Patents

Literature

370results about How to "Reduce production risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

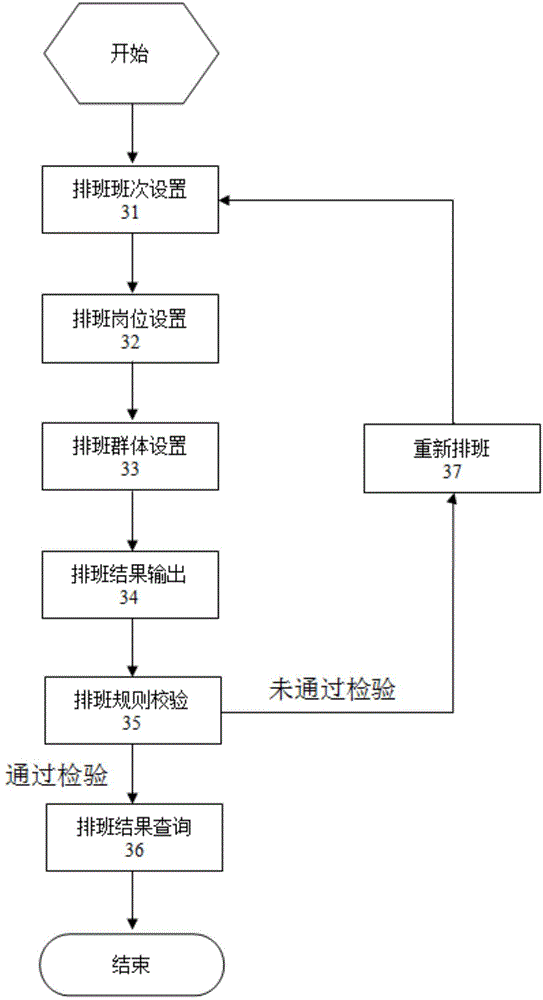

Operation workshop scheduling modeling method based on genetic algorithm

InactiveCN103870647AOptimizing and Harmonizing OperationsImprove Design PerformanceGenetic modelsSpecial data processing applicationsAlgorithms performanceTrace diagram

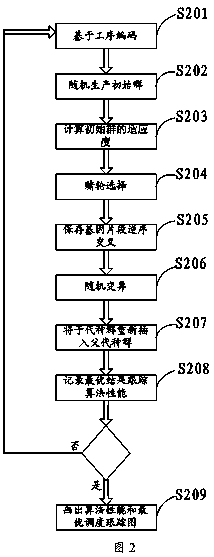

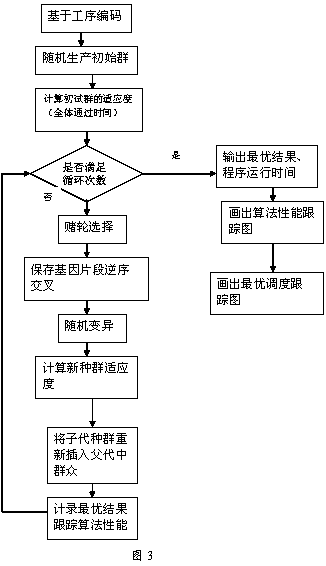

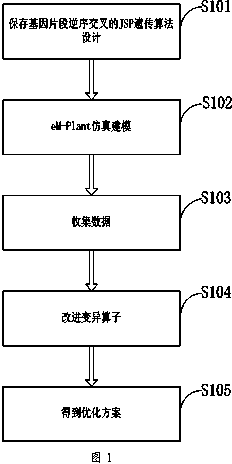

The invention discloses an operation workshop scheduling modeling method based on a genetic algorithm. The method comprises the steps of JSP genetic algorithm design of reverse cross of a stored gene segment, eM-Plant simulation modeling, data collection, improvement of mutation operator and obtaining of an optimized scheme; the JSP genetic algorithm design of the reverse cross of the stored gene segment comprises the steps of randomly generating an initial group according to a sequence code, calculating the fitness of the initial group, judging whether the cycling times is satisfied, outputting an optimal result and program running time if the cycling times is satisfied, drawing an algorithm performance trace diagram, drawing an optimal scheduling trace diagram, selecting through a roulette wheel if the cycling times cannot be satisfied, reversely crossing the stored gene segment, randomly mutating the gene segment, calculating the fitness of a novel population, re-inserting a filial-generation population to the parental population, and recording the performance of the optimal result trace algorithm. By adopting the method, the running of the production workshop can be optimized and coordinated, the design effect is good, the process is simple, and the production danger and production cost can be reduced.

Owner:XIAN TECH UNIV

Urethane acrylate waterborne UV coating and preparation method thereof

ActiveCN101629050ALow VOC contentPrevent extractionPolyurea/polyurethane coatingsPolyether coatingsSocial benefitsEmulsion

Owner:GUANGDONG HUARUN PAINT CO LTD

Method for preparing silicon dioxide aerogel by normal pressure drying method using rice hull ash as raw material

A method for dry producing the silica dioxide aerogel from rice husk ash as raw material in atmosphere pressure, belongs to the technical field of chemical industry materials producing, which comprises the following steps: leaching the rice husk ash formed by rice husk burning in the inorganic strongly basic aqueous solution and inorganic corrosive acid neutralizing basic solution to get the silica dioxide hydrosol, treating the hydrosol with organo-silicon compound to get the hydrogel, then ageing, water scrubbing, replacing the moisture in hydrogel with a organic solvent, and drying in atmosphere pressure to get the silica dioxide aerogel with the specific surface area about 400-800 m.

Owner:TSINGHUA UNIV

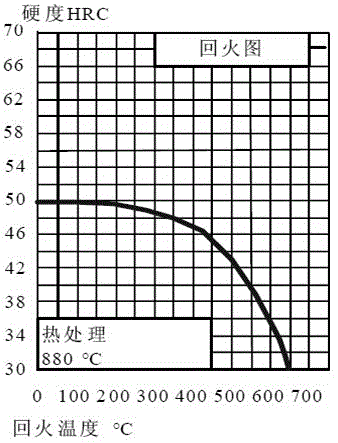

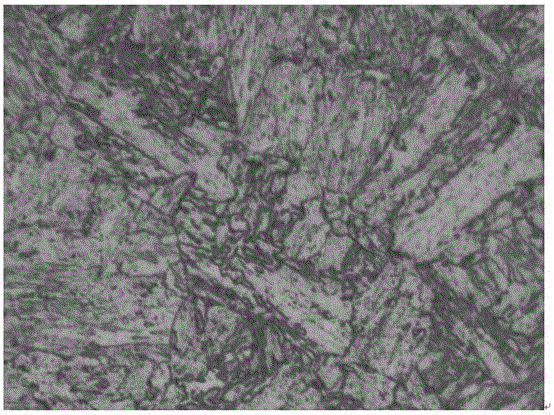

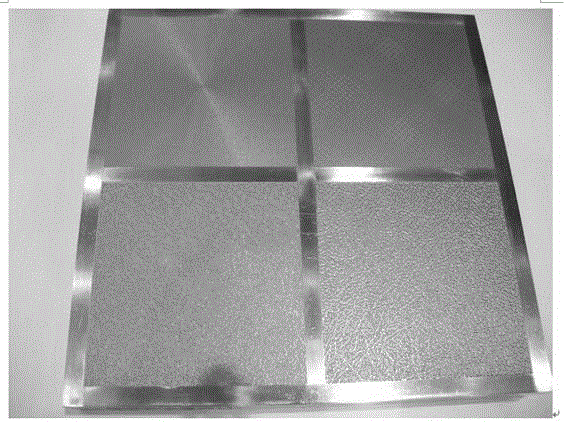

Boron microalloyed die steel and preparation process thereof

The invention relates to boron microalloyed die steel and a preparation process thereof and belongs to the technical field of alloy steel preparation processes. The main alloy elements in alloy chemical components of the die steel comprise, by mass, 0-0.20% of C, 0-0.20% of Si, 1.20-1.60 of Mn, 1.10-1.50% of Cr, 0-0.30% of Ni, 0.20-0.35% of Mo, 0-0.10% of V, less than 0.015% of P, less than 0.005% of S, 0.005-0.01% of B, and the balance Fe. The preparation process of the steel includes the following steps of conducting burdening, smelting, casting and hot delivery; conducting high temperature diffusion heat treatment, multi-directional forging hot working and post-forging hydrogen diffusion tempering treatment; and finally conducting quenching-and-tempering heat treatment so as to obtain a tempered martensite structure with the hardness being 32-38 HRC. The boron microalloyed die steel and the preparation process thereof have the advantages that the prepared die steel has low cost, high hardenability, high hardness, high polishing performance and high skin grain etching performance.

Owner:RUGAO HONGMAO HEAVY FORGING

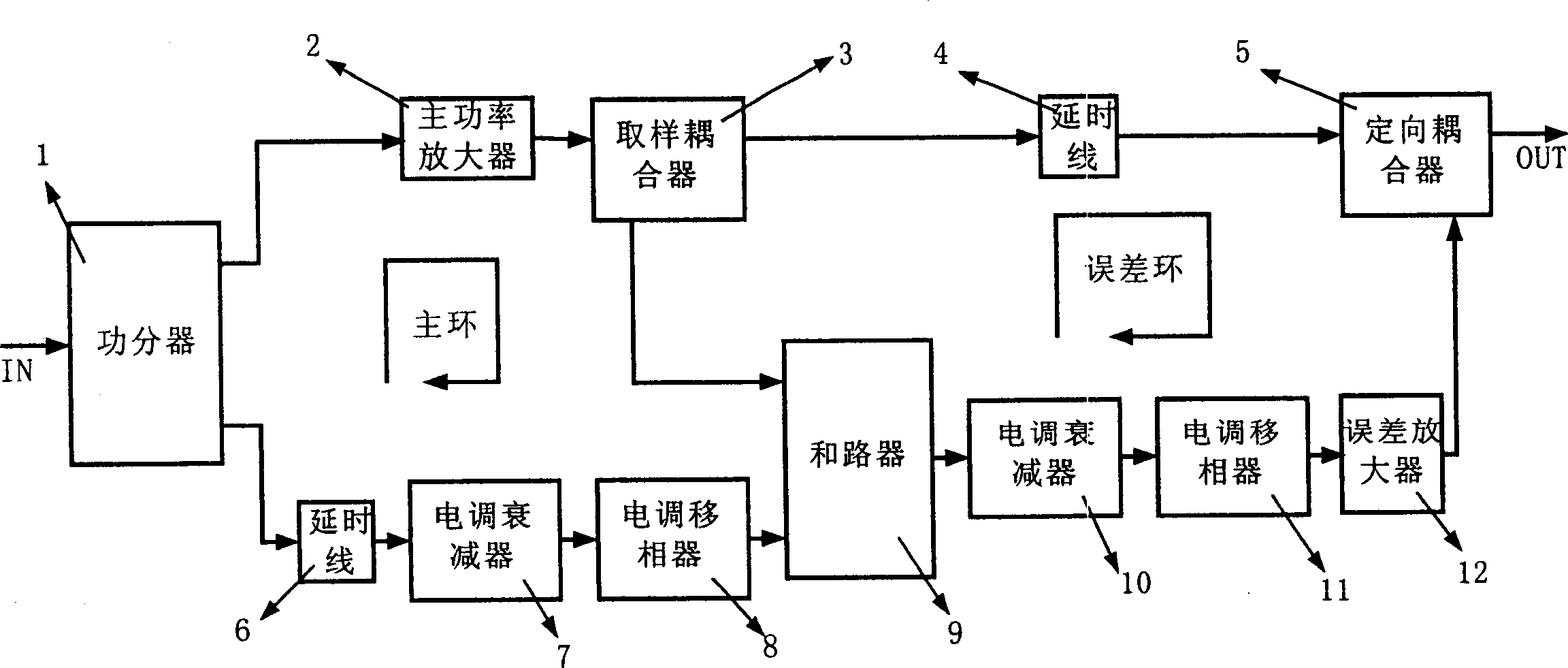

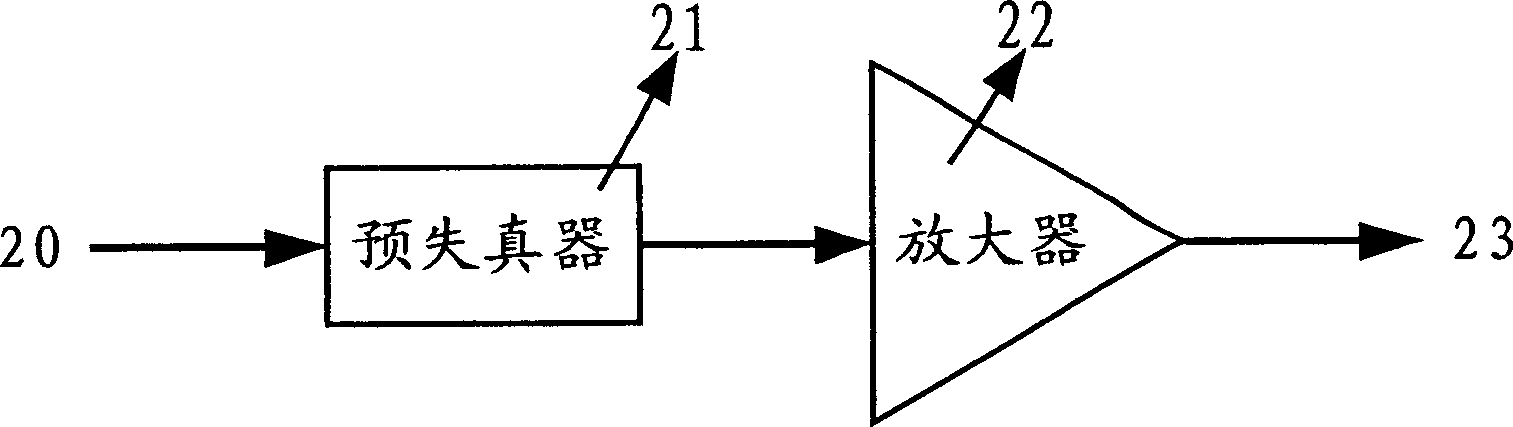

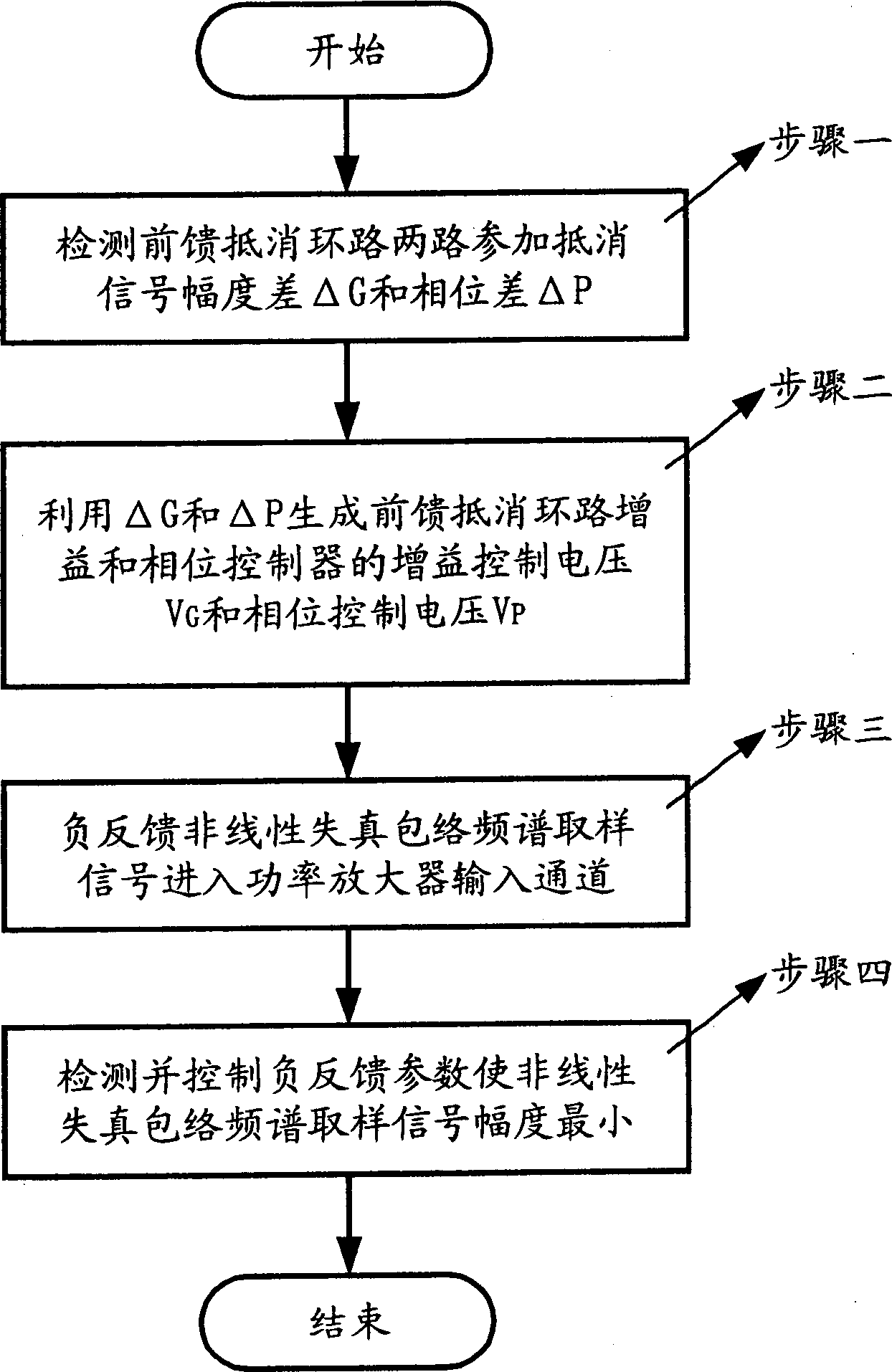

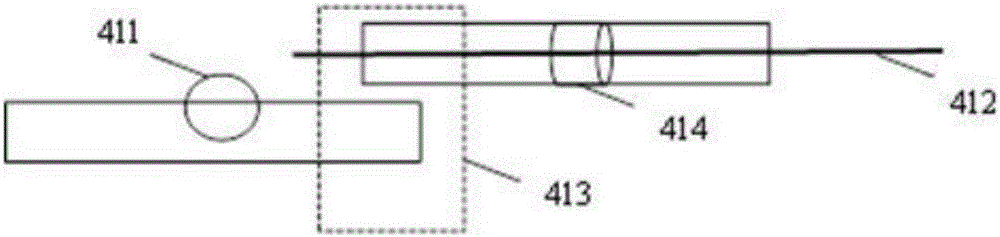

Power amplifier linearization method and linear power amplifier device

InactiveCN1516493AAchieve the effect of linear power amplificationGood effectTransmission control/equalisingAmplifier modifications to reduce detrimental impedenceNonlinear distortionFrequency spectrum

The invention relates to a kind of linearization method of power amplifier in signal process field, the invention acquires the enveloped spectrum information of nonlinear distorted signal of power amplifier from front feedback signal counteraction loop, and feedbacks then to the input channel of power amplifier through degenerative feedback loop, and superimposes and modulates the enveloped spectrum, with the input signal, and forms the input signal pre-skewness, realizes the linear amplification of power amplifier. The device includes front feedback signal counteraction model, nonlinear skewness enveloped spectrum degenerative feedback model which is the enveloped spectrum information acquired from the front feedback signal counteraction model, and feedbacks it to the input channel of the power amplifier to be modulated into the enveloped spectrum.

