Process for preventing self-polymerization or co-polymerization of C5 diolefins in separation process of petroleum C5 distillate

A technology for petroleum carbon five fractions and separation process, applied in chemical instruments and methods, purification/separation of hydrocarbons, hydrocarbons, etc., can solve the problem that the polymerization inhibitor is not very suitable, and achieve good polymerization inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

[0012] 1. Preparation of polymerization inhibitor

[0013] The required amount of component A diethylhydroxylamine and component B tert-butyl catechol are dissolved in a solvent to prepare a polymerization inhibitor for later use, and the total content of component A and component B is controlled to be 30-40 wt%. The specific solvents used in each embodiment and the weight ratio of component A to component B are listed in Table 2.

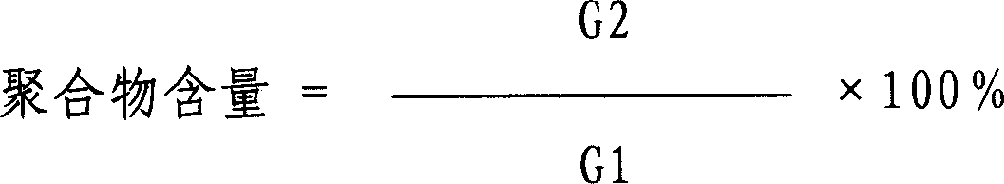

[0014] 2. Sealing test of polymerization inhibitor

[0015] Fill a 500ml plastic bottle with 450ml carbon five fraction sample. The sample components are shown in Table 1. Then add the polymerization inhibitor prepared in each of the above embodiments into the plastic bottle in the required amount. A rusty iron nail is placed in a 30ml glass tube, and then a 15ml carbon five sample is taken out of the plastic bottle and injected into the glass tube and sealed. Place the sealed tube in a constant temperature oil bath at 120°C for 20 hours, take it out f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com