Patents

Literature

167 results about "Production risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of Risk Production. Risk Production means that a particular silicon wafer fabrication process has established baseline in terms of process recipes, device models, and design kits, and has passed standard wafer level reliability tests.

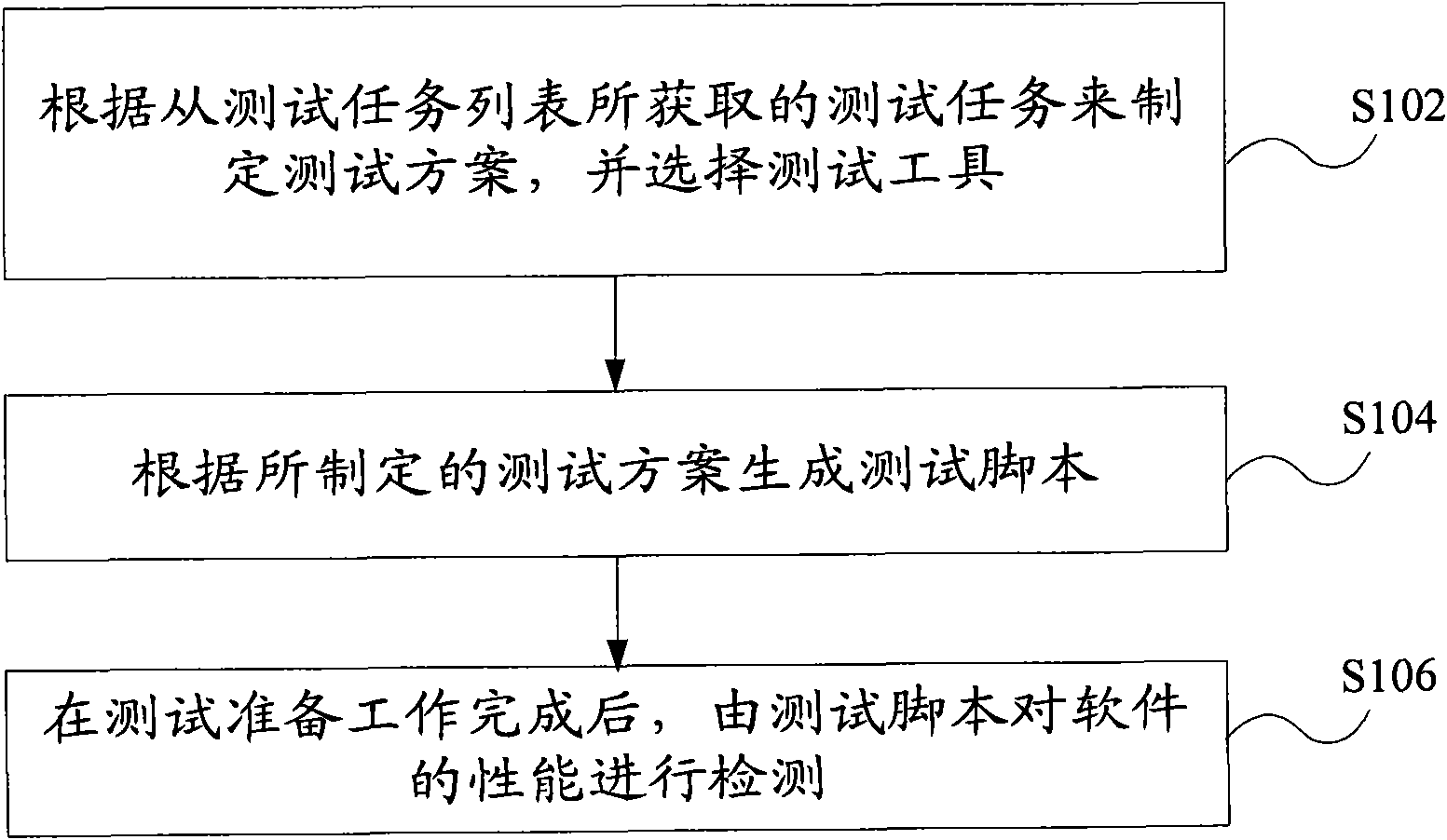

Method for testing software performance

The invention provides a method for testing software performance. The method comprises the following: step 1, formulating a test proposal according to a test task acquired from a test task list and selecting a test tool; step 2, generating a test script according to the formulated test proposal; and step 3, testing software performance through the test script after finishing test preparation work. Therefore, on the basis of software test work in general meaning, the method has further expansion and promotion, establishes an independent test-quality evaluation mechanism oriented to performance innovatively according to production versions, can control production quality more effectively and reduce the production risk and hidden trouble of software product versions by establishing a strict test output-permission evaluation mechanism and utilizing means and methods for testing the performance of the production versions.

Owner:BEIJING SHIJI TUOYUAN SOFTWARE TECH DEV

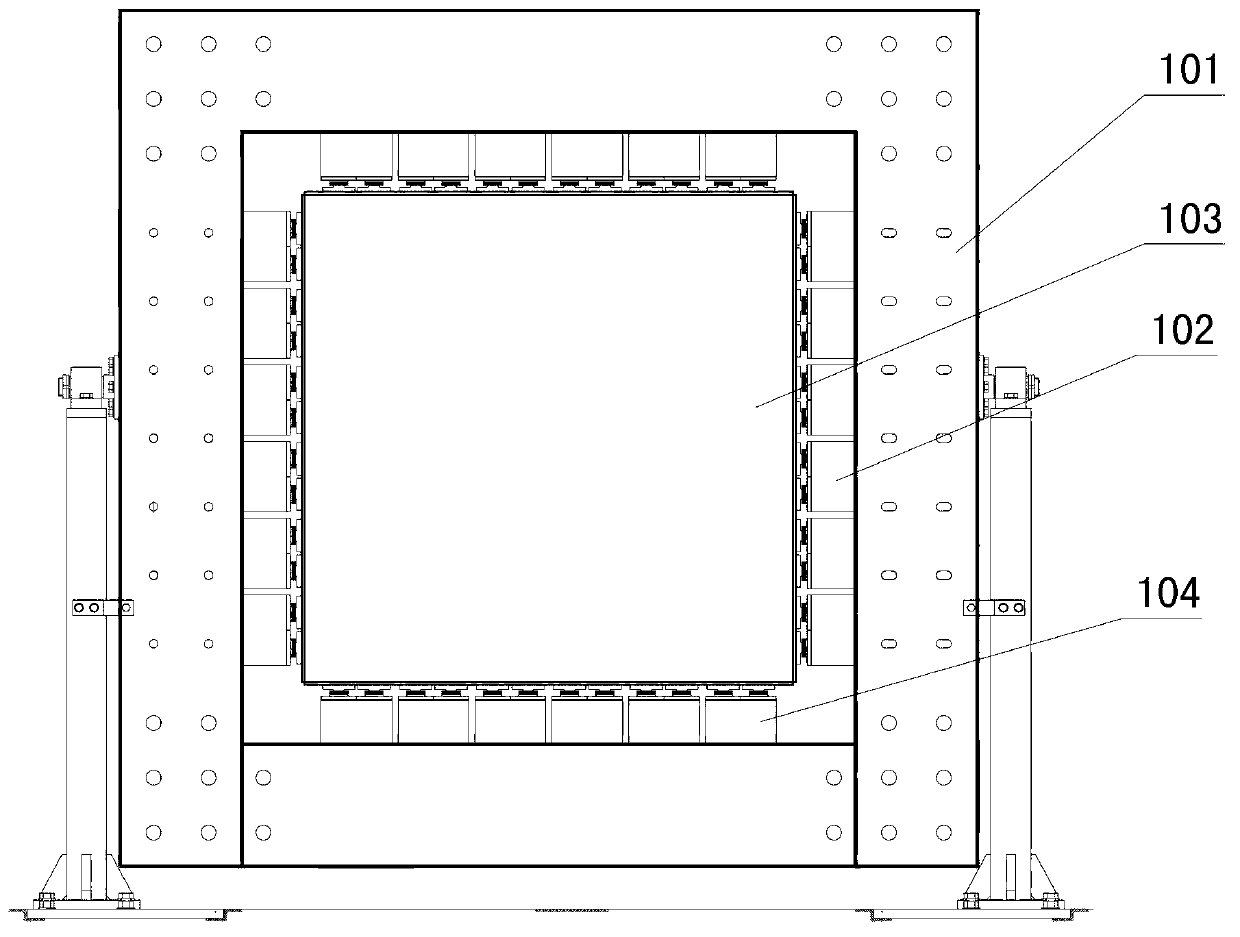

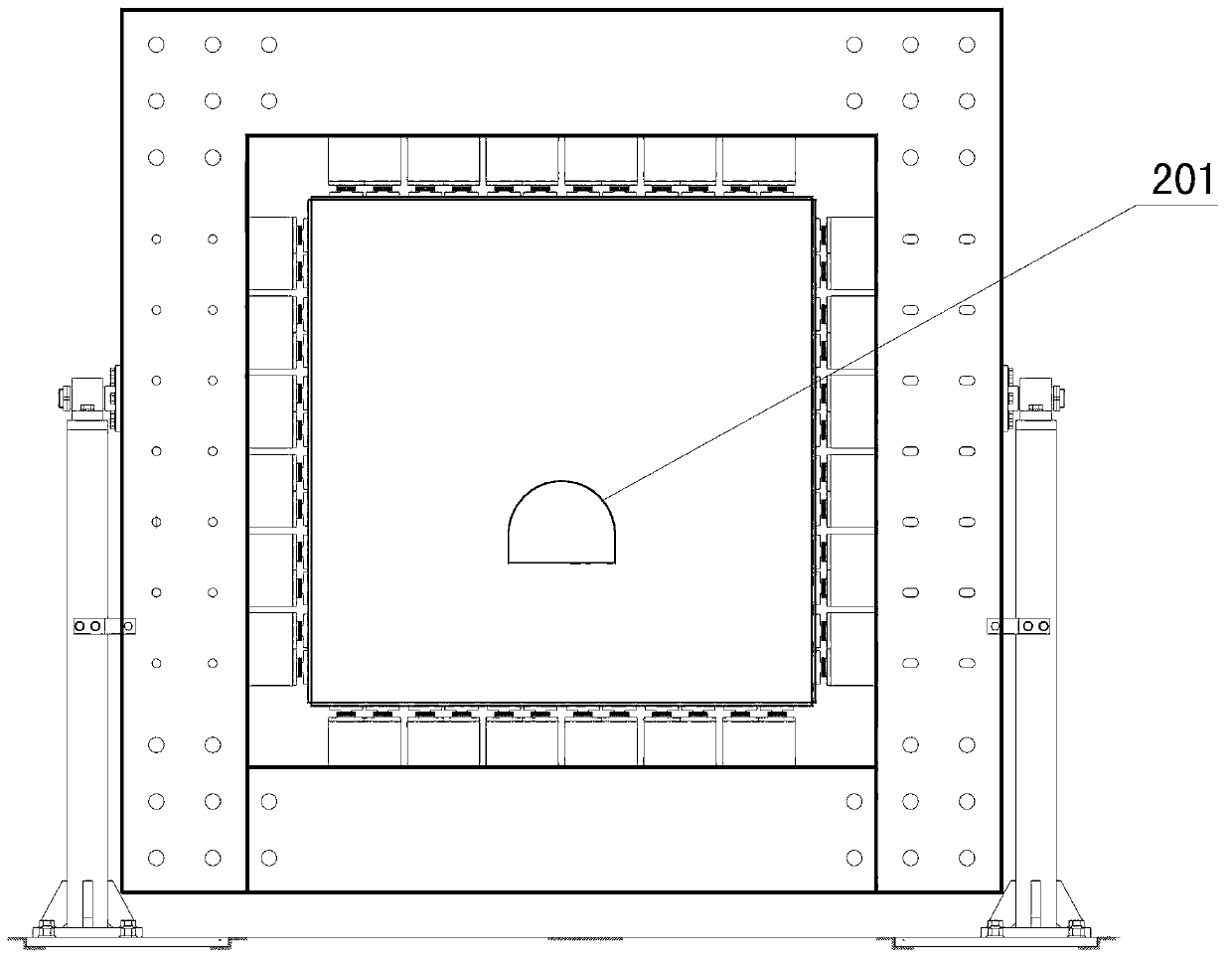

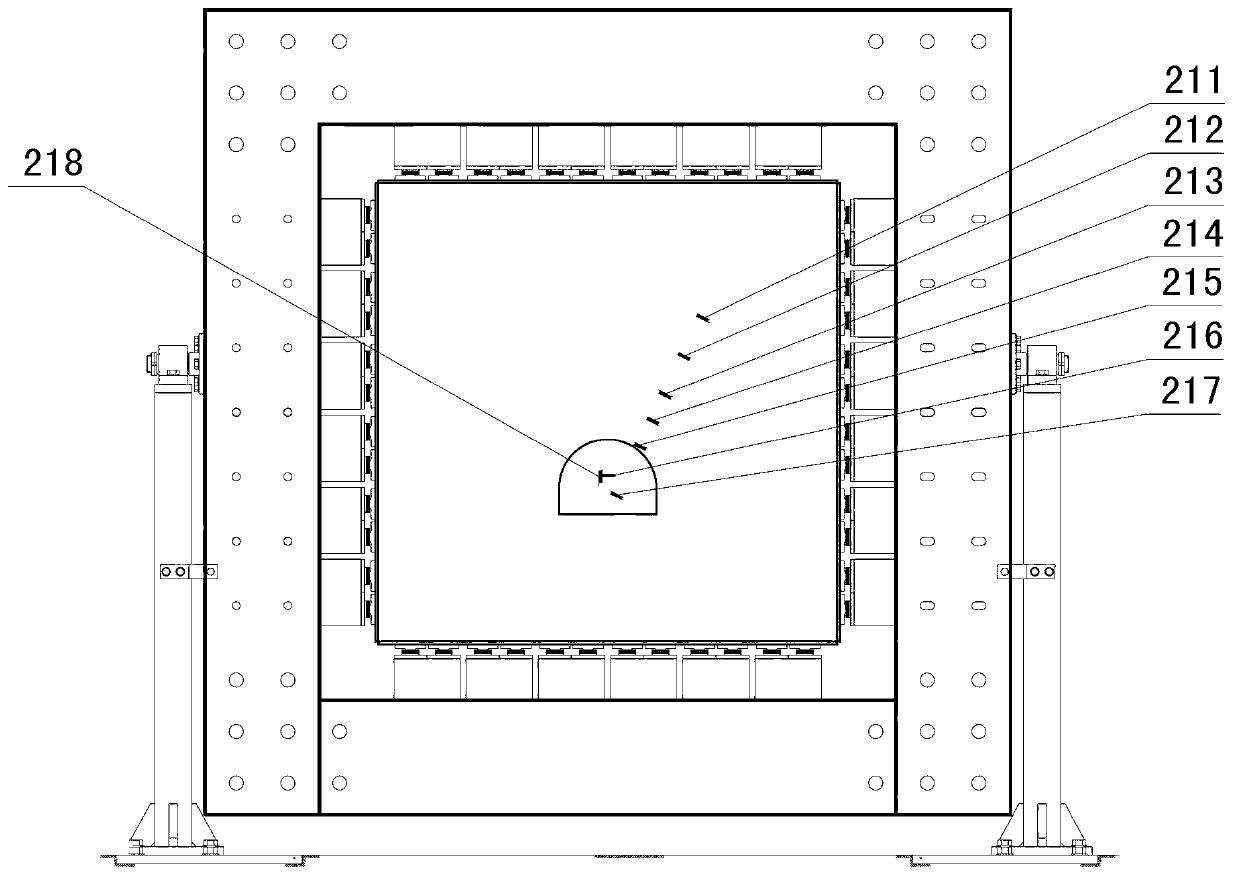

Method for simulating roadway rock burst based on coaction of static load and blast load

InactiveCN103344491AReduce the risk of safety productionIncrease productivityMaterial strength using tensile/compressive forcesDetonatorModel testing

The invention discloses a method for simulating roadway rock burst based on coaction of a static load and a blast load. The method comprises the following steps of: A, selecting cement mortar and ramming a model in a rock model testing machine, and embedding a pressure sensor, an acceleration sensor and a strain gage in the model body; B, maintaining the model body within 28 days, applying initial crustal stress to the model body by utilizing the rock model testing machine, and testing force and deformation field distribution characteristics of the model body under the action of the static load; C, simulating actual cavern excavation characteristics, and measuring force and deformation field distribution characteristics in the model body after excavation each time; and D, drilling in the model body, mounting explosive cartridges and detonators in the drill bores, filling with loess, and detonating the explosive. By utilizing the method, the occurrence scale and time of deep roadway rock burst can be effectively predicted, damage of rock burst disasters on mine production settings can be reduced, the mine safety production risk is greatly reduced, and the production efficiency of the mine is greatly improved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

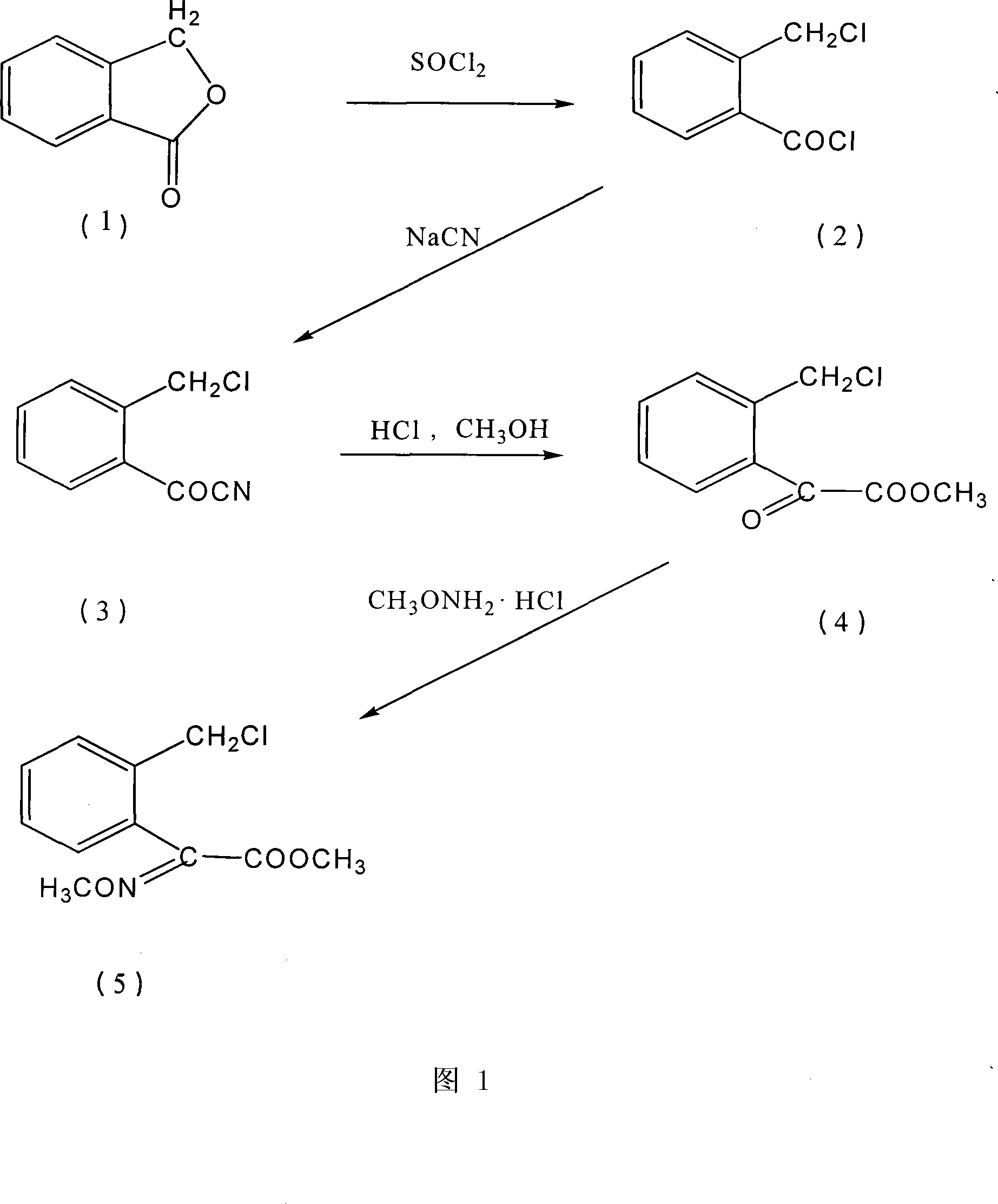

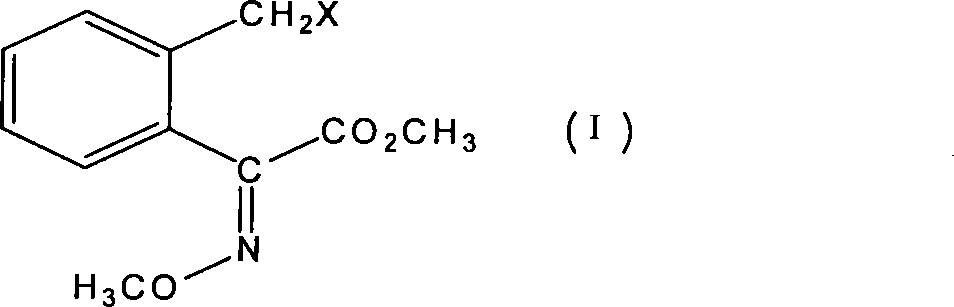

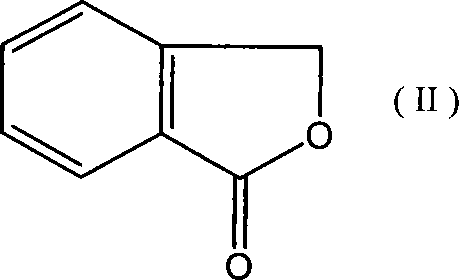

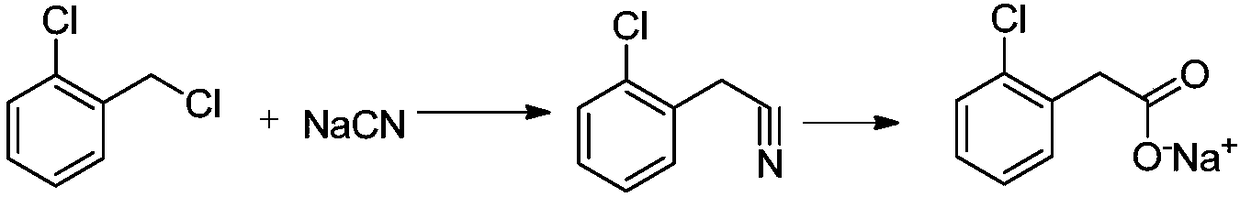

Method for preparing bactericidal agent intermediate (E)-2-(2'-chloromethyl)phenyl-2-methoxy imino methyl acetate

ActiveCN101139308AReduce energy consumptionReduce riskBiocideFungicidesPotassium cyanideProduction risk

The preparation method of the fungicide intermediate (E)-2-(2'-chloromethyl)-2-methicillin imino acetic methyl ester is: 1) the phenyl phthalate and the thionyl dihalide react with the influence of a catalyst; the catalyst is the Louis acid and phosphonic derivative; 2) the product of the first step and the alkali metal cyanide react with the influence of the organic solvent and phase transfer catalyst; the organic solvent is selected from the non-polar aromatic solvent or the halogen hydrocarbon; the phase transfer catalyst is selected from the halide of the four-level nitride or the ammonium salt; the alkali metal cyanide is selected from the sodium cyanide and potassium cyanide; 3) the products of the second step and the methanol react under the condition with the organic solvent and the chlorinated hydrogen; 4) the products of the third step and the methicillin amine hydrochloride under the condition with the organic solvent; thus, the target product can be got. The energy consumption and production risk of the present invention are obviously lowered; the relative collection rate is high; the safety in the production process is improved; and the present invention has no drawbacks such as the obstruction.

