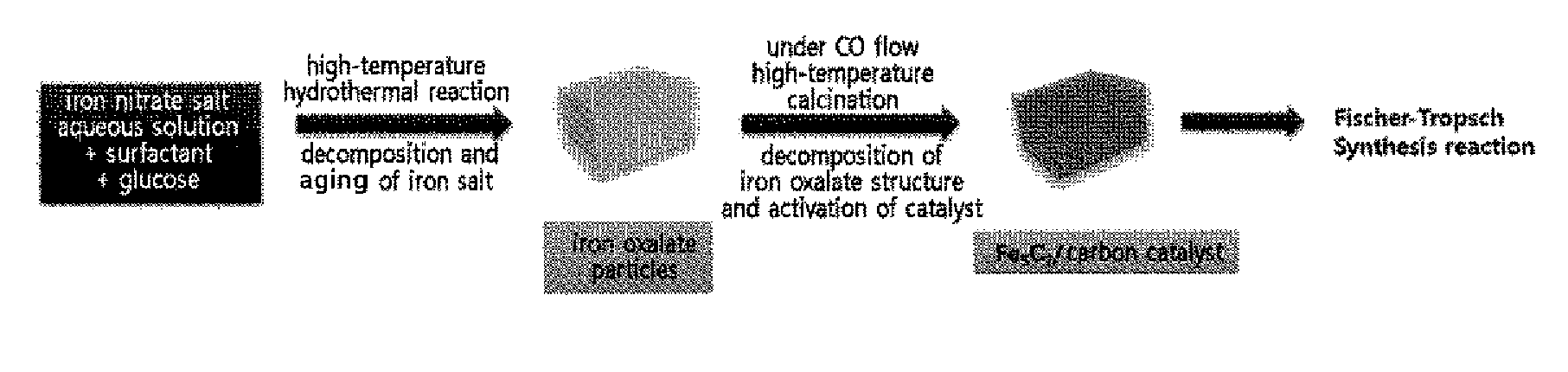

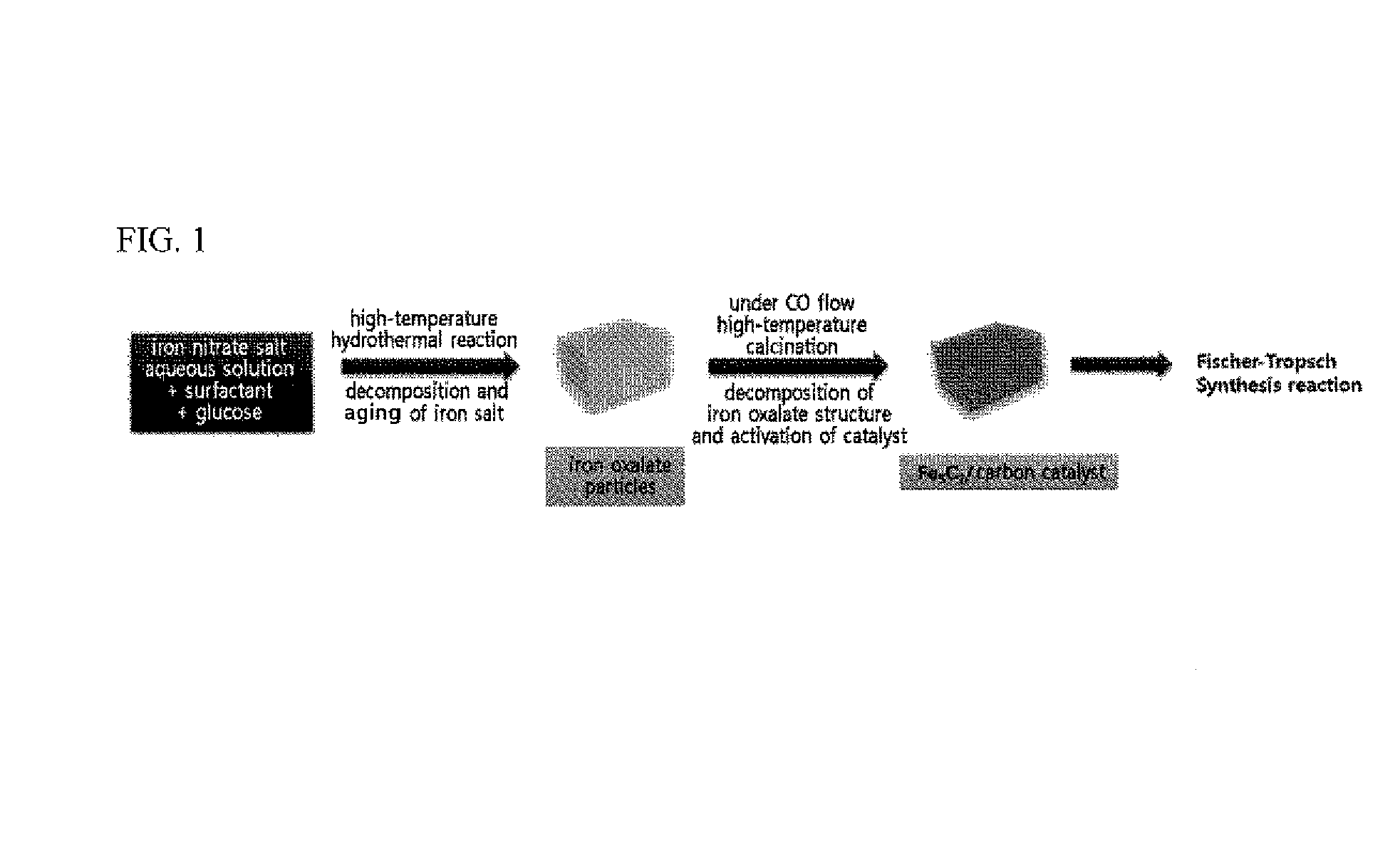

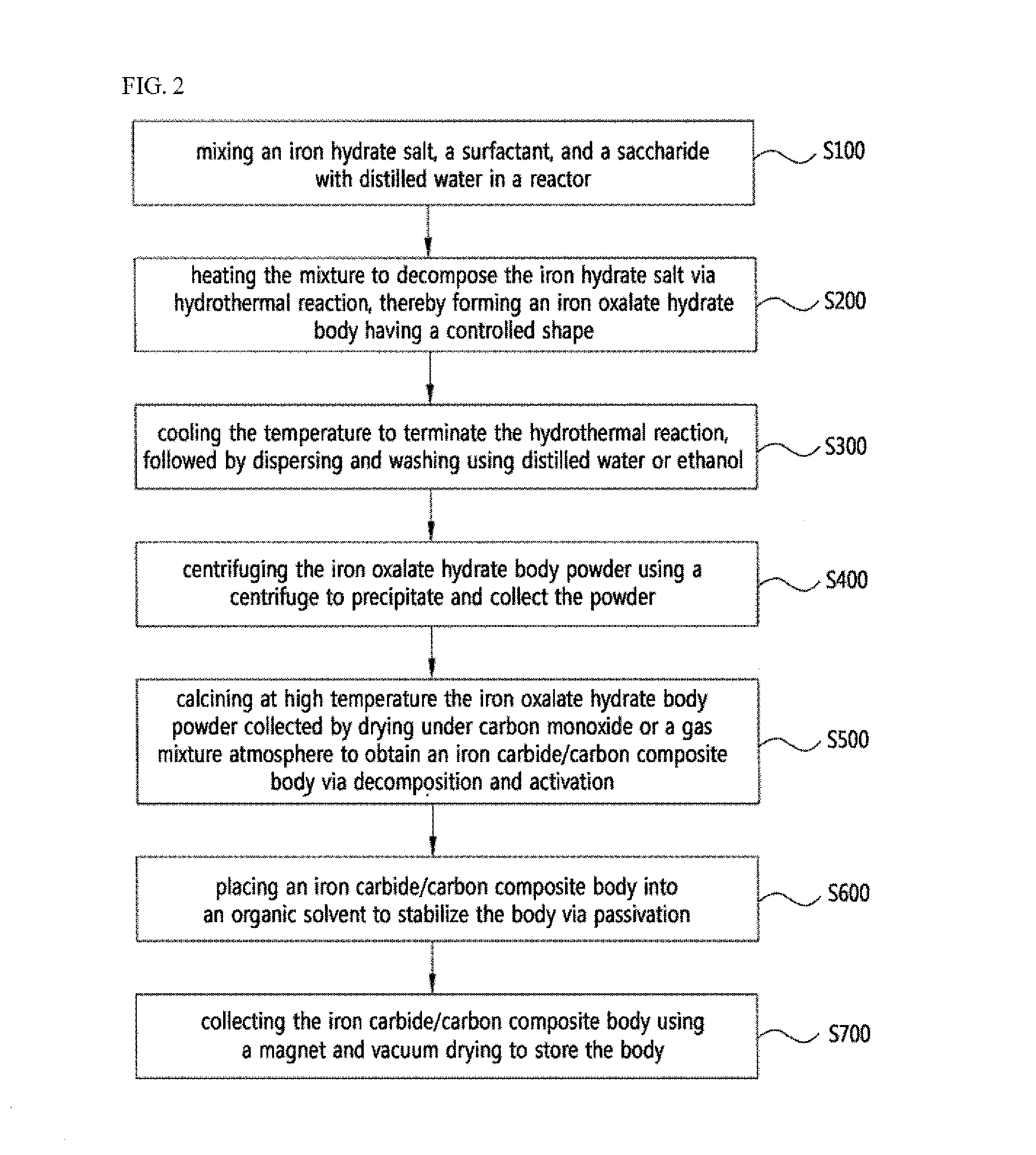

Metal carbide/carbon composite body having porous structure by three-dimensional connection of core-shell unit particles, preparation method thereof, and use of the composite body

ActiveUS20160096167A1Promote reaction efficiencyDiffusion fastOrganic compound preparationOxygen compounds preparation by reductionCarbon compositesCarbide

The present invention relates to a metal carbide / carbon composite body having a porous structure, in which core-shell unit particles are three-dimensionally connected, a preparation method thereof, and the use of the composite body. More specifically, the present invention provides a metal carbide / carbon composite body, a preparation method thereof, and the use of the composite body, wherein the composite body is formed by high-temperature calcination of a metal oxalate hydrate body under a carbon monoxide-containing gas atmosphere, wherein the metal carbide / carbon composite body has a porous structure in which core-shell unit particles are three-dimensionally connected, wherein the core-shell unit particles comprise a metal carbide core formed by thermal decomposition of a metal oxalate hydrate; and a graphitic carbon shell, the product resulting from Boudouard reaction of carbon monoxide, formed on the metal carbide core.

Owner:KOREA INST OF ENERGY RES

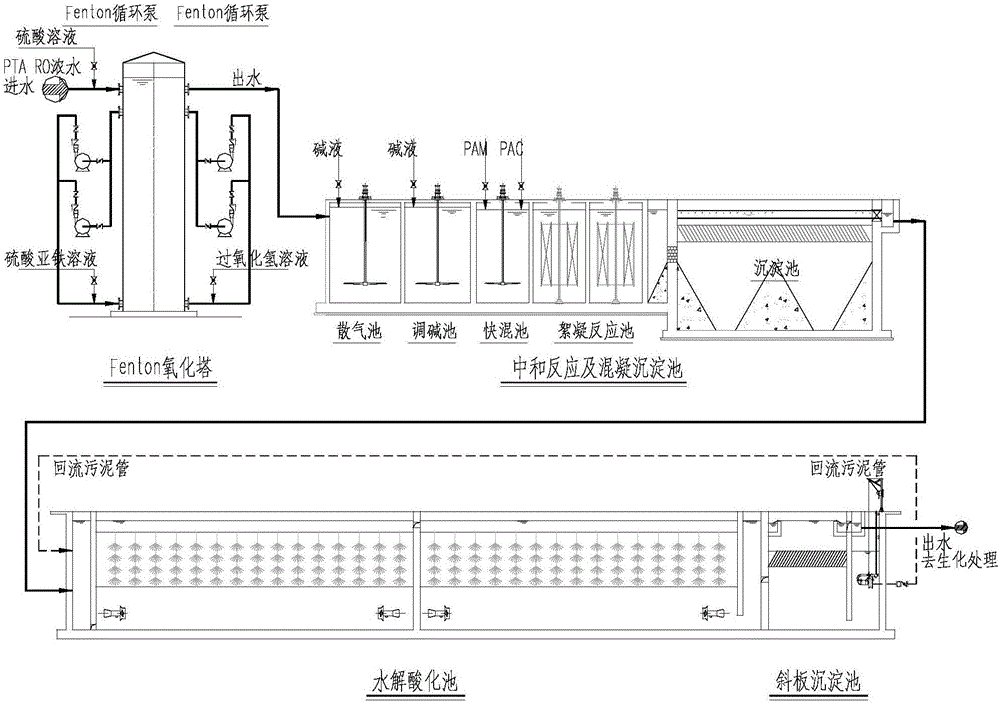

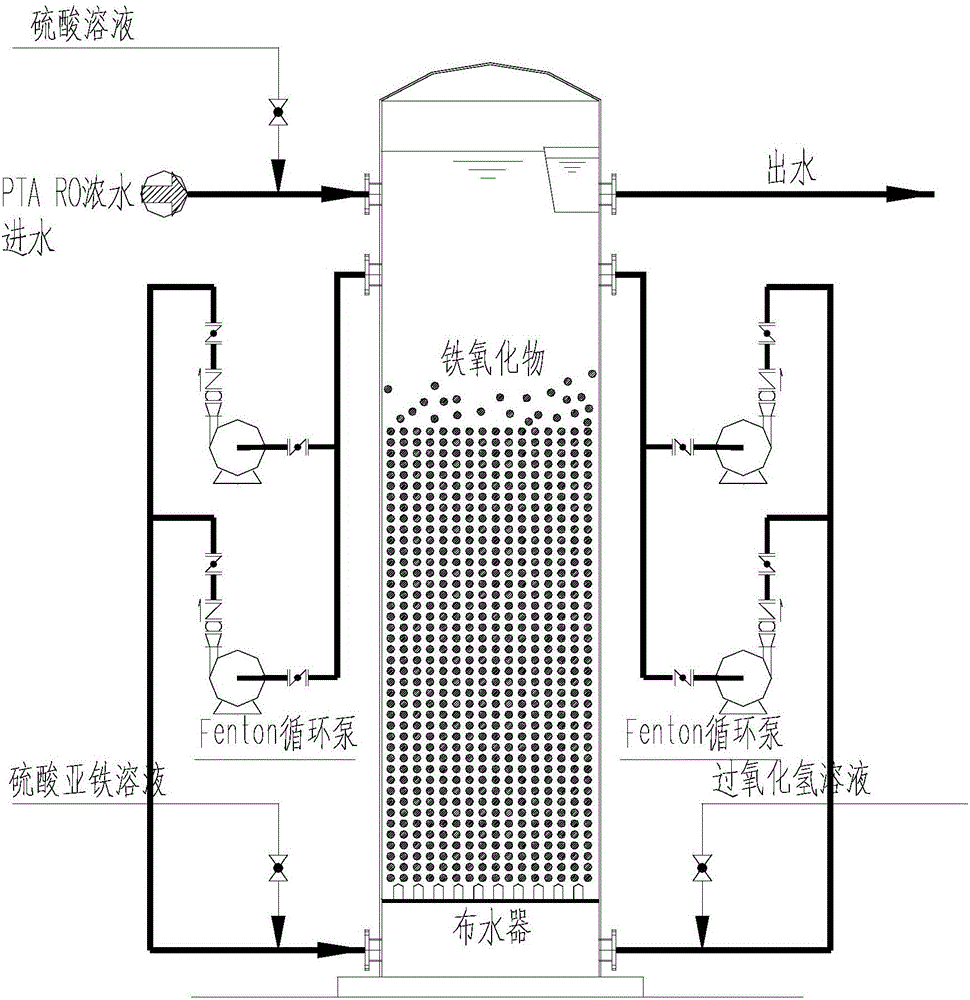

Pretreatment method for remaining RO concentrated water obtained after double-membrane desalination recycling of PTA sewage

InactiveCN106186554AEfficient preprocessingImprove biodegradabilityWater treatment compoundsMultistage water/sewage treatmentPretreatment methodDesalination

The invention discloses a pretreatment method for remaining RO concentrated water obtained after double-membrane desalination recycling of PTA sewage. The method is used for solving the problem that downstream garden type terminal sewage plant standard treatment cannot reach the standard for discharge due to the fact that remaining RO concentrated water obtained after existing PTA sewage recycling is difficultly subjected to direct biochemical and deep treatment. The method is technically characterized in that two pretreatment technologies of Fenton oxidation and hydrolysis acidification are organically combined, optimal design is performed through two technological types, the operation cost of Fenton oxidation is lowered, and the hydrolytic acidification treatment efficiency is also improved. Advanced oxidation and biological pretreatment are organically combined better. The technology is mainly applied to the field of petrifaction and similar industrial wastewater treatment.