Owner:ZTE CORP

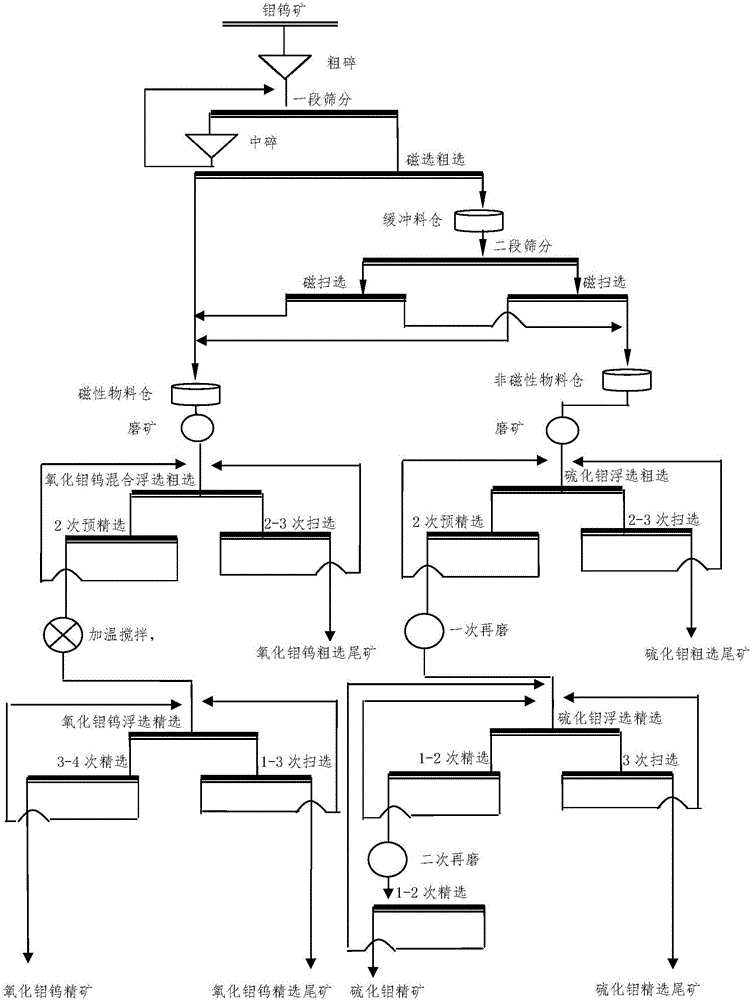

Beneficiation method for separating molybdenum-tungsten oxide ore and molybdenum sulfide ore from molybdenum tungsten ore

InactiveCN106076590AEliminate the need for deslimingThe beneficiation process is simpleFlotationMagnetic separationNon magneticMagnetic characteristic

The invention relates to a beneficiation method for separating molybdenum-tungsten oxide ore and molybdenum sulfide ore from molybdenum tungsten ore. The beneficiation method comprises the steps that magnetic separation is conducted on raw separation molybdenum sulfide ore at least twice, so that the raw separation molybdenum sulfide ore subjected to magnetic separation is divided into magnetic ore containing molybdenum-tungsten oxide and non-magnetic ore containing molybdenum sulfide; and a molybdenum-tungsten oxide flotation process is conducted on the magnetic ore, and a molybdenum sulfide flotation process is conducted on the non-magnetic ore, so that molybdenum-tungsten oxide concentrate and molybdenum sulfide concentrate are obtained. According to the beneficiation method for separating the molybdenum-tungsten oxide ore and the molybdenum sulfide ore from the molybdenum tungsten ore, the magnetic ore containing molybdenum-tungsten oxide and the non-magnetic ore containing molybdenum sulfide are separated out before ore grinding by means of the magnetic characteristic of iron-bearing ore in skarn in a magnetic separation and flotation combined way, so that the floatability of the ore is improved, the beneficiation feed grades of the molybdenum sulfide ore and the and molybdenum-tungsten oxide ore subjected to flotation are increased, and a subsequent flotation technological process is simplified; and in addition, grading index fluctuation caused by the change of the characteristics of the ore is reduced, and the mine production cost can be reduced easily.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

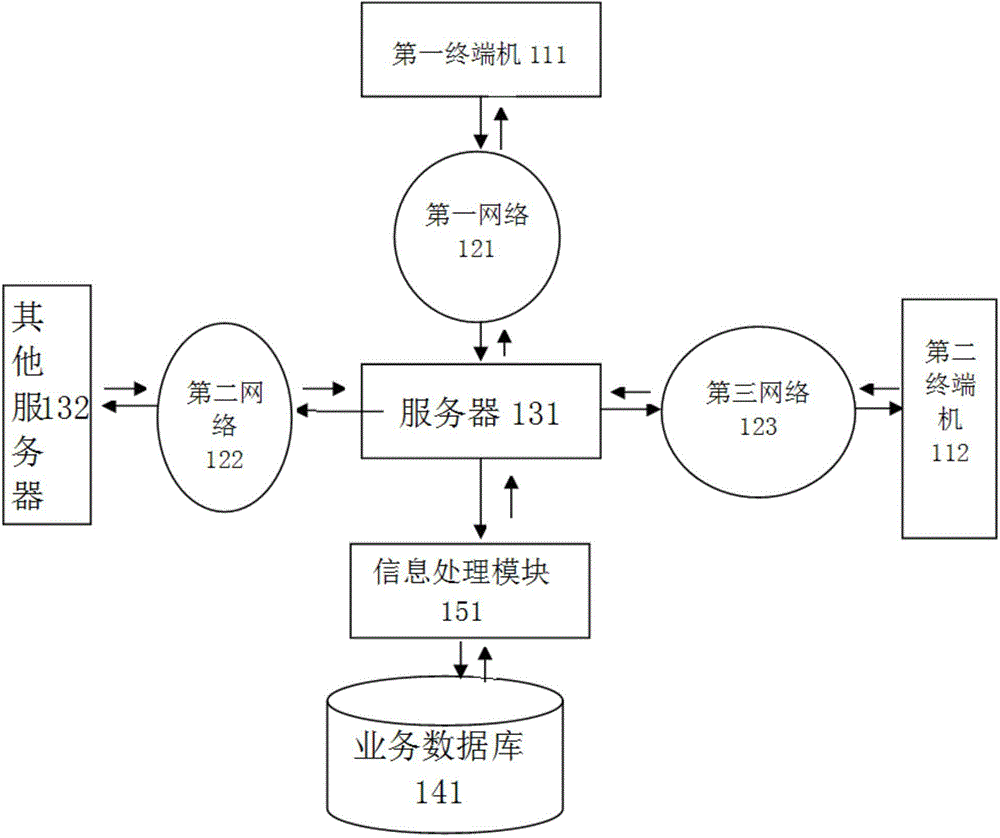

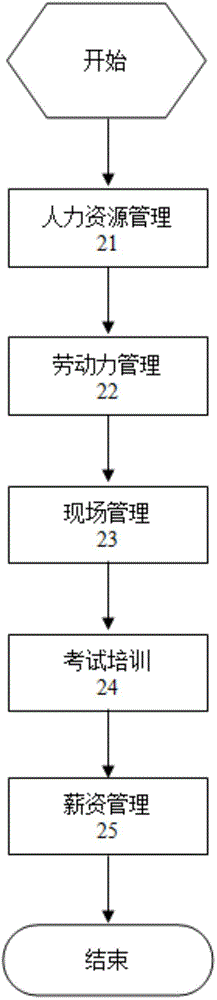

Real-time labor management system and management method

The invention discloses a real-time labor management system comprising a first terminal machine, a second terminal machine, a server, a business database and an information processing module. The first terminal machine is connected to the server through a first communication network for data exchange; the second terminal machine is connected to the server through a third communication network for data exchange; the business database is connected to the server for data exchange; the server is provided with the information processing module inside. The invention further discloses a real-time labor management method. The system has the advantages that the normal operation and management are facilitated, the fault rate is low, and maintenance is facilitated; visualization windows are provided to employer enterprises for monitoring the sites, product risks are reduced, service and management of a human resource management enterprises can be enhanced, the personnel management and site management problems are solved, the labor can be managed effectively in real time, the management cost is reduced, and the labor disputes are reduced.

