Patents

Literature

156results about How to "Good inhibition effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plant source bacteriostasis and detoxification deodorant and preparation method and application of plant source bacteriostasis and detoxification deodorant

InactiveCN103168803ASpeed up conversionGood antibacterial effectBiocideDispersed particle separationHordeum vulgareCapsaicin

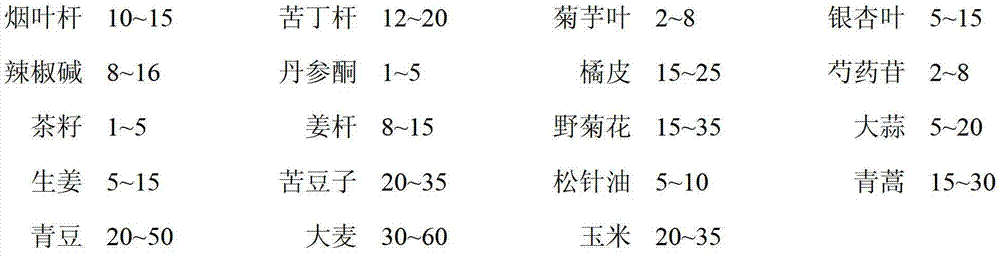

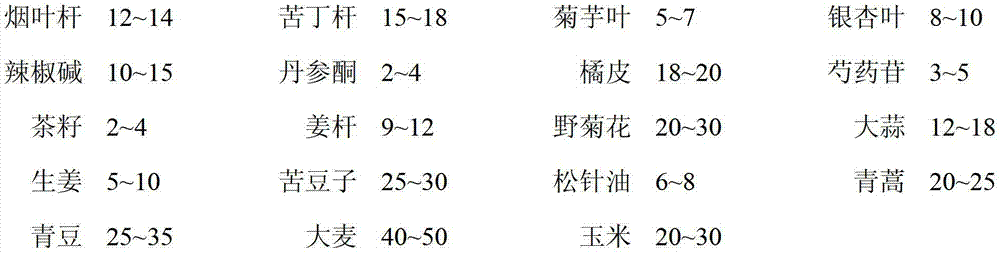

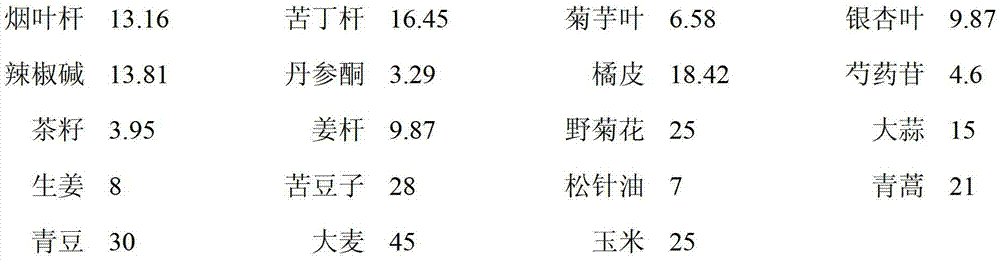

The invention provides a plant source bacteriostasis and detoxification deodorant. The plant source bacteriostasis and detoxification deodorant is prepared by the following plant materials in parts by weight: 10-15 parts of tobacco stems, 12-20 parts of Ilex latifolia Thunb stems, 2-8 parts of Helianthus tuberosus Linn leaves, 5-15 parts of ginkgo biloba, 8-16 parts of capsaicin, 1-5 parts of tanshinone, 15-25 parts of orange peel, 2-8 parts of paeoniflorin, 1-5 parts of tea seed, 8-15 parts of ginger stems, 15-35 parts of wild chrysanthemum flower, 5-20 parts of garlic, 5-15 parts of ginger, 20-35 parts of sophora alopecuroides, 5-10 parts of pine needle oil, 15-30 parts of artemisia annua, 20-50 parts of green beans, 30-60 parts of barley and 20-35 parts of corn. The plant source bacteriostasis and detoxification deodorant provided by the invention has the advantages of high biological activity, strong broad-spectrum antibacterial property, fast insect and egg killing, good environment-friendly property, safety, high efficiency and the like. The invention also provides a preparation method and application of the plant source bacteriostasis and detoxification deodorant.

Owner:陈士进 +2

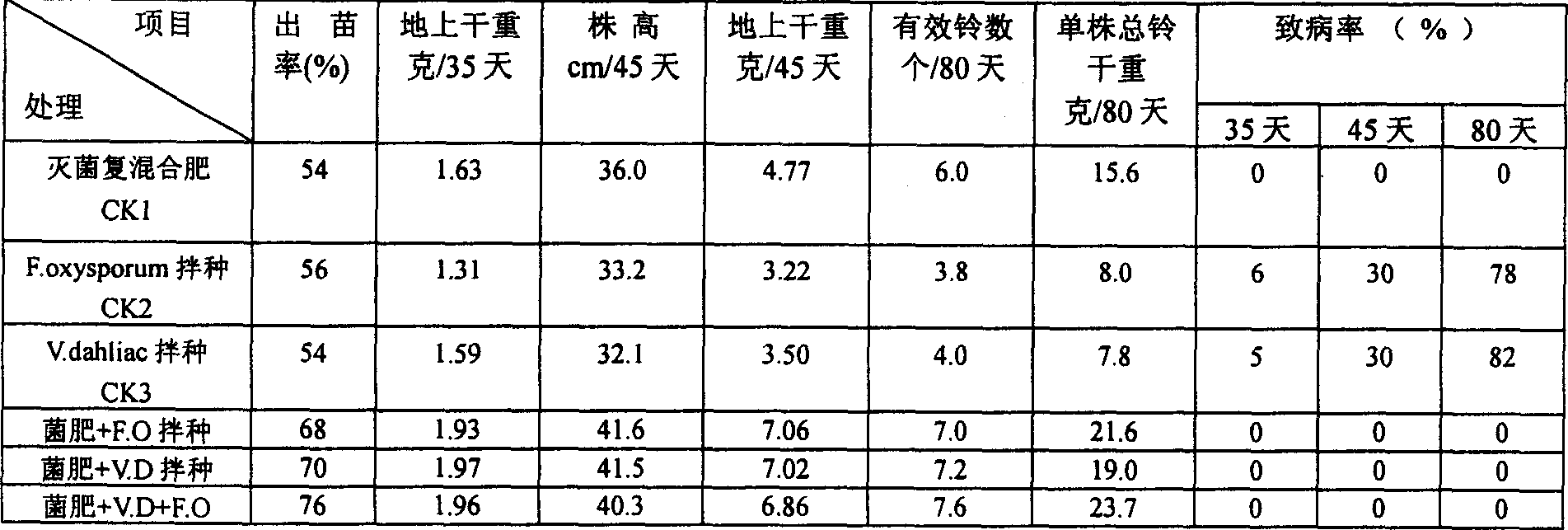

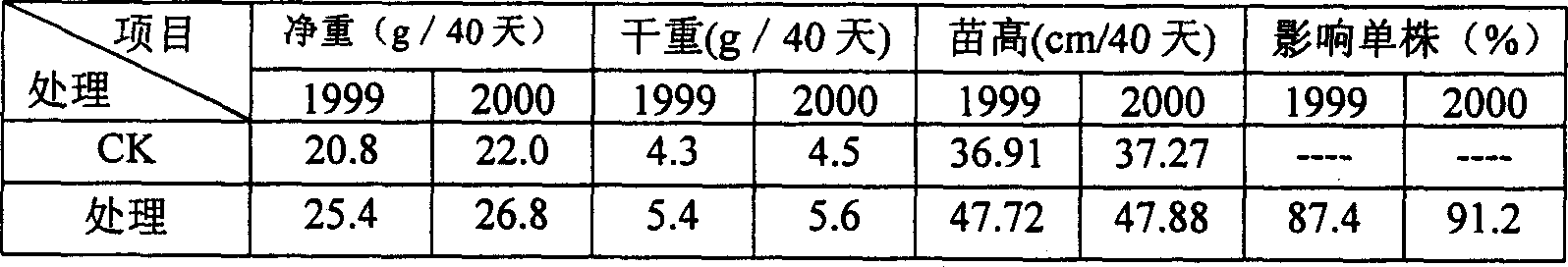

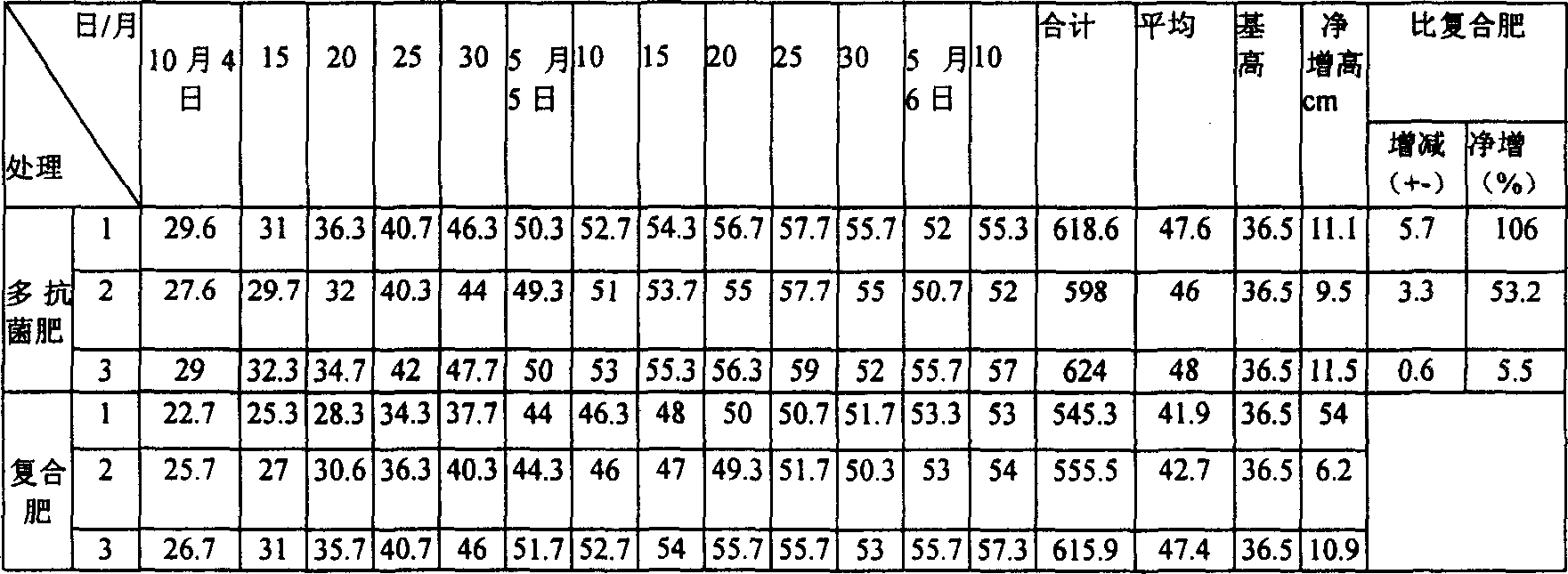

Microorganic fertilizer against various bacteria and its preparation and use

InactiveCN1490280APromote crop growthReduce soil borne diseasesBacteriaHorticulture methodsFertilizerTrichoderma

A multi-resistant microbial fertilizer is prepared from jelly-like bacillus, Bacillus licheniformis, Jingyang streptomycete and trichoderma through determining the proper culture and fermenting conditions, slant culturing, Erlenmeyer flask culturing, fermenting and / or solid culturing, proportional mixing and adsorbing by carrier. Its application method is also disclosed.

Owner:SOIL & FERTILIZER INST CHINESE ACAD OF AGRI SCI

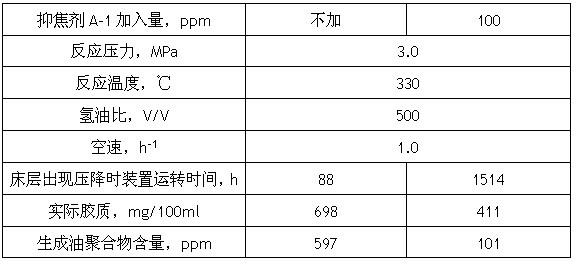

Butadiene polymerization inhibitor used in separation system of ethylene unit

InactiveCN102126910AReduce dosageGood inhibition effectDistillation purification/separationHydrocarbonsButadiene DioxideOrganosolv

The invention relates to the field of chemical additives, in particular to a butadiene polymerization inhibitor used in a separation system of an ethylene unit. The butadiene polymerization inhibitor is prepared from the following raw materials in percent by weight: 2-10 percent of radical capturing agent, 2-15 percent of antioxidant, 2-10 percent of metal passivating agent, 60-92 percent of organic solvent and 2-15 percent of clean dispersing agent. The butadiene polymerization inhibitor is prepared by the steps of: firstly adding 60-92 percent of the organic solvent in a container at normaltemperature under normal pressure, sequentially adding 2-10 percent of the radical capturing agent, 2-15 percent of the antioxidant, 2-10 percent of the metal passivating agent and 2-15 percent of the clean dispersing agent under stirring, uniformly stirring and completely dissolving to form a liquid. In the butadiene polymerization inhibitor provided by the invention, besides the efficient radical capturing agent, a synergetic effect is also specially considered with respect to components compatibility, thus, the polymerization inhibition effect is improved and the consumption of the polymerization inhibitor is decreased. The butadiene polymerization inhibitor provided by the invention is applied to a depropanizing column and a reboiler of the ethylene unit, and can effectively prevent butadiene from polymerizing and depositing on the surfaces of the devices.