Owner:EAST CHINA ENG SCI & TECH +1

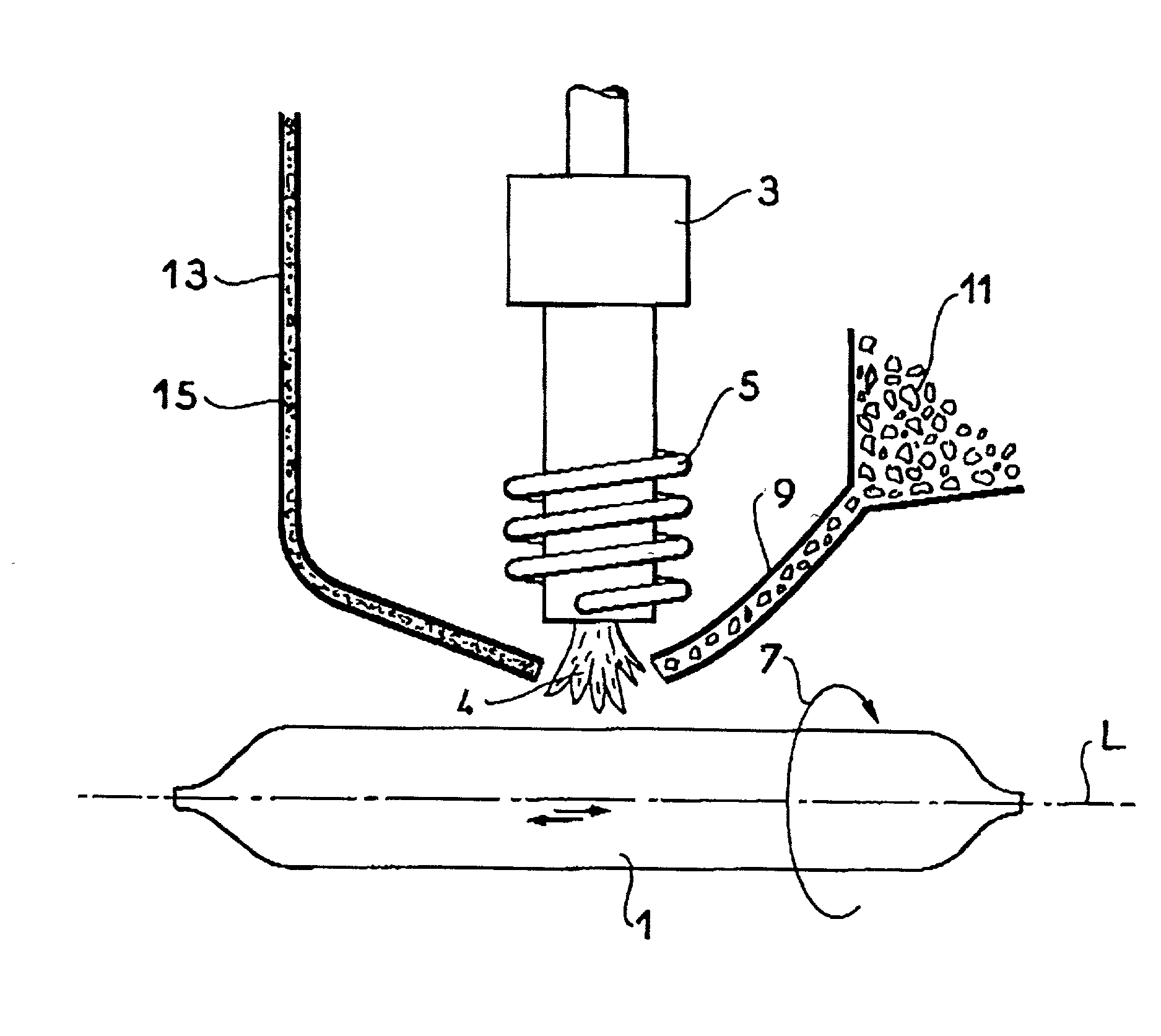

Method of purifying natural or synthetic silica, and application thereof to depositing purified natural or synthetic silica on an optical fiber preform

InactiveUS20010001366A1Improve efficiencyPromote reaction efficiencyLiquid surface applicatorsMolten spray coatingSilica particleLithium

Natural or synthetic silica is deposited on a preform set into rotation in front of a plasma torch which moves back and forth substantially parallel to a longitudinal direction of the preform, a first feed duct feeds the plasma with grains of natural or synthetic silica while a second feed duct feeds the plasma with a fluorine or chlorine compound, preferably a fluorine compound, mixed with a carrier gas Any sodium or lithium contained in the grains of natural or synthetic silica react with the fluorine or chlorine of the fluorine or chlorine compound, thereby making it possible to improve the optical quality of fibers drawn from a preform built up with natural or synthetic silica, and to do so at reduced cost.

Owner:ALCATEL LUCENT SAS

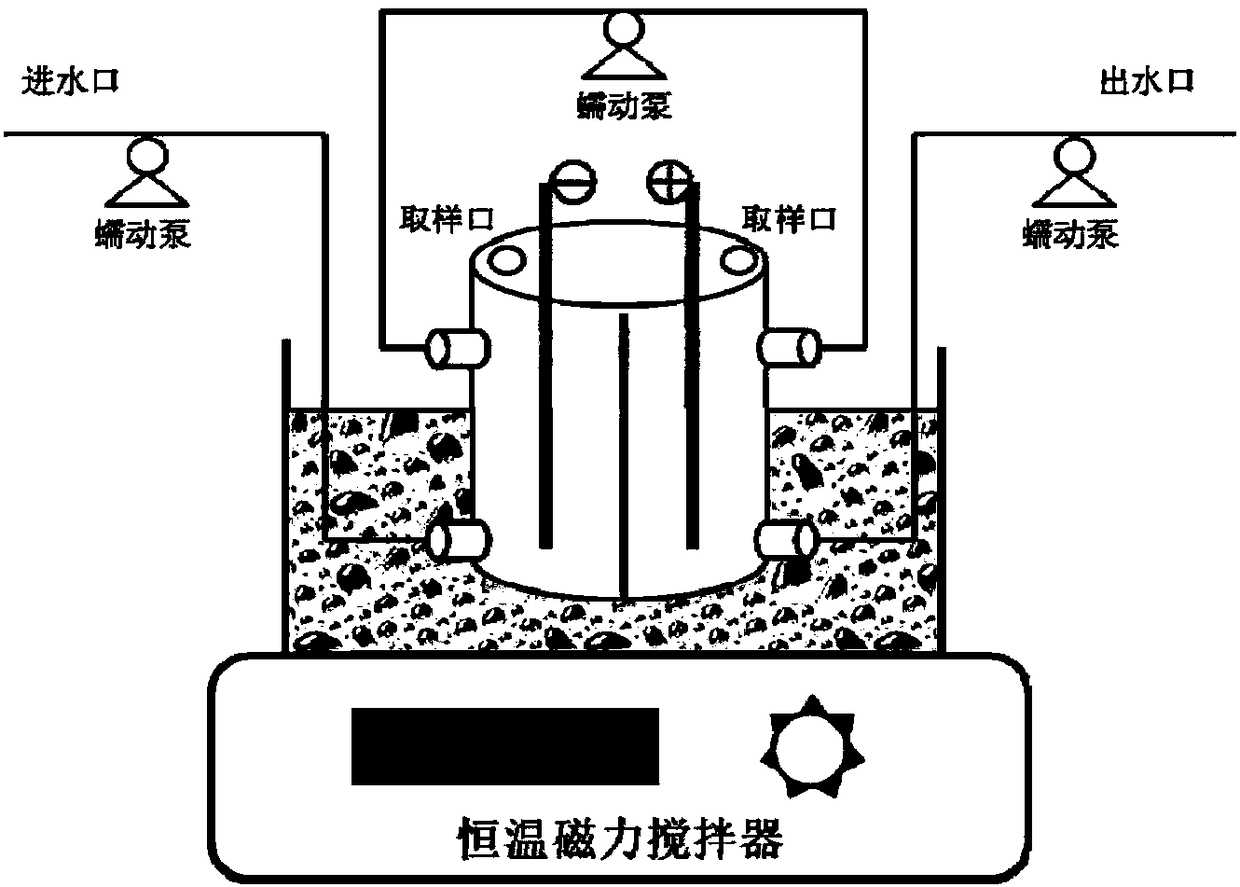

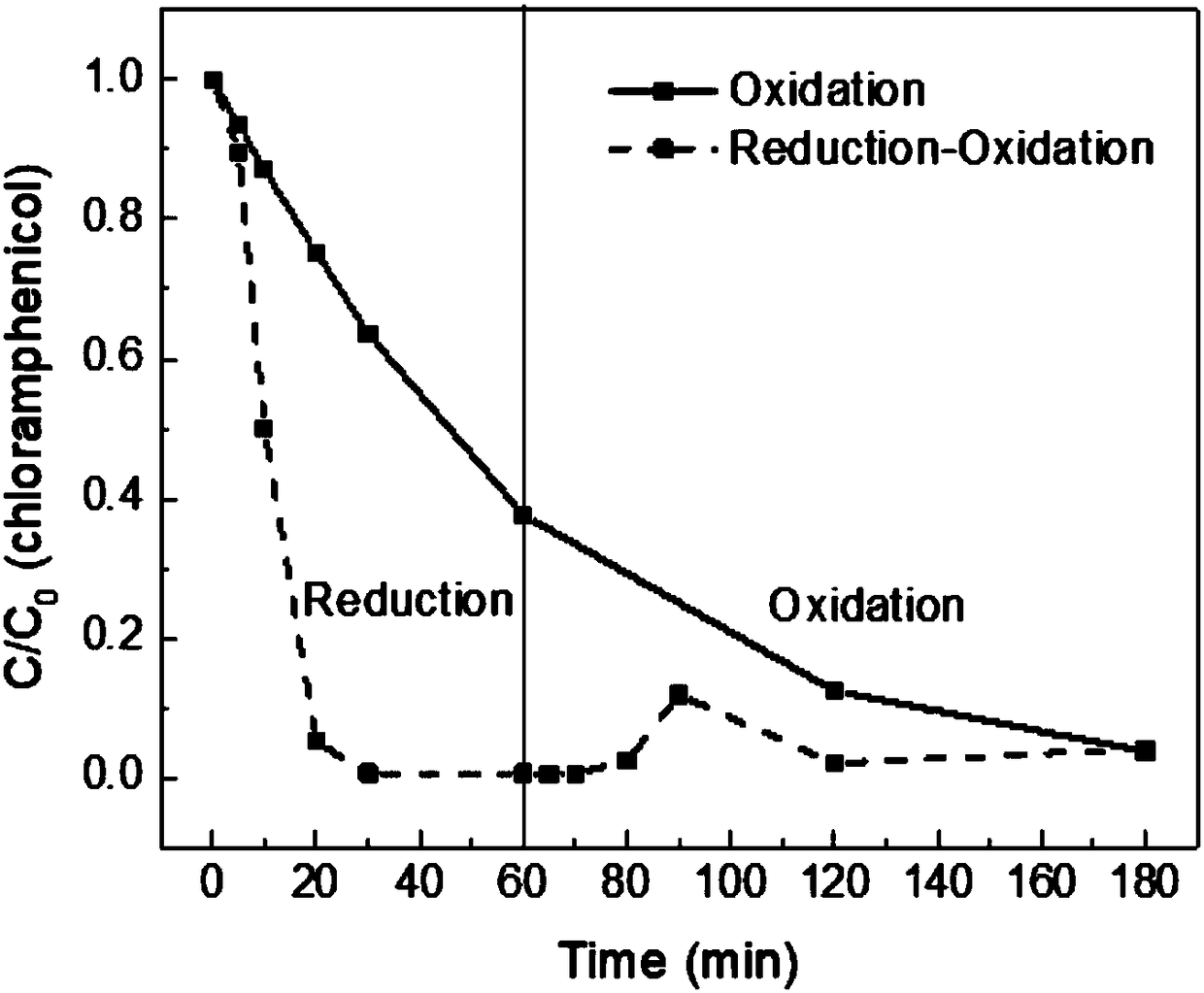

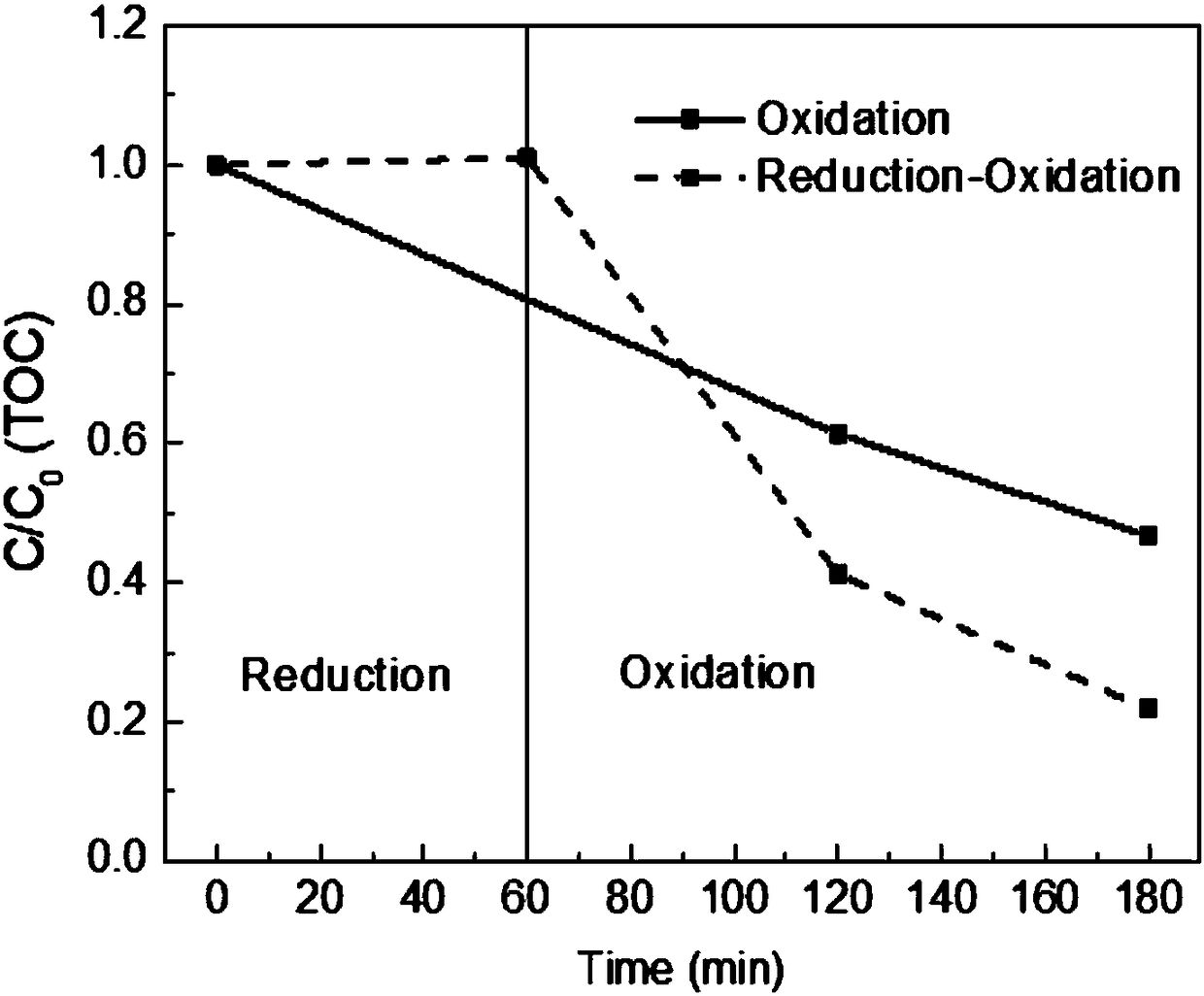

Method for treating chloramphenicol wastewater by electrochemical reduction oxidization and reactor of method

InactiveCN108383216AGood removal effectGood reaction efficiency and mineralization rateWater contaminantsWater/sewage treatment using germicide/oligodynamic-processToxicityCHLORAMPHENICOL TOXICITY

The invention discloses a method for treating chloramphenicol wastewater by electrochemical reduction oxidization and a reactor of the method. The method comprises the following steps: introducing thechloramphenicol wastewater into a cathode chamber of a reactor main body to fully fill the whole reactor main body; carrying out magnetic stirring to start electrochemical treatment; enabling the wastewater to be subjected to reduction reaction in the cathode chamber; conveying the wastewater treated by the cathode chamber into an anode chamber through a connecting pipeline between the cathode chamber and the anode chamber; enabling the wastewater to be subjected to oxidization reaction in the anode chamber, wherein the current density of the oxidization reaction is 10 to 30mA / cm<2>, the staying time of the wastewater in the cathode chamber and the anode chamber is 1 to 2h and the reaction temperature is 10 to 30 DEG C. According to the method disclosed by the invention, the disadvantagesof a single oxidization method that the treatment efficiency on the chloramphenicol wastewater is low and the toxicity of the treated wastewater is high are overcome through a reduction oxidization method; the concentration of the chloramphenicol wastewater can be efficiently reduced through the reactor and the method, the toxicity of the wastewater is reduced and the biodegradability of the wastewater is improved.

