Patents

Literature

102 results about "Diethylhydroxylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diethylhydroxylamine (DEHA) is an organic compound with the formula (C₂H₅)₂NOH. It is a colorless liquid, although it is usually encountered as a solution. It is mainly used as an oxygen scavenger in water treatment.

Fenton and Fenton-like system fortifier and using method thereof

ActiveCN101792205AReduce dosageEasy to useWater treatment parameter controlWater treatment compoundsSulfite saltHydrazine compound

The invention provides a Fenton and Fenton-like system fortifier and a using method thereof, which relate to a water treating fortifier and a using method thereof and overcomes the defects that the pH value of the Fenton and Fenton-like system reaction water body is limited, the adding amount of Fe<2+> is overhigh in the Fenton reaction, and the reaction speed is low in Fenton-like reaction. The fortifier is selected from ascorbic acid, sodium sulfite, lithium sulfite, potassium sulfite, magnesium sulfite, calcium sulfite, hydroxylamine, hydroxyl-ammonium perchlorate, hydroxylamine sulfate, hydrazine, N,N-diethylhydroxylamine, carbohydrazide, ethanolamine, a hydroxylamine solution or N,N,N',N'-tetra substituted phenylenediamines. The using method has the following steps of: adding the Fenton and Fenton-like system fortifier, fortificated chemicals and peroxide into the treated water body; and then, uniformly stirring to react. The fortifier can accelerate the reaction of water treatment and decrease the using amount of the fortificated chemicals.

Owner:HARBIN INST OF TECH

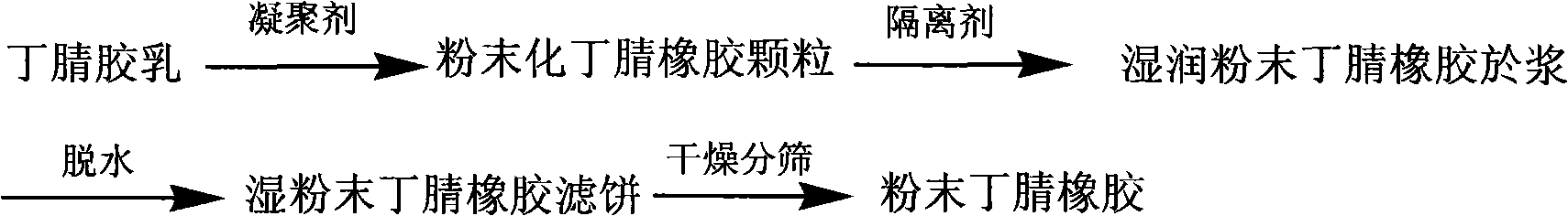

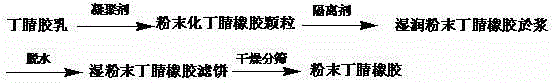

Method for producing cross-linking powder nitrile-butadiene rubber with medium and high nitrile content

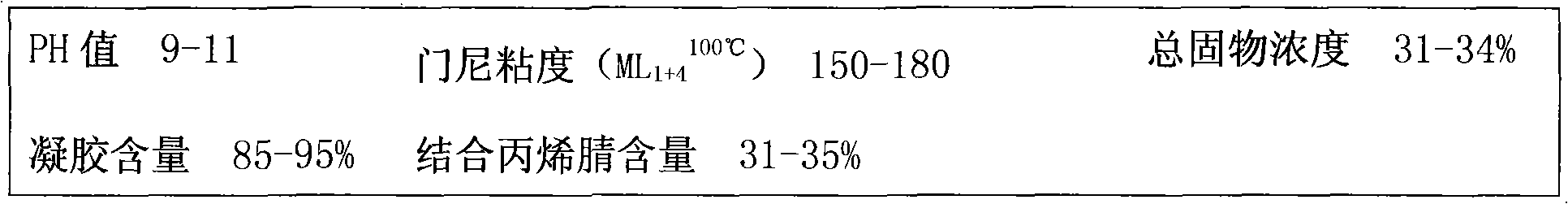

The invention relates to a method for producing cross-linking powder nitrile-butadiene rubber with medium and high nitrile content; the method comprises the steps of synthesizing nitrile-butadiene rubber slurry, then flocculating the nitrile-butadiene rubber slurry followed by separating and powdering, and dehydrating and drying. In the stage of polymerization reaction, potassium carbonate is added to be a buffering agent of the reaction, and the mixed liquor of diethylhydroxylamine, hydroxylamine sulphate, potassium hydroxide and soft water is used as a composite terminator; in the stage of separating and powdering, WSL and DLTP are added to be an antiager, and univalent sodium salt and bivalent magnesium salt or univalent sodium salt or bivalent calcium salt are taken as a flocculant forcarrying out flocculating, separating and powdering on the nitrile-butadiene rubber slurry at 30-75 DEG C. The invention is simple in production technique, easy for operation, low in production cost,less in energy consumption and high in conversion rate which can be more than 95%; a novel composite terminator is adopted, so that mooney is stable and termination effect is good; the rubber powderis finer, and dispersity during processing is improved; and the heat-resistant quality of the product is very good, the wear resistance is good, and the invention can satisfy the requirement on application in high friction composite brake shoes of trains.