Owner:JIANGSU GENGYUN CHEM CO LTD

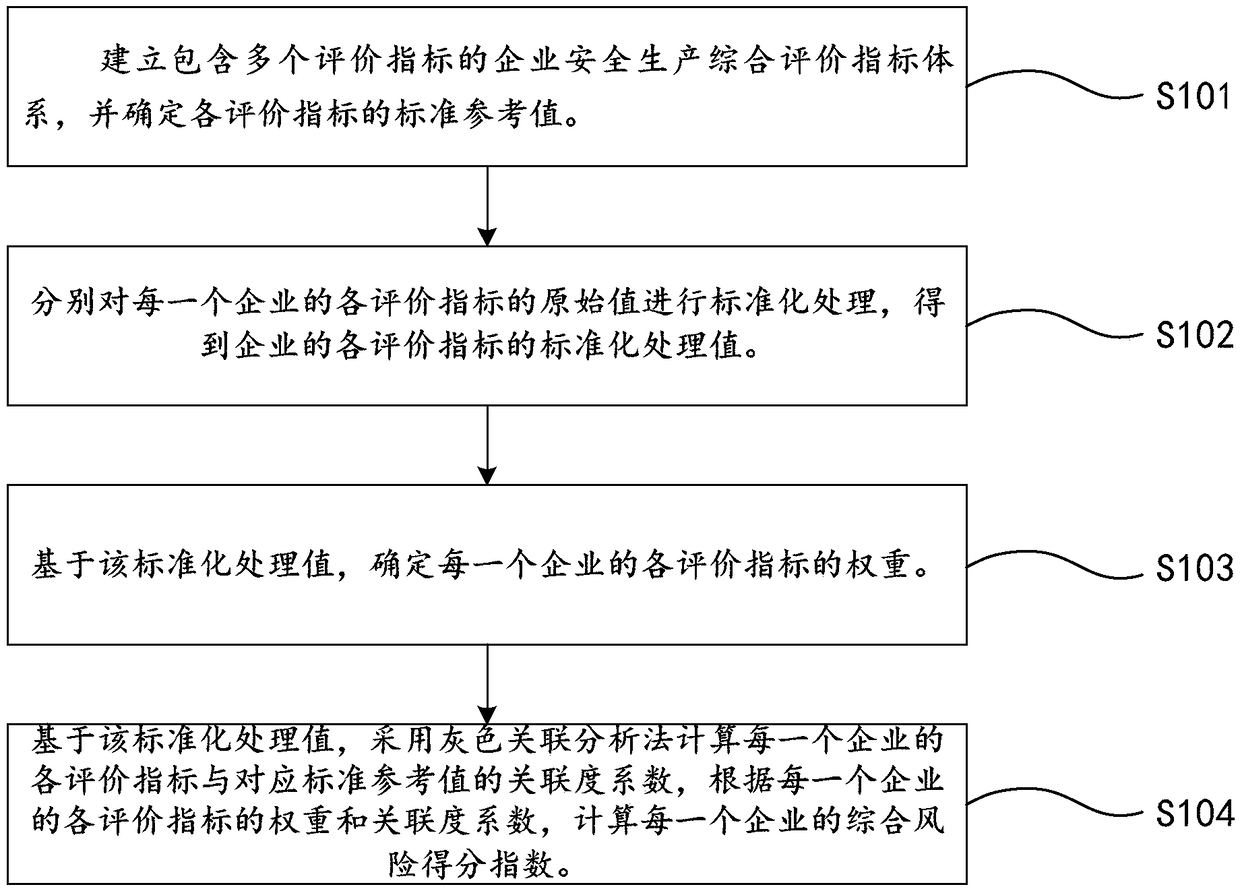

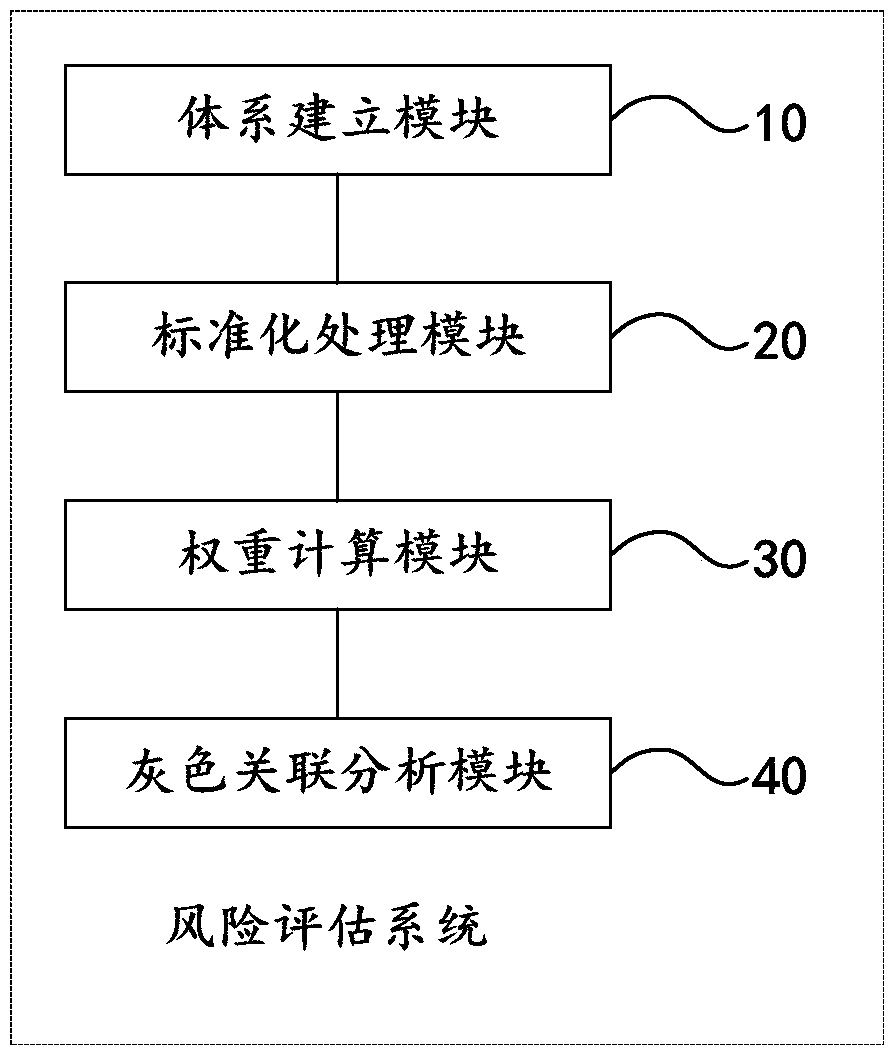

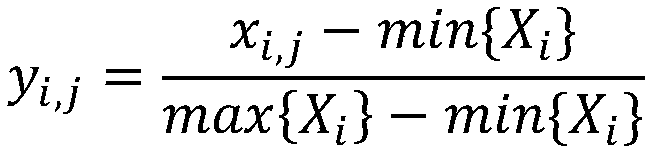

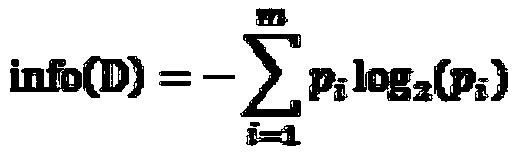

Safety production risk assessment method and system based on multi-level grey relational analysis

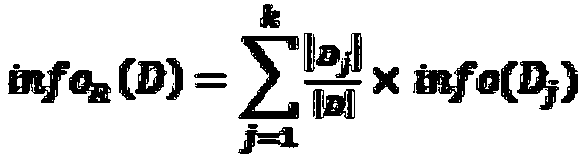

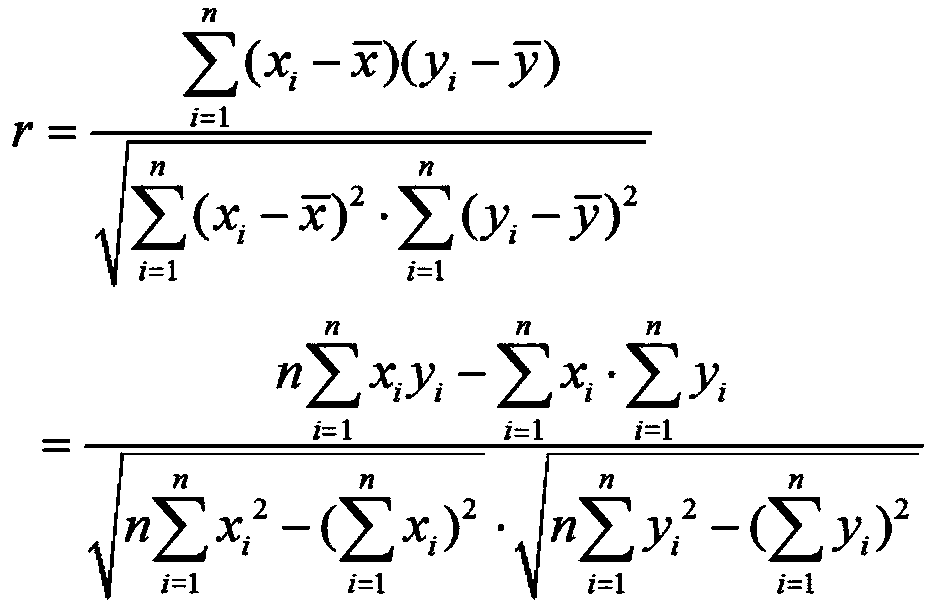

The invention relates to the technical field of enterprise safety production comprehensive risk assessment, in particular to a safety production risk assessment method and system based on multi-levelgrey correlation analysis. The risk assessment method includes the following steps: establishing a comprehensive evaluation index system of enterprise safety in production which includes multiple evaluation indexes; Standardizing the original value of each evaluation index of each enterprise; Determining the weights of each evaluation index of each enterprise; by using the grey relational analysismethod,calculating the relational coefficient of each evaluation index, and calculating the comprehensive risk score index of each enterprise according to the weight and the relational coefficient. The safety production risk assessment method and system based on multi-level grey relational analysis comprises a plurality of evaluation indexes, Overcoming the one-sidedness of single index as a riskassessment standard, the method and system can evaluate the comprehensive risk of any enterprise qualitatively or quantitatively, which is helpful for enterprises to find their own problems, and canalso provide the reference data for the regulatory department of the enterprise 's safe production status.

Owner:SHENZHEN URBAN PUBLIC SAFETY & TECH INST CO LTD

Method for preparing hydrophobic silica aerogel from rice husk ash based aquagel

The invention provides a method for preparing hydrophobic silicon dioxide aerogel by rice hull ash based water gel. The silicon dioxide water gel obtained by taking rice hull ash as materials is subjected to solvent replacement, surface finish in the siloxane phase and normal-pressure drying treatment to prepare the silicon dioxide aerogel with hydrophobic characteristics. For the aerogel prepared, the specific surface area reaches between 500 and 1000m<2> / g, the volume density is between 0.08 and 0.3g / cm<3>, and the sizes of the micropores are mainly distributed in the range of between 1 and 100nm. The method adopts advanced technologies of the solvent replacement, the surface finish and the preparation of the normal-pressure aerogel, thereby unnecessarily using expensive organic resources, avoiding the use of supercritical drying equipment which is commonly used in the convention preparation of the silicon dioxide aerogel and has problems of high price, low efficiency and high risk and the technological investment, and obviously lowering production risk and production cost. Moreover, the method also has the advantages of simple process, strong manageability and suitable mass production and application.

Owner:TONGJI UNIV

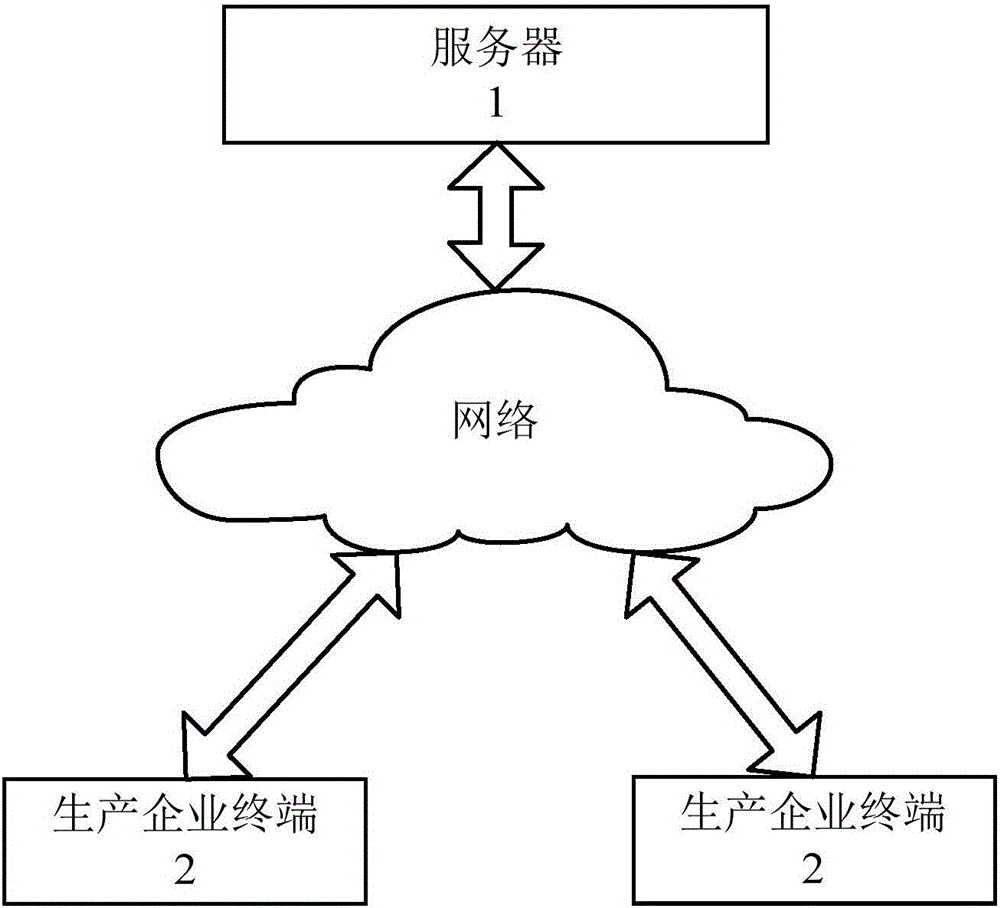

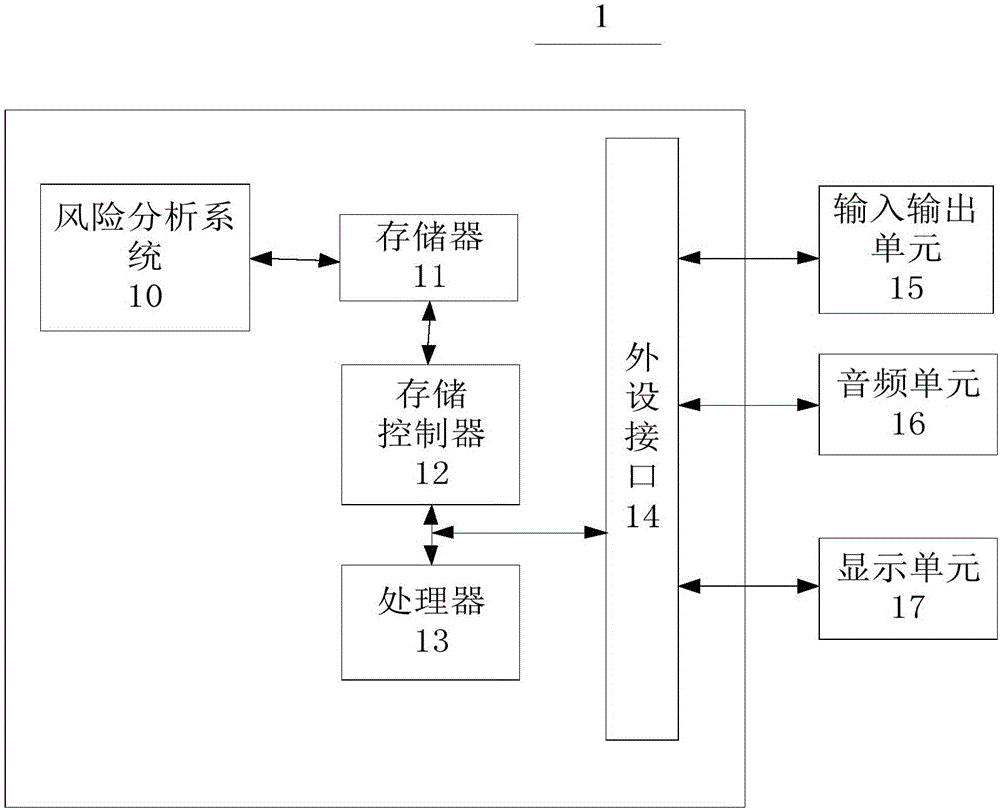

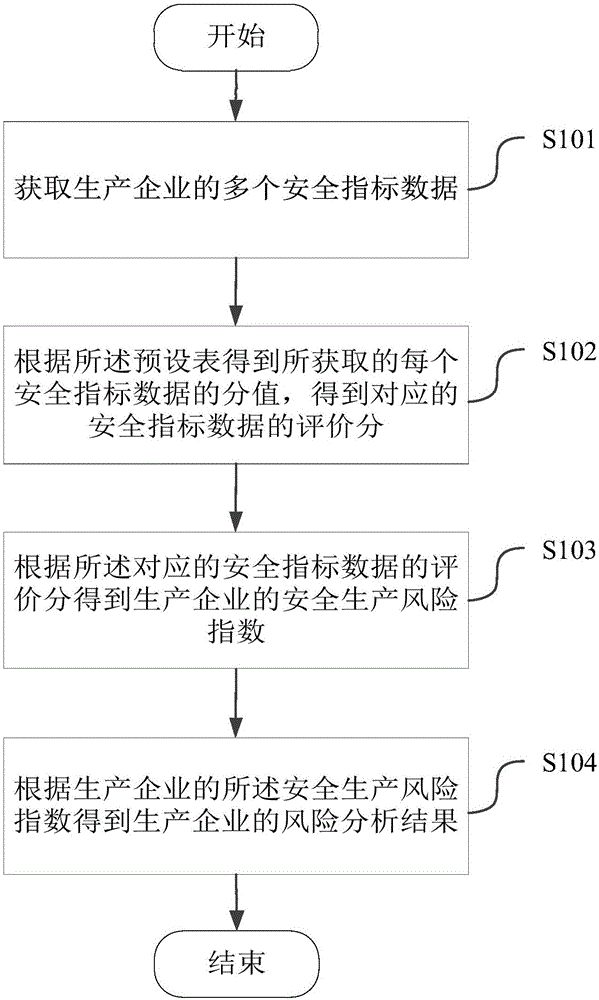

Risk analysis method and system

InactiveCN106485418ATimely rectificationThe process is simple and fastResourcesSafety indexRisk profiling

Embodiments of the invention provide a risk analysis method and system, and relate to the technical field of enterprise production risk analysis. The method is applied to a safety production risk analysis system. The system stores a preset table. The preset table stores scores corresponding to multiple pieces of safety index data, and each piece of safety index data corresponds to a score. The method comprises the steps of obtaining the safety index data of a production enterprise; obtaining the scores of the obtained safety index data according to the preset table, and obtaining evaluation scores of the corresponding safety index data; obtaining safety production risk indexes of the production enterprise according to the evaluation scores of the corresponding safety index data; and obtaining a risk analysis result of the production enterprise according to the safety production risk indexes of the production enterprise. By applying the method and the system, the production risk of the production enterprise can be efficiently and accurately evaluated; and the method and the system are wide in statistics range and high in practicality.