Owner:LANZHOU DAYANG CHEM

High-gloss anti-crack adhesive for multilayer plywood and method for manufacturing multilayer plywood

ActiveCN103265921AImprove clarityImprove plasticizing effectLaminationLamination apparatusWear resistantRoom temperature

A high-gloss anti-crack adhesive for multilayer plywood is provided. The multilayer plywood is mutually glued and laminated by a single layer material. The adhesive includes a urea-formaldehyde resin adhesive and additive and added additives therein, a melamine resin adhesive and added additives therein. The preparation methods of the urea-formaldehyde resin adhesive and the melamine resin adhesive are creatively improved by inventors. The free formaldehyde in the obtained adhesive is less than 0.1%. Operation is easy, equipment is easy to get, no pollution generates, implementation is easy and price is inexpensive. The high-gloss anti-crack adhesive can be used for the multi-layer plywood, has excellent pre-pressing property, can mold at room temperature in 30-40 min, and has bonding strength >= 1.0 MPa, formaldehyde emission <= 1.0 mg / L, which is below requirements of GB / T18580-2001 E1 level, and gloss >= 85 DEG. In the environment with sudden changes in temperature, the high-gloss anti-crack adhesive has the advantages of preventing wear-resistant material cracking and bubbling as a result of thermal expansion and cool contraction.

Owner:ZHEJIANG DILONG NEW MATERIAL

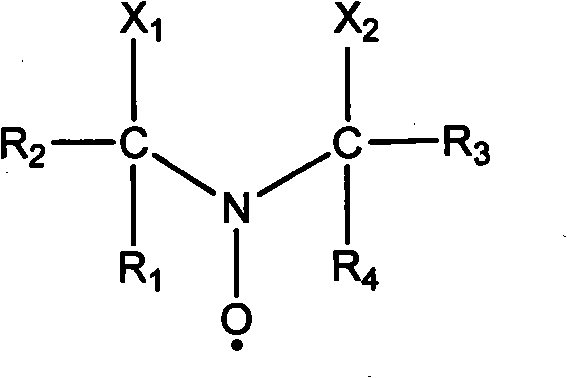

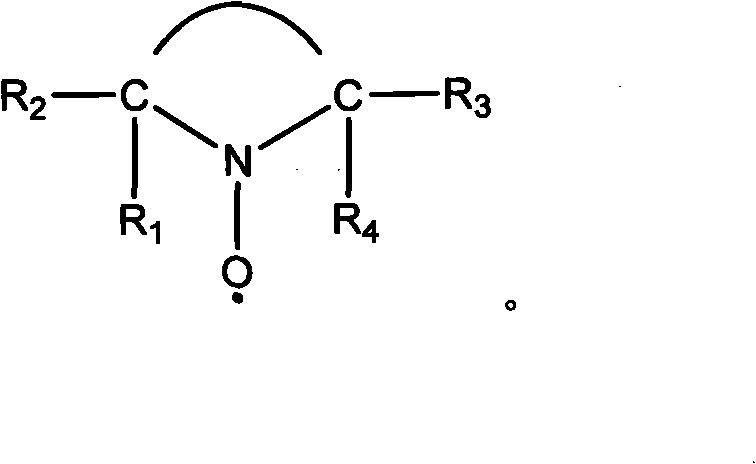

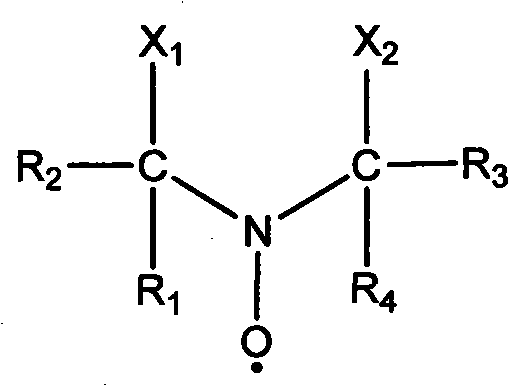

High efficiency composite polymerization inhibitor for refining styrene and its application

InactiveCN1974503AGood inhibition effectLow costHydrocarbon purification/separationHydrocarbonsSolubilityOrganic solvent

The present invention relates to one kind of high efficiency composite polymerization inhibitor for refining styrene. The composite polymerization inhibitor is re-compounded with aromatic amine compound, nitrogen-oxygen free radical or phenothiazine, and nitrophenol compound in certain proportion, and through dissolving in organic solvent. The composite polymerization inhibitor has the synergistic effect of the polymerization retarder and polymerization inhibitor, obviously polymerization inhibiting effect higher than single polymerization inhibitor, lowered toxicity and raised solubility, and can meet the requirement for styrene rectifier to run stably for long term.

Owner:DALIAN UNIV OF TECH

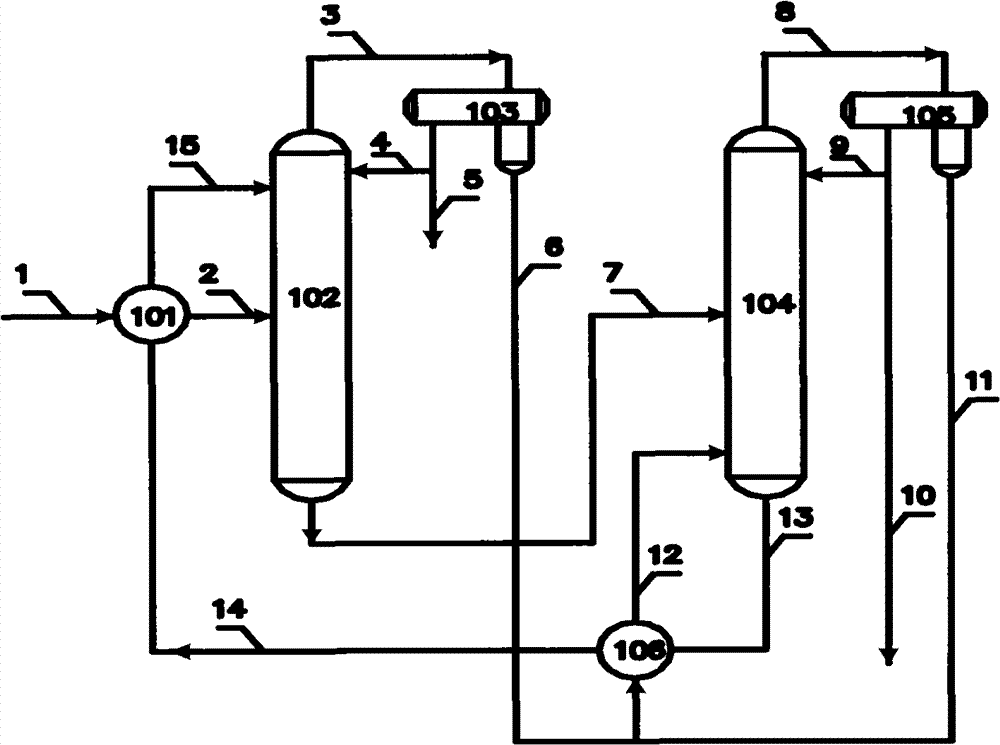

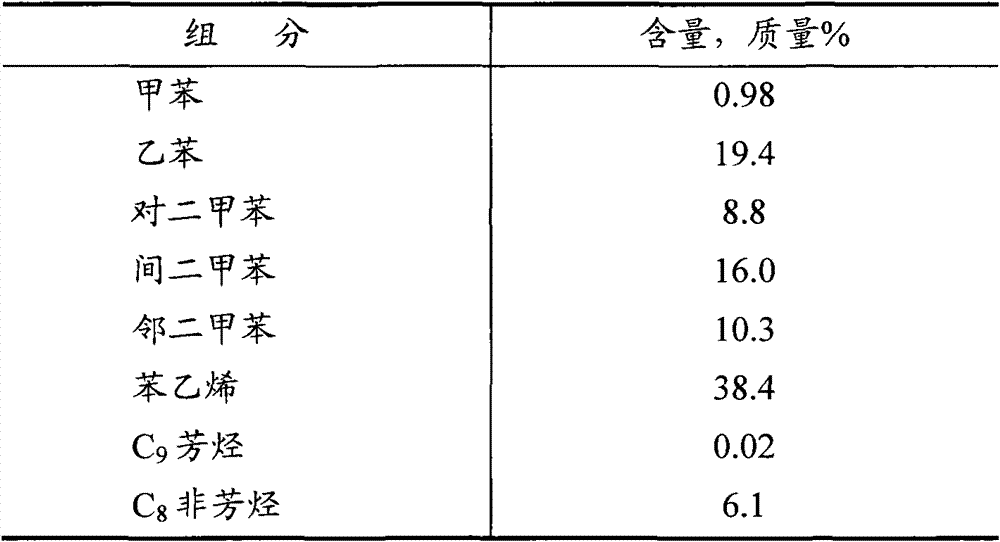

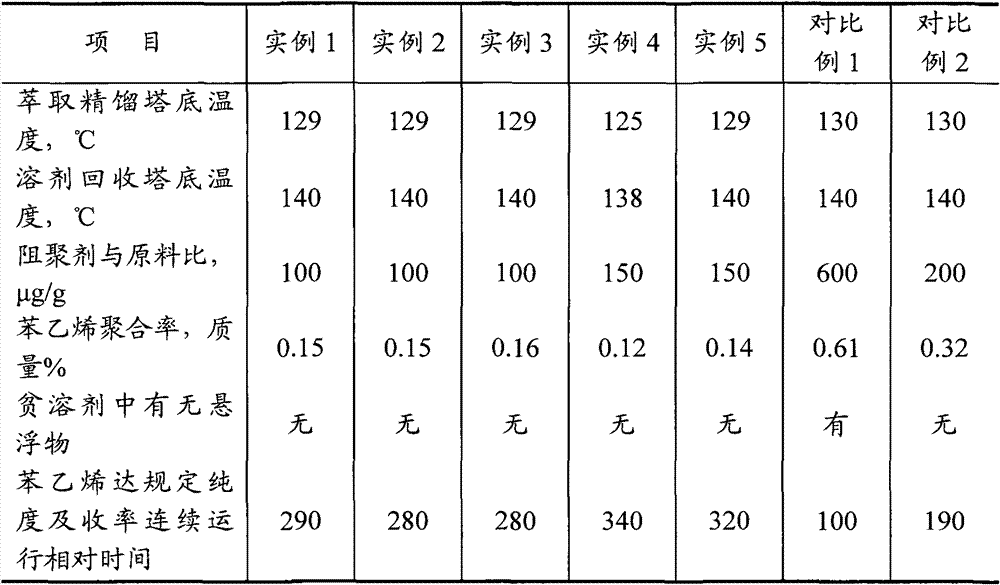

Method for extracting, distilling and recovering styrene from hydrocarbon mixture

ActiveCN103360201APrevent precipitationGood inhibition effectDistillation purification/separationHydroxylamineHydrocarbon mixtures

The invention relates to a method for extracting, distilling and recovering styrene from a hydrocarbon mixture. The method comprises the following steps of: extracting, distilling and recovering the styrene from the hydrocarbon mixture by using a composite solvent in the presence of a polymerization inhibitor. The composite solvent comprises 80-99% by mass of a main solvent, 0.01-19% by mass of an auxiliary solvent and 0.1-2.0% by mass of water, wherein the main solvent is a sulfone compound, and the auxiliary solvent is metoxyphenol or the mixture of the metoxyphenol and the glycol monomethyl ether. The polymerization inhibitor comprises 40-80% by mass of free radicals of nitrogen and oxygen, 15-50% by mass of nitro-phenol and derivatives thereof and 5-30% by mass of N, N-diethyl hydroxylamine. The use amount of the polymerization inhibitor is 10-500mug / g of the amount of the hydrocarbon raw material. Because the composite solvent is used together with the polymerization inhibitor, the use amount of the polymerization inhibitor can be decreased, and the rate of polymerization of the styrene can be reduced significantly.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-efficiency environmentally-friendly polymerization inhibitor of styrene

ActiveCN102249842AGood inhibition effectAvoid disadvantagesDistillation purification/separationHydrocarbonsSolubilityPhosphorous acid

The invention relates to a high-efficiency environmentally-friendly polymerization inhibitor of styrene, and a use method thereof. The compound polymerization inhibitor comprises nitroxide free radical compounds, hydroxylamine compounds, nitrophenol compounds and phosphite ester compounds. The compound polymerization inhibitor utilizes ingeniously synergistic effects of the above compounds, thus overcomes respectively defects of a retarder and an actual polymerization inhibitor and improves obviously polymerization inhibiting effects. Simultaneously, the compound polymerization inhibitor realizes that the use of high toxic substances is reduced; toxicity is reduced; the solubility in styrene or ethylbenzene is increased; and good economic benefits are obtained.