Owner:HUANGSHAN HUALAN TECH

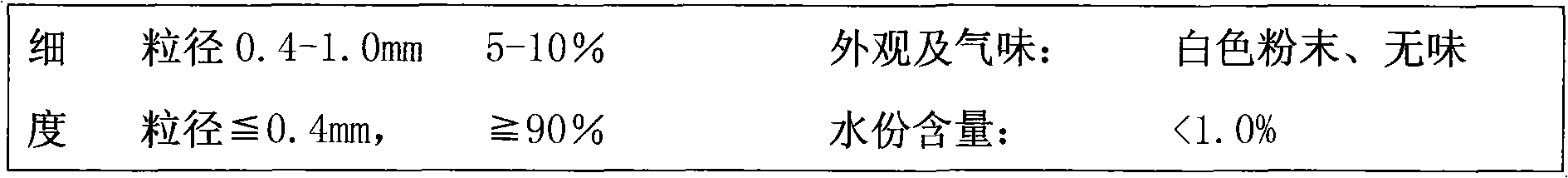

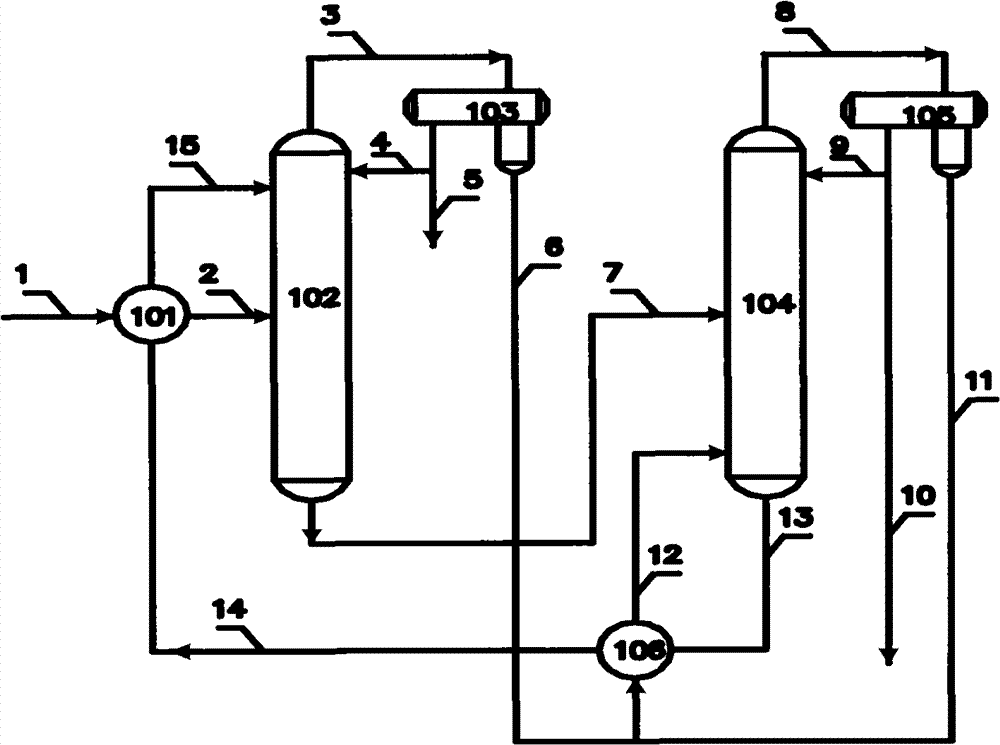

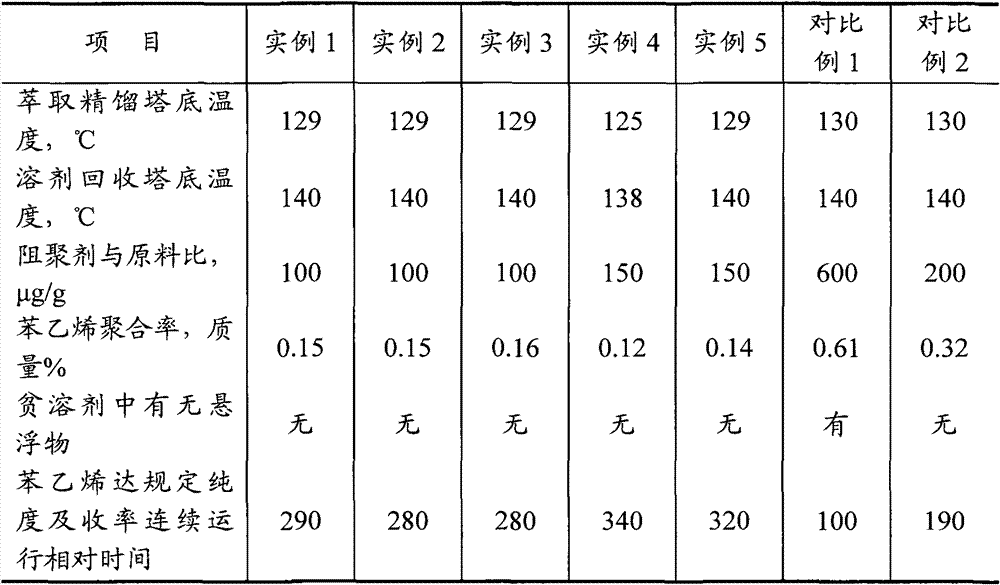

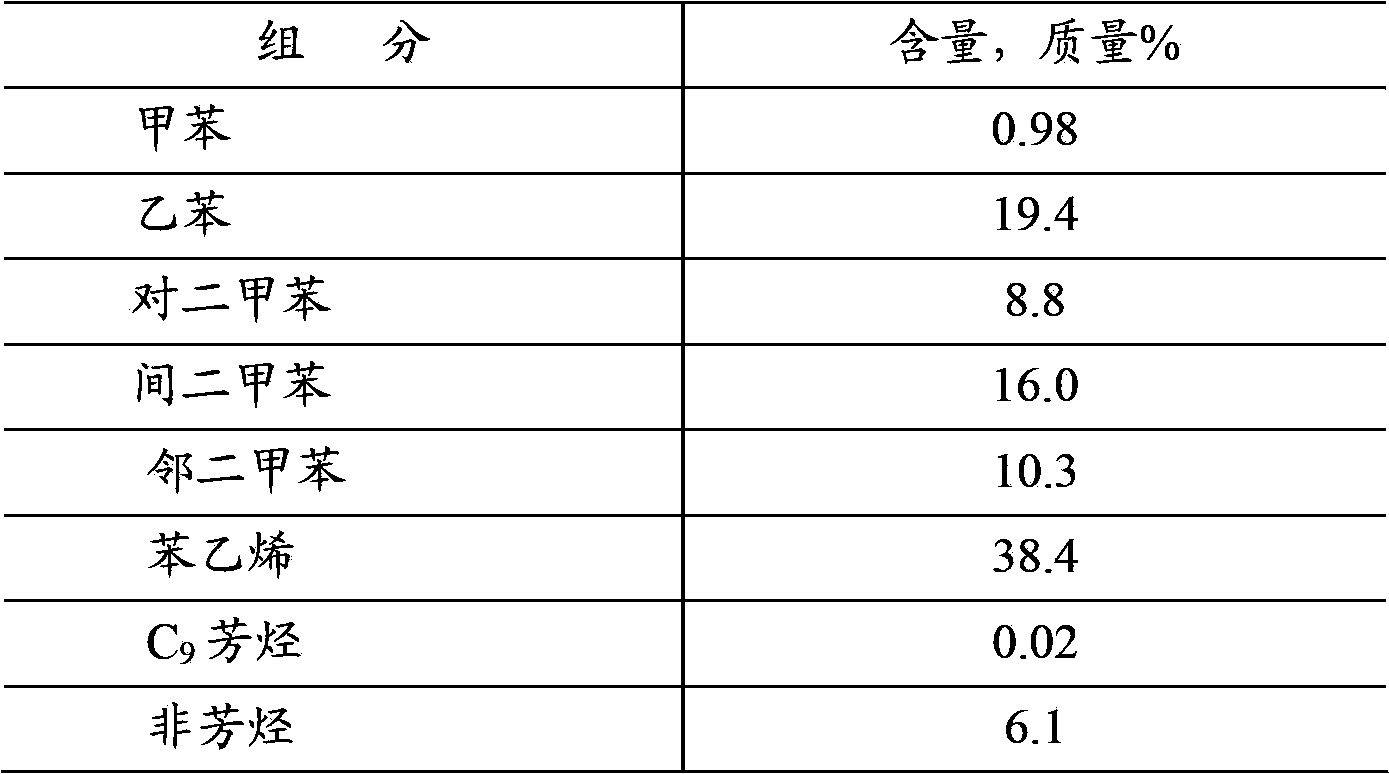

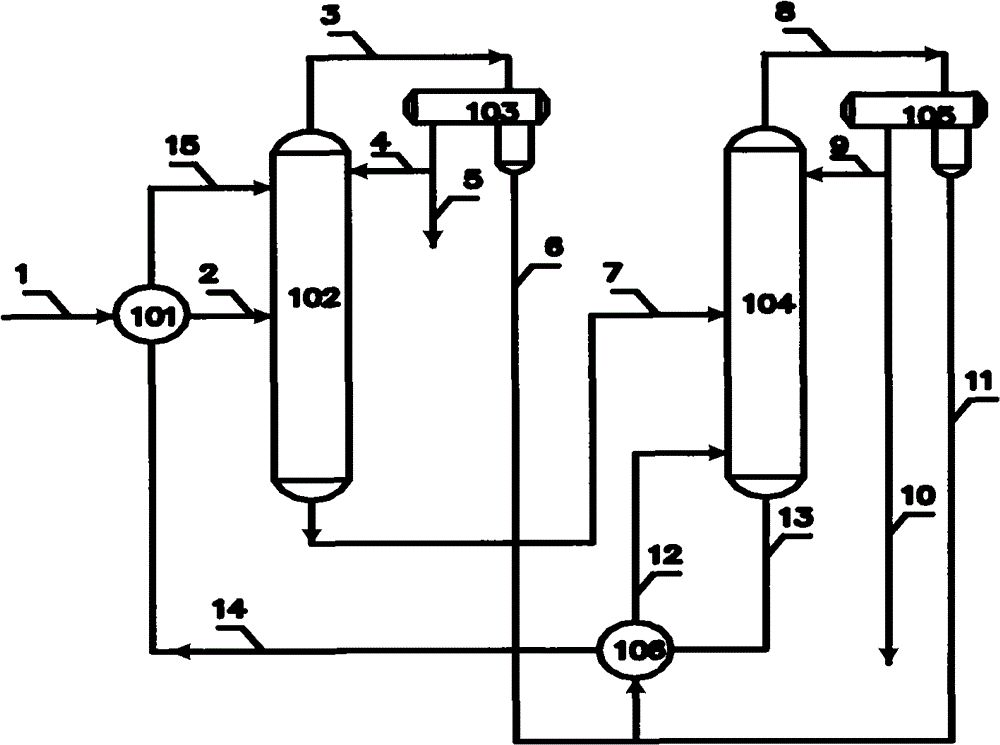

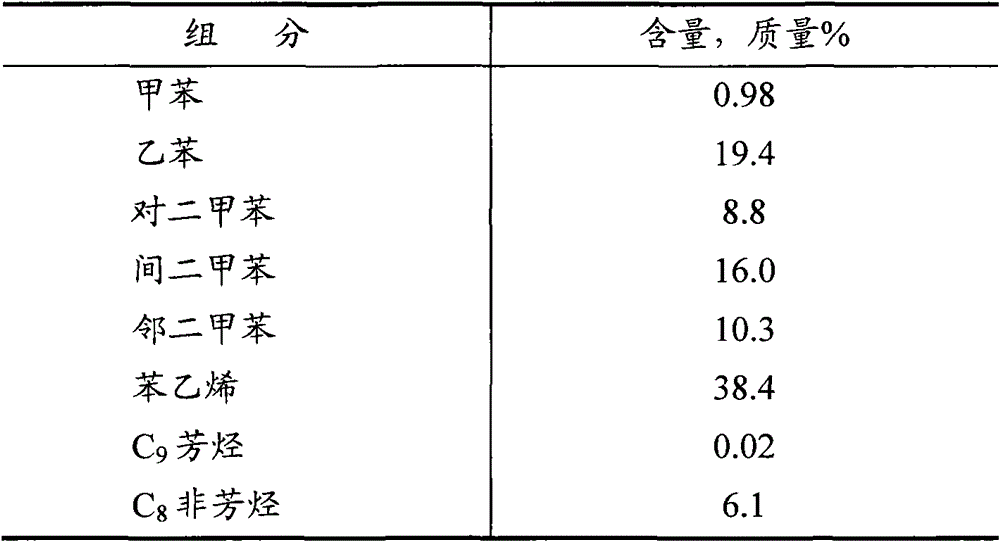

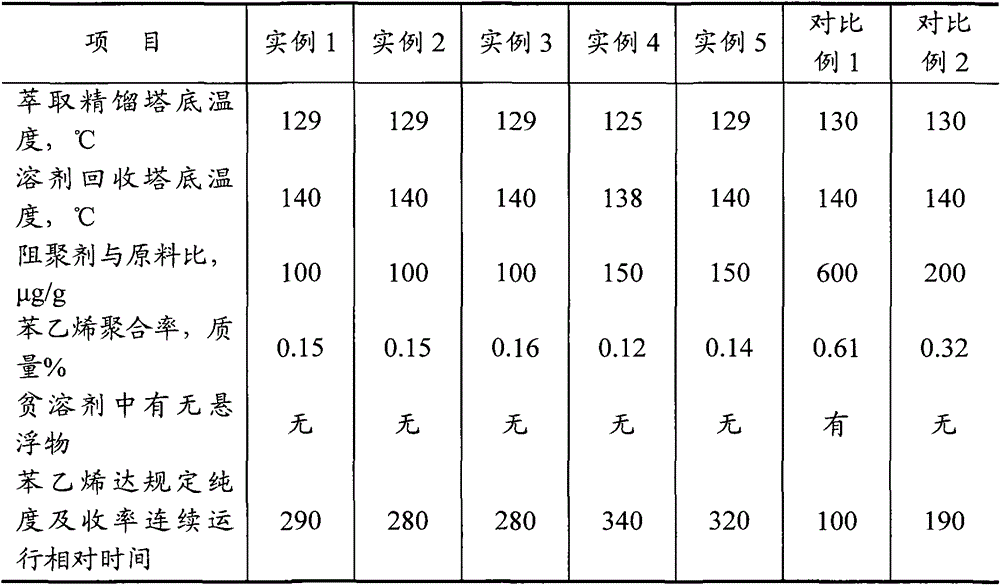

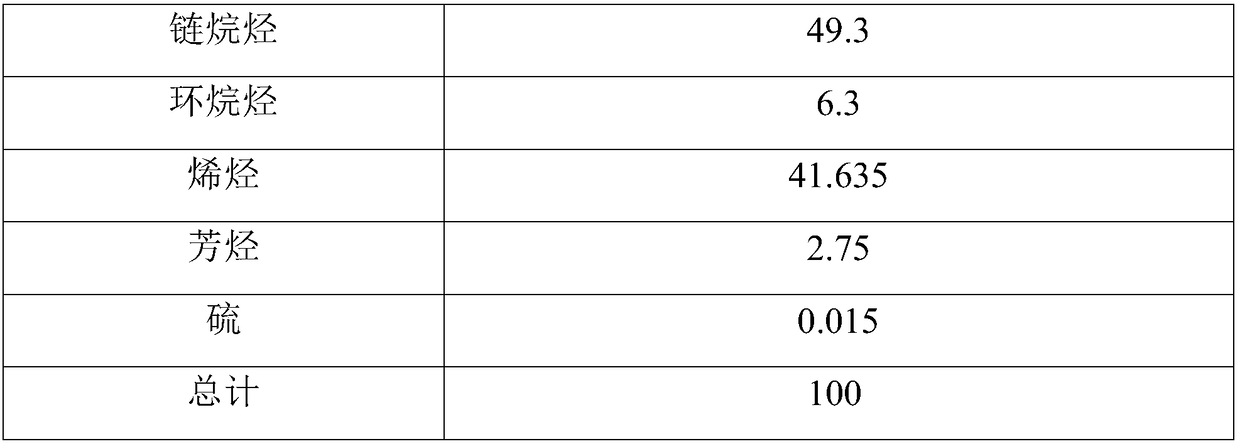

Method for extracting, distilling and recovering styrene from hydrocarbon mixture

ActiveCN103360201APrevent precipitationGood inhibition effectDistillation purification/separationHydroxylamineHydrocarbon mixtures

The invention relates to a method for extracting, distilling and recovering styrene from a hydrocarbon mixture. The method comprises the following steps of: extracting, distilling and recovering the styrene from the hydrocarbon mixture by using a composite solvent in the presence of a polymerization inhibitor. The composite solvent comprises 80-99% by mass of a main solvent, 0.01-19% by mass of an auxiliary solvent and 0.1-2.0% by mass of water, wherein the main solvent is a sulfone compound, and the auxiliary solvent is metoxyphenol or the mixture of the metoxyphenol and the glycol monomethyl ether. The polymerization inhibitor comprises 40-80% by mass of free radicals of nitrogen and oxygen, 15-50% by mass of nitro-phenol and derivatives thereof and 5-30% by mass of N, N-diethyl hydroxylamine. The use amount of the polymerization inhibitor is 10-500mug / g of the amount of the hydrocarbon raw material. Because the composite solvent is used together with the polymerization inhibitor, the use amount of the polymerization inhibitor can be decreased, and the rate of polymerization of the styrene can be reduced significantly.

Owner:CHINA PETROLEUM & CHEM CORP +1

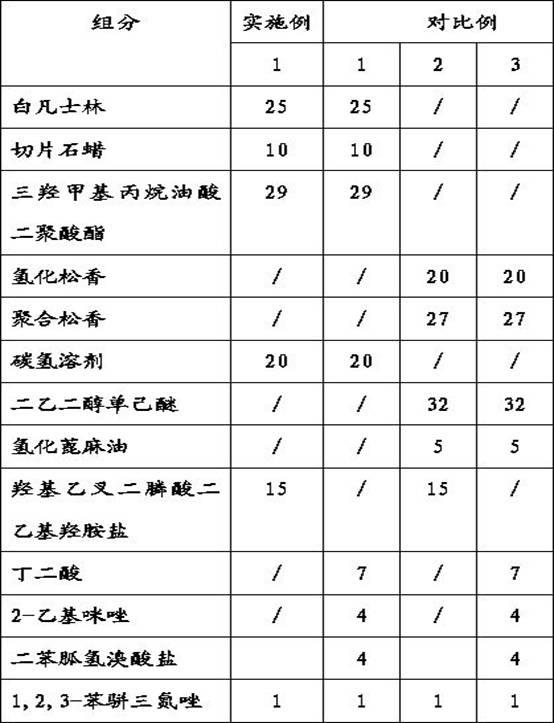

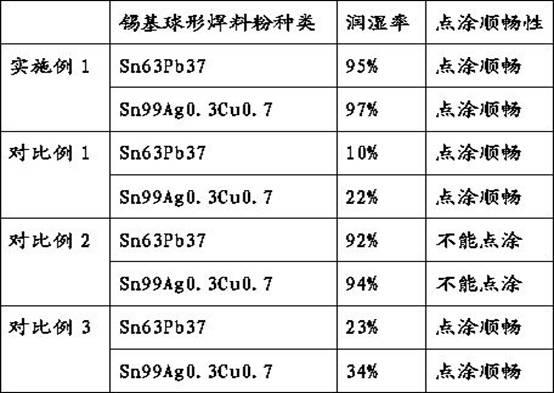

Paste welding combination and preparation method and application thereof

ActiveCN102513736ALow viscosityRapid heat welding processWelding/cutting media/materialsSoldering mediaO-Phosphoric AcidHydroxylamine

The invention provides a paste welding combination and a preparation method and application thereof. The paste welding combination contains the following components according to percentage by weight: 10-14% of white Vaseline, 5-20% of sliced paraffin, 5-30% of trimethylolpropane oleic acid dimeric esters, 5-40% of hydrocarbon solvent, 2-20% of salt activator and 0.05-5% of corrosion inhibitor. The salt activator is the salt formed through neutralization reaction of organic phosphoric acid and diethyl hydroxylamine. The preparation method of the paste welding combination includes the following steps: preparing white Vaseline, sliced paraffin and trimethylolpropane oleic acid dimeric esters in proportion, heating to be clear solution, then cooling to paste, mixing the paste with the salt activator and the corrosion inhibitor, grinding and obtaining the paste welding combination. The combination and tin-based soft solder alloy powder can be combined to be further made into soldering paste. The paste welding combination has the advantages of being strong in weld-aid activity, long in storage period and capable of being spread on a point. The preparation method and application thereof are suitable for rapid heating welding of a plurality of metal materials.

Owner:厦门市及时雨焊料有限公司

Water-soluble styrene polymerization inhibitor

ActiveCN103467230AHigh inhibition efficiencyLow boiling pointHydrocarbon purification/separationHydrocarbonsHydroxylamineOrganic solvent

The invention discloses a water-soluble styrene polymerization inhibitor, comprising a free radical or a derivative thereof, an amine substance, an anti-oxidant, a reducing agent, a dispersant and water in a mass ratio of 40-90: 0-50: 0-10: 0-15: 0-10, wherein the ratio of the total mass of the free radical or the derivative thereof, the amine substance, the anti-oxidant, the reducing agent and the dispersant to the water is 1: 1-9, and the amine substance is one selected from the group consisting of diethylhydroxylamine, diisopropylhydroxylamine, hydroxylamine hydrochloride, morpholine hydroxylamine, N-isopropylhydroxylamine, N,N-dialkylhydroxylamine and N,N-dihydroxyalkylhydroxylamine or a mixture of more than two selected from the group in any ratio. The polymerization inhibitor provided by the invention has the advantages of low consumption, high efficiency, reduction in usage of organic solvents posing harm to the environment and human bodies, high polymerization inhibition efficiency and a low addition amount.

Owner:金浦新材料股份有限公司

Polymerization inhibitor for preventing self-polymerization or co-polymerization of C5 diolefins

InactiveCN1699311AGood inhibition effectHydrocarbon purification/separationHydrocarbonsButylphthalideComposition B

The invention relates to a polymerization inhibitor for preventing self-polymerization or co-polymerization of C5 diolefins, which comprises composition A: diethylhydroxylamine, composition B: tert-butyl pyrocatechol, and solvent, wherein the solvent is selected from benzene, toluene, dimethylbenzene or ethylbenzene, the weight ratio of the composition A and the composition B being (0.5-6):1, the total content of the composition A and the composition B in the polymerization inhibitor being 25-45wt%. Compared with the prior art, the invention can realize better polymerization inhibiting effect, and no extra separation process is needed in the current C5 distillate separation procedure.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Process for preventing self-polymerization or co-polymerization of C5 diolefins in separation process of petroleum C5 distillate

InactiveCN1699310AGood inhibition effectHydrocarbon purification/separationHydrocarbonsComposition BButylphthalide

The invention provides a process for preventing self-polymerization or co-polymerization of C5 diolefins in separation process of petroleum C5 distillate, which consists of charging polymerization inhibitor into C5 distillate material, and making the polymerization inhibitor maintain a finite amount in the C5 distillate material, the polymerization inhibitor comprises composition A: diethylhydroxylamine, and composition B: tert-butyl pyrocatechol, the weight ratio of the composition A and the composition B being (0.5-6):1, the quantity of polymerization inhibitor in the C5 distillate material is sustained at 30-600ppm calculated on the total amount of the composition A and the composition B. The invention can realize better polymerization inhibiting effect, and no extra separation process is needed in the current C5 distillate separation procedure.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD +1

