Vacuum infusion molding process for compound material and flow guide net thereof

A technology of diversion net and diversion tube, applied in the field of composite material vacuum infusion molding process, can solve problems such as affecting production efficiency, slow resin flow, white spot diversion time, etc., to reduce production risk, complete immersion effect, and process stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

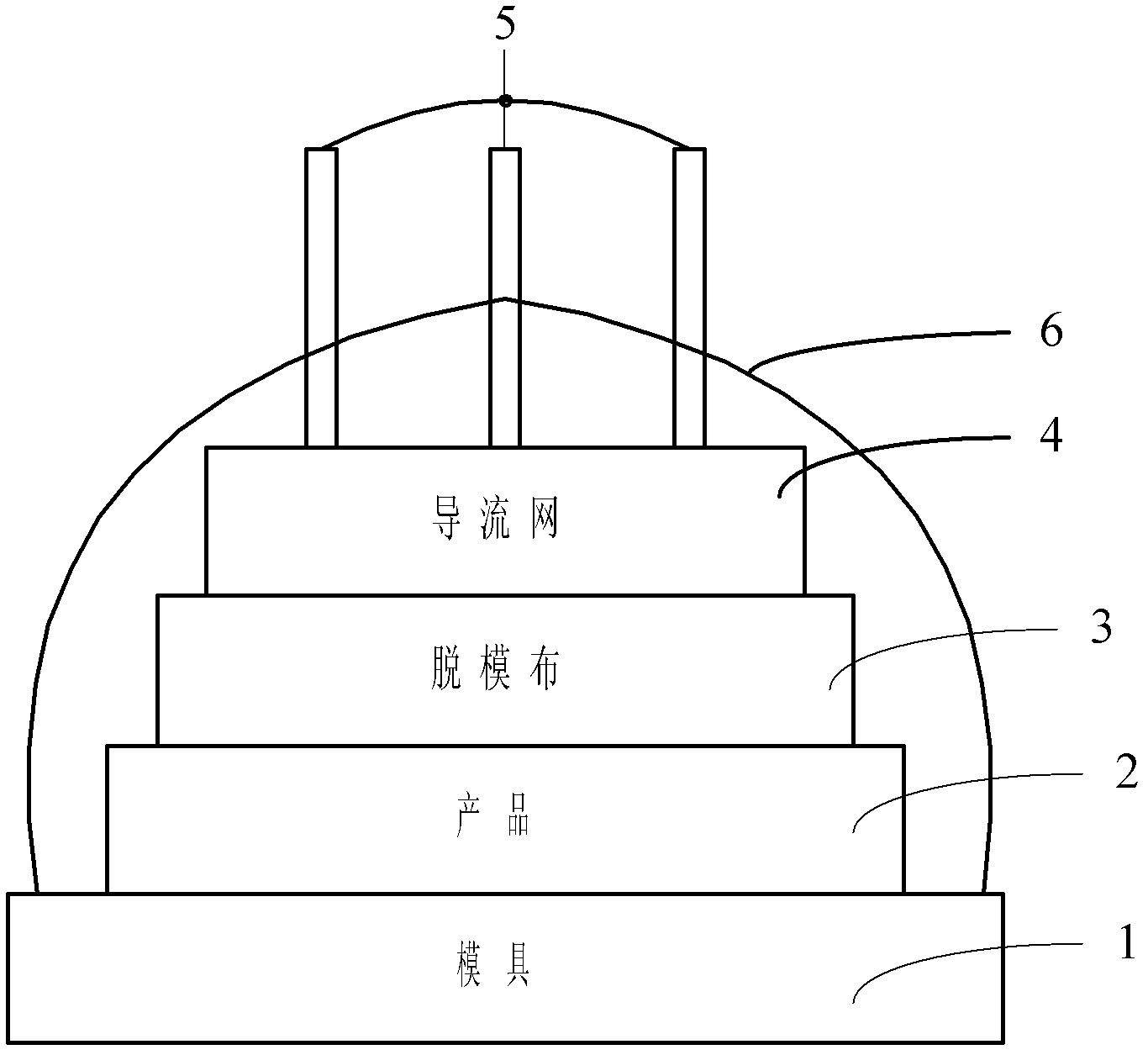

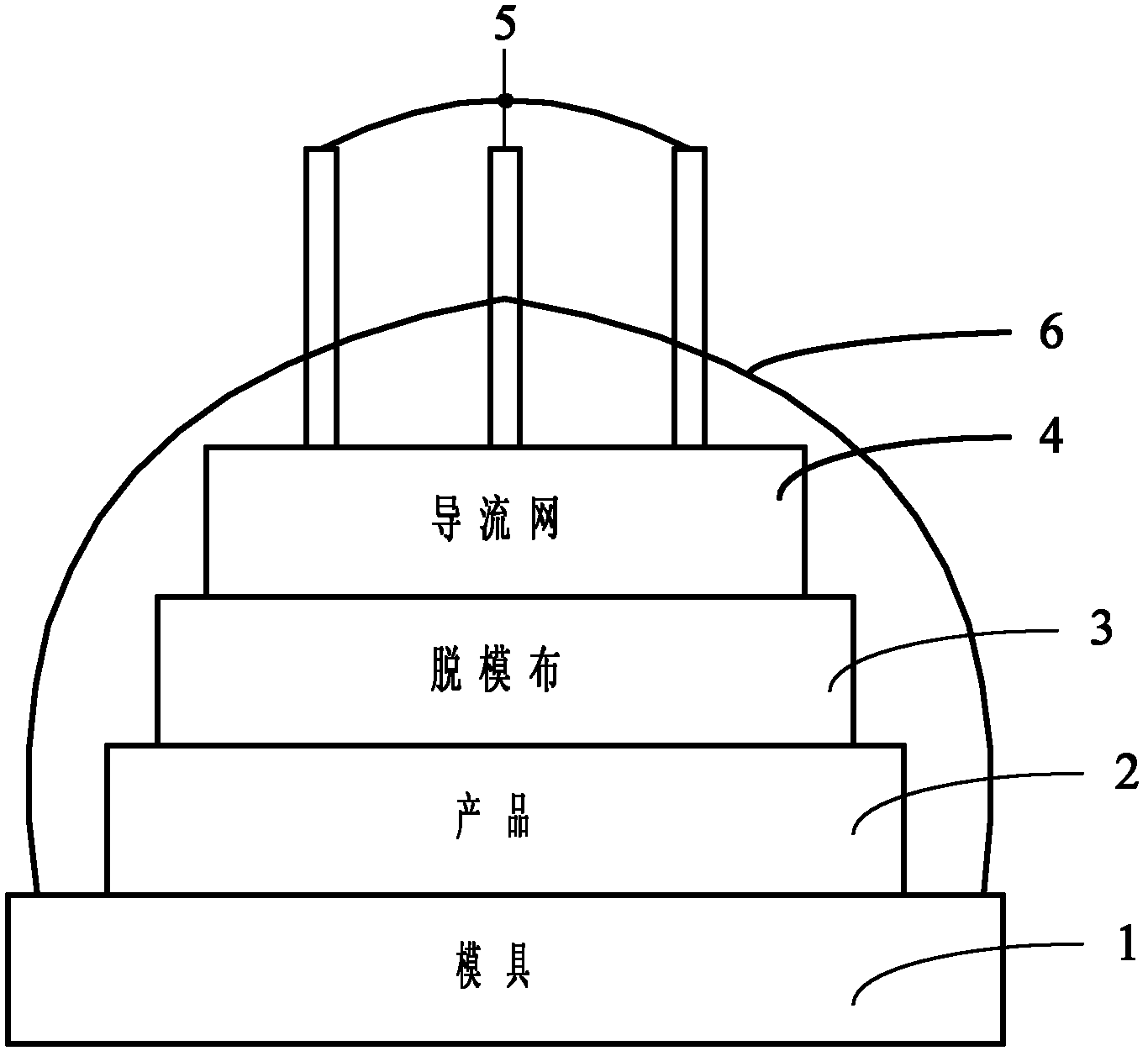

[0019] Such as figure 1 As shown, the composite material vacuum infusion molding process of the present invention is mainly implemented in the following manner.

[0020] A layer of release cloth 3 is laid on the entire surface of the mold 1. The function of the release cloth 3 is to make the product 2 in the mold 1 easy to separate from the mold 1 after curing. The release cloth 3 has the function of filtering and penetrating. Also can not lay release cloth 3 for easy demoulding or small product.

[0021] On the upper surface of the release cloth 3, a flow guiding net 4 is laid. The diversion net 4 that is applicable to this case is a kind of diversion net that makes specially. Optimally, the material used in the production adopts a two-component distribution ratio, using 1-2 kg of plastic masterbatch particles for every 100 kg of HDPE (high-density polyethylene) plastic particles, adding them to the hopper, and entering the extruder through an automatic feeding device.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com