Owner:CHINA PETROLEUM & CHEM CORP +2

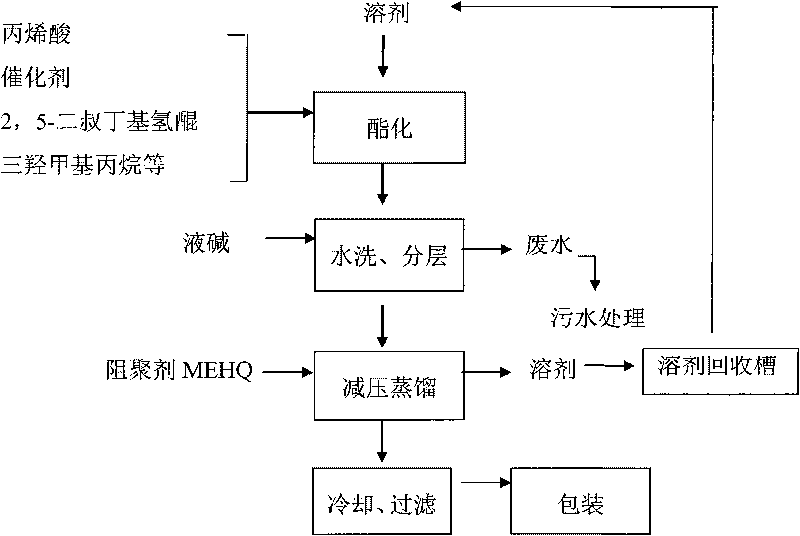

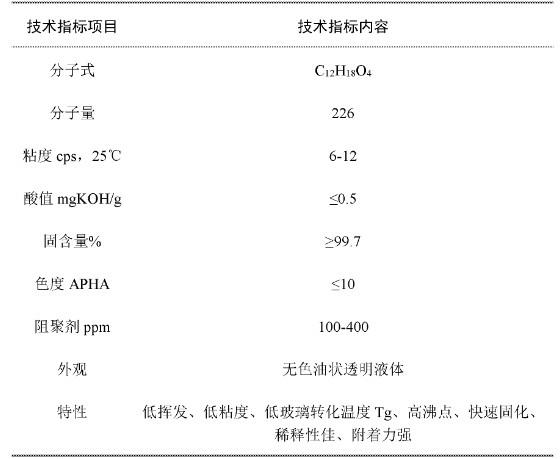

Trimethylolpropane triacrylate and preparation method thereof

ActiveCN101704745AShort reaction timeEasy to washOrganic compound preparationCarboxylic acid esters preparationReaction temperatureWaste treatment

The invention relates to trimethylolpropane triacrylate and a preparation method thereof. The formula of the trimethylolpropane triacrylate comprises the following raw materials in part by weight: solvent 20-50, trimethylolpropane 18-25, catalyst 4-8, 2,5-di-tert-butylhydroquinone 0.06 to 0.1 and acrylic acid 15-20. The preparation method comprises: placing the raw materials into a reaction kettle according to requirements of the formula and stirring the raw materials to perform reaction for 2 to 9 hours; starting a vacuum pump and raising the temperature in the reaction kettle till refluxingis generated and keeping refluxing for 1 to 3 hours; stopping raising the temperature when detecting the mass percentage of hydroxyl in reaction solution is 2 to 4 percent; adding caustic soda liquidinto the reaction kettle, controlling the pH value of the solution to be 7 to 8; standing the solution for delamination; leading waste water in the lower layer to a waste water treatment system; preferably adding polymerization inhibitor into the solution from which the waste water is removed; and distilling the solution at reduced pressure to remove methylbenzene and obtaining the product. Compared with the prior art, the method has the advantages of short reaction time, few by products, low reaction temperature and low production cost.

Owner:CAC NANTONG CHEM

Film-spraying waterproof material, and preparation and application methods thereof

InactiveCN104710849AGood inhibition effectImprove system adaptabilityCoatingsEthylenediamineEthylenediamine tetraacetate

The invention discloses a film-spraying waterproof material which is prepared from the following raw materials in parts by weight: 100 parts of magnesium acrylate monomer solution, 0.01-0.1 part of tetrasodium ethylenediamine tetraacetate, 0.01-0.1 part of copper acetate, 2-20 parts of silica white and 2-20 parts of calcium carbonate. The invention also discloses a preparation method of the film-spraying waterproof material, which comprises the following steps: adding the tetrasodium ethylenediamine tetraacetate and copper acetate into the magnesium acrylate monomer solution, uniformly stirring and mixing, adding the silica white and calcium carbonate, and stirring with a high-speed dispersion machine to obtain the film-spraying waterproof material. The invention also discloses an application method of the film-spraying waterproof material. The film-spraying waterproof material disclosed by the invention solves the problem that the original film-spraying waterproof material must be stored and transported in the refrigeratory state under high-temperature conditions, saves the cost, widens the application range, and lays solid foundation for the development of the film-spraying waterproof material.

Owner:成都市嘉洲新型防水材料有限公司

Mirabilis jalapa seed endosperm extract and application thereof in cosmetics

InactiveCN103816085APleasant smellSkin feels fresh and not greasyCosmetic preparationsToilet preparationsReflux extractionDistillation

The invention discloses a mirabilis jalapa seed endosperm extract. The mirabilis jalapa seed endosperm extract is prepared by the following steps: crushing dried and pure mirabilis jalapa seed endosperm to pass through a sieve with the granularity of 40 meshes, soaking the mirabilis jalapa seed endosperm powder in ethanol which is 4-7 times of the weight of the mirabilis jalapa seed endosperm powder and has the mass concentration of 75-95%, performing reflux extraction, filtering while heating, and performing reduced pressure distillation for recovering the ethanol, and performing secondary filtering to obtain the mirabilis jalapa seed endosperm extract. The cosmetic prepared by the novel and unique formula does not contain any artificially synthetic preservative or pigment, is uniform and stable in pasty fluid, pleasant in fragrance, fresh and cool but not greasy in skin feel, is suitable for people of all ages and both sexes, is a natural skin care product which integrates the effects of beauty, maintenance and treatment into a whole, and has a good market development prospect.

Owner:NORTHWEST UNIV(CN)

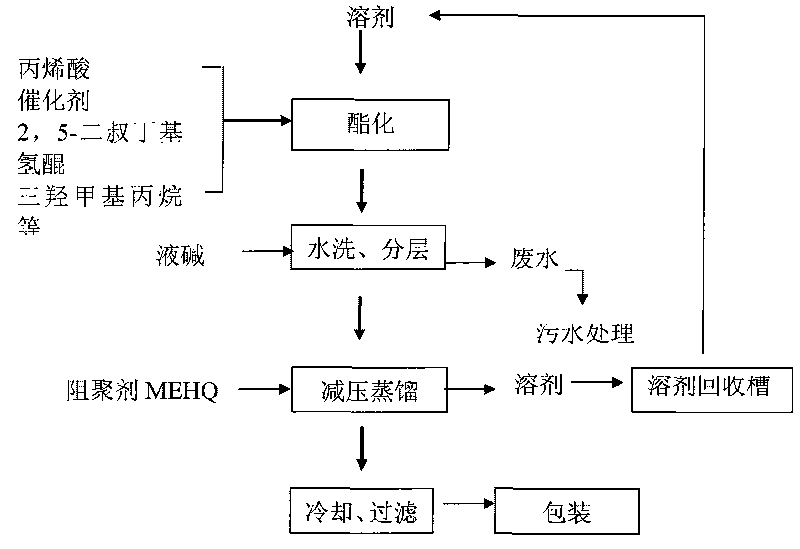

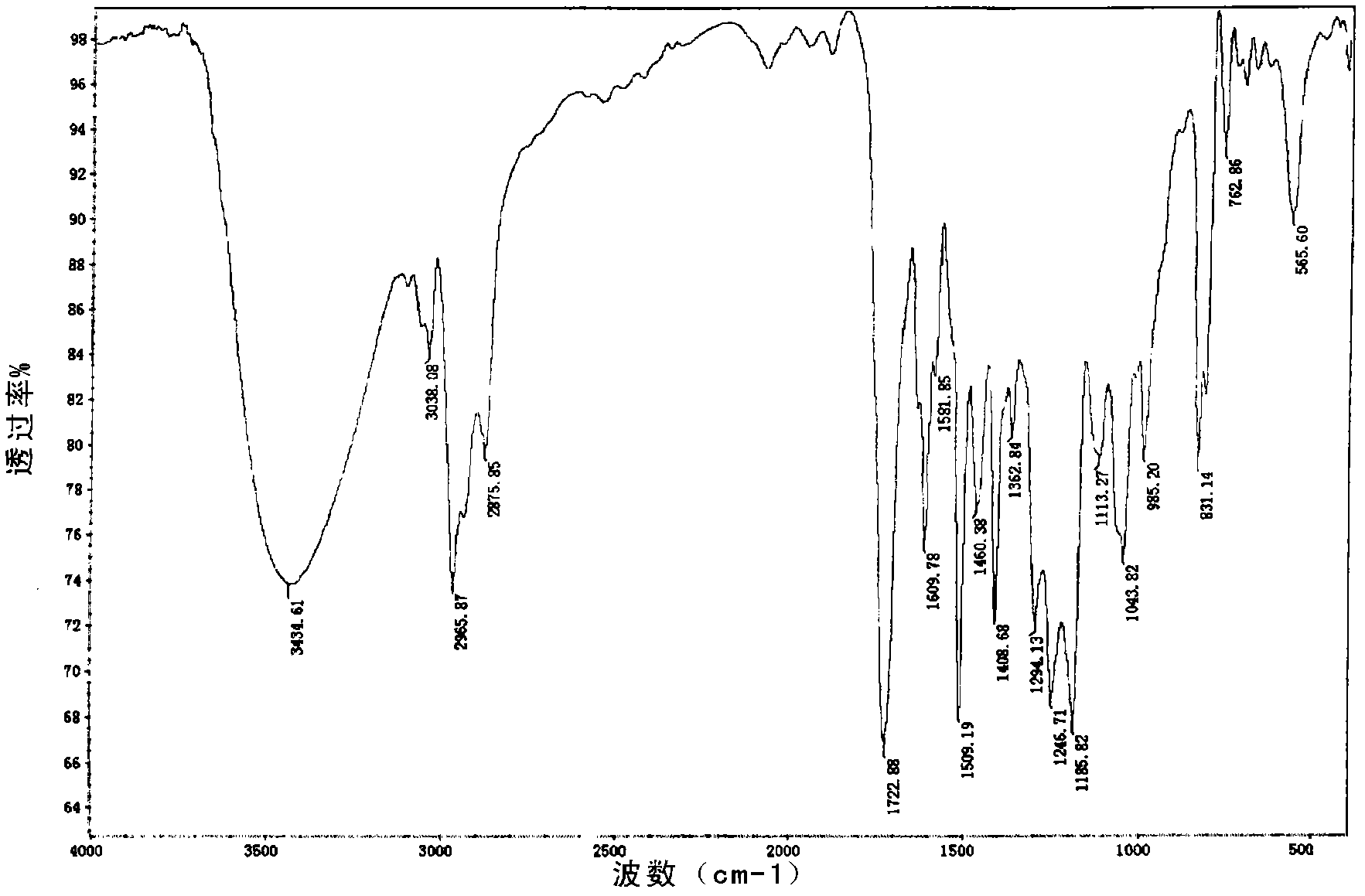

Method for preparing 3-(methacryloxy)propyltrimethoxysilane

ActiveCN101121724AHigh catalytic efficiencyLow costGroup 4/14 element organic compoundsSilanesDissolution

The invention discloses a preparation method of the 3-(methacryloyl oxygen) propyl tri-methoxy silane. The steps are: first the platinum chloride acid, isopropanol and the compound A are used as the raw materials; the platinum chloride acid is added into the isopropyl alcohol; after the dissolution, the compound A is added and then to be heated; secondly, the polymerization-preventing reagent phenothiazine and ZJ-701 are added into the tri-methoxy silane to dissolve the raw material X; thirdly, the polymerization-preventing reagent N, N'-drophenyl-p-phenylenediamine are added in the methacrylate allylic ester to dissolve the raw material Y; fourthly, the polymerization-preventing reagent ZJ-701 and ZJ-101 are added in the reaction materials after the reaction between the raw materials and the catalysts to dissolve to get the 3-(methacryloyl oxygen) propyl tri-methoxy silane. The invention is of the simple preparation, the high efficiency, the little consumption, the strong selectivity, and the high collection rate of the products; the polymerization-preventing effects of the polymerization-preventing technology are good; the polymerization-preventing reagents are not easy to be gelated; the consumption is little; the polymerization-preventing reagents are easily separated from the products; the products are easy to be decolorized, good in quality, and have no harm to the catalyst.

Owner:湖北武大有机硅新材料股份有限公司

Resin system capable of realizing automatic oxidation, automatic initiation and radiation curing and preparation method thereof

ActiveCN102807539AEasy to makeCheaply madeCarbamic acid derivatives preparationOrganic compound preparationChemistryHardness

The invention provides a resin system capable of realizing automatic oxidation, automatic initiation and radiation curing and a preparation method thereof, relates to a coating obtained by resin capable of realizing automatic oxidation, automatic initiation and radiation curing and provides a coating composition of the resin system capable of realizing automatic oxidation, automatic initiation and radiation curing. The resin system capable of realizing automatic oxidation, automatic initiation and radiation curing disclosed by the invention comprises a segment capable of realizing radiation curing and a segment realizing automatic oxidation, so that the coating obtained by curing the resin system containing two groups has favorable balanced hardness and flexibility and adhesive power and overcomes the contradiction between the hardness and the flexibility and the adhesive power, which is difficult in solving for a long term.

Owner:GUANGDONG HUARUN PAINT CO LTD

Antibacterial PE water supply pipe

The invention discloses an antibacterial PE water supply pipe. The antibacterial PE water supply pipe is prepared from the following raw materials in parts by weight: 80-100 parts of a polyethylene raw material, 20-30 parts of a regenerated polyethylene material, 2-4 parts of an antioxidant, 12-24 parts of a compound antibacterial agent, 1-3 parts of a lubricant, 2-5 parts of a dispersing agent and 1-3 parts of an anti-impact modifier, wherein the compound antibacterial agent contains an inorganic antibacterial material and an organic antibacterial material in a mass ratio of (2-4) to 1, and the inorganic antibacterial material contains Muyu stone sphere powder, zeolite powder, zinc oxide and nano-silver. The antibacterial efficiency of the antibacterial PE water supply pipe reaches above 99%, and the antibacterial cycle is long.