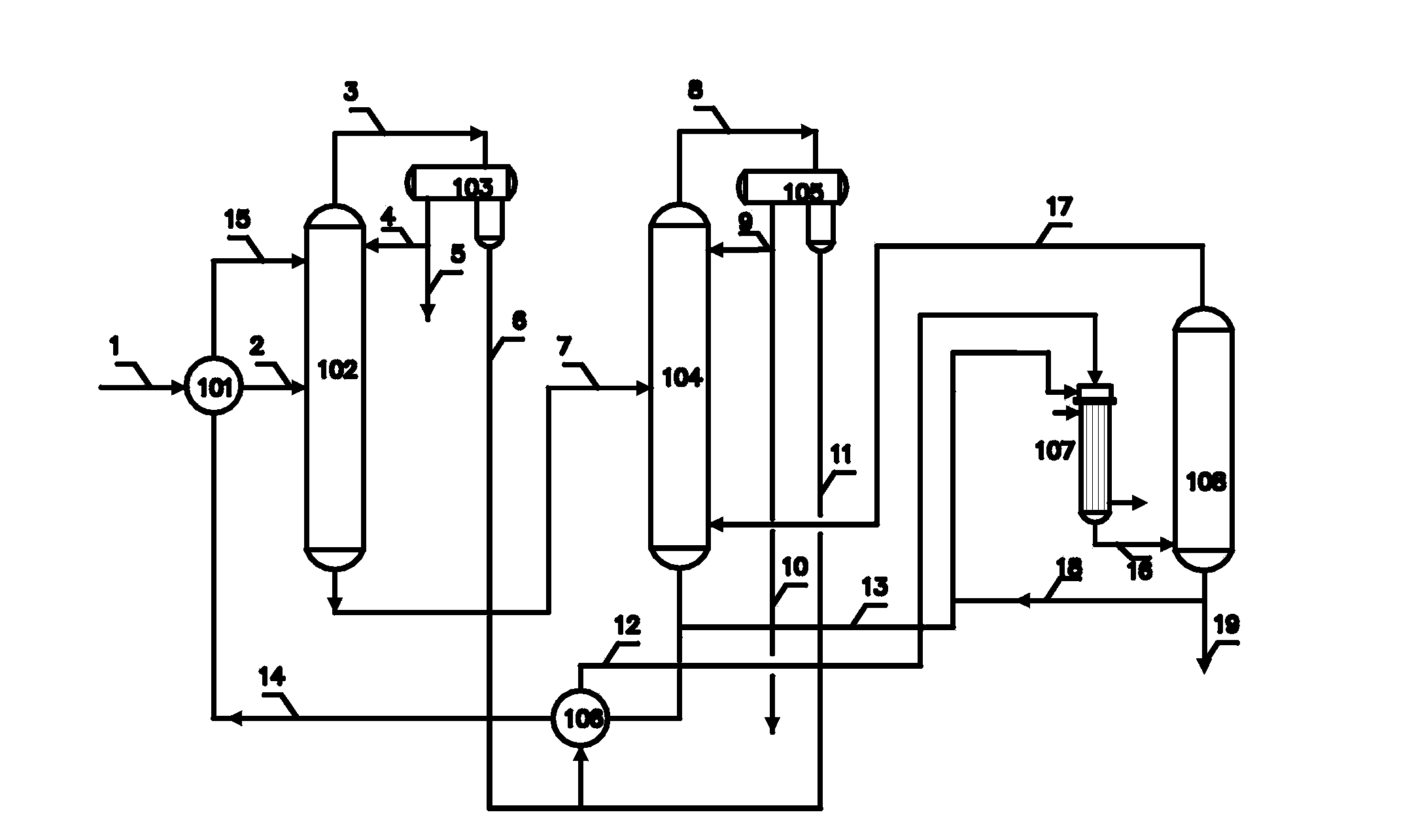

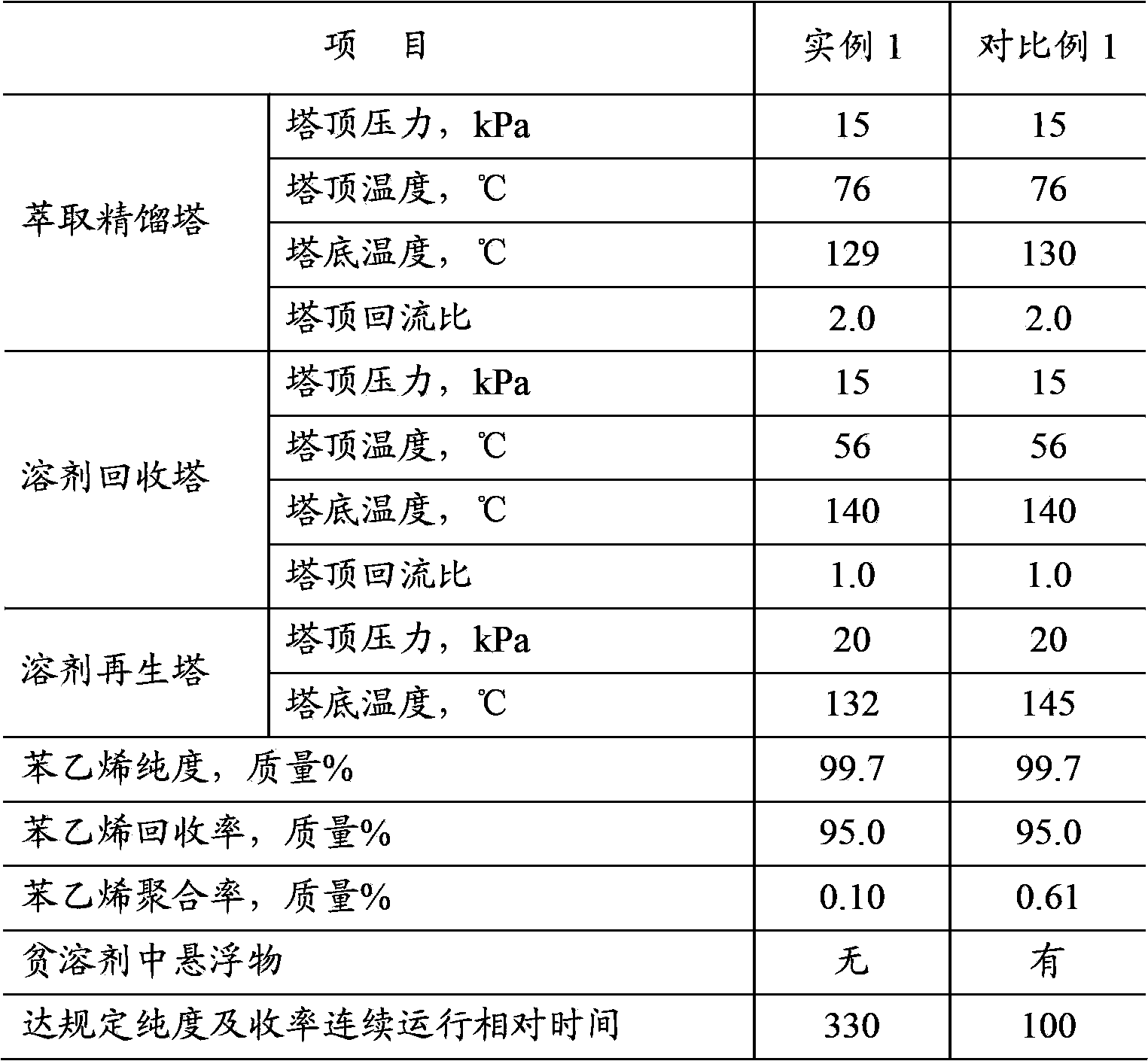

Method for separating styrene from hydrocarbon mixture by extractive distillation

ActiveCN103664498AReduce the probability of aggregationInhibit aggregationDistillation purification/separationHydrocarbon mixturesExtractive distillation

The invention discloses a method for separating styrene from a hydrocarbon mixture by extractive distillation. The method comprises the following steps: performing extractive distillation on the hydrocarbon mixture with a compound solvent in the presence of a polymerization inhibitor; after extractive distillation, feeding a styrene-containing rich solvent into a solvent recovery tower, and separating styrene and a compound lean solvent out; removing high-boiling-point impurities from a part of the compound lean solvent with a falling film evaporation method to regenerate the solvent; feeding the regenerated compound lean solvent into the solvent recovery tower once again, wherein the compound solvent comprises 80-99 mass percent of a major solvent, 0.01-19 mass percent of a cosolvent and 0.1-2.0 mass percent of water; the major solvent is selected from sulfone compounds; the cosolvent is selected from metoxyphenol and / or ethylene glycol monomethyl ether; the polymerization inhibitor contains 10-60 mass percent of free radicals of nitroxide, 30-70 mass percent of nitrophenol and derivatives thereof, and 5-35 mass percent of N,N-diethylhydroxylamine. Through the method, the polymerization of styrene in an extractive distillation process can be reduced to the maximum extent, and the stable running period of an extractive distillation device is effectively prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

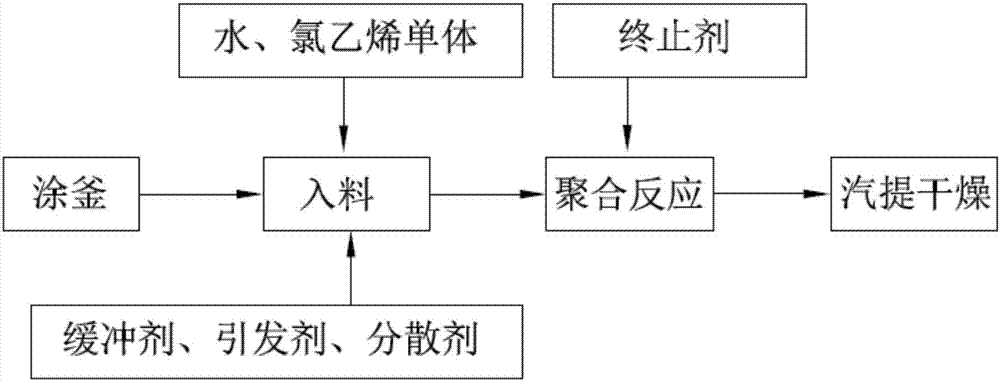

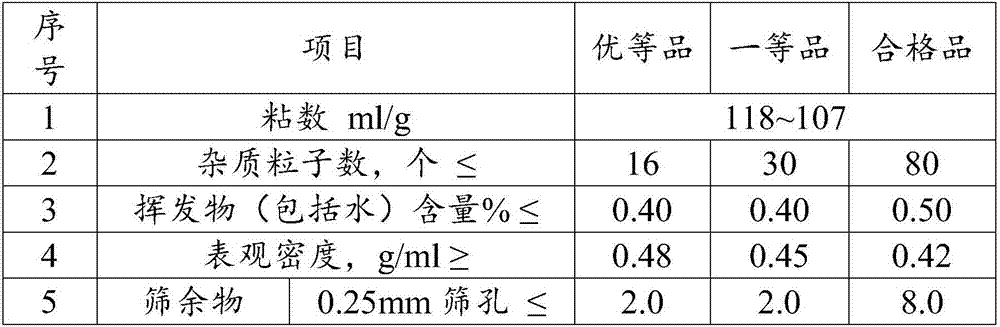

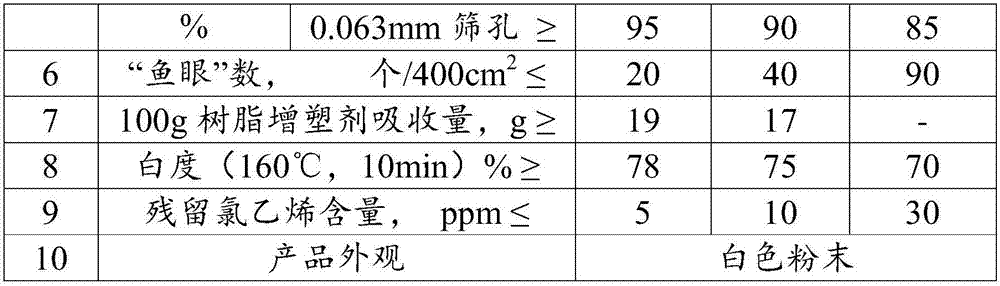

High-whiteness polyvinyl chloride resin and preparation method thereof

The invention discloses a preparation method of high-whiteness polyvinyl chloride resin. The preparation method comprises the following steps: 1, adding a vinyl chloride monomer, an initiator, a dispersant and water into a polymerization kettle, beginning a polymerization reaction and performing timing, 2, measuring a pressure drop in the polymerization kettle when the polymerization reaction time reaches 230-250 min, and adding a diethylhydroxylamine compound terminator to terminate the polymerization reaction to obtain polyvinyl chloride slurry when the pressure drop in the polymerization kettle reaches a set value or the polymerization reaction time reaches 440-460 min, and 3, performing steam stripping and drying on the polyvinyl chloride slurry obtained in Step 2 to obtain the polyvinyl chloride resin. According to the high-whiteness polyvinyl chloride resin and the preparation method of the polyvinyl chloride resin, the whiteness of the polyvinyl chloride resin is higher, stable between 88 and 91, considerably higher than an industrial standard, and very competitive; the thermal stability time is stable between 173 s and 188 s by detection; the thermal stability is excellent.

Owner:ЦИНХАЙ СОЛТ ЛЕЙК ИНДАСТРИ ГРУП КО ЛТД

Method for preparing gamma-chloropropyl trichlorosilane by multicomponent compound catalysis

InactiveCN101624398AHigh product contentQuality improvementSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydroxylamineDistillation

The invention discloses a method for preparing gamma-chloropropyl trichlorosilane by multicomponent compound catalysis, which adopts trichlorosilane and chloropropene as main raw materials to synthesize the gamma-chloropropyl trichlorosilane; besides chloroplatinic acid is taken as main catalyst, the reaction system is also added with alicyclic amine and phenylene diamines compound which are taken as cocatalyst, triisopropanolamine and 2, 4-pentandione that are taken as activator, as well as resorcinol and diethyl hydroxylamine that are used as inhibitor; after hydrosilylation, the finished product is obtained by distillation and rectification. The method can greatly increase the content of the produced product, improve the appearance of the product, reduce impurities of the product, improve the quality of the product and lower the production cost.

Owner:青岛中科荣达新材料有限公司

Method for removing iron deposits from within closed loop systems

Diethylhydroxylamine (DEHA) and di-isopropylhydroxylamine can be used to remove iron deposits from the surfaces of closed loop systems. A closed loop system can be cleaned of iron deposits by first contacting the surface of the closed loop system having iron deposits with an aqueous solution of an oxygen scavenger; and then introducing diethylhydroxylamine, di-isopropylhydroxylamine, or mixtures thereof; into the closed loop system at a concentration sufficient to cause the iron deposits to release from the surface of the closed loop system. It can be desirable to use a filter or strainer to trap and remove the particulate iron deposits once they have been released from the surface of the closed loop system. In the alternative, a dispersant can be used to prevent released particulate iron deposits from reforming as scale.

Owner:BAKER HUGHES INC

Method for synthesizing di-[propyltriethoxysilane]-tetrasulfide

InactiveCN101885734AImprove stabilityIncrease contentSilicon organic compoundsHydroxylamineDistillation

The invention discloses a method for synthesizing di-[propyltriethoxysilane]-tetrasulfide, which comprises the following steps of: (1) mixing and stirring water, sodium sulfide, sodium hyposulfate, elemental sulfur and diethyl hydroxylamine, pumping n-amylamine and isobutylamine into the mixture under the vacuum degree of 0.04 to 0.06MPa, and reacting the mixture for 20 to 40 minutes at the temperature of between 30 and 50 DEG C; (2) adding dodecyltrimethylammonium chloride, tetrabutyl ammonium bromide and hydroxy pyridine into the reaction solution obtained in the (1) under normal pressure, stirring the solution, then adding gamma-chloropropyltriethoxysilane into the solution, reacting the solution for 30 to 60 minutes at the temperature of between 40 and 50 DEG C, continuously reacting the solution for 60 to 80 minutes at the temperature of between 60 and 80 DEG C, filtering the oil phase, and pumping the filtrate into a distillation still; and (3) distilling the filtrate in the distillation still under the vacuum degree of more than or equal to 0.096MPa at the temperature of less than or equal to 160 DEG C when the temperature of the top gas phase is more than 108 DEG C to obtain a product Si-69.

