Patents

Literature

56results about How to "Realize quantitative output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

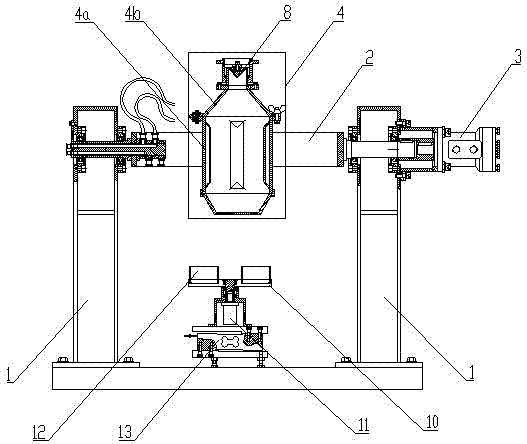

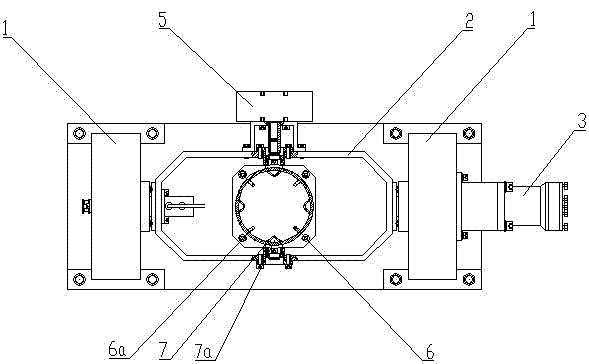

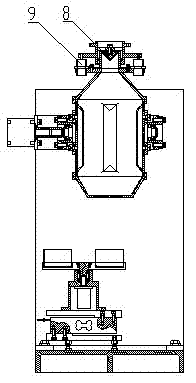

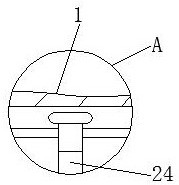

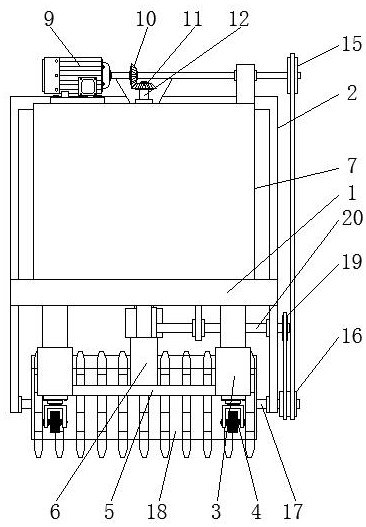

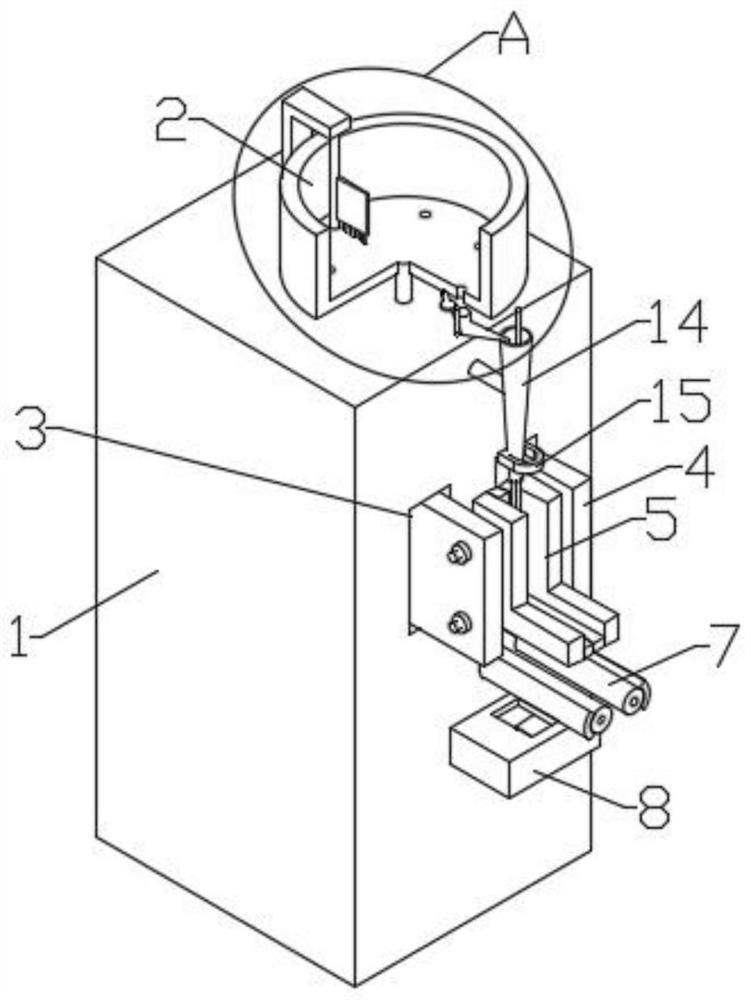

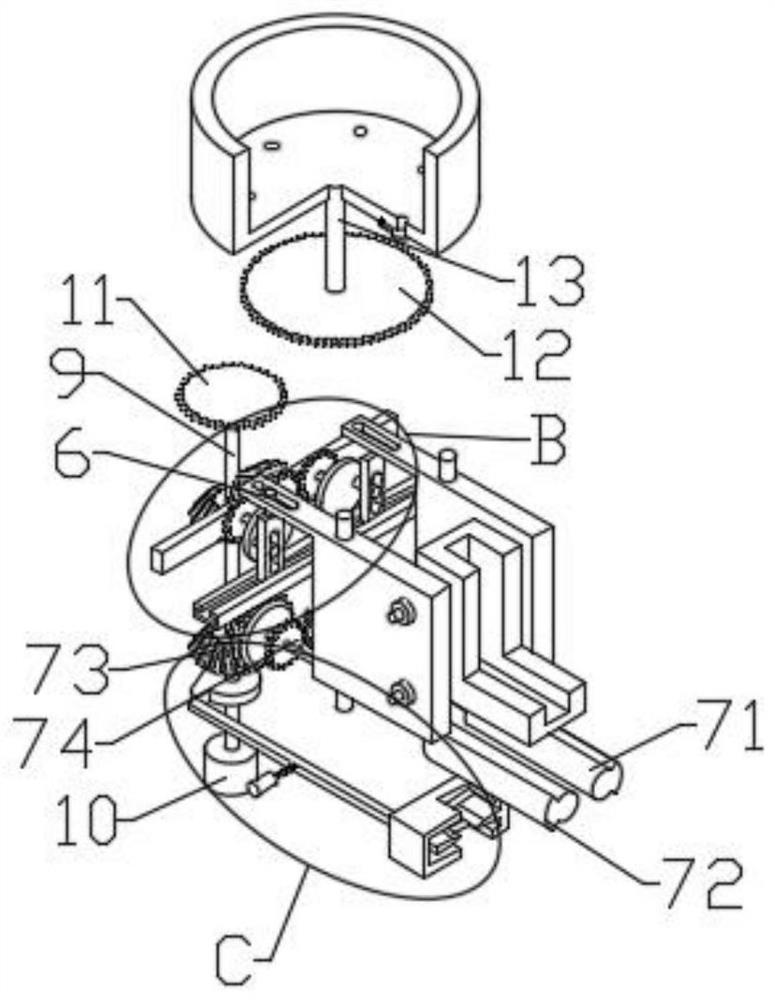

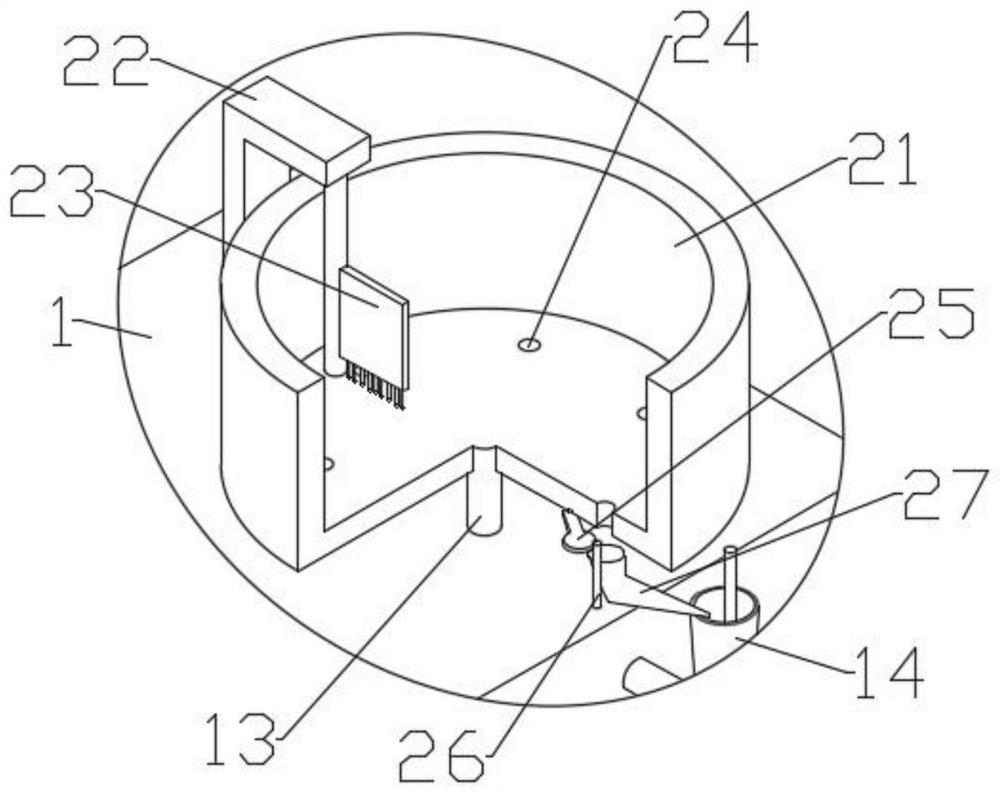

Automatic drug mixer

ActiveCN102350253AAchieve compound movementRealize quantitative outputRotating receptacle mixersTransportation and packagingInsertion stentEngineering

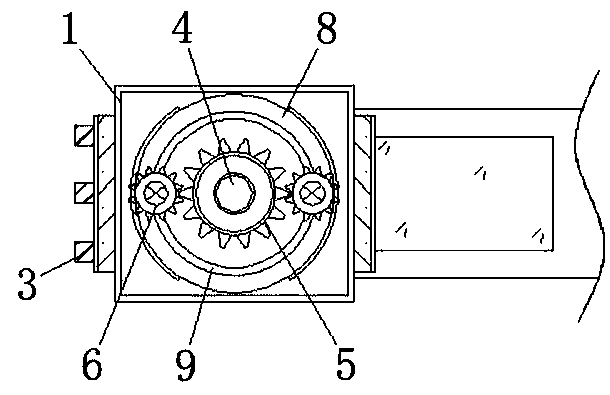

The invention discloses an automatic drug mixer, comprising two parallel supports, a jib arranged on the supports in rotating cooperation as a corss arm, a spin motor to drive the jib to rotate, a drug mixing pan arranged on the jib and a material receiving apparatus under the drug mixing pan. The drug mixing pan is rotatably cooperated with the jib in a way that the drug mixing pan conducts reciprocating swings towards two ends of the jib, and a swing motor is rotatably cooperated with the drug mixing pan. The spin motor can drive the drug mixing pan to tumble around a jib rotating shaft, meanwhile the swing motor can drive the drug mixing pan to swing around a vertical line of the jib rotating shaft to realize compound movement of the drug mixing pan. The automatic drug mixer can substitute manual drug mixing to realize automation, enhance drug mixing effect and efficiency effectively and improve production environment. rotating speeds of the two motors can be adjusted to realize different movement tracks of the drug mixing pan to facilitate exploration of an optimum drug mixing time and movement track. In addition, the invention can realize automatic quantification material distribution and raise production efficiency effectively.