Owner:ANHUI GUODENG PIPE IND TECH CO LTD

Polymerization inhibitor for preventing self-polymerization or co-polymerization of C5 diolefins

InactiveCN1699311AGood inhibition effectHydrocarbon purification/separationHydrocarbonsButylphthalideComposition B

The invention relates to a polymerization inhibitor for preventing self-polymerization or co-polymerization of C5 diolefins, which comprises composition A: diethylhydroxylamine, composition B: tert-butyl pyrocatechol, and solvent, wherein the solvent is selected from benzene, toluene, dimethylbenzene or ethylbenzene, the weight ratio of the composition A and the composition B being (0.5-6):1, the total content of the composition A and the composition B in the polymerization inhibitor being 25-45wt%. Compared with the prior art, the invention can realize better polymerization inhibiting effect, and no extra separation process is needed in the current C5 distillate separation procedure.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Process for preventing self-polymerization or co-polymerization of C5 diolefins in separation process of petroleum C5 distillate

InactiveCN1699310AGood inhibition effectHydrocarbon purification/separationHydrocarbonsComposition BButylphthalide

The invention provides a process for preventing self-polymerization or co-polymerization of C5 diolefins in separation process of petroleum C5 distillate, which consists of charging polymerization inhibitor into C5 distillate material, and making the polymerization inhibitor maintain a finite amount in the C5 distillate material, the polymerization inhibitor comprises composition A: diethylhydroxylamine, and composition B: tert-butyl pyrocatechol, the weight ratio of the composition A and the composition B being (0.5-6):1, the quantity of polymerization inhibitor in the C5 distillate material is sustained at 30-600ppm calculated on the total amount of the composition A and the composition B. The invention can realize better polymerization inhibiting effect, and no extra separation process is needed in the current C5 distillate separation procedure.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD +1

High-quality polymerization inhibitor and preparation technology of same

InactiveCN103030590AGood inhibition effectIncrease added valueOrganic chemistryDistillation2,2,6,6-Tetramethylpiperidine

The invention discloses high-quality 4-methoxyl-2, 2, 6, 6-tetramethylpiperidinol (polymerization inhibitor 705 for short) and a preparation technology of the same. The high-quality polymerization inhibitor is prepared by the processes of: firstly, preparing tetramethylpiperidinol, and then, carrying out mixing, oxidizing, filtering, molecular distillation, packaging and on the like. The technology for preparing the polymerization inhibitor 705 comprises carrying out oxidization on tetramethylpiperidinol and acetaldehyde. According to the technology disclosed by the invention, the polymerization inhibitor 705 is obtained by molecular distillation and purification, thus, high-quality products can be provided for the clients and the company.

Owner:南通市振兴精细化工有限公司

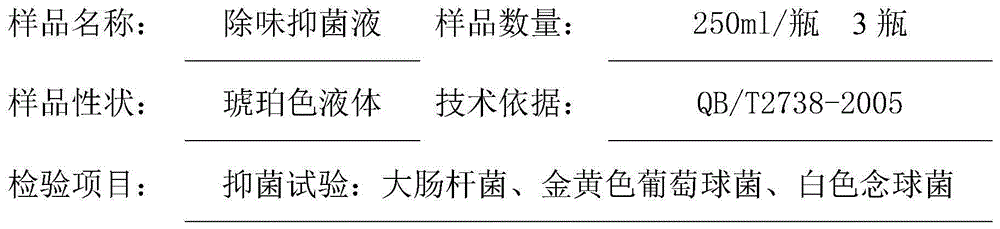

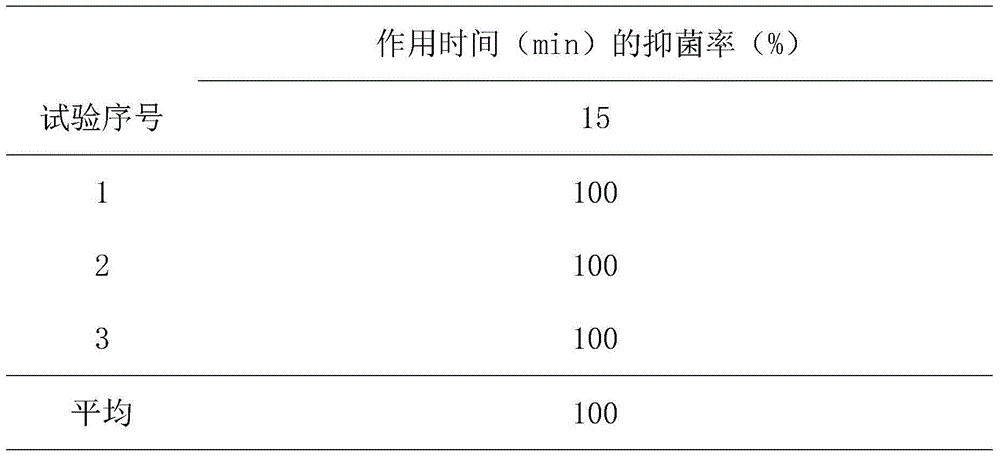

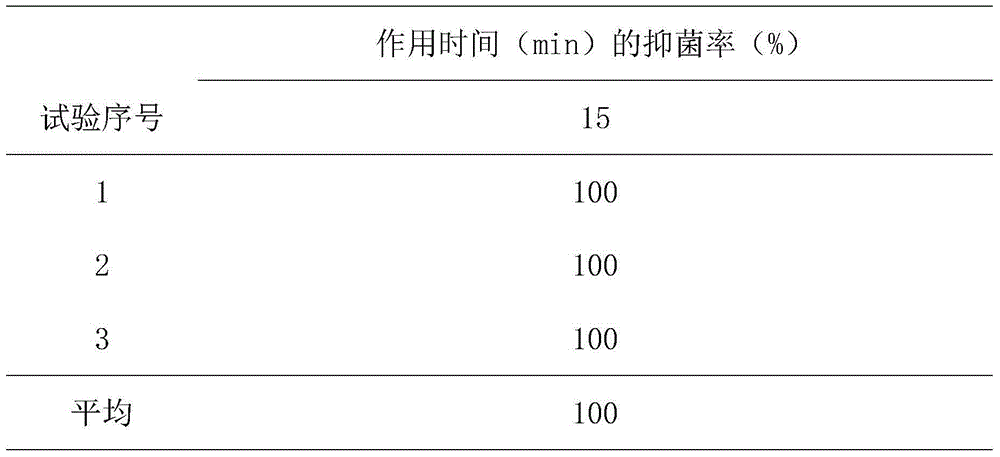

Deodorization fungicide as well as preparation method and application method thereof

The invention relates to a deodorization fungicide. The deodorization fungicide is obtained by soaking, decocting, fermenting, distilling and fermenting raw materials which are pseudolarix, madder, shinyleaf pricklyash root, aloe, sanguisorba officinalis, radix angelicae dahuricae, felwort, hemp seeds and muskroot-like semiaquilegia root, and the deodorization fungicide is applied to the air in a spraying manner. The deodorization fungicide has the effects of killing fungi, deodorizing and purifying the air and has strong effect of inhibiting and killing Gram positive bacteria, Gram negative bacteria and fungi.

Owner:深圳市月宫生物科技有限公司

Preparation method for methoxyethyl methacrylate

InactiveCN102351693AReduce dosageHigh catalytic efficiencyPreparation by ester-hydroxy reactionChemical industryTransesterificationAzeotropic distillation

The invention discloses a preparation method for methoxyethyl methacrylate. The method comprises the following steps of: reacting methyl methacrylate and methoxy ethanol serving as raw materials by using a reactive rectification transesterification process in the presence of a catalyst and a polymerization inhibitor; performing azeotropic distillation to timely remove methanol produced by reaction; distilling an obtained reaction product containing methoxyethyl methacrylate under a reduced pressure condition; and removing excessive methyl methacrylate and then removing the catalyst and the polymerization inhibitor to obtain a methoxyethyl methacrylate product, wherein the catalyst is a composite catalyst, and the polymerization inhibitor is a composite polymerization inhibitor. The preparation method has the advantages of good catalysis effect, short reaction time, high reaction efficiency, good polymerization inhibition effect, high reaction kettle efficiency, high product quality and yield and the like.

Owner:里光

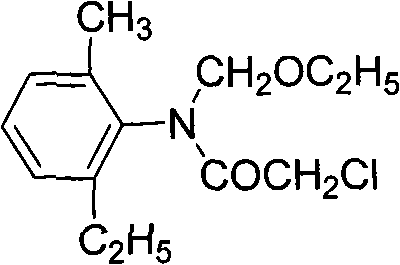

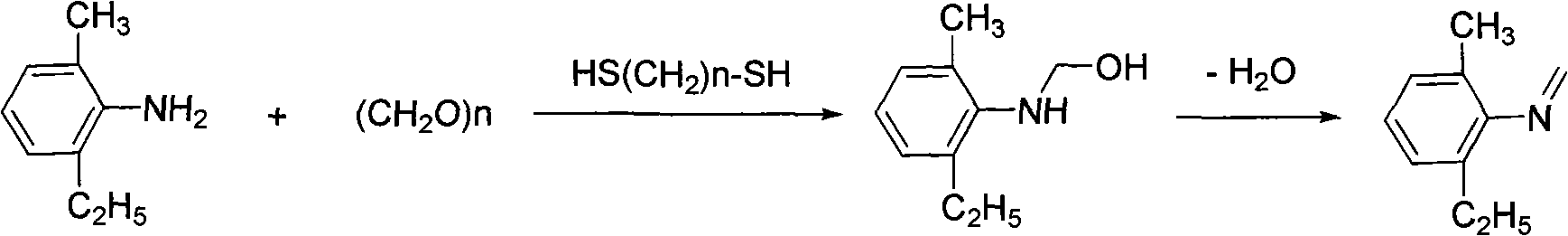

Preparation method of N-methylene-2-methyl-6-ethylaniline

ActiveCN101565387AGood inhibition effectHigh synthetic yieldImino compound preparationReaction rateOrganosulfur compounds

The invention provides a preparation method of N-methylene-2-methyl-6-ethylaniline, which takes a liquid organosulfur compound as a polymerization inhibitor; and the N-methylene-2-methyl-6-ethylaniline is generated by the condensation reaction and then the dehydration reaction between 2-methyl-6-ethylaniline and paraformaldehyde. The polymerization inhibitor prevents the generation of the polymerization reaction of a target object and reduces the possibility of condensation reaction, thus stabilizing the reaction rate, simplifying the technological operation, and improving the purity and yield of the target object, namely, methene; the content of the methene is more than 98 percent, and the synthesis yield is more than 96 percent, thus guaranteeing the quality of the final product, namely, acetochlor. The method is suitable for large-scale industrialized production, and has more significant economic benefit.

Owner:NUTRICHEM LAB CO LTD

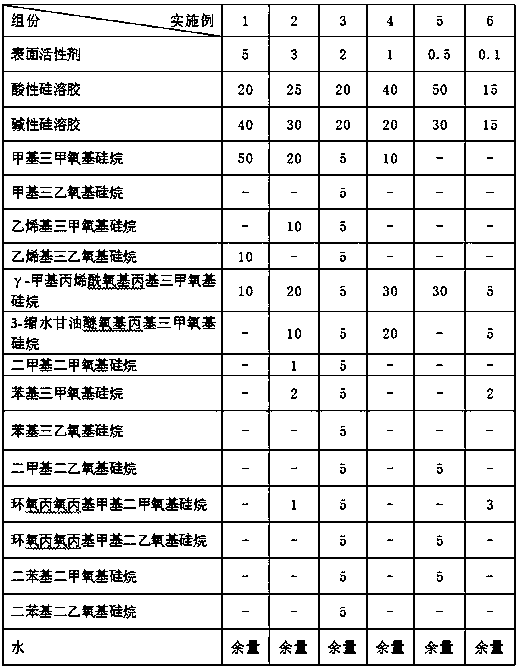

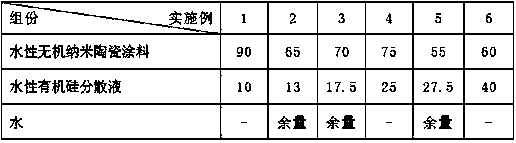

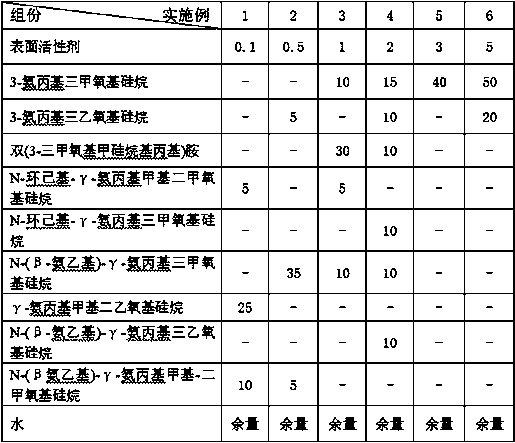

Normal temperature cured super weather-resistant and wear-resistant high-hardness water-based inorganic nanoceramic coating and preparation method thereof

ActiveCN109266057AImprove the inhibition effectImprove weather resistanceCoatingsWeather resistanceEmulsion

The invention relates to a normal temperature cured super weather-resistant and wear-resistant high-hardness water-based inorganic nanoceramic coating and a preparation method thereof. The inorganic nanoceramic coating comprises a water-based inorganic nanoceramic coating, water-based organosilicon dispersion liquid and water, wherein the water-based inorganic nanoceramic coating comprises the following raw materials: a water-based inorganic nanoceramic emulsion, a pigment, a filler, a wetting dispersing agent, a non-stick leveling agent, a thickening agent and water; the water-based inorganicnanoceramic emulsion comprises silica sol, silane, a surfactant and water; and the water-based organosilicon dispersion liquid comprise amino silane, a surfactant and water. The preparation method comprises a step of uniformly mixing the water-based inorganic nanoceramic coating and the water-based organosilicon dispersion liquid in weight ratio of (1-4):1, thereby obtaining the normal temperature cured super weather-resistant and wear-resistant high-hardness water-based inorganic nanoceramic coating. The coating product provided by the invention can be diluted with any water and stored stably for 1 year or longer, and has the characteristics of high hardness, high wear resistance, high weather resistance, normal temperature curing and the like.