Owner:NANJING UNIV

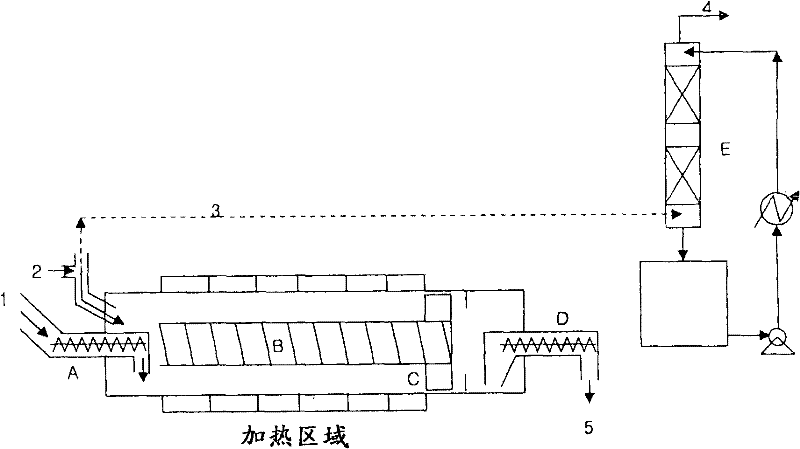

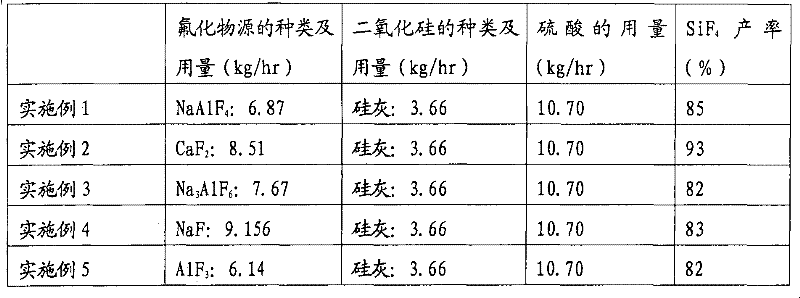

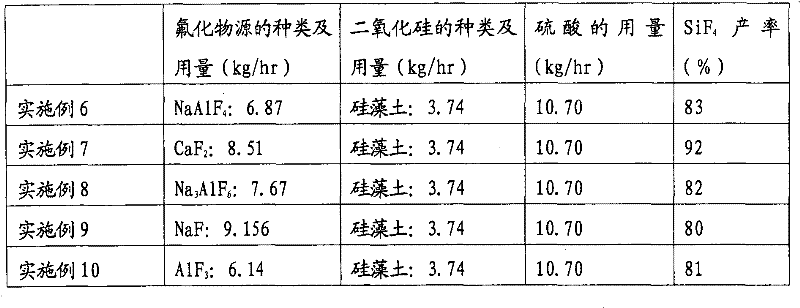

Method for continuous production of tetrafluorosilane by using various fluorine-containing substances, amorphous silica and sulfuric acid

InactiveCN102275934ANo clogging issuesLess quantityHalogenated silanesHexafluorosilicic acidSilica gel

The present invention relates to a method of continuously producing tetrafluorosilane (SiF4) by using various fluorinated materials, amorphous silica (SiO2) and sulfuric acid (H2SO4). According to the present invention, the yield of tetrafluorosilane can increase and it can be continuously produced in an environmentally friendly manner with low cost. In addition, the amount of hydrogen fluoride generated during the reaction is minimized and thus the corrosion of devices can be minimized, and the pipeline blockage and yield decrease of SiF4 can be prevented by passing the reaction product which is a mixture gas of SiF4 and water through an H2SO4 scrubber at a high temperature to remove water, which can prevent the generation of silica gel and hexafluorosilicic acid by the side-reaction of condensed water and SiF4.

Owner:KCC CORP CO LTD

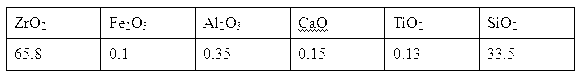

Process for hydrothermally preparing zirconium oxychloride with low alkali consumption

The invention relates to a process for hydrothermally preparing zirconium oxychloride with low alkali consumption, and belongs to the technical field of compound preparation. The process comprises the following steps: stirring crushed superfine zircon sand (ZrSiO4) powder with a NaOH solution to prepare slurry, and then placing the slurry into an autoclave to perform hydrothermal reaction, and thus generating amorphous or crystalline acmite sodium zirconium silicate (Na2ZrSiO5) precursors under a condition with the temperature of 200-300 DEG C, the pressure of 3-7MPa and the reaction time of 3-12 hours; and then removing sodium by use of hydrochloric acid, removing silicon, purifying, concentrating and crystallizing to obtain zirconium oxychloride crystals. The process can be used for not only solving the problems such as high NaOH consumption, high energy consumption, recycling incapability of excessive alkali and serious pollution to the environment in the process of preparing the zirconium oxychloride from zircon sand by an alkali fusion method, but also realizing low impurity content and high purity of a zirconium oxychloride product obtained by the method.

Owner:安徽通湾科技有限公司

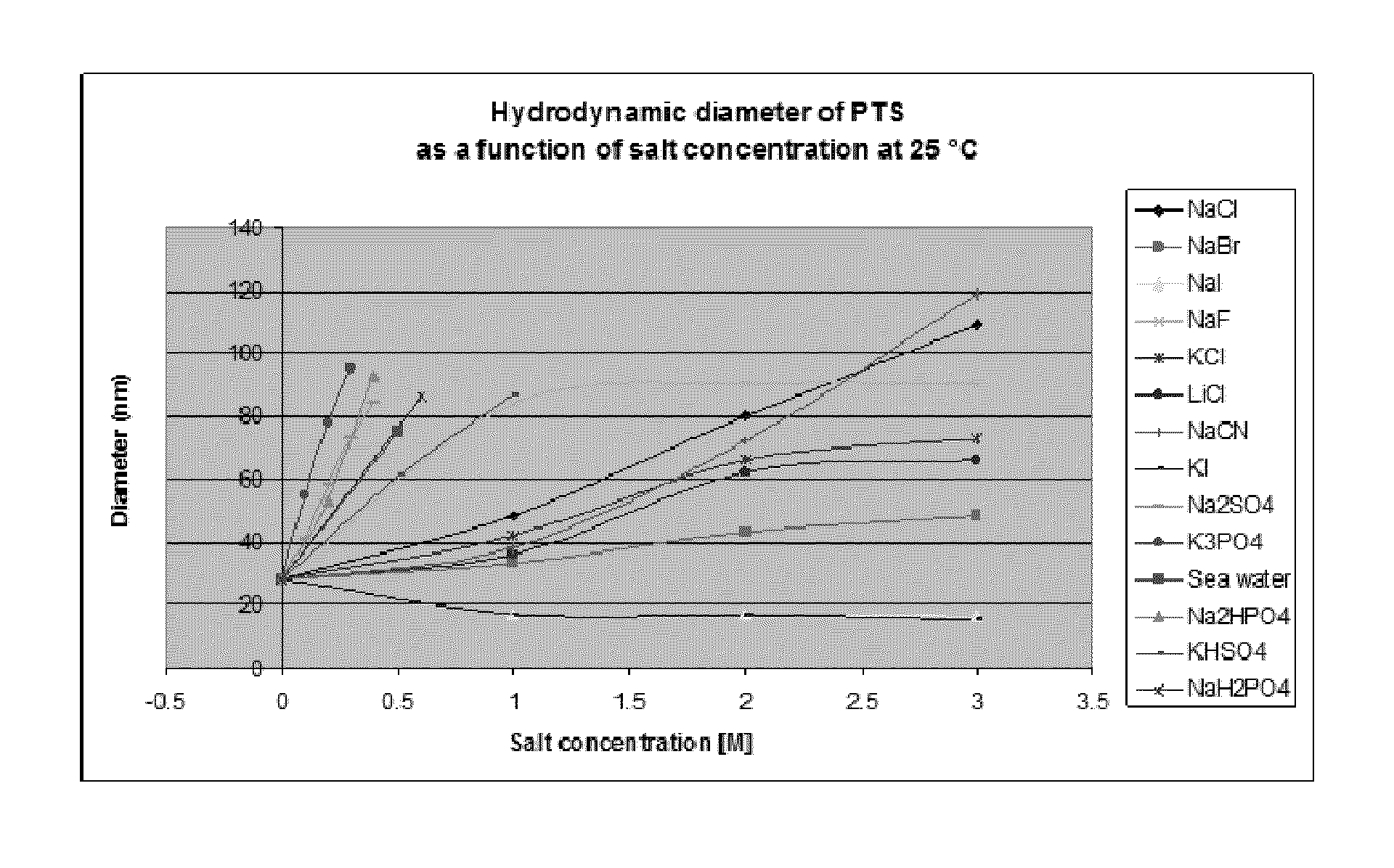

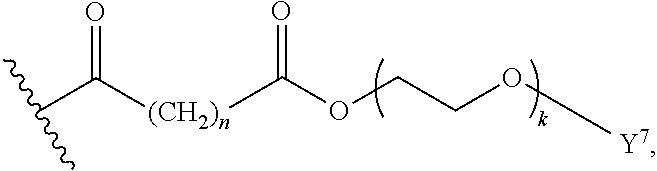

Surfactant-enabled transition metal-catalyzed chemistry

ActiveUS8785665B2Eliminating option for PEG-relatedPromote reaction efficiencyUrea derivatives preparationCarboxylic acid nitrile preparationSolventBond formation

Owner:MYCELL TECH

Hydrogenation dechlorinating catalyst for synthesizing trifluoroethylene and novel preprocessing process of carrier of catalyst

ActiveCN102211028BHigh catalytic activityImprove reaction stabilityPreparation by dehalogenationCatalyst activation/preparationActivated carbonPlatinum

The invention discloses a catalyst used for preparing trifluoroethylene by hydrogenating and dechlorinating trifluorochlor oethylene, comprising a first catalyst, a second catalyst and an assistant, wherein the first catalyst is one or combination of more than two of palladium, ruthenium and platinum, the second catalyst is Fe and / or Cu, and the assistant is selected from one or combination of more than two of V, Bi and K. The invention also discloses an activated carbon carrier preprocessing method of the catalyst for preparing the trifluoroethylene by hydrogenating and dechlorinating the trifluorochlor oethylene and an application of the prepared catalyst in trifluoroethylene preparation. The catalyst prepared by the method disclosed by the invention has the advantages of high catalytic activity and catalyst efficiency, good trifluoroethylene selectivity, strong reaction stability, mild reaction condition, simple catalyst preparation and processing process and the like.

Owner:SINOCHEM LANTIAN

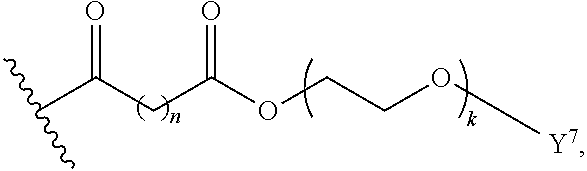

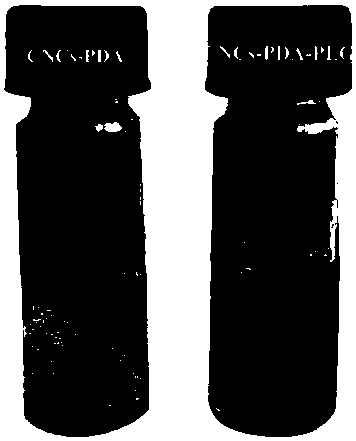

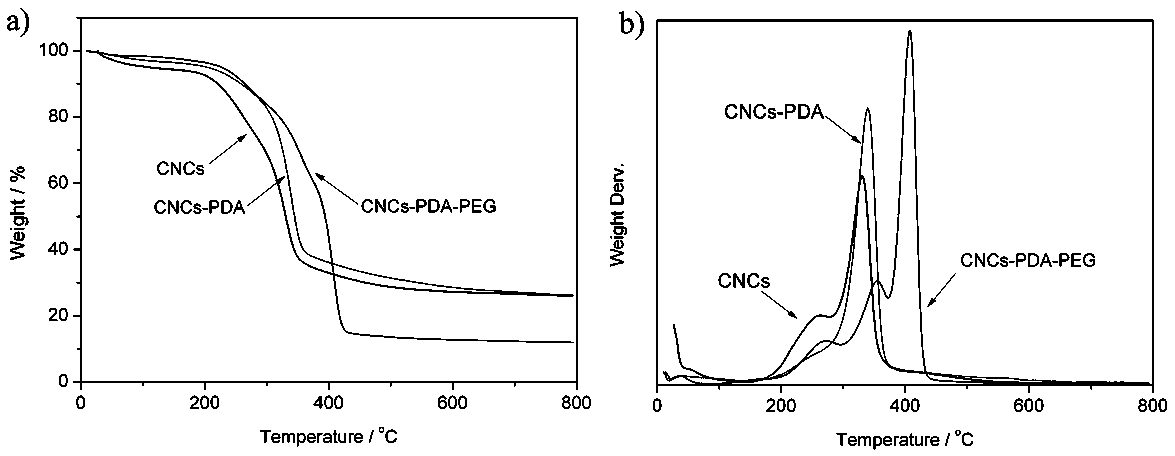

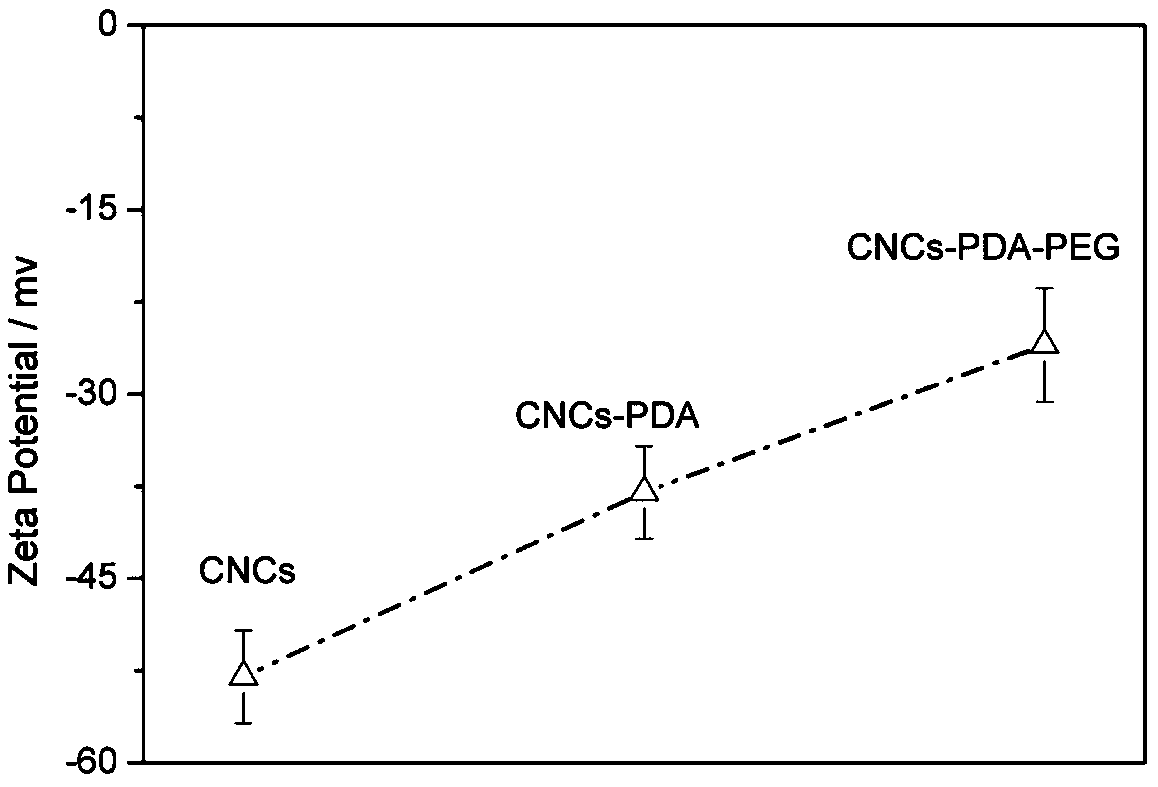

Nano-cellulose/polydopamine/polyethylene glycol composite material and preparation method thereof

The invention discloses a nano-cellulose / polydopamine / polyethylene glycol composite material. The nano-cellulose / polydopamine / polyethylene glycol composite material is prepared by modifying the surface of nano-cellulose through polydopamine and is grafted with polyethylene glycol; the polyethylene glycol is the polyethylene glycol which is subjected to amination or sulfhydrylation modification orterminated by methoxyl. Meanwhile, the invention provides a corresponding preparation method. The nano-cellulose / polydopamine / polyethylene glycol composite material disclosed by the invention can be dispersed in polar solvents, such as water, N',N-dimethylformamide, dimethyl sulfoxide or ethyl alcohol, again; the dispersibility is high; a settlement phenomenon is avoided; the thermal stability ishigh; moreover, the composite material is only limited to modify the surface of the nano-cellulose (CNCs); the structures of nano-crystals of the CNCs are not influenced.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

Synthesis process of tetrabenzylthiuram disulfide

ActiveCN111018761AReduced Competitive ResponsesIncreased process safetyOrganic chemistryInorganic saltsOrganosolv

The invention provides a synthesis process of tetrabenzylthiuram disulfide. The synthesis process comprises the following steps: carrying out a mixed reaction on dibenzylamine and carbon disulfide inwater to generate an intermediate product, and carrying out an oxidation reaction on the intermediate product and hydrogen peroxide to prepare tetrabenzylthiuram disulfide. According to the process, water is used as a medium, so operation safety is high, no organic solvent is left in the product, and no inorganic salt by-product is generated; and the competitive reaction of the raw materials and the intermediate is effectively reduced, so product yield is improved.

