Suspension polymerization method for polyvinyl chloride (PVC)

A technology of suspension polymerization and polyvinyl chloride, which is applied in the field of polymer synthesis, can solve the problems of large residual amount of dispersant, abnormal dispersion system, accumulation of dispersant, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

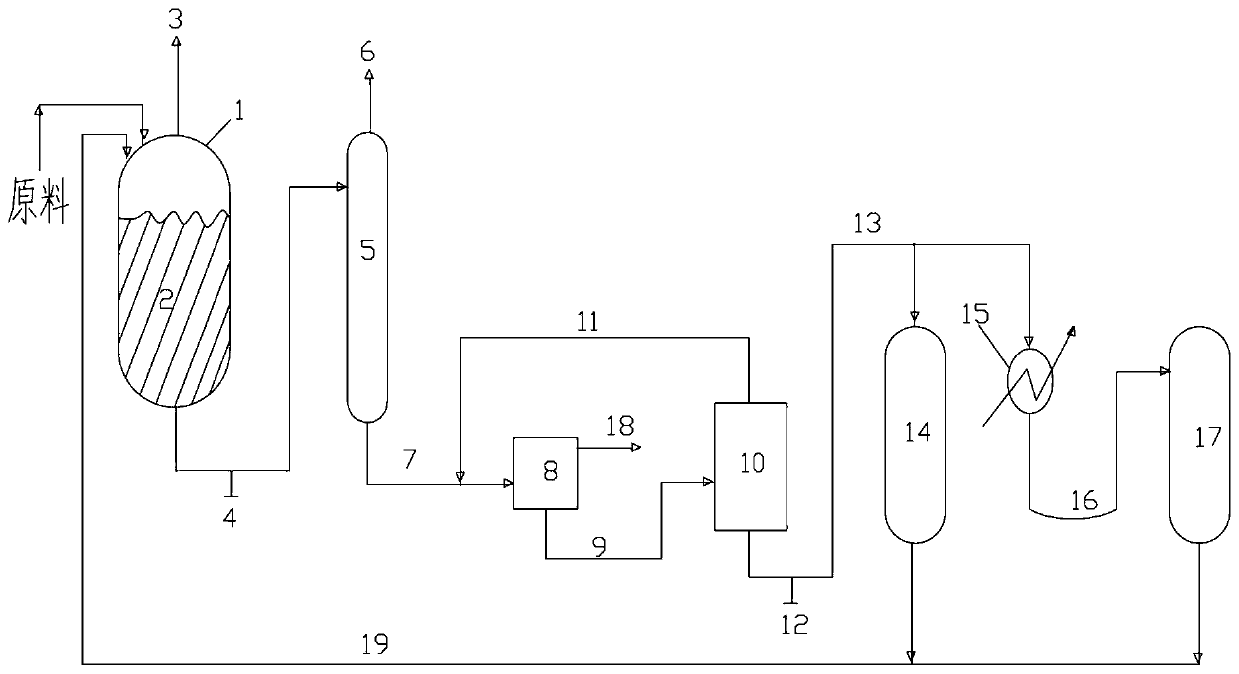

[0102] As a kind of embodiment of the present invention, polyvinyl chloride suspension polymerization method implementation process is as follows:

[0103] like figure 1 As shown in the process flow diagram, add vinyl chloride monomer, purified centrifuge mother liquor 19, other components and additives, including initiator, defoamer, buffer, dispersant and antioxidant, etc. Vinyl chloride suspension polymerization assistant. Polymerization is carried out at 35-75°C, preferably 45-70°C, to produce SG-1 to SG-8 polyvinyl chloride resins. When the target conversion is reached, the terminator is added. Blowdown and unreacted monomer recovery operations are then performed.