Owner:CHANGSHA HUANGMEI PAINT

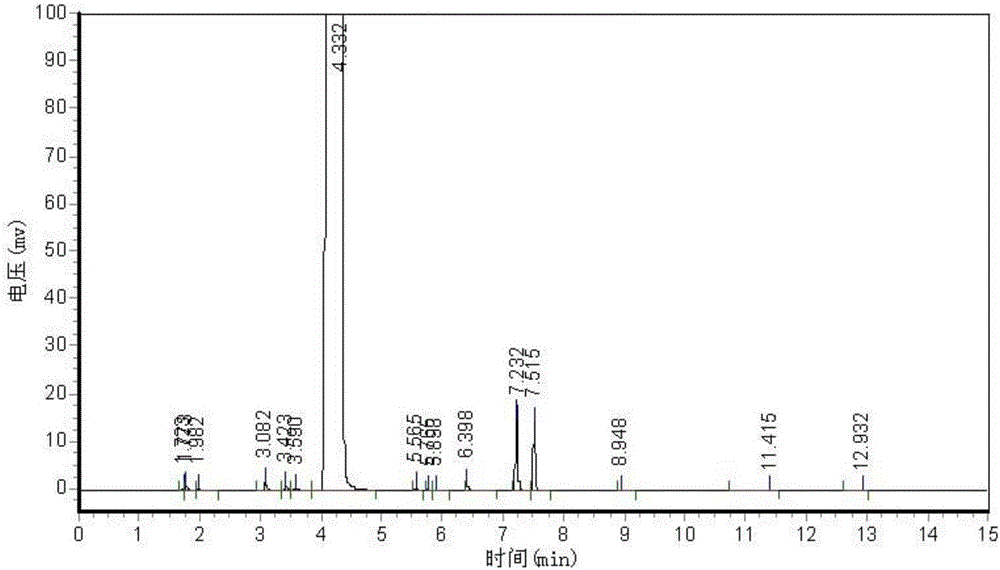

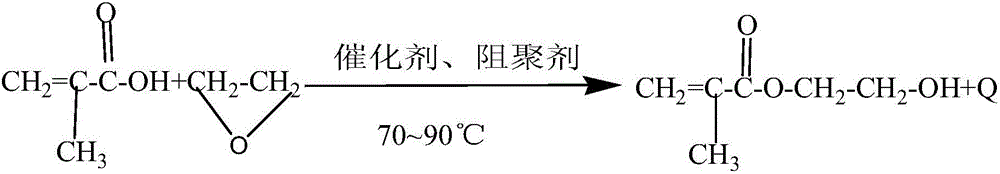

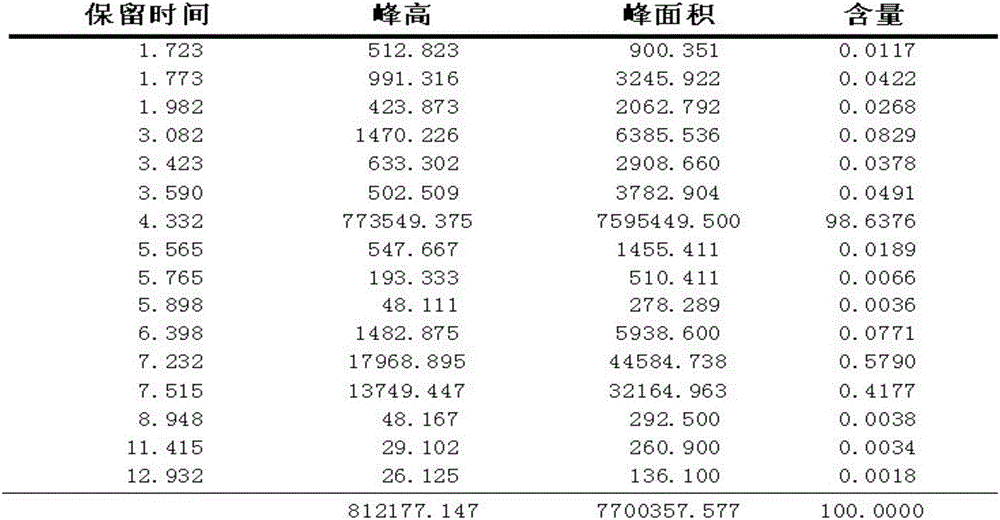

Preparation technique of high-purity hydroxyethyl methacrylate

InactiveCN105968011AImprove dispersionImprove the inhibition effectOrganic compound preparationCarboxylic acid esters preparationChemistry(Hydroxyethyl)methacrylate

The invention provides a preparation technique of high-purity hydroxyethyl methacrylate. A rectification process is added in a purification process; a polymerization inhibitor is replenished through a spraying way in a phase transformation process of the rectification process; meanwhile, the vacuum degree and the working temperature of a tower top are controlled; the flash polymerization, in a rectifying tower, of the hydroxyethyl methacrylate is avoided, so as to achieve the purposes of being stable in operation, being capable of effectively preventing polymerization and improving product quality, thereby improving the purity of a hydroxyethyl methacrylate product.

Owner:CHANGZHOU HICKORY CHEM

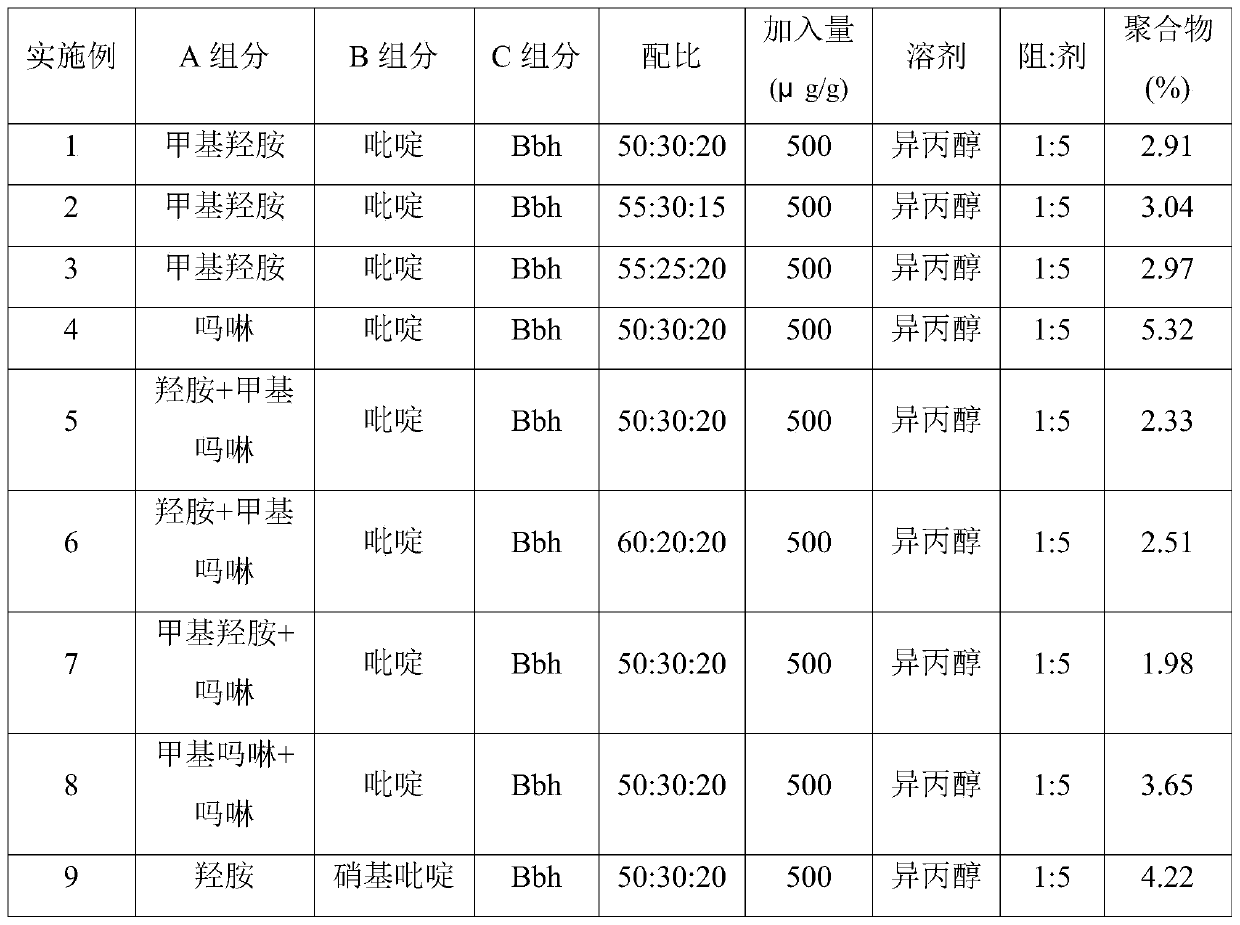

Polymerization inhibitor for preventing alkyne polymerization

ActiveCN105503502AGood inhibition effectHydrocarbon purification/separationHydrocarbonsPartial oxidationMorpholine