Owner:WEIFANG WORLD CHEM

Production method for micro-crosslinking type powdered acrylonitrile-butadiene rubber containing middle and high content of nitrile

The invention relates to a production method for micro-crosslinking type powdered acrylonitrile-butadiene rubber containing middle and high content of nitrile. Firstly, nitrile rubber paste is synthetized, then agglomerated and isolated into powder, and finally dehydrated and dried. In the polymerization reaction stage, potassium carbonate is added as a reaction buffer agent, and diethylhydroxylamine, hydroxylamine sulfate, a mixed solution of potassium hydroxide and soft water are added as a composite terminating agent. In the isolation and powdering stage, WSL and DLTP are added as an antiager, monovalent sodium salts and divalent magnesium salts or monovalent sodium salts and divalent calcium salts are used as a coagulant, and the nitrile rubber paste is agglomerated and isolated into powder at 30-75 DEG C. The production process of the present invention is simple, easy to operate, low in production costs, small in energy consumption, and high in conversion rate which can reach more than 95%. The production method employs a new composite terminating agent, which is stable in mooney and good in termination effect. The powdered acrylonitrile-butadiene rubber is relatively fine, therefore dispersibility is improved during processing. The product is very good in heat resistance and wear resistance, and can meet the application requirements of train high friction brake block.

Owner:HUANGSHAN HUALAN TECH

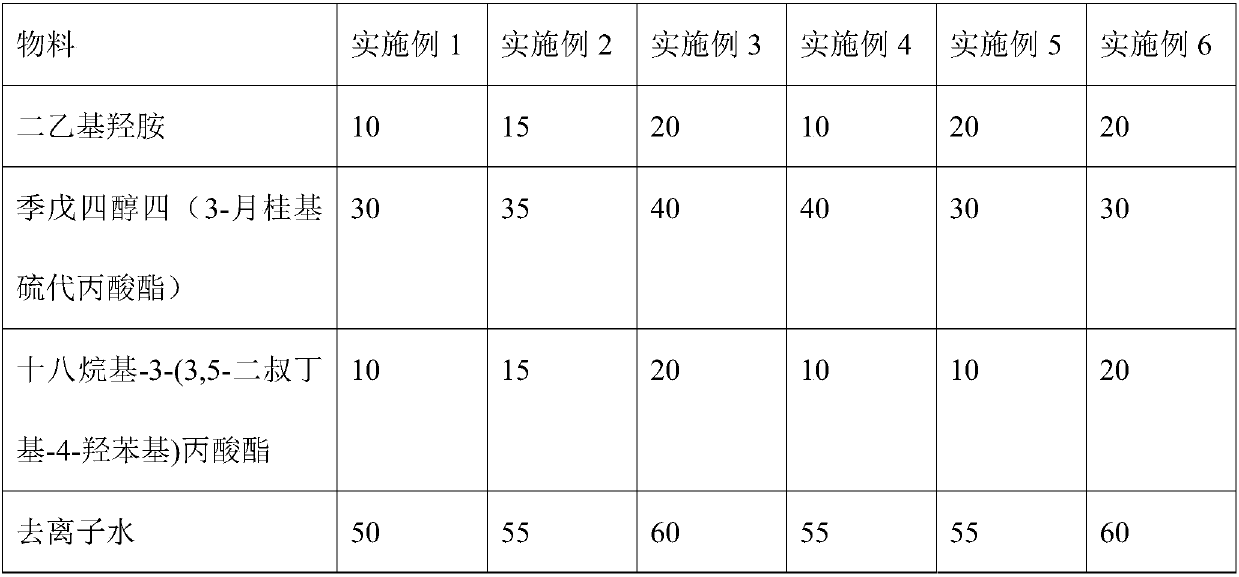

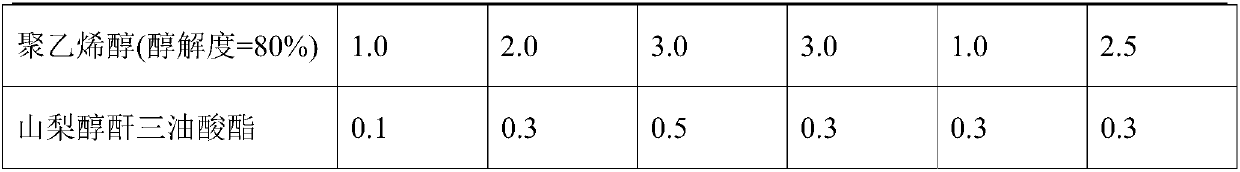

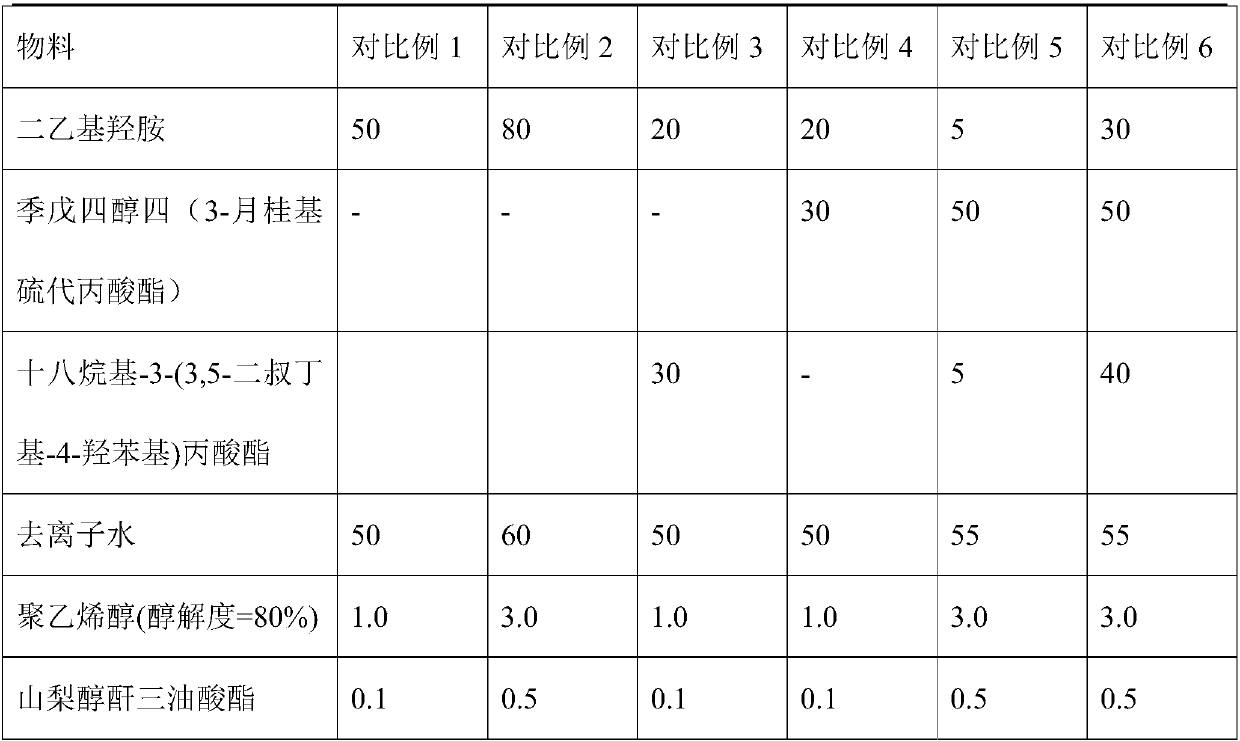

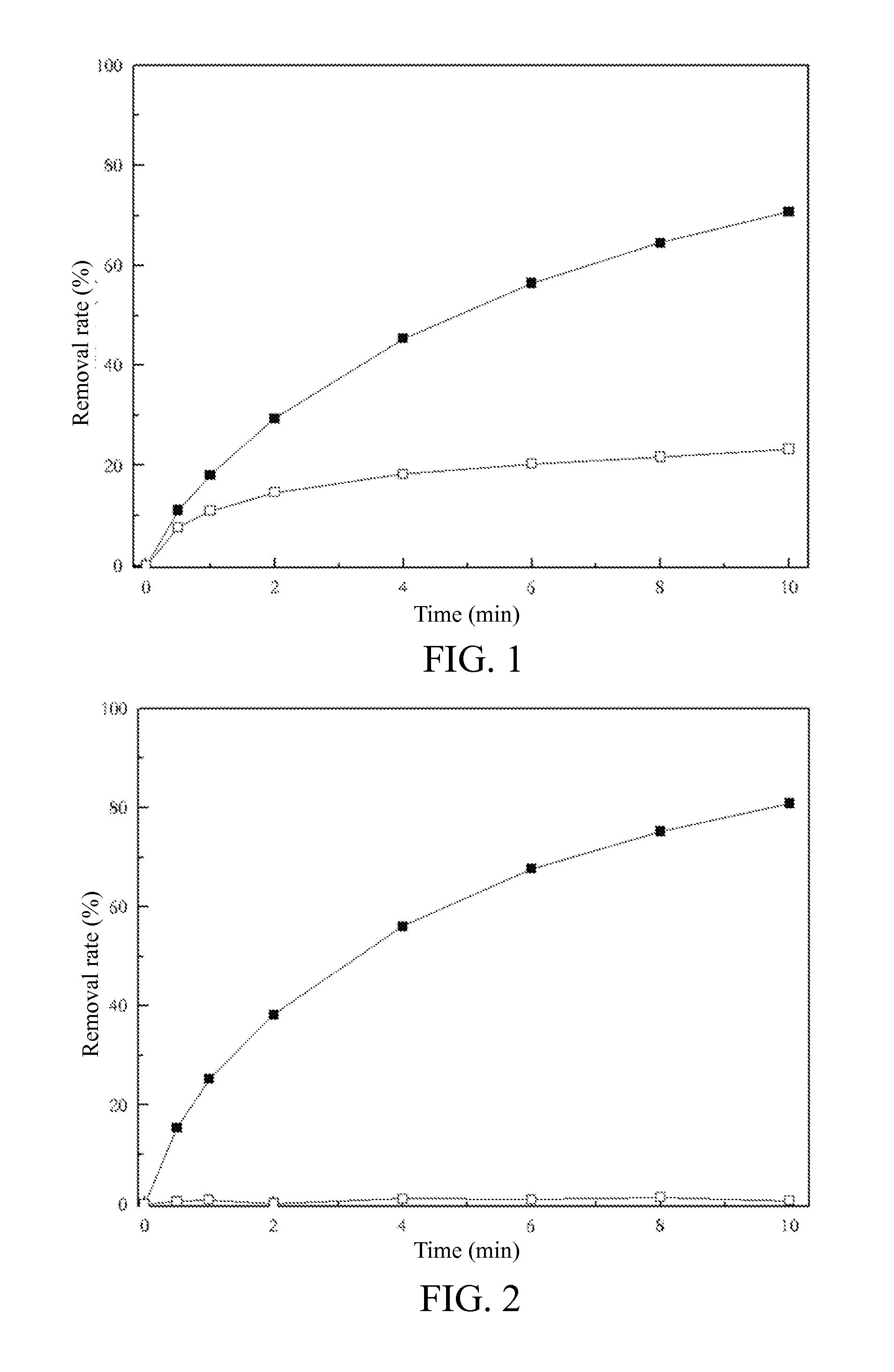

Vinyl chloride polymerization terminator as well as preparation method and application thereof

ActiveCN110760019AGood polymerization termination effectImprove aging whitenessPropionatePolymer science

The invention belongs to the field of resin synthesis, and particularly relates to a vinyl chloride polymerization terminator as well as a preparation method and application thereof. The terminator comprises the following raw materials in parts by weight: 10-20 parts of diethyl hydroxylamine, 30-40 parts of pentaerythritol tetra(3-dodecylthiopropionate), 10-20 parts of octadecyl-3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate, 50-60 parts of deionized water, 1-3 parts of a dispersing agent and 0.1-0.5 part of an emulsifying agent. All the components have a synergistic effect, so that a good vinyl chloride polymerization termination effect can be achieved, the aging whiteness of the resin can be effectively improved, and the vinyl chloride polymerization terminator has the advantages that the termination efficiency is high, PVC (vinyl chloride) resin has high whiteness and a PVC transparent product has low yellow indexes. The invention further provides a preparation method of the vinylchloride polymerization terminator. The preparation method ensures that the emulsion of the composite terminator is stable and uniform in each batch when being metered and added, and has favorable flowability in a process pipeline.