Owner:GUANGZHOU HONGHAI NETWORK TECH DEV CO LTD

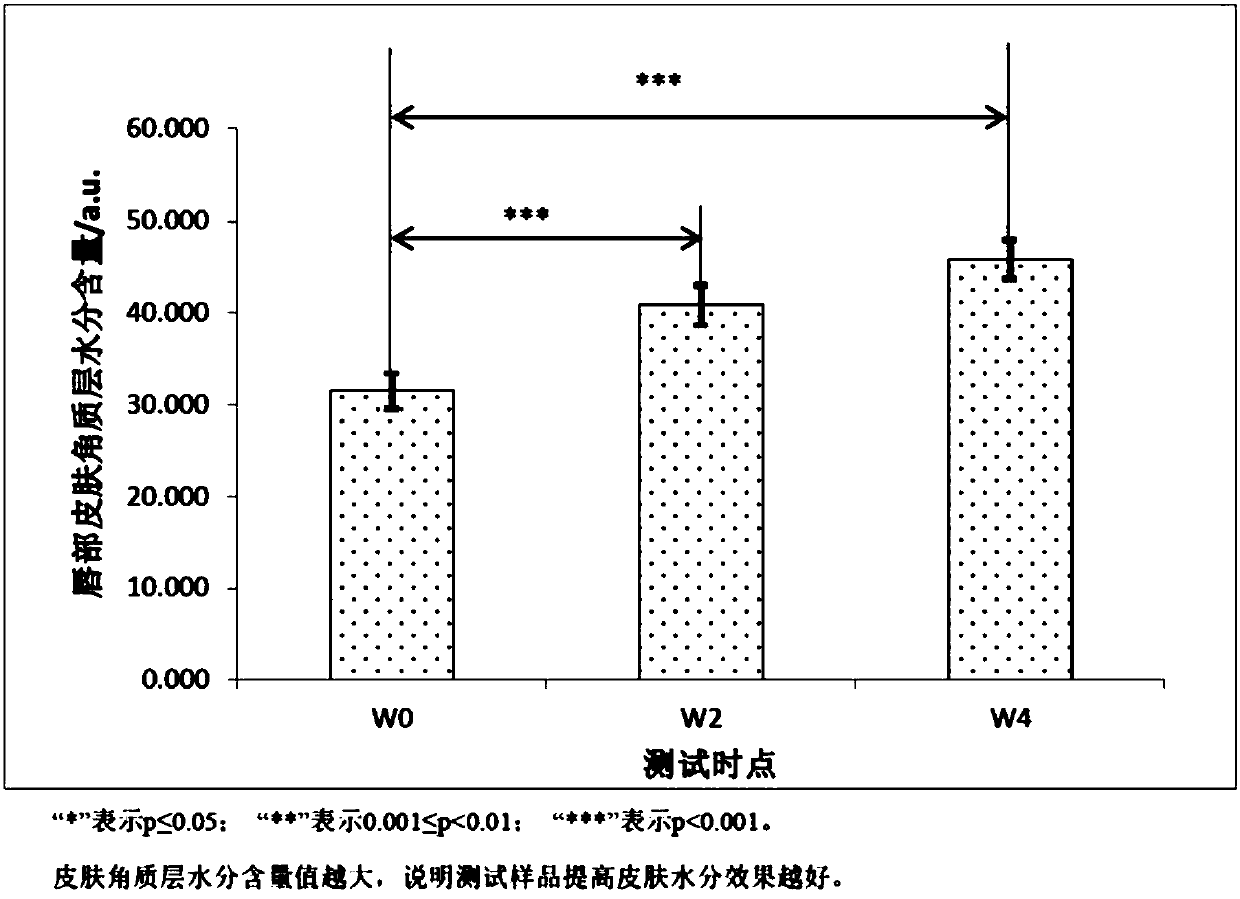

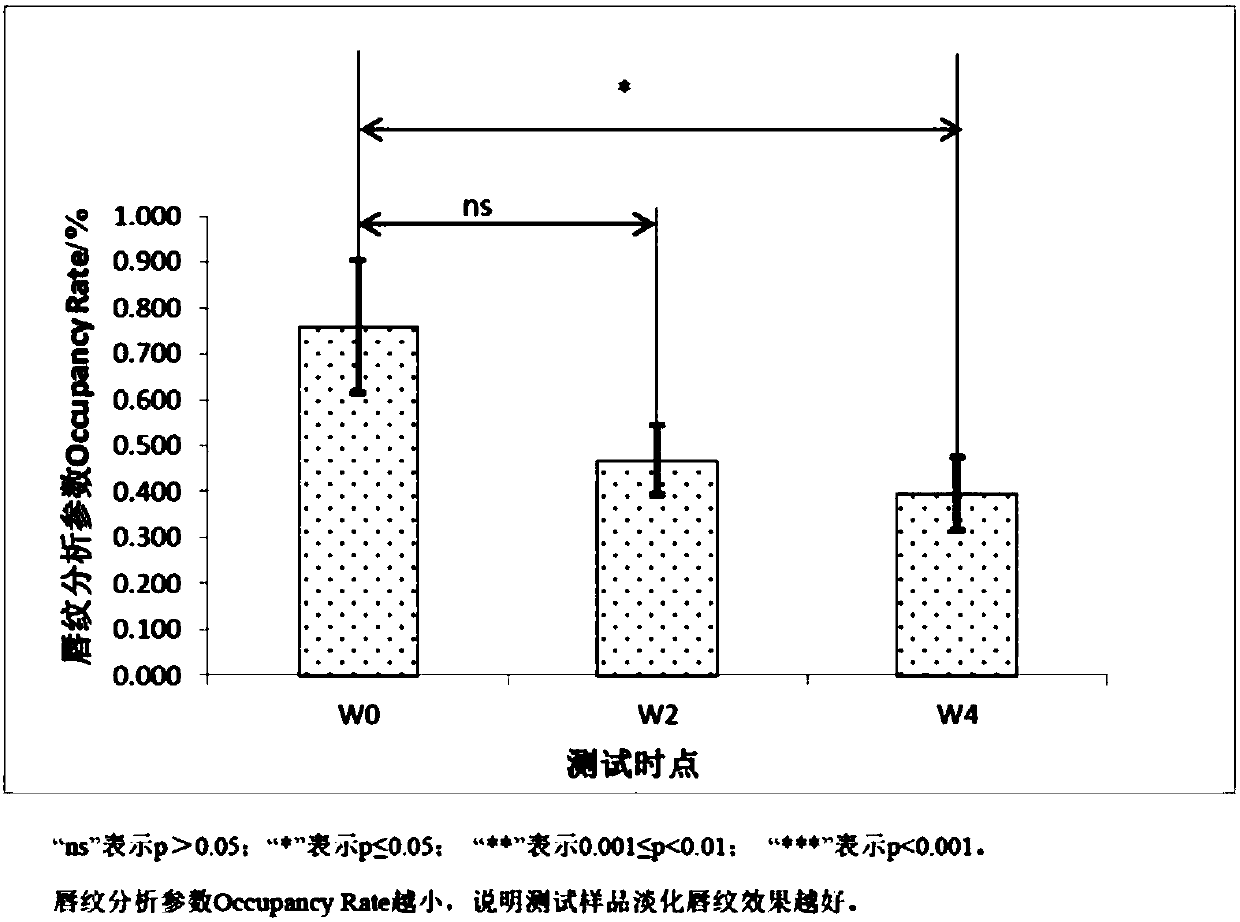

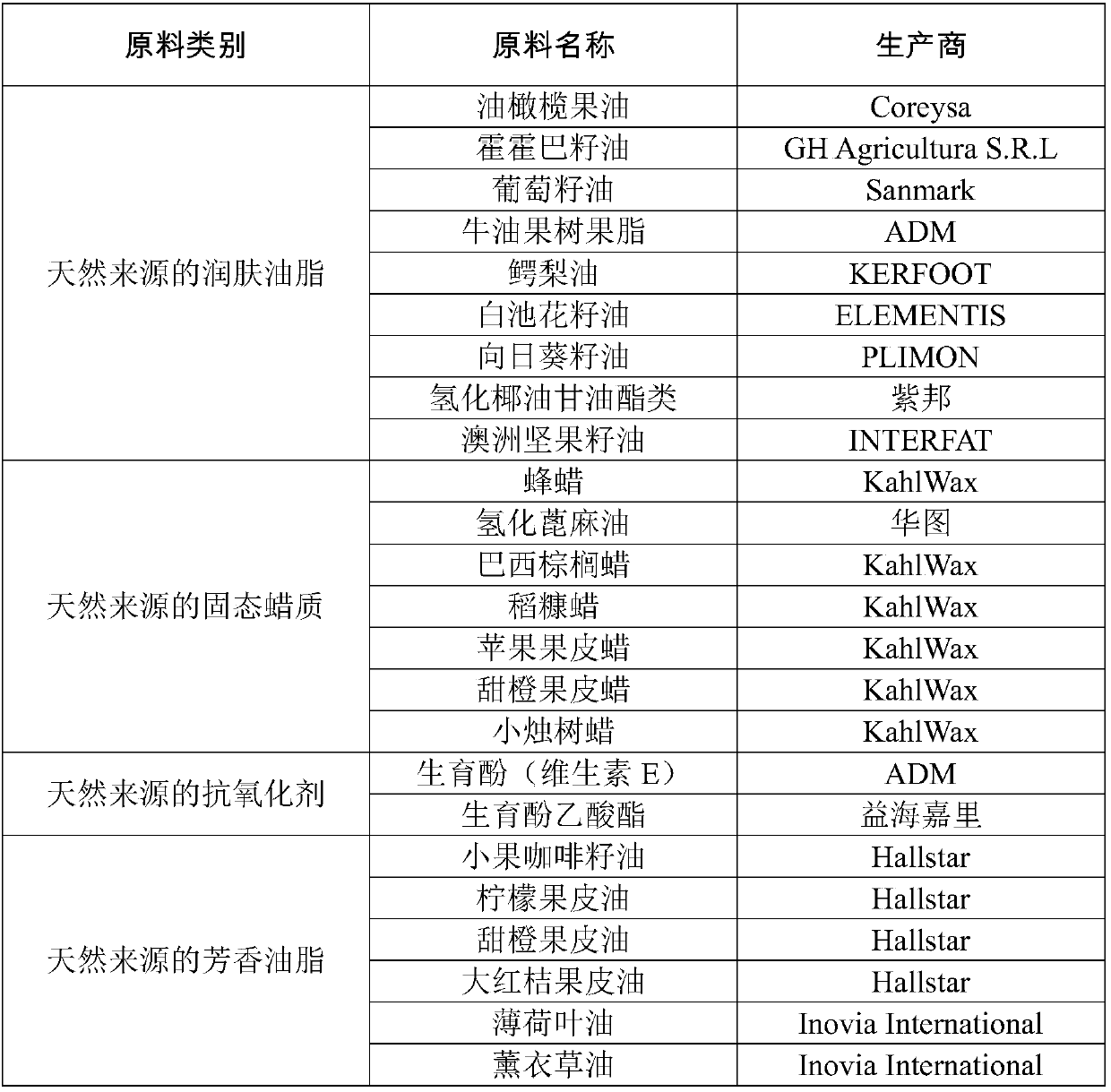

Flavored lip balm of pure natural origin

InactiveCN107661275AWith natural fragranceImprove securityCosmetic preparationsToilet preparationsNatural sourceWax

Owner:NOX BELLCOW COSMETICS CO LTD

Method for preparing amino-terminated polyurethane

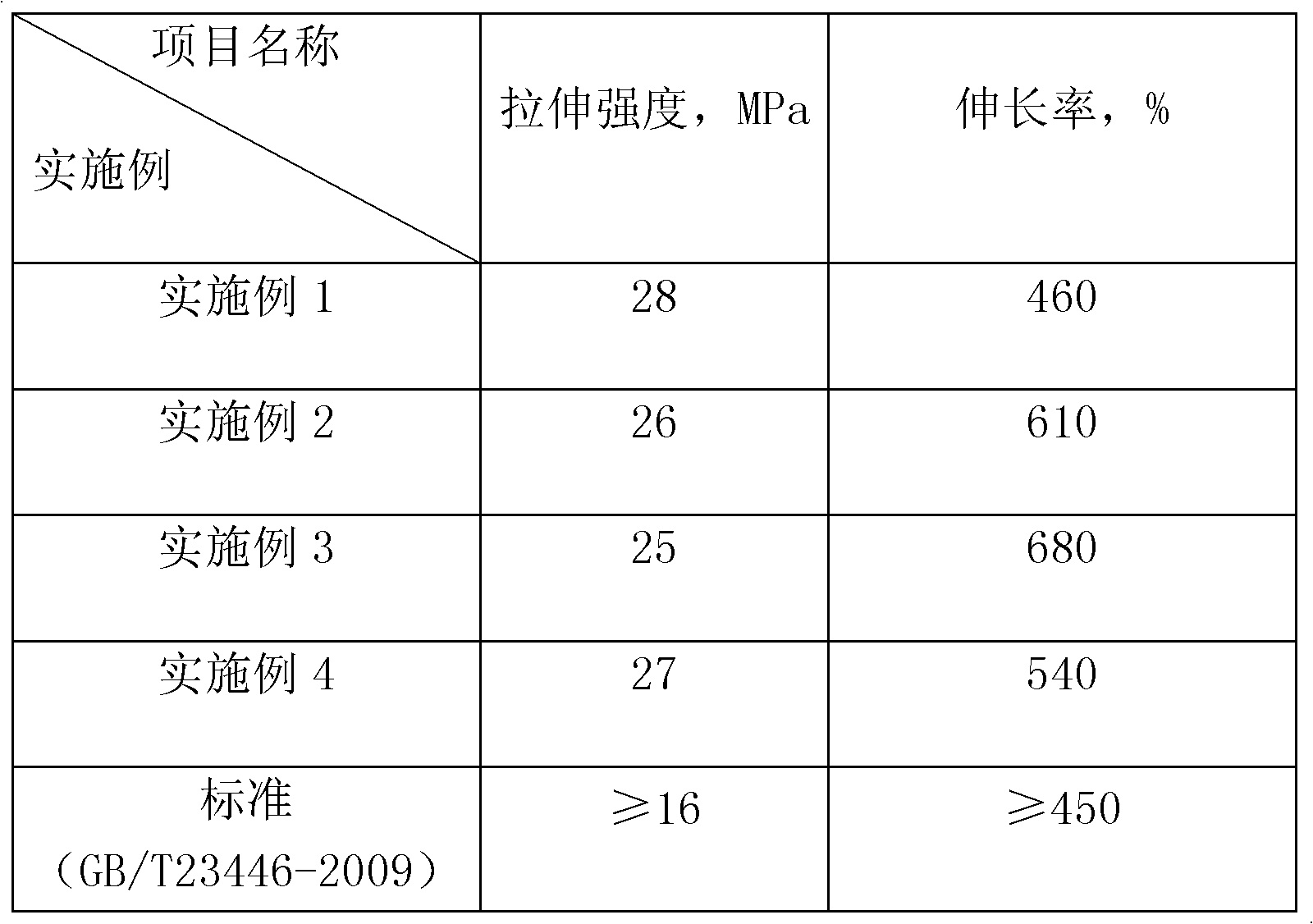

InactiveCN102432804AHigh elongationImprove bending resistancePolyurea/polyurethane coatingsReaction rateProduction risk

The invention relates to the technical field of preparation of active amino-terminated functional compounds, in particular to a method for preparing amino-terminated polyurethane by using a steric hindrance protection method. The method concretely comprises the following steps: respectively selecting isophorone diisocyanate and isophorone diisocyanate which have similar functional groups and different reactive activities as blocking modification raw materials; realizing a reaction rate gradient through steric hindrance protection; and directly functioning amino at two ends of a main structure to prepare the amino-terminated polyurethane. The amino-terminated polyurethane is directly and efficiently prepared through the steric hindrance protection method, thus, the defect that isocyanic acid rapidly reacts with the amino is avoided, the reaction process has a certain speed gradient, the generation of a crosslinking structure is inhibited, the production risk and the production energy consumption are remarkably reduced, and the product performance and the production efficiency are increased.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

Automatic drug mixer

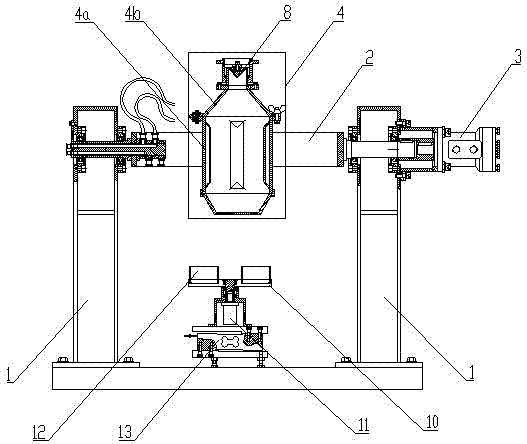

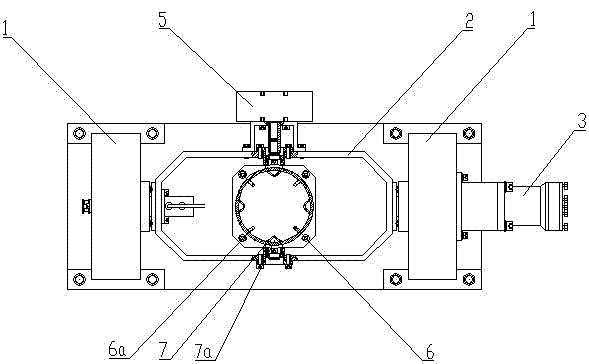

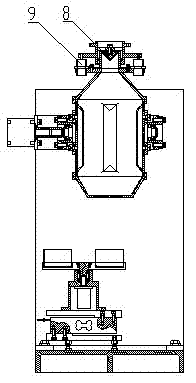

ActiveCN102350253AAchieve compound movementRealize quantitative outputRotating receptacle mixersTransportation and packagingInsertion stentEngineering

The invention discloses an automatic drug mixer, comprising two parallel supports, a jib arranged on the supports in rotating cooperation as a corss arm, a spin motor to drive the jib to rotate, a drug mixing pan arranged on the jib and a material receiving apparatus under the drug mixing pan. The drug mixing pan is rotatably cooperated with the jib in a way that the drug mixing pan conducts reciprocating swings towards two ends of the jib, and a swing motor is rotatably cooperated with the drug mixing pan. The spin motor can drive the drug mixing pan to tumble around a jib rotating shaft, meanwhile the swing motor can drive the drug mixing pan to swing around a vertical line of the jib rotating shaft to realize compound movement of the drug mixing pan. The automatic drug mixer can substitute manual drug mixing to realize automation, enhance drug mixing effect and efficiency effectively and improve production environment. rotating speeds of the two motors can be adjusted to realize different movement tracks of the drug mixing pan to facilitate exploration of an optimum drug mixing time and movement track. In addition, the invention can realize automatic quantification material distribution and raise production efficiency effectively.

Owner:CHONGQING HUAAO PHARMA IND CO LTD

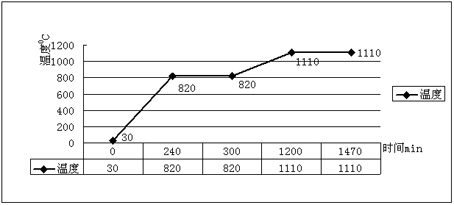

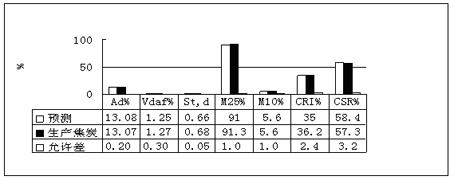

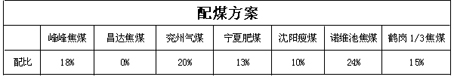

Method for predicting quality of industrially produced coke by using 40kg test coke oven

ActiveCN101957359AReduce production riskRealize production benefitsCoke ovensFuel testingEngineeringProduction risk

The invention relates to a method for predicting quality of industrially produced coke by using a 40kg test coke oven and belongs to the technical field of metallurgical test. The technical scheme comprises the following steps of: firstly, taking test coal according to the ratio of industrial production, mixing, crushing and producing coke in the 40kg test coke oven; secondly, making an industrial analysis sample and a terminal performance sample to obtain corresponding technical indexes; and finally, predicting the quality of the industrially produced coke according to the technical index test result of the test coke. The method has the advantages that the 40kg small coke oven test coke is used for predicting the industrially mass produced coke. Through the small coke oven test, an optimal coal blending scheme can be found according to the conditions of coal source, the coke with high quality can be produced, the production risks can be reduced and the production benefit can be maximized.

Owner:唐山建龙简舟钢铁有限公司

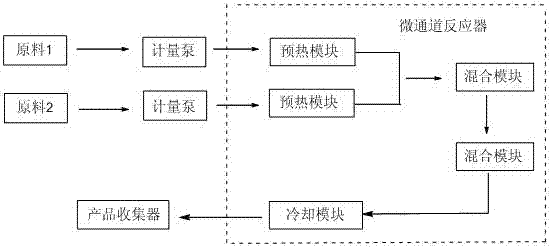

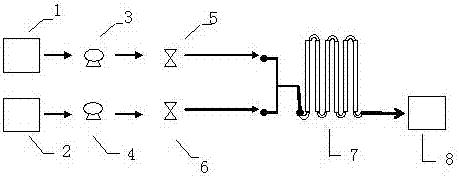

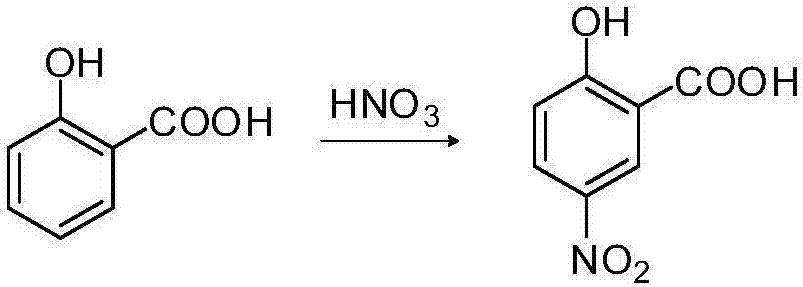

5-nitrosalicylic acid preparation process adopting microchannel continuous flow reactor

InactiveCN107353208AReduce generationSimple preparation processChemical industryChemical/physical/physico-chemical microreactorsIce waterRetention time

The invention relates to a novel 5-nitrosalicylic acid preparation process adopting a microchannel continuous flow reactor and belongs to the technical field of organic synthesis. According to the process, salicylic acid is taken as a raw material, concentrated nitric acid or a mixture of concentrated nitric acid and glacial acetic acid is taken as a nitrification reagent, the raw material and the nitrification reagent are injected into a reaction module of the microchannel reactor by a metering pump respectively, a material discharged from the reactor is directly injected into ice water, solids are separated out, and 5-nitrosalicylic acid is obtained through water washing. Continuous, efficient, safe and energy-saving industrial production is realized with the microchannel continuous flow process, the preparation process is simple, conditions are mild, retention time is short, product quality is stable, consumed acid content is reduced, yield is high and reaches 75% or higher, and industrial popularization and application are greatly facilitated.