Owner:成都鼎安华智慧物联网股份有限公司

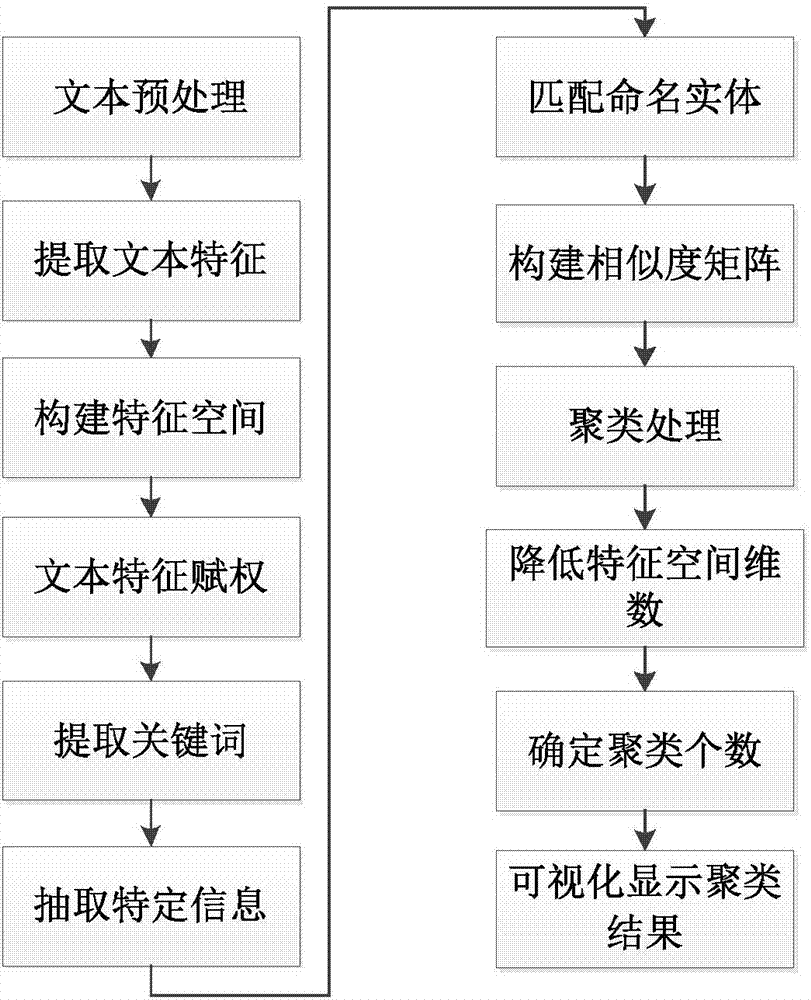

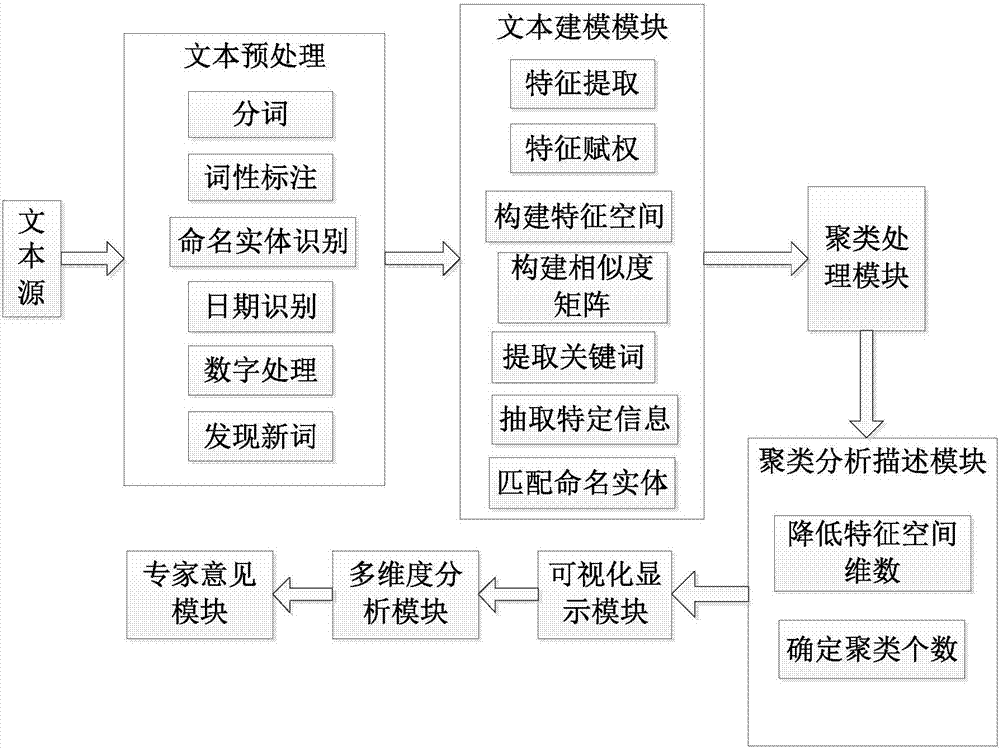

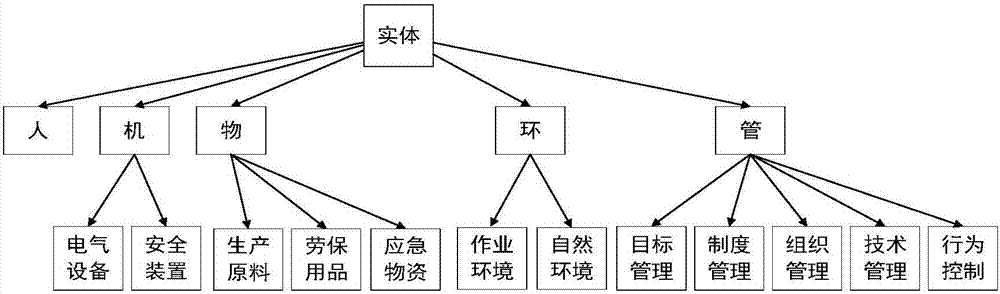

Semantic analysis method, electronic device and storage medium and diagnosis system

InactiveCN107291697APrevent and reduce safety production accidentsSemantic analysisCharacter and pattern recognitionSecure stateProduction risk

The invention discloses a semantic analysis method. The semantic analysis method comprises the steps of text preprocessing, text modeling, clustering treatment and clustering result visualized presentation. The invention also relates to an electronic device and a computer-readable storage medium. A computer program is executed by a processor through the semantic analysis method. The invention also relates to a semantic analysis diagnosis system. The semantic analysis diagnosis system comprises a text preprocessing module, a text modeling module, a clustering treatment module and a visualized presentation module. Safe production non-structural data are processed through the semantic analysis technology, elements of safe production big data are classified and concluded, correlation of the elements are analyzed through correlation rules, potential risk factors are found through clustering, and a safe production risk analysis model applicable to potential risk identification business data is established to control unsafe behaviors of people, unsafe states of objects and machines, unsafe factors of environment and deficiency in management; by coordinating the relation among people, machine, object, environment and management, the semantic analysis method achieves the aim of preventing and reducing production accidents.

Owner:浙江图讯科技股份有限公司

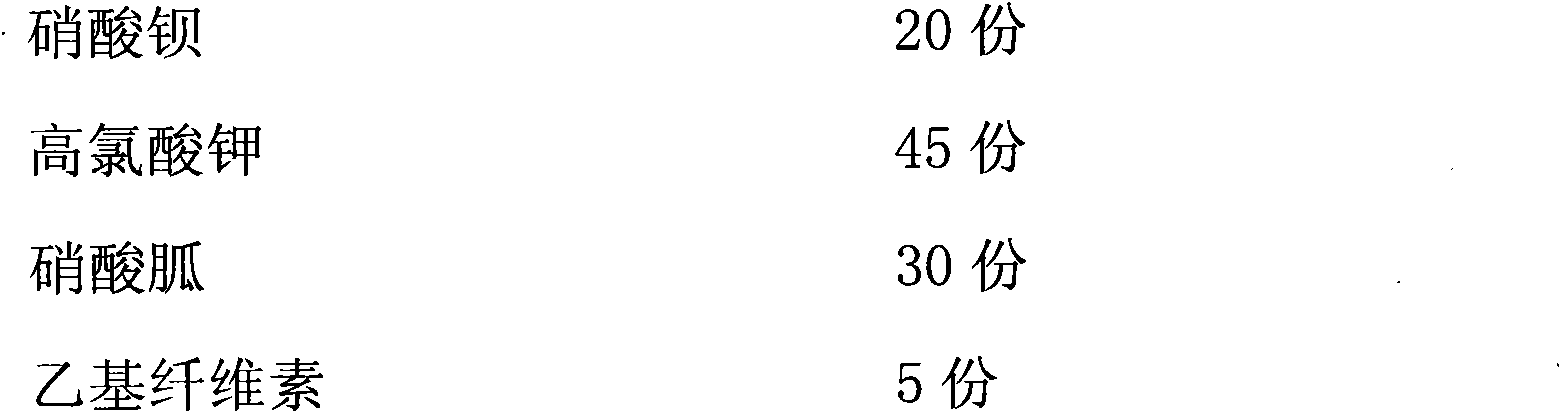

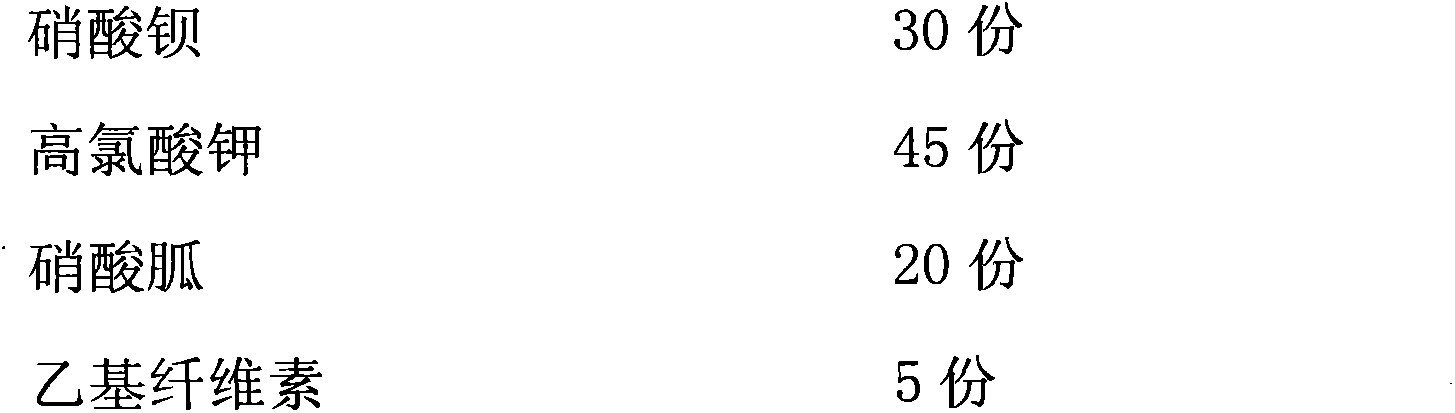

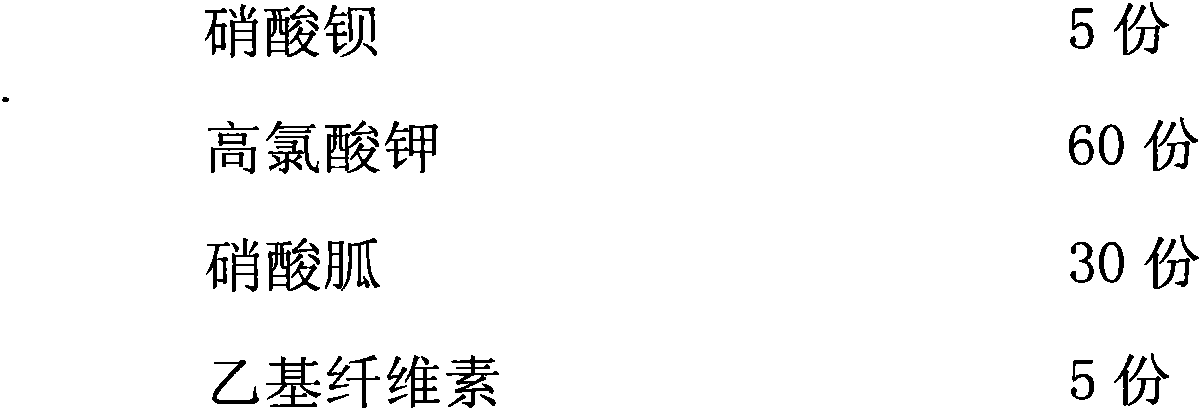

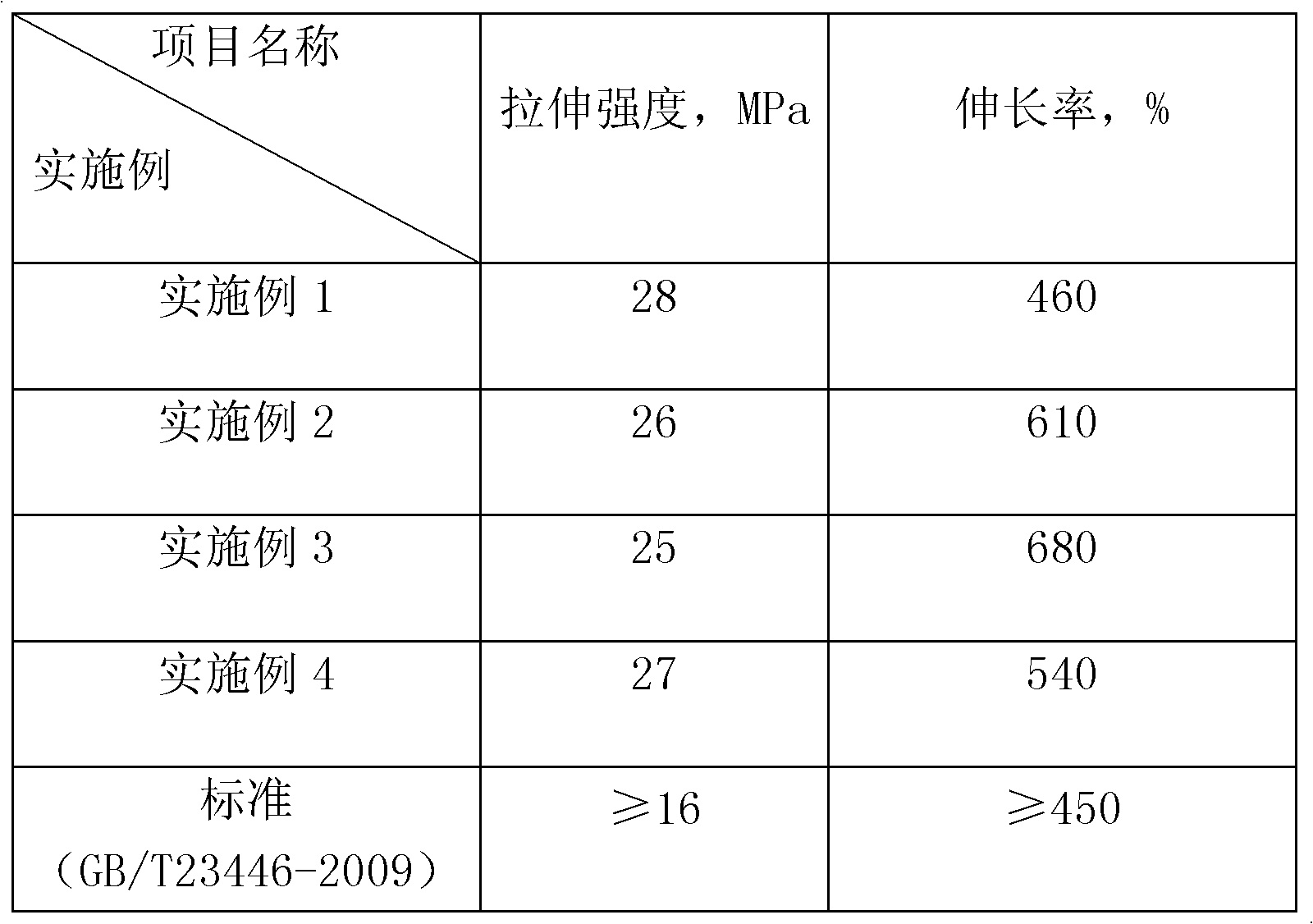

Sulfur-smoke-free powder composition and preparation method thereof

InactiveCN103214322ADisadvantages of Avoiding Cryogenic DecompositionSolve the disadvantage of easy moisture absorptionExplosivesNitro compoundBarium nitrate

The invention discloses a sulfur-smoke-free firework powder composition and a preparation method thereof. According to the powder composition, potassium perchlorate and barium nitrate are used as oxidants, and a nitro-compound is used as a flammable agent, so that the safety and environment-friendliness of the firework production are greatly improved, the production cost of the firework powder is lowered, and various indexes are excellent through the detection. The preparation method of the sulfur-smoke-free firework powder composition is simple and mainly comprises the simple processes of mixing, pelletizing, drying and screening. According to the sulfur-smoke-free firework powder composition and the preparation method thereof disclosed by the invention, the problems that the conventional black powder is poor in safety, easy to absorb moisture, large in production risk and the like are solved. The sulfur-smoke-free firework powder composition has the advantages of having an emission effect better than that of black powder, achieving zero-exhaustion of sulfur dioxide and the like. The sulfur-smoke-free firework powder composition is extensively applicable to preparing firework propellant powder and 3-8-inch powder of large festive fireworks.