Owner:CHONGQING HUAAO PHARMA IND CO LTD

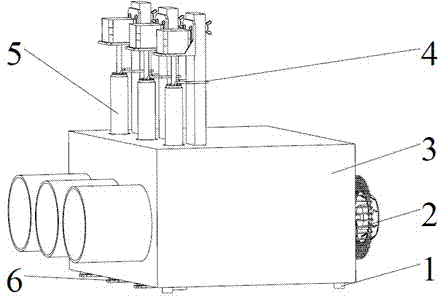

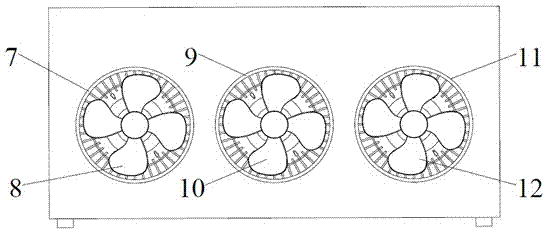

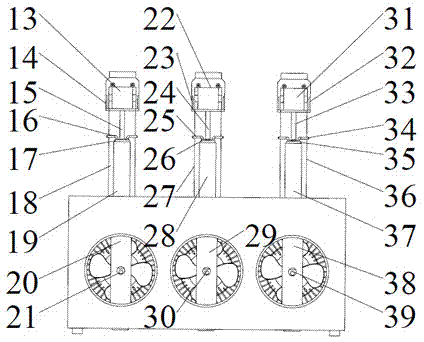

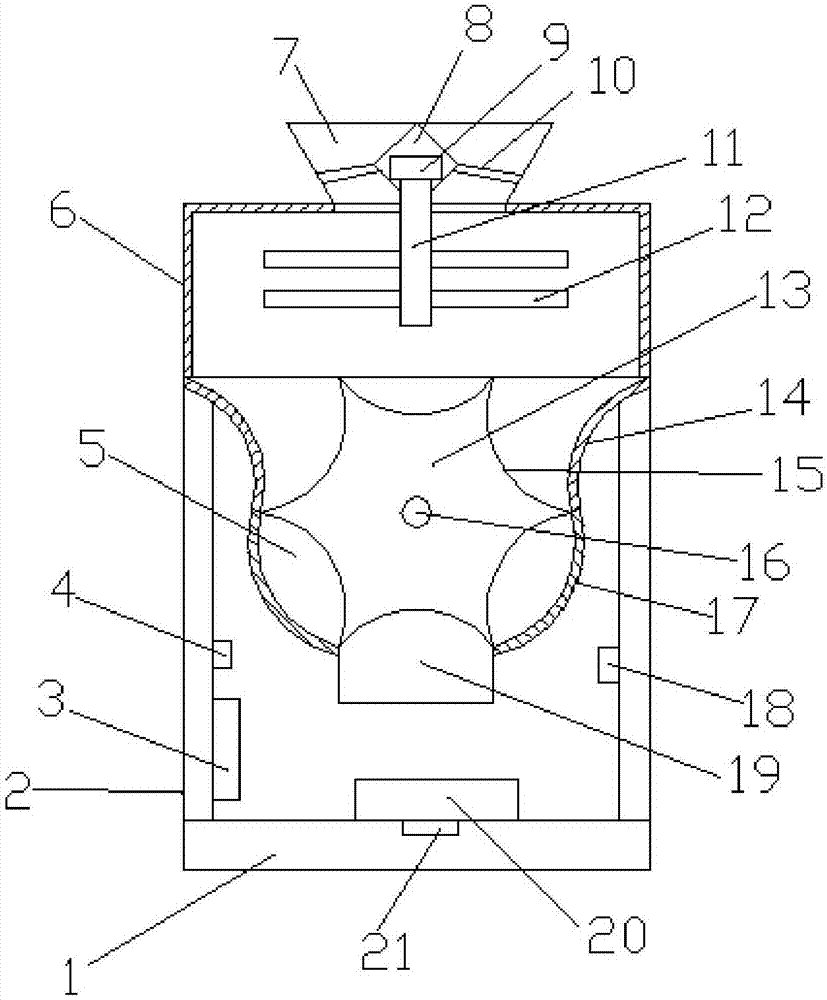

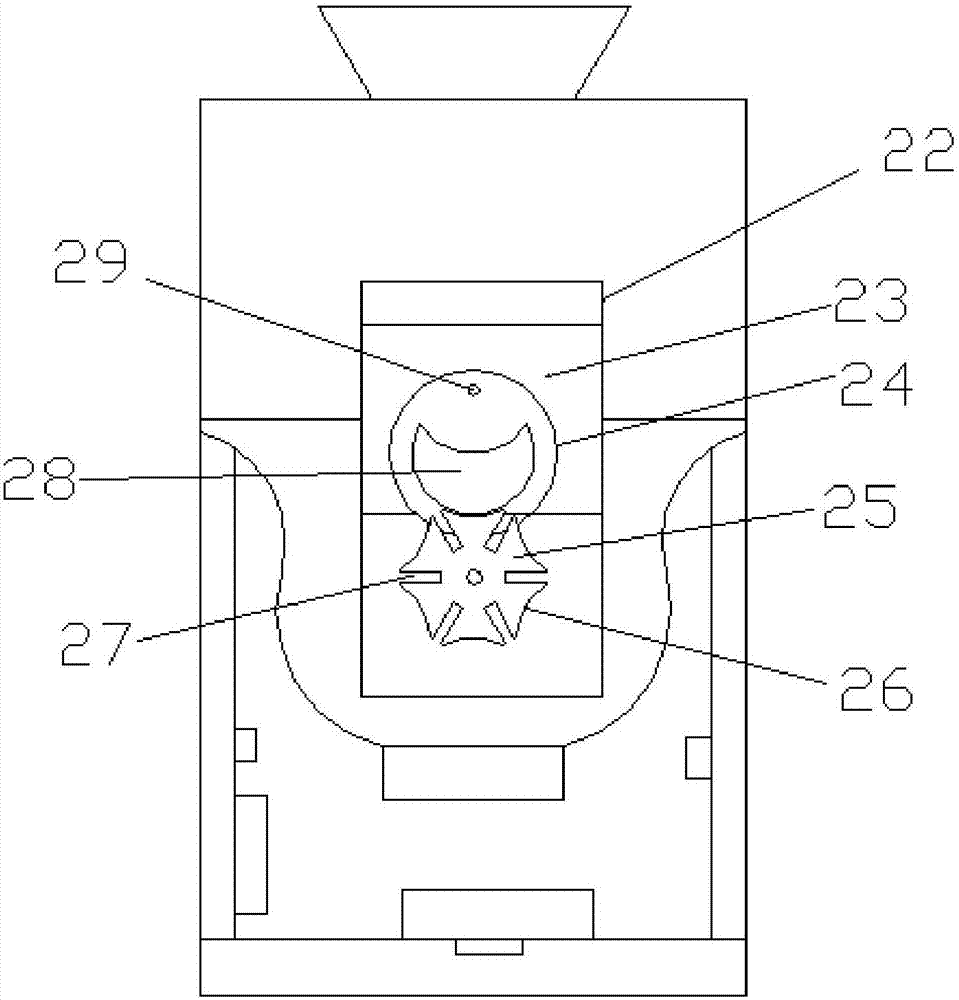

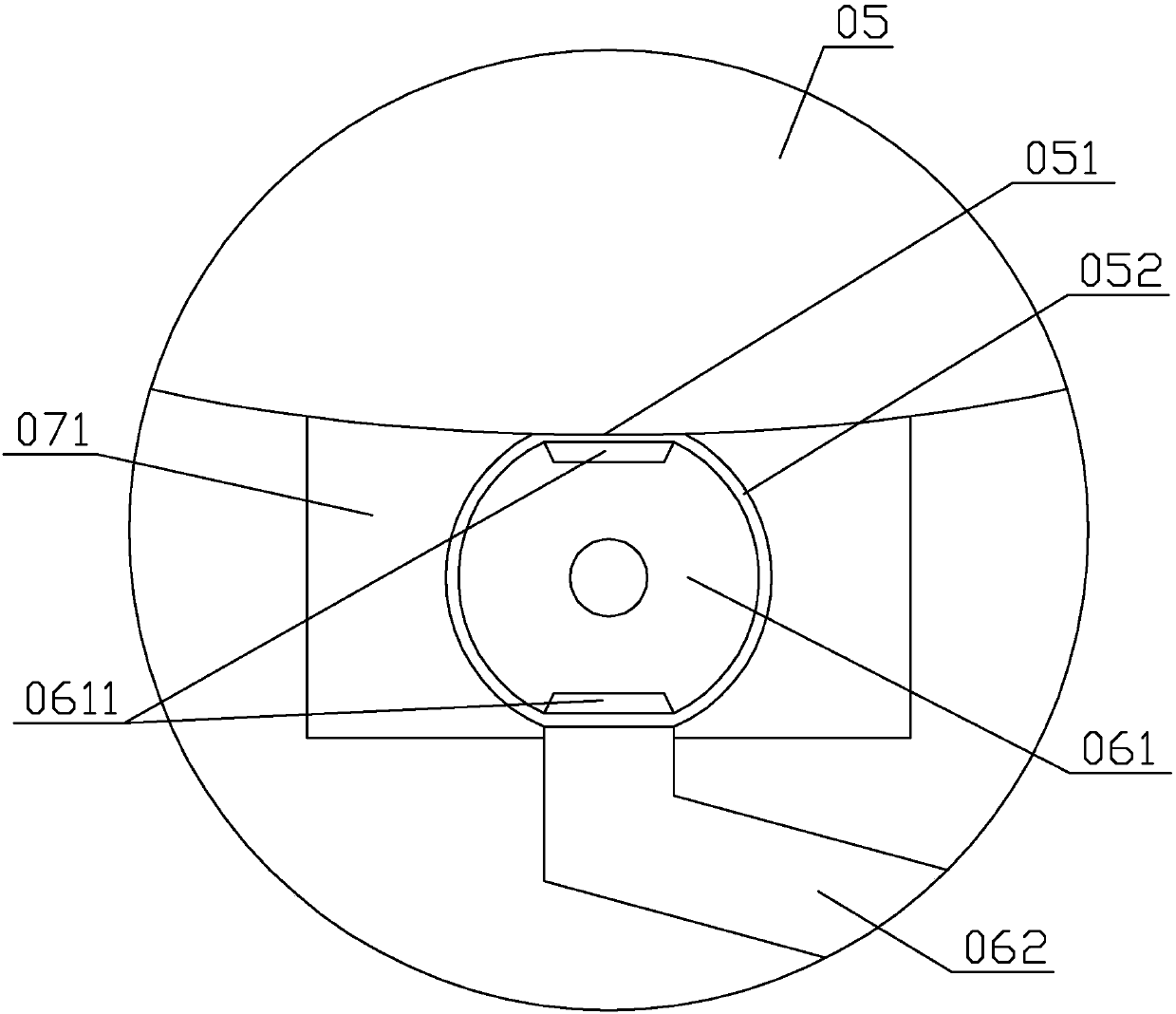

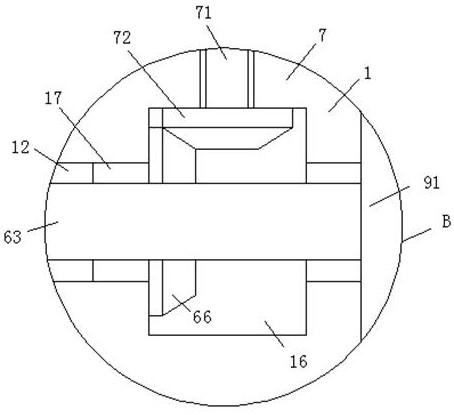

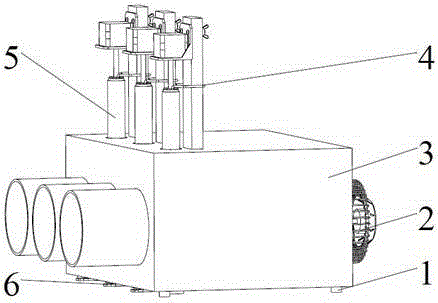

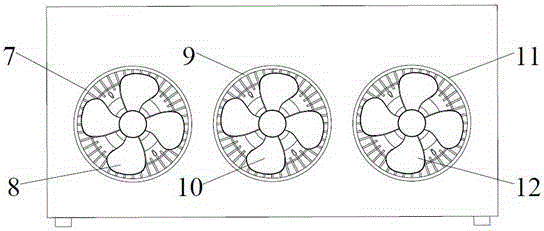

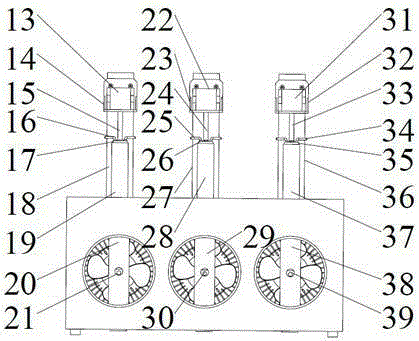

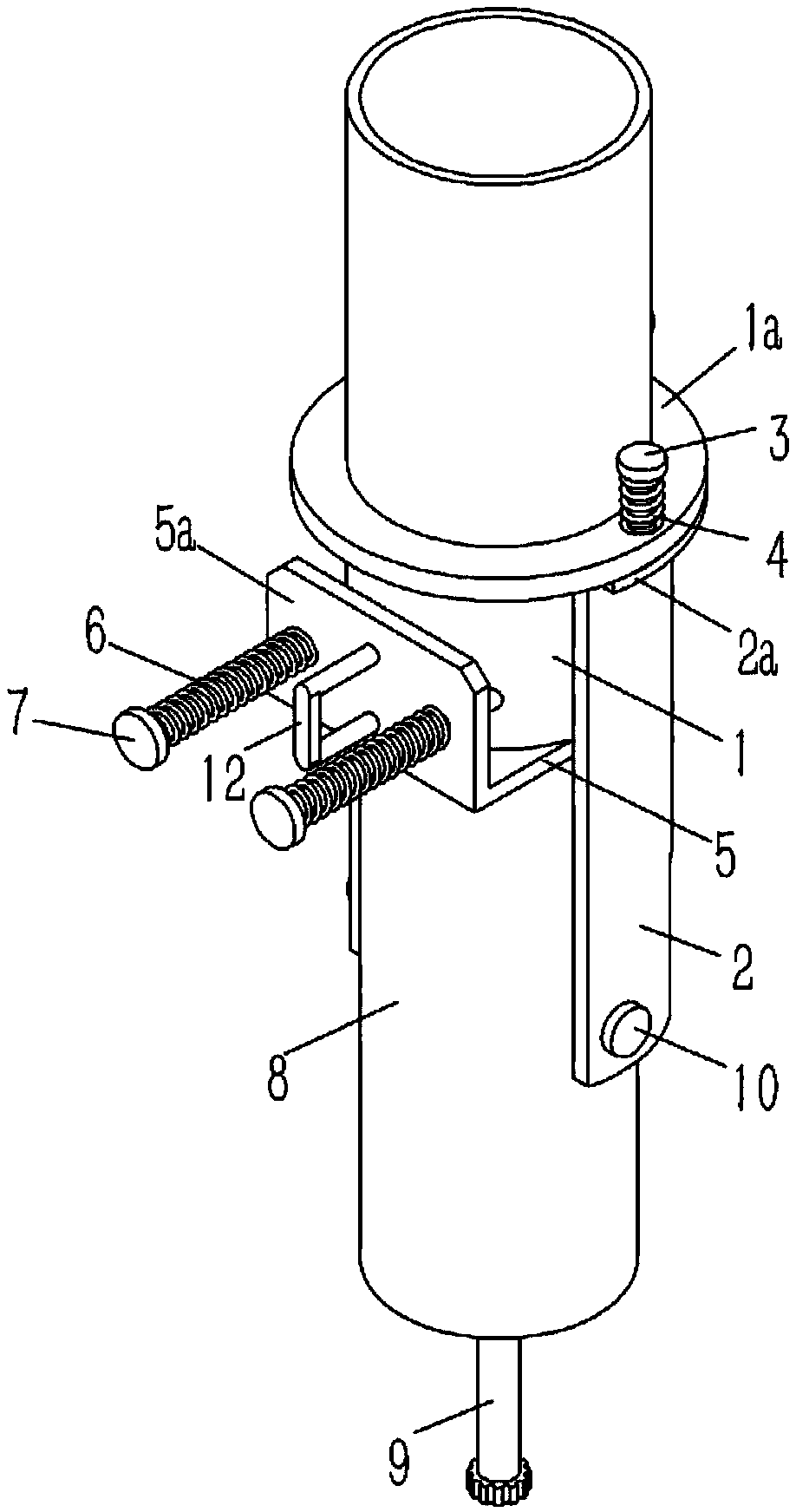

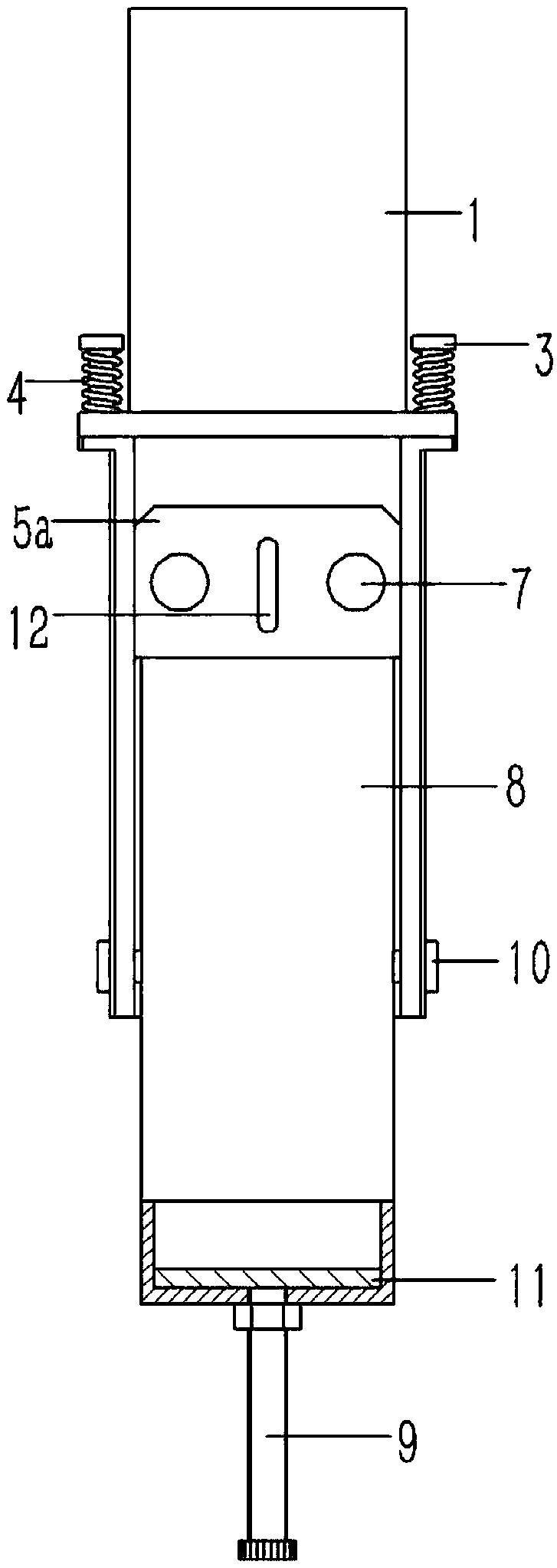

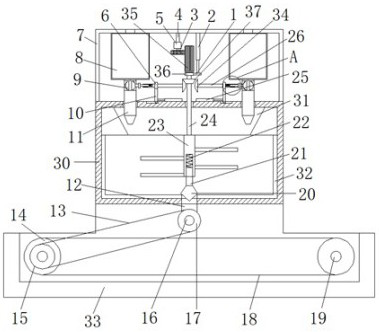

Virtual smell generation device driven by stepping motor

InactiveCN103926941ARealize quantitative outputAchieve directional outputFlow control using electric meansLinear motionEngineering

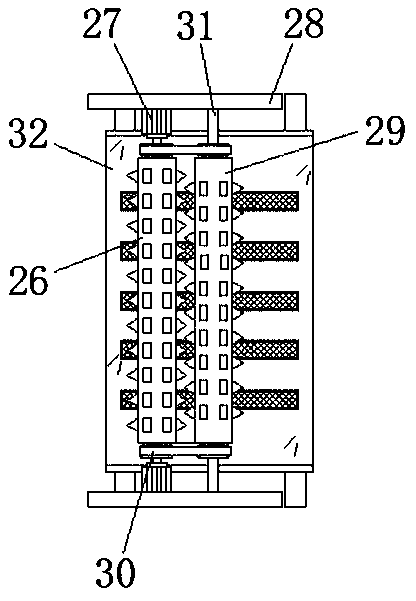

The invention discloses a virtual smell generation device driven by a stepping motor. The device comprises a directional air supply mechanism, a quantitative air discharge mechanism and a shell. The directional air supply mechanism and the quantitative air discharge mechanism are respectively installed on the shell. According