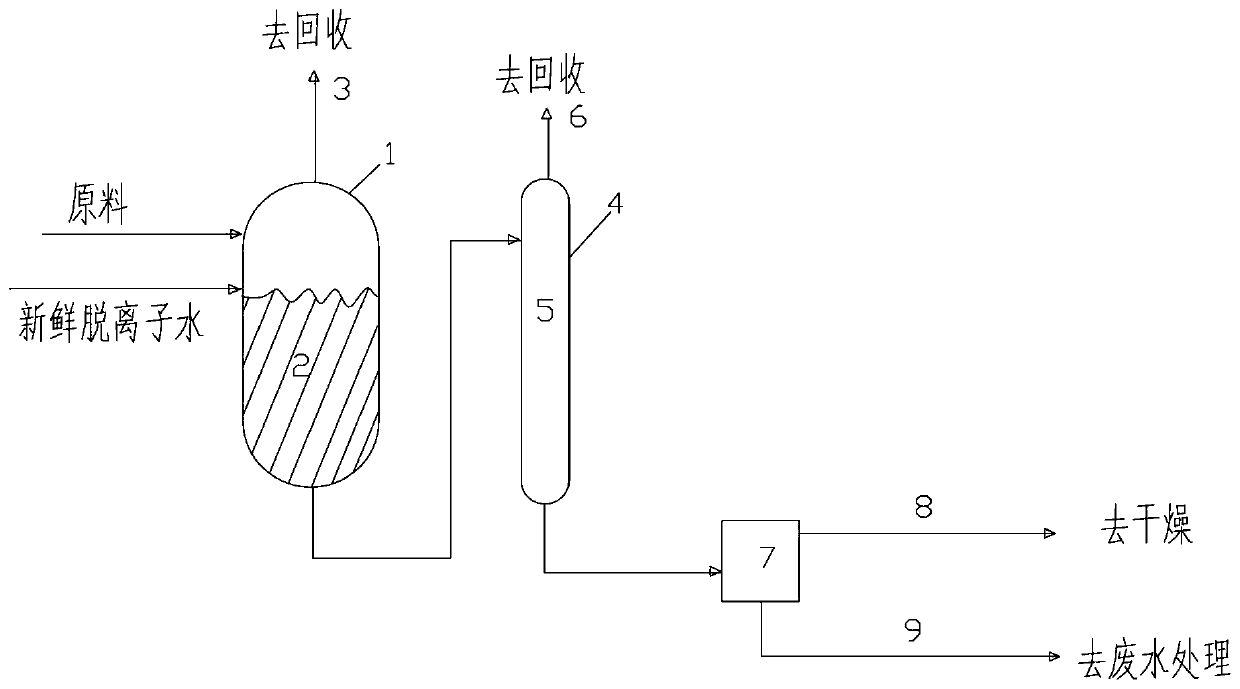

[0104] The unreacted monomer 3 in the polymerizer 1 is sent to the recovery system (not shown), the polymerized reaction mixture slurry 2 produced in the polymerizer 1 is sent to the stripper 5, and the unreacted monomer 6 is sent to the recovery system ( not shown), the degassed reaction mixture slurry 7 ...

Embodiment 1

[0109] Carry out polyvinyl chloride suspension polymerization with aforementioned polymerization flow process, wherein, polymerization monomer is vinyl chloride, and initiator is cumyl peroxyneodecanoate (CNP) and bis(2-ethylhexyl) peroxydicarbonate ( EHP), the dispersant is Japanese Kuraray polyvinyl alcohol PVA-224E and L-10 and hydroxypropyl methylcellulose (HPMC), and suspension polymerization is carried out at a polymerization temperature of 57°C to produce SG-5 polyvinyl chloride resin. The amount of addition of each material is listed in Table 1. When the target conversion rate is reached, a terminator is added to end the current round of polymerization, and then discharge and unreacted monomer recovery operations are performed.

[0110] like figure 1 As shown in the process flow diagram, the slurry with a solid content of about 20% is pumped into the mixing tank (not shown) from the bottom of the stripping tower, and then pumped into the centrifuge from the mixing tan...

experiment example 1

[0126] Experimental example 1 centrifuge mother liquor stability test

[0127] The quality of the filtered centrifuged mother liquor was monitored, and the results are listed in Table 2. From the test results of various indicators of the centrifuged mother liquor in Table 2, it was found that after repeated use of multiple batches, the test data of each index of the centrifuged mother liquor basically remained unchanged, indicating that the reuse stability of the centrifuged mother liquor was good.