Owner:LIUYANG HELI HIGH TECH DEV CO LTD

Method for preparing amino-terminated polyurethane

InactiveCN102432804AHigh elongationImprove bending resistancePolyurea/polyurethane coatingsReaction rateProduction risk

The invention relates to the technical field of preparation of active amino-terminated functional compounds, in particular to a method for preparing amino-terminated polyurethane by using a steric hindrance protection method. The method concretely comprises the following steps: respectively selecting isophorone diisocyanate and isophorone diisocyanate which have similar functional groups and different reactive activities as blocking modification raw materials; realizing a reaction rate gradient through steric hindrance protection; and directly functioning amino at two ends of a main structure to prepare the amino-terminated polyurethane. The amino-terminated polyurethane is directly and efficiently prepared through the steric hindrance protection method, thus, the defect that isocyanic acid rapidly reacts with the amino is avoided, the reaction process has a certain speed gradient, the generation of a crosslinking structure is inhibited, the production risk and the production energy consumption are remarkably reduced, and the product performance and the production efficiency are increased.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

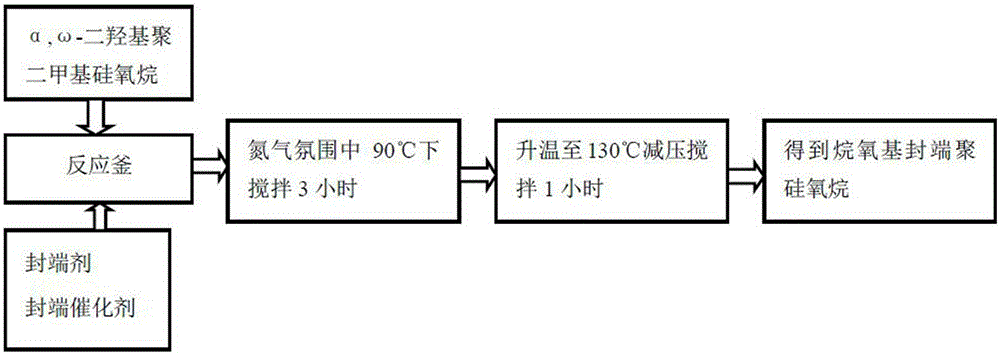

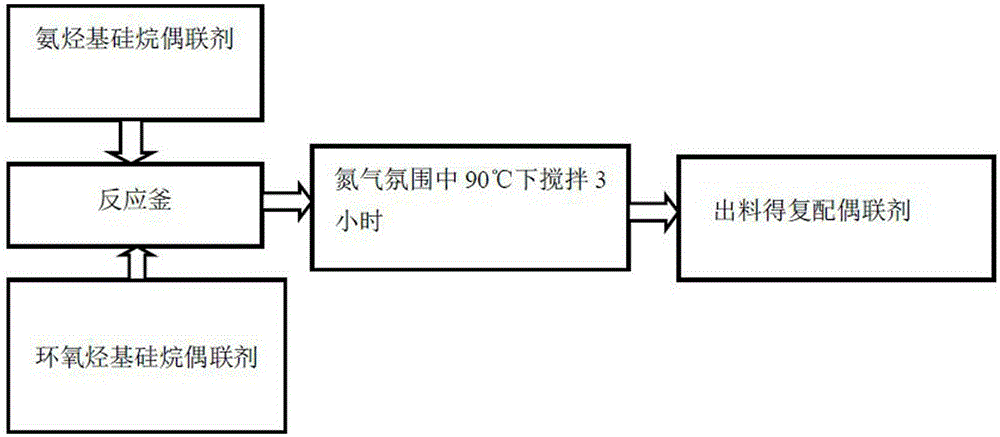

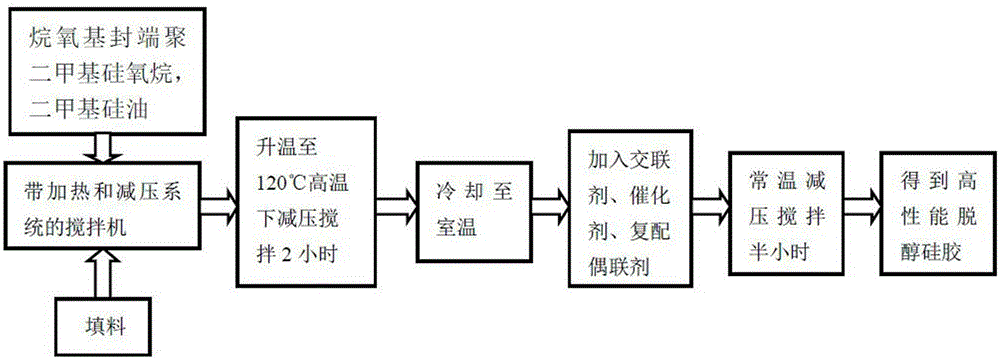

High-performance dealcoholized organosilicon adhesive and preparation technique thereof

InactiveCN105176482AReduce bonding requirementsMeet the bonding requirementsNon-macromolecular adhesive additivesShortening procedureAdhesive

The invention provides a high-performance dealcoholized organosilicon adhesive which is a high-performance dealcoholized sealant prepared by compounding an alkoxy-terminated polydimethylsiloxane base adhesive with a coupling agent as a bonding assistant. The invention also provides a preparation method of the high-performance dealcoholized organosilicon adhesive. The high-performance dealcoholized organosilicon adhesive shortens the surface viscosity reduction time, obviously enhances the curing speed, and satisfies the requirements of most industries for enhancing production efficiency and shortening procedure time consumption. No viscosity peak exists in the production process, thereby greatly enhancing the production and lowering the production risk. The high-performance dealcoholized organosilicon adhesive has favorable bonding property, and can satisfy the bonding requirements of most substrates. Due to the enhancement of the storage stability, the allowed storage time of the product is up to 12 months or above, thereby reducing the loss caused by performance reduction due to transportation and storage.

Owner:FOSHAN SILTOP NEW MATERIAL CO LTD

A non-coal mine safety production risk prediction and early warning platform

The invention relates to a non-coal mine safety production risk prediction and early warning platform which comprises a data acquisition module, a data ETL processing module, a data prediction moduleand an early warning module. The data acquisition module transmits the acquired non-coal mine production index data needing to be analyzed to the data ETL processing module for processing; and the processed index data is transmitted to the data prediction module, the data prediction module carries out safety production risk prediction according to the received data and transmits a prediction result to the early warning module, and risk prediction and early warning of non-coal mine safety production are achieved. The non-coal mine safety production and risk monitoring data can be collected, arranged, predicted, early-warned and analyzed, macroscopic decision support is provided for government supervision departments, and risk early-warning services are provided for enterprises.

Owner:CHINA ACAD OF SAFETY SCI & TECH

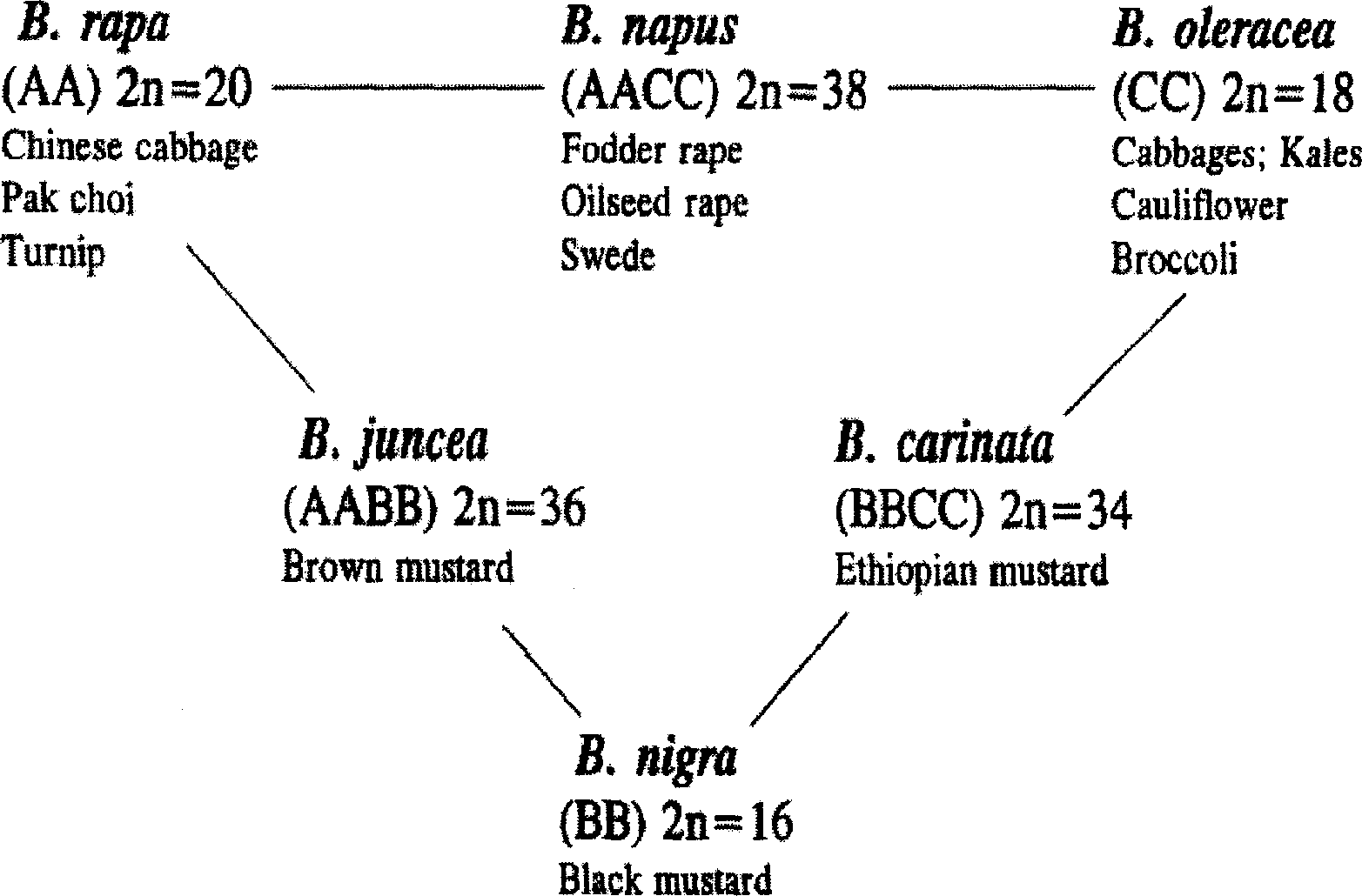

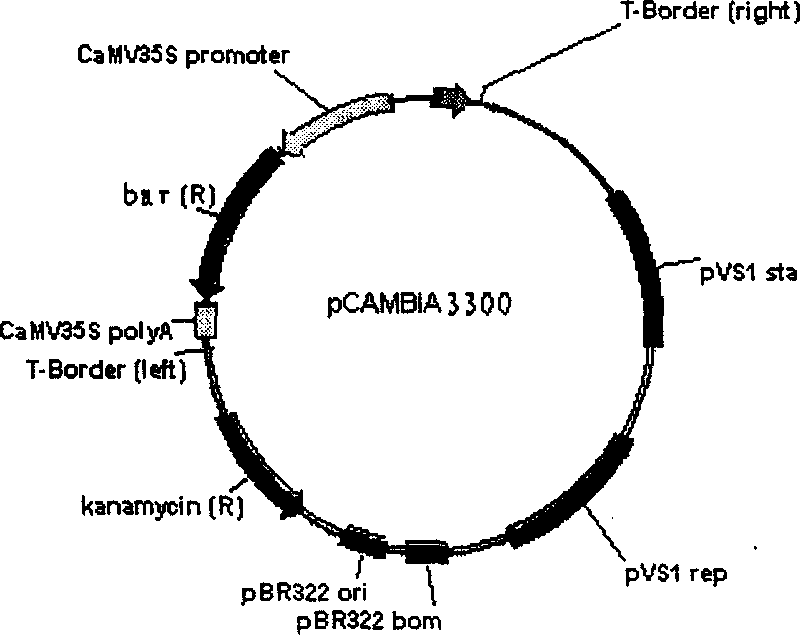

Directional gene transfer method of cabbage type rape C chromosome set

InactiveCN1884518AEasy to operateMicrobiological testing/measurementHorticulture methodsProduction riskGene transfer

The invention discloses a directional genetically modified method of wild cabbage rape C genome, and the steps include: A. breeding and conversion mediated by wild cabbage agrobacterium tumefaciens: first preparing agrobacterium tumefaciens bacterial solution, next preparing explant, thirdly laying the explant into the agrobacterium tumefaciens bacterial solution for breeding and conversion, fourthly checking resistance of herbicide, and fifthly checking PCR molecule; B. artificially synthesizing genetically modified wild cabbage rape, first artificially synthesizing cabbage cellular genetically modified wild cabbage rape, next artificially synthesizing wild cabbage cellular genetically modified wild cabbage rape, finally performing colorant layer duplication to artificially synthesized haploid rape; C. rating the genetically modified rape. The invention is of simple operation, the accidental purpose gene can be transferred on wild cabbage rape C chromosome with high accuracy, and the obtained genetically modified rape is of small production risk when the environment deactivates in accidentally genetically modified diffusion.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

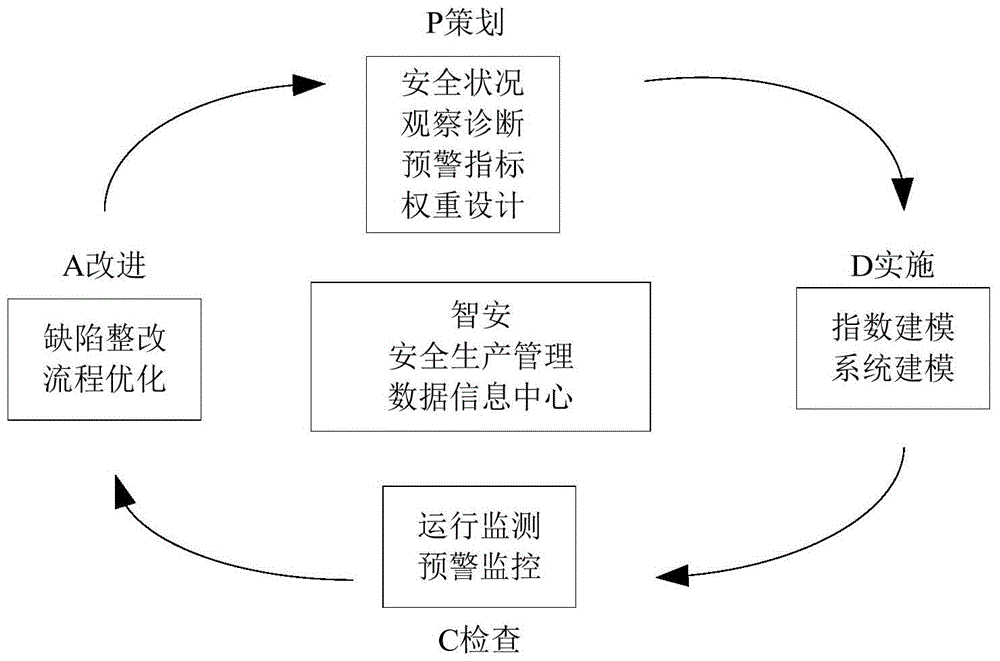

Method used for enterprise safety production risk early warning

InactiveCN105678446AIncrease or decrease the number of indicatorsMeet the needs of useResourcesIntrinsic safetyMedicine

The invention discloses a method for early warning of enterprise safety production risks. The method establishes a comprehensive early warning closed-loop (PDCA) process management model and open and hierarchical early warning index pool construction, and uses early warning index algorithms to evaluate safety production indexes The present invention aims to effectively improve the prevention and immunity of enterprise safety production management, help enterprises reduce the risk of accidents from the source of accidents, realize the intrinsic safety of enterprises, and lay a solid foundation for building a safe and preventive production environment and a harmonious and safe society.

Owner:浙江图讯科技股份有限公司

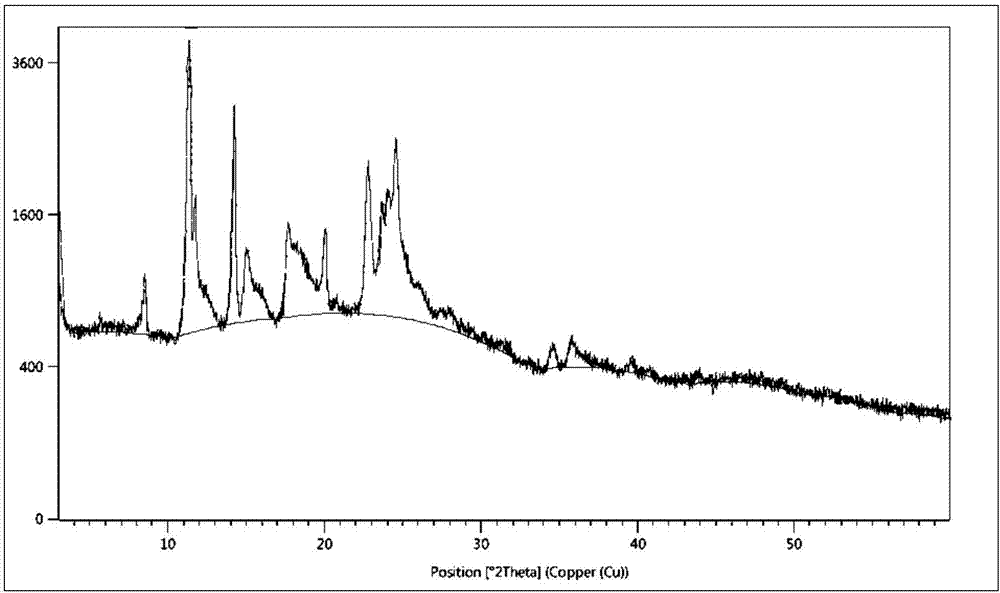

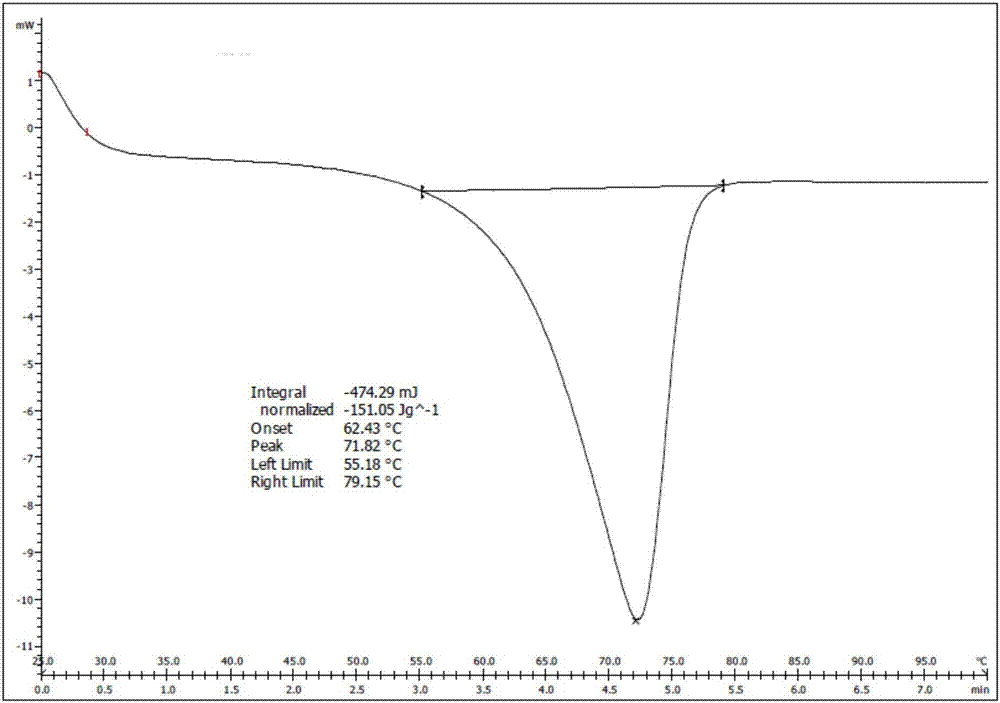

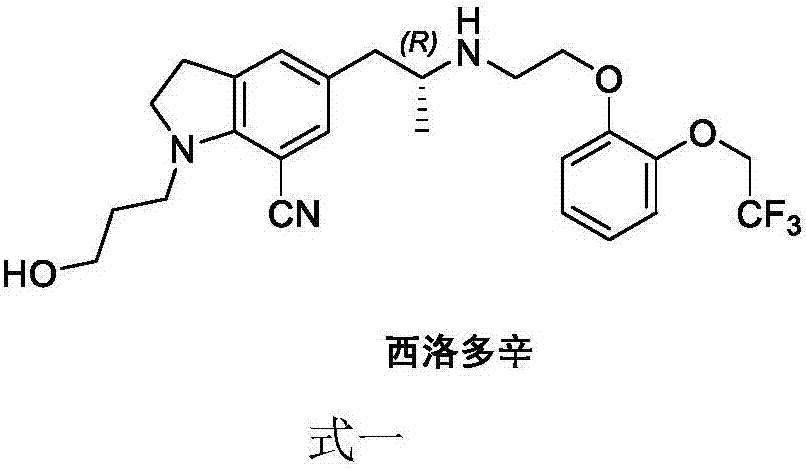

Synthesizing method of silodosin and intermediate thereof

ActiveCN107056675ASimplify conversion stepsHigh reaction yieldOrganic chemistry methodsProduction riskHydrolysis

The invention relates to the field of medicine chemistry, aims to solve the problems that the prior art is complex in reaction steps, high in production risk, low in yield, and the like, and provides a synthesizing method of silodosin and an intermediate thereof. The synthesizing method includes: using hydrochloric acid / acetic acid to perform deacetylation on chloride 2 to obtain indoline 3, performing SN2 substitution reaction to obtain imide 4, performing N alkylation reaction to obtain benzoate 5, reducing carbonyl to obtain indoline 6, performing Vilsmeier reaction to obtain aldehyde 7, performing oximation dewatering to obtain nitrile 8, performing hydrazine hydrate reaction to obtain amine 9, performing L-tartaric acid separation on the amine 9 to obtain the silodosin key intermediate 10, performing condensation under an alkaline condition to obtain a compound 11, allowing the compound 11 to have salt formation crystallization with L-malic acid to form salt 12, and performing alkaline hydrogen peroxide hydrolysis on the salt 12 to obtain the silodosin 1. The synthesizing method has the advantages that the L-malic acid is used to perform the salt formation crystallization, impurities such as bipolymer which are hard to remove are removed effectively, high reaction conversion rate is achieved, industrial production cost is lowered effectively, and synthesizing safety is increased by avoiding the use of dangerous reagents.