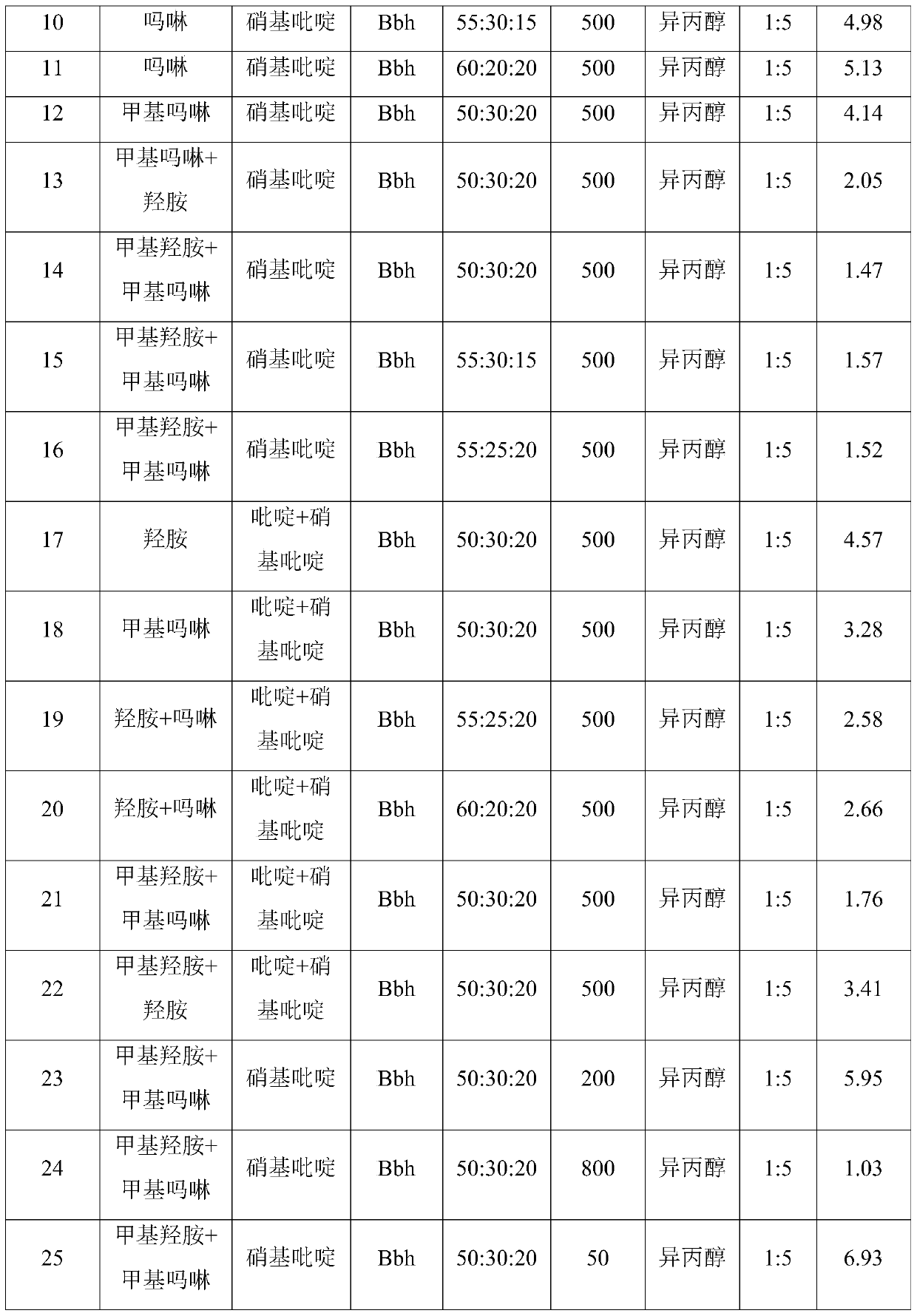

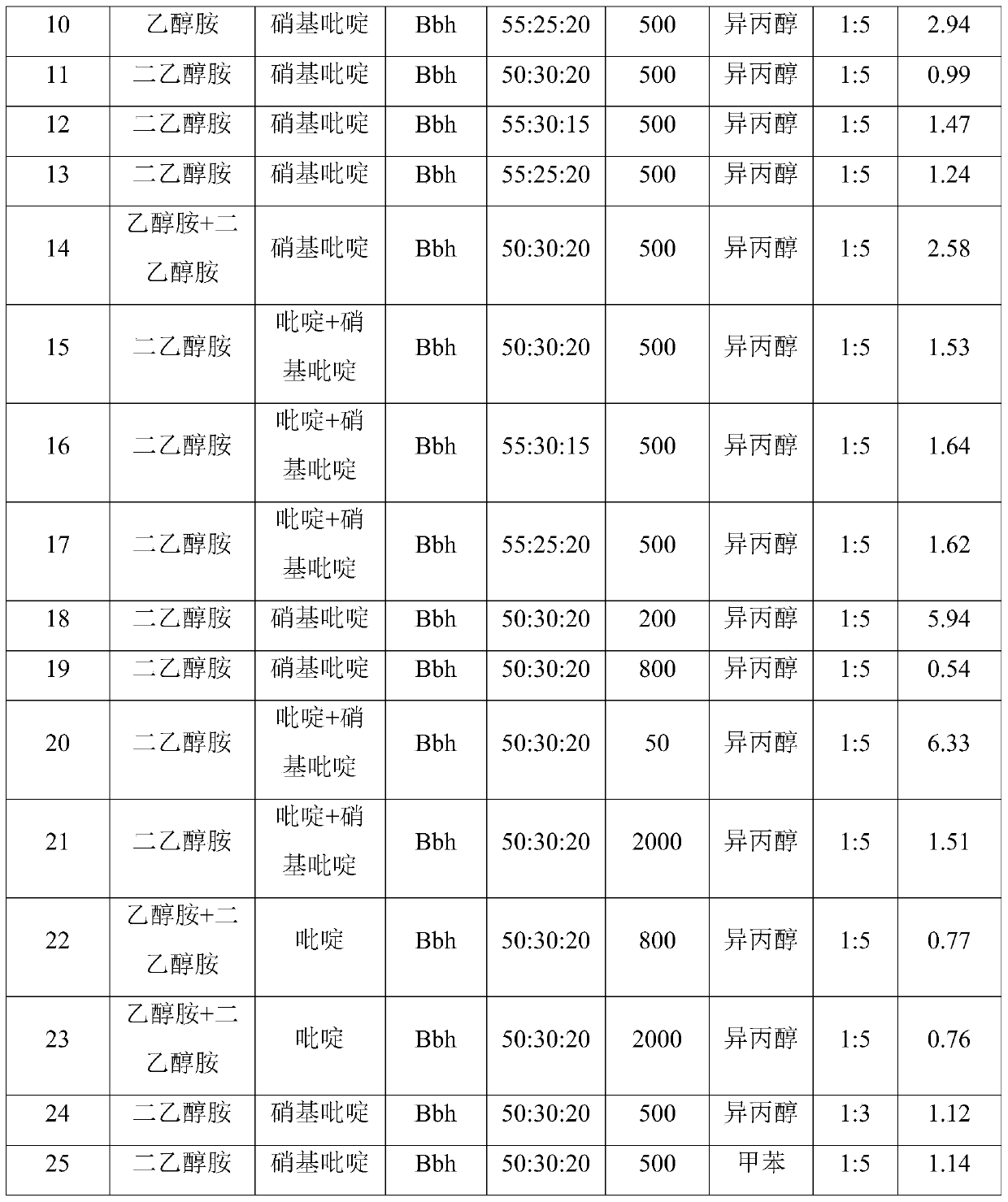

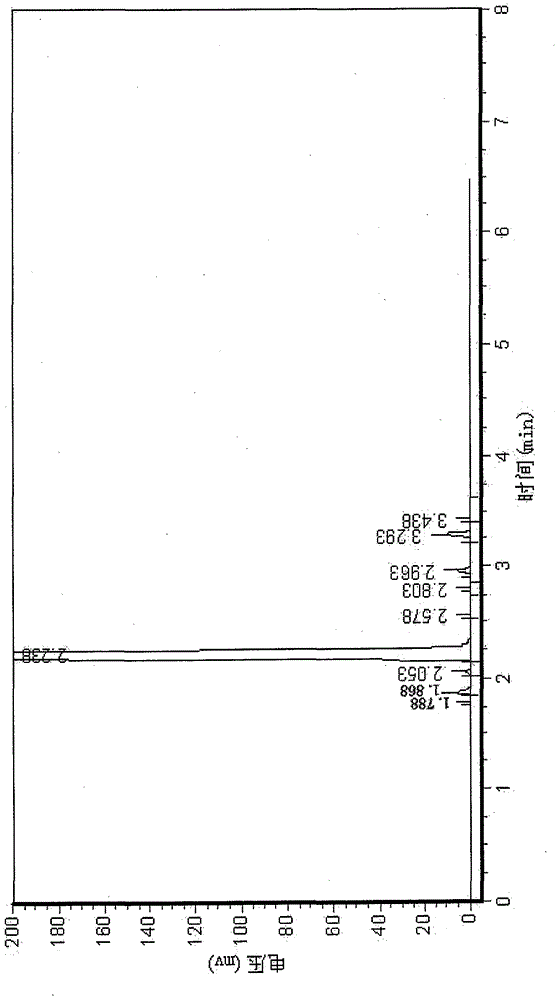

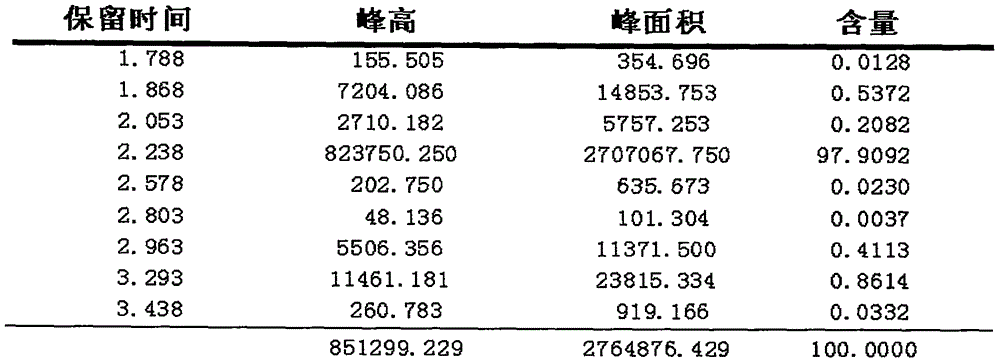

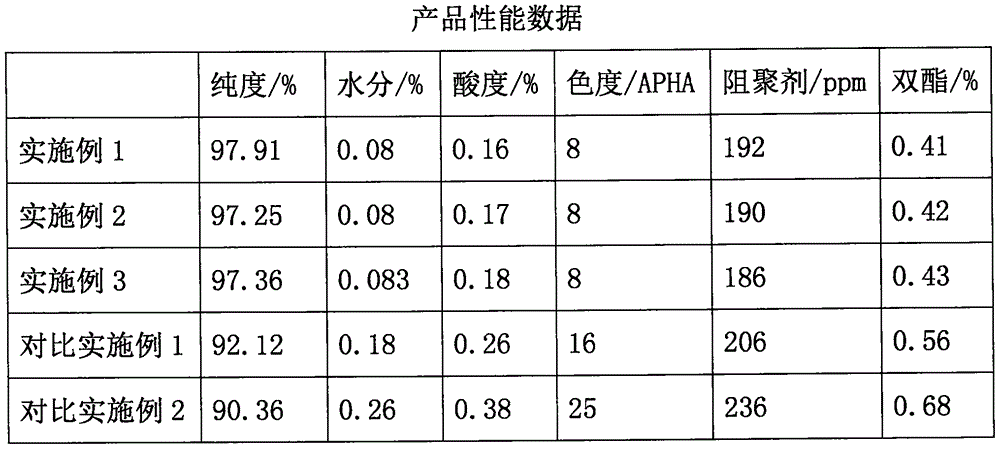

The invention relates to a polymerization inhibitor for preventing alkyne polymerization, and aims to solve the problems that in the natural gas partial oxidation process for producing acetylene, the alkyne polymerization happens easily, the system and pipelines are obstructed, and the normal operation of devices is influenced. The polymerization inhibitor is composed of the following components in percentages by weight: 50 to 60 wt% of component A namely hydroxylamine compounds or / and morpholine compounds, 20 to 30 wt% of component B namely pyridine or / and nitropyridine, and 10 to 20 wt% of component C namely acylhydrazone compounds. The provided polymerization inhibitor well solves the technical problems mentioned above, and can be applied to natural gas partial oxidation process for producing acetylene so as to prevent alkyne polymerization.

