Method for preparing benzoyl peroxide

A technology for benzoyl peroxide and benzoyl peroxide first product, which is applied in the field of preparation of benzoyl peroxide, can solve the problems of difficult to achieve safe production, large floor space, difficult temperature control, etc., and achieves increased output and quality, reduce strength, reduce the effect of production risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

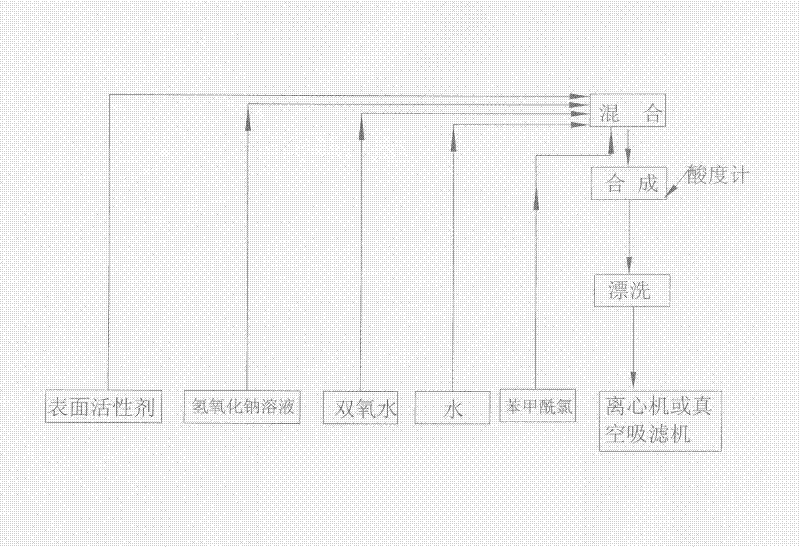

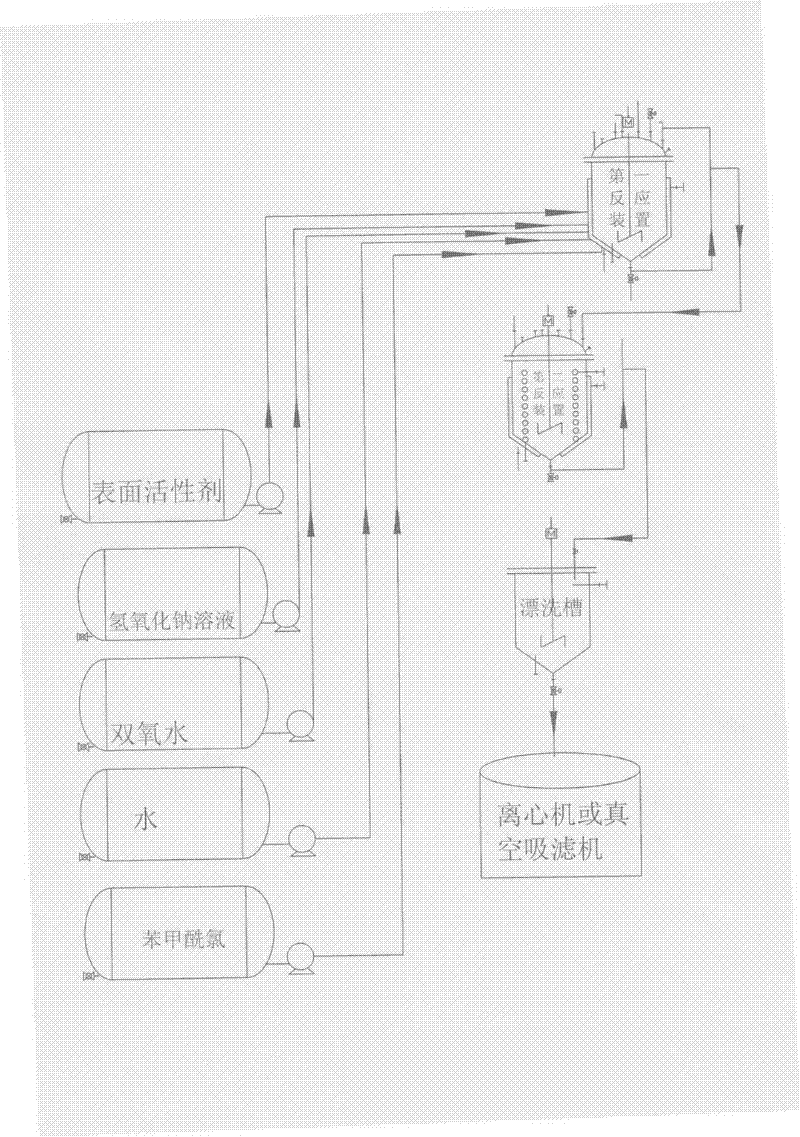

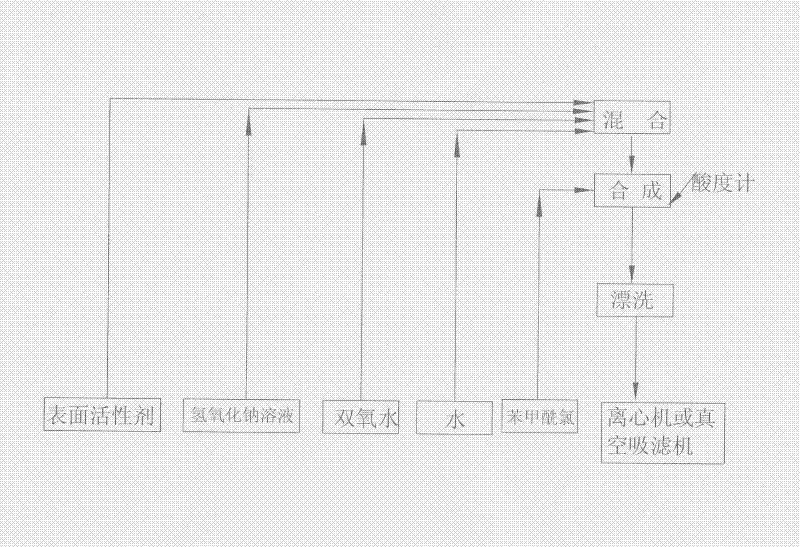

[0033] please see figure 1 and figure 2 .

[0034]A) To prepare the primary product of benzoyl peroxide, prepare the reaction mother liquor before the reaction starts, and pre-fill 31Kg of sodium chloride, 250Kg of water, and 10% sodium hydroxide solution in the first reaction device of 500L 2Kg, mass percentage concentration is 70% hydrogen peroxide 13Kg and the mass percentage concentration is 0.1% surfactant i.e. sodium lauryl sulfate solution 7Kg is mixed with reaction mother liquor, then water, mass percentage concentration is 10% hydrogen Sodium oxide solution, mass percentage concentration are 70% hydrogen peroxide, mass percentage concentration are 0.1% tensio-active agent namely sodium lauryl sulfate solution and the benzoyl chloride of technical grade purity with 70Kg / h, 82.4Kg / h, respectively The flow rate of 10Kg / h, 7Kg / h, 28.8Kg / h is added to the first reaction device, the reaction is stirred by the paddle stirrer of the first reaction device, and the reaction ...

Embodiment 2

[0037] please see figure 1 and figure 2 .