Owner:ZHEJIANG TIANYU PHARMA

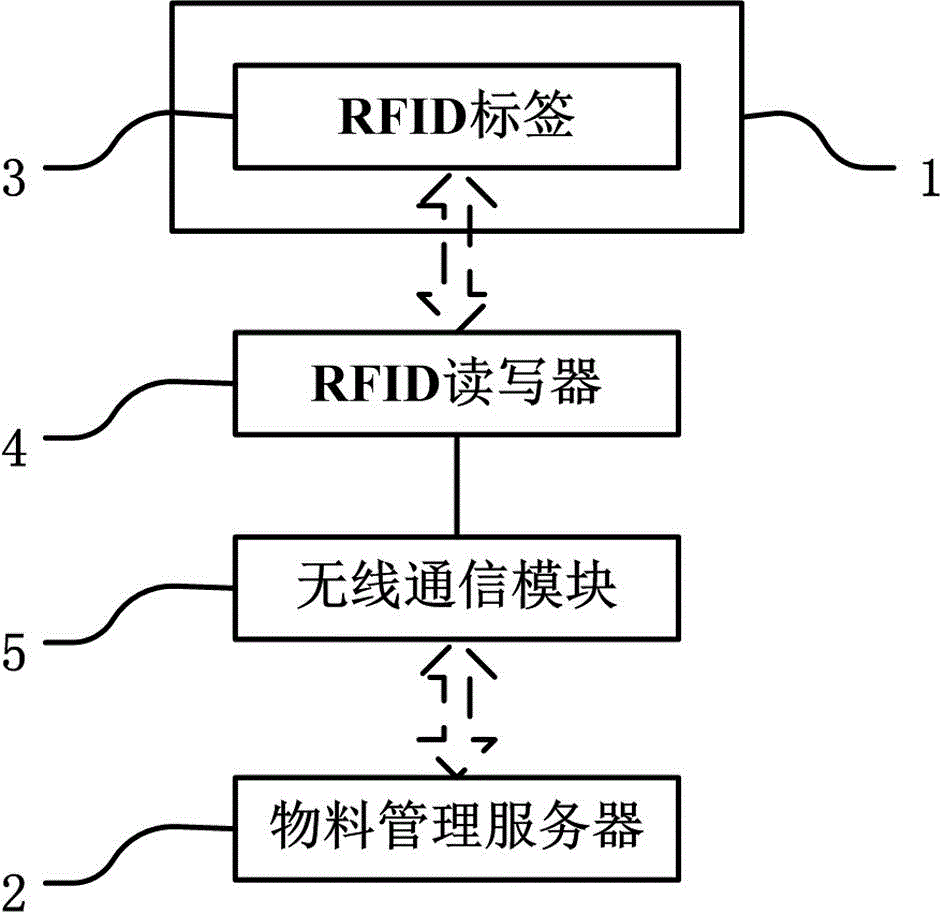

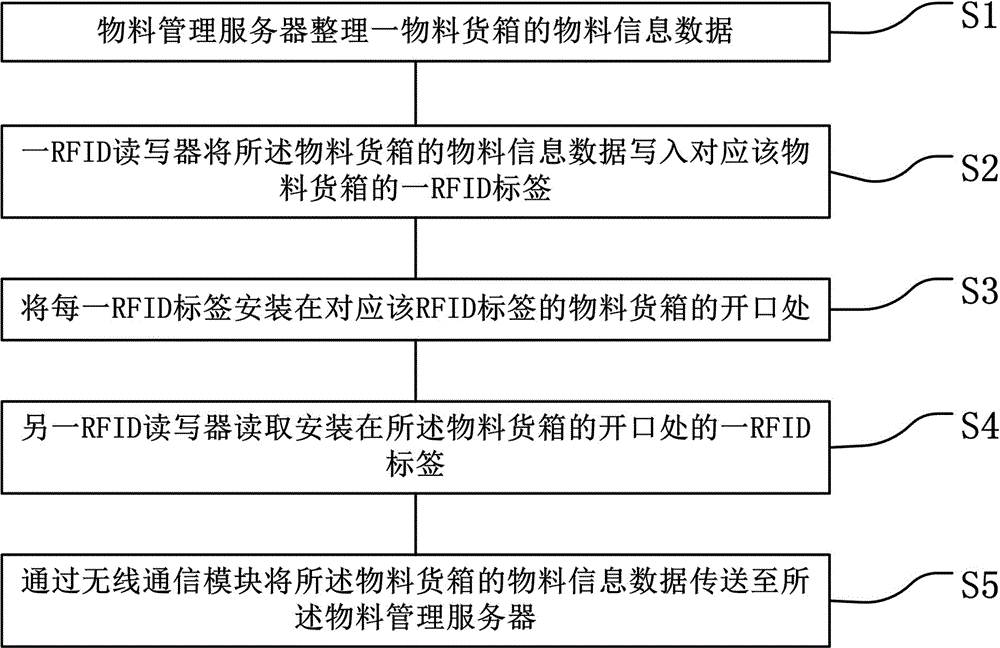

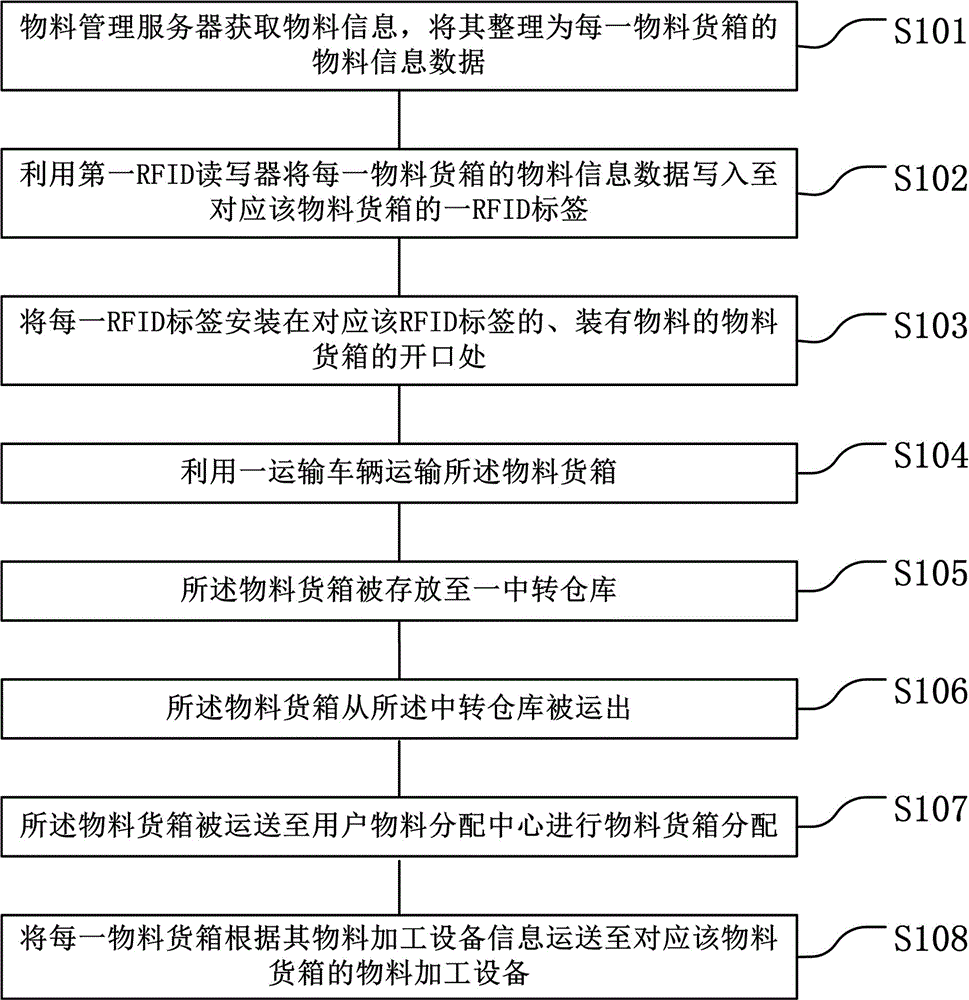

Material delivery method based on RFID

InactiveCN104537514AFast deliveryPrecise deliveryCo-operative working arrangementsLogisticsProduction lineProduction risk

The invention provides a material delivery method based on RFID. The method comprises the following steps: sorting material information data by using a material management server; writing the material information data in an RFID label; mounting the RFID label at an opening of a material container; transporting the material container and reading the material information data; storing the material container in a transit warehouse and reading the material information data; transporting the material container out of the transit warehouse and reading the material information data; reading the material information data by a material allocation center and allocating the material container; transporting the material container to material processing equipment, and the like. The method disclosed by the invention has the advantages that a corresponding relationship between the material and the material processing equipment can be built before the material leaves factory; the delivery, casing, transportation, transit storage and delivery to a production line of the material are monitored and managed during the overall processes, so that the material can be delivered accurately; material loss and damage can be effectively prevented; the delivery reliability is improved; the delivery efficiency is improved; the production risk is reduced.

Owner:EAST CHINA UNIV OF SCI & TECH

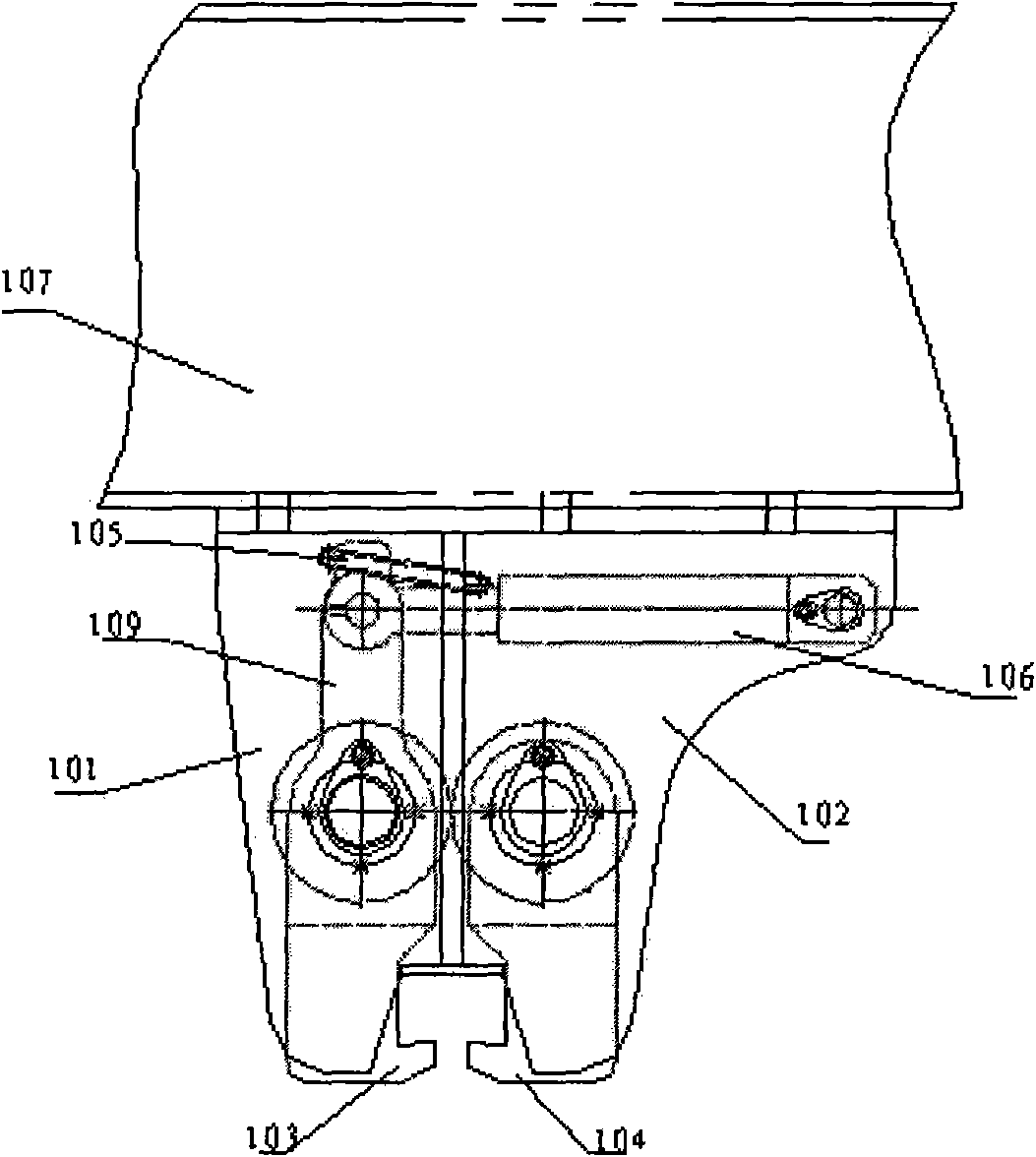

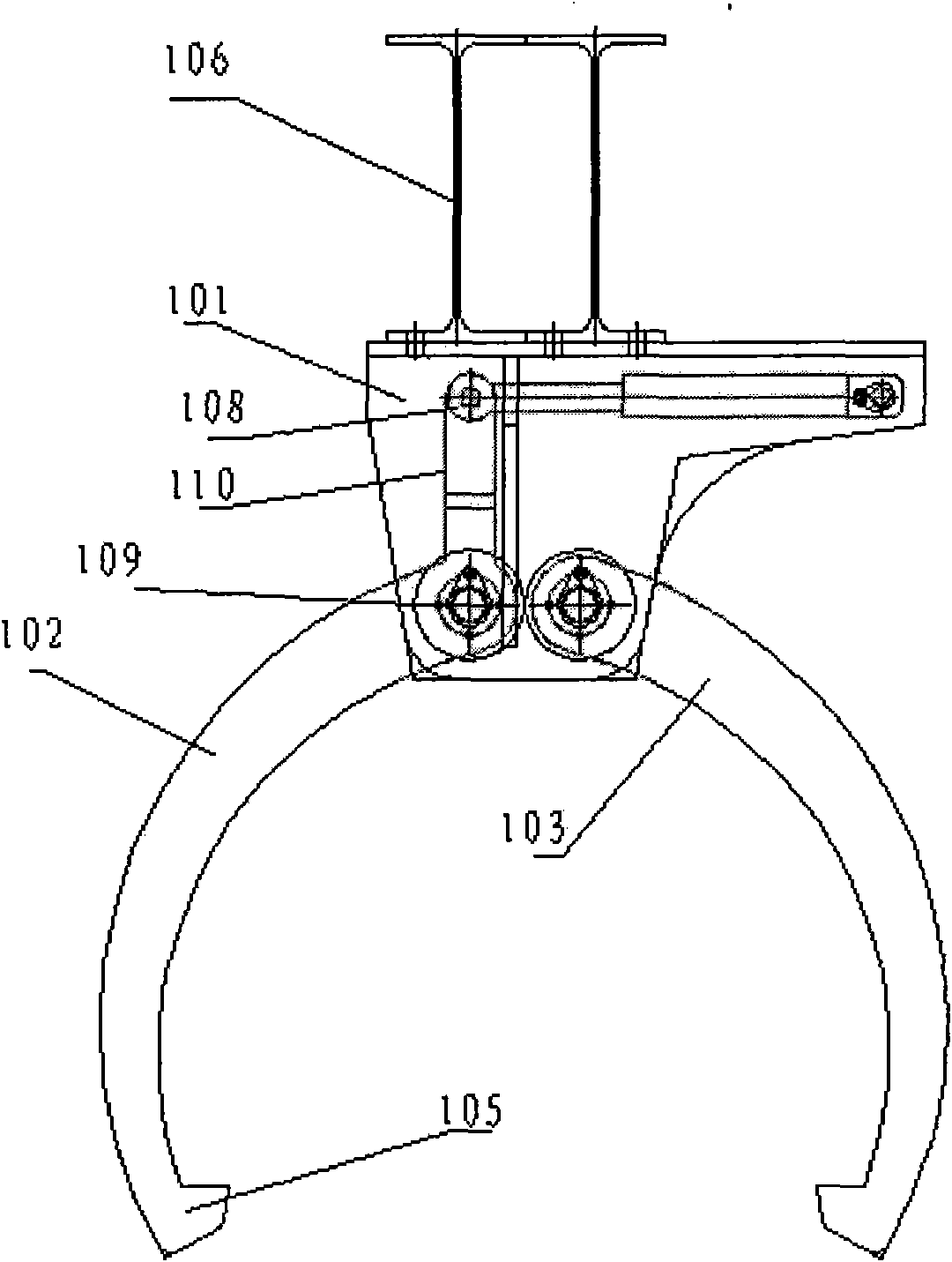

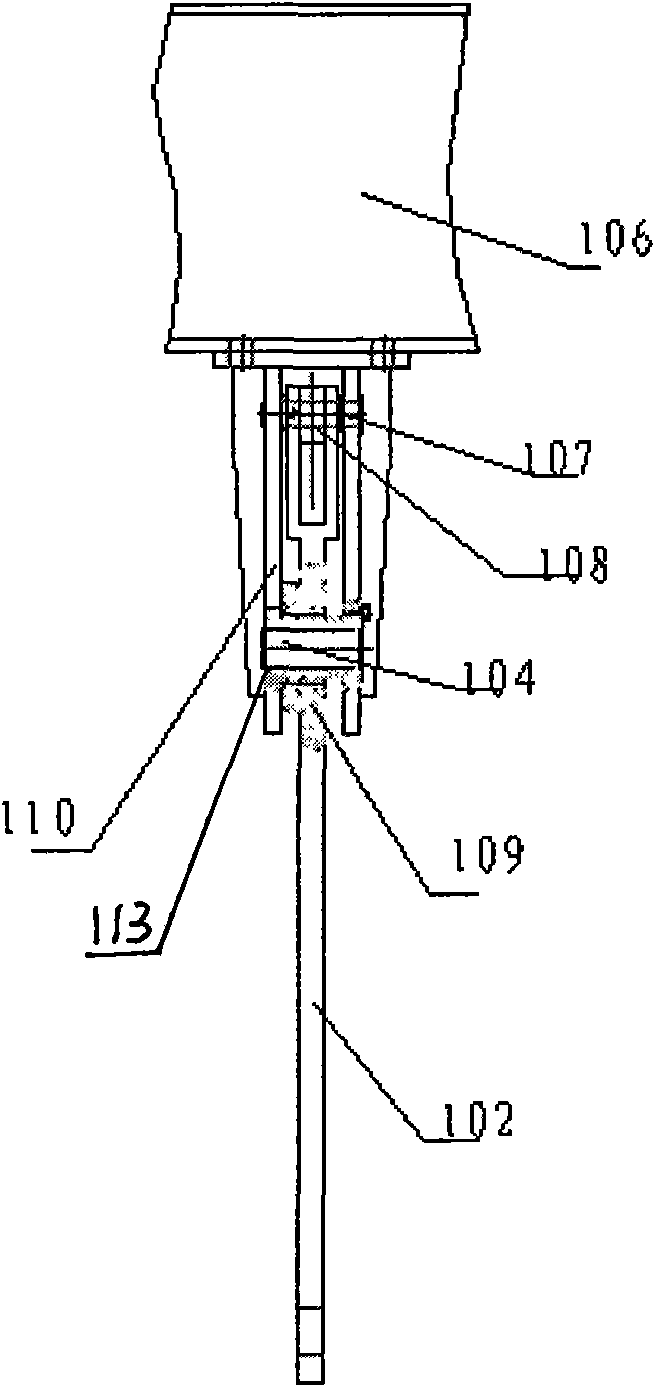

Tubular pile upper mould and hoisting system thereof

ActiveCN101967823ASolve the production risk of swinging left and rightLoad-engaging elementsBulkheads/pilesProduction riskIndustrial engineering

The invention discloses a tubular pile upper mould and a hoisting system thereof. The hoisting system consists of a hoisting tool system and a mould system, wherein the hoisting tool system consists of a hoisting tool left arm, a hoisting tool right arm, a left clamp hook, a right clamp hook, a pull rod, a telescopic rod, a bracket, a hinge pin, an oscillating rod, a clamp outer frame, an upper hinge pin and an oil cylinder; the mould system consists of the tubular pile upper mould and an upper mould T-shaped frame; and the hoisting tool system is connected to the lower end of a travelling crane. The tubular pile upper mould and the hoisting system thereof have the advantages that: the system effectively reduces the production risk that the conventional tubular pile mould is easily unhooked when hoisted or oscillates left and right due to the high-strength wire ropes; meanwhile, the hoisting and unloading of the tubular pile mould can be automatically finished by only one travelling crane operator, and the production efficiency is 3 times that of the conventional hoisting system.