Owner:HEBI YUANHAO CHEM CO LTD

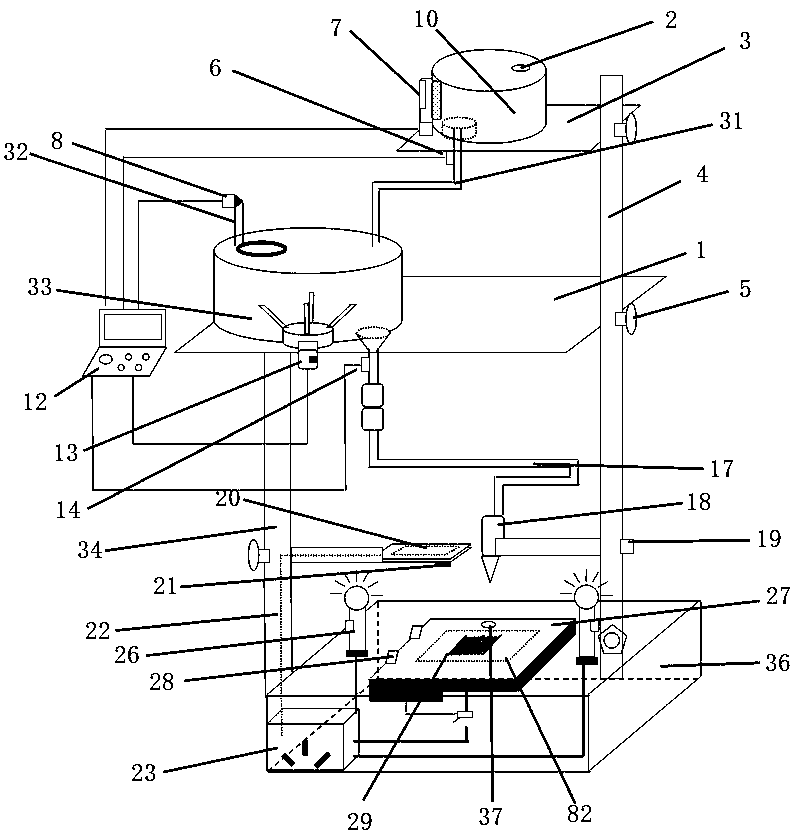

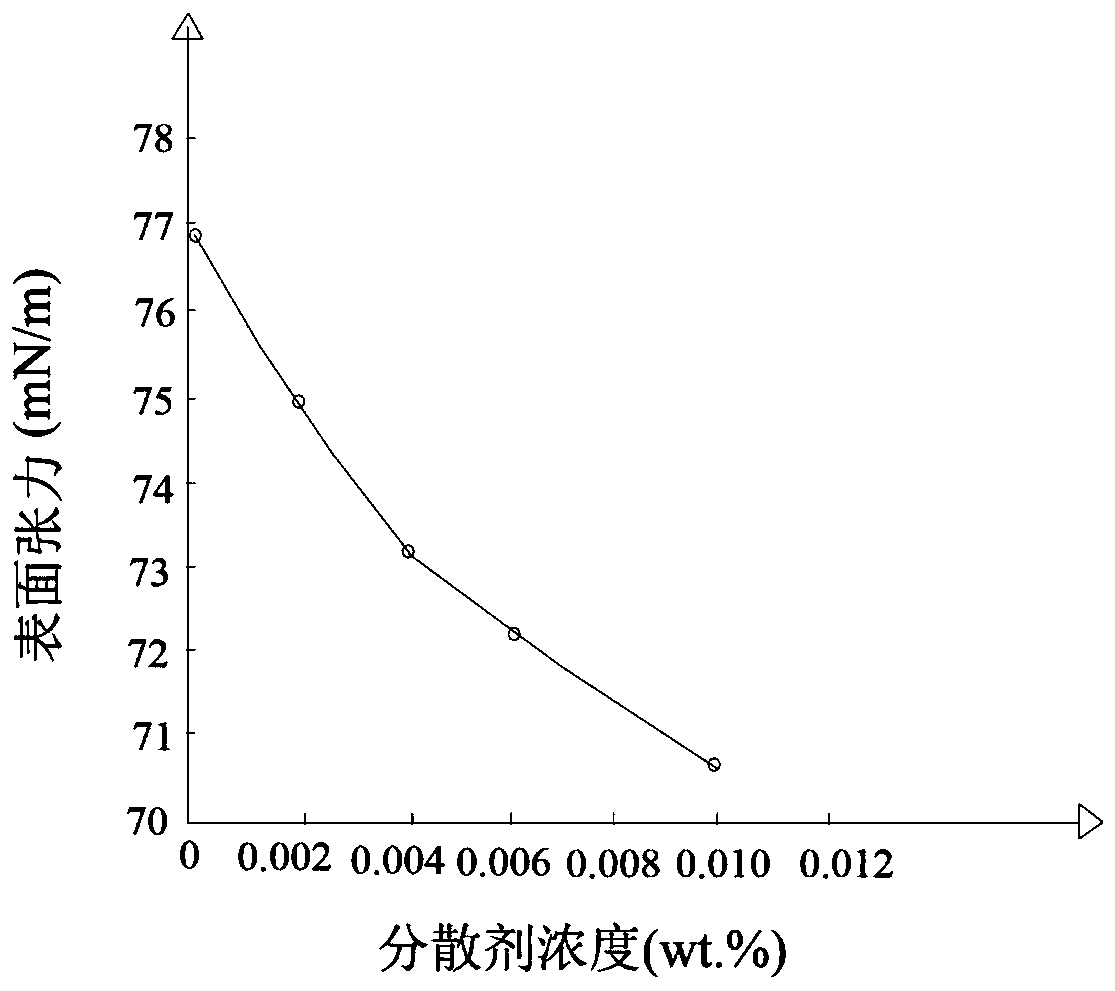

Lithium hexafluorophosphate synthesis technology with high reaction efficiency

ActiveCN106186004AImprove reaction efficiencyStable temperatureLithium compoundsReaction temperaturePhysical chemistry

The invention discloses a lithium hexafluorophosphate synthesis technology with high reaction efficiency. The technology is characterized by: letting lithium fluoride anhydrous hydrogen fluoride solution from a blending tank pass through an intermediate tank and transferring the solution to a constant temperature mixing cooling kettle by a lithium fluoride anhydrous hydrogen fluoride solution intermediate pump, pumping the feed liquid in the mixing cooling kettle into a reaction tower feed inlet by a circulating absorption pump, performing atomization by an atomizing nozzle, then subjecting the processed feed liquid to full heat transfer and mass transfer with phosphorus pentafluoride gas from a phosphorus pentafluoride purification section, and carrying out synthetic reaction at a temperature at 0-10DEG C and under ordinary pressure, subjecting a little unreacted phosphorus pentafluoride gas to further reactive absorption by the lithium fluoride anhydrous hydrogen fluoride solution in a tail gas balance absorber, making the reacted solution enter the mixing cooling kettle to further participate in circulating absorption reaction. And the reaction tower, the tail gas balance absorber and the constant temperature mixing cooling kettle compose an airtight reaction system. The technology provided by the invention can realize continuous and automatic production, the production cost is low and the product consistency is good.

Owner:JIANGSU JIUJIUJIU TECH

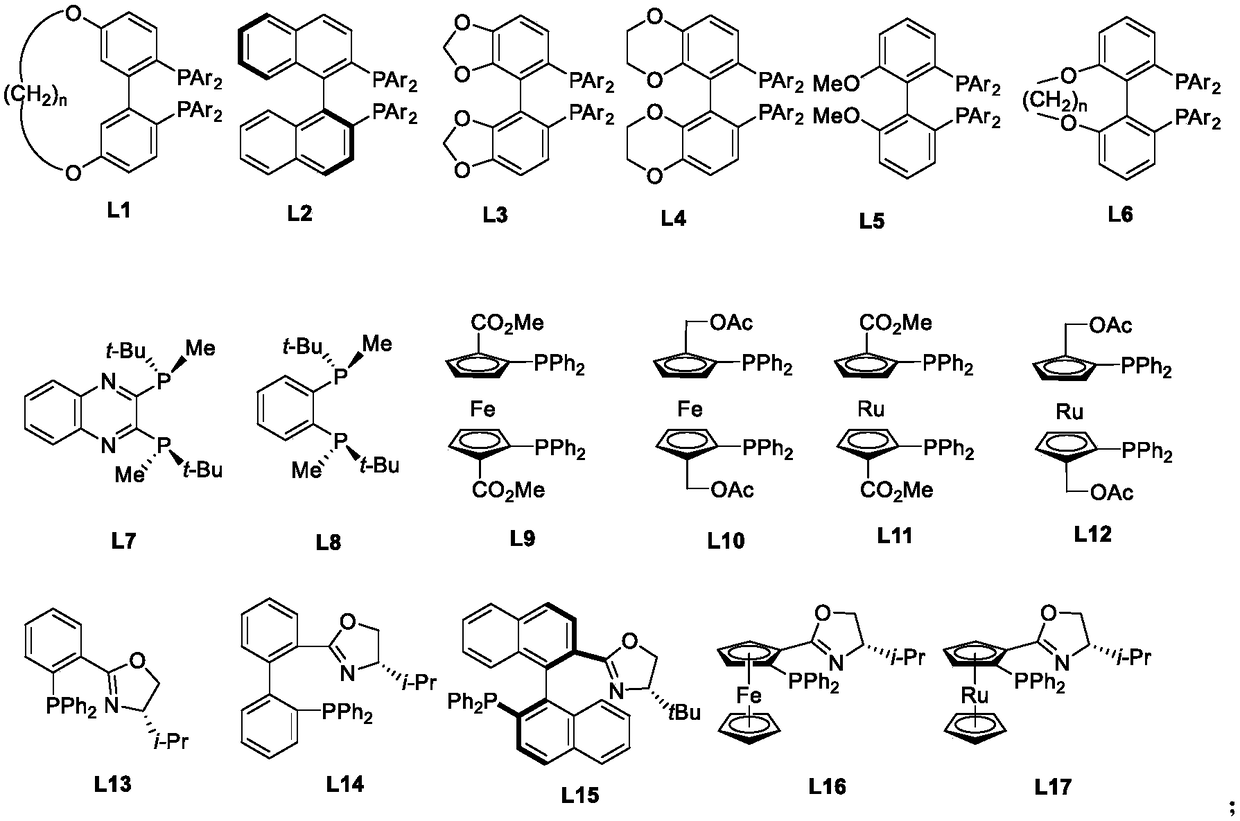

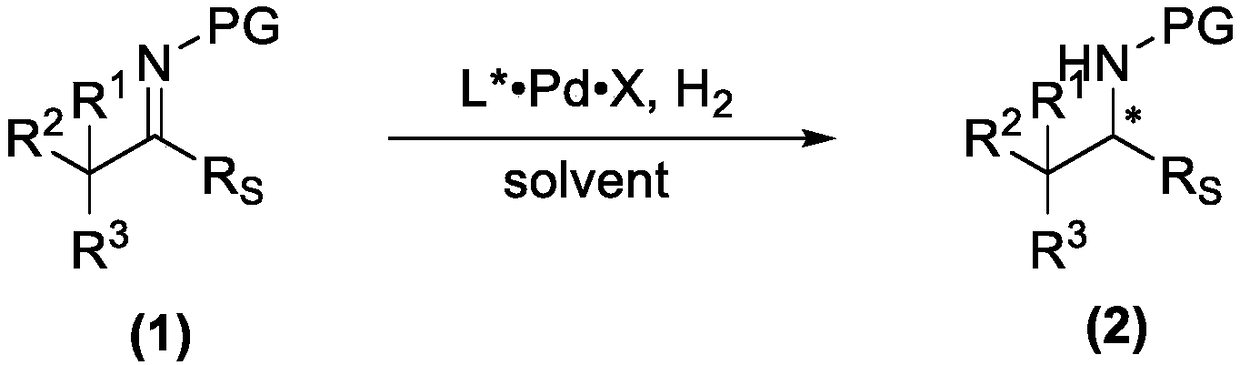

Method for preparing high-steric-hindrance chiral amines from Z-type high-steric-hindrance imines through asymmetric palladium-catalyzed hydrogenation

ActiveCN109400508AEfficient preparationMild conditionsOrganic chemistry methodsSulfonic acid amide preparationHydrogen pressurePalladium catalyst

The invention relates to the technical field of chemical engineering, particularly to a method for preparing high-steric-hindrance chiral amines from Z-type high-steric-hindrance imines through asymmetric palladium-catalyzed hydrogenation. The method comprises the following step of, in solvent and at certain hydrogen pressure and temperature, hydrogenating the Z-type high-steric-hindrance chiral amines shown as the formula (1) to the high-steric-hindrance chiral amines shown as the formula (2) under catalysis of chiral palladium catalysts, wherein the structural formulas of the formula (1) andthe formula (2) are shown as followings. The method for preparing the high-steric-hindrance chiral amines from the Z-type high-steric-hindrance imines through asymmetric palladium-catalyzed hydrogenation is mild in conditions and simple in operation and can achieve good reaction yield and efficiency as well as high application effects.

Owner:SHANGHAI JIAO TONG UNIV

Device and method for detecting pesticide residue and nitrite based on scanning code type paper chip

ActiveCN109444120AReduce testing costsControl the detection timeMaterial analysis by observing effect on chemical indicatorImaging processingPesticide residue

The invention relates to a device and a method for detecting pesticide residue and nitrite based on a scanning code type paper chip by adopting a microfluidic technology and an image processing technology to identify, detect and record the pesticide residue and nitrite harmful substances. The method includes, arranging a plurality of layers of microfluidic paper chips inside a heating chip detection cavity, wherein a plurality of layers of the microfluidic paper chips consist of five layers which are glued together from top to bottom, each layer has a chip bar code detection areal adding, by adropper, mixed liquid into a chip sample inlet drop by drop; showing, by the chip bar code detection area of each layer, different colors according to a composition of the sample mixed liquid; imaging and scanning, by intelligent mobile equipment, a color development result of a plurality of layers of the microfluidic paper chips to obtain a detection result. The method applies an inhibition principle of organophosphorus pesticides on acetylcholine esterase and a diazonium coupling reaction of aminobenzenesulfonic acid and N-1-naphthylethylenediamine dihydrochloride under an acidic condition,and integrates automatic sample introduction, intelligent heating, reaction, color development and result analysis, recording and processing.