[0128] Wherein, the concentration of the polymerization inhibitory component adopts the titration analysis method among the present invention to measure; The solid content before and after filtration adopts the gravimetric method to measure, specifically as follows:

[0129] (1) Required instruments and equipment: vacuum pump, Buchner funnel, suction filter bottle, oven, analytical balance, etc.

[0130] (2) Step: Dry the filter paper (permeate pore size ≤ 0.1 μm) in an oven at 5...

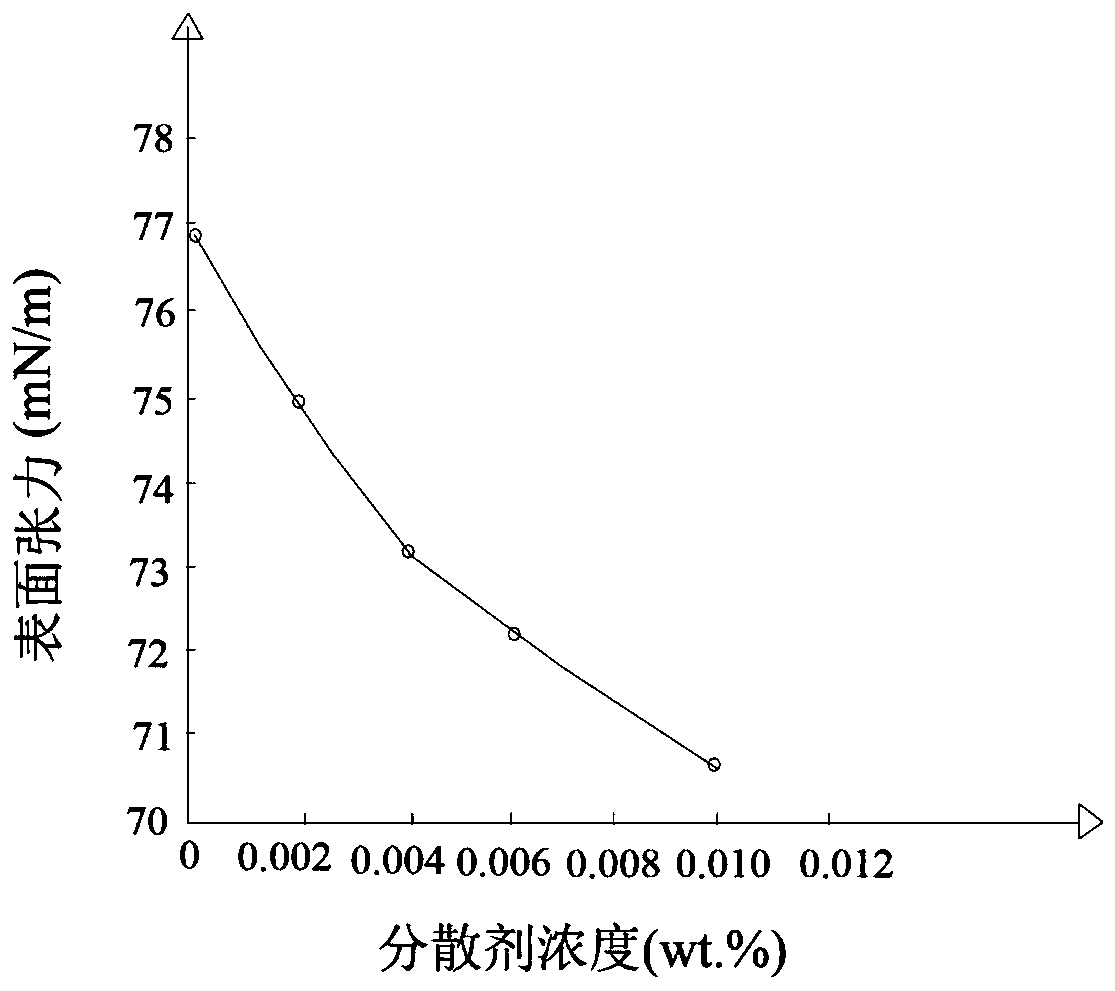

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com