Owner:ZHEJIANG KNSN PIPE & PILE

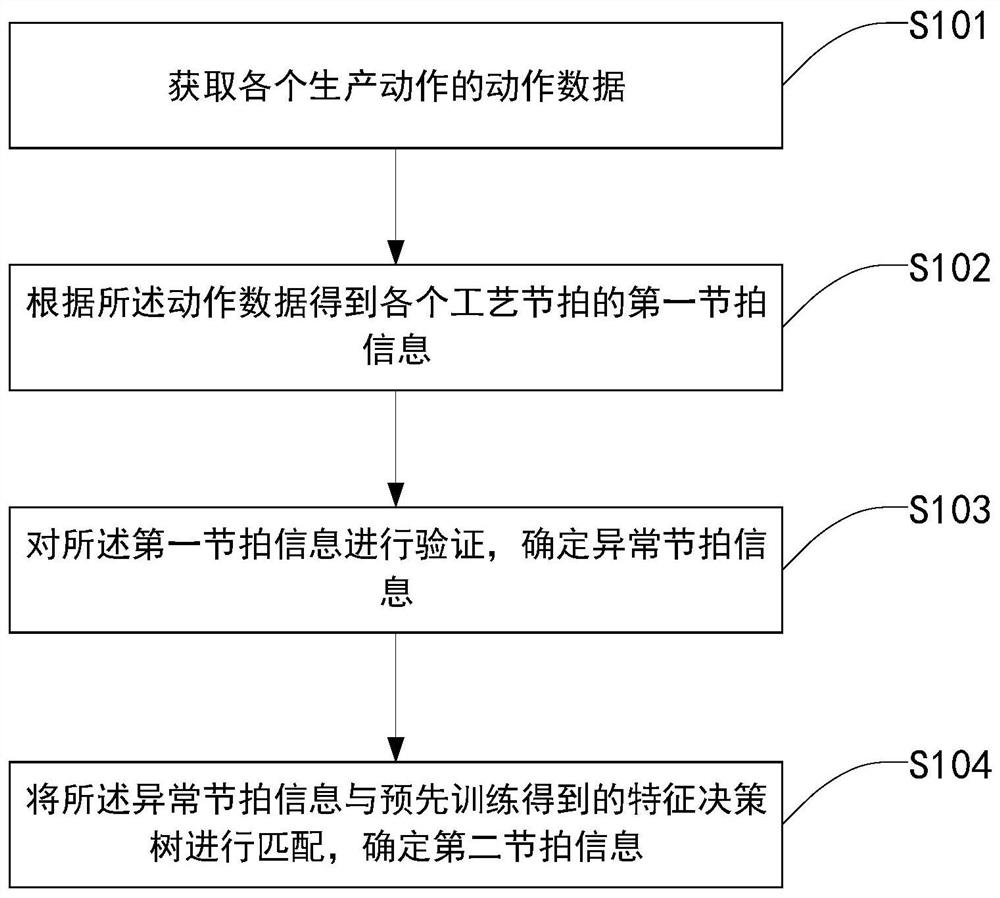

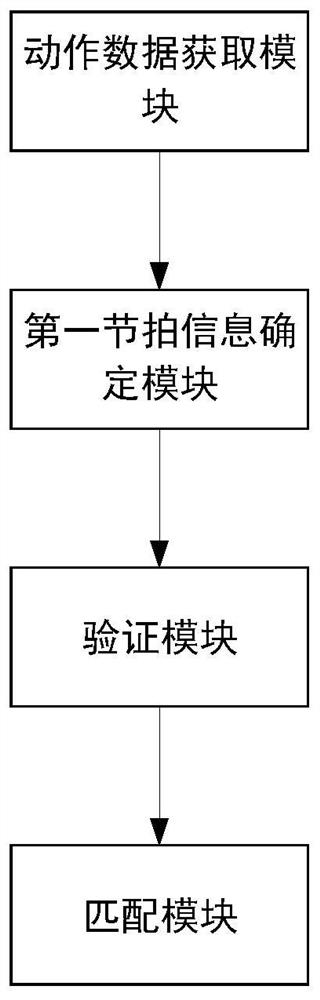

Process beat processing method, system and device and storage medium

ActiveCN111860605AImprove accuracyIncrease productivityData processing applicationsCharacter and pattern recognitionProduction riskIndustrial engineering

The invention discloses a process beat processing method, system and device and a storage medium. The method comprises the steps of obtaining action data of each production action; obtaining first beat information of each process beat according to the action data; verifying the first beat information, and determining abnormal beat information; and matching the abnormal beat information with a feature decision tree obtained by pre-training, and determining second beat information. According to the invention, the abnormal beat information is matched with the feature decision tree; the determinedsecond beat information can accurately represent the process beat in the production process; the invention can adapt to process beat statistics under various conditions, greatly improves the accuracyof the process beat statistics result, facilitates the subsequent process adjustment and optimization of the actual production condition according to the process beat statistics result, guarantees the improvement of the production efficiency and the production quality, and reduces the production risk and the production cost. The invention can be widely applied to the technical field of productionprocesses.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD +1

Special long-acting slow-release fertilizer for rice

InactiveCN104341242APromote sustainable developmentImprove stress resistanceSuperphosphatesAlkali orthophosphate fertiliserMinor elementPotassium

The invention discloses a special long-acting slow-release fertilizer for rice, of which the nutritive elements comprise nitrogen, phosphorus, potassium, secondary and minor elements, beneficial nutrients, organic matters, a non-coating slow-release agent and a soil conditioner. The raw materials for providing the nutritive elements comprise urea, ammonium chloride, ammonium dihydrogen phosphate, a calcium magnesia phosphate fertilizer, ordinary superphosphate, potassium chloride, zinc sulfate monohydrate, organic matters, a non-coating slow-release agent and a soil conditioner. The special long-acting slow-release fertilizer for rice can implement slow-release, and is effective for the whole process after single-dose application; and thus, the special long-acting slow-release fertilizer for rice can satisfy the nutrient demands of rice in the whole growth period after single-dose application. The special long-acting slow-release fertilizer for rice combines utilization and maintenance of soil, can supply nutrients, can also loosen the soil and enhance the soil fertility, has higher utilization ratio, enhances the stress tolerance of rice, lowers the agricultural production risks, balances the nutrients, implements scientific fertilizer application, has the advantages of complete nutrients, multiple functions and scientific formula, and solves the problems caused by purposeless fertilizer application, unbalanced fertilizer application and the like.

Owner:HUBEI YISHIZHUANG AGRI TECH

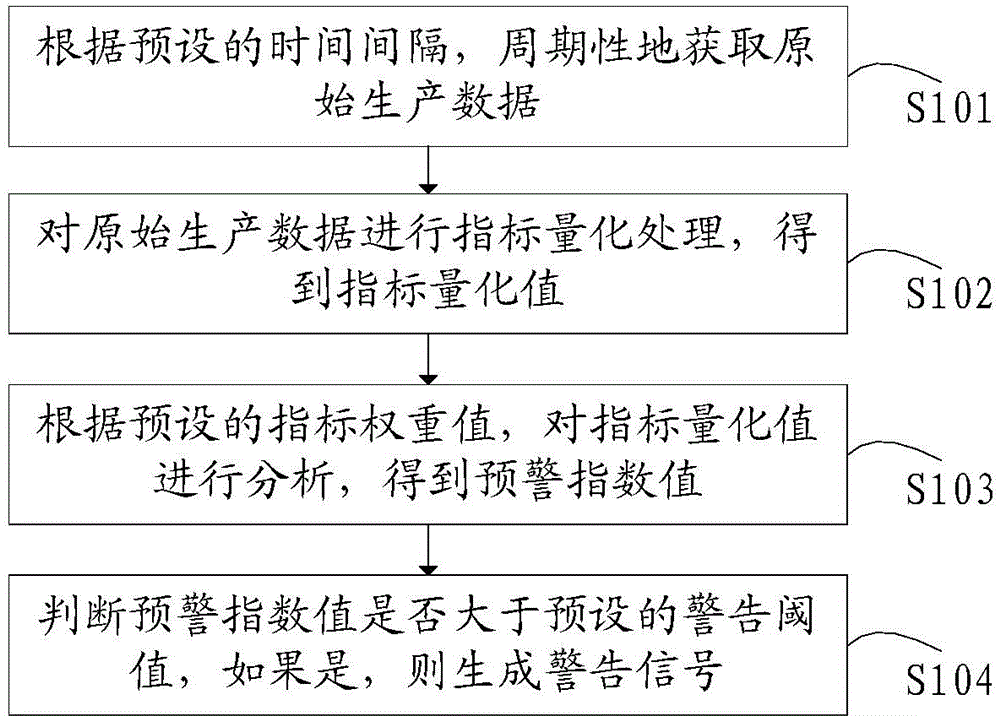

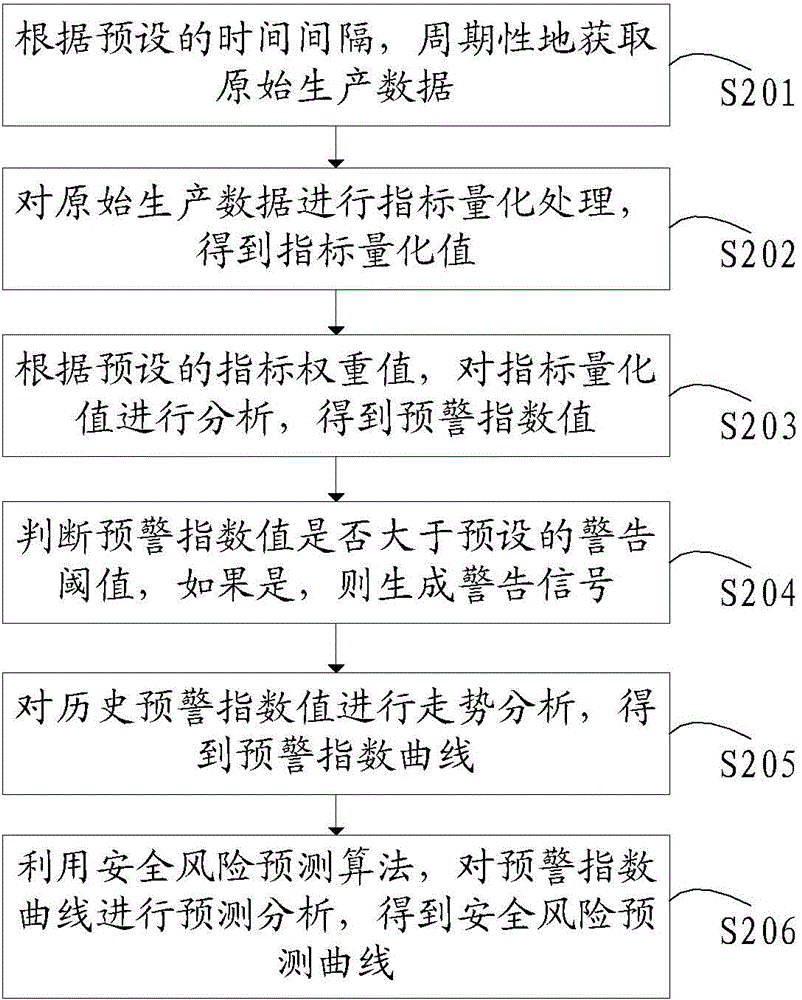

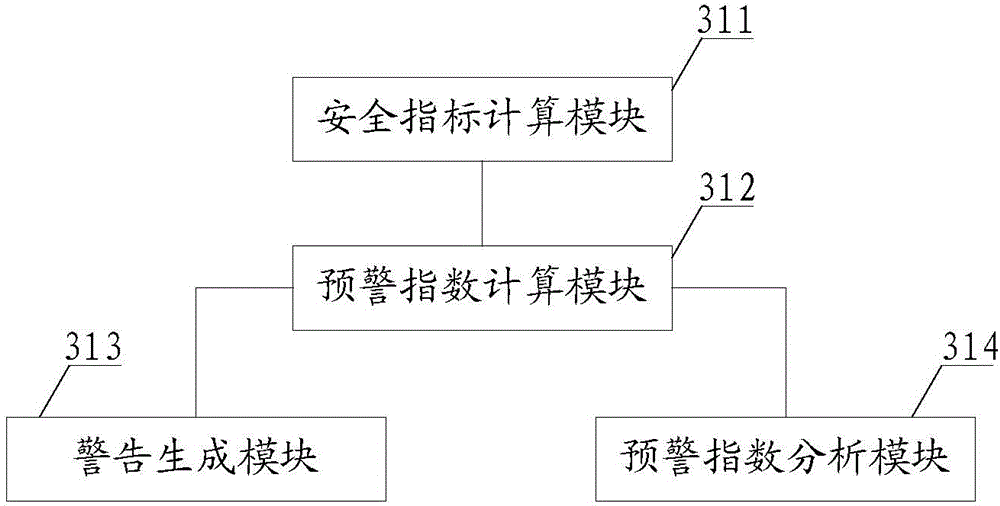

Method, device and system for giving early warning about production risk

InactiveCN104463363AImprove production safetyReduce safety incidentsForecastingProduction riskData mining

The invention discloses a method, device and system for giving an early warning about a production risk. The method includes the steps that according to a preset time interval, original production data are acquired periodically; index quantification treatment is conducted on the original production data, so that an index quantification value is acquired; according to a preset index weight value, the index quantification value is analyzed, and therefore an early warning index value is acquired; whether the early warning index value is larger than a preset warning threshold value or not is judged, and if yes, a warning signal is generated. In the system, index quantification treatment is conducted on the original production data, so that the index quantification value is acquired; then, the index weight value which is stored in advance is used for analyzing the index quantification value, so that the early warning index value is acquired; when the early warning index value is larger than the preset warning threshold value, the warning signal is actively generated, related personnel can be prompted in time to take corresponding measures, a production safety coefficient of an enterprise is increased, and the possibility in which safety accidents occur is reduced.

Owner:浙江图讯科技股份有限公司

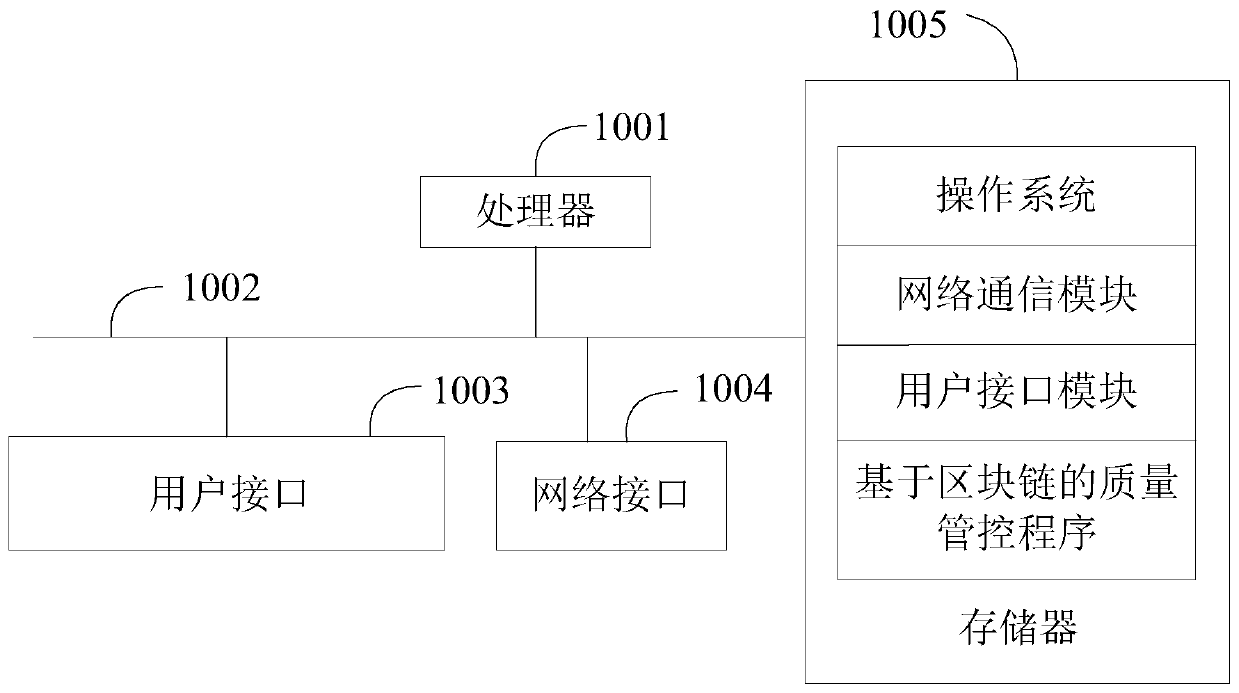

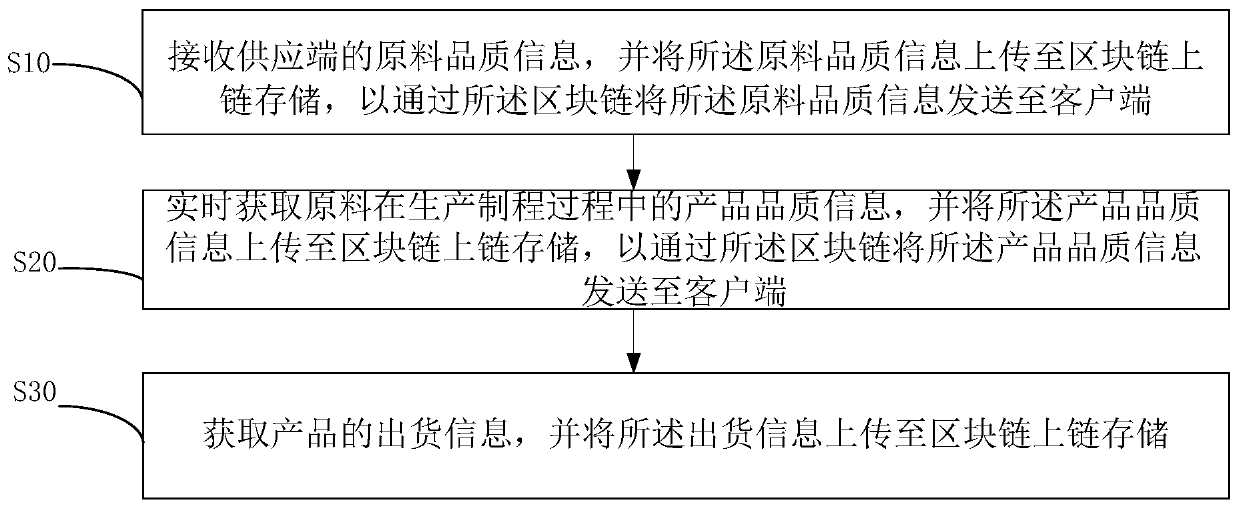

Quality control system and method based on block chain and computer readable storage medium

InactiveCN111339195ADatabase distribution/replicationDigital data protectionQuality control systemProduction risk

The invention discloses a quality control system and method based on a block chain, and a computer readable storage medium. The system comprises a production process module which is used for monitoring the product quality information in a production process in real time, and dynamically adjusting the production process parameters according to the product quality information; the data collection and analysis module is used for acquiring product quality measurement data in the production process in real time, generating a product quality risk evaluation report according to the product quality measurement data, identifying key information in the product quality risk evaluation report, and uploading the key information to a blockchain upper chain for storage; and the intelligent quality decision monitoring module is used for acquiring the product quality measurement data of the data collection and analysis module so as to generate a product production risk report according to the production management and control standard parameters and the product quality measurement data, thereby realizing prevention of potential risks of product quality in the product manufacturing process in advance.