Owner:JIANGSU UNIV

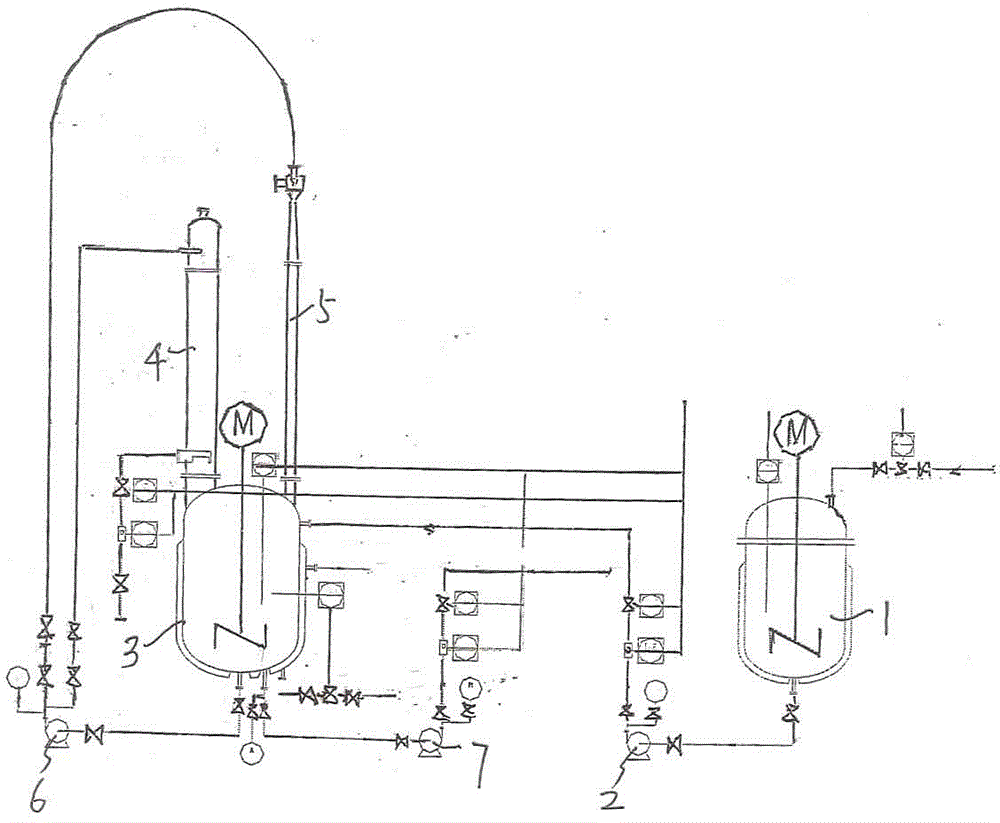

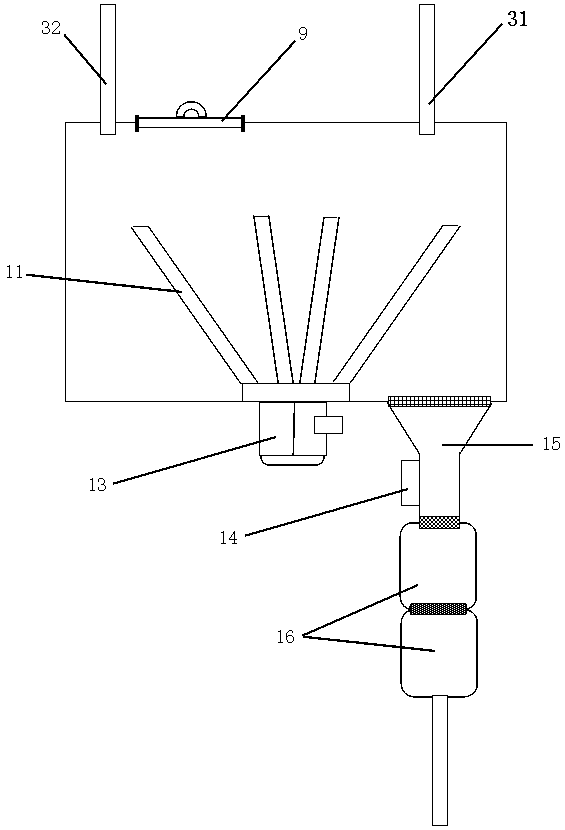

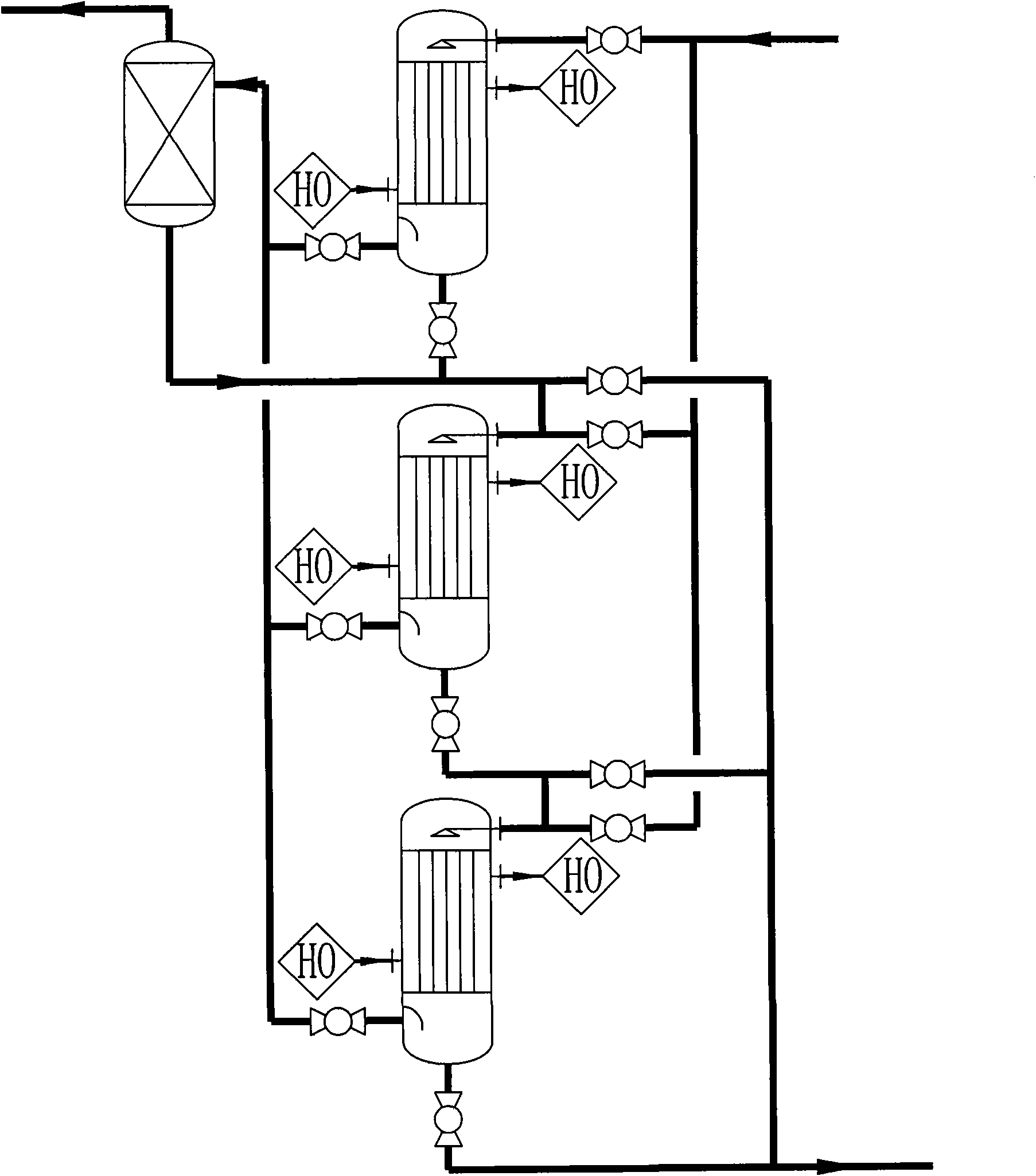

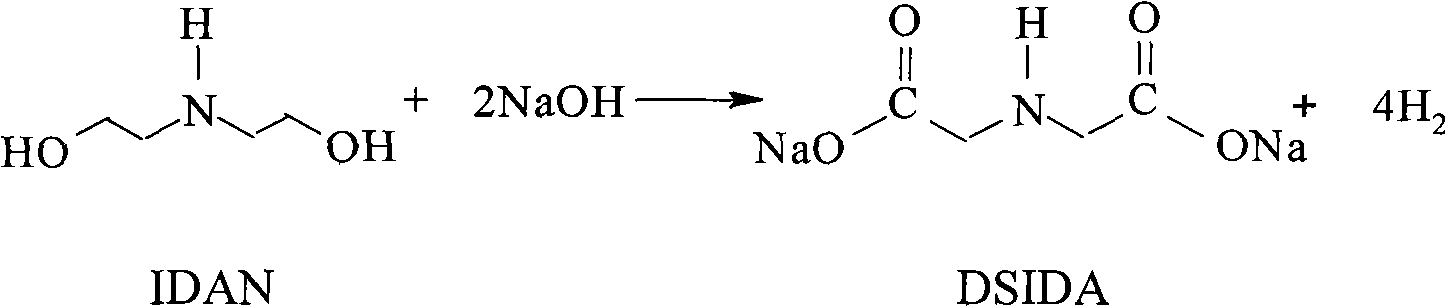

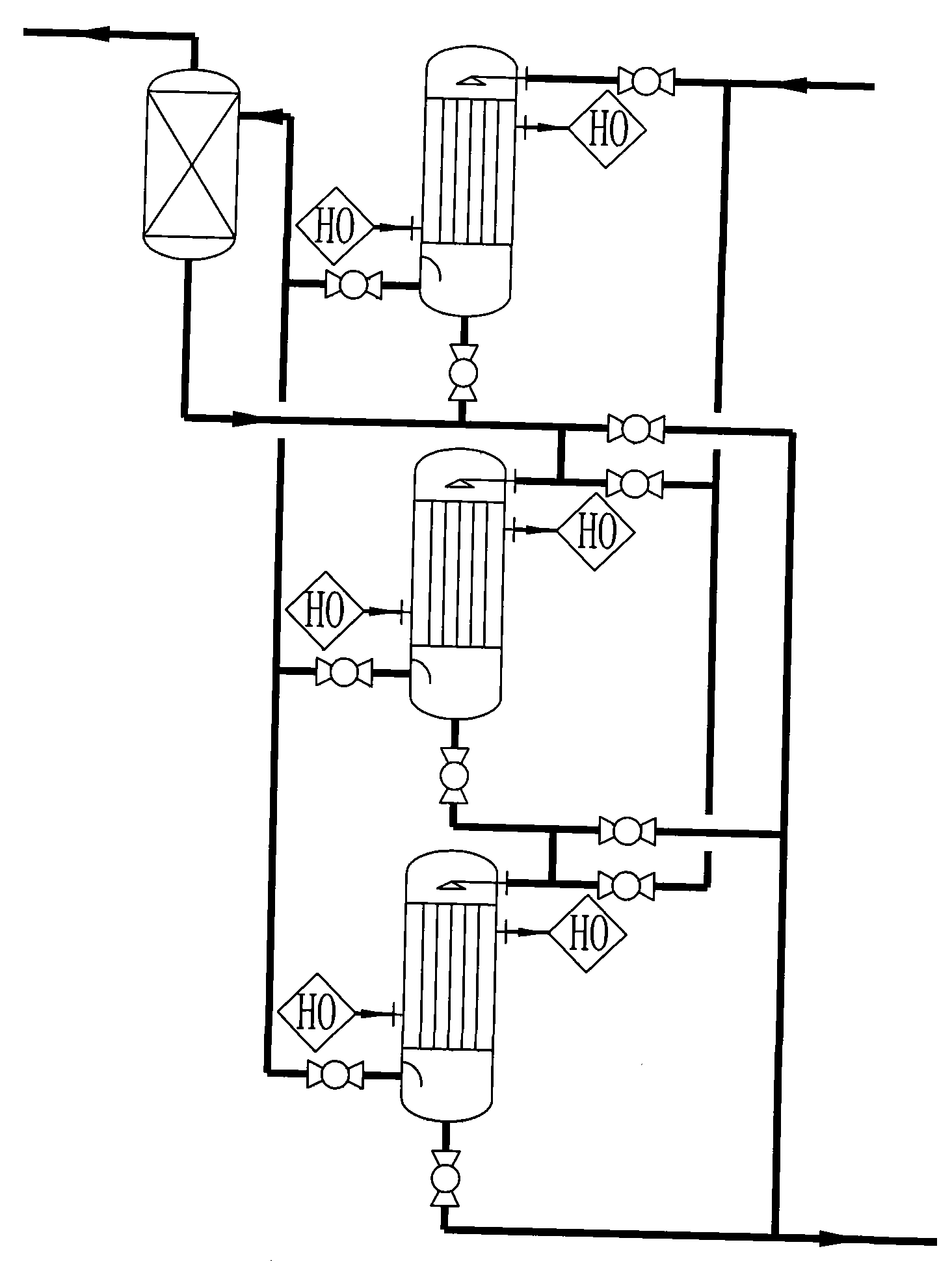

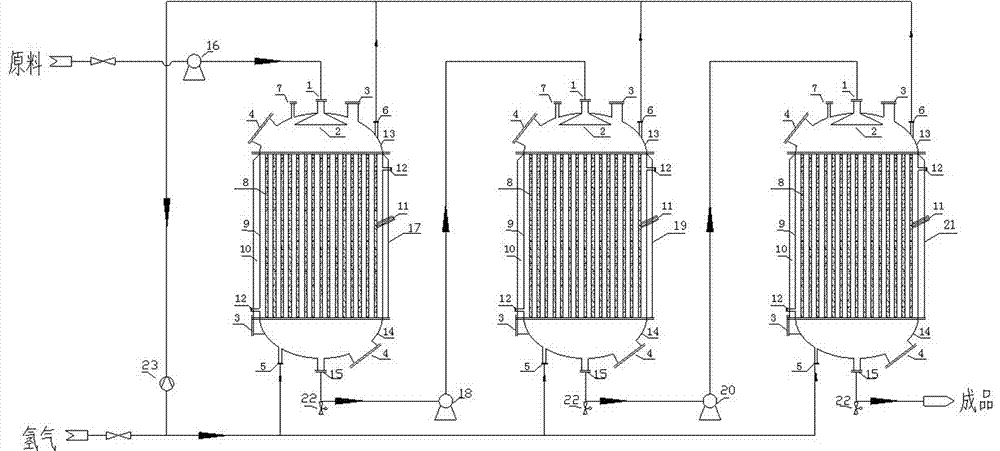

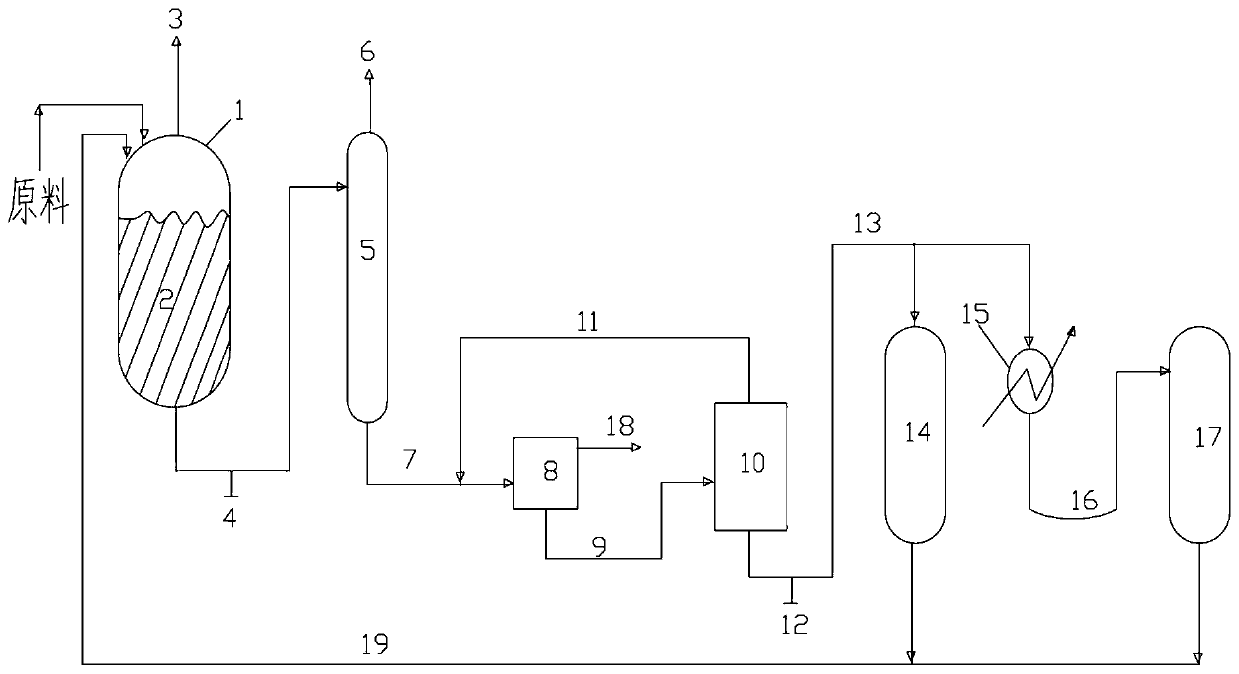

Synthesis as well as tail gas treatment technology and device of iminodiacetate

InactiveCN102050751AReduce typesEfficient removalOrganic compound preparationHydrogen separation using liquid contactDehydrogenationDiethanolamine

The invention relates to a synthesis technology and device of iminodiacetate. The technology uses diethanol amine as a main raw material and comprises the following steps: dissolving the diethanol amine, mixing with a caustic soda solution and deionized water evenly to prepare a feed liquid the mass concentration of which is 10-30%, and transferring the feed liquid into a multistage tubular reactor loaded with a solid catalyst through a metering pump to perform catalytic dehydrogenation reaction to obtain iminodiacetate; and treating the gas generated through catalytic dehydrogenation and the tail gas separated from the discharged liquid to recycle hydrogen. The device comprises the multistage tubular reactor which is designed on the basis of a kinetic model of isothermal constant-pressure reaction, wherein the multistage tubular reactor is formed by connecting 2 to 5 tubular reactors in series; each reactor is formed by a plurality of tubes; the same amount of catalyst is evenly filled in each tube; the upper part or lower part of each reactor is provided with a gas-liquid separator which is used for separating the gas generated through the dehydrogenation reaction from the discharged liquid; and the back of the gas-liquid separator is connected with a demister which is connected with a tail gas treatment device used for purification treatment through a regulating valve. The device provided by the invention has the characteristics that the technological operation is simple, the product yield is no less than 98%, the continuous production can be realized, the work efficiency can be increased, and the like.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