Owner:CHINA PETROLEUM & CHEM CORP

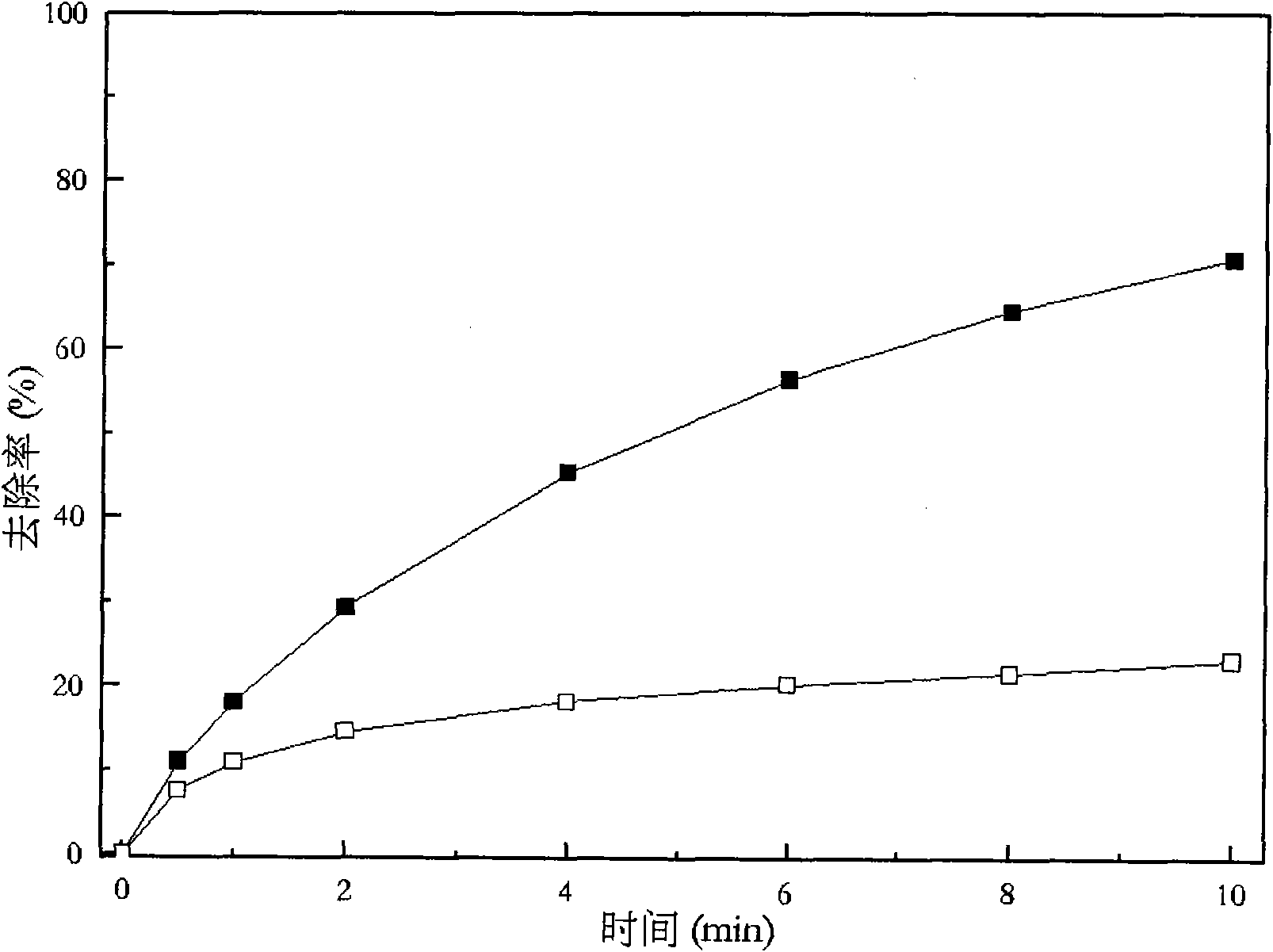

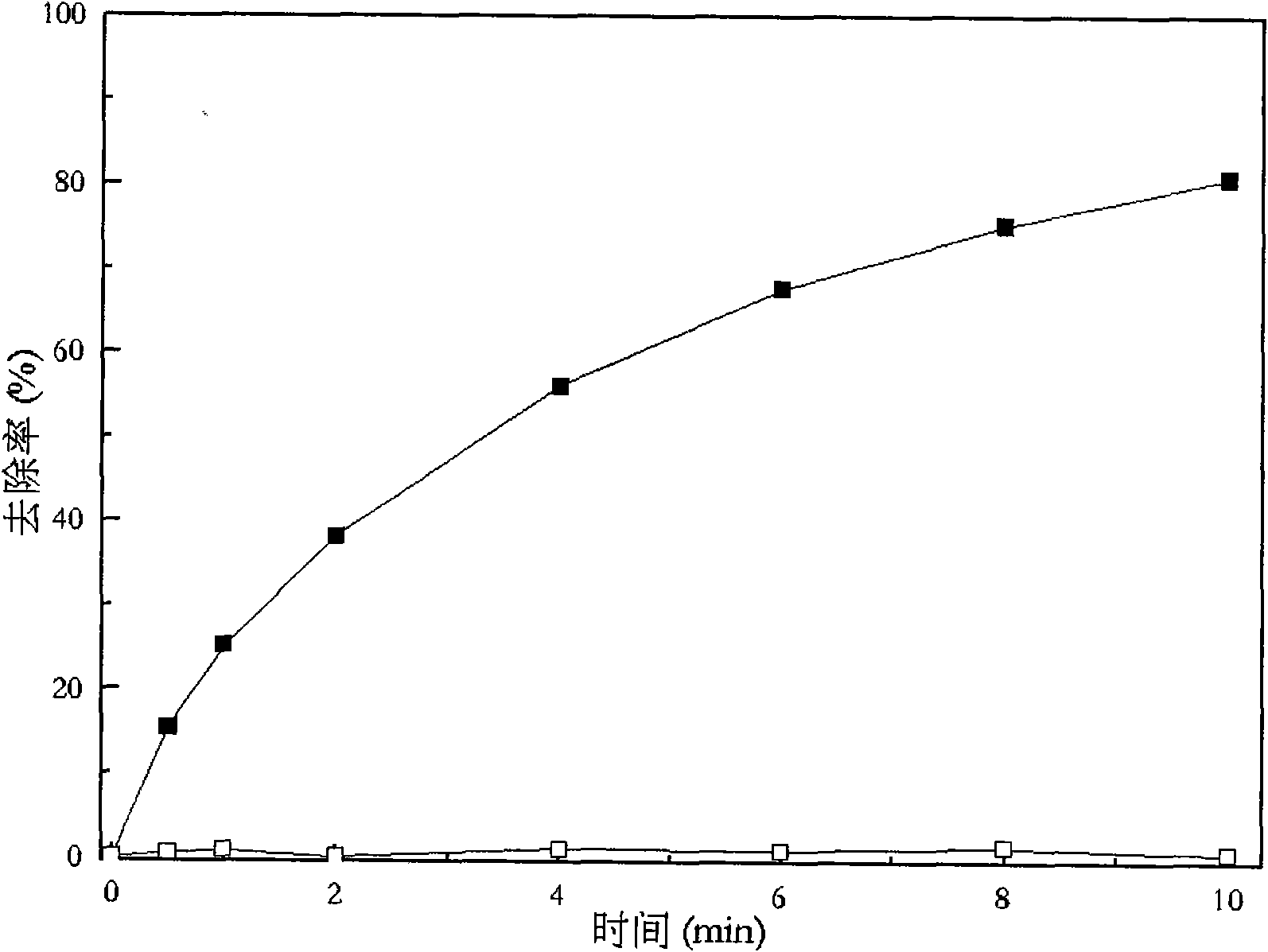

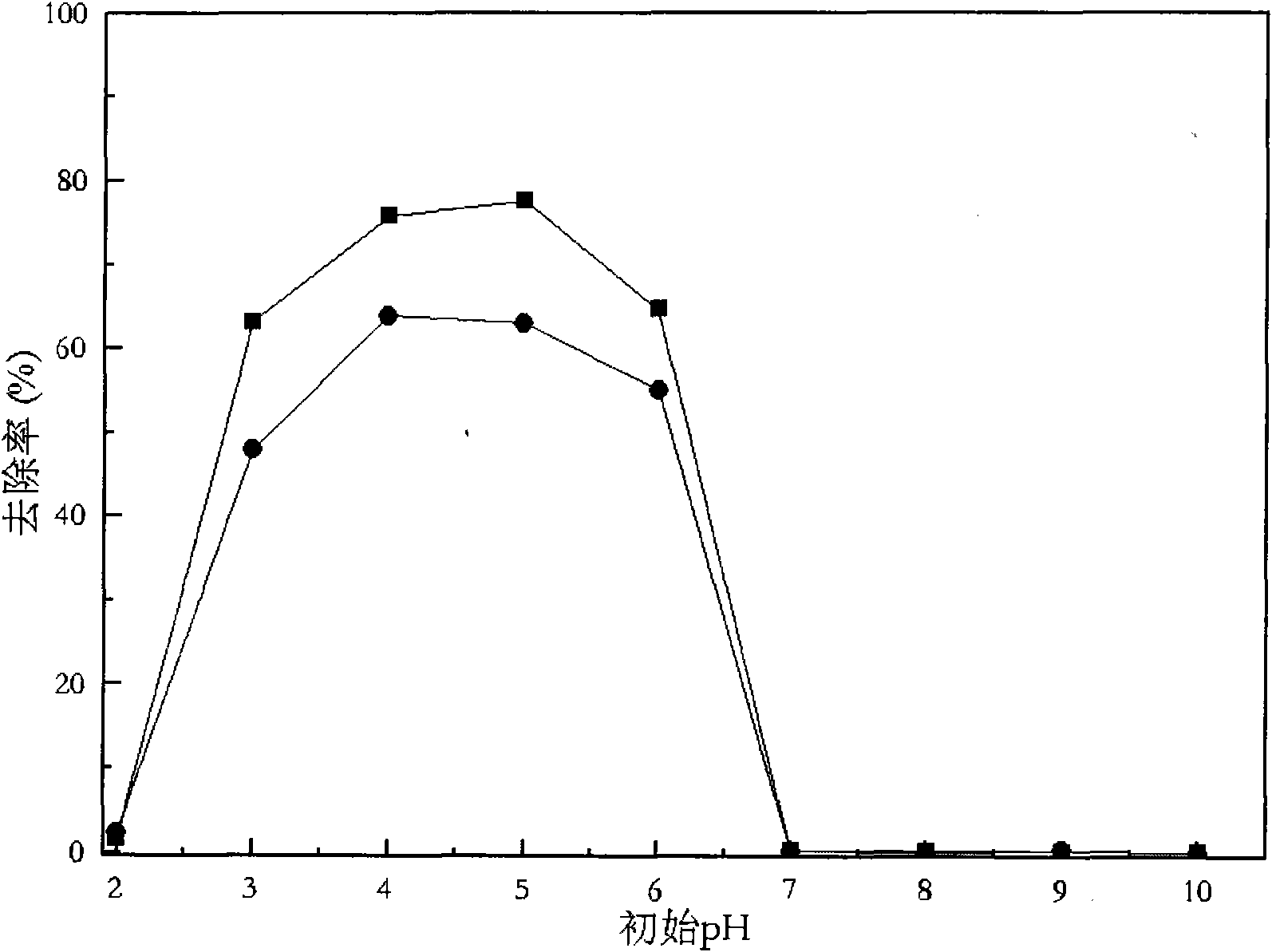

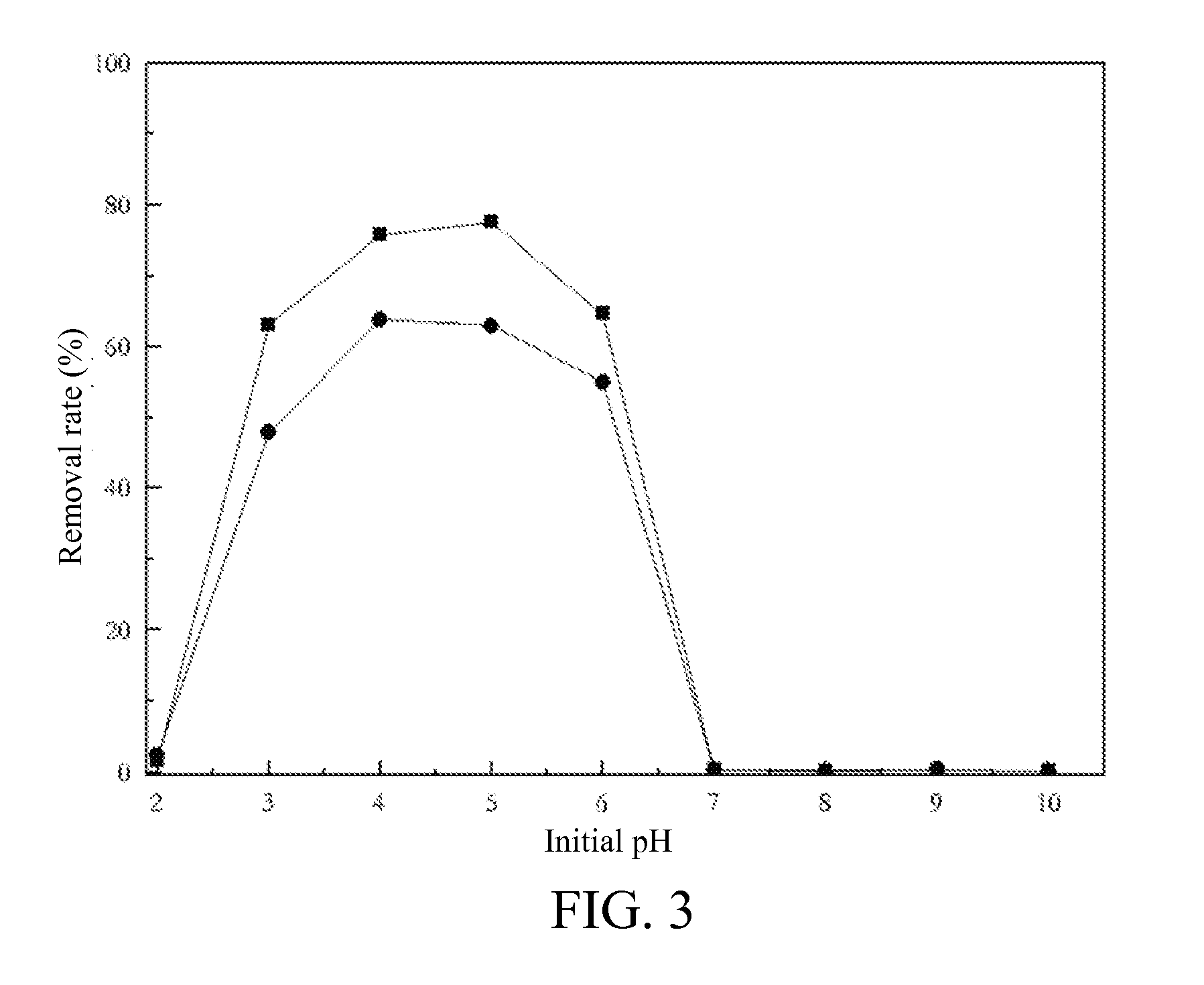

Fenton and Fenton-Like System Hardening Agent and Usage Thereof

InactiveUS20120305497A1Efficient use ofWide rangeWater treatment parameter controlOrganic chemistryHydrazine compoundSulfite salt

Fenton and Fenton-like system enhancing agent and the usage thereof are provided. It relates to a water treatment enhancer (enhancing agent) and the usage thereof. It widens water pH range of Fenton and Fenton-like system reaction. It reduces amount of Fe2+ required for Fenton reaction. It increases rate of Fenton-like reaction. The enhancing agent is selected from sodium sulfite, lithium sulfite, potassium sulfite, magnesium sulfite, calcium sulfite, hydroxylamine hydrochloride, hydroxylamine perchlorate, hydroxylamine sulfate, hydrazine, N,N-diethylhydroxylamine, amino ethanolamine, hydroxylamine solution or N,N,N′,N′-tetrasubstituted p-phenylenediamine. The method of use of enhancing agent comprises the steps of: adding Fenton or Fenton-like system enhancing agent, an agent for enhancement and hydrogen peroxide into water subject to treatment; and mixing and allowing reaction. The enhancing agent can increase the rate of reaction for the water treatment and reduce the dosage of the agent for enhancement.