Owner:PUYANG VOCATIONAL & TECHN COLLEGE

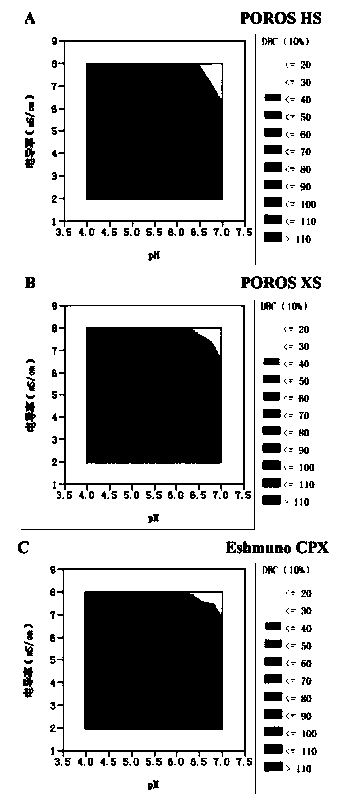

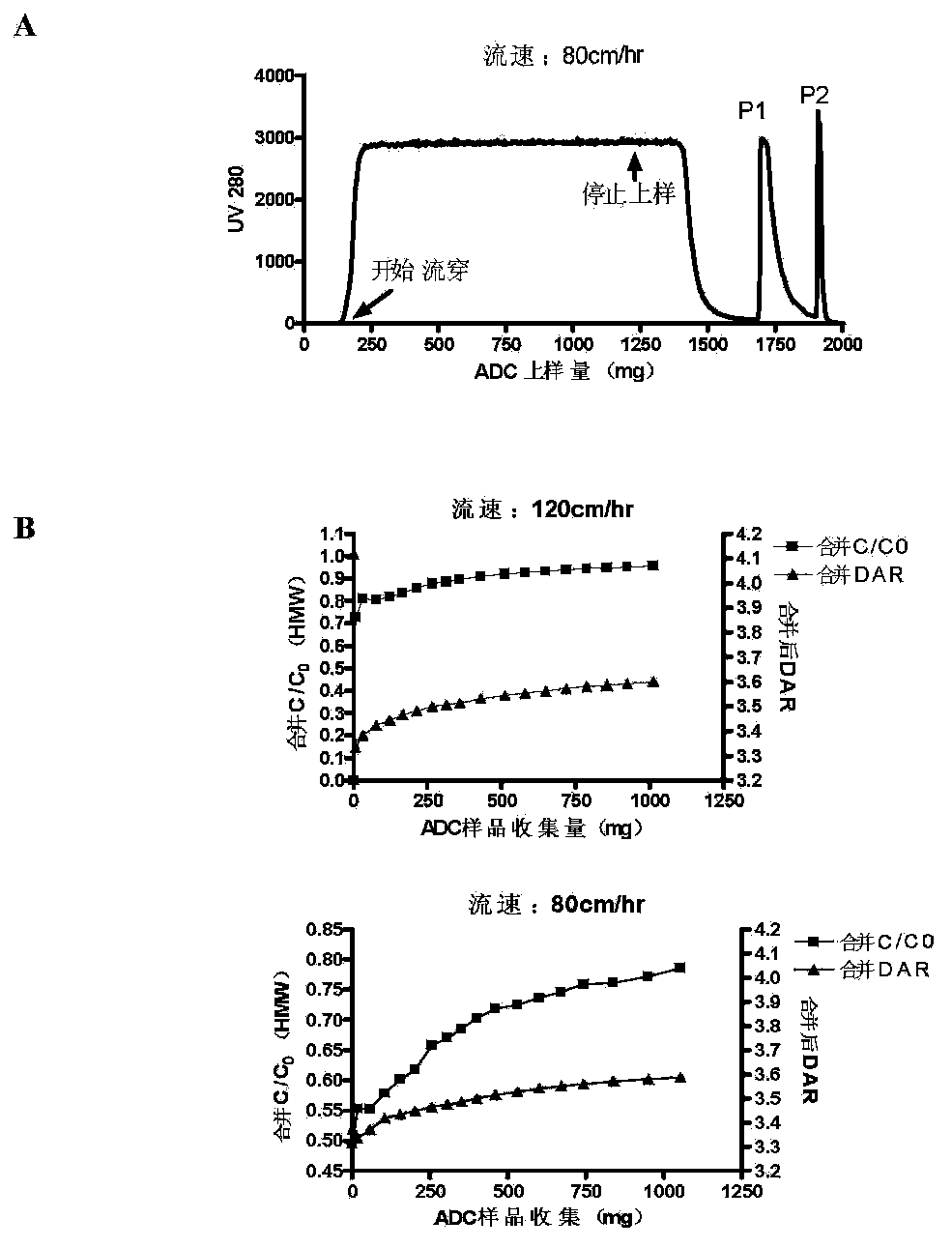

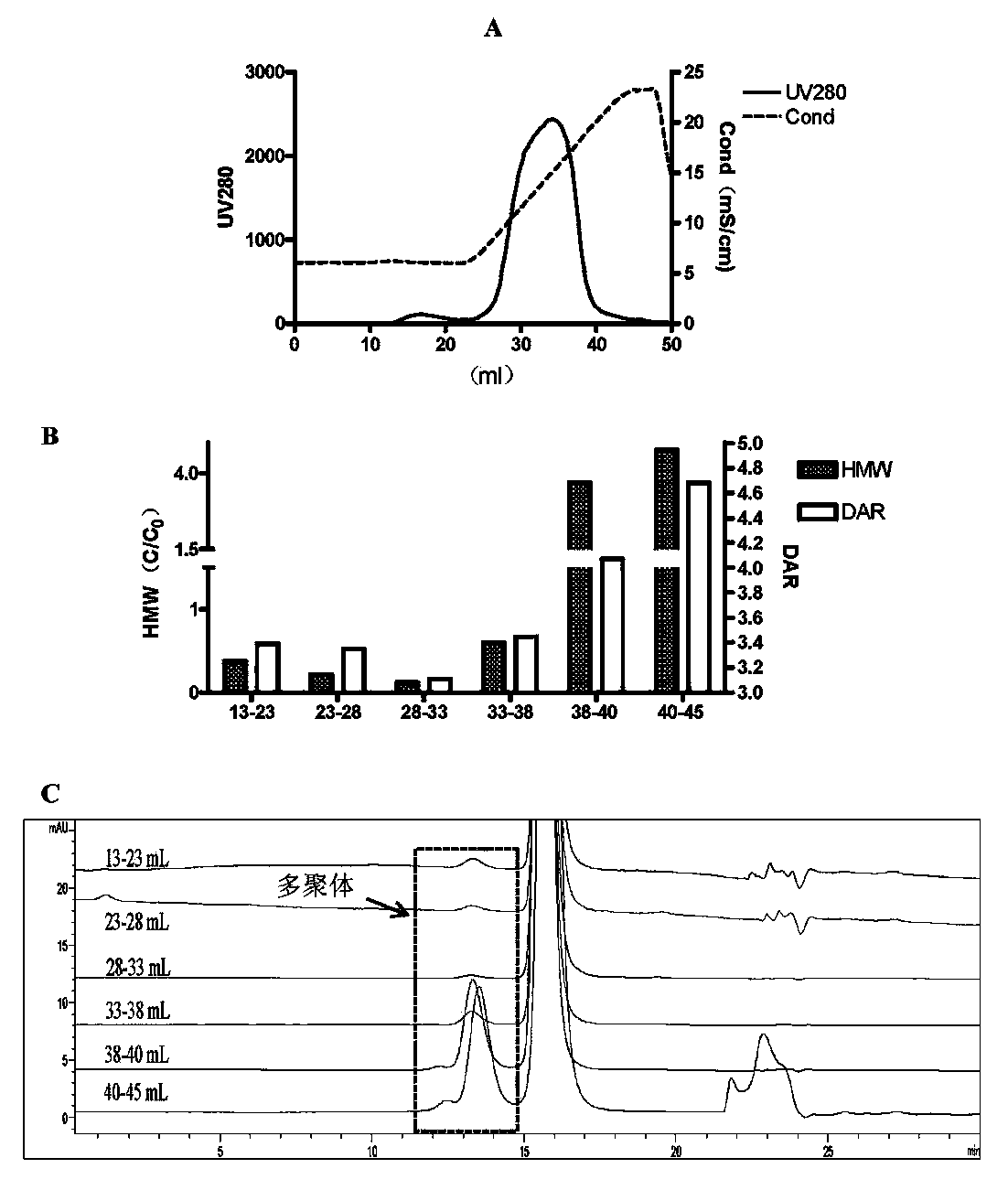

ADC (antibody-drug conjugate) cation exchange chromatographic purification method

ActiveCN104208719AExpand the scope of applicationSimple and efficient operationCation exchanger materialsOrganic anion exchangersAntiendomysial antibodiesCationic exchange

The invention provides an ADC cation exchange chromatographic purification method. The ADC cation exchange chromatographic purification method can be used for performing purification in a combined elution mode or an overload mode, control the DAR (drug antibody ratio) of ADC drugs within a target technology range and meanwhile achieve the effects of eliminating polymers. The ADC cation exchange chromatographic purification method is a novel ADC preparation and purification technique, reduces the production cost and risk, meanwhile, achieves control to the mole DAR of micromolecules / antibodies and polymers of the ADC drugs, is beneficial to development of ADC production processes with higher controllability, lower cost and lower risks, obtains products with higher quality and guarantees medication safety and therapeutic effects.

Owner:BEIJING MABWORKS BIOTECH +1

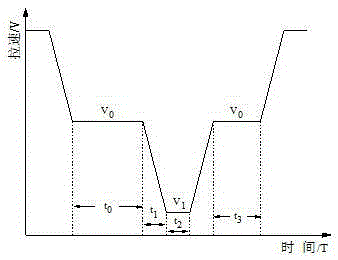

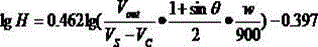

Control method for continuous casting of different steel grade

The invention relates to a control method for continuous casting of the different steel grade. The method comprises the following steps: firstly, according to the shape and structural parameters of a tundish flow control device, the mixed casting tonnage M is determined, and the value is the molten steel amount correspondingly when the height of the liquid level of the molten steel in a tundish is the height of a retaining dam; according to following formulas, the remaining steel amount of the previous steel grade is determined as Mo (shown in the specification), and when casting of a molten steel large ladle of a previous furnace is finished, speed begins to be slowly reduced; the mixed casting initial tonnage of the tundish is M1, the pull speed is reduced to the lowest pull speed V0 during normal production of the steel grade, and the retaining time is t0; thirdly, according to the casting cross section, the large ladle cast-on tonnage is selected, when the remaining weight of the tundish is M2, the pull speed is reduced to V1 from V0, and large ladle cast-on operation is carried out; fourthly, after large ladle cast-on operation, the amount of molten steel of the tundish is kept M, the pull speed is kept V1, after t2, the pull speed rises to V0, the reference formula of t2 is shown in the specification, the pull speed rises to V0, meanwhile, the molten steel amount of the tundish is kept M, after the retaining time t3 is equal to 5 min to 8 min, the opening degree of a sliding plate of the large ladle is gradually increased, the tonnage of the tundish rises to the normal casting tonnage, and the pull speed rises to the normal production target value.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

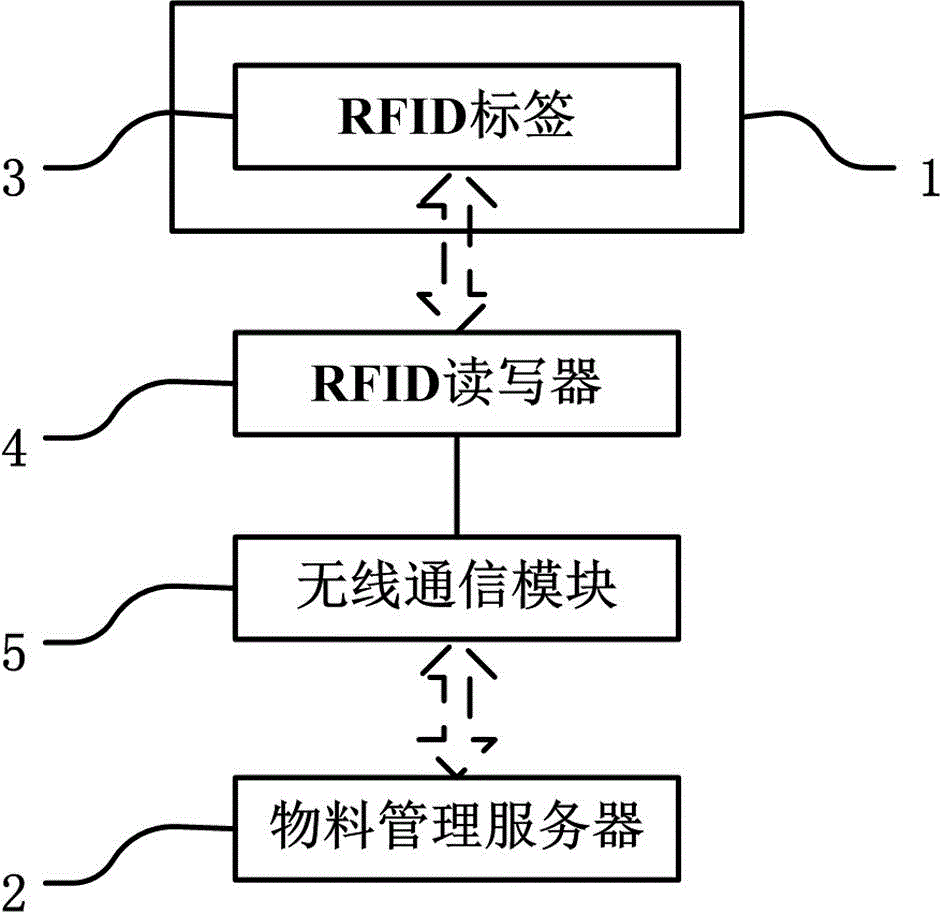

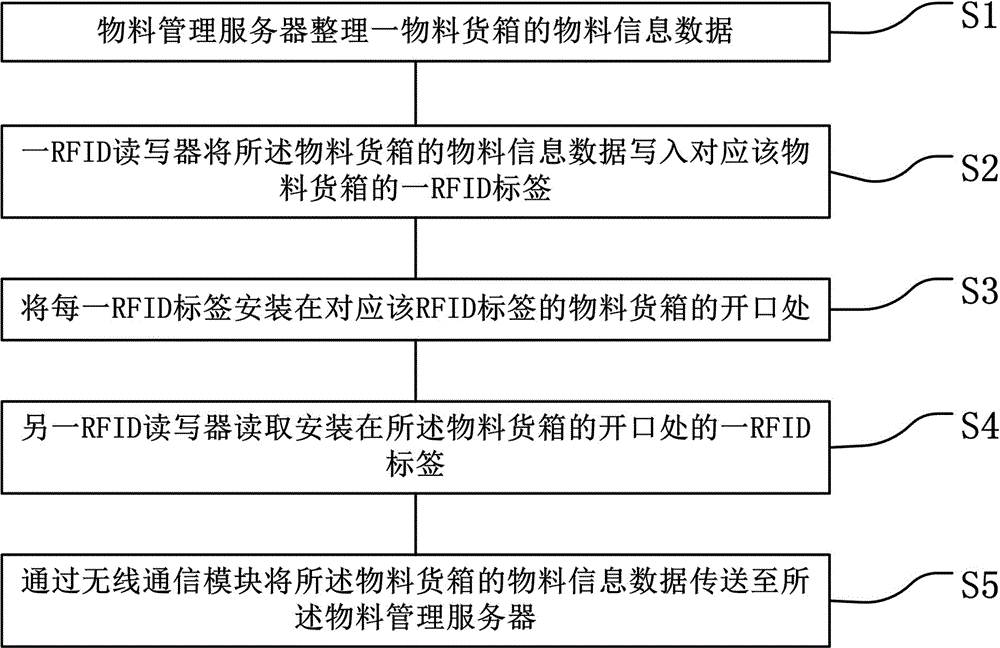

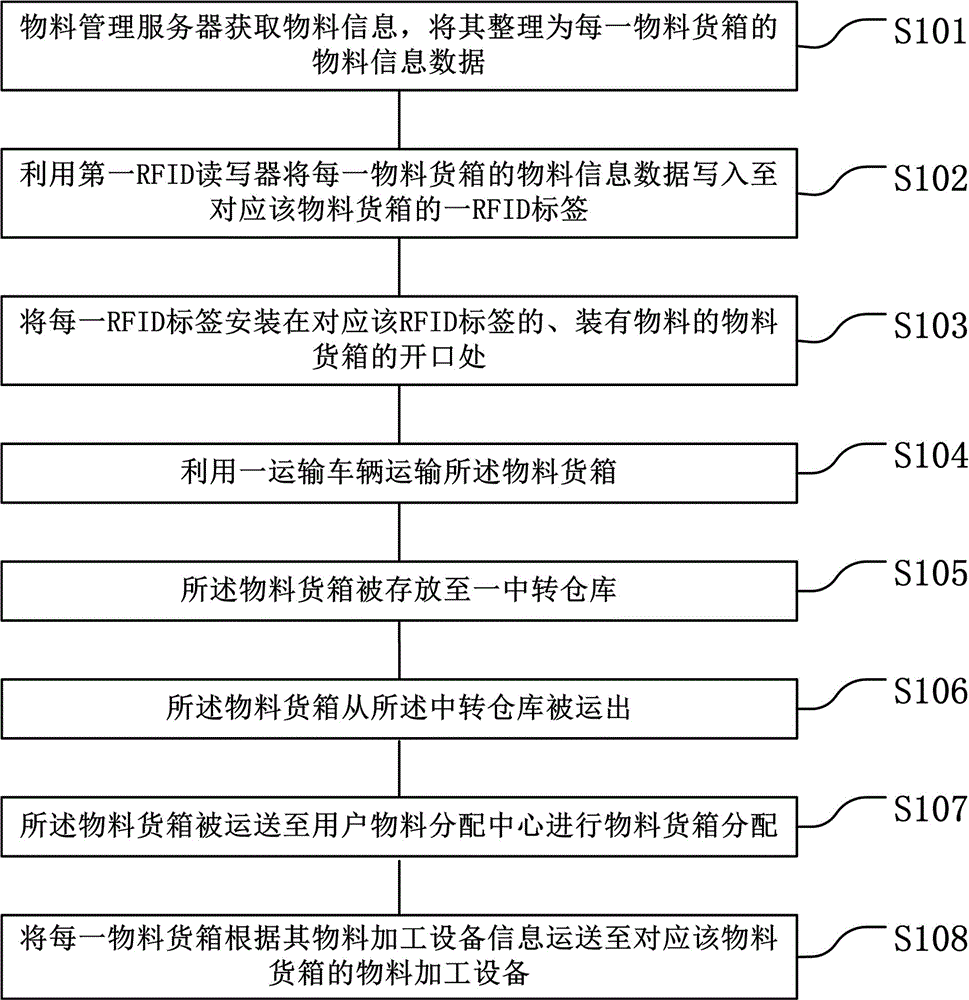

Material delivery method based on RFID

InactiveCN104537514AFast deliveryPrecise deliveryCo-operative working arrangementsLogisticsProduction lineProduction risk