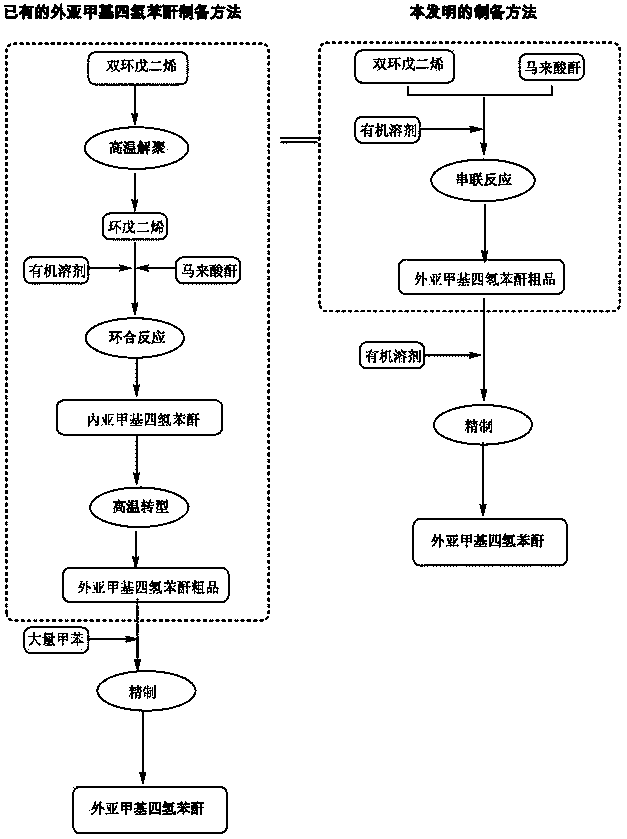

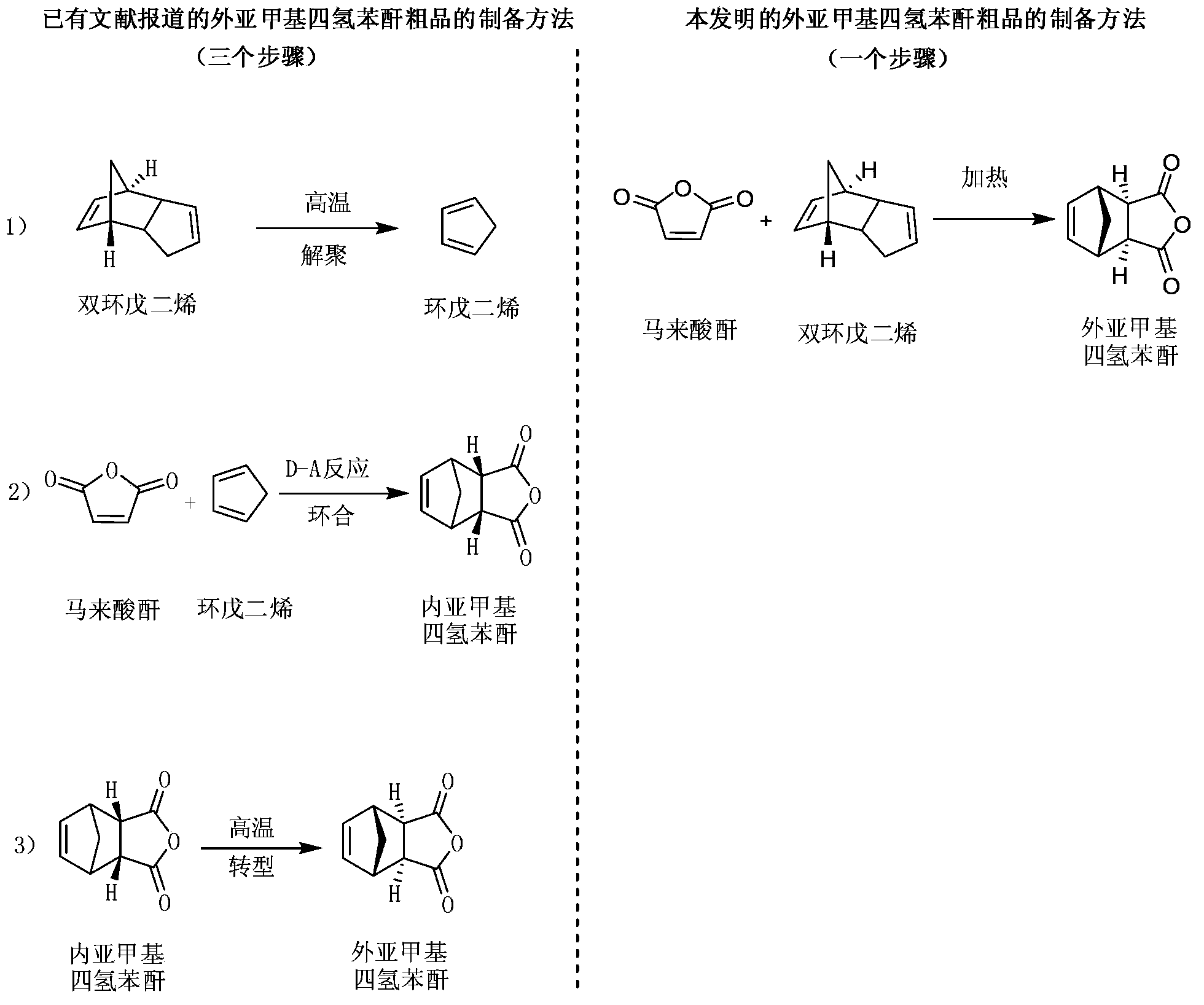

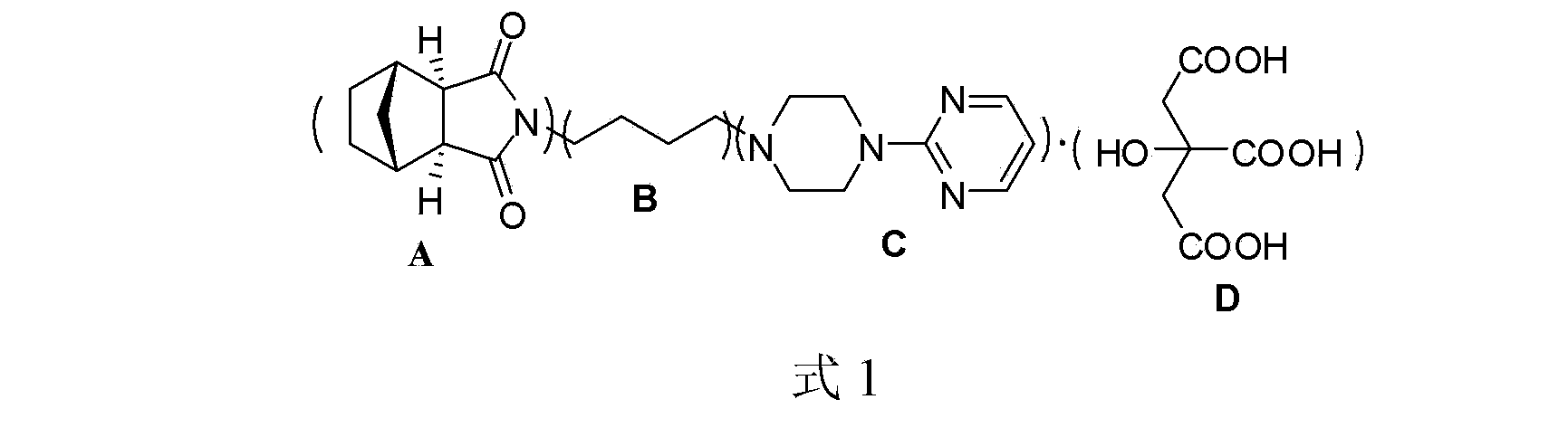

Preparation and refining method of exo-methylene tetrahydrophthalic anhydride and its use in preparation of tandospirone

ActiveCN103848801ASimple manufacturing processIncrease profitOrganic chemistryChemical recyclingDepolymerizationHigh energy

The invention relates to a preparation and refining method of exo-methylene tetrahydrophthalic anhydride and its use in preparation of tandospirone. The preparation and refining method realizes high-efficiency combination of depolymerization of dicyclopentadiene, cycloaddition of cyclopentadiene and maleic anhydride, and transformation of endo-methylene tetrahydrophthalic anhydride, is free of a single dicyclopentadiene depolymerization process, is free of a reaction intermediate product separation process, effectively solves the problem that the existing exo-methylene tetrahydrophthalic anhydride preparation method has defects of complex dicyclopentadiene depolymerization processes, low conversion rate, low yield, serious environmental pollution, high energy consumption, long production cycle and harsh storage condition requirements, and has the advantages of high yield, good quality, eco-friendly solvent, low cost and good industrial production applicability.

Owner:SICHUAN CREDIT PHARMA

Methods and devices for amplification of nucleic acid

ActiveUS8741815B2Improve sealingMaximize efficiencyHeating or cooling apparatusMicrobiological testing/measurementEmulsionChemistry

The present invention relates to methods and devices for amplifying nucleic acid, and, in particular, amplifying so as to generate products on a surface without the use of emulsions. In a preferred embodiment, a plurality of groups of amplified product are generated on the surface, each group positioned in different (typically predetermined) locations on said surface so as to create an array.

Owner:ISOPLEXIS

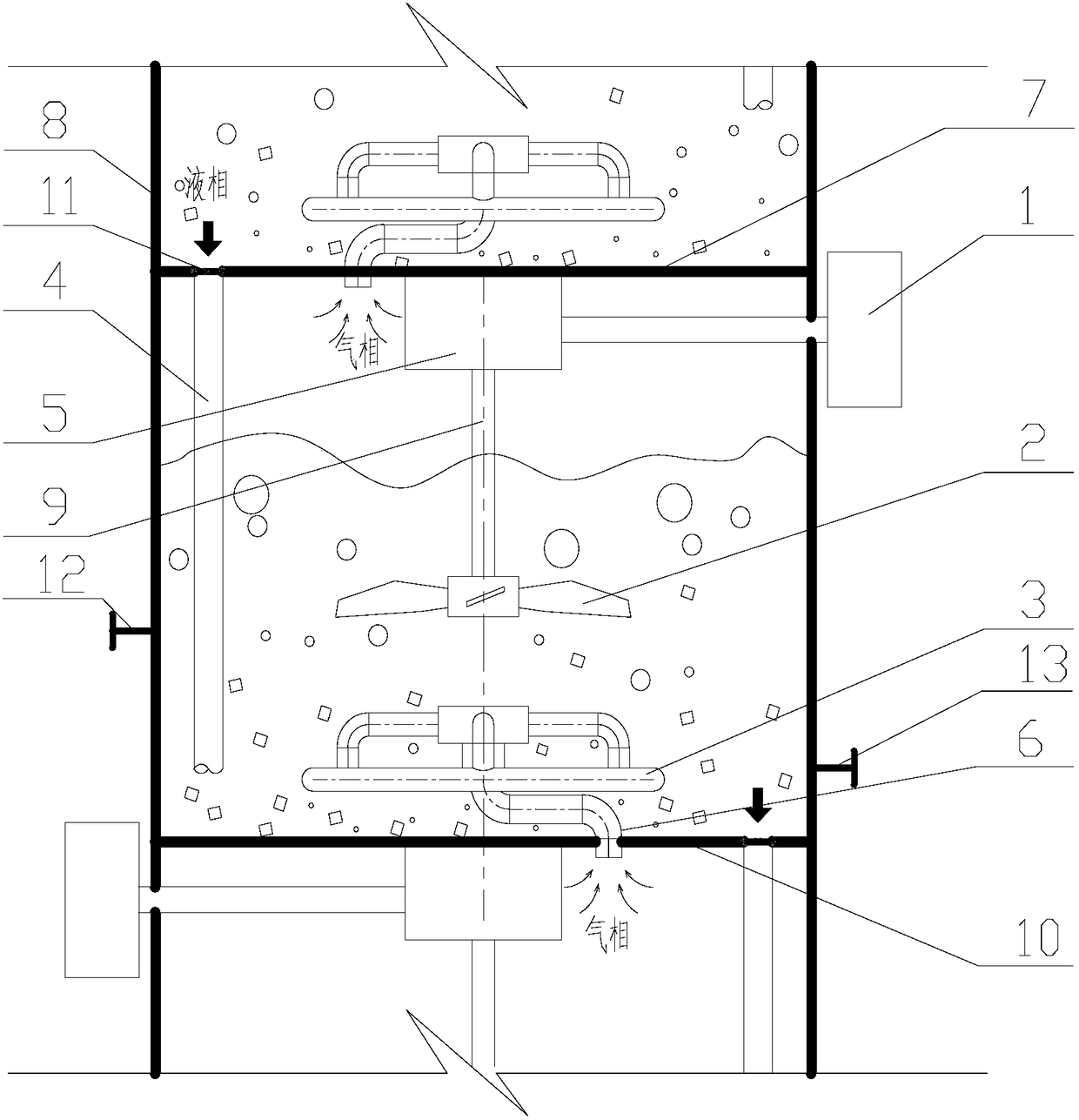

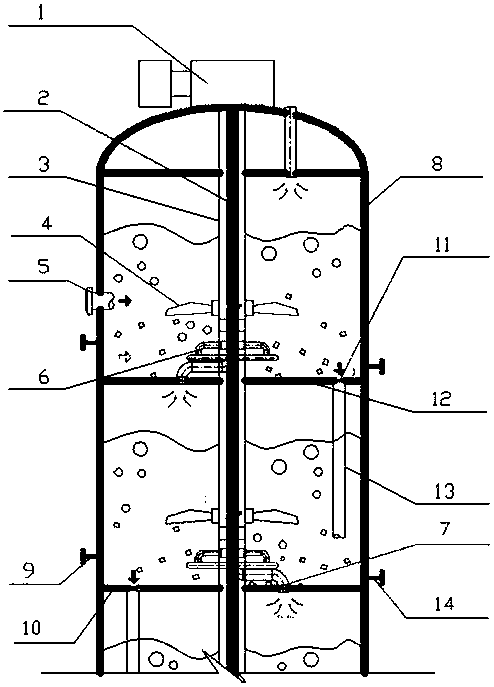

Novel pneumatic stirring catalytic distillation device

ActiveCN108261792AStir wellWell mixedPreparation by ester-hydroxy reactionChemical industrySolid phasesCatalytic distillation

The invention relates to a novel pneumatic stirring catalytic distillation device. The distillation device mainly solves the problem that the gas, liquid and solid phases between tower plates in the catalytic rectification tower cannot be uniformly mixed. According to the novel pneumatic stirring catalytic distillation device, each tower plate separately utilizes a pneumatic stirrer in the side, astirring paddle is suspended on the top of the tower plate in the form of top suspension, each tower plate is provided with a riser pipe and a downcomer, a gas inlet of the riser pipe is arranged inone side of each tower plate without a pneumatic pump, the upper part of the riser pipe is connected to a gas distributor, gas in the lower tower plate is uniformly sprayed into a liquid-solid mixtureon the tower plate through the gas distributor, the upper part of the downcomer is provided with a filter net for preventing a particle or microsphere catalyst from falling into the lower tower plate, and the lower part of the downcomer is arranged at the lower part of the tower plate. The device extending below the liquid levels of the adjacent lower plates well solves the above problem and canbe used in a catalytic distillation tower.

Owner:SINOPEC SHANGHAI ENG +1

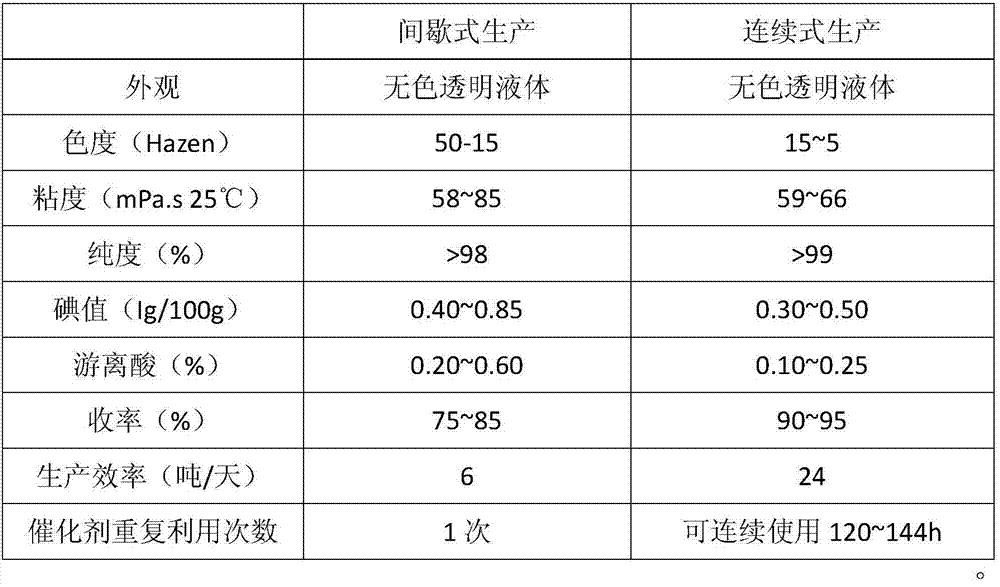

Method for preparing methylhexahydrophthalic anhydride by means of continuous hydrogenation

ActiveCN107089961AWell distributedImprove conversion rateOrganic chemistryChemical/physical processesThree levelFixed bed

The invention discloses a method for preparing methylhexahydrophthalic anhydride by means of continuous hydrogenation and belongs to the field of organic chemicals. A three-level split-tube fixed bed reactor is adopted for circularly continuous hydrogenating; a split-tube type structure is adopted in the split-tube fixed bed reactor; a solid catalyst is arranged between tube passes; a heat medium is arranged in a shell pass; hydrogen respectively enters from the bottom of each level of split-tube fixed bed reactor in parallel; unreacted hydrogen passes by each split tube and then returns to a hydrogen compressor from the upper part of the reactor; the raw material, methyltetrahydrophthalic anhydride, gradually passes by a high pressure pipe pump, is conveyed to the upper part of the split-tube reactor and is sprayed by a distributor located at the top in the reactor so as to be uniformly distributed on the surface of the solid catalyst and react with hydrogen; after circular reaction through the three-level reactor, the hydrogenating conversion rate is close to 100%. According to the method, the production of methylhexahydrophthalic anhydride by means of continuous hydrogenation is realized, the technical process is clean and the catalyst is reused.

Owner:河南惠成新材料有限公司

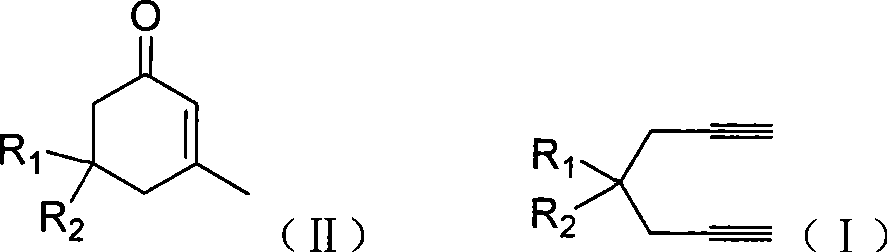

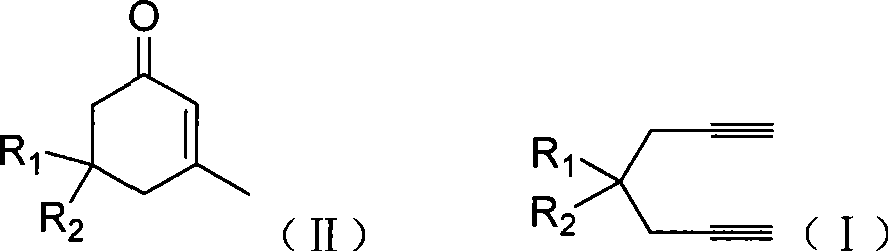

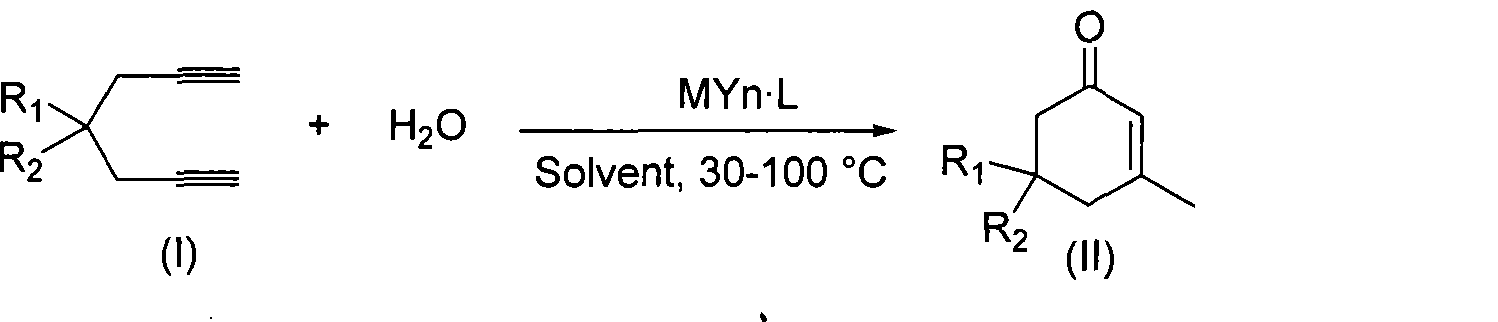

Preparation of 2-pimelie kelone compound

ActiveCN101412667AEasy to operatePromote reaction efficiencyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCyclohexenoneChemical products

The invention discloses a method for preparing 2-cyclohexenone compound, which comprises the following steps: under the action of a metallic catalyst MYn.L, 1, 6-heptadiyne compound showed in formula (I) taken as a raw material is reacted in an ionic liquid at a temperature of between 0 and 150 DEG C; after the reaction liquid is treated, the 2-cyclohexenone compound showed in formula (II) is prepared; and at the same time, the ionic liquid fixed with the metallic catalyst can be recycled. The method has the advantages of simple and reliable operation, high yield and selectivity, repeated recycling and use of the noble metal catalyst, environmental protection, and the like. Because the cyclohexenone compound is a good raw material for synthesizing medicines, pesticides and chemical products, the method has wide industrial application prospect.