to the quantitative air discharge mechanism, a lead screw is driven by the stepping motor to make linear motion, a perfume bottle is pressed, and then smells are sprayed quantitatively. According to the directional air supply mechanism, the smells are blown out along an air supply tube of the shell through rotation of a fan. According to the virtual smell generation device driven by the stepping motor, the lead screw is driven by the stepping motor to make linear motion, the perfume bottle is pressed, and then the smells can be quantitatively output; the smells can be directionally output through the directional air supply mechanism. Through the virtual smell generation device driven by the stepping motor, three smells can be generated and transmitted, and hardware support is provided for human-computer interaction of virtual reality olfactory perception.

Owner:ZHEJIANG SCI-TECH UNIV

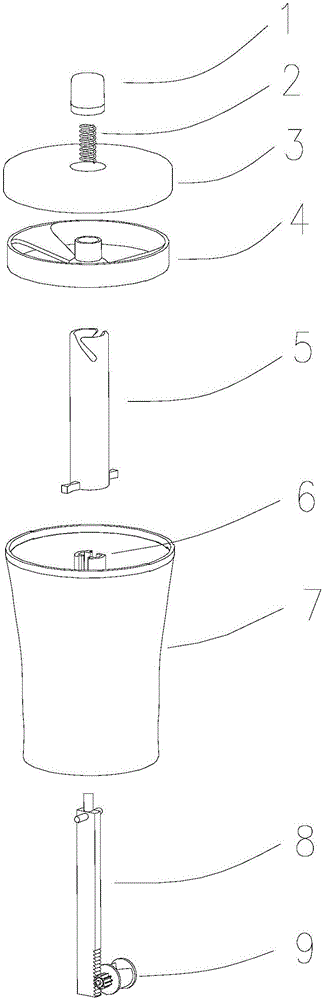

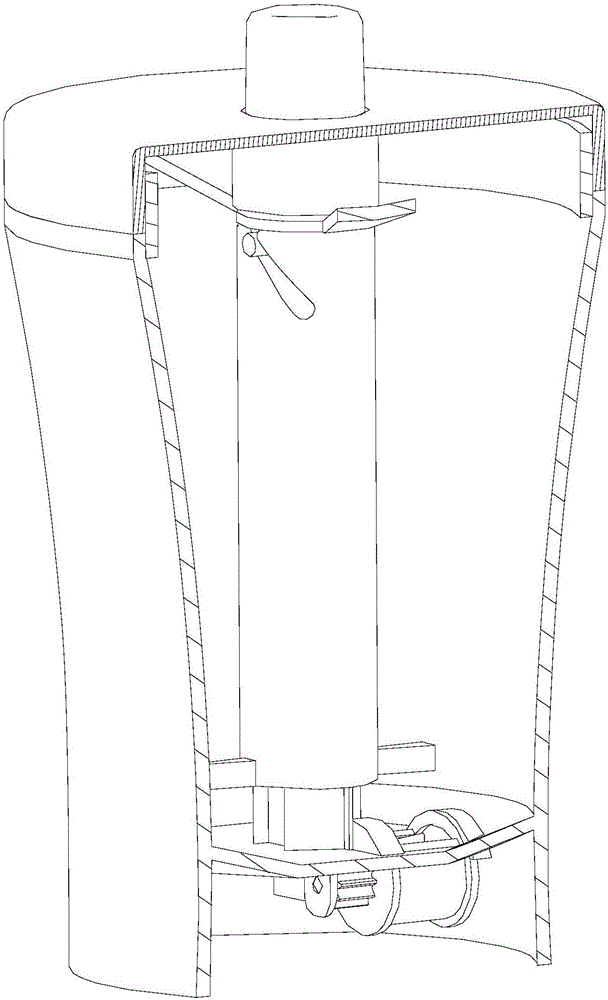

Quantitative feeding device for pets

InactiveCN107950415ACleverly structuredReasonable arrangementAnimal feeding devicesEngineeringCompanion animal