The invention provides a material delivery method based on RFID. The method comprises the following steps: sorting material information data by using a material management server; writing the material information data in an RFID label; mounting the RFID label at an opening of a material container; transporting the material container and reading the material information data; storing the material container in a transit warehouse and reading the material information data; transporting the material container out of the transit warehouse and reading the material information data; reading the material information data by a material allocation center and allocating the material container; transporting the material container to material processing equipment, and the like. The method disclosed by the invention has the advantages that a corresponding relationship between the material and the material processing equipment can be built before the material leaves factory; the delivery, casing, transportation, transit storage and delivery to a production line of the material are monitored and managed during the overall processes, so that the material can be delivered accurately; material loss and damage can be effectively prevented; the delivery reliability is improved; the delivery efficiency is improved; the production risk is reduced.

Owner:EAST CHINA UNIV OF SCI & TECH

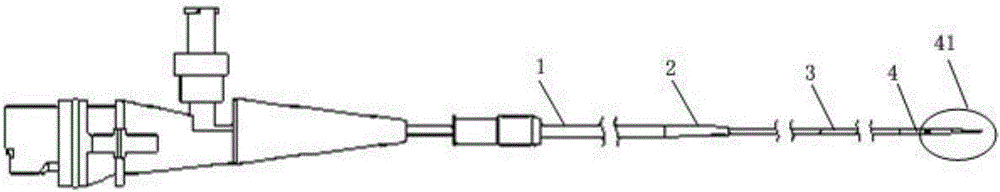

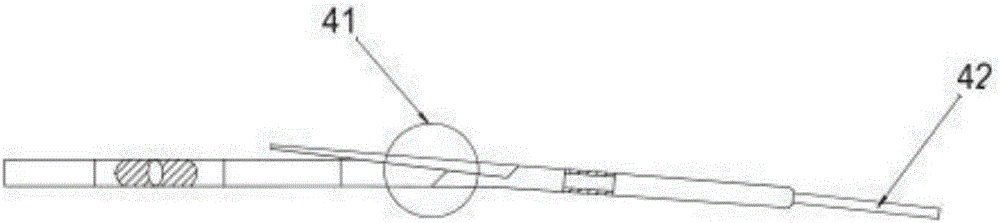

Intravascular ultrasound catheter and rapid forming method thereof

ActiveCN105147336AEasy to produceIncrease productivityOrgan movement/changes detectionSurgerySurgical riskTransducer

The invention discloses an intravascular ultrasound catheter and a rapid forming method thereof. The catheter comprises a sleeve tube which is of a one-time formed structure. A transducer with a rotation driving wire is arranged at the far end of the sleeve tube, and the near end of the sleeve tube is connected with a driving / retreating device. A wire guide opening is formed in the far end of the sleeve tube. The method includes the steps that the sleeve tube is formed through a one-time forming method; the wire guide opening is formed in the far end of the sleeve tube. According to the intravascular ultrasound catheter and the rapid forming method thereof, the one-time forming method is used for forming the sleeve tube, production efficiency is greatly optimized, production cost is lowered, no connecting section exists, the reliability of the catheter is improved, and surgical risks are reduced.

Owner:上海爱声生物医疗科技有限公司 +1

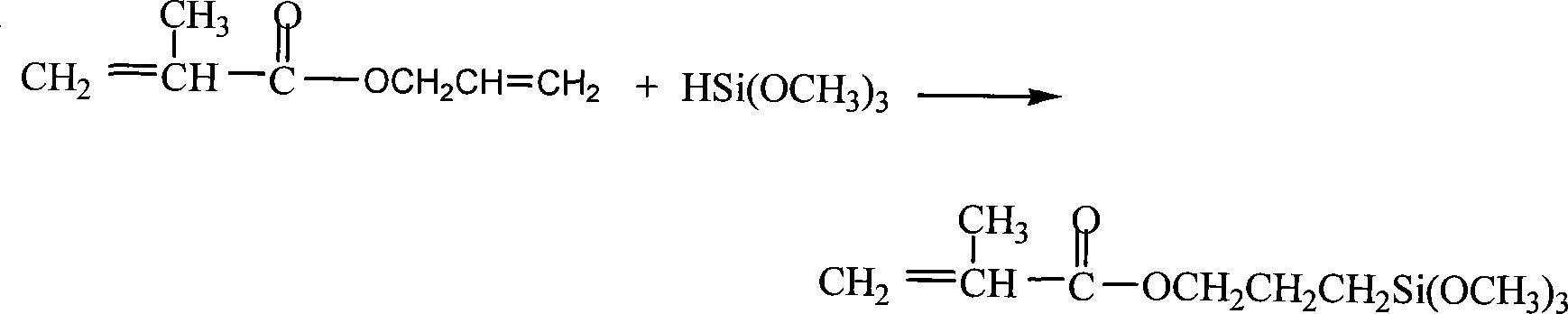

Method for preparing 3-(methacryloxy)propyltrimethoxysilane

ActiveCN101121724AHigh catalytic efficiencyLow costGroup 4/14 element organic compoundsSilanesDissolution

The invention discloses a preparation method of the 3-(methacryloyl oxygen) propyl tri-methoxy silane. The steps are: first the platinum chloride acid, isopropanol and the compound A are used as the raw materials; the platinum chloride acid is added into the isopropyl alcohol; after the dissolution, the compound A is added and then to be heated; secondly, the polymerization-preventing reagent phenothiazine and ZJ-701 are added into the tri-methoxy silane to dissolve the raw material X; thirdly, the polymerization-preventing reagent N, N'-drophenyl-p-phenylenediamine are added in the methacrylate allylic ester to dissolve the raw material Y; fourthly, the polymerization-preventing reagent ZJ-701 and ZJ-101 are added in the reaction materials after the reaction between the raw materials and the catalysts to dissolve to get the 3-(methacryloyl oxygen) propyl tri-methoxy silane. The invention is of the simple preparation, the high efficiency, the little consumption, the strong selectivity, and the high collection rate of the products; the polymerization-preventing effects of the polymerization-preventing technology are good; the polymerization-preventing reagents are not easy to be gelated; the consumption is little; the polymerization-preventing reagents are easily separated from the products; the products are easy to be decolorized, good in quality, and have no harm to the catalyst.

Owner:湖北武大有机硅新材料股份有限公司

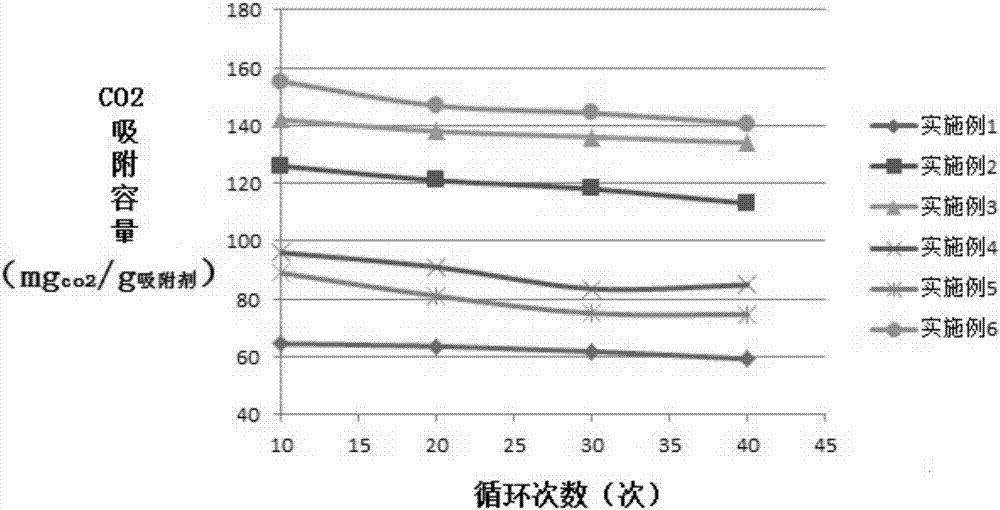

Calcium oxide-based high-temperature CO2 adsorbent and its preparation method

ActiveCN107376826AImprove wear resistanceImprove thermal stabilityGas treatmentOther chemical processesChemistryCo2 adsorption

The invention discloses a calcium oxide-based high-temperature CO2 adsorbent and a preparation method thereof. The adsorbent comprises a carrier M and a main active component CaO loaded on the carrier M. The carrier M is further loaded with a structural stabilizing aid A. The general formula of calcium oxide-based high-temperature CO2 adsorbent is <x>CaO.A.<100-x-a>M, wherein x is the mass percentage of CaO; a is the mass percentage of A; x is no less than 5% and no more than 60%; and a is no less than 0.1% and no more than 50%. The calcium oxide-based high-temperature CO2 adsorbent in the invention has high wear resistance, high thermal stability and high activity; the adsorbent loses no more than 20% of CO2 adsorption capacity after 40 adsorption-desorption cycles and has a wear rate is 0.1 to 1 wt% / h; the adsorbent can be prepared by using individual impregnation solutions or a mixed impregnation solution; and the preparation method provided by the invention is simple in process, free of production of waste water, friendly to environment, easy to repeat and especially suitable for large-scale industrial production and application.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Special long-acting slow-release fertilizer for rice

InactiveCN104341242APromote sustainable developmentImprove stress resistanceSuperphosphatesAlkali orthophosphate fertiliserMinor elementPotassium

The invention discloses a special long-acting slow-release fertilizer for rice, of which the nutritive elements comprise nitrogen, phosphorus, potassium, secondary and minor elements, beneficial nutrients, organic matters, a non-coating slow-release agent and a soil conditioner. The raw materials for providing the nutritive elements comprise urea, ammonium chloride, ammonium dihydrogen phosphate, a calcium magnesia phosphate fertilizer, ordinary superphosphate, potassium chloride, zinc sulfate monohydrate, organic matters, a non-coating slow-release agent and a soil conditioner. The special long-acting slow-release fertilizer for rice can implement slow-release, and is effective for the whole process after single-dose application; and thus, the special long-acting slow-release fertilizer for rice can satisfy the nutrient demands of rice in the whole growth period after single-dose application. The special long-acting slow-release fertilizer for rice combines utilization and maintenance of soil, can supply nutrients, can also loosen the soil and enhance the soil fertility, has higher utilization ratio, enhances the stress tolerance of rice, lowers the agricultural production risks, balances the nutrients, implements scientific fertilizer application, has the advantages of complete nutrients, multiple functions and scientific formula, and solves the problems caused by purposeless fertilizer application, unbalanced fertilizer application and the like.

Owner:HUBEI YISHIZHUANG AGRI TECH

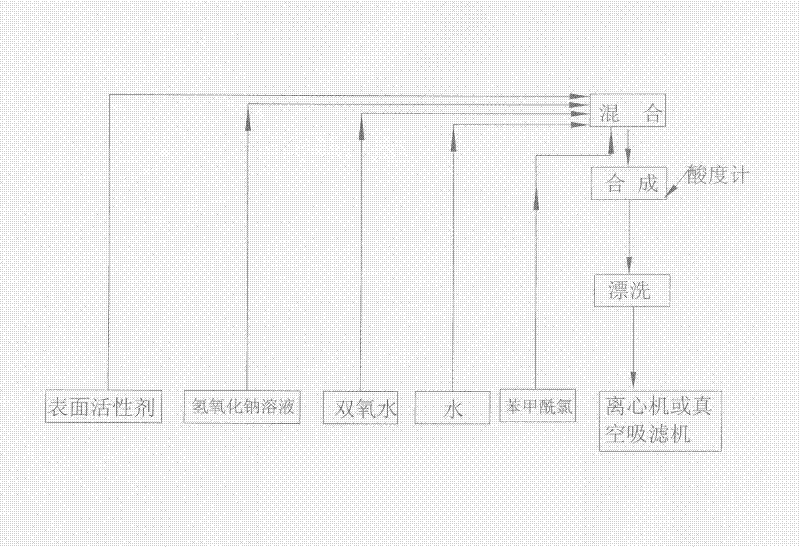

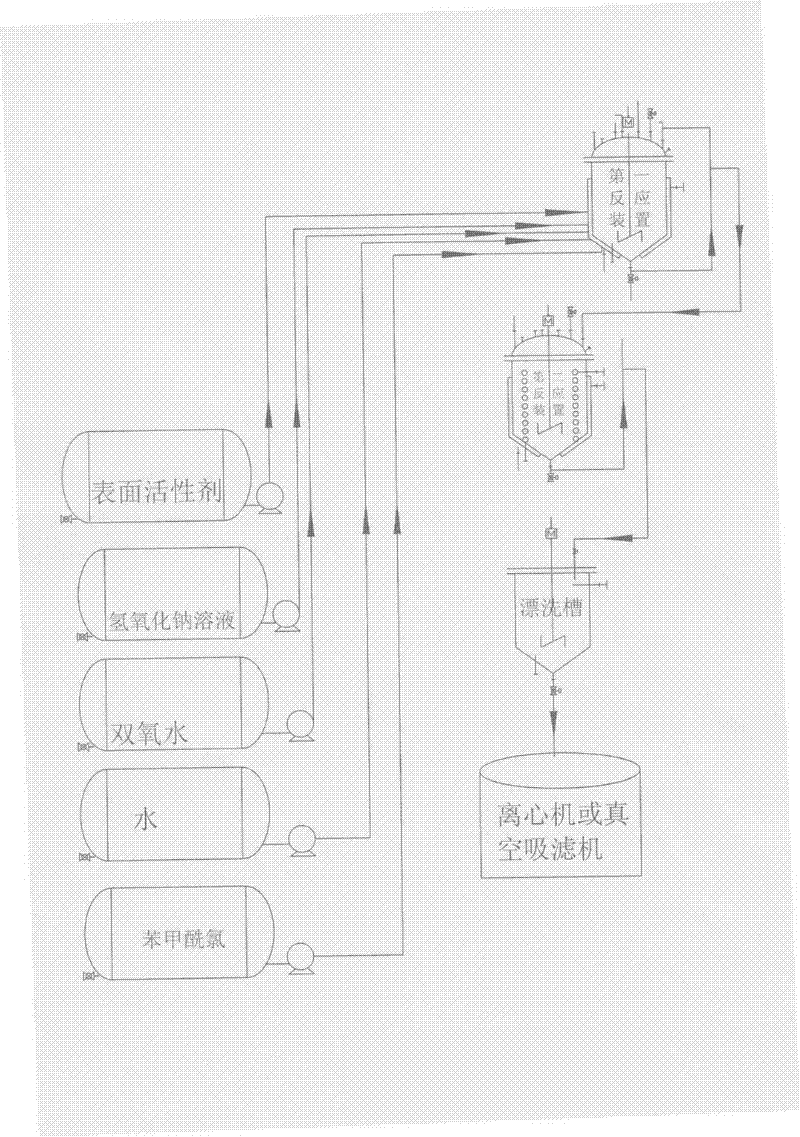

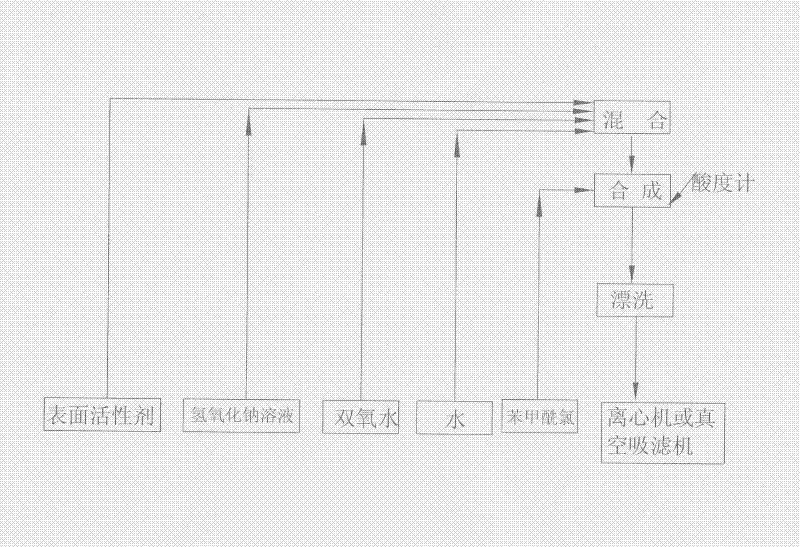

Method for preparing benzoyl peroxide

ActiveCN102199115AReduce intensityMeet the requirements of industrial automatic continuous productionOrganic compound preparationPeroxy compound preparationBenzoyl peroxideDibenzoyl Peroxide

The invention relates to a method for preparing benzoyl peroxide, which belongs to the technical field of preparation of organic peroxide. The method comprises the steps of: preparing a benzoyl peroxide crude product; and preparing a benzoyl peroxide finished product as follows: rinsing the benzoyl peroxide crude product, and then performing solid-liquid separation by introducing a solid-liquid separation device to obtain the benzoyl peroxide finished product. The method provided by the invention has the advantages that the industrialized automatic and continuous production requirements are satisfied, the operation intensity of workers is reduced, the hazards in production are reduced, and the production quantity and the quality are improved.