Owner:ZHEJIANG UNIV OF TECH

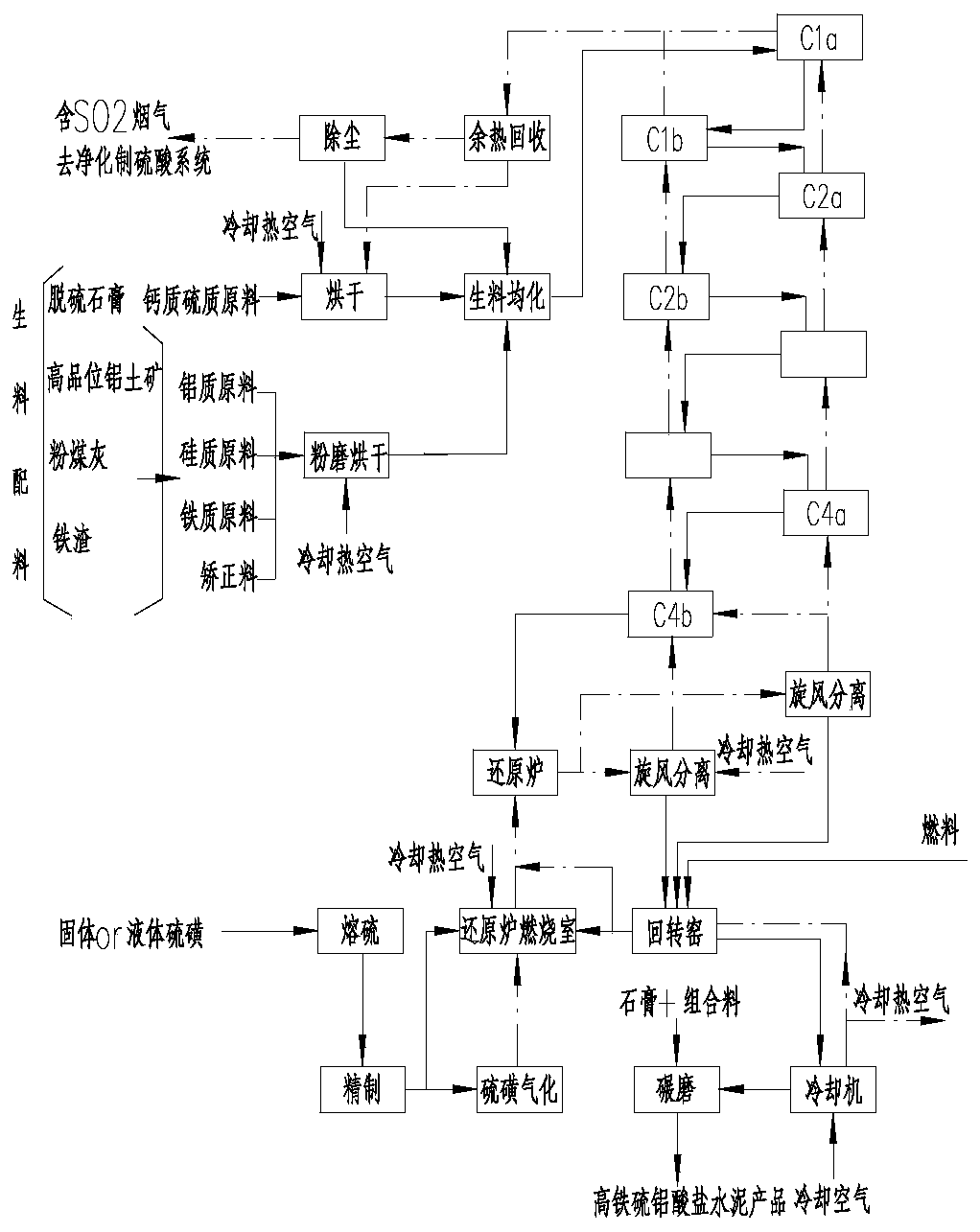

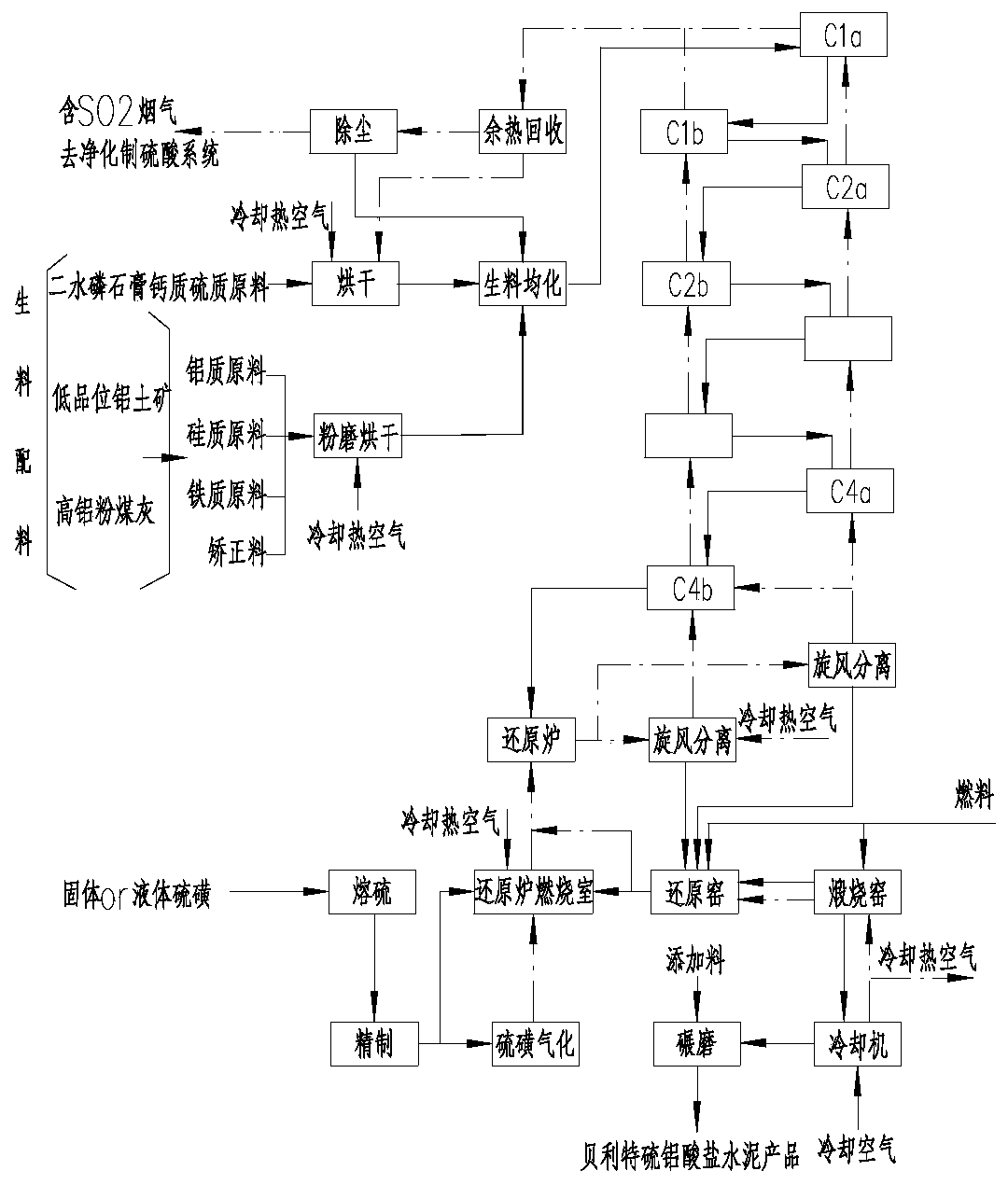

Method for preparation of belite sulphoaluminate cement and co-production of sulfuric acid by reducing gypsum with sulfur gas

ActiveCN111574080AControl the amount of decompositionSave resourcesSulfur compoundsEnergy inputAluminateProcess equipment

The invention relates to a method for the preparation of belite sulphoaluminate cement and the co-production of sulfuric acid by reducing gypsum with sulfur gas. According to the method, industrial byproduct gypsum is used as a main raw material; an alkalinity coefficient (C), an aluminum-sulfur ratio (P) and an aluminum-silicon ratio (N) are controlled according to the application requirements ofthe belite sulphoaluminate cement clinker; one or more of low-grade bauxite, coal ash, coal gangue, red mud, clay and iron slag are selected as ingredients, the gas sulfur is adopted as a reducing agent, so that the gypsum is promoted to be decomposed; and therefore, the belite sulphoaluminate cement is prepared, and meanwhile, high-concentration gas-phase SO2 flue gas is obtained and used for preparing sulfuric acid from follow-up flue gas. Compared with the prior art, the method can consume a large amount of industrial gypsum and save limestone and natural gypsum resources, meanwhile, can obtain high-quality belite sulphoaluminate cement and industrial sulfuric acid products; and the method has the advantages of simple process, high implementation performance of system control indexes,convenient operation and management, advanced process equipment, low device investment, low energy consumption, low operation cost and high automation degree.

Owner:上海三夫工程技术有限公司 +1

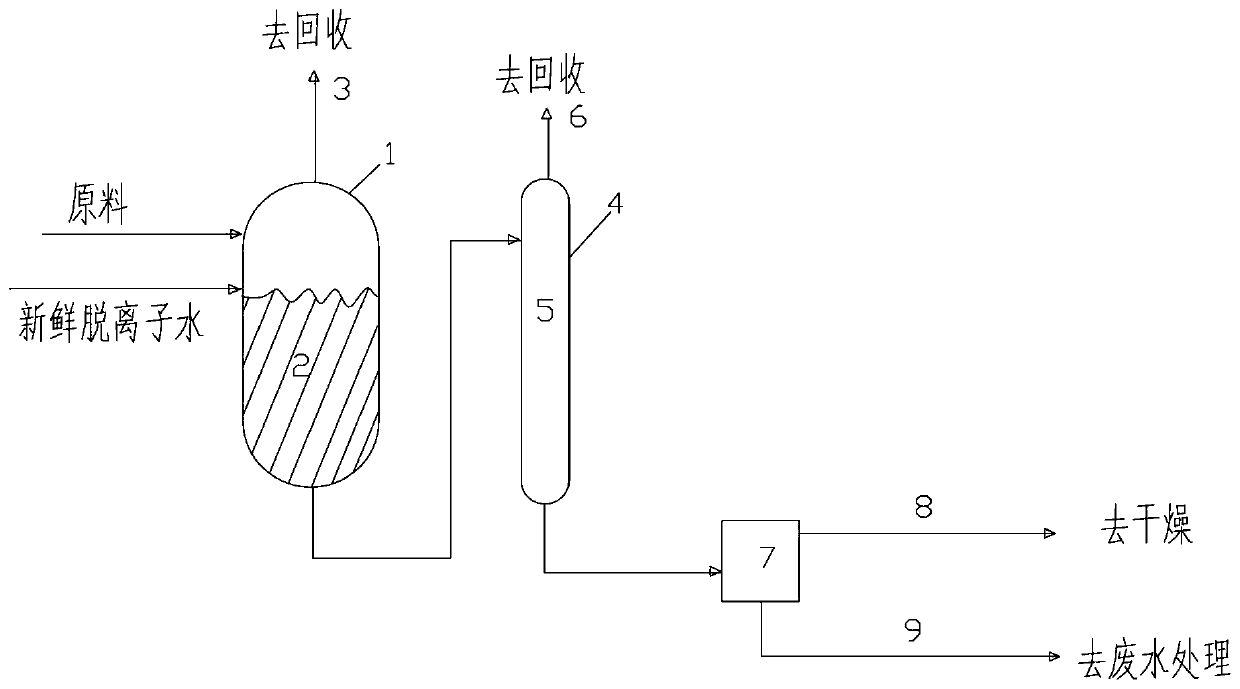

Suspension polymerization method for polyvinyl chloride (PVC)

The invention relates to a suspension polymerization method for PVC. The method comprises the following steps: a) adding a terminator to a PVC suspension polymerization system to terminate polymerization, performing centrifugation and separation and purifying a suspension polymerized aqueous-phase reaction mixture to obtain centrifugal mother liquor; b) taking the centrifugal mother liquor as a reaction raw material to be recycled to the PVC suspension polymerization system to carry out polymerization continuously; c) repeating the steps a) and b), wherein in the step a), controlling the equivalent concentration of polymerization inhibiting components in the centrifugal mother liquor at 7.8*10<-6>N to 3.1*10<-5>N. The method can accurately analyze the concentration and the residual dispersion amount of the polymerization inhibiting components in the centrifugal mother liquor, and remove obstacles for the reuse of the centrifugal mother liquor in the PVC suspension polymerization system, so that the centrifugal mother liquor can be efficiently reused in the suspension polymerization, thereby not only saving a lot of deionized water and further recycling a large amount of thermal energy and PVC resin and additives and being obvious in energy-saving effect, in addition, the production cost of PVC can be significantly reduced and economic benefits are good.

Owner:杰瑞德工业设备(北京)有限公司

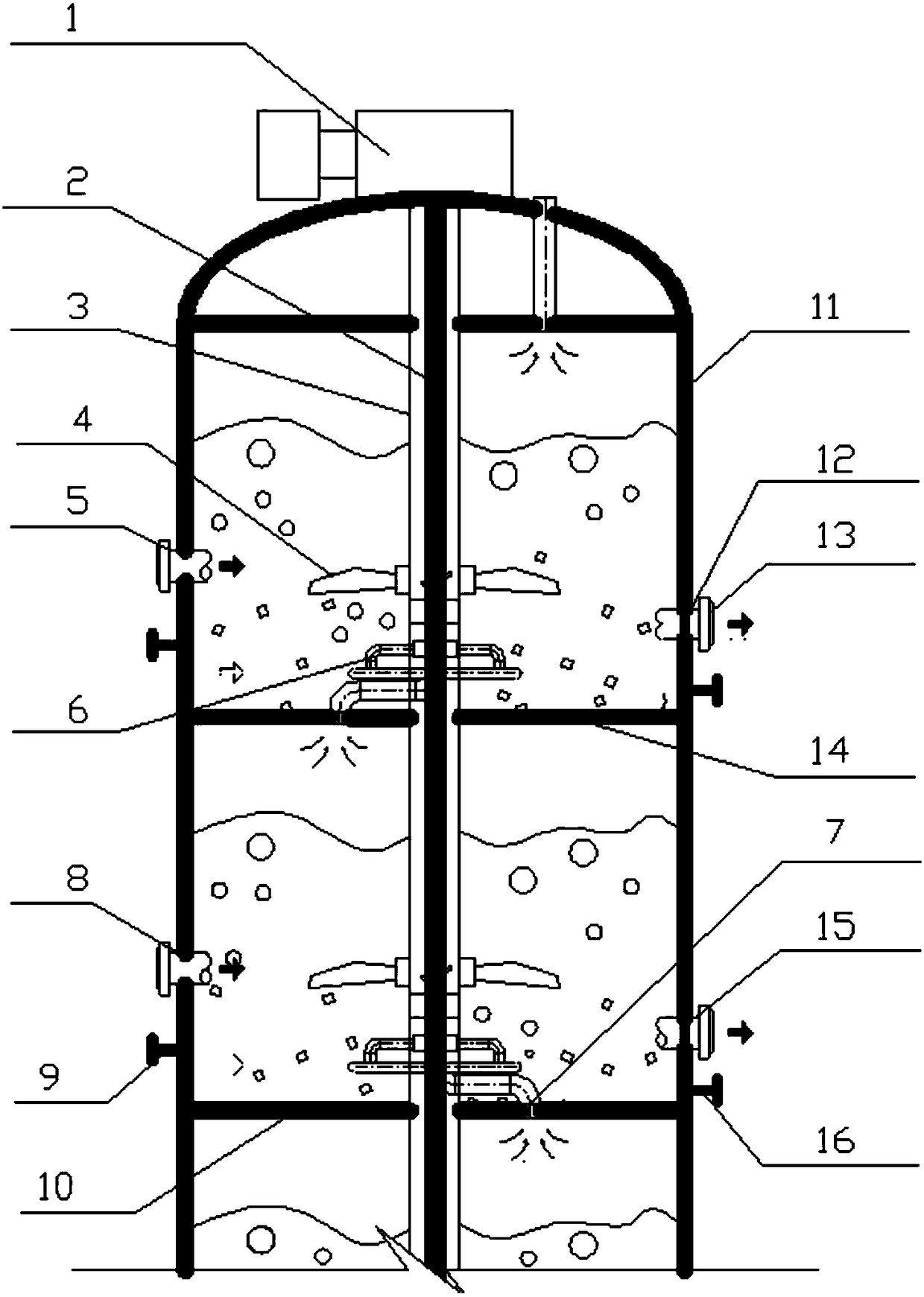

Novel long-shaft magnetic pump type reactor

ActiveCN108246222AWell mixedImprove the mixing effectPreparation by ester-hydroxy reactionEnergy based chemical/physical/physico-chemical processesGas phaseDistillation

The invention relates to a novel long-shaft magnetic pump type reactor and mainly solves the problem of uneven mixing of gas, liquid and solid in the prior art. The novel long-shaft magnetic pump typereactor is adopted, the reactor is penetrated through by 1-2 long shafts, the long shaft is wrapped by a long sleeve, a bearing is additionally added in the inner part of the long shaft, the shaft and the bearing are completely isolated from a medium on the outer side, a paddle soaked in the medium is coupled with the shaft through the principle of a magnetic pump, the stirring effect is achieved, a standpipe is distributed on each layer of column plate in the reactor, an air inlet of the standpipe is arranged on one side of the long shaft of the reactor, the upper part of the standpipe is connected with a gas distributor, the center of the gas distributor is arranged on the long shaft, a gas phase from the column plate on the lower layer is evenly sprayed into a liquid solid mixture on the column plate through the gas distributor, the technical scheme that each layer of the column plate is provided with liquid phase inlet and outlet facilities better solves the above problem, and thenovel long-shaft magnetic pump type reactor can be used in the catalytic reaction distillation of the gas-liquid-solid three phases.

