Complex solvent and application thereof

A composite solvent and co-solvent technology, which is applied in the petroleum industry, azeotropic/extractive distillation, and hydrocarbon oil treatment, can solve the problems of difficult separation of solvents and aromatics, poor selectivity of aromatics, etc., to reduce selectivity, ensure selectivity, The effect of high solubility and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0033] According to a preferred embodiment of the present invention, the olefin polymerization inhibitor is tert-butylcatechol and / or 2-sec-butyl-4,6-dinitrophenol, and the preferred olefin polymerization inhibitor and composite solvent When the main solvent and co-solvent are used together, it has a better effect of inhibiting the polymerization of olefins, and the performance of the composite solvent is more excellent.

[0034] The present invention has a wide range of options for the sulfone compound, which can be various sulfone compounds commonly used in the art. For example, the sulfone compound can be selected from sulfolane, 3-methylsulfolane, dimethyl sulfone and di-n- At least one of propyl sulfones, preferably sulfolane. Sulfolane has better solubility in hydrocarbons and better selectivity to aromatics.

[0035] During the operation of the compound solvent mainly composed of sulfone compounds, due to the O in the system 2The mixing of sulfone compounds is prone t...

Embodiment 1

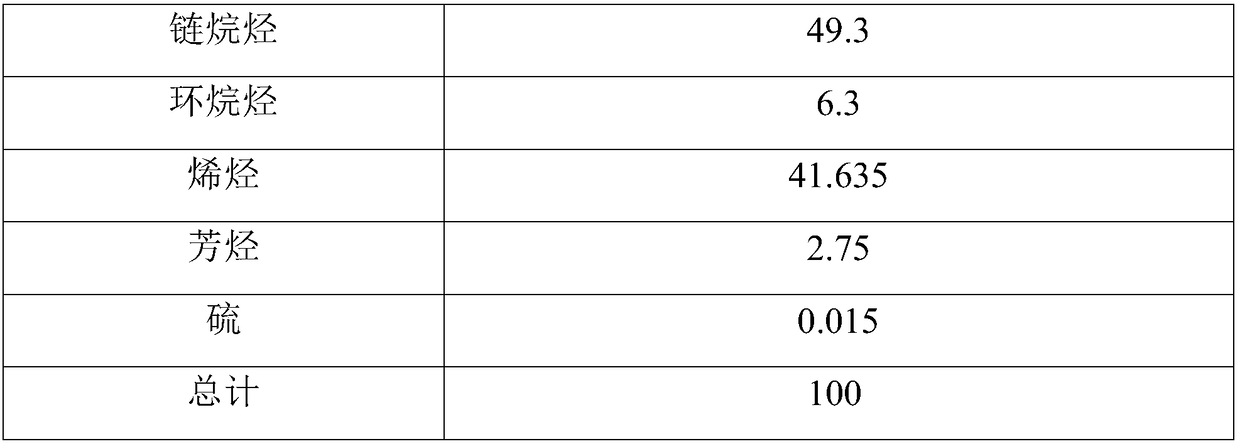

[0050] The medium gasoline fraction is introduced into the middle part of the extractive distillation tower, and the composite solvent F-1 (see Table 2 for the specific composition) is introduced into the extractive distillation tower from the top (the mass ratio of the composite solvent to the medium gasoline fraction is 2:1), and after extraction Distillation, extractive distillation conditions include: the temperature of entering the tower is 84°C, the temperature of the top of the tower is 76-77°C, the temperature of the bottom of the tower is 158-160°C, the operating pressure of the top of the tower is 0.1MPa, and the raffinate is discharged from the top of the extractive distillation tower Oil, the extracted oil rich in aromatics and sulfides at the bottom of the extractive distillation tower enters the stripping tower for stripping. The feed mass ratio was 1. The lean solvent is obtained at the bottom of the tower, and the sulfur-rich aromatics are obtained at the top o...

Embodiment 2

[0058] According to the method described in Example 1, the difference is that the composite solvent F-2 of the same quality and different composition is used to replace the composite solvent F-1. The composition of composite solvent F-2 is shown in Table 2. After the system has been in operation for 6 months, the resulting poor solvent has a pH value of about 7, and there is no polymerized olefin suspension in the poor solvent. Only 3.5% by weight of aromatics, 3.2% by weight of sulfur, and 94.9% by weight of olefins are present in the raffinate; 96.5% by weight of aromatics, 96.8% by weight of sulfur, 5.1% by weight of olefins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com