Owner:江苏强盛功能化学股份有限公司

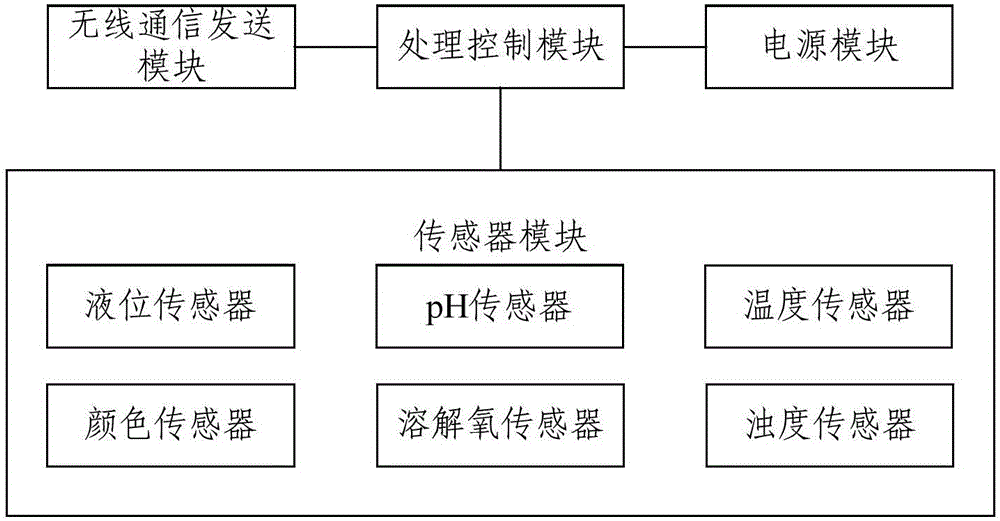

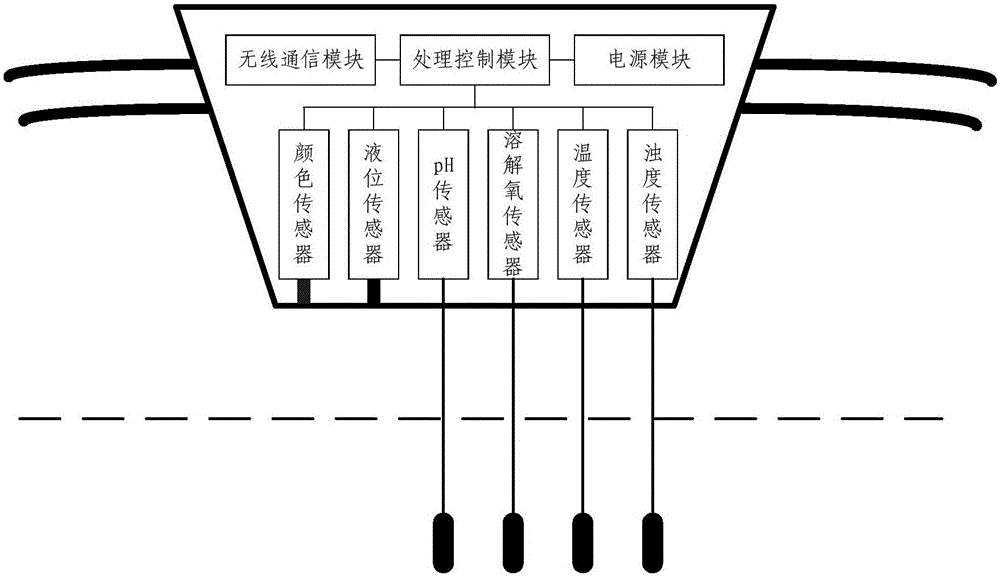

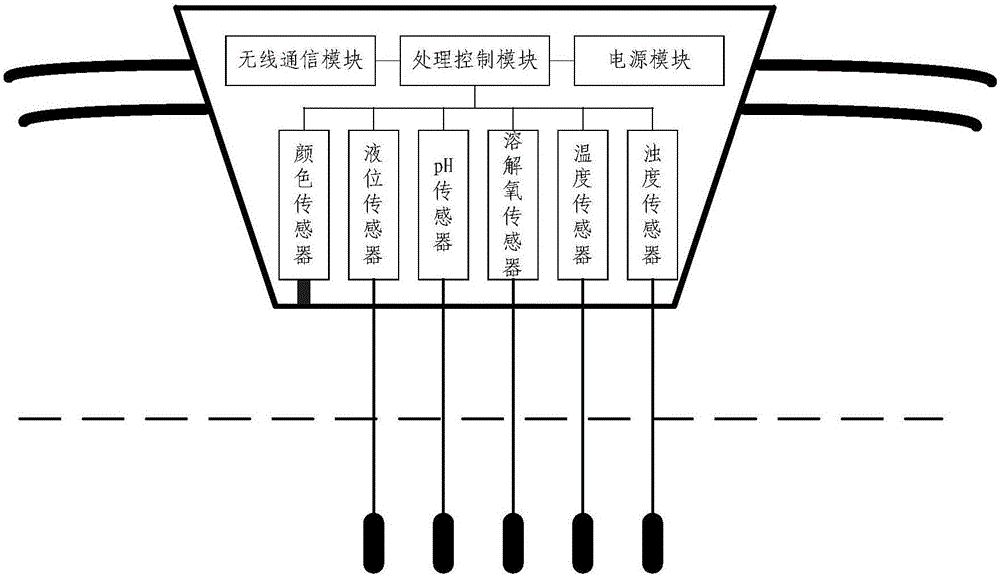

Parameter monitoring device, system and method for monitoring wine making parameters

InactiveCN106568474ARealize monitoringReal-time monitoring of key parametersMeasurement devicesAcquisition timeMiniaturization

The invention provide a parameter monitoring device, system and method for monitoring wine making parameters. The method includes that a sensor module acquires the liquor data and transmits the acquired data to a processing control module; the processing control module completes the preprocessing of the acquired data and transmits the processed acquired data to a wireless communication transmission module; the wireless communication transmission module transmits the acquisition time, the parameter monitoring device ID number, the received liquor data, and the electric quantity data of the parameter monitoring device power supply to a parameter processing device, and the parameter processing device stores, counts and displays the received data and sends alarm information when abnormality occurs. The invention realizes the real-time monitoring of the liquor parameters and the monitoring of all the wine barrels, and prevents the barrels from being opened to cause the air entering to further result in the oxidation and pollution of the liquor. The device and system have on-line and dormant states, and are designed with low-power miniaturized components.

Owner:CHINA AGRI UNIV

Composite aqueous UV coating

InactiveCN102516864APrevent extractionAchieving the purpose of aggregationPolyurea/polyurethane coatingsPolymer scienceAcrylate ester

The present invention discloses a composite aqueous UV coating, which comprises the following components by mass 0.1-48 parts of polyoxyethylene acrylate, 0.1-48 parts of water-soluble epoxy acrylic grafted urethane resin, 0.3-5 parts of additive, 2-5 parts of photoinitiator, 0.03- 0.8 parts of defoamer, 0.03-0.6 parts of wetting agent, 30-75 parts of deionized water; wherein at least one of polyoxyethylene acrylate and water-soluble epoxy acrylic grafted urethane resin is required. The preparation method comprises the following steps weighting the components by mass ratio, then mixing polyoxyethylene acrylate and water-soluble epoxy acrylic grafted urethane resin to obtain a mixture, and then adding the photoinitiator, the defoamer, the wetting agent and the aqueous additive in the mixture, stirring for 1-2 hours, and then slowly adding 0.1-5% of etherified melamine aqueous solution by using a phase inversion method. The UV coating of the present invention has advantages of good adhesion on all kinds of materials, environmental protection and no toxicity, high film hardness, excellent glossiness and fluid resistance performance.

Owner:SOUTH CHINA UNIV OF TECH

Low-cost extra-deep-drawing-quality cold-rolled galvanized steel strip and preparation method thereof

ActiveCN105648322AReduce contentGuaranteed timelinessHot-dipping/immersion processesChemical compositionNitrogen

The invention discloses a low-cost extra-deep-drawing-quality cold-rolled galvanized steel strip and a preparation method thereof. The steel strip is prepared from, by mass percent, 0.001% to 0.005% of C, 0.07% to 0.12% of Mn, not larger than 0.012% of S, not larger than 0.012% of P, not larger than 0.03% of Si, 0.010% to 0.060% of Als, not larger than 0.0040% of N, 0.0015% to 0.0030% of B and the balance Fe and inclusion within an allowed range. According to the galvanized steel strip, the reasonable carbon content is controlled to reduce the content of free carbon in steel as much as possible; and meanwhile, a certain amount of boron is added to fix interstitial nitrogen and part of carbon, and therefore the timeliness of an extra-deep-drawing-quality galvanized product can be guaranteed. According to the galvanized steel strip, boron is used for fixing carbon atoms, so that the cost of an alloy material is greatly reduced, meanwhile, the heating temperature and soaking temperature of a galvanization procedure can be greatly reduced, and therefore production difficulty and energy consumption are effectively lowered.

Owner:唐山钢铁集团高强汽车板有限公司 +2

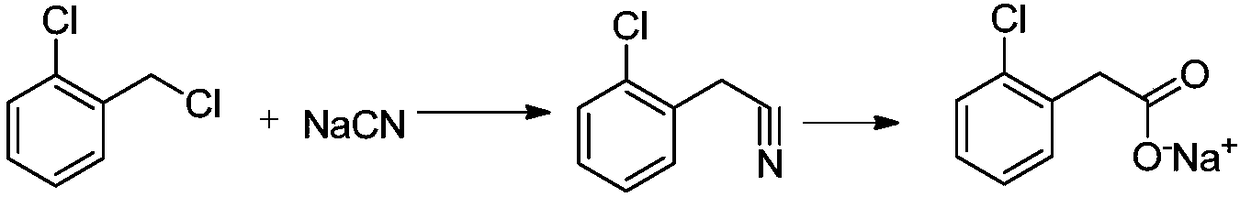

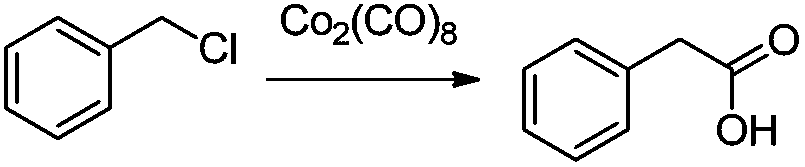

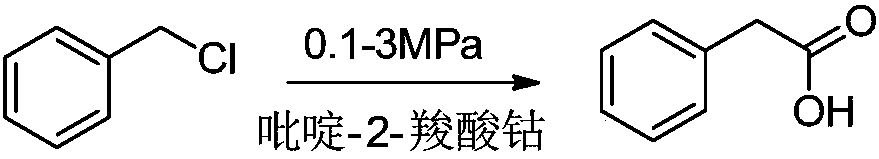

Preparation method of phenylacetic acid type compound

ActiveCN109320413AEasy to getAvoid Production Safety RisksCarboxylic acid nitrile preparationOrganic compound preparationGas phasePhenylacetic acid

The invention discloses a preparation method of a phenylacetic acid type compound. The preparation method of the phenylacetic acid type compound I comprises the following steps that in a solvent and aCO gas phase system, a benzyl halide type compound II, pyridine-2-cobalt carboxylate, palladium acetate and alkaline neutralizers take carbonylation reaction to obtain the phenylacetic acid type compound I. A mixed catalytic system has a synergistic effect; the whole use quantity of catalysts is greatly reduced. When the mixed catalyst is used, a better catalytic effect can be achieved; the characteristics of easily obtaining the catalyst, avoiding the production safety risk of toxic three wastes and the like, reducing the reaction pressure, realizing mild reaction conditions, reducing the production risk, facilitating the production and the like are realized. The formulas are shown in description.

Owner:JIANGSU LIANHE CHEM TECH +2

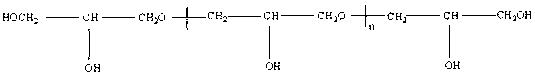

Preparation method and application of polyether type thick oil demulsifying agent

InactiveCN102702463ALow costGood demulsification effectDewatering/demulsification with chemical meansEther preparation by compound dehydrationBiodieselGlycerol

The invention relates to a preparation method and an application of a polyether type thick oil demulsifying agent. The method comprises the steps of polyglycerol synthesis, polyether synthesis and polyether type thick oil demulsifying agent preparation. The thick oil demulsifying agent adopts polyglycerol with different polymerization degrees as initiators, alkali metal hydroxide is used as catalysts, epoxypropane polymerization is initiated, polyether macromolecular compounds are obtained, then, the polyether macromolecular compounds take reaction with polyisocyanate in aromatic solvents, and the final demulsifying agent product is obtained. The detail method steps are shown as the specification. The preparation method and the application have the advantages that by-product glycerol generated in the biodiesel production process is used as raw materials, ethylene oxide used as synthesis raw materials of the polyether type demulsifying agent is replaced, the raw material cost is low, the production risk is low, the thick oil demulsifying effect is good, and the preparation method is particularly suitable for thick oil dehydration at lower temperature, and the utilization rate of the glycerol can be greatly improved, so the development of the biodiesel industry is promoted.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