Owner:ZHENGZHOU YOUAI NETWORK TECH CO LTD

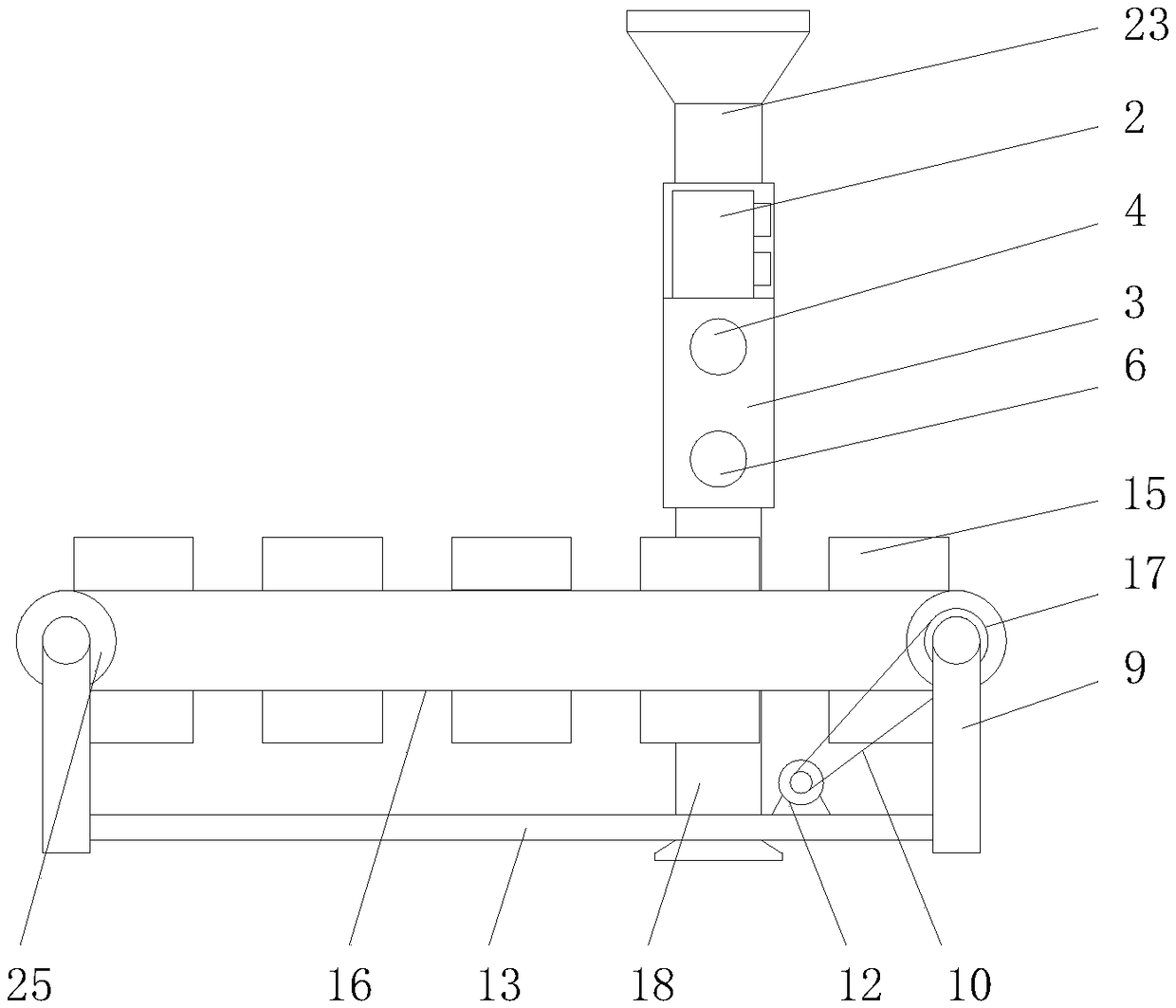

Multifunctional medicine box

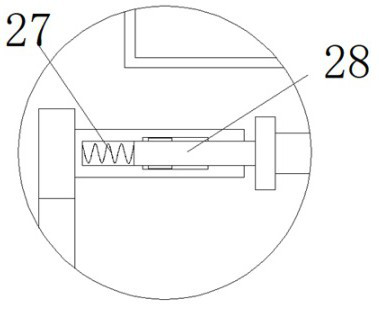

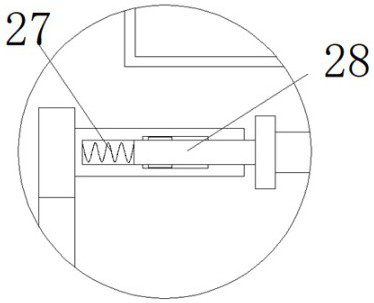

ActiveCN107854320AMeet storage needsRealize quantitative outputOral administration deviceDomestic articlesPharmaceutical SubstancesMechanical engineering

The invention discloses a multifunctional medicine box, comprising a refrigerating box for holding common medicines, a storage box operating at normal temperature, a sundries box for holding small instruments, a tablets storage box for holding tablets, and a tablets conveying and boxing mechanism for being used with the tablets storage box. A bottom medicine outlet of the tablets storage box discharges single tablets through a screening wheel, the tablets are passed by a conveying pipe and a receiving tray and are then loaded in a box body, and the box body conveys the tablets to the dischargeend via a conveyer belt so that a user can take and carry the tablets. Bulk tablets can be discharged for boxing to facilitate carrying out by a user; the whole process has no need for the user to contact the tables, and satiation is better accordingly; the tablets conveying and boxing mechanism allows tablets to be quantitatively discharged through the cooperation of the screening wheel and a servo motor, so that it is convenient to control the quantity of tablets to be carried or supplied; the tablets conveying and boxing mechanism may be matched with multiple tablets storage boxes so as torespectively box the various stored tablets; the multifunctional medicine box is convenient to use and suitable for use at home or in hospitals.

Owner:WENZHOU PEOPLES HOSPITAL

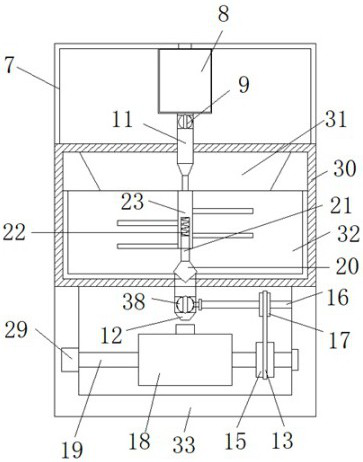

Processing device of honey tea

InactiveCN108813502AImprove the mixing effectAvoid cloggingRotary stirring mixersTransportation and packagingPulp and paper industryCam

The invention belongs to the technical field of honey processing equipment, and particularly discloses a processing device of honey tea. The device comprises a stirring bucket in which a revolving shaft is arranged, the upper part of the revolving shaft is provided with a first stirring rod, the middle of the stirring bucket is in sliding connection with a filter plate, which is provided with an annular sliding chute, the annular sliding chute is provided with two arc-shaped convex blocks which are provided with sliding cavities connected with the annular sliding chute, a cutting knife is fixed on the lower side of the first stirring rod, the lower end of the cutting knife is in sliding connection with the interior of the annular sliding chute, the lower part of the revolving shaft is in sliding connection with a circular ring on which two second stirring rods are fixed, a connecting rod is arranged between the circular ring and the filter plate, the lower surface of the stirring bucket is communicated with two discharging pipes, the lower ends of the discharging pipes are provided with pressure valves, two material pushing plugs are connected on a side wall of the stirring bucketin a sliding mode, the upper ends of the material pushing plugs are provided with elastic parts, and the lower ends of the stirring rods are provided with cams. According to the scheme, the filter plate and the second stirring rods are driven to go up and down to and fro, the stirring effect and efficiency are improved, and the quantitative discharging of honey is realized through the material pushing plugs.

Owner:桐梓县德毓蜂业发展有限公司

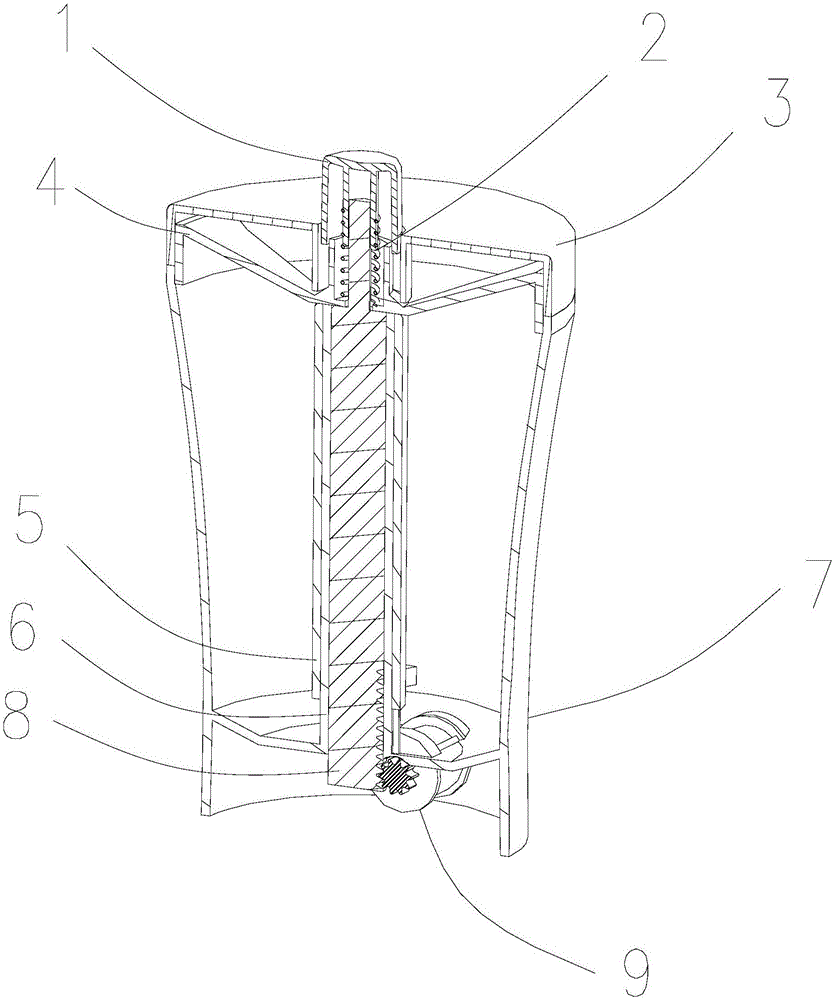

Tank realizing quantitative material discharging function

Owner:SHENZHEN DINGBIAO WOWO TECH CO LTD

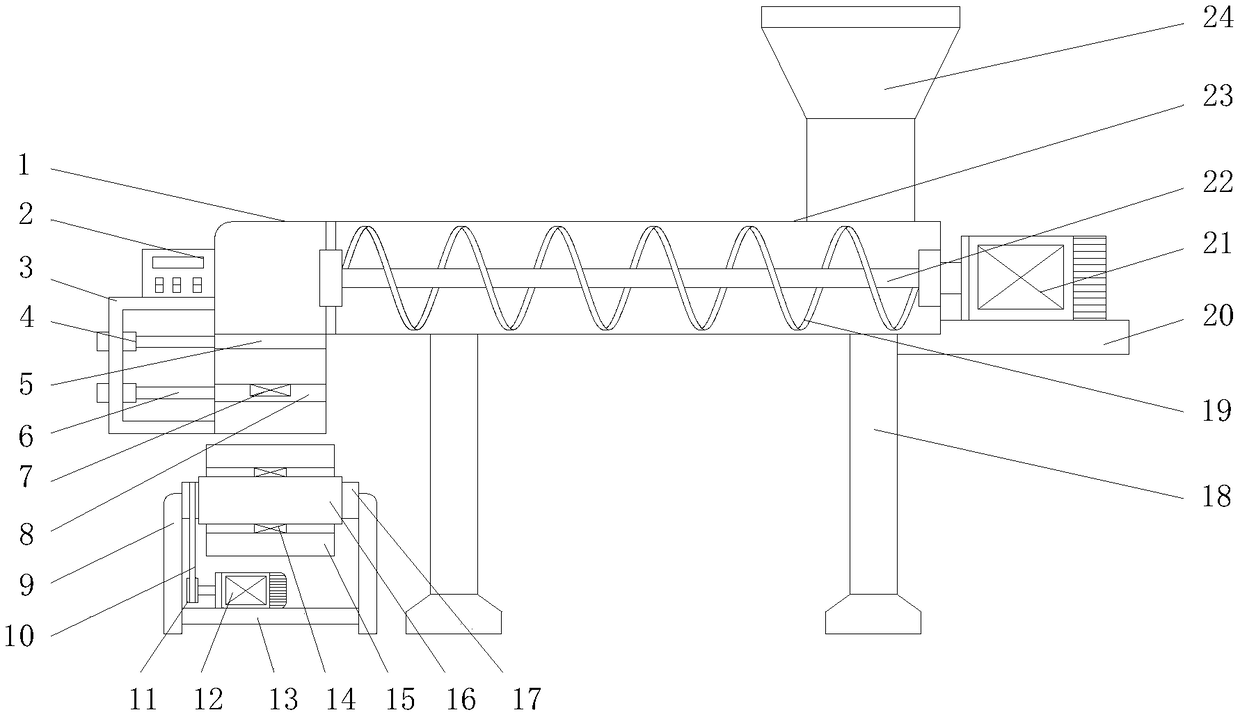

Material conveying device with metering function

InactiveCN109178805AGood practicalityHigh degree of mechanizationPackagingSpecial purpose weighing apparatusEngineeringMechanical engineering

The invention discloses a material conveying device with a metering function. The material conveying device comprises a first weighing sensor, a conveying belt and a second conveying barrel. A spiralshaft is mounted in the second conveying barrel. A spiral blade is mounted on the surface of the spiral shaft. A first conveying barrel is mounted on one side of the second conveying barrel. A first electric push rod is mounted on the inner side of a mounting rack. A second electric push rod is mounted at the position, below the first electric push rod, of the inner side of the mounting rack. A driving roller is mounted on the inner side of one supporting leg. A conveying belt is mounted on the surfaces of the driving roller and a driven roller. Material containing trays are mounted on the surface of the conveying belt, and second weighing sensors are mounted in the material containing trays. According to the material conveying device, through the arrangement of the structures of a motor,the spiral blade, the first electric push rod, the second electric push rod, the first weighing sensor, a servo motor, the material containing trays, the second weighing sensors and the conveying belt, the problems that quantitative discharging and automatic conveying cannot be achieved are solved.