Owner:SHENZHEN DIANLIAN TECH CO LTD

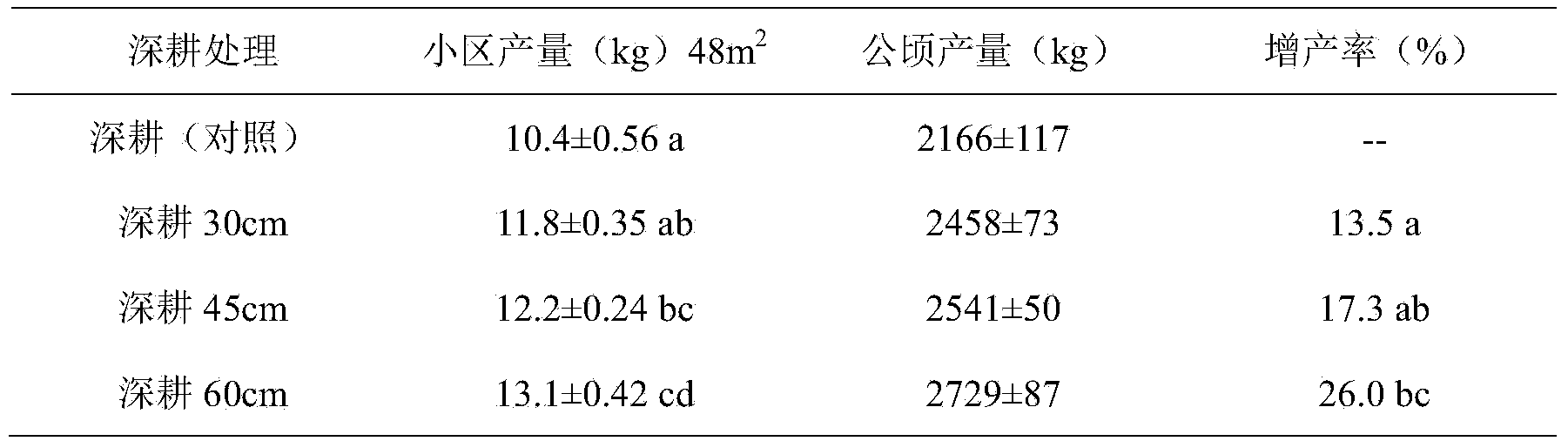

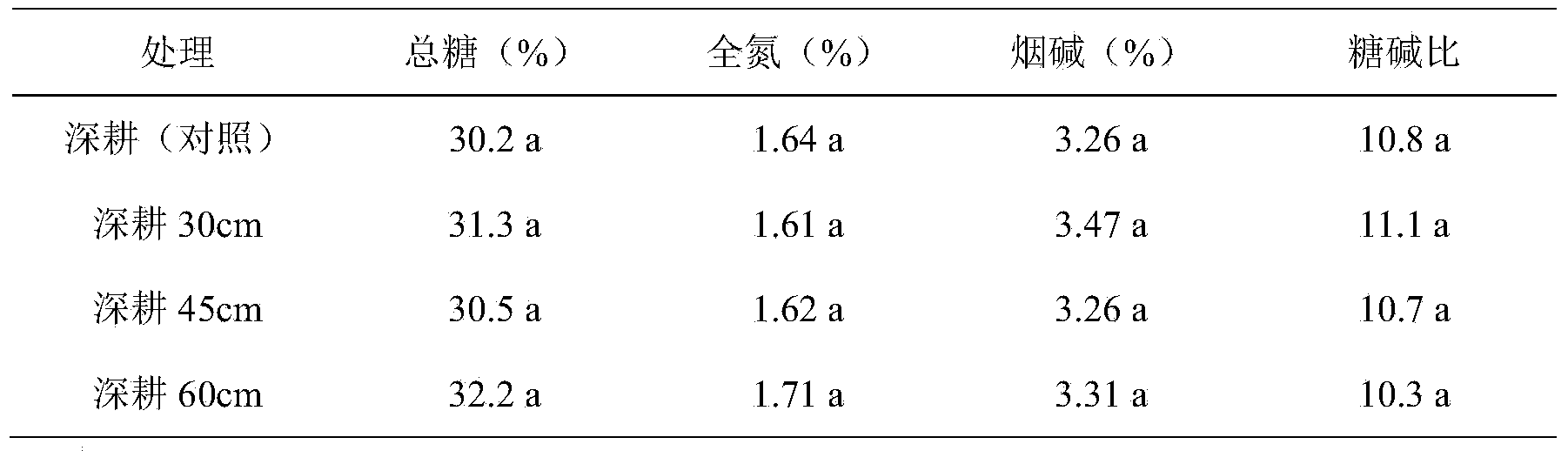

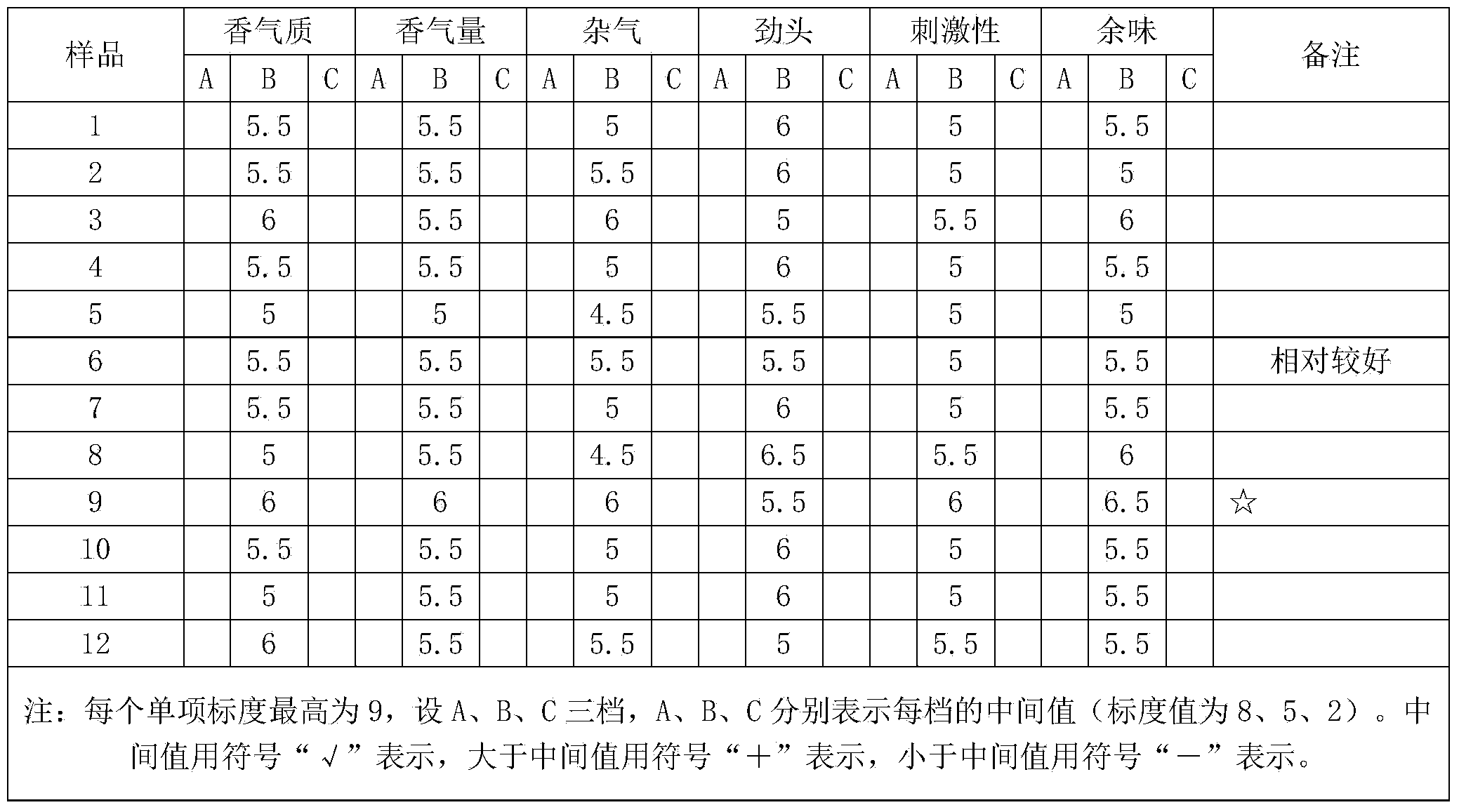

Red-soil dry sloping field tobacco deep plowing, fertilization and level planting integrated planting method

The invention relates to a red-soil dry sloping field tobacco deep plowing, fertilization and level planting integrated planting method. Soil in a 50cm-deep soil layer is mixed through mechanical strip type deep plowing, fertilization is conducted in a matched manner, then ridges are leveled and finally tobacco is planted. The method is simple and feasible, the planting efficiency of tobacco in red-soil dry sloping fields in south China can be obviously improved, the production risk caused by insufficient rainwater is reduced and the problem of lack in fields for tobacco and staple food grain production is avoided.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

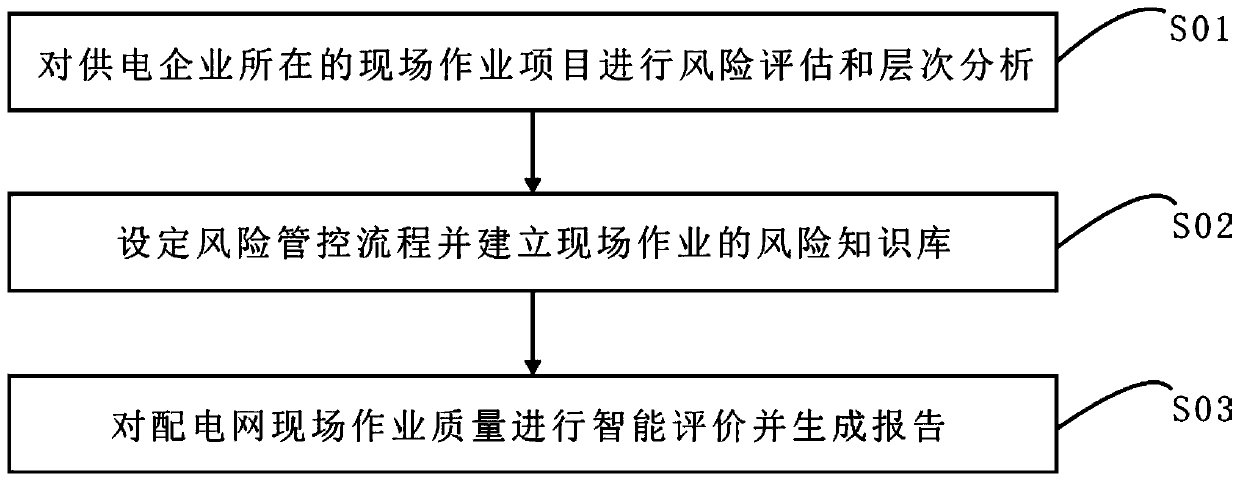

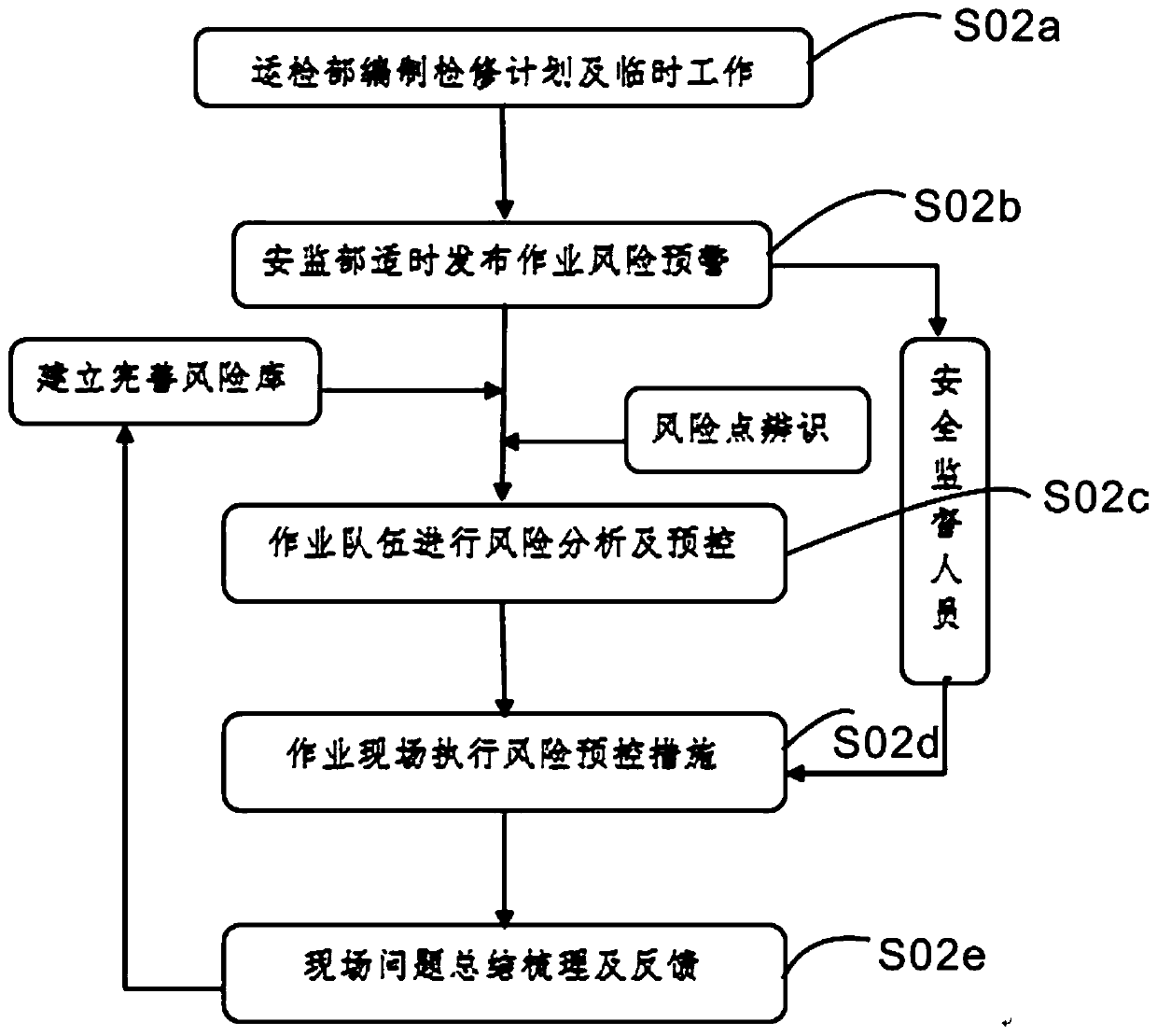

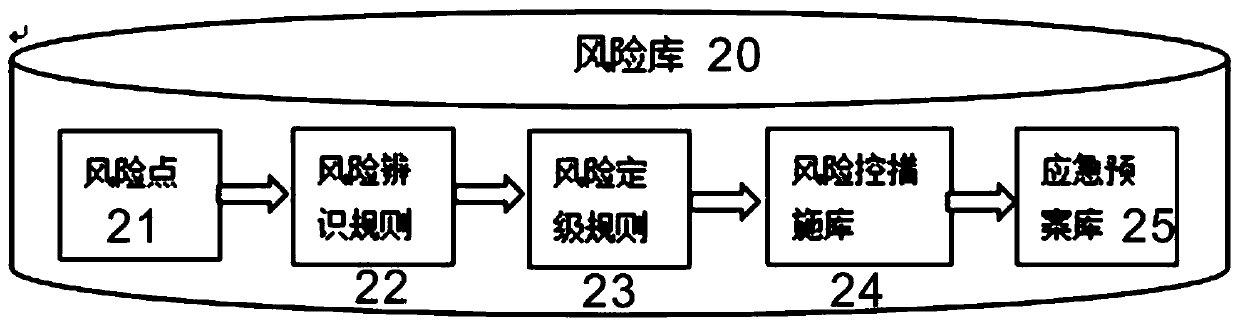

Power distribution network field operation risk management and control method

PendingCN110490453AImprove the quality of workImprove the level of security management and controlResourcesInformation technology support systemQuality levelQuality of work

The invention provides a power distribution network field operation risk management and control method. The method comprises the following steps: S01, performing risk assessment and hierarchical analysis on a field operation project where a power supply enterprise is located; S02, setting a risk management and control process and establishing a risk knowledge base of field operation; wherein the risk knowledge base comprises risk points, a risk identification rule base, a risk grading rule base, a risk pre-control measure base and an emergency plan base; and S03, carrying out intelligent evaluation on the field operation quality of the power distribution network and generating a report. According to the invention, through establishing and effectively operating a field operation safety production risk management and control system, field operation is managed and controlled from the source, synchronization of operation project plan arrangement and safety risk analysis and synchronizationof risk assessment early warning and risk pre-control management are achieved, controllability, controllability and controllability of field operation are ensured, and the working quality level of field operation personnel and the safety management and control level of an electric power department are further improved.

Owner:国网河南省电力公司新野县供电公司

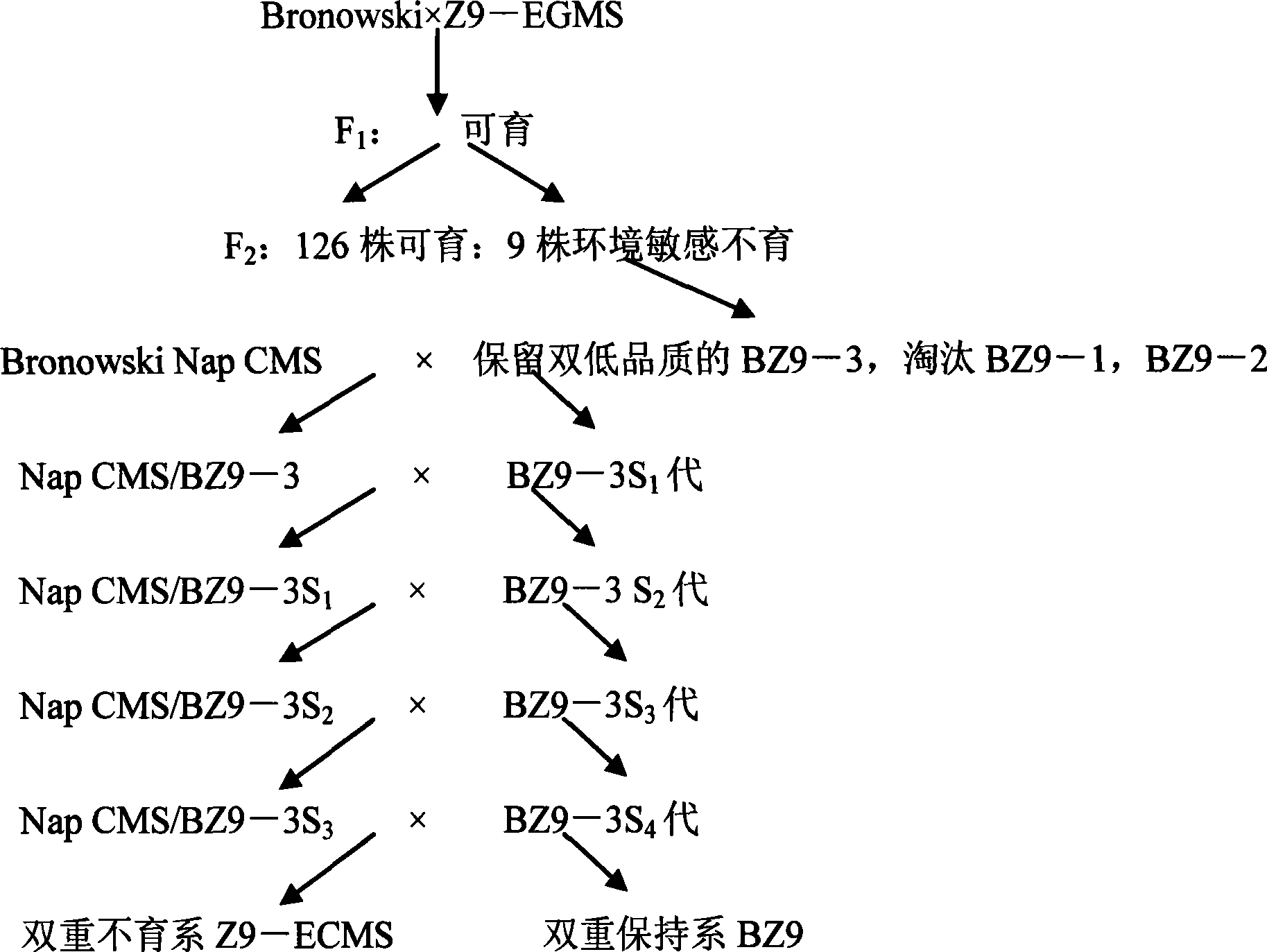

Seed selection method of cabbage type rape twofold sterile line

InactiveCN101390493AImprove the purity of seed productionIncrease productionPlant genotype modificationAgricultural sciencePetal

The invention discloses a breeding method for novel brassica napus dual-sterile lines. The method adopts the environment-sensitive genic sterile material to hybridize the Nap CMS-maintainer line; the offspring select the environment-sensitive genic sterile plant testcross to maintain Nap CMS; the environment-sensitive genic sterile gene is guided into the Nap CMS, and the bred dual-sterile lines are completely sterile, with flat petals, white pollen-free stamens and stable flowering fertility. Most normal varieties can resume the fertility, so as to greatly expand the utilization range of the rapeseed heterosis and reduce the seed production risk; moreover, the method can improve the purity of hybrid seed production and provides a technical support to increase the hybrid seed yield.

Owner:NORTHWEST A & F UNIV

Method for selective breeding of rice thermo-sensitive permanent genic male sterile line by adopting bridge parents

InactiveCN103814814ASolution rangeSolve problems such as the tight seed production seasonPlant genotype modificationAgricultural scienceHeterosis

The invention discloses a method for selective breeding of a rice thermo-sensitive permanent genic male sterile line by adopting bridge parents. With utilization of a hybridization technology, recessive genic male sterile genes for expressing sterility under conditions of high temperature and low temperature are respectively introduced into appropriate bridge parents; through hybrid backcross and trait screening, a pair of near-isogenic lines having bridge parent genetic backgrounds and respectively carried with a high temperature genic male sterile trait and a low temperature genic male sterile trait are bred; the rice permanent genic male sterile line is produced through outcrossing breeding of the pair of near-isogenic lines, so that production risks brought because the two kinds of thermo-sensitive genic male sterile lines are affected by the environment in the production process of two-line hybrid rice seeds are avoided, a two-line hybrid rice seed production system which can randomly select a seed production base and a seed production season is established, and a new way for utilization of rice heterosis is developed.

Owner:RICE RES ISTITUTE ANHUI ACAD OF AGRI SCI

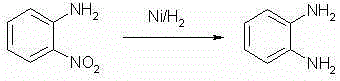

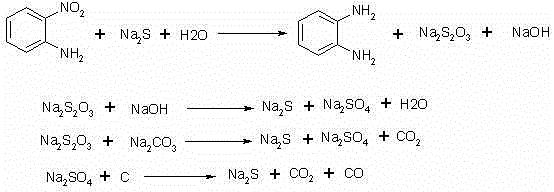

Improved synthetic method for preparing o-phenylenediamine by reducing o-nitroaniline

ActiveCN105017028AHigh recovery rateAvoid security issuesOrganic compound preparationAlkali metal sulfides/polysulfidesReaction temperatureProduction risk

The invention relates to an improved synthetic method for preparing o-phenylenediamine by reducing o-nitroaniline. The method comprises adding o-nitroaniline and sodium sulfide according to the molar ratio of 1:1.5-2 into a reaction vessel, injecting water, controlling the weight ratio of sodium sulfide to water to be 1:1-20, controlling the reaction temperature to be 50-150 DEG C, reacting for 1-5 h, crystallizing and separating o-phenylenediamine, so as to obtain reaction waste water; concentrating the reaction waste water to obtain a solid residue; performing medium-temperature calcining on the residue, concretely adding an inorganic base into the residue and controlling the temperature of medium-temperature calcining to be 300-600 DEG C; performing high-temperature calcining on the residue, concretely mixing with carbon powder, and controlling the temperature of high-temperature calcining to be 900-1200 DEG C; and performing separation filtering, concretely using water to dissolve the post-calcined product, filtering and recovering superfluous carbon powder and obtaining a filtrate which is a sodium sulfide aqueous solution. The method realized continuous efficient wastewater processing, is beneficial for reducing discharge of ' three wastes (waste gas,waste water and industrial residue) ', reduces safe production risk, improves sodium sulfide recovery rate, and is relatively suitable for large-scale production of o-phenylenediamine in industry.