Owner:HARBIN INST OF TECH

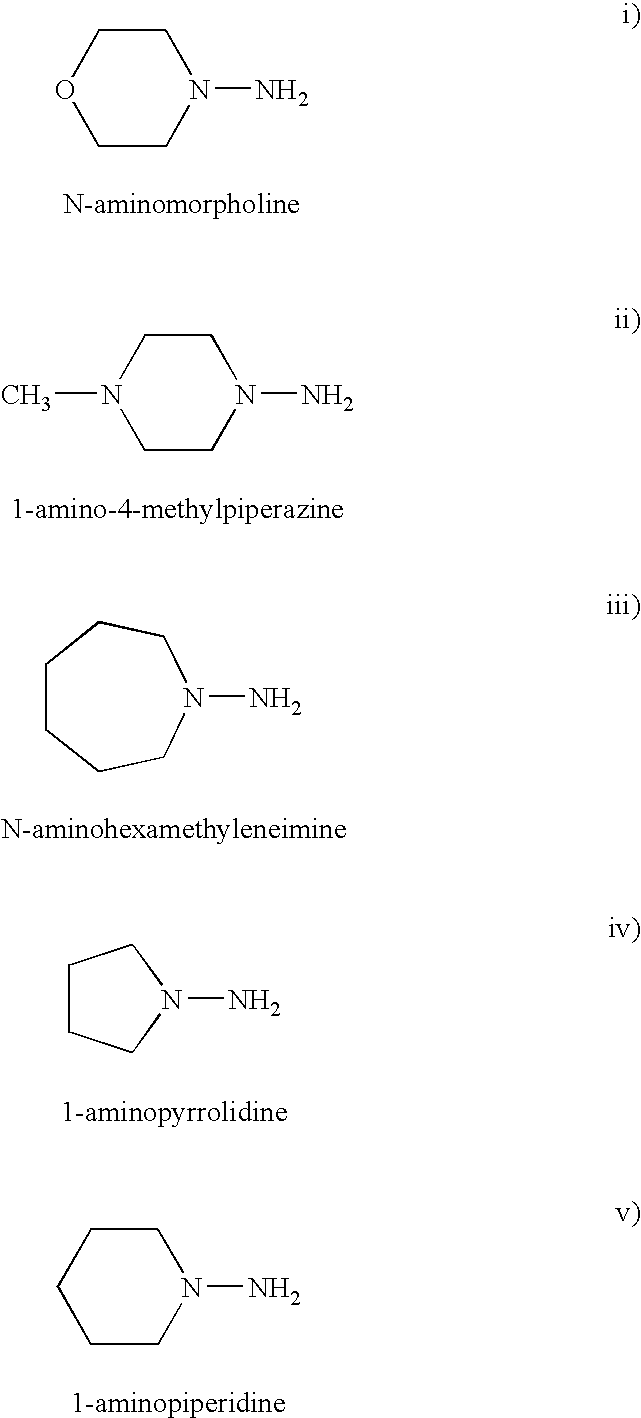

Oxygen scavenger and the method for oxygen reduction treatment

InactiveUS20050156143A1Avoid corrosionReduce removalBiocideLighting and heating apparatusHydrazine compoundHydroxylamine Hydrochloride

Oxygen scavenger which can exhibit excellent oxygen reduction effect in a wide variety of conditions is provided as an alternative volatile oxygen scavenger to hydrazine. The oxygen scavenger contains a heterocyclic compound having N-substituted amino group such as 1-amino-4-methylpiperazine and a hydroxylamine compound such as N,N-diethylhydroxylamine. The oxygen scavenger may further contain a polyhydric phenol type catalyst such as pyrogallol. By adding the oxygen scavenger to feed water of a water system of a boiler, oxygen reduction treatment of the water system is carried out.

Owner:KURITA WATER INDUSTRIES LTD

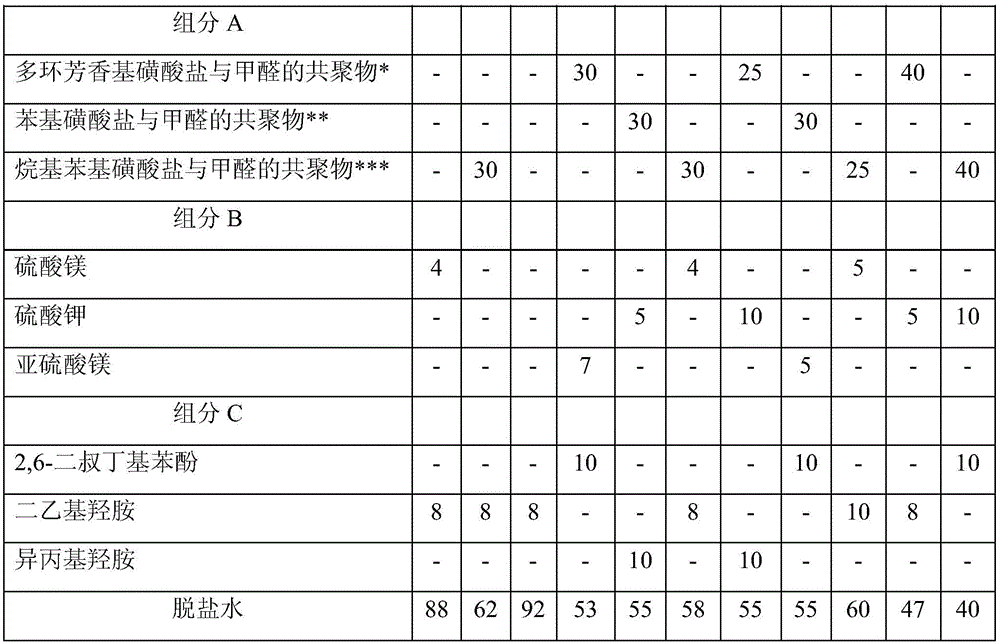

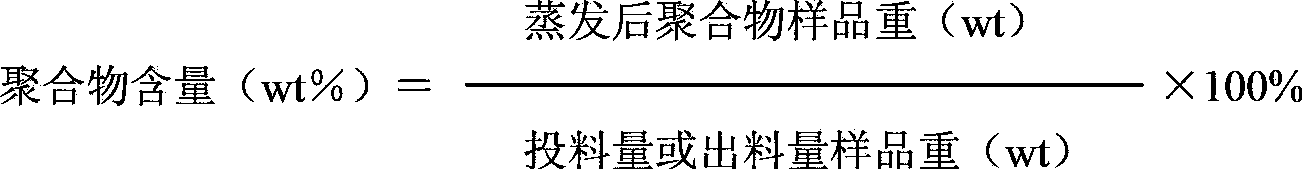

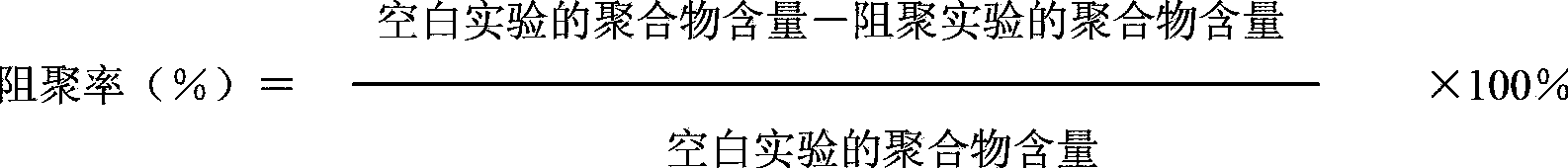

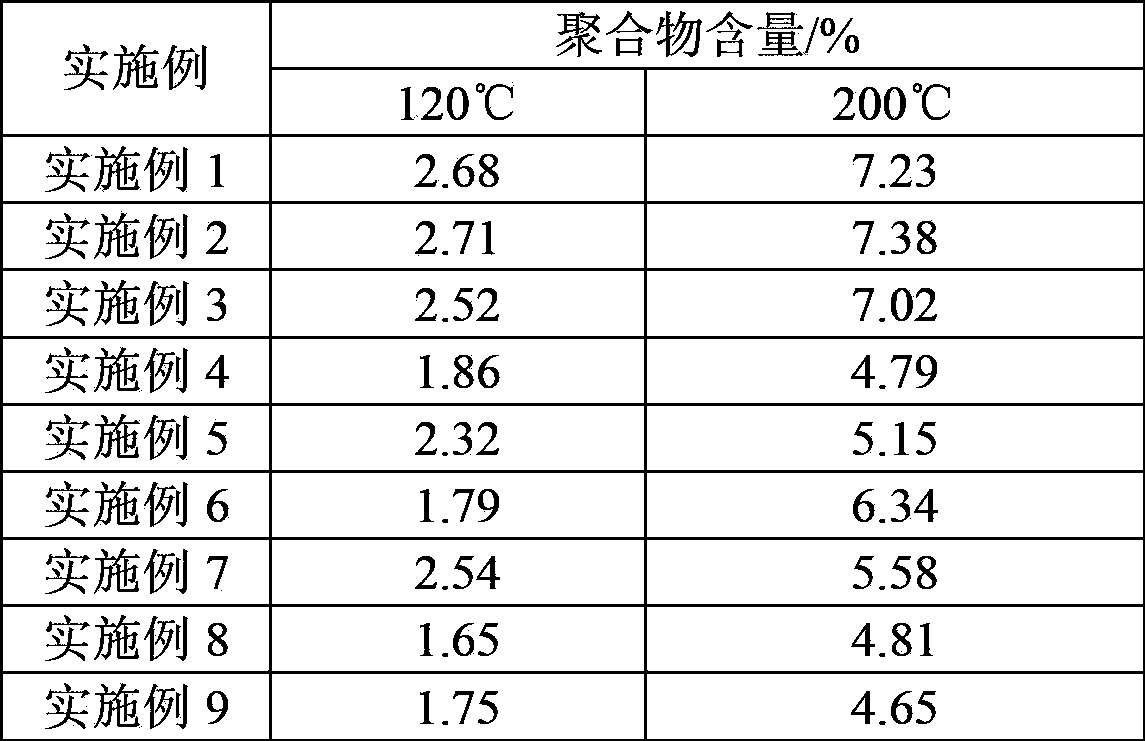

Water soluble dispersing scale inhibitor and application of water soluble dispersing scale inhibitor in acrylonitrile production device

ActiveCN106565537ANo pollution in the processEasy to useCarboxylic acid nitrile purification/separationHydroxylamineAcrylonitrile

The invention discloses a water soluble dispersing scale inhibitor and an application of the water soluble dispersing scale inhibitor in an acrylonitrile production device. The water soluble dispersing scale inhibitor comprises a component A, a component B and a component C. The component A is a copolymer of aryl sulfonate and formaldehyde. The component B is one or more of magnesium sulfate, potassium sulfate and magnesium sulfite. The component C is one or more of 2,6-di-tert-butylphenol, diethylhydroxylamine and isopropyl hydroxylamine. The mass ratio of the component A to the component B to the component C is 10-50:1-10:1-10. By adopting the water soluble dispersing scale inhibitor, scale formed by free radical polymerization and dispersion can be effectively inhibited, so that the scale is uniformly dispersed in a water phase, thus, the situation that the scale is precipitated in the acrylonitrile production device is avoided, and the production operation cycle of the device can be prolonged.

Owner:北京万智石油化工有限公司 +1

C5 diolefin auto-agglutination or copolymerization inhibition method

ActiveCN103896711AGood inhibition effectHydrocarbon purification/separationHydrocarbonsAgglutinationDiethylhydroxylamine

The invention relates to a C5 diolefin auto-agglutination or copolymerization inhibition method in C5 fraction separation process of petroleum, a polymerization inhibitor is added into a C5 fraction material, the polymerization inhibitor in the C5 fraction material is maintained at a certain amount, the polymerization inhibitor comprises component A N, N-diethylhydroxylamine, component B N,N'-di-sec-butyl-1,4-phenylenediamine and component C succinimide, the weight ratio of component A to component B to component C is (0.1-3):1-3 :0.1-3, and taking the total amount of the component A, component B and component C as a reference, the polymerization inhibitor in the C5 fraction material is maintained at the amount of 20-600ppm; the polymerization inhibitor used in the method is good in polymerization inhibition effect and good in versatility, a big difference in the boiling point between each component and solvent and isoprene, cyclopentadiene (or dicyclopentadiene), piperylene and other diolefins in C5 fraction is existed, so that the components and solvents can be separated in the separation process without further increase of a separation process.

Owner:PETROCHINA CO LTD

Multifunctional C3 polymerization inhibitor

InactiveCN102766008AAlso has a dispersion effectDisperse fastHydrocarbon purification/separationHydrocarbonsIsobutanolHydroxylamine

The invention provides a multifunctional C3 polymerization inhibitor which is formed by the following components by weight percentage of: 15-40% of 2,6-ditertiary butyl phenol, 10-20% of diethyl hydroxylamine, 5-15% of isobutanol, 5-15% of monobutyl imidodicarbonic diamide, 1-5% of propylene glycol polypropylene oxide polyoxyethylene block polyether, and of the balance of #190 solvent oil. Meanwhile, the invention further provides a method for preparing the polymerization inhibitor. The polymerization inhibitor can be rapidly dispersed so as to realize the inhibition effect on olefin polymerization to the greatest extent; and meanwhile, the polymerization inhibitor can effectively remove scales.

