Preparation method and application of polyether type thick oil demulsifying agent

A polyether-type, demulsifier technology is applied in the preparation of ether, dehydration/demulsification by chemical methods, dehydration of hydroxyl-containing compounds to prepare ether, etc. It can solve the problems of high production cost, carcinogenicity, flammable and explosive raw materials, etc. Achieve good economic benefits and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

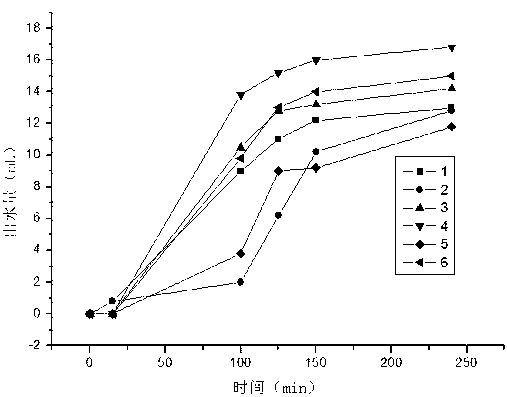

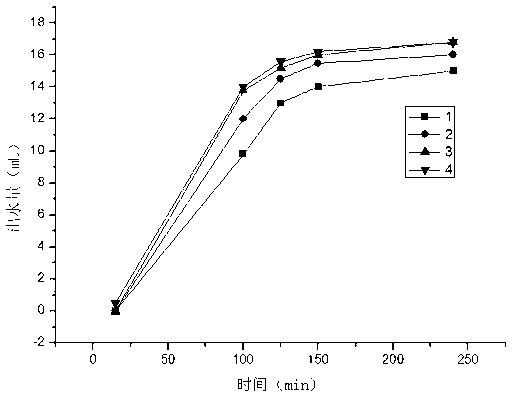

Examples

Embodiment 1

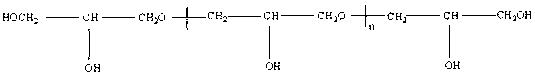

[0047] (1) Synthesis of polyglycerol

[0048] In a four-necked flask equipped with a water separator, a thermometer, and a stirrer, add 150 g of glycerin and 4.5 g of powdered sodium hydroxide, and raise the temperature to 250 ° C by passing nitrogen gas. Glycerol, the degree of polymerization is 2-12. After the reaction, vacuumize 133.3KPa at 250°C for 0.5h, cool down to 90°C, add acetic acid to neutralize the catalyst, make the pH of the polyglycerol product 7, separate and purify, Prepare polyglycerol for use;

[0049] (2) Synthesis of polyether and preparation of polyether heavy oil demulsifier

[0050] Add 50g of tetrapolyglycerol as the raw material and 2.5g of catalyst potassium hydroxide into the autoclave; replace the air in the reactor with nitrogen, turn on the stirrer, keep the speed at 150 rpm, and heat the reactor to 100°C; after the temperature is constant, start dripping Add propylene oxide, the mass ratio of polyglycerol to propylene oxide is 1:2; the catalyst...

Embodiment 2

[0051] Example 2 Synthesis of polyether and preparation of polyether type heavy oil demulsifier

[0052] Add 50 g of decaglycerol as starter and 1.5 g of potassium hydroxide catalyst into the autoclave; replace the air in the reactor with nitrogen, turn on the stirrer, keep the speed at 150 rpm, and heat the reactor to 100°C; after the temperature is constant, Start to add propylene oxide dropwise, the molar ratio of polyglycerol to propylene oxide is 1:3; the catalyst accounts for 3% by weight of the starting material, and the reactor pressure is kept at Between 0.2-0.4MPa, the reaction temperature is between 110-140°C. A total of 100 g of propylene oxide was added, and after the pressure of the reactor dropped, the reaction was continued at this temperature for 60 minutes to complete the reaction, and the residual monomer was absorbed by decompression. After cooling down, open the kettle and take out the product. Add 100 g of the obtained polyether and 150 g of toluene int...

Embodiment 3

[0053] Example 3 Synthesis of polyether and preparation of polyether type viscous oil demulsifier

[0054] Add 50 g of decaglycerin as raw material and 1.5 g of catalyst potassium hydroxide into the autoclave; replace the air in the reactor with nitrogen, turn on the stirrer, keep the speed at 150 rpm, and heat the reactor to 100°C; after the temperature is constant, start dripping Add propylene oxide, the molar ratio of polyglycerol to propylene oxide is 1:3; the catalyst accounts for 3% by weight of the starting material, and the pressure of the reactor is kept at 0.2- Between 0.4MPa and the reaction temperature between 110-140°C. A total of 150 g of propylene oxide was added, and after the pressure of the reactor dropped, the reaction was continued at this temperature for 60 minutes to complete the reaction, and the residual monomer was absorbed by decompression. After cooling down, open the kettle and take out the product. Add 100 g of the obtained polyether and 150 g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com