Owner:CHINA PETROLEUM & CHEM CORP +1

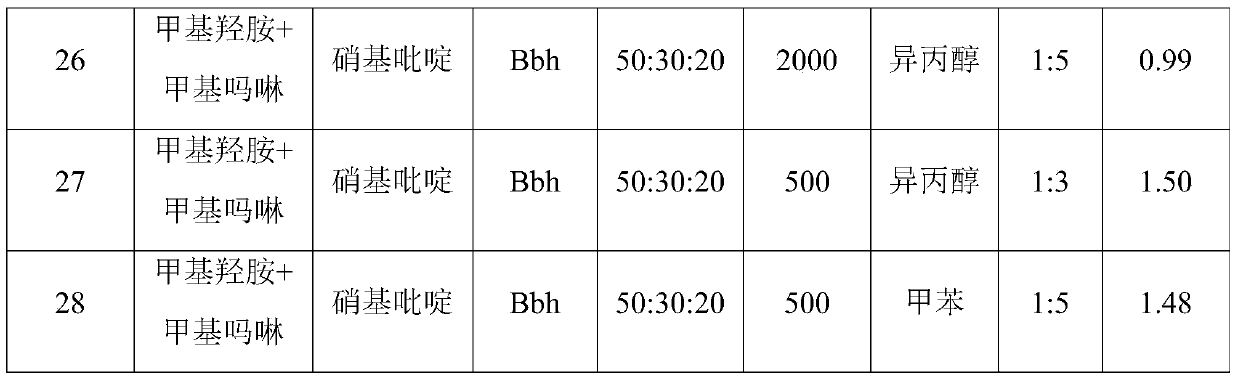

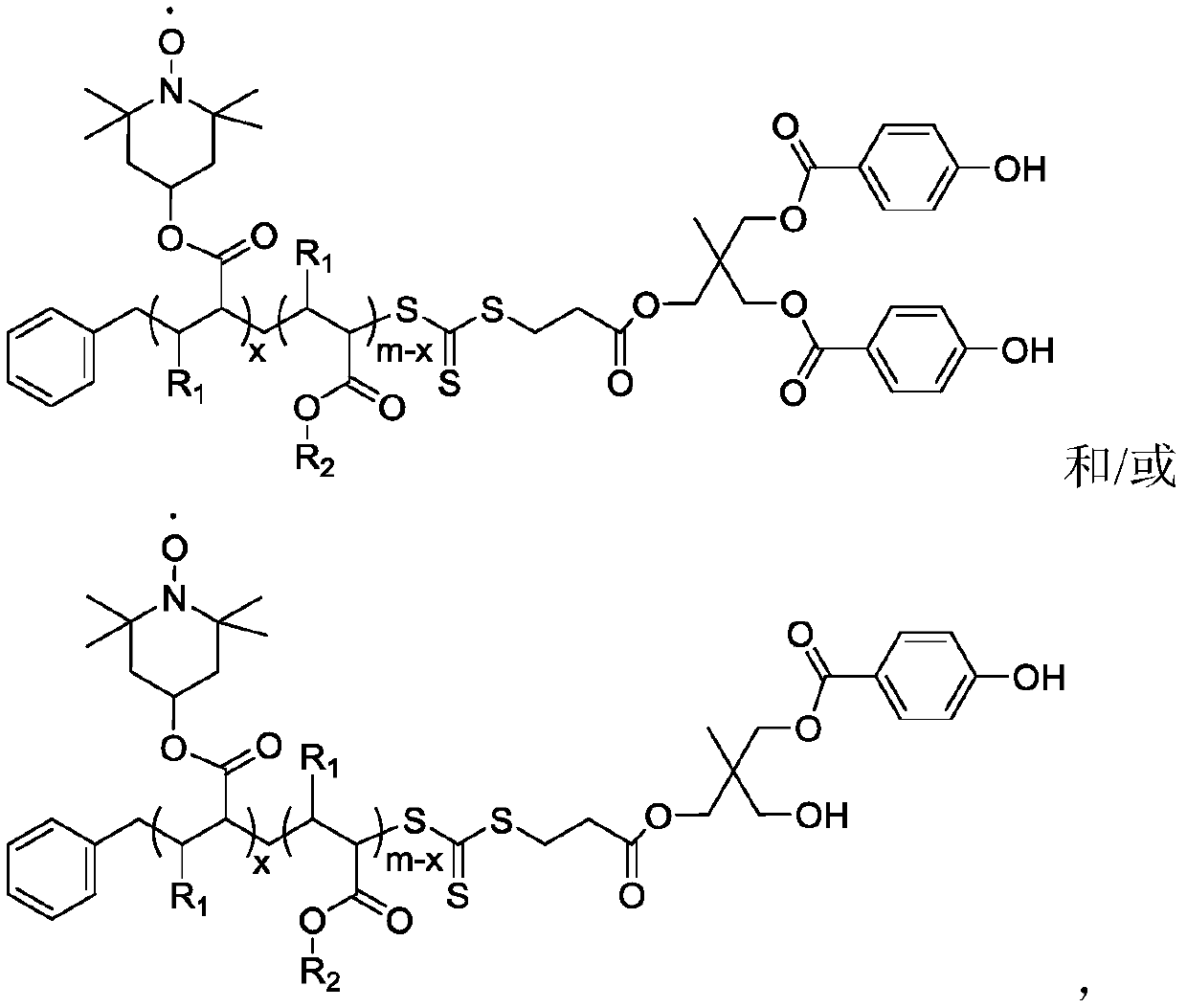

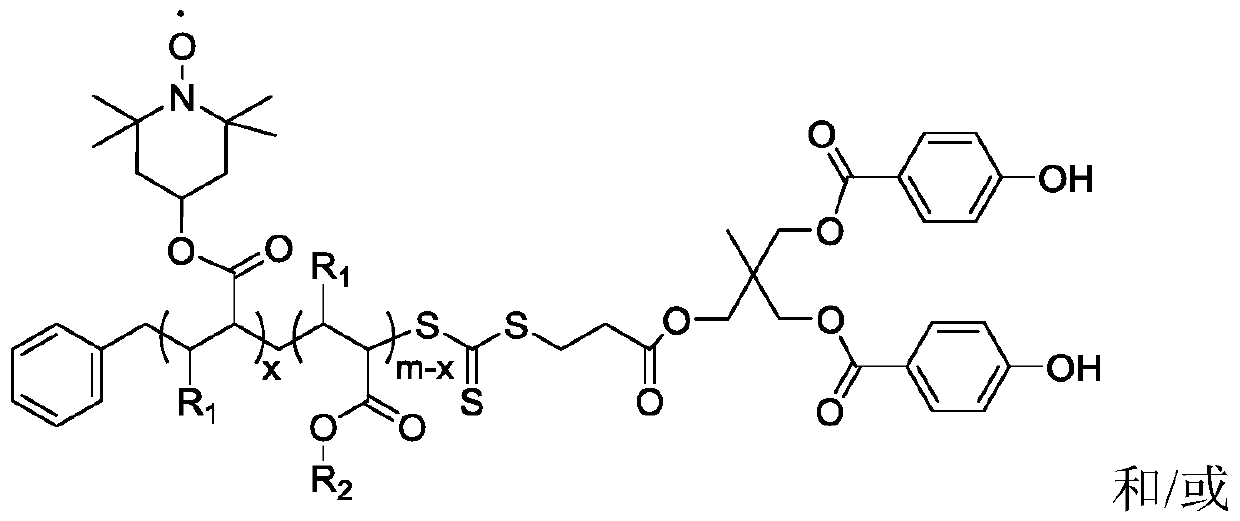

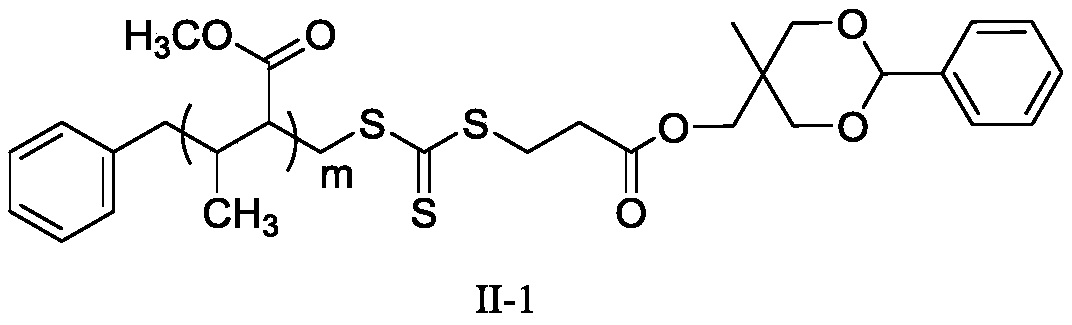

Polymerization inhibitor and preparation method and application thereof

ActiveCN110903422AIncrease modification densityGuaranteed amount of modificationOrganic compound preparationPreparation by ester-hydroxy reactionMethacrylatePolymer science

The invention discloses a polymerization inhibitor and a preparation method and application thereof. The polymerization inhibitor comprises a compound as shown in a general structural formula which isdescribed in the specification and / or another compound shown in another general structural formula which is described in the specification. In the general structural formulas, R1 is H or a methyl group; R2 is a methyl group or an ethyl group; m is in a range of 20-40, preferably 25-35; and x is greater than or equal to 1 and less than or equal to m. The polymerization inhibitor is a high-molecular homogeneous-phase load type polymerization inhibitor and is applicable to a high-boiling-point (methyl)acrylate reaction system. The polymerization inhibitor can effectively prevent the polymerization of raw materials and products; and in the separation process, the entrainment effect of products on the polymerization inhibitor is significantly reduced, and the purity of the products is ensured.Downstream use requirements on the polymerization inhibitor are met, so the polymerization inhibitor has good application prospects.

Owner:WANHUA CHEM GRP CO LTD

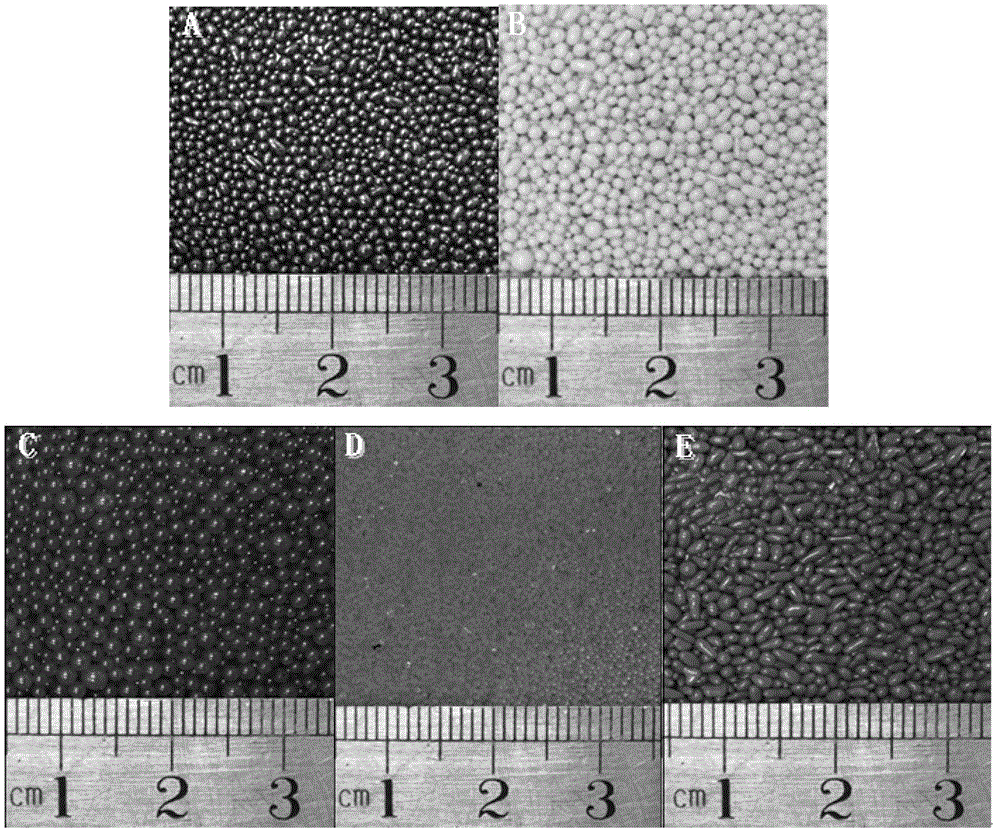

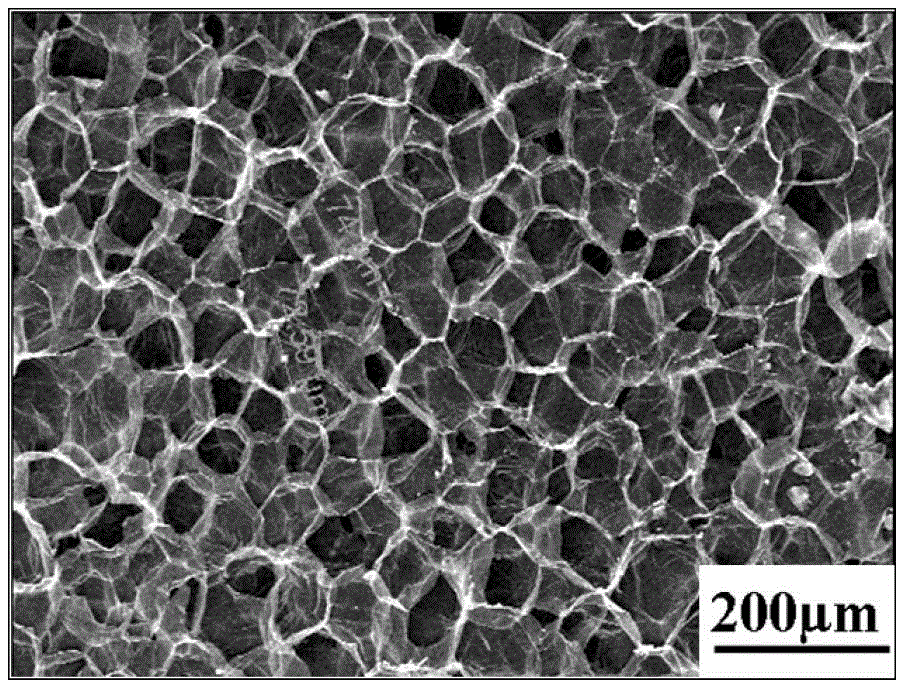

Expandable polystyrene resin bead with high color strength and high light fastness and preparation process thereof

The invention discloses an expandable polystyrene resin bead with high color strength and high light fastness and a preparation process thereof. The expandable polystyrene resin bead with high color strength and high light fastness is characterized in that resin beads prepared by the preparation process are uniform in particle size and have bright and controllable color, high color strength and high light fastness, and foamed products made of the resin beads are uniform in color and cell density and have structures with closed cells which are high in strength. The preparation process includes steps of preparing color paste with pigment particle size about 1 micrometer by dispersing and grinding techniques, then obtaining monomers containing precisely dispersed organic pigment with high color strength by phase transformation of the color paste, and finally initiating the colored monomers to complete polymerization. The expandable polystyrene resin bead with high color strength and high light fastness and the preparation process thereof have the advantages that the pigment prepared by the preparation process is fine and uniform in particle size and easy to develop, can disperse among the monomers precisely, and can be compatible with foaming agents and polymers well; and further, products with a small quantity of the pigment have satisfied brilliance and color strength, a polymerized system is stable and controllable without obvious inhibition, and reactions can be completed within a normal time.