Owner:天津市瑞德赛恩新材料开发有限公司

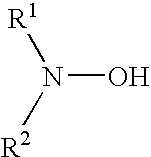

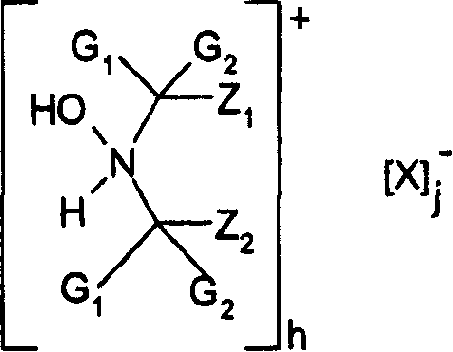

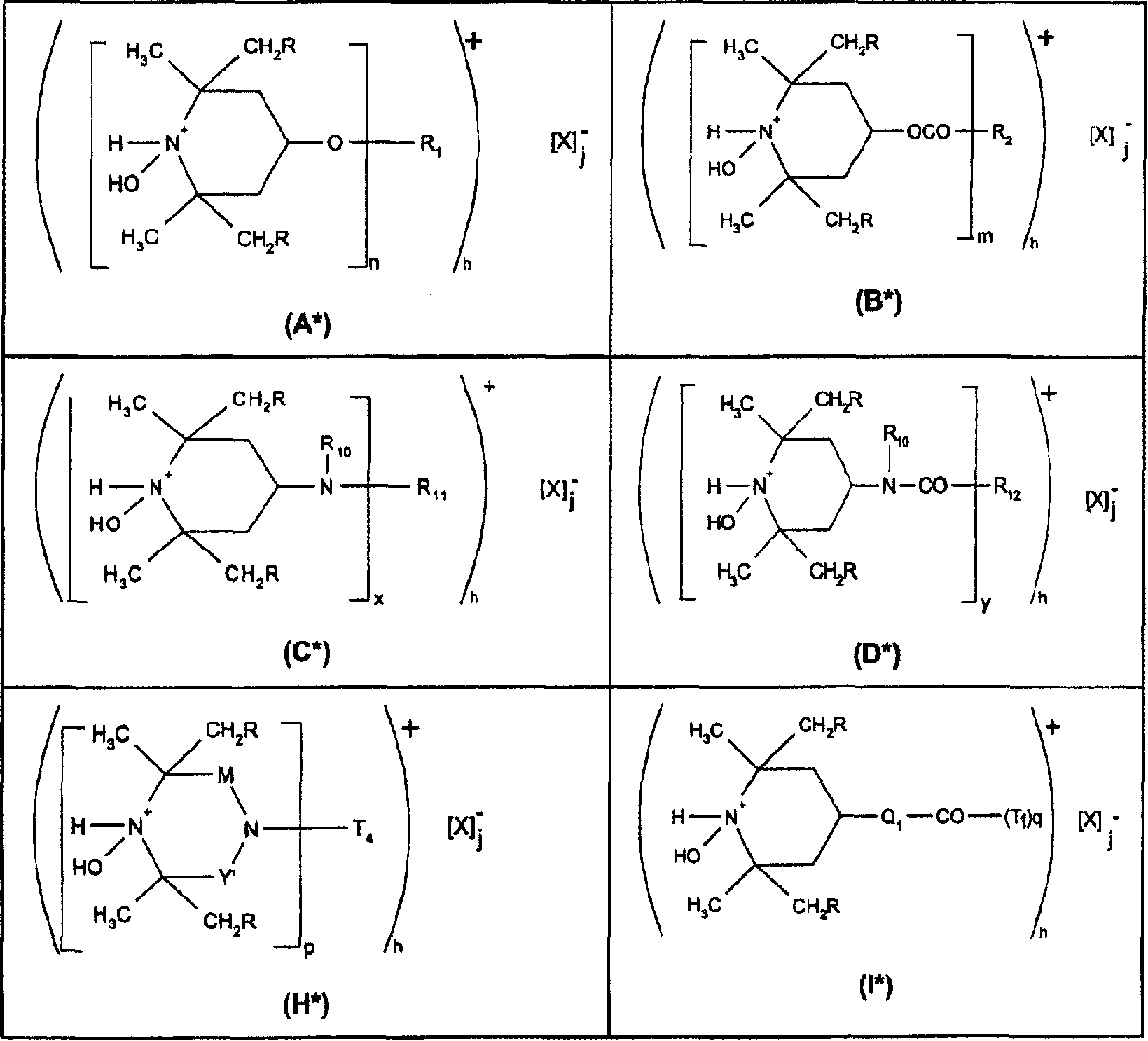

Ink-jet ink and recording material

The invention relates to an ink jet ink or ink jet recording material comprising at least one sterically hindered N-hydroxylamine strong acid salt of the formula (I) wherein G1 and G2 are e.g. C1-C4alkyl, Z1 and Z2 are each methyl, or Z1 and Z2 together form a linking moiety such as, for example, 1-hydroxy-2,2,6,6-tetramethyl-4-hydroxypiperidinium chloride or bis(1-hydroxy-2,2,6,6-tetramethylpiperidin-4-yl) sebacate dihydrochloride; X is an anion of a strong acid, or comprising at least one dialkyl N-hydroxylamine salt of the formula (R51,R52N-OH) . (HY), for example, chloride, bisulfate, sulfate, phosphate, nitrate, ascorbate, formate, acetate, benzoate, oxalate, citrate, a carboxylate of thylenediaminetetraacetic acid or of diethylene-triaminepentaacetic acid or polyacrylate salts of N,N-diethylhydroxylamine, N,N-bis(2-hydroxypropyl)hydroxylamine, N,N-bis(3-hydroxypropyl)hydroxylamine, N,N-dibenzyl-hydroxylamine or the N,N-di(alkyl)hydroxylamine produced by the direct oxidation of N,N-di(hydrogenated tallow)amine.

Owner:CIBA SPECIALTY CHEM HLDG INC

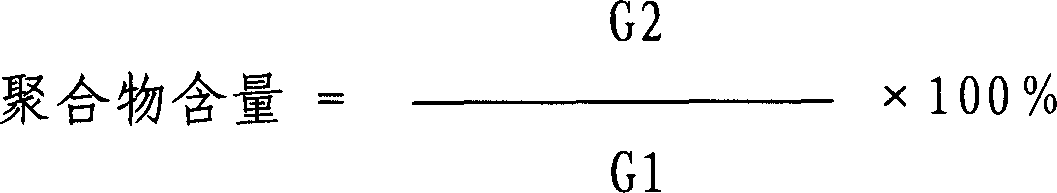

Preparation method of polymerization inhibitor

InactiveCN108727521AImprove stabilityNot easy to decomposeChemical inhibitorsChemical industryCross-link

The invention discloses a preparation method of a polymerization inhibitor and belongs to the technical field of chemical industry. According to the preparation method, cross-linked polystyrene microspheres and liquid bromine are used as base materials; 2,2,6,6-tetramethyl-4-piperidyl methacrylate is added as a monomer to form a polymer; then 4,6-binitro-2-sec-butylphenol is added and compounded,so that on one hand, the activity of a hemi-ketone free radical generated by phenol with an electron-donating group is improved; furthermore, a peroxy free radical is easy to combine to generate quinone for inhibiting the polymerization of styrene; on the other hand, when the steric hindrance of a substituent group is relatively great, the generated hemi-ketone free radical is more stable; N,N-diethylhydroxylamine is added and easily reacts with 2,2'-azobisisobutyronitrile or a primary free radical in a system to generate an R2NO free radical under a polymerization condition; the stable free radical can be subjected to rapid chain transfer and has polymerization retardation performance; the stable free radical assists the polymerization inhibitor base materials to increase continuous action time and the polymerization inhibition efficiency is increased. By adopting the preparation method, the problems of a current polymerization inhibitor that the storage period is relatively short, polymerization reaction easily occurs and the polymerization inhibition action time is relatively short are solved.

Owner:雷春生

Method for synthesizing diethylhydroxylamine

ActiveCN109096144AHigh activityHigh selectivityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidHeteropoly acid

The invention discloses a method for synthesizing diethylhydroxylamine. The method comprises steps as follows: (1), a solid acid catalyst supported with heteropoly acid is added to a fixed bed reactor, and the temperature of the fixed bed reactor is controlled to be 40-60 DEG C; (2), a mixed aqueous solution of triethylamine, acetic acid and hydrogen peroxide is injected into the fixed bed reactor, and the mixed aqueous solution stays in the fixed bed reactor for 2-24 h; (3), a product obtained from an outlet of the fixed bed reactor enters a cracking reaction kettle and is cracked, and diethylhydroxylamine is obtained; the temperature of the cracking reaction kettle is 100-120 DEG C, and the pressure is 600-700 mmHg. With the adoption of the method, potential safety hazard in a productionprocess can be reduced, and product purity is higher; the method is one new method which is capable of meeting the industrial demand of diethylhydroxylamine and quite high in practicability.