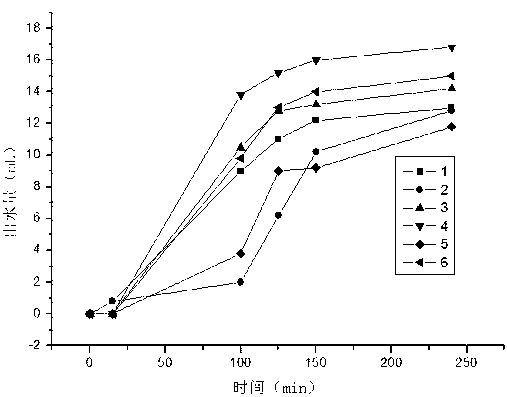

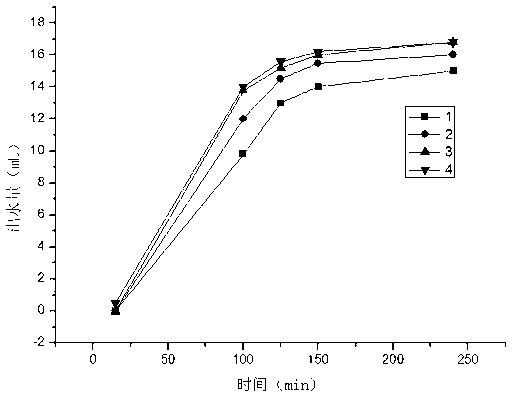

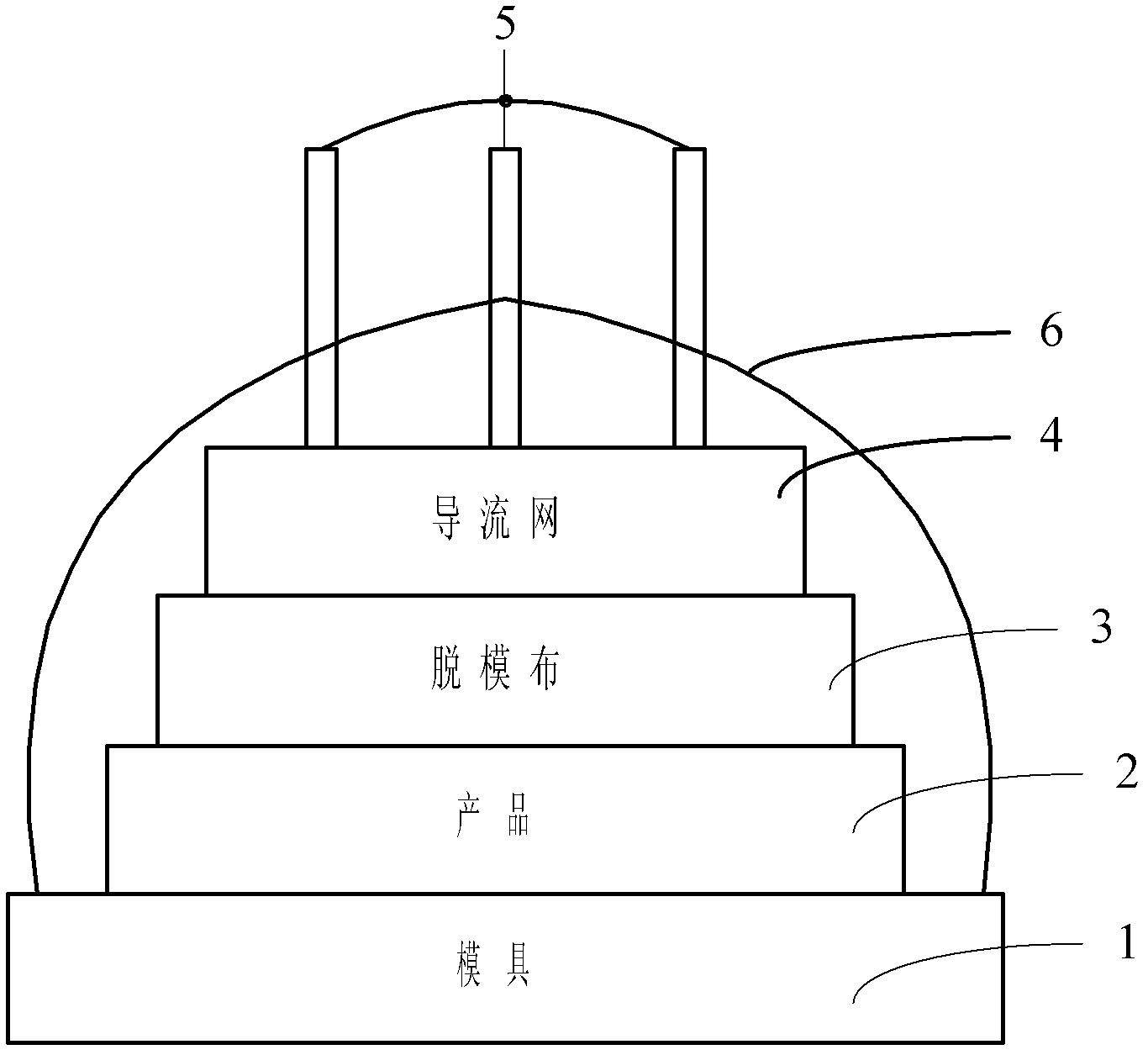

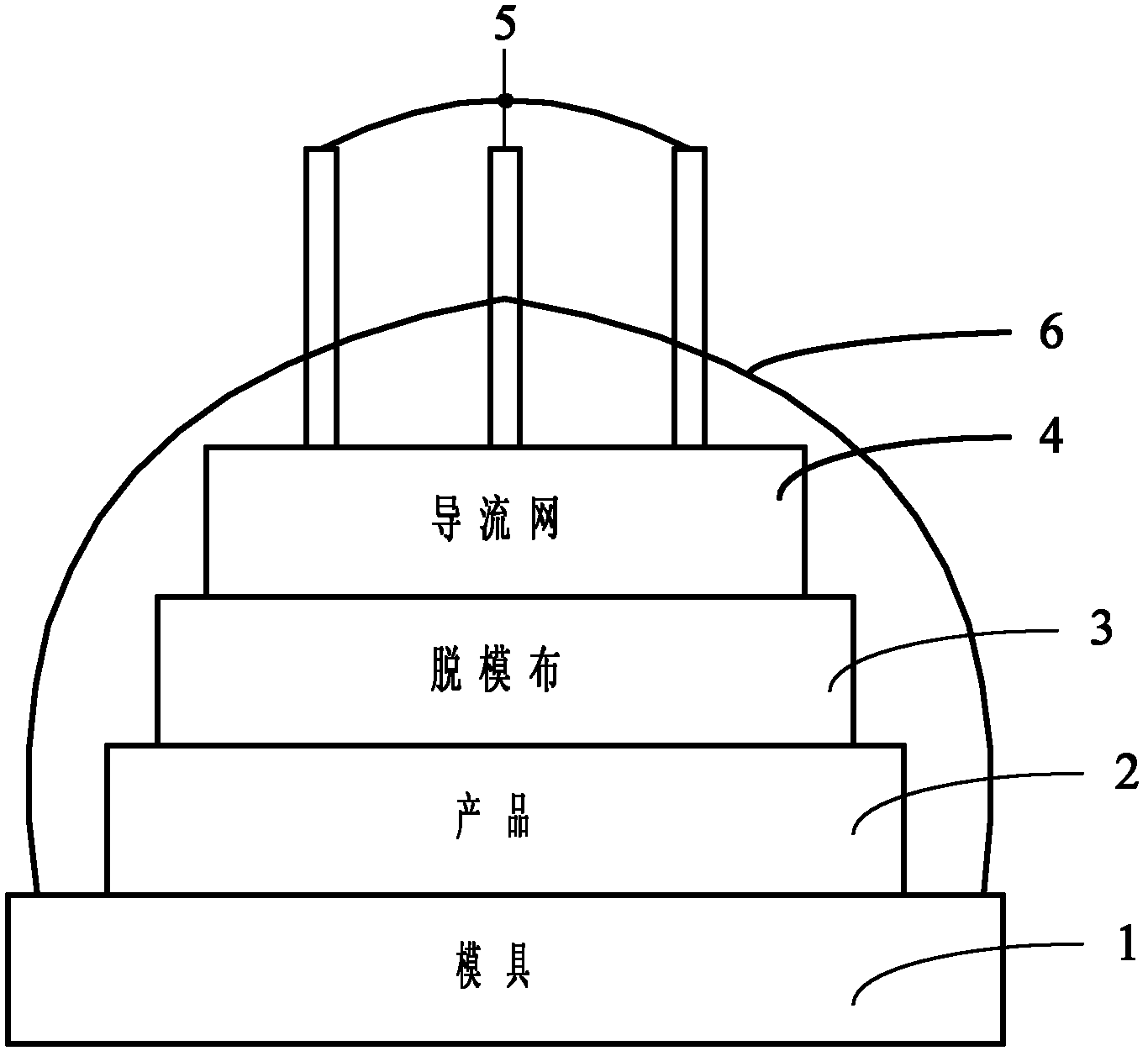

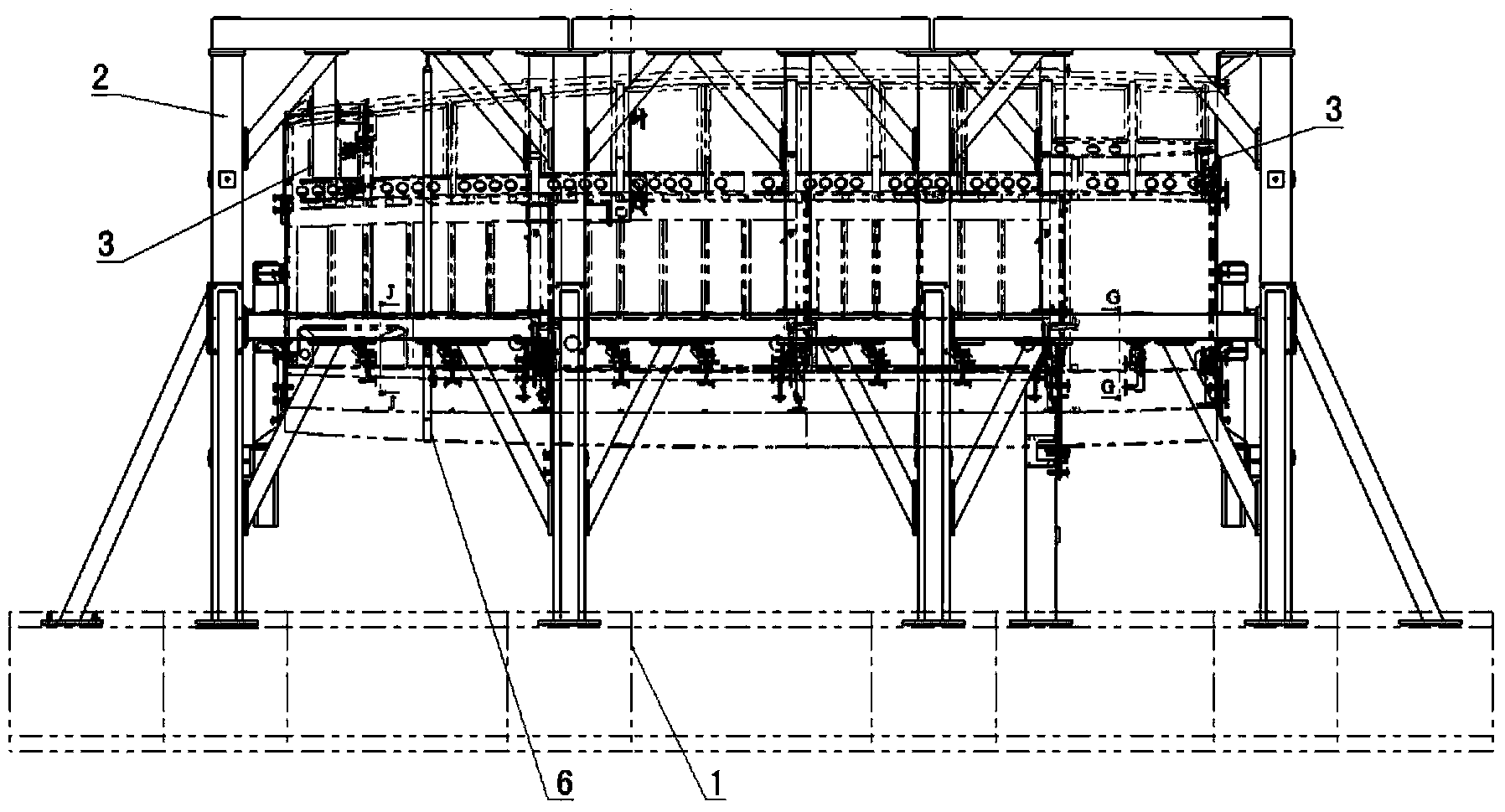

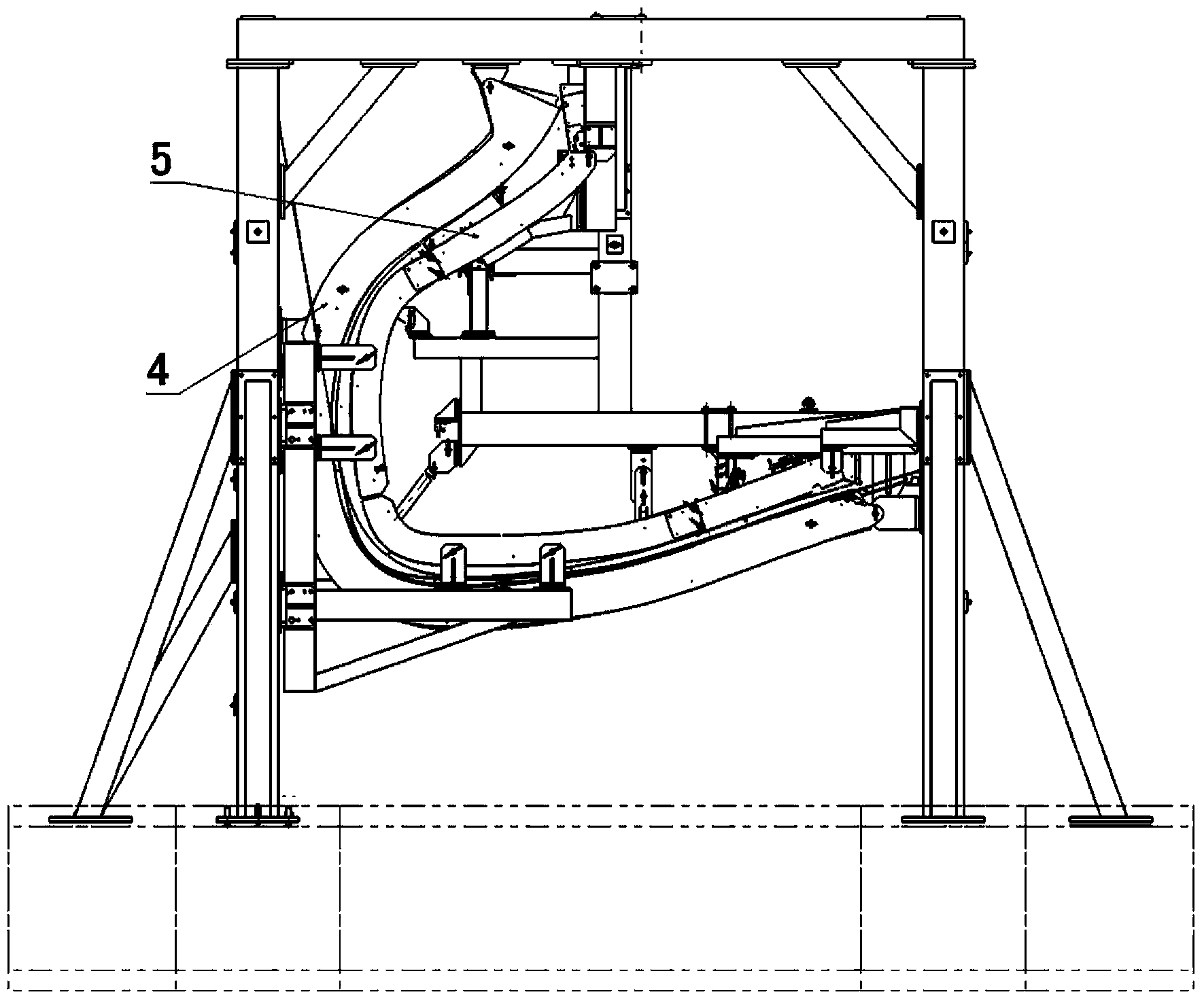

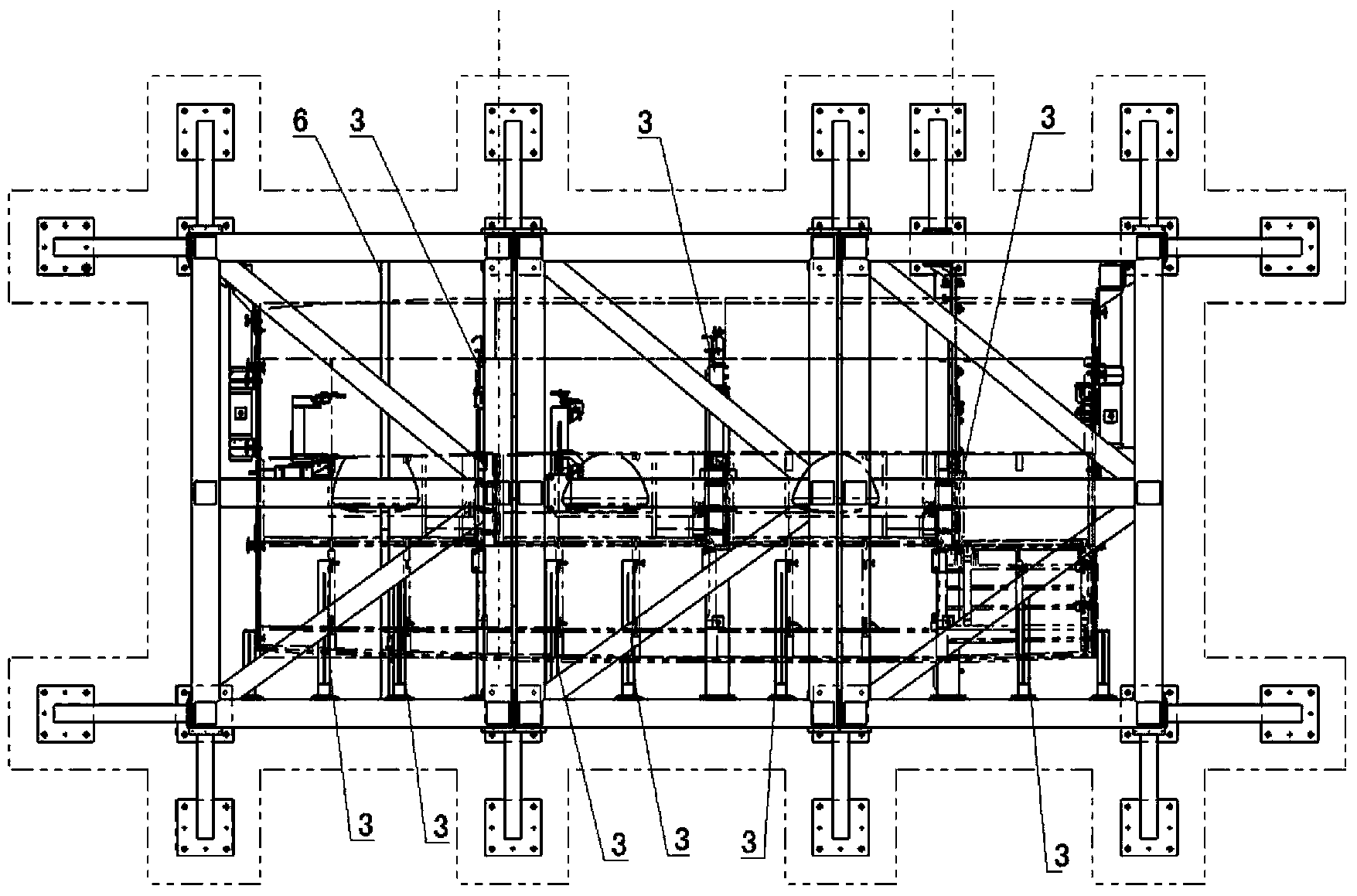

Vacuum infusion molding process for compound material and flow guide net thereof

The invention relates to a vacuum infusion molding process for a compound material and a flow guide net thereof. The vacuum infusion molding process for the compound material comprises the following steps: paving the flow guide net on the surface of a product in a die, and arranging a flow guide tube on the flow guide net, wherein the flow guide net is arranged according to the structure of the product; blending 1-2kg of plastic color master batch particles with each 100kg of high-density polyethylene (HDPE) plastic particles adopted by the flow guide net; adding to a hopper; entering an extruding machine through an automatic feeding device; heating at the position of a machine barrel of the extruding machine to fuse the HDPE plastic particles and the plastic color master batch particles; then, extruding by an extruding screw of the extruding machine; and finally, extruding by a die head of the extruding machine after heating is performed by the five section of a machine head. Molded meshes are rhombic small blocks in shape; at least one layer of vacuum bag is buckled above the flow guide net and the flow guide pipe; the vacuum bag and the die are sealed; and the flow guide pipe penetrates the vacuum bag, and the penetrating part is sealed, thereby, the phenomenon that the product defect is caused because resin infusion is too slow or incomplete cannot occur.