Owner:江阴市华亚化工有限公司

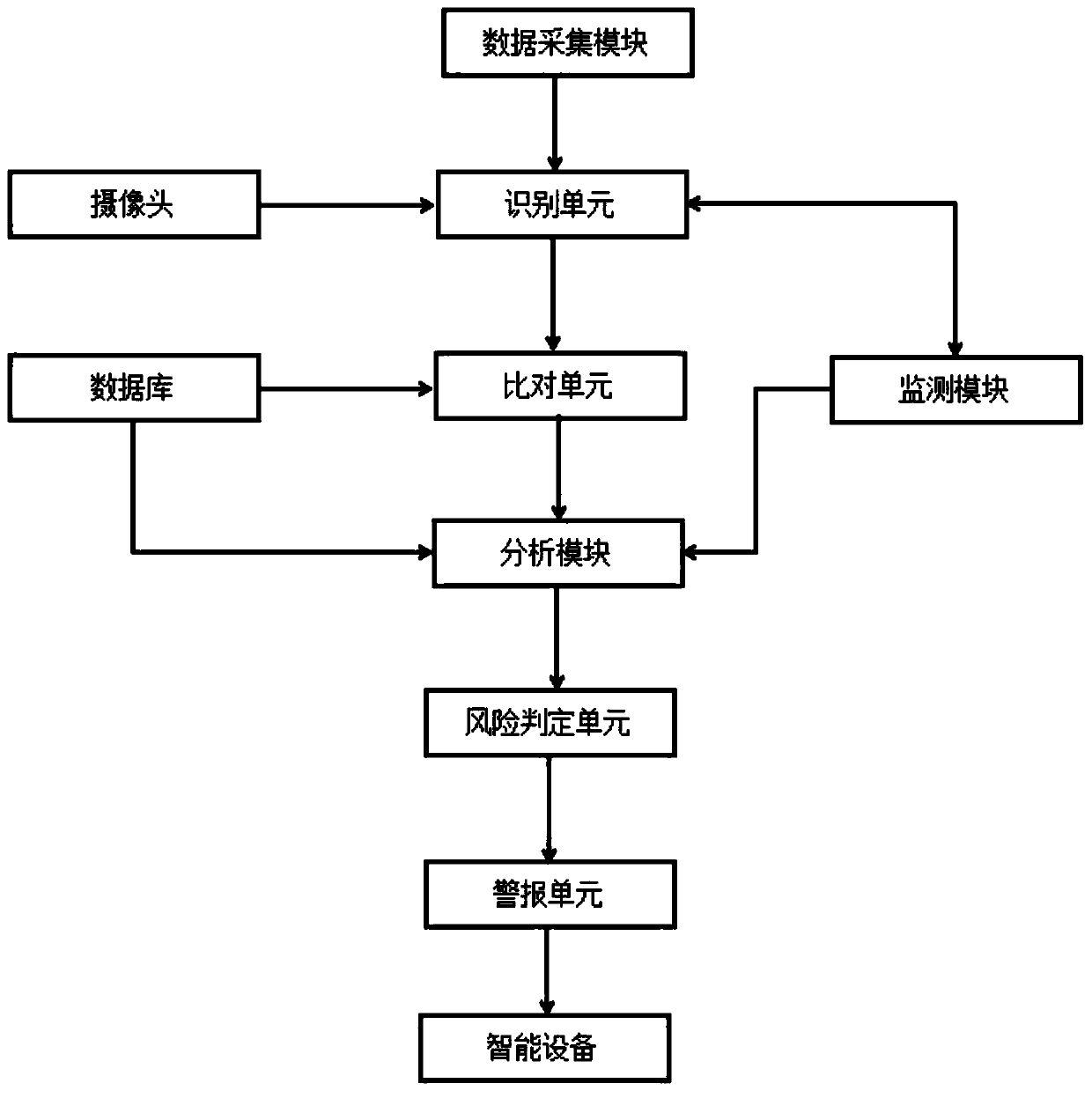

Industrial enterprise safety production risk identification system and method thereof

InactiveCN110796372AResolve identifiabilitySolve the problem of analysisResourcesMetadata still image retrievalHazardous substanceData acquisition

The invention discloses an industrial enterprise safety production risk identification system, comprising a data acquisition module, a camera, a database, an identification unit, a comparison unit, amonitoring module, an analysis module, an alarm unit, a risk determination module and an intelligent device, wherein the data acquisition module is used for acquiring material information and worker moving speed data; the data acquisition module transmits material information to the identification unit; and the identification unit is used for respectively marking materials as harmful material dataand harmless material data through RoHS harmful substance detection equipment, and transmitting harmless material data to the comparison unit. According to the industrial enterprise safety productionrisk identification system, the time for workers to leave the production workshop when an accident occurs is calculated through the analysis module; and the worker separation time is compared with the reaction time of the worker separation time and the reaction time of the worker separation time, so that the evacuation risk of the worker when an accident occurs is obtained, the evacuation risk isevaluated, and the potential safety hazard in the material is found in advance, and the safety evacuation risk is made, and the life guarantee of the worker is improved.

Owner:安徽健峰注册安全工程师服务有限公司

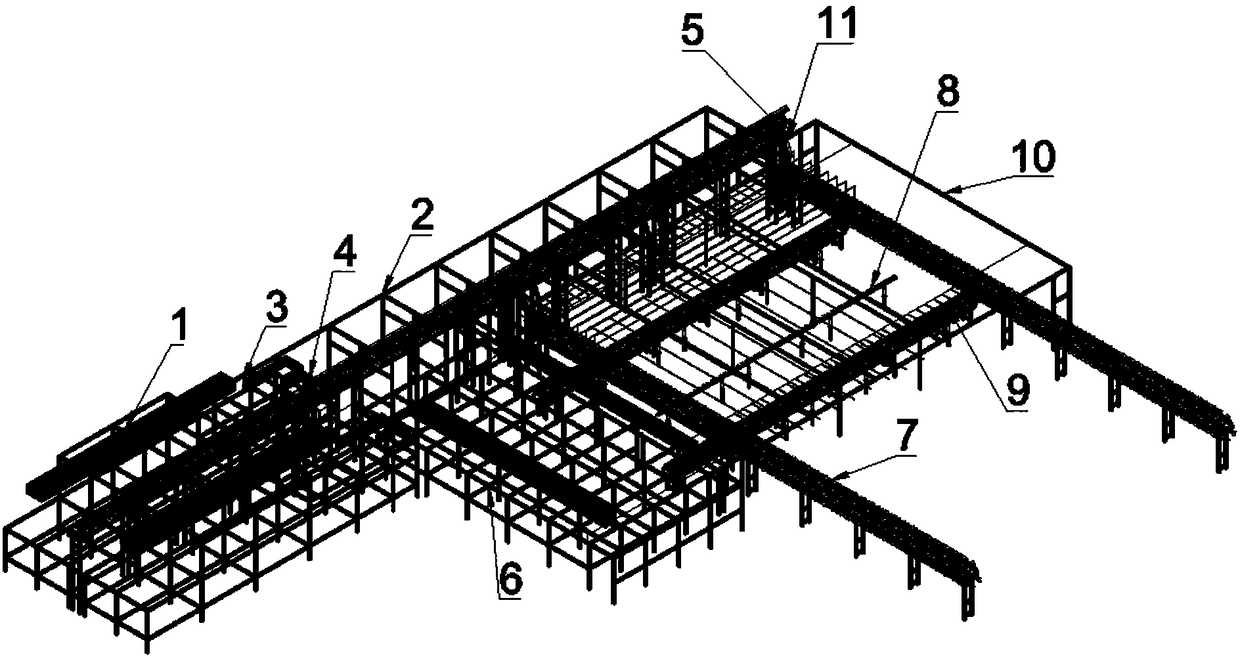

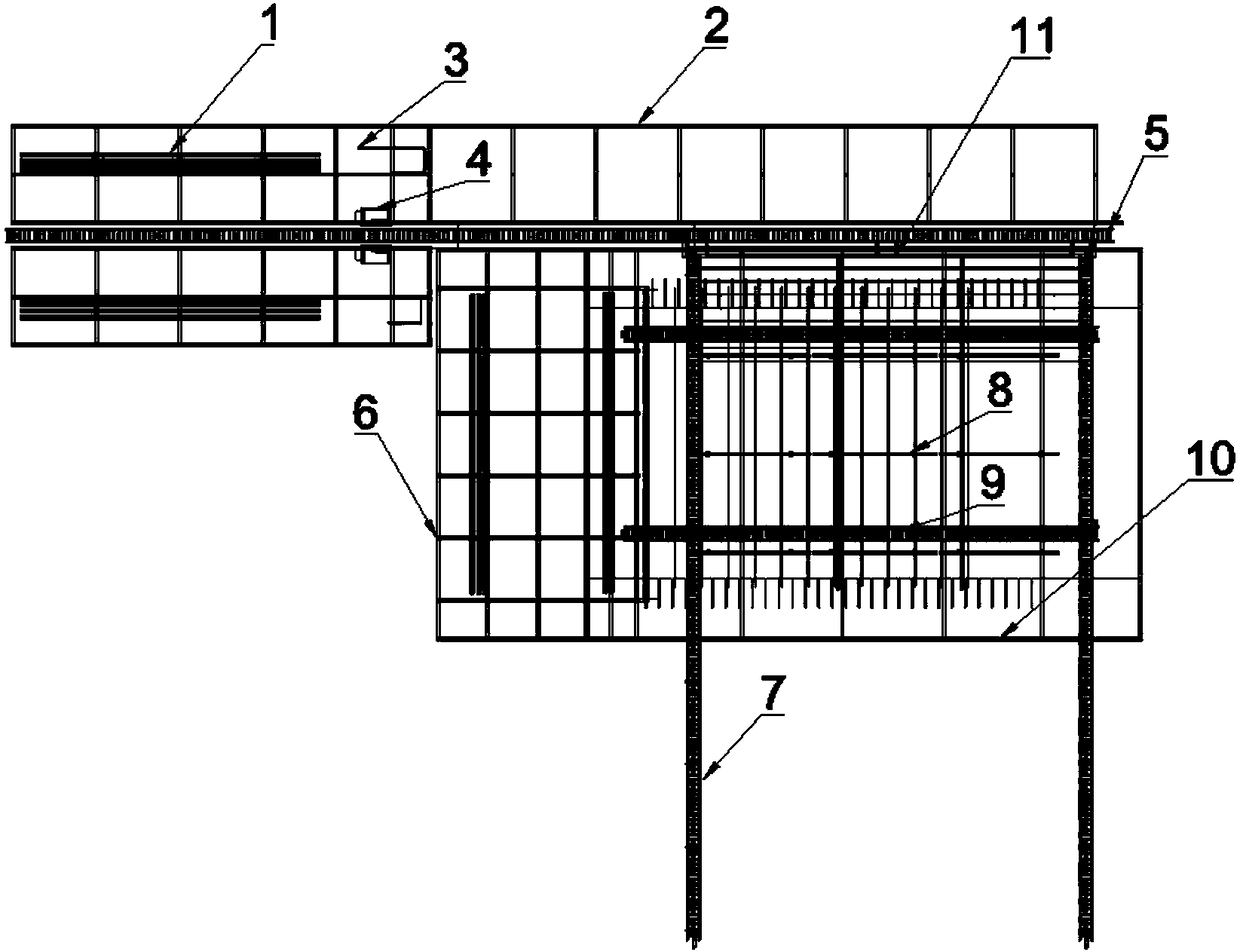

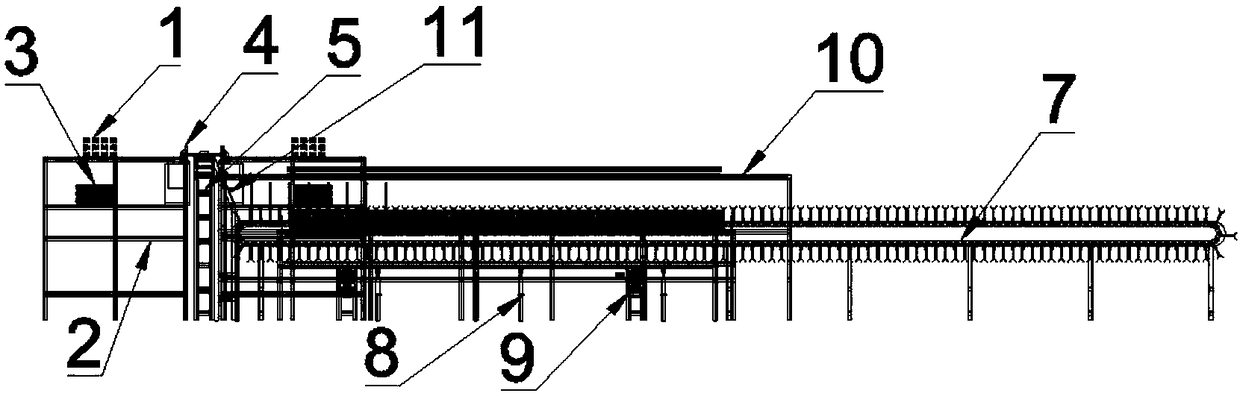

Double-layer steel bar mesh machining device

PendingCN108580758AReduce the difficulty of binding installationReduce difficultyWire networkButt weldingSurface construction

The invention discloses a double-layer steel bar mesh machining device. The device comprises a stirrup conveying device, a steel bar erecting device and a flash butt welding machine are arranged at the corresponding positions of one end of the stirrup conveying device, and transverse conveying devices perpendicular to the stirrup conveying device are arranged at the corresponding positions of theother end of the stirrup conveying device; the end, close to the transverse conveying devices, of the stirrup conveying device, is provided with a first sliding device used for vertically erecting stirrups from the plane to the vertical direction; the device further comprises a stress rib jacking device which is arranged at the corresponding positions of the transverse conveying devices and used for jacking distributed lower-layer stress ribs to the positions under the stirrups; and the device further comprises a stacking and distributing platform which is arranged above the corresponding positions of the transverse conveying devices and used for distributing upper-layer stress ribs on the upper surfaces of the stirrups. According to the double-layer steel bar mesh machining device, the construction efficiency is improved, the yield of the steel bar installation quality is improved, the labor cost is reduced, the storehouse surface construction safety is improved, and the safety production risk of slope operation is reduced.

Owner:SINOHYDRO BUREAU 5

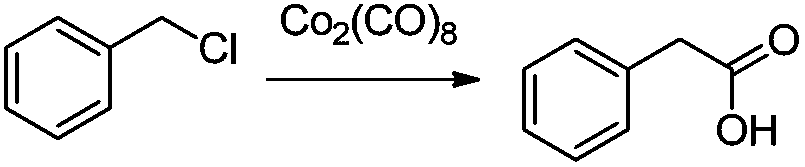

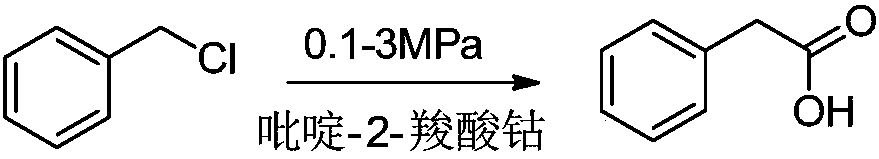

Preparation method of phenylacetic acid type compound

ActiveCN109320413AEasy to getAvoid Production Safety RisksCarboxylic acid nitrile preparationOrganic compound preparationGas phasePhenylacetic acid

The invention discloses a preparation method of a phenylacetic acid type compound. The preparation method of the phenylacetic acid type compound I comprises the following steps that in a solvent and aCO gas phase system, a benzyl halide type compound II, pyridine-2-cobalt carboxylate, palladium acetate and alkaline neutralizers take carbonylation reaction to obtain the phenylacetic acid type compound I. A mixed catalytic system has a synergistic effect; the whole use quantity of catalysts is greatly reduced. When the mixed catalyst is used, a better catalytic effect can be achieved; the characteristics of easily obtaining the catalyst, avoiding the production safety risk of toxic three wastes and the like, reducing the reaction pressure, realizing mild reaction conditions, reducing the production risk, facilitating the production and the like are realized. The formulas are shown in description.

Owner:JIANGSU LIANHE CHEM TECH +2

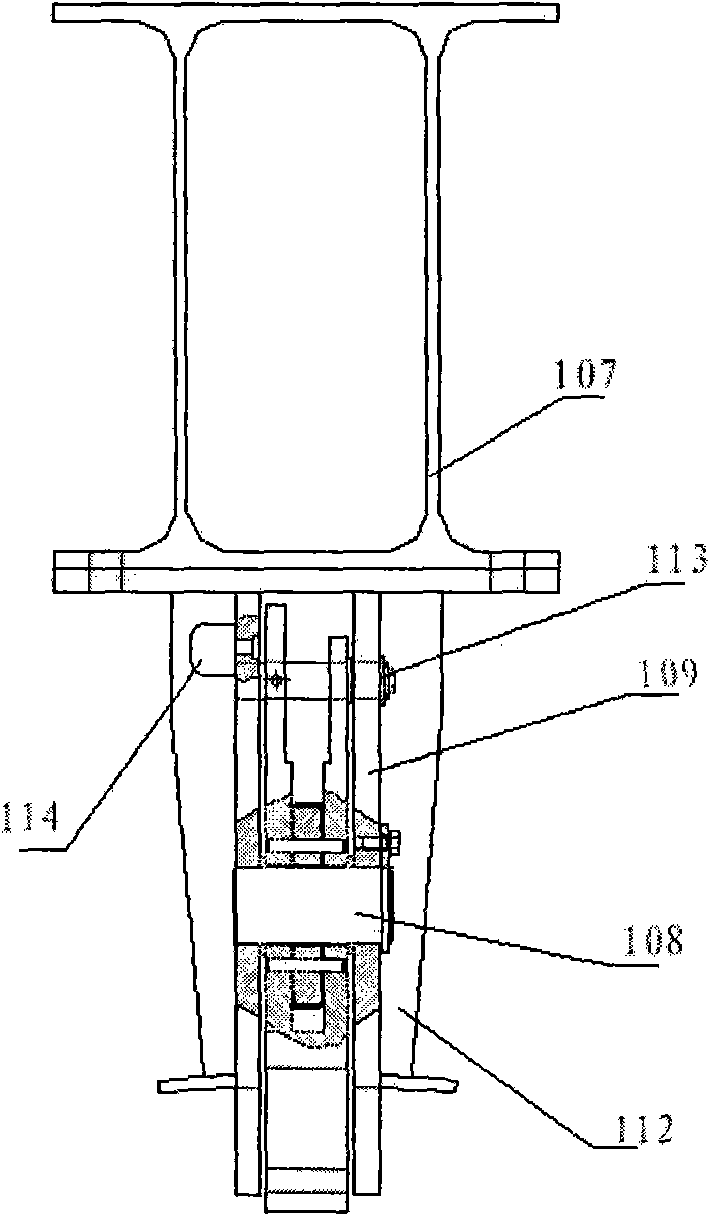

Pipe pile lower die and lifting system thereof

ActiveCN102001134ASolve the production risk of swinging left and rightMouldsLoad-engaging elementsMotor driveControl system

The invention discloses a pipe pile lower die and a lifting system thereof, which consist of a lifting appliance system and a die system, wherein the lifting appliance system consists of a bracket, a lifting appliance left arm, a lifting appliance right arm, a pin shaft, a lifting hook, a hanging bracket, an upper gear pin shaft, an upper gear, a lower gear, a middle gear and a chain; the die system consists of the pipe pile lower die and a lower die lug boss; the lifting appliance system is connected at the lower end of a crane; and a motor drives a pinion to work and is controlled by a crane control system. The invention has the advantages that: the system effectively solves the problems that the traditional pipe pile dies are easily unhooked during lifting or result in production risk due to movement from side to side of a high-strength steel cable, simultaneously the pipe pile lower die can be automatically lifted and unloaded by only one crane operator, and the production efficiency is three times that of the traditional lifting system.

Owner:ZHEJIANG KNSN PIPE & PILE

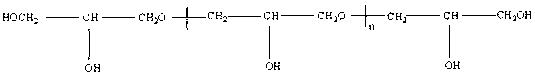

Preparation method and application of polyether type thick oil demulsifying agent

InactiveCN102702463ALow costGood demulsification effectDewatering/demulsification with chemical meansEther preparation by compound dehydrationBiodieselGlycerol

The invention relates to a preparation method and an application of a polyether type thick oil demulsifying agent. The method comprises the steps of polyglycerol synthesis, polyether synthesis and polyether type thick oil demulsifying agent preparation. The thick oil demulsifying agent adopts polyglycerol with different polymerization degrees as initiators, alkali metal hydroxide is used as catalysts, epoxypropane polymerization is initiated, polyether macromolecular compounds are obtained, then, the polyether macromolecular compounds take reaction with polyisocyanate in aromatic solvents, and the final demulsifying agent product is obtained. The detail method steps are shown as the specification. The preparation method and the application have the advantages that by-product glycerol generated in the biodiesel production process is used as raw materials, ethylene oxide used as synthesis raw materials of the polyether type demulsifying agent is replaced, the raw material cost is low, the production risk is low, the thick oil demulsifying effect is good, and the preparation method is particularly suitable for thick oil dehydration at lower temperature, and the utilization rate of the glycerol can be greatly improved, so the development of the biodiesel industry is promoted.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com