Owner:DALIAN UNIV OF TECH

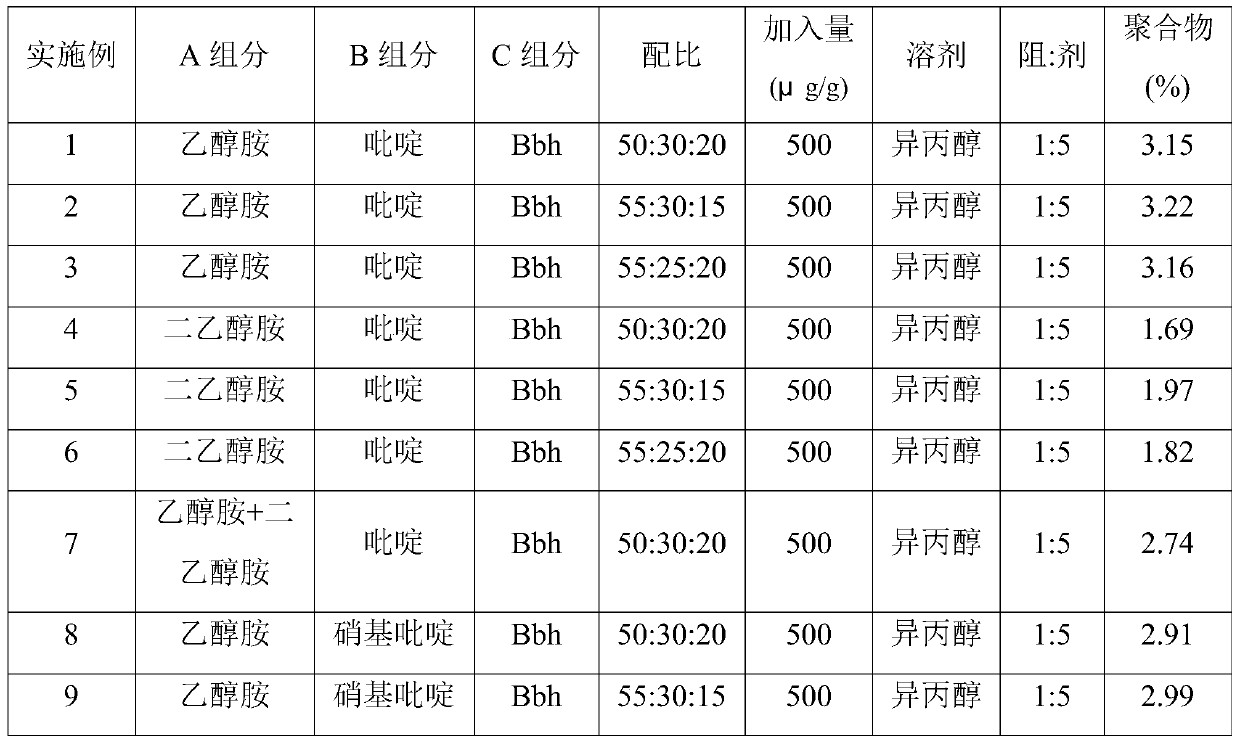

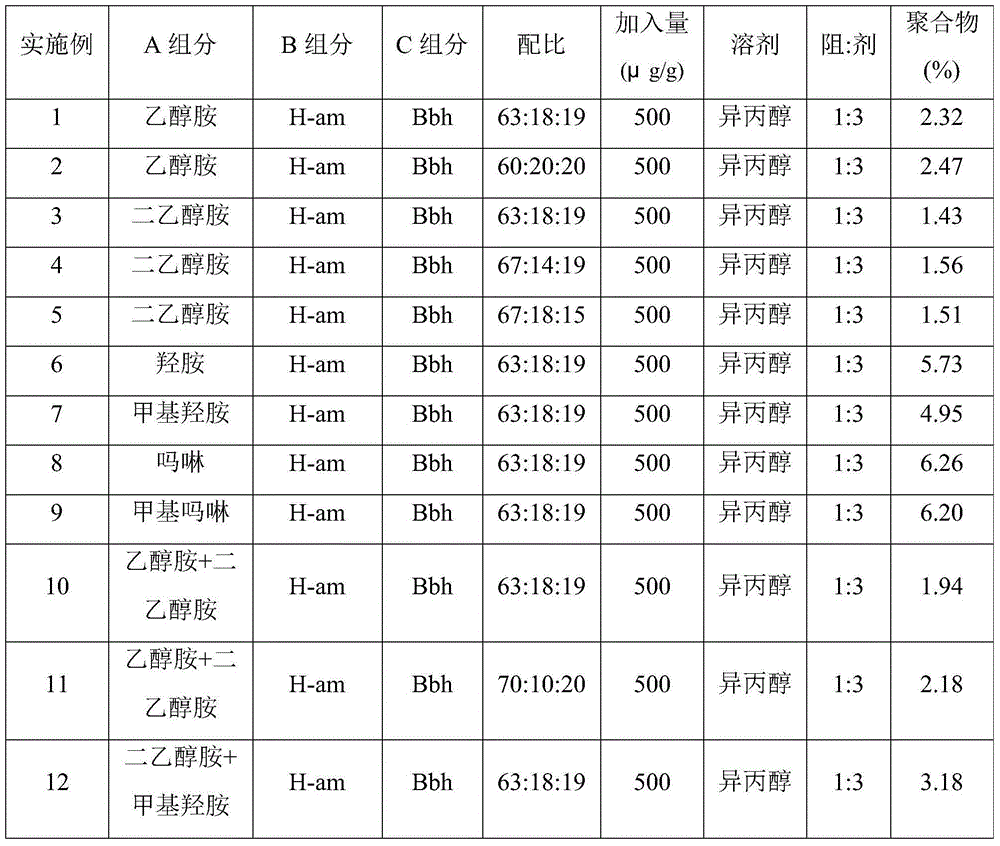

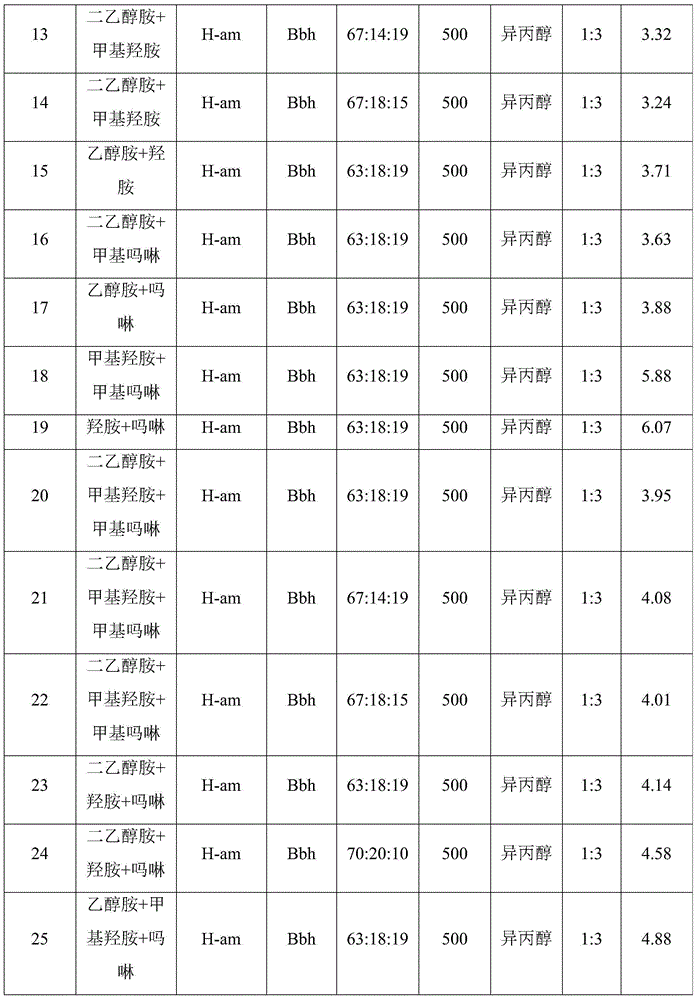

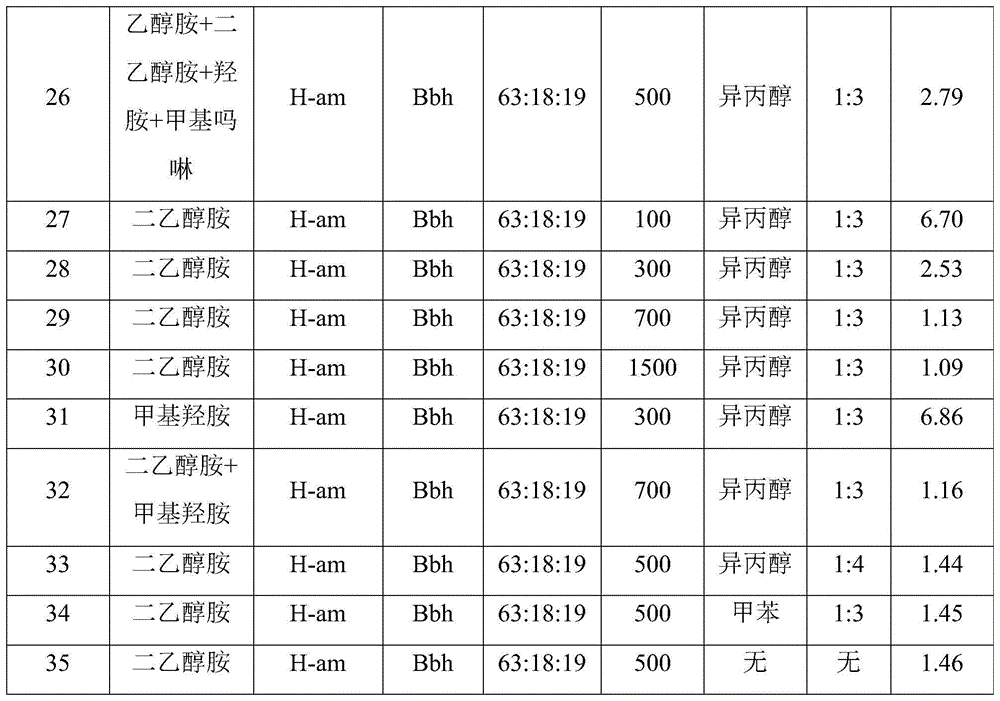

Compounded polymerization inhibitor for inhibiting alkyne polymerization

ActiveCN105503503AGood inhibition effectHydrocarbon purification/separationHydrocarbonsPartial oxidationAlkyne

The invention relates to a compounded polymerization inhibitor for inhibiting alkyne polymerization, and aims to solve the problems that in the natural gas partial oxidation process for producing acetylene, the alkyne polymerization happens easily, the system and pipelines are obstructed, and the normal operation of devices is influenced. The compounded polymerization inhibitor is composed of the following components in percentages by weight: 50 to 60 wt% of component A namely ethanol amine compounds, 20 to 30 wt% of component B namely pyridine or / and nitropyridine, and 10 to 20 wt% of component C namely acylhydrazone compounds. The provided compounded polymerization inhibitor well solves the technical problems mentioned above, and can be applied to natural gas partial oxidation process for producing acetylene so as to prevent alkyne polymerization.

Owner:CHINA PETROLEUM & CHEM CORP +1

Technology for preparing high-purity 2-hydroxyethyl acrylate

InactiveCN106631790AEfficient recyclingGood dispersionOrganic compound preparationCarboxylic acid esters preparationOperating temperaturePolymerization

The invention discloses a technology for preparing high-purity 2-hydroxyethyl acrylate and relates to the field of 2-hydroxyethyl acrylate preparation technologies. The technology has the advantages that a rectification process is added during purification, a polymerization inhibitor is supplemented through spraying during phase transformation in the rectification process, and the vacuum degree and the operating temperature of a tower top are controlled to eradicate flash polymerization of the 2-hydroxyethyl acrylate in a rectifying tower, so that operation stability is achieved, polymerization can be prevented effectively, the product quality is improved, and the purity of the 2-hydroxyethyl acrylate is enhanced.

Owner:CHANGZHOU HICKORY CHEM

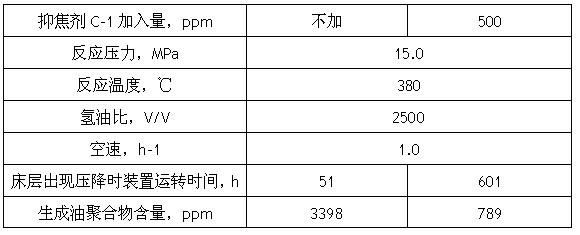

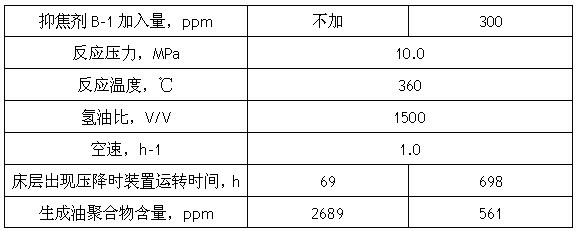

Coal tar and crude benzene hydrogenated special coke inhibitor and preparation method thereof

InactiveCN101979471AReduce the amount addedWide operating temperatureTreatment apparatus corrosion/fouling inhibitionOrganic sulfide compoundBenzene

The invention discloses a coal tar and crude benzene hydrogenated special coke inhibitor and a preparation method thereof. The coke inhibitor is formed by mixing two parts, wherein one part is a polymerization inhibiting and coke resisting component which is a mixture of organic phosphorus compound, phenolic compound, amine compound, high molecular weight polyamine and organic sulfide; and the other part is a hydrogen supply stabilizing component which is generated oil obtained by fractionating low-temperature coal tar or crude benzene to obtain a fraction of 170 to 230 DEG C and then selectively hydrogenating the fraction. The coke inhibitor is specially used in the hydrogenation process of inferior raw materials such as coal tar, crude benzene and the like of coal coking byproducts, can effectively inhibit coking and scaling of the inferior raw materials such as coal tar, crude benzene and the like of the coal coking byproducts, prolongs the continuous running period of a hydrogenation device, and promotes the economic benefit.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Preparation method and application for supported catalysis/polymerization-inhibition macroporous resin microsphere

ActiveCN108855229AAvoid cloggingLong catalyst lifeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCross-linkFoaming agent

The invention relates to a preparation method and application for a supported catalysis / polymerization-inhibition macroporous resin microsphere. The preparation method comprises the following steps that methacrylic acid and styrene serve as monomers, under the action of a cross-linking agent, a pore-forming agent and an initiator, monomer polymerization and polymer balling are carried out so as toobtain the macroporous resin microsphere, the microsphere is cleaned by using a solvent so as to remove the pore-foaming agent, then esterified modification is carried out with a polymerization inhibitor, and sulfonation treatment is carried out with a catalyst so as to obtain the supported catalysis / polymerization-inhibition macroporous resin microsphere. The microsphere simultaneously has the effects of catalyzing olefine acid synthesis and preventing product monomer self-polymerization, is suitable for synthesis of acrylate monomers and is particularly suitable for a fixed bed acid alkeneaddition technology.

Owner:WANHUA CHEM GRP CO LTD

Method for preparing 1,6-hexanediol diacrylate

InactiveCN102659586ALow costSimple processOrganic compound preparationCarboxylic acid esters preparationSolventHydrolysis

The invention discloses a method for preparing 1,6-hexanediol diacrylate. The method comprises the following steps of orderly adding 1,6-hexanediol, acrylic acid, one or more solvents, a catalyst and one or more polymerization inhibitors into a reaction flask, heating, carrying out backflow, washing the reaction solution by using a mixed solution comprising one or more of a sodium bicarbonate solution, a sodium chloride solution, a sodium hydroxide solution and distilled water, carrying out layering, collecting an upper organic phase, carrying out drying dehydration of the upper organic phase by one or more drying agents, filtering and carrying out a reduced-pressure solvent removal process on the upper organic phase at a temperature of 40 to 60 DEG C to obtain 1,6-hexanediol diacrylate. The method adopts raw materials having low costs and has the characteristics of simple processes, easy operation, short reaction period and easily controllable reaction. 1,6-hexanediol diacrylate obtained by the method has the chroma below 10, good transparency, good flexibility, hydrolysis resistance, heat resistance and chemical solvent resistance.

Owner:LEIYANG YOUWEI NEW MATERIAL

Compound polymerization inhibitor

ActiveCN105566035AGood dispersionGood inhibition effectHydrocarbon purification/separationHydrocarbonsPartial oxidationMorpholine

The invention relates to a compound polymerization inhibitor. The compound polymerization inhibitor solves the technical problem that the gas partial oxidation method for preparing acetylene easily causes alkyne polymerization so that a system and a pipe are blocked and device normal operation is influenced. The compound polymerization inhibitor comprises, by mass, 60-70% of an ingredient A, 10-20% of an ingredient B and 10-20% of an ingredient C. The ingredient A comprises one or more of an ethanol amine compound, a hydroxylamine compound and a morpholine compound. The ingredient B is hexamine. The ingredient C is an acylhydrazone compound. The compound polymerization inhibitor solves the above problems and can be used in the field of alkyne polymerization inhibition in the process for preparing acetylene through gas partial oxidation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com