Owner:SHANGHAI LEADGO TECH

Aircraft main landing gear hatch door assembling coordinate platform

InactiveCN104118575AGuaranteed functionGuaranteed Reliability RequirementsAircraft assemblyJet aeroplaneAirplane

The invention belongs to the technical field of aircraft assembling, and relates to an aircraft main landing gear hatch door assembling coordinate platform which comprises a foundation, a main frame, hatch door intersection positioning assemblies, hatch door appearance detecting boards, main landing gear fairing process fake frames and a tension belt assembly. The main frame is installed on the foundation. The hatch door intersection positioning assemblies, the hatch door appearance detecting boards, the main landing gear fairing process fake frames and the tensioning belt assembly are installed on the main frame. The positioning coordinates of the hatch door intersection positioning assemblies are the same as the assembling interaction coordinates of an aircraft actual hatch door. The inner shape of the hatch door appearance detecting boards is the same as the theoretical appearance of the hatch door, and the inner shape of the hatch door appearance detecting boards is larger than the theoretical appearance of the hatch door. The two ends of the coordinate platform are provided with the main landing gear fairing process fake frames which are totally the same with aircraft main landing frame fairing lap joint frames in appearance. By means of the aircraft main landing gear hatch door assembling coordinate platform, the production cost and assembly risk are reduced, actual assembling workloads are reduced, and the development cycle is shortened.

Owner:HARBIN

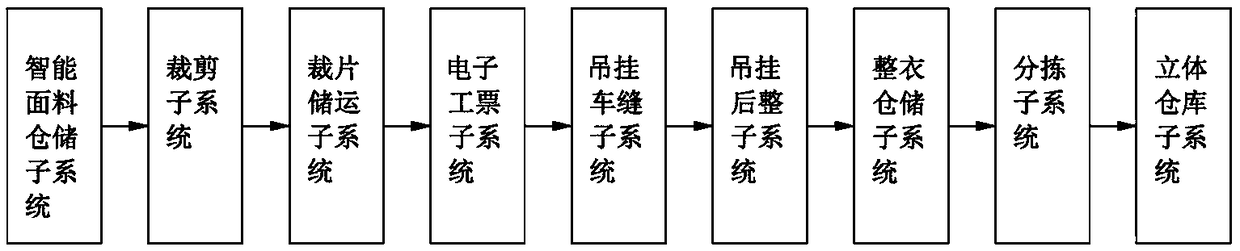

Internet of things-based cloud control method for hoisting system

InactiveCN108734237AReduce shipping costsReduce production riskCo-operative working arrangementsStorage devicesProgram planningProcessing plants

The invention relates to the technical field of clothes manufacturing, in particular to an Internet of things-based cloud control method for a hoisting system. The Internet of things-based cloud control method for hoisting system is suitable for the hoisting system including a cloud platform and a plurality of machining plants, and is characterized by comprising the following steps that: a processing plant uploads production data to a cloud platform in real time, and receives and execute a control command coming from the cloud platform, wherein the production data include one or more worksheetdata, production efficiency data and production progress data, the control command comprises a worksheet allocating command; and the cloud platform receives orders coming from a retail store and allocates the orders according to the production data of each machining plant, and transmits a worksheet allocating command to a corresponding plant in order to implement the order allocation. The directcommunication between the retail store and the machining plant is realized through the cloud platform; intermediate loops between the generation of the orders and a machining plan are avoided; and theinformation is more accurate. The reasonable utilization and allocation of the resources are facilitated; the cost is saved more; and environmental friendliness is achieved.

Owner:水财

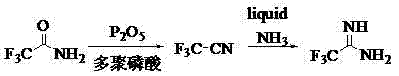

Preparation method of trifluoroacetamidine

The invention relates to a preparation method of trifluoroacetamidine. The trifluoroacetamidine is an important chemical intermediate with wide purposes. A preparation method comprises the following steps that trifluoroacetamide is used as raw materials, polyphosphoric acid is selected as solvents under the effect of phosphorus pentoxide as dehydrating agents, trifluoroacetonitrile can be fast prepared through dehydration reaction, the generated trifluoroacetonitrile gas is introduced into a liquid ammonia kettle after being cooled, and the trifluoroacetamidine can be prepared. When the method is used for preparing the trifluoroacetamidine, various problems caused when the trifluoroacetonitrile gas with high toxicity is directly adopted as raw materials are avoided, the production risk is reduced, meanwhile, the operation difficulty is also reduced, the product yield is also improved, in addition, the preparation method has the advantages that the production process is simple, the product yield and the product purity are higher, and the like. The preparation method is suitable for industrial production.

Owner:JIANGSU TETRA NEW MATERIAL TECH

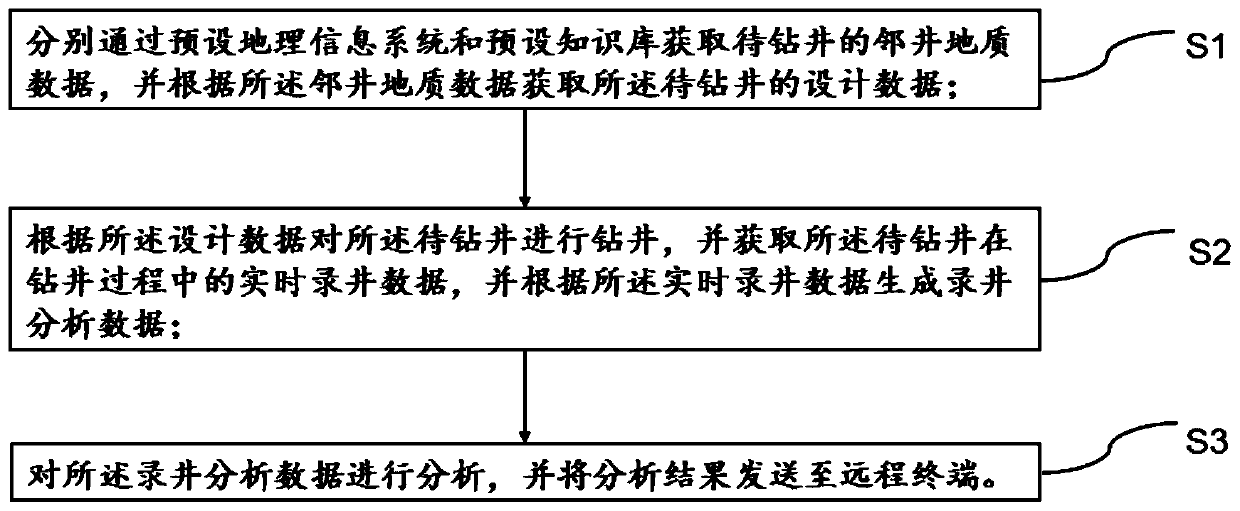

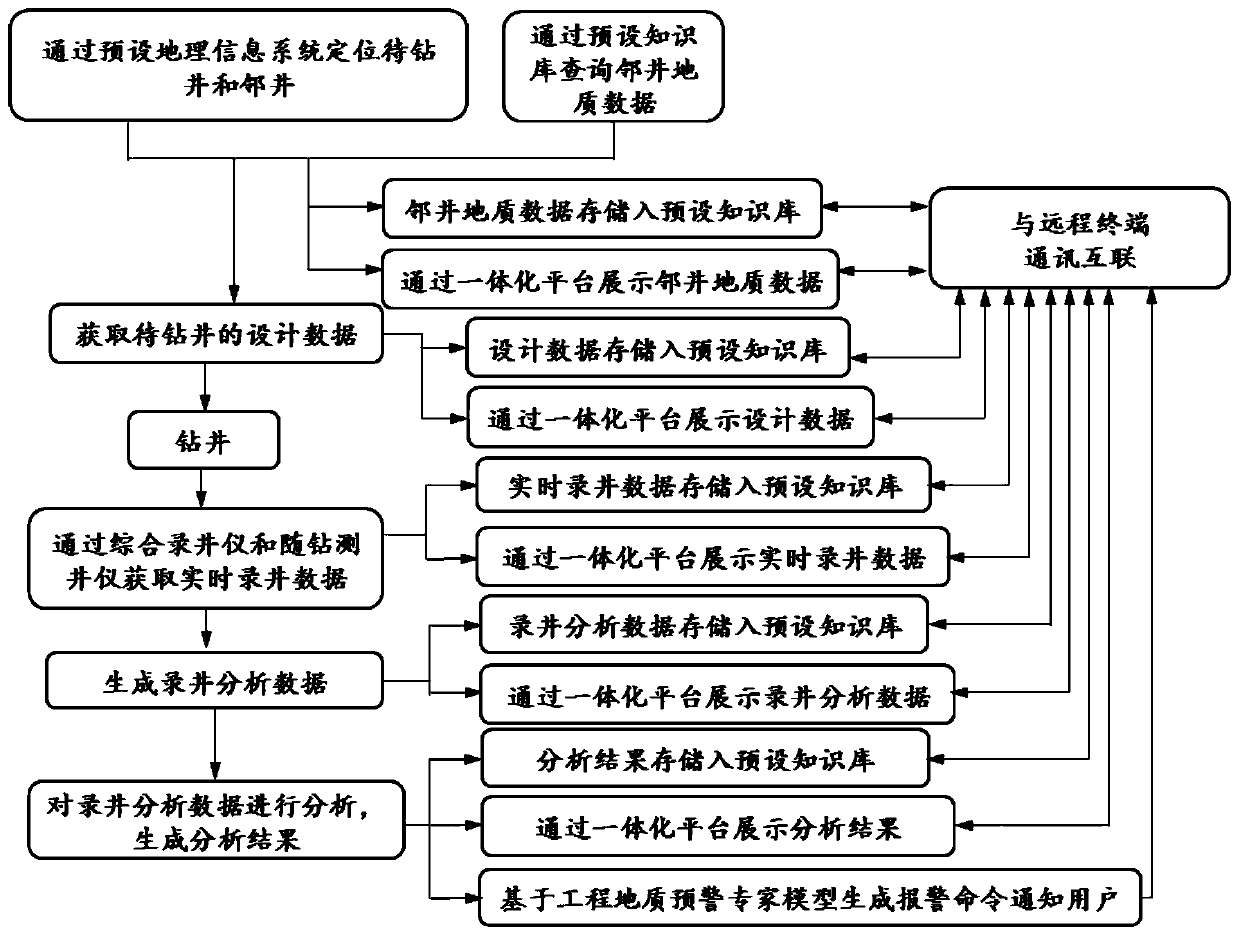

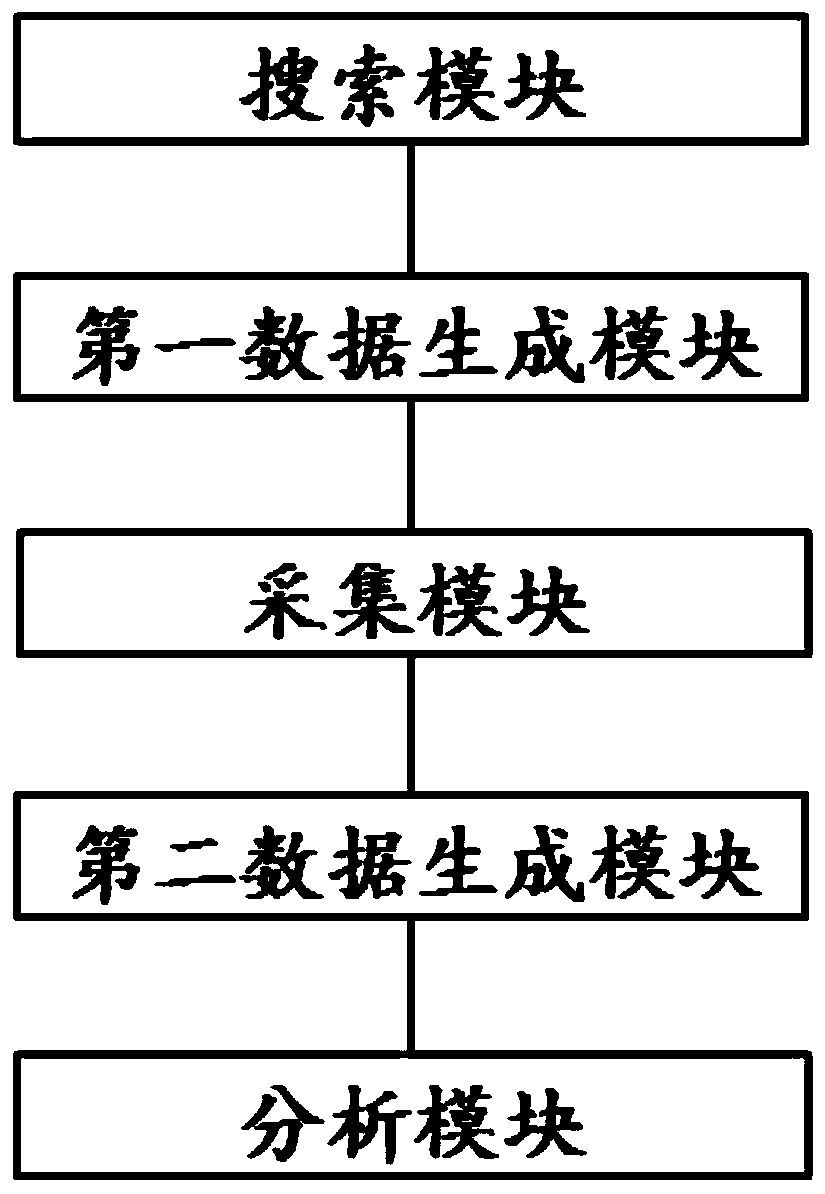

A remote logging method and system

PendingCN109766396APromote generationEasy to monitor in real timeGeographical information databasesSpecial data processing applicationsData synchronizationAnalysis data

The invention relates to a remote logging method and system, and the method comprises the steps of obtaining the adjacent well geological data of a to-be-drilled well through a preset geographic information system and a preset knowledge base, and obtaining the design data of the to-be-drilled well according to the adjacent well geological data; drilling the to-be-drilled well according to the design data, obtaining real-time logging data of the to-be-drilled well in the drilling process, and generating logging analysis data according to the real-time logging data; and analyzing the logging analysis data, and sending an analysis result to a remote terminal. According to the present invention, a set of remote logging technical process capable of supporting integration of well site logging data acquisition, transmission, publishing and application of the whole process can be established, the data synchronization and the interconnection of a well site and a remote terminal can be achieved,a remote cooperation function can be achieved, the real-time dynamic monitoring of the logging work can be achieved, and the early warning is conducted in time when abnormity occurs.

Owner:WUHAN SHENGHUAWEIYE TECHNOLGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com