Method for preparing 3-(methacryloxy)propyltrimethoxysilane

A technology of propyltrimethoxysilane and methacryloxy, which is applied in the field of preparation of 3-propyltrimethoxysilane, can solve the problem of high performance of polymerization inhibitors and poor polymerization inhibition effect of polymerization inhibitors. Ideal, it is difficult to achieve the effect of polymerization inhibition, etc., to achieve the effect of reducing cost and production risk, easy to remove color, exothermic temperature and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: Preparation of catalyst: Using chloroplatinic acid, isopropanol, and compound A as raw materials, add compound A after dissolving chloroplatinic acid in isopropanol, and then heat to 65-85° C. for 1-3 hours to obtain liquid catalyst. The mass ratio of chloroplatinic acid, isopropanol and compound A is: 1:70~75:20~25.

[0018] The compound A is tetramethyldivinyldisiloxane or 1,3,5,7-tetramethyltetravinylcyclotetrasiloxane or 1,4-cyclooctadiene or 1,5-cyclo One of octadiene or acetylacetone or 2,5-dimethyl-2,4-hexadiene.

Embodiment 2

[0019] Embodiment 2: target product is synthesized

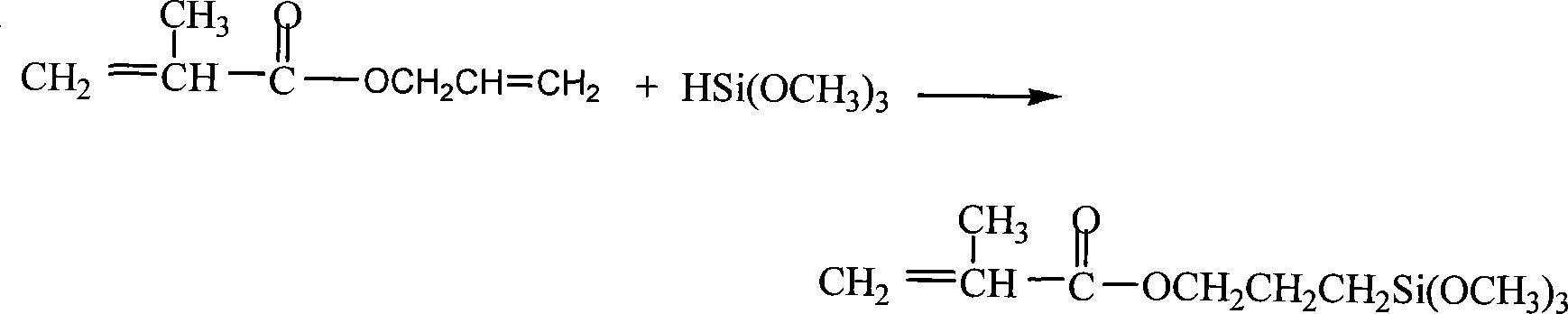

[0020] The reaction formula is as follows:

[0021]

[0022] In the reactor, add 85 grams to 330 kilograms of trimethoxysilane, and then add 0.0005 to 0.001 times the amount of catalyst (prepared in the embodiment), 0.0005 to 0.001 times the amount of polymerization inhibitor phenothiazine and 0.0005 to 0.001 times the amount of polymerization inhibitor ZJ-701, the temperature is raised to 70 to 85 ° C, and the methacrylic acid alkene mixed with 0.0005 to 0.001 times the amount of polymerization inhibitor N, N'-diphenyl-p-phenylenediamine is added dropwise. Propyl ester is added dropwise within 10 minutes to 3 hours. After the dropwise addition, keep warm at 85-95° C. for 2-3 hours. The product content in the reactant is 85-88% according to sampling analysis.

[0023] Add 0.0005-0.001 times the amount of polymerization inhibitor ZJ-701 and 0.001-0.002 times the amount of polymerization inhibitor ZJ-101 to the above react...

Embodiment 3

[0024] Embodiment 3: the preparation of novel catalyst: with 0.1g chloroplatinic acid (H 6 PtCl 6 ·6H 2 O) Add 7.5ml of isopropanol, after the chloroplatinic acid is completely dissolved, add 2.5ml of tetramethyldivinyldisiloxane or acetylacetone, and then heat to 65-85°C for 1 hour to prepare a liquid catalyst (number 1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com