Owner:NANJING UNIV OF TECH

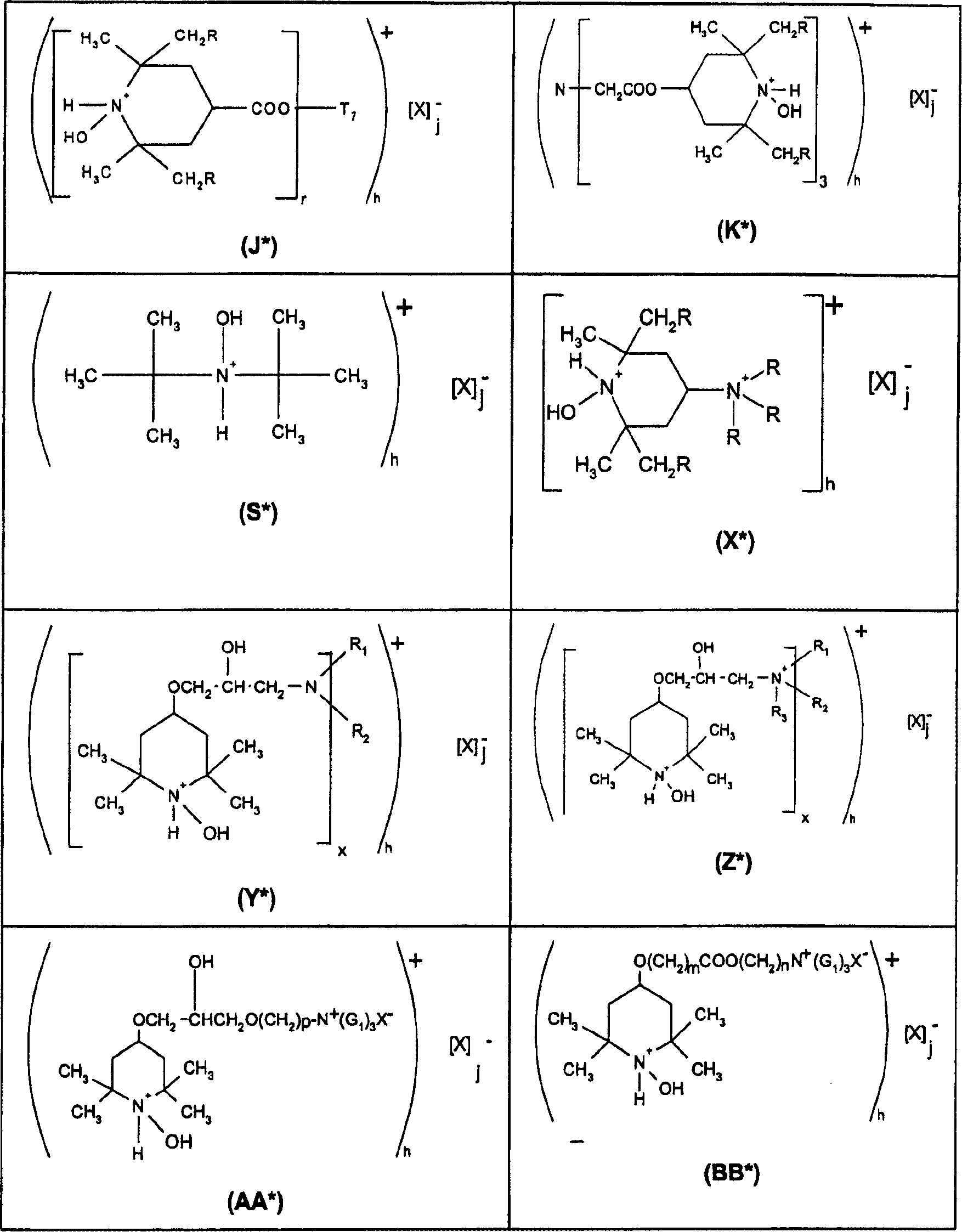

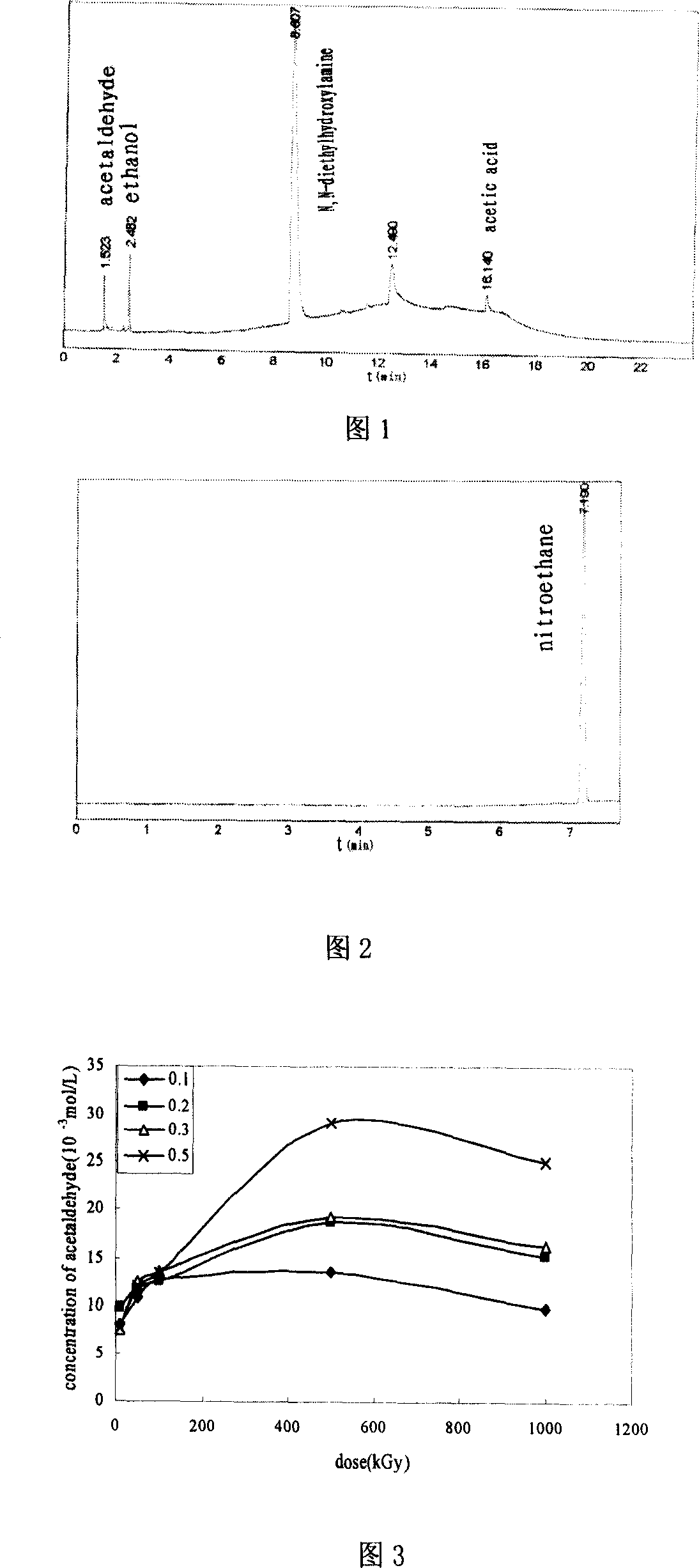

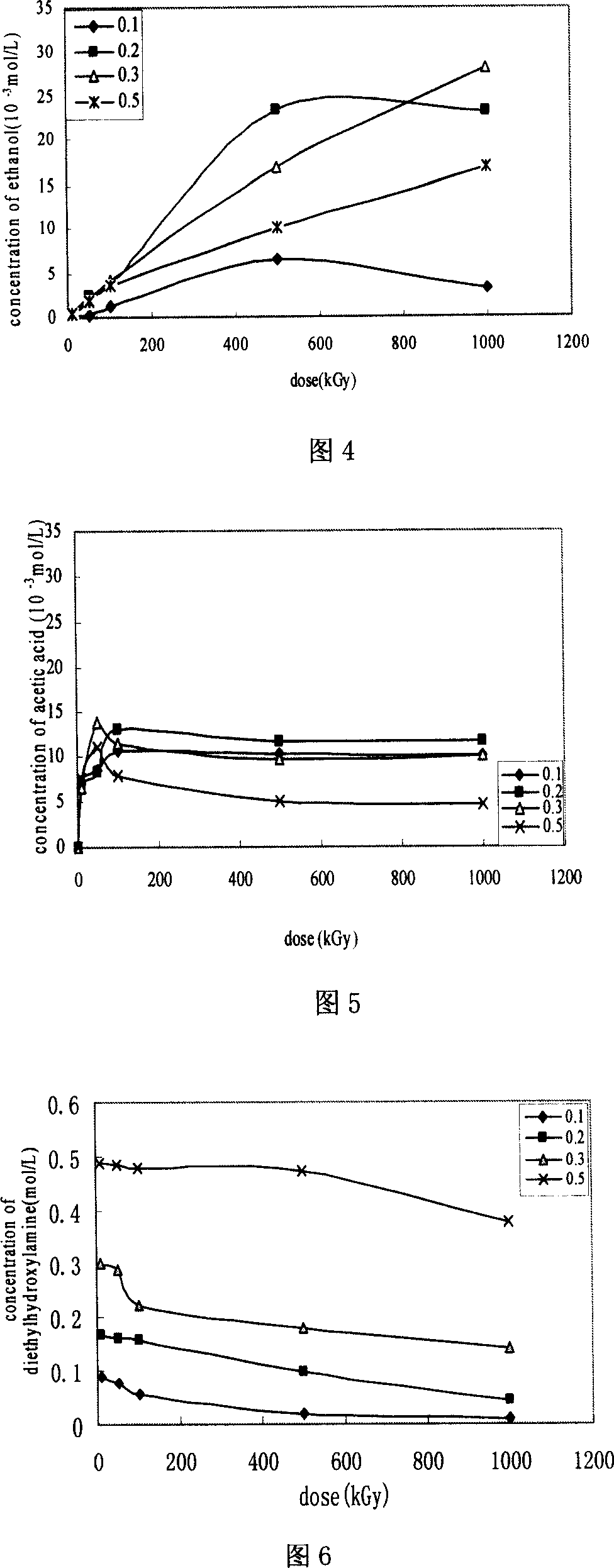

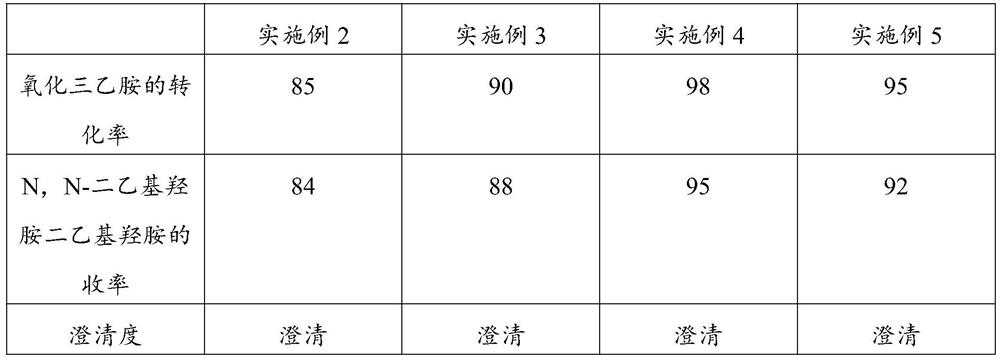

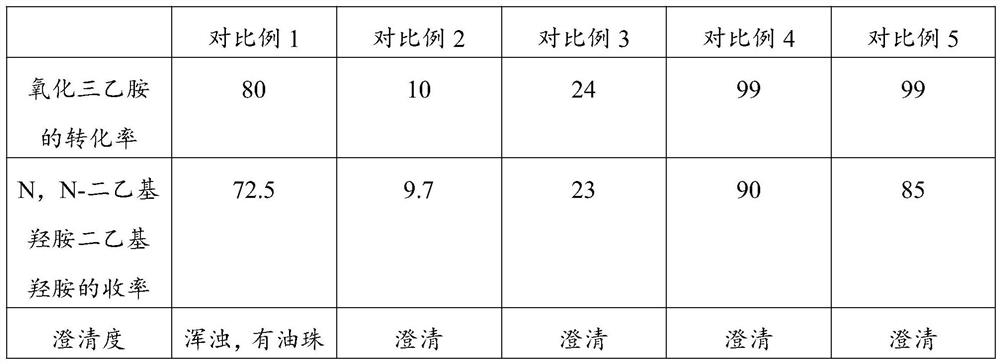

Analysis method while alcohol, aldehyde, acetic acid, nitroethane and N,N-diethylated hydroxylammonium hydroxylamine common existing

The invention relates to ethanol, acetaldehyde, acetic acid, nitro ethane and N, N-diethyl-hydroxylamine analytical method. It's an organic analysis technology. This analysis technology uses gas chromatography by high separation efficiency and high sensitivity FFAR capillary and flame ionization, rapid qualitative and quantitative analysis of ethanol, acetaldehyde, acetic acid, nitro ethane and N, N-Diethyl-hydroxylamine. The invention has short analysis time, fast, simple, convenient and high-precision, can analysis coexist ethanol, acetaldehyde, acetic acid, nitro ethane and N, N-Diethyl-hydroxylamine quickly.

Owner:SHANGHAI UNIV

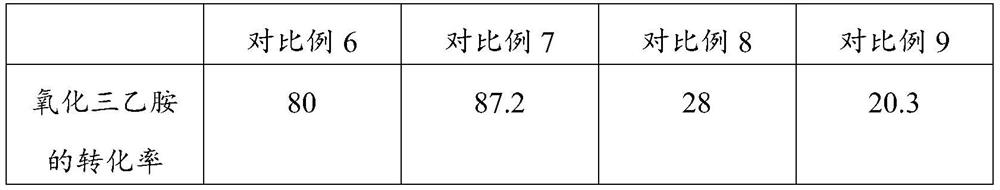

Preparation method of N,N-diethyl hydroxylamine

ActiveCN112375011AHigh yieldHigh clarityOrganic chemistryChemical/physical/physico-chemical processesHydroxylaminePtru catalyst

The invention discloses a preparation method of N,N-diethyl hydroxylamine. The preparation method comprises the following steps: reacting following raw materials: triethylamine, a catalyst and hydrogen peroxide with a mass percentage of 27.5% to prepare triethylamine oxide; continuously injecting the obtained triethylamine oxide into a tubular reactor, and reacting at the temperature of 100-200 DEG C under a pressure of 1-2 atm to obtain N,N-diethyl hydroxylamine. The tubular reactor is used as a reaction medium for triethylamine oxide cracking, so that the use of white oil is avoided, the clarity of the product is improved, and the production efficiency of the product is improved.

Owner:JINING KENDRAY CHEM TECH CO LTD

Graphene material for lithium battery and preparation method thereof

InactiveCN106784844ALower internal resistanceExtend your lifeCell electrodesElectrical batteryInternal resistance

The invention discloses a graphene material for a lithium battery and a preparation method thereof. The graphene material for the lithium battery contains raw materials of potassium hydroxide, active carbon, Ni-Co lithium manganate, graphene oxide, sodium hydroxide, sodium borohydride, lithium nitrate, triethylene tetramine, N, N-diethylhydroxylamine and N, N-diethyl ethylene diamine. The graphene material for the lithium battery, disclosed by the invention, has the advantages that the mechanical property is excellent, the internal resistance of the battery is reduced, the service life of the battery is prolonged, the heat-conducting property is excellent, the raw materials are cheap, the operation is simple, the electrical conductivity is excellent, the battery is rapidly and fully charged within 5-9 minutes, large-current discharging performance and low temperature performance of the battery are improved, the stability of the battery is good, the battery can be charged and discharged for 400-500 times in circulation, the battery capacity reaches 700-900 mAh, the process is simple and easy to operate, the product quality and the product yield are stable and easy to control, and the graphene material can be widely produced and continuously replace the existing materials.

Owner:江苏悠谷未来科技有限公司

Method for recovering styrene from hydrocarbon mixture by extractive distillation

ActiveCN103360201BPrevent precipitationGood inhibition effectDistillation purification/separationHydroxylamineHydrocarbon mixtures

The invention relates to a method for extracting, distilling and recovering styrene from a hydrocarbon mixture. The method comprises the following steps of: extracting, distilling and recovering the styrene from the hydrocarbon mixture by using a composite solvent in the presence of a polymerization inhibitor. The composite solvent comprises 80-99% by mass of a main solvent, 0.01-19% by mass of an auxiliary solvent and 0.1-2.0% by mass of water, wherein the main solvent is a sulfone compound, and the auxiliary solvent is metoxyphenol or the mixture of the metoxyphenol and the glycol monomethyl ether. The polymerization inhibitor comprises 40-80% by mass of free radicals of nitrogen and oxygen, 15-50% by mass of nitro-phenol and derivatives thereof and 5-30% by mass of N, N-diethyl hydroxylamine. The use amount of the polymerization inhibitor is 10-500mug / g of the amount of the hydrocarbon raw material. Because the composite solvent is used together with the polymerization inhibitor, the use amount of the polymerization inhibitor can be decreased, and the rate of polymerization of the styrene can be reduced significantly.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing diethylhydroxylamine from peracetic acid

ActiveCN109096143AHigh activityHigh selectivityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidDistillation

The invention discloses a method for synthesizing diethylhydroxylamine from peracetic acid. The method comprises the following steps: (1) a mixed aqueous solution containing a heteropolyacid supportedsolid acid catalyst, triethylamine, acetic acid and hydrogen peroxide is subjected to a reaction at 35-70 DEG C for 3-16 h, then hydrogen peroxide and peracetic acid which are not reacted completelyare removed, and oxidized triethylamine is obtained by distillation; (2) oxidized triethylamine is subjected to reduced-pressure distillation at 50-80 DEG C under inert gas protection, temperature isincreased to 80-150 DEG C for pyrolysis when distillate is obviously reduced, and diethylhydroxylamine is obtained. Compared with a traditional hydrogen peroxide oxidizing agent, peracetic acid is taken as an oxidizing agent, selectivity of the product diethylhydroxylamine is high, and the heteropolyacid supported catalyst is high in activity and selectivity and recyclable.

Owner:NANJING UNIV OF TECH

Complex solvent and application thereof

ActiveCN108728155AImprove solubilityHigh selectivityAzeotropic/extractive distillationHydrocarbon oils treatmentHydroxylamineExtractive distillation

The invention relates to the field of aromatics extraction and discloses a complex solvent and application thereof. The complex solvent comprises a main solvent, a cosolvent and an olefin polymerization inhibitor. Based on the total weight of the complex solvent, the content of the main solvent is 70-99 wt%, the content of the cosolvent is 0.999-29.9 wt%, and the content of the olefin polymerization inhibitor is 10-1000ug / g; the main solvent is selected from sulfone compounds; the cosolvent is selected from at least one of N-methyl pyrrolidone, triglycol monomethyl ether, tetraethylene glycolmonomethyl ether, furfural and dimethylacetamide; the olefin polymerization inhibitor is selected from at least one of p-tert-butylcatechol, diethylhydroxylamine, dipropyl hydroxylamine, 2-sec-butyl-4,6-dinitrophenol and sodium nitrite. The complex solvent has high selectivity on aromatic hydrocarbons and sulfides, is capable of reducing the selectivity of the olefins and inhibiting olefin polymerization, and is very suitable to be used during extractive distillation.

Owner:BEIJING ENERGY ENG TECH

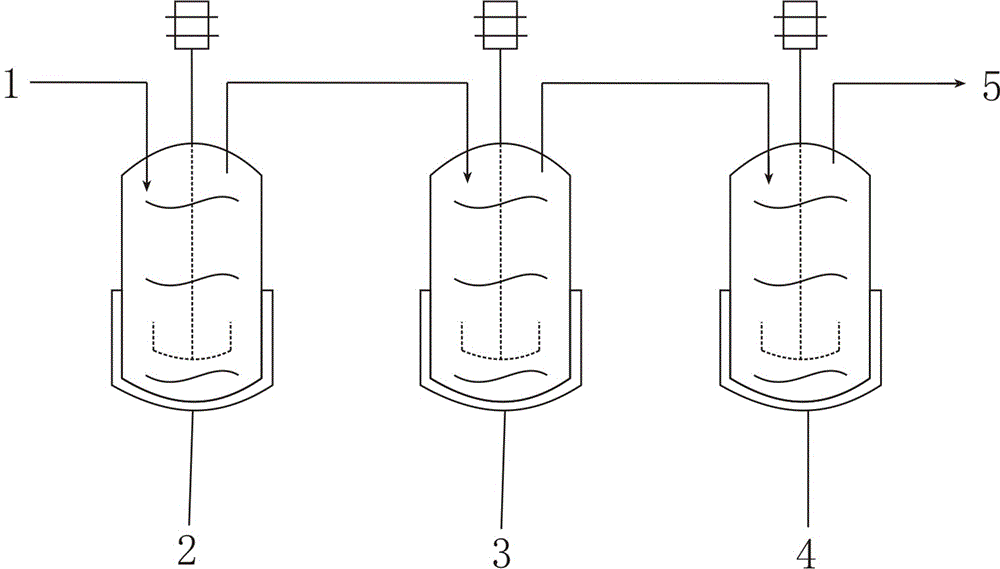

Byproduct comprehensive utilization method in diethyl hydroxylamine production

InactiveCN106349003AReduce pollutionSimple production processPreparation by halogen additionHydroxylamineReaction temperature

The invention relates to a byproduct comprehensive utilization method in diethyl hydroxylamine production. The method comprises the following steps: pyrolysis and rectification purification are carried out on the raw material triethylamine under the action of a catalyst to obtain diethyl hydroxylamine, the diethyl hydroxylamine reduced pressure pyrolysis section generates a vacuum exhaust ethylene, and the vacuum exhaust ethylene sequentially passes through a reaction kettle I, a reaction kettle II and a reaction kettle III, wherein the reaction kettle I and reaction kettle II are filled with bromine water, the bromination reaction temperatures in the reaction kettle I and reaction kettle II are 10-80 DEG C, the reaction kettle III is filled with water, and the holding temperature of the reaction kettle III is 5-50 DEG C; and after the vacuum exhaust ethylene is subjected to absorption reaction in the reaction kettle I and reaction kettle II, the ethylene inside is converted into 1,2-dibromoethane, and the unreacted vacuum exhaust ethylene is subjected to water sealing through the reaction kettle III and sent to a torch to be combusted. The method provided by the invention has the advantages of simple production technique, mild reaction and low energy consumption, can effectively lower the production cost, enhances the economic benefits and reduces the environmental pollution.

Owner:JINING KENDRAY CHEM TECH CO LTD

Organic-phosphonate-based organic energy-saving and emission-reduction agent for industrial boiler

InactiveCN104773848AReduce sewage rateReduce rateScale removal and water softeningPhosphateMorpholine

The invention discloses an organic-phosphonate-based organic energy-saving and emission-reduction agent for an industrial boiler. The organic-phosphonate-based organic energy-saving and emission-reduction agent comprises, by mass, 15%-25% of 1-Hydroxyethylidene-1,1-diphosphonic acid, 10%-15% of butane phosphate-1,2,4-tricarboxylic acid, 5%-10% of maleic acid-acrylic copolymer, 2%-3% of morpholine, 1%-2% of diethylhydroxylamine, 0.2 %-0.8% of tannin alkali metal salt and the balance water. The organic-phosphonate-based organic energy-saving and emission-reduction agent is free of inorganic chemical ingredients, all the components in the formula are organic, the water dissolved solid matter, the blowdown rate and the heating surface scaling rate of the industrial boiler are lowered effectively, and the chemical cleaning period of the boiler is prolonged; the agent is high in scale inhibition corrosion inhibition efficiency, small in feeding quantity, free of poison, low in cost, wide in ingredient source, stable in high-temperature performance, capable of adjusting the return condensate quality and lowering the return water system corrosion rate and suitable for industrial boilers of various types and various supply water quality conditions, and the boiler operation water quality index of the boilers is not affected in use.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com