Owner:SINOPEC SHANGHAI ENG +1

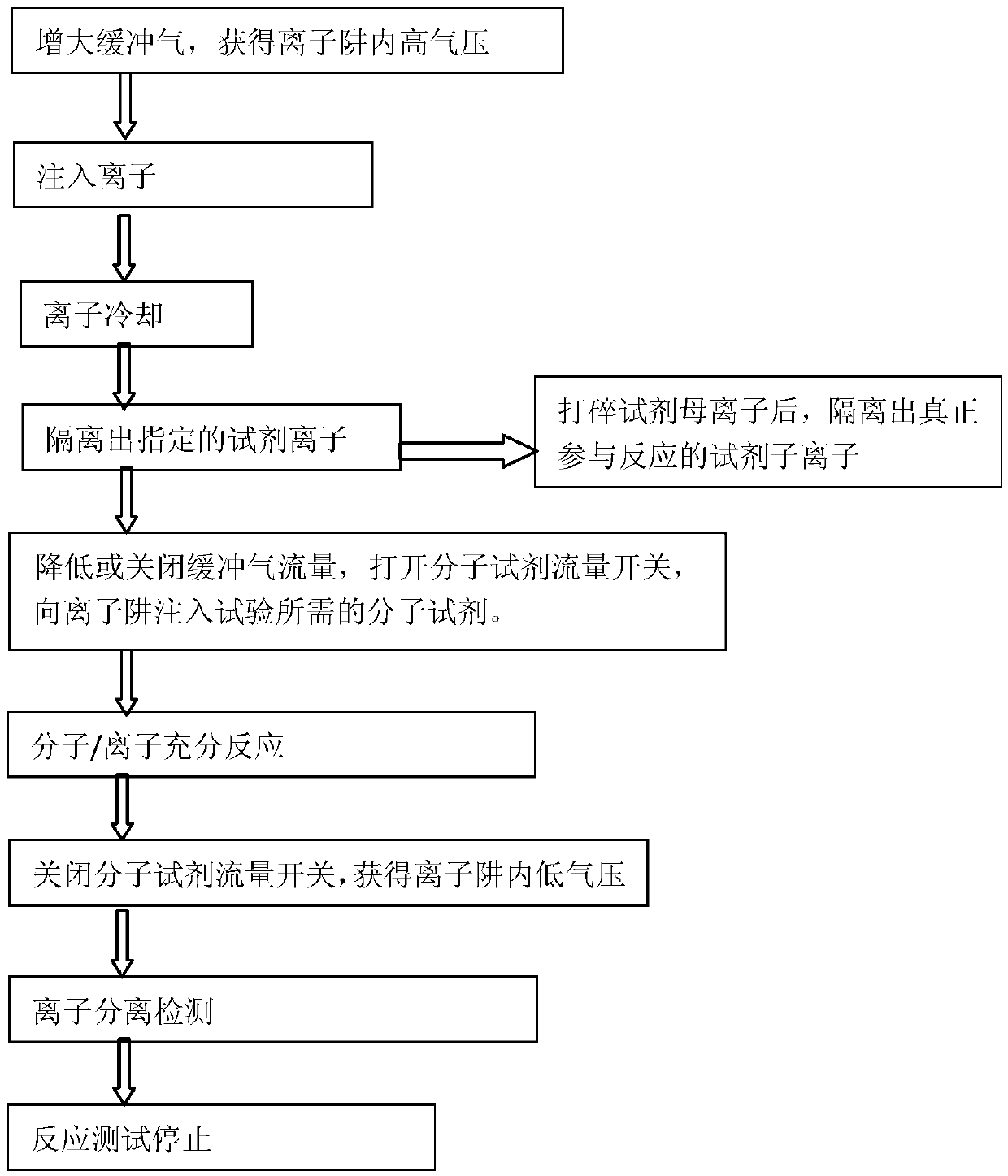

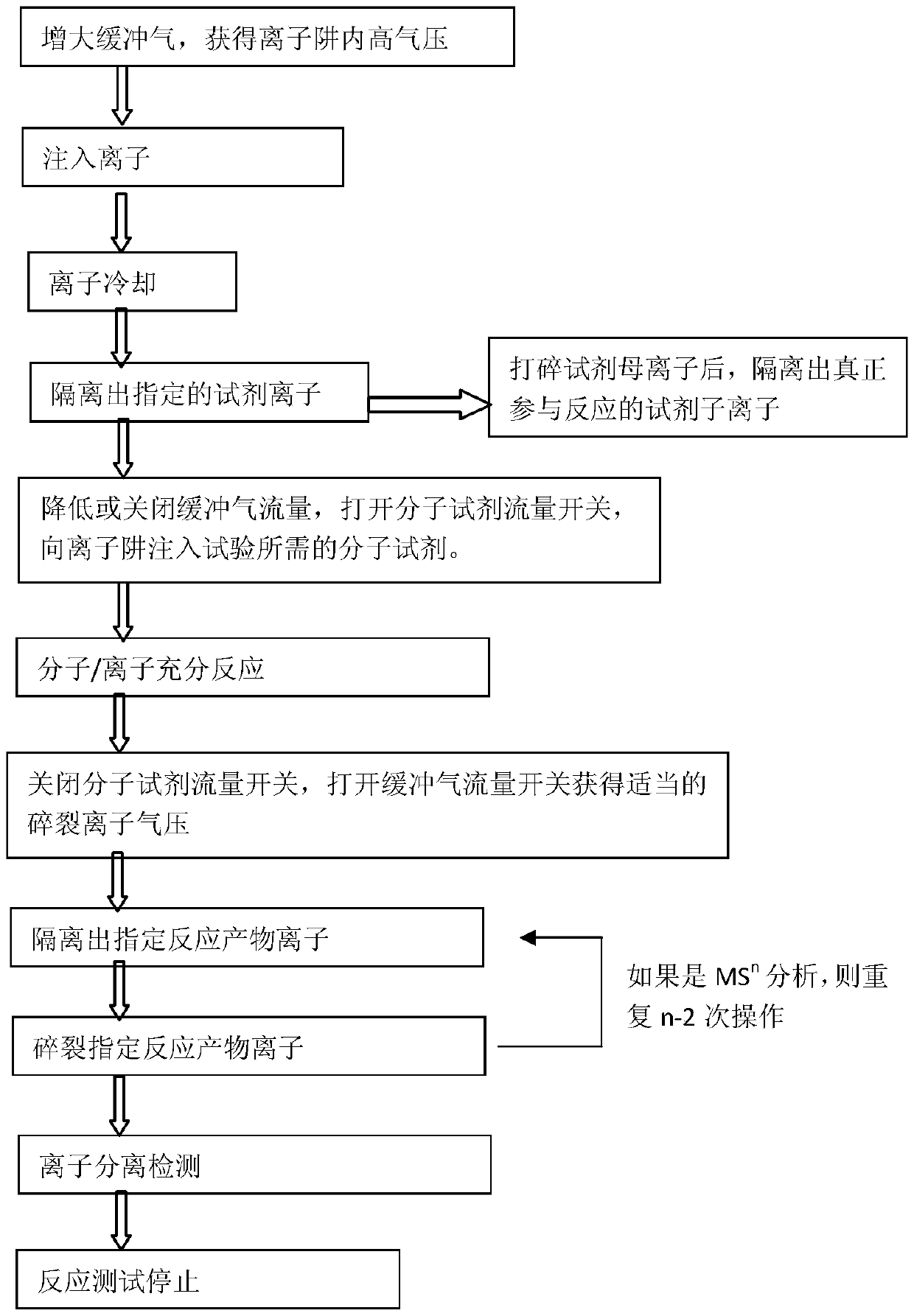

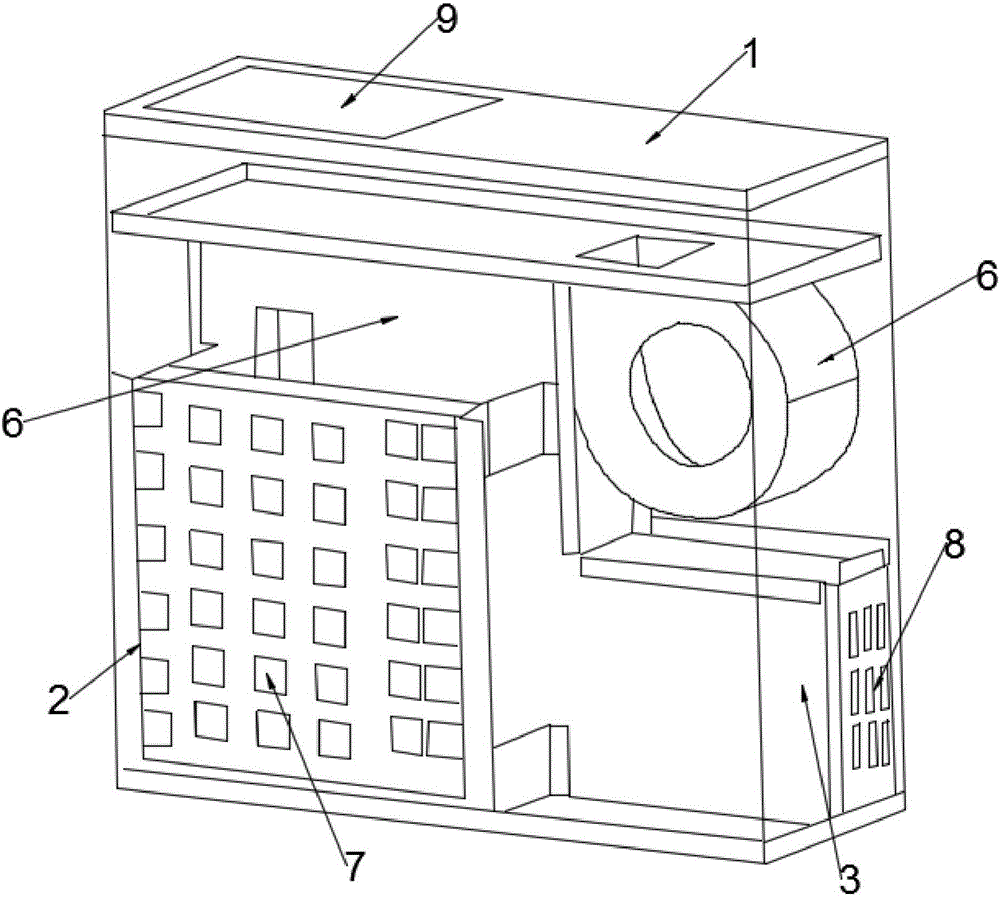

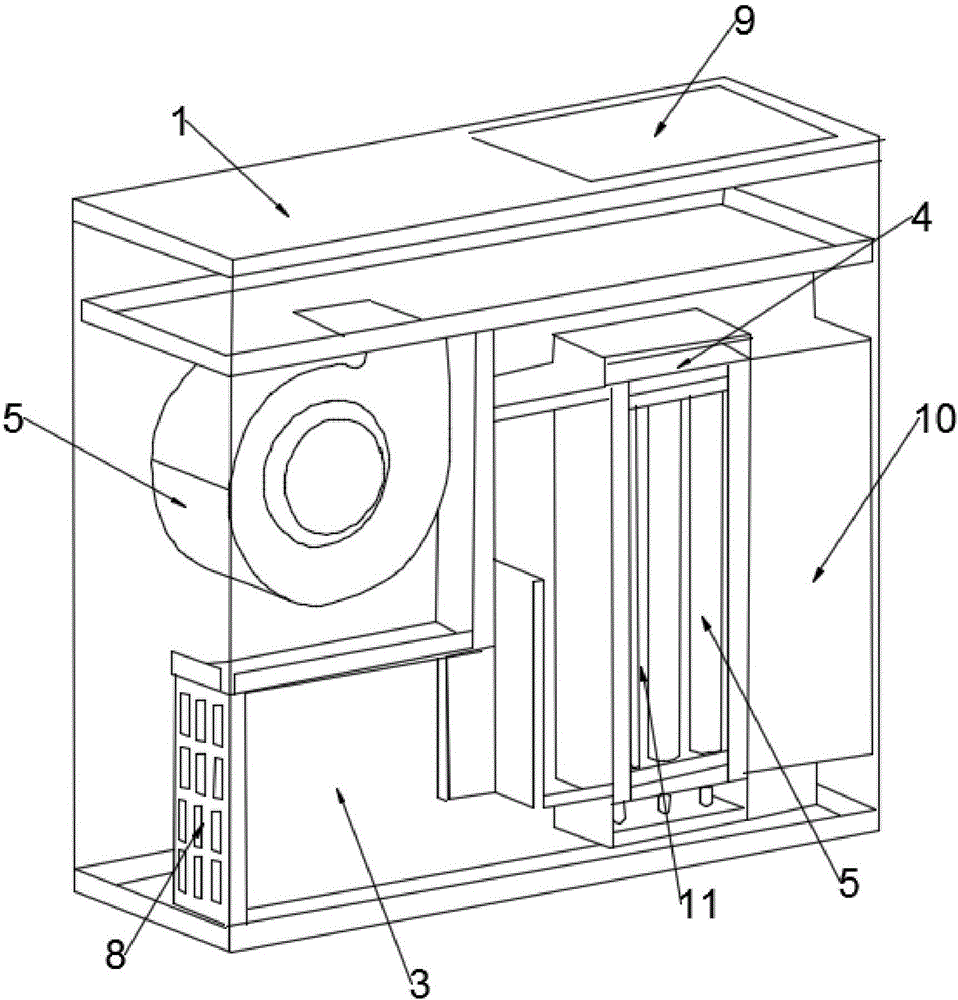

Efficient simple molecules/ions reaction mass spectrometry apparatus and operation method therefor

InactiveCN105551928APromote reaction efficiencyImprove responseParticle separator tube detailsControl systemMass Spectrometry-Mass Spectrometry

The invention provides an efficient simple molecules / ions reaction mass spectrometry apparatus and an operation method therefor. The efficient simple molecules / ions reaction mass spectrometry apparatus comprises a set of apparatuses, including an ion trap mass analyzer, an accurate control system for controlling reagent molecules to be introduced to the ion trap, an accurate control system for introducing buffer air flow, a vacuum gauge and an ion trap air pressure automatic regulation functional module. In addition, the invention also provides an operation method for the system for performing efficient molecules / ions reaction, and accurate measurement for molecules / ions reaction products.

Owner:NAT INST OF METROLOGY CHINA

Integrated photo-catalytic sterilization air refreshing device

InactiveCN106705265APromote reaction efficiencyImprove reaction efficiencyMechanical apparatusLighting and heating apparatusPhoto catalyticUltraviolet

The invention discloses an integrated photo-catalytic sterilization air refreshing device. The integrated photo-catalytic sterilization air refreshing device comprises a shell, filters, a reaction box, a power supply, an ultraviolet lamp tube and a fan, wherein the filter, the reaction box, the power supply, the ultraviolet lamp tube and the fan are mounted in the shell; a filler tube is mounted in the reaction box and is filled with titanium dioxide powder; the filters comprise a first primary filter, a second primary filter and a high-efficiency and low-resistance filter; a clean air outlet and a dirty air inlet are formed in the exterior of the shell. The integrated photo-catalytic sterilization air refreshing device is simple and convenient to use; through the adoption of the first primary filter, the second primary filter, the high-efficiency and low-resistance filter and the reaction box filled with titanium dioxide powder, spores, fungi, bacteria and viruses can be effectively killed; volatile oxides can be removed; titanium dioxide powder in the device is large in surface area, high in reaction efficiency and low in loss; the device is convenient to maintain; the overall device does not need to be integrally dismounted or replaced; only the filler tube needs to be replaced; the device is long in service life and excellent in using effect.

Owner:BEIJING JINHAOYUAN PURIFICATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com