Owner:芜湖佩林郁松计量科技有限公司

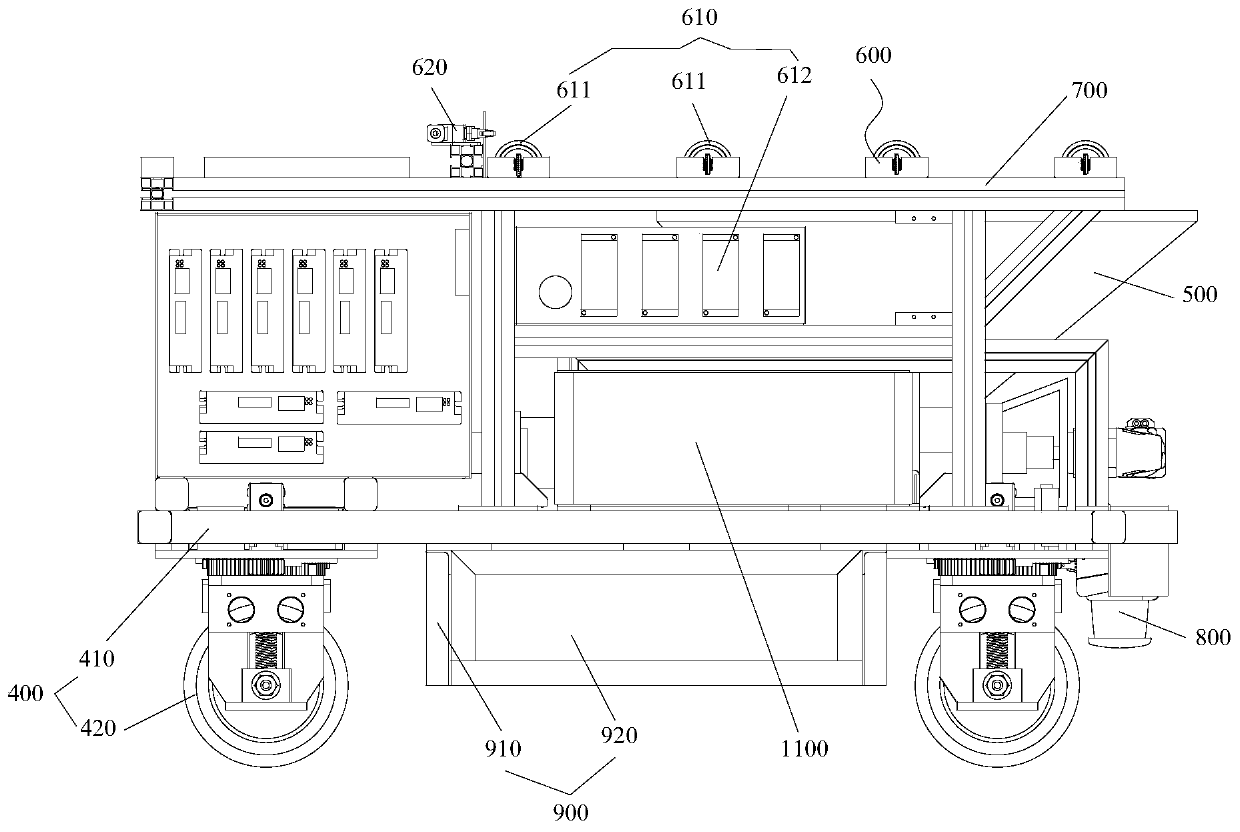

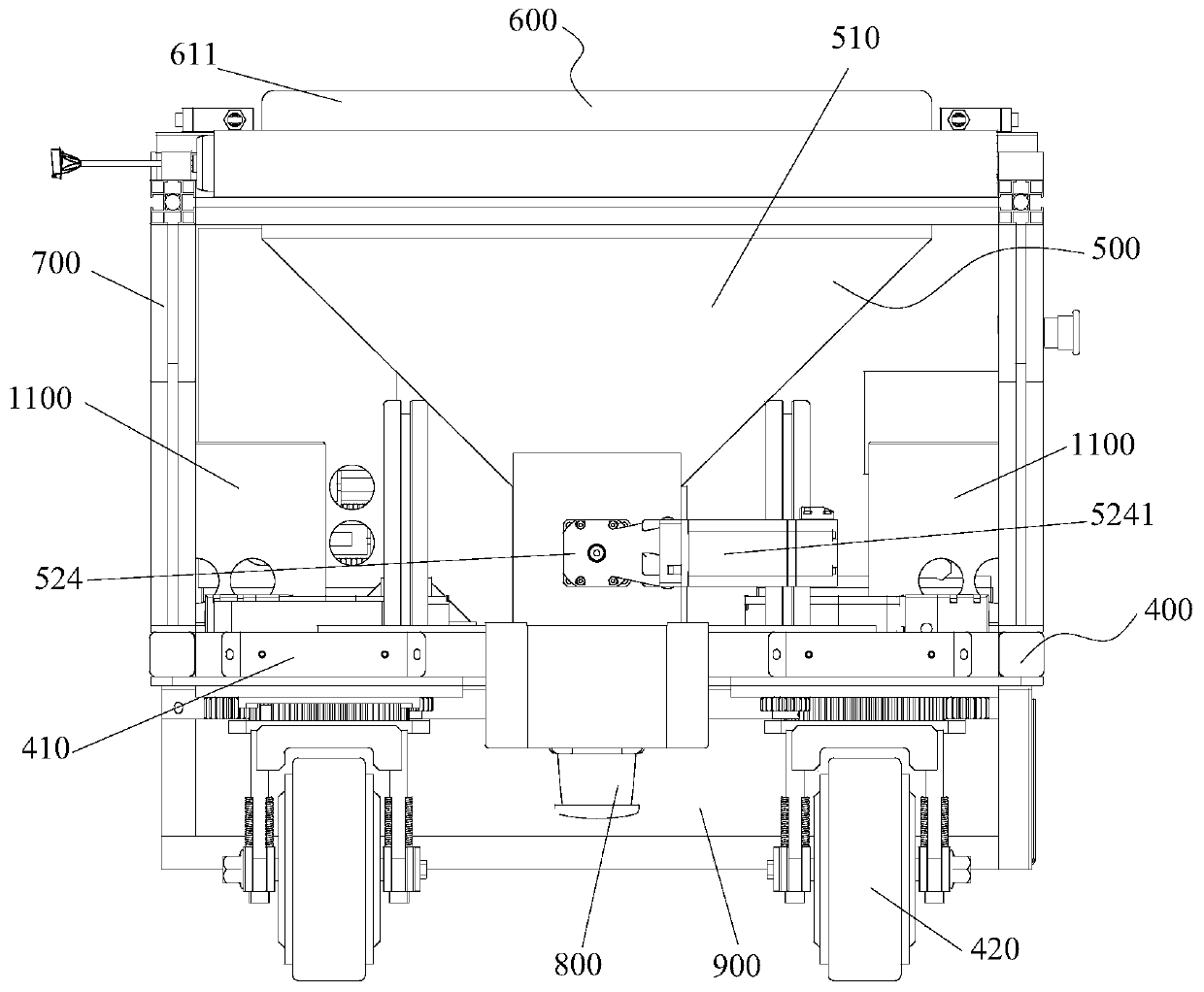

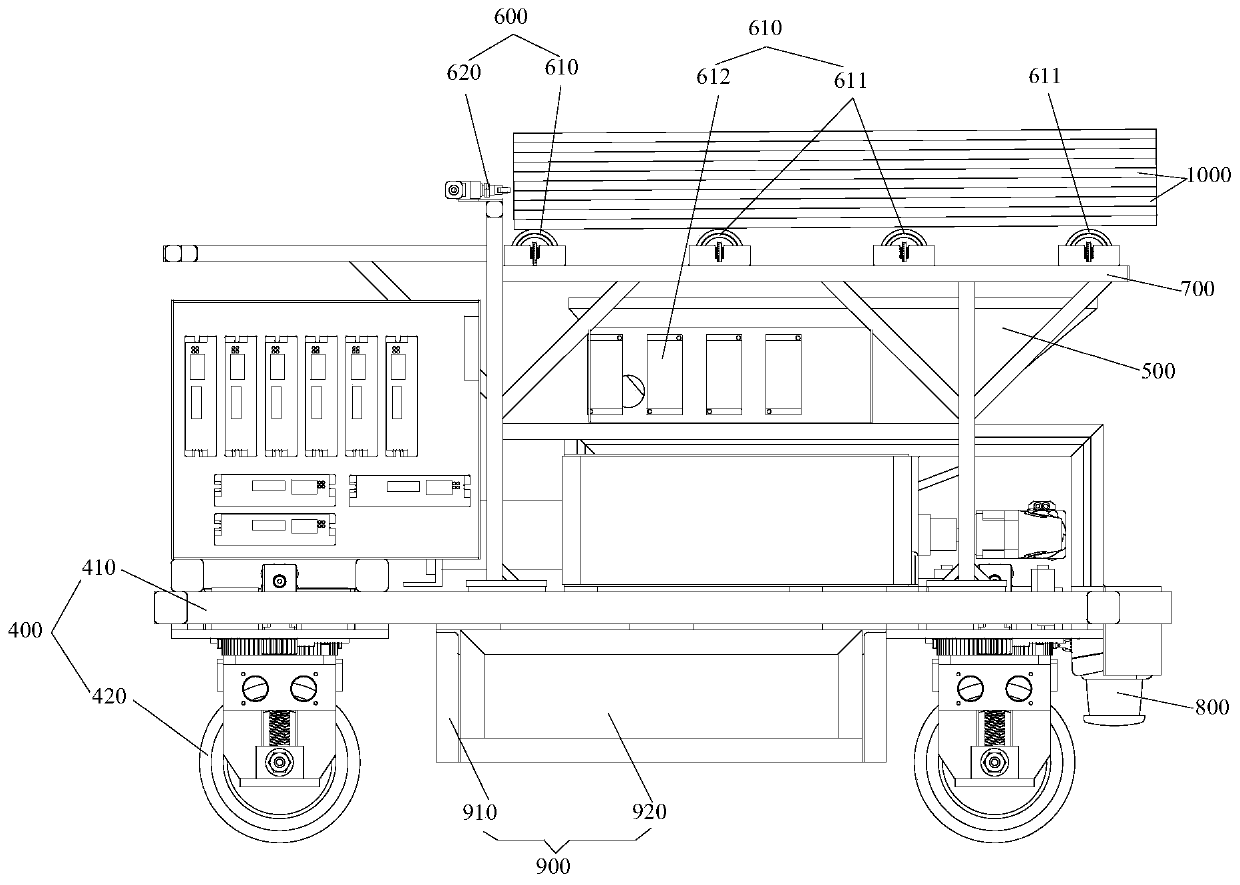

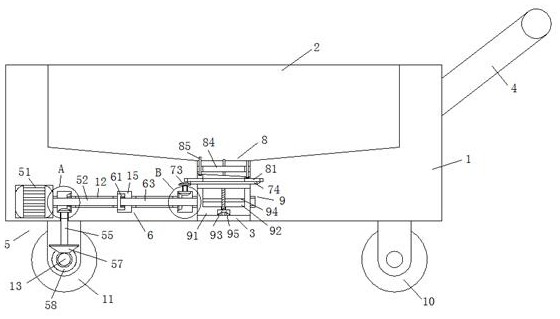

Material conveying device and floor tile paving and pasting system with device

InactiveCN110388031ARealize loading operationRealize transportationBuilding constructionsVehiclesSteering wheelUltimate tensile strength

The invention provides a material conveying device and a floor tile paving and pasting system with the device. The material conveying device comprises a vehicle body assembly, and a semi-fluid material conveying device, the vehicle body assembly comprises a vehicle body and multiple steering wheels arranged on the vehicle body, the semi-fluid material conveying device is arranged on the vehicle body and comprises a storage structure and a feeding assembly, the feeding assembly comprises a screw rod and a screw rod pump, the screw rod conveys semi-fluid material in the storage structure into the screw rod pump, and the screw rod pump outputs the semi-fluid material according to the preset output amount. The problems that in the prior art, the semi-fluid material conveying efficiency is low,and the labor intensity of workers is increased are solved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

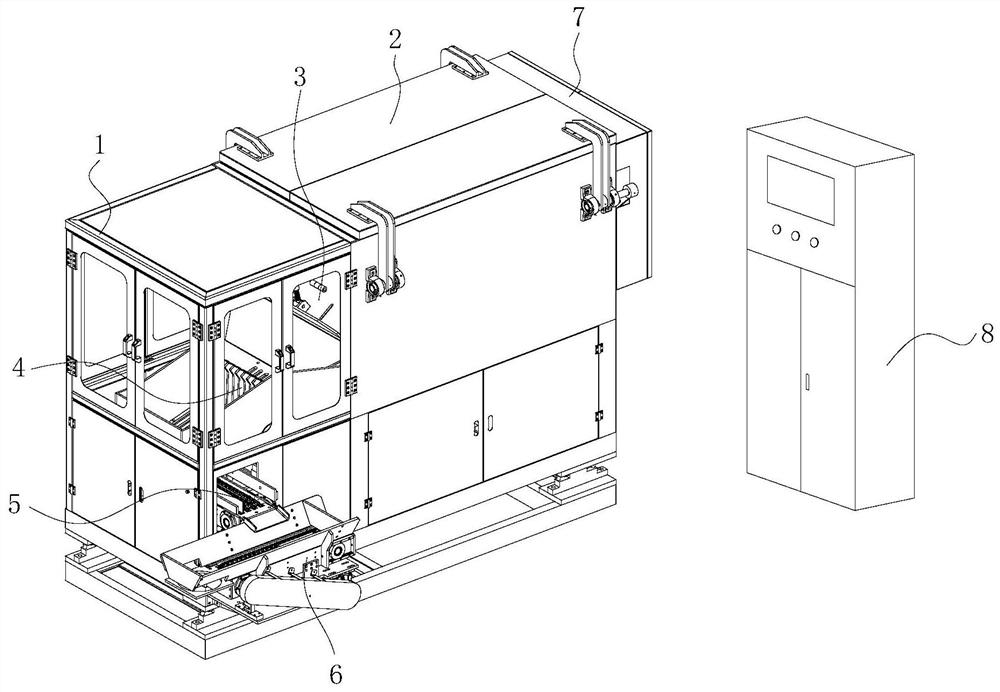

Aerated concrete production and processing system

InactiveCN112123583AStir wellIncrease productivityCement mixing apparatusEngineeringStructural engineering

The invention relates to the field of concrete preparation, and particularly relates to an aerated concrete production and processing system. The aerated concrete production and processing system comprises a stirring tank, a main shaft and an auxiliary shaft, wherein first grooves of cylindrical structures are symmetrically formed in the stirring tank; second grooves of arc-shaped structures are formed between the first grooves; the first grooves communicate with the second grooves separately; the main shaft and the auxiliary shaft are inserted into the first grooves separately; one end of themain shaft penetrates through the first grooves and the second grooves to make contact with one end of the auxiliary shaft; a rotating shaft is fixedly installed at the end, making contact with the auxiliary shaft, of the main shaft; an inserting groove is formed in the end, making contact with the main shaft, of the auxiliary shaft; the rotating shaft and the inserting groove are correspondinglyformed and inserted; and a plurality of connecting rods are fixedly installed on the main shaft and the auxiliary shaft separately, and alternately arranged separately. The aerated concrete production and processing system can be used for uniformly stirring concrete, so that steam is fully mixed with the concrete, and the aerated concrete production and processing system is suitable for popularization.

Owner:杭州天佳建材科技有限公司

Kitchen waste comprehensive treatment production device

InactiveCN110940153AEasy to separateRotation is not affectedDrying solid materials without heatDrying machines with local agitationDrive motorPollutant

The invention discloses a kitchen waste comprehensive treatment production device which comprises an outer shell, a first drive motor, an electric telescopic rod, a second drive motor and a heater. Support plates are welded to the surfaces of the left end and the right end of the outer shell. The upper surface of the outer shell is connected with a feeding pipe. The outer surface of a cross rod isconnected with a lantern ring. A crushing box communicating with a connecting pipe is arranged on the right side of the outer shell. An inner plate with the middle position of an open structure is arranged below a crushing plate. A second crushing roller is arranged on the right side of a first crushing roller. A conveying belt is arranged below the second crushing roller. The right end of the crushing box communicates with a drying box. A second collection box is arranged at the bottom end in the drying box. According to the kitchen waste comprehensive treatment production device, quantitative discharging can be achieved, when waste is fed and conveyed into the crushing box, attached and left waste can be vibrated to fall off, and meanwhile newly-generated liquid pollutants can be separated conveniently after crushing.

Owner:新乡市中天星火机械有限公司

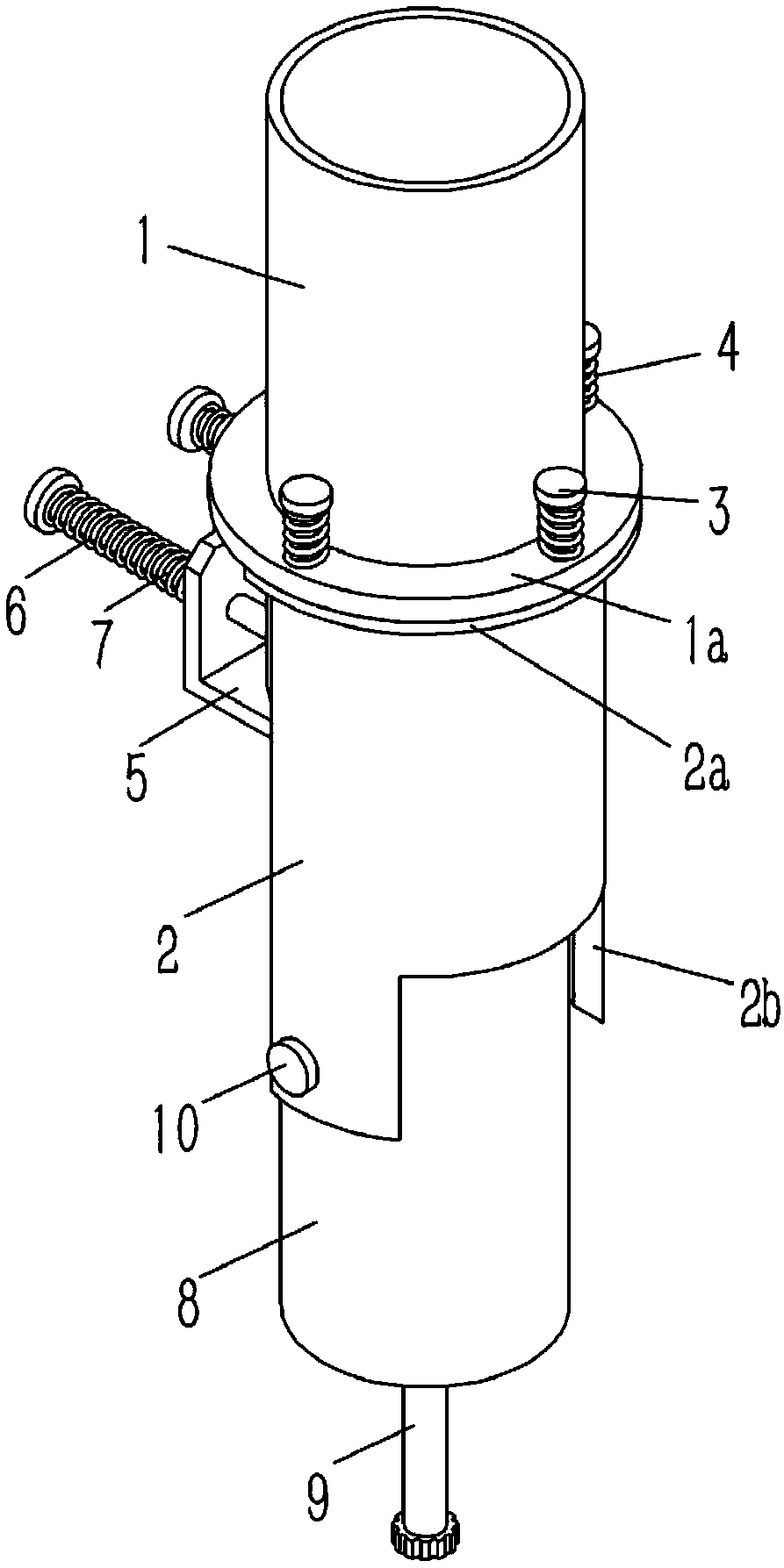

Plastic pipe cutting machine

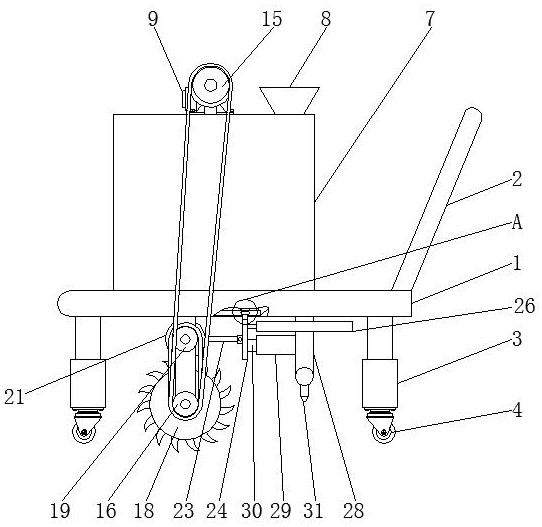

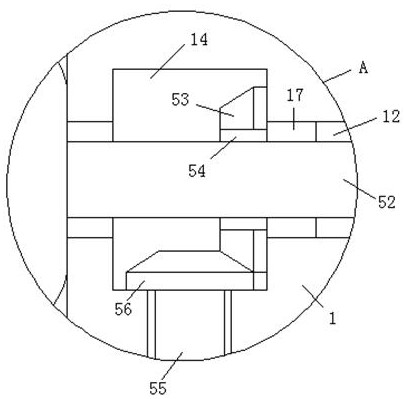

ActiveCN108177188ARealize quantitative outputPlay a limiting roleMetal working apparatusElectric machineryEngineering

The invention discloses a plastic pipe cutting machine comprising a machine seat and a cutting knife. The machine seat is provided with a material box for discharging plastic pipes intermittently anda machining mechanism for cutting the material pipes, and first motors are symmetrically arranged on the two sides of the material box. The machining mechanism comprises a rotary disc and a guiding table, a storing table is arranged on the rotary disc, and a knife groove is formed in the storing table and communicates with a storing groove. A through hole is formed in the bottom of the storing table, a negative pressure chamber is formed in the rotary disc and internally slidably connected with a negative pressure block, and a third spring is arranged between the negative pressure block and the negative pressure chamber. A discharging outlet communicating with the negative pressure chamber is formed in the machine seat, a third rack and a friction arm are slidably connected to the guidingtable, and a fourth spring is arranged between the third rack and the guiding table. A second motor is arranged on the third rack, and a fan gear is arranged on each first motor. According to the scheme of the plastic pipe cutting machine, the problem that as for a current plastic pipe cutting mode, powdered scraps are inconvenient to collect is solved mainly.

Owner:宁波鑫神泽汽车零部件有限公司

Heavy metal polluted soil improvement and remediation device for ecological remediation of mining areas

InactiveCN113068466APrevent crystallizationMeet needsSpadesTilling equipmentsManufacturing cost reductionDrive wheel

The invention discloses a heavy metal contaminated soil improvement and remediation device for ecological remediation of mining areas. The heavy metal contaminated soil improvement and remediation device comprises a bottom plate, a driving wheel, a first belt pulley and a nozzle. A push handle is fixed to the bottom plate, an automatic telescopic rod is fixed to the bottom plate, universal wheels are fixed at the lower end of the automatic telescopic rod, and a transverse plate is fixed to the automatic telescopic rod. A water pipe is connected with a cylinder, the water pipe is connected with a liquid mixing box, a piston is arranged in the cylinder, and the nozzle is connected with the water pipe. According to the heavy metal contaminated soil improvement and remediation device for ecological remediation of the mining areas, a liftable plowing device is adopted, the height of a plowing roller can be adjusted, then the plowing effect of different depths is achieved, and the actual requirement is met; the continuous stirring effect on mixing is achieved through a stirring mechanism, crystallization of mixed liquid is avoided, and the effects of quantitative discharging and automatic spraying are achieved by matching with a linkage rotating mechanism; and the heavy metal contaminated soil improvement and remediation device is compact in structure, multiple functions are achieved through a single power source, and therefore the manufacturing cost is reduced.

Owner:鄂尔多斯应用技术学院

Dry-mixed pretreatment cement mortar stirring device

PendingCN113799257AQuality improvementAvoid spillingSievingDischarging apparatusProcess engineeringPre treatment

The invention discloses a dry-mixed pretreatment cement mortar stirring device, and belongs to the technical field of constructional engineering. The dry-mixed pretreatment cement mortar stirring device comprises a base, the base further comprises a base frame, the base frame is located at the top end of the base and fixed to the side wall of the top end of the base, a stirring barrel is fixed to the inner side wall of the base frame, the side wall of the top end of the stirring barrel is rotationally connected with a rotating rod, and the outer side wall of the rotating rod is fixedly sleeved with stirring blades. Mud sand is screened and fed through a screening and discharging assembly, stones and cakes contained in the mud sand can be separated out, meanwhile, discharging can be conducted more quickly, blocking is not likely to happen, the quality of the dry-mixed mud sand is improved, the workload of stirring blades is reduced, the service life of the stirring device is prolonged, quantitative discharging is conducted on a discharging pipe through a quantitative discharging assembly, slow overflowing cannot be caused when a material collecting box conducts material collecting again, mud sand pouring waste is avoided, meanwhile, workers can conveniently conduct material collecting control according to construction requirements, the cost is saved, and the processing efficiency is improved.

Owner:江苏铨旺建材科技有限公司

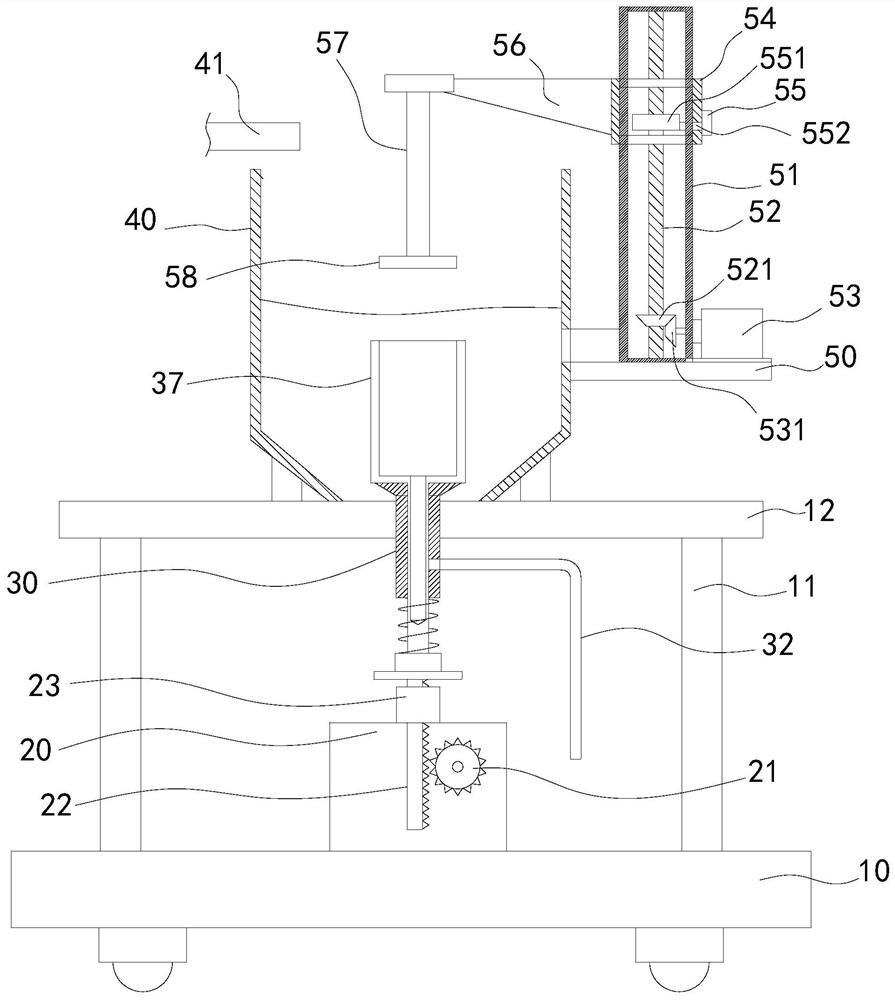

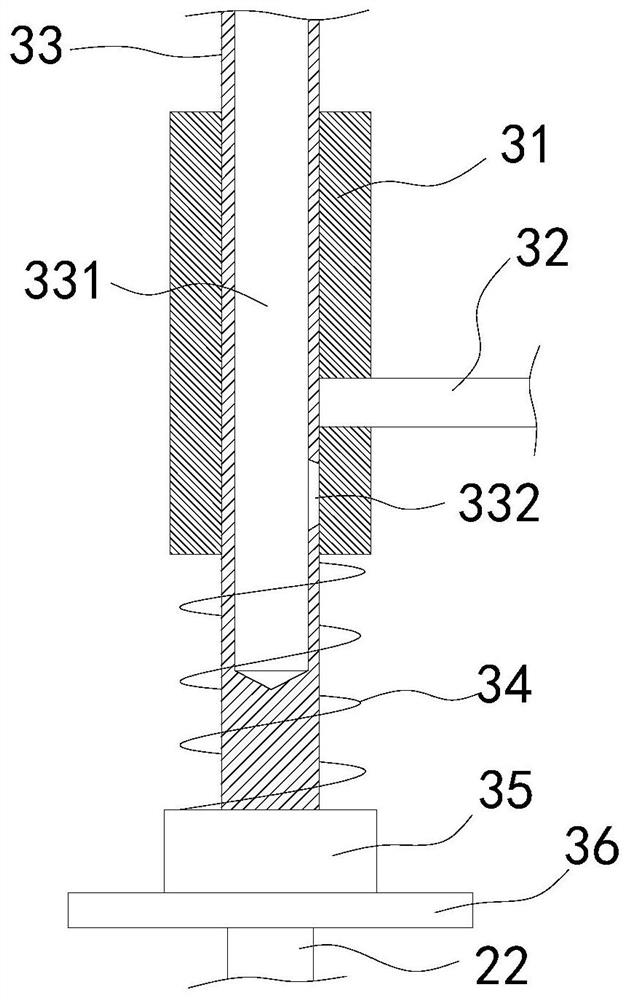

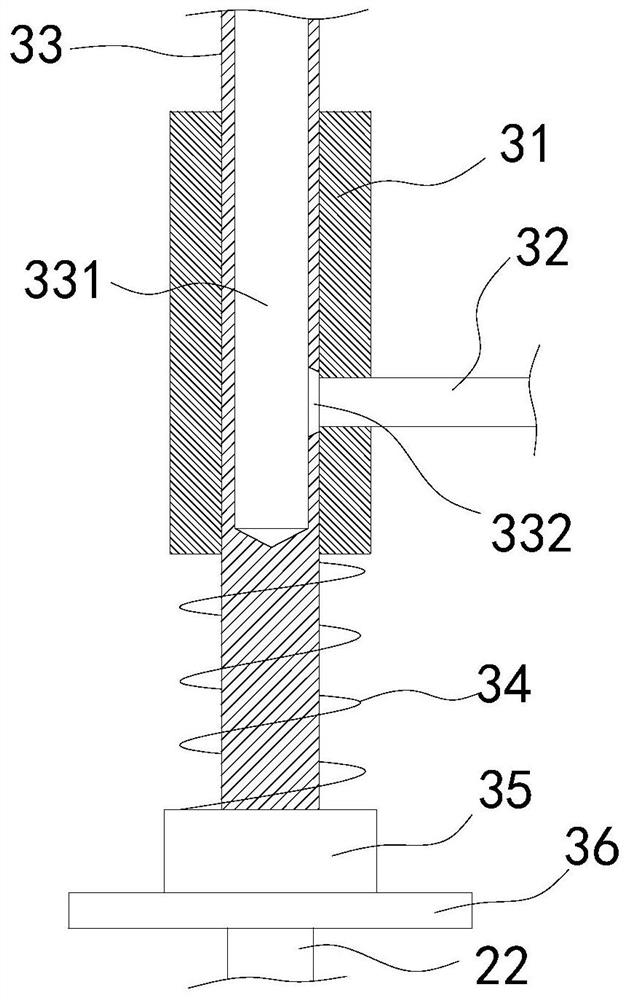

Quantitative discharging device for sodium silicate solution on intelligent production line

ActiveCN111731535ARealize quantitative outputControl the output speedLiquid materialThermodynamicsLiquid state

The invention discloses a quantitative discharging device for a sodium silicate solution on an intelligent production line. The device comprises a movable base, a discharging mechanism and a driving mechanism. Supporting rods are arranged on the movable base, the top ends of the supporting rods are provided with a workbench, the middle of the workbench is provided with a liquid storage tank, and aliquid inlet pipe is arranged above the liquid storage tank. The discharging mechanism is arranged in the middle of the liquid storage tank and comprises a fixing pipe arranged in the center of the bottom of the liquid storage tank, the fixing pipe is arranged on the workbench in an embedded manner, a liquid outlet pipe communicates with the outer wall of the fixing pipe, a movable rod verticallypenetrates through the interior of the fixing pipe, and the top end of the movable rod is provided with a liquid inlet cylinder. The driving mechanism is arranged below a connection plate. Compared with the prior art, the quantitative discharging device can achieve quantitative discharging of liquid sodium silicate by arranging the discharging mechanism and can also control the discharging speed.

Owner:桐乡市恒立化工股份有限公司

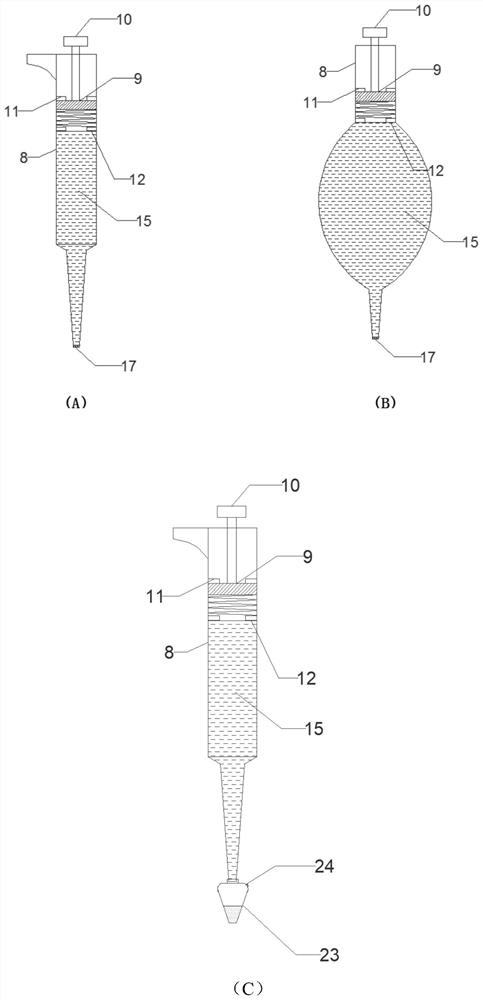

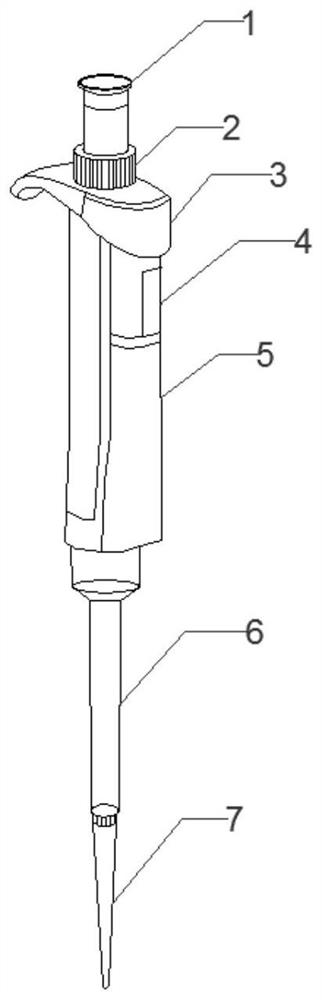

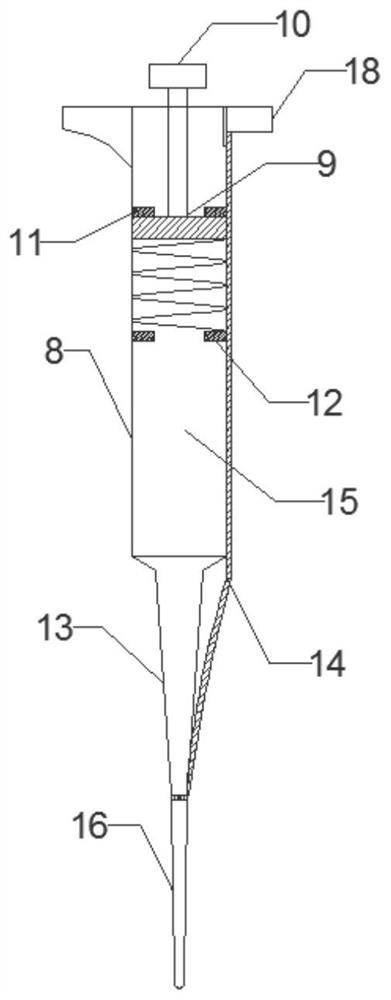

Freeze-drying preparation based on quantitative pipetting device

The invention provides a freeze-drying preparation based on a quantitative pipetting device. The freeze-drying preparation comprises the quantitative pipetting device capable of quantitatively sucking and discharging a dissolving solution, or a packaging device for packaging the freeze-drying preparation, the dissolving solution is packaged in the quantitative pipetting device, or independently packaged in a packaging product, or separately packaged with the freeze-drying preparation in the packaging device. The freeze-drying preparation can be dissolved by using the quantitative dissolving solution, the operation is convenient and fast, and the use effect of the freeze-drying preparation is optimized.

Owner:常州柚盾实业投资有限公司

Garden ecological nursery stock planting and fertilizing device

InactiveCN112470645AEasy to plant and fertilizeAvoid more strenuous implementationFertiliser distributersAgricultural scienceSteering wheel

The invention relates to the field of garden planting, in particular to a garden ecological nursery stock planting and fertilizing device. The garden ecological nursery stock planting and fertilizingdevice comprises a cart frame, a discharging hole, a driving mechanism, a first transmission mechanism, a second transmission mechanism, a material ramming mechanism, a feeding mechanism, a steering wheel and a driving wheel, a material cavity is formed in the upper end of the cart frame, the discharging hole is formed in the center of the lower end of the material cavity, the material ramming mechanism and the feeding mechanism are both arranged in the discharging hole, the material ramming mechanism is arranged at the upper end of the discharging hole, and the feeding mechanism is arranged below the material ramming mechanism. By rotating a rotating plate of the feeding mechanism, a threaded rod can be driven to rotate, and therefore a quantitative sliding plate slides in a quantitativecavity, the internal volume of the quantitative cavity is finally changed, quantitative discharging of fertilizer can be achieved, the discharging amount of the fertilizer can be freely controlled according to the amount of the fertilizer needed by nursery stocks, and the situations of fertilizer waste and poor nursery stock growth caused by insufficient fertilizer are avoided. and poor growth ofthe nursery stock caused by insufficient fertilizer is avoided.

Owner:赵云

Stepping motor driven virtual olfactory smell generation device

InactiveCN103926941BRealize quantitative outputAchieve directional outputFlow control using electric meansLinear motionEngineering

The invention discloses a virtual smell generation device driven by a stepping motor. The device comprises a directional air supply mechanism, a quantitative air discharge mechanism and a shell. The directional air supply mechanism and the quantitative air discharge mechanism are respectively installed on the shell. According to the quantitative air discharge mechanism, a lead screw is driven by the stepping motor to make linear motion, a perfume bottle is pressed, and then smells are sprayed quantitatively. According to the directional air supply mechanism, the smells are blown out along an air supply tube of the shell through rotation of a fan. According to the virtual smell generation device driven by the stepping motor, the lead screw is driven by the stepping motor to make linear motion, the perfume bottle is pressed, and then the smells can be quantitatively output; the smells can be directionally output through the directional air supply mechanism. Through the virtual smell generation device driven by the stepping motor, three smells can be generated and transmitted, and hardware support is provided for human-computer interaction of virtual reality olfactory perception.

Owner:ZHEJIANG SCI-TECH UNIV

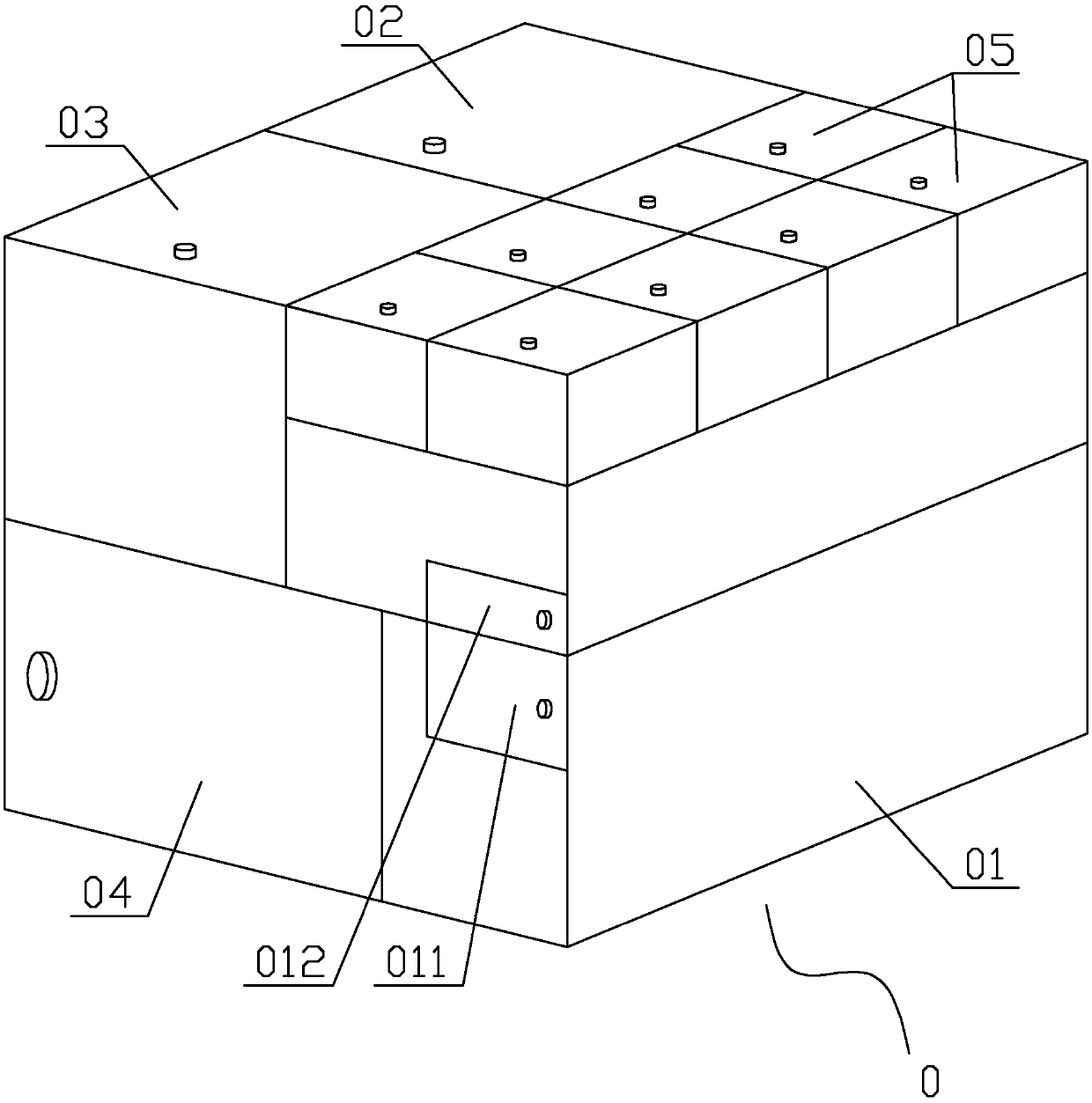

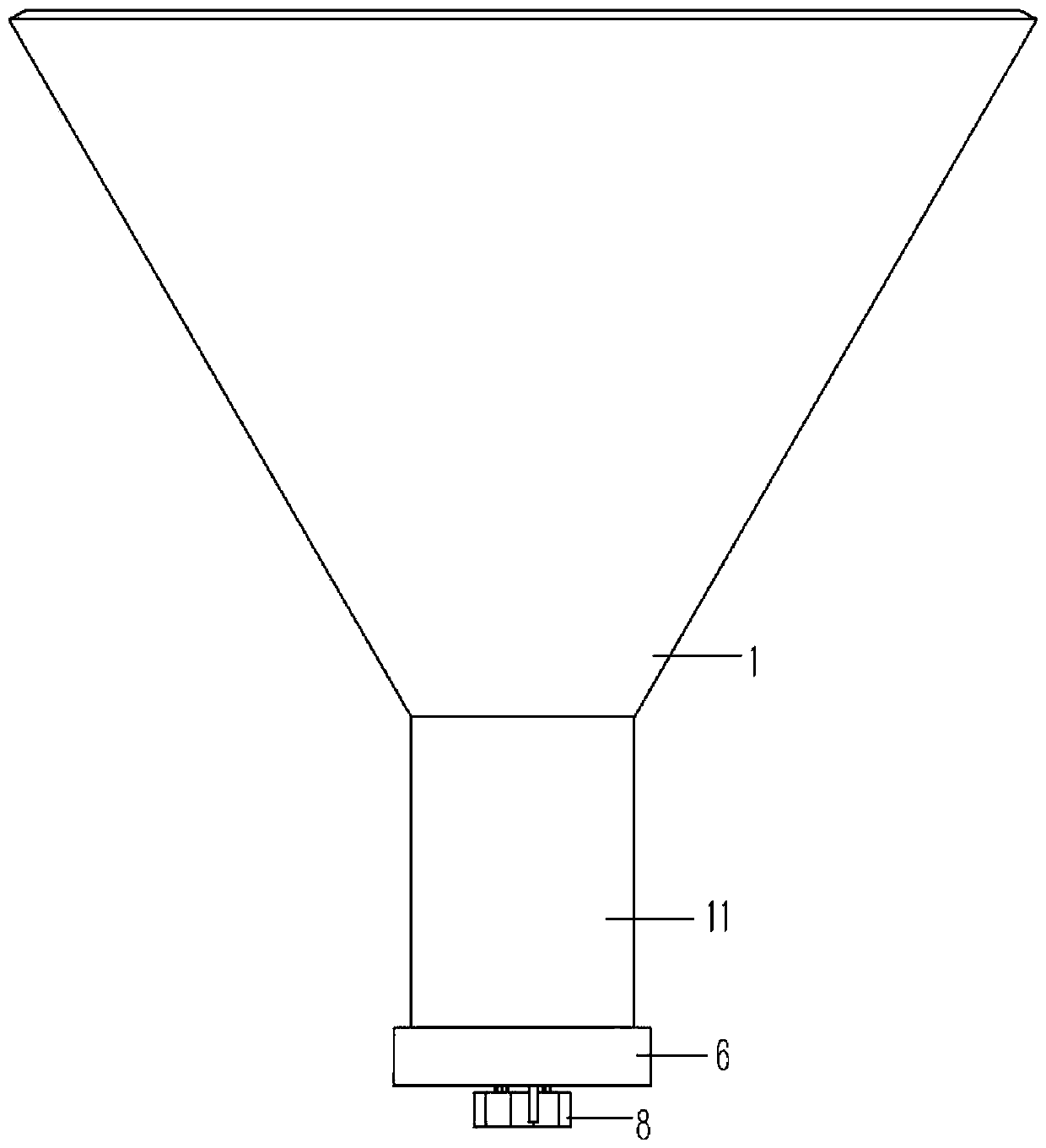