[0038] A) To prepare the primary product of benzoyl peroxide, prepare the reaction mother liquor before the reaction starts, and pre-fill 25Kg of sodium chloride, 250Kg of water, and 20% sodium hydroxide solution in the first reaction device of 500L 22Kg, mass percent concentration is 65% hydrogen peroxide 8Kg, mass percent concentration is 0.1% surfactant i.e. 5Kg of sodium dodecylsulfonate solution is configured as reaction mother liquor, then water, mass percent concentration is 20% by pump Sodium hydroxide solution, mass percentage concentration are 65% hydrogen peroxide, mass percentage concentration are 0.1% tensio-active agent namely sodium dodecylsulfonate solution and the benzoyl chloride of technical grade purity respectively with 105Kg / h, 61.8Kg / The flow rate of h, 10.8Kg / h, 10.5Kg / h, 34.6Kg / h is added to the first reaction device, the paddle stirrer of the first reaction device is used to stir the reaction, and the re...

Embodiment 3

[0041] please see figure 1 and figure 2 .

[0042] A) To prepare the primary product of benzoyl peroxide, prepare the reaction mother liquor before the reaction starts, and pre-fill 22Kg of sodium chloride, 250Kg of water, and 30% sodium hydroxide solution in the first reaction device of 500L 22Kg, mass percent concentration is 50% hydrogen peroxide 6Kg, mass percent concentration is 0.1% surfactant i.e. 4Kg of sodium dodecylbenzene sulfonate solution is configured into reaction mother liquor, then water, mass percent concentration is 30% by pump Sodium hydroxide solution, mass percent concentration is 50% hydrogen peroxide, mass percent concentration is 0.1% surfactant i.e. sodium dodecylbenzenesulfonate solution and benzoyl chloride of industrial grade purity with 140Kg / h, 54.9 The flow rate of Kg / h, 14Kg / h, 14Kg / h, 40.4Kg / h is added to the first reaction device, the paddle stirrer of the first reaction device is used to stir the reaction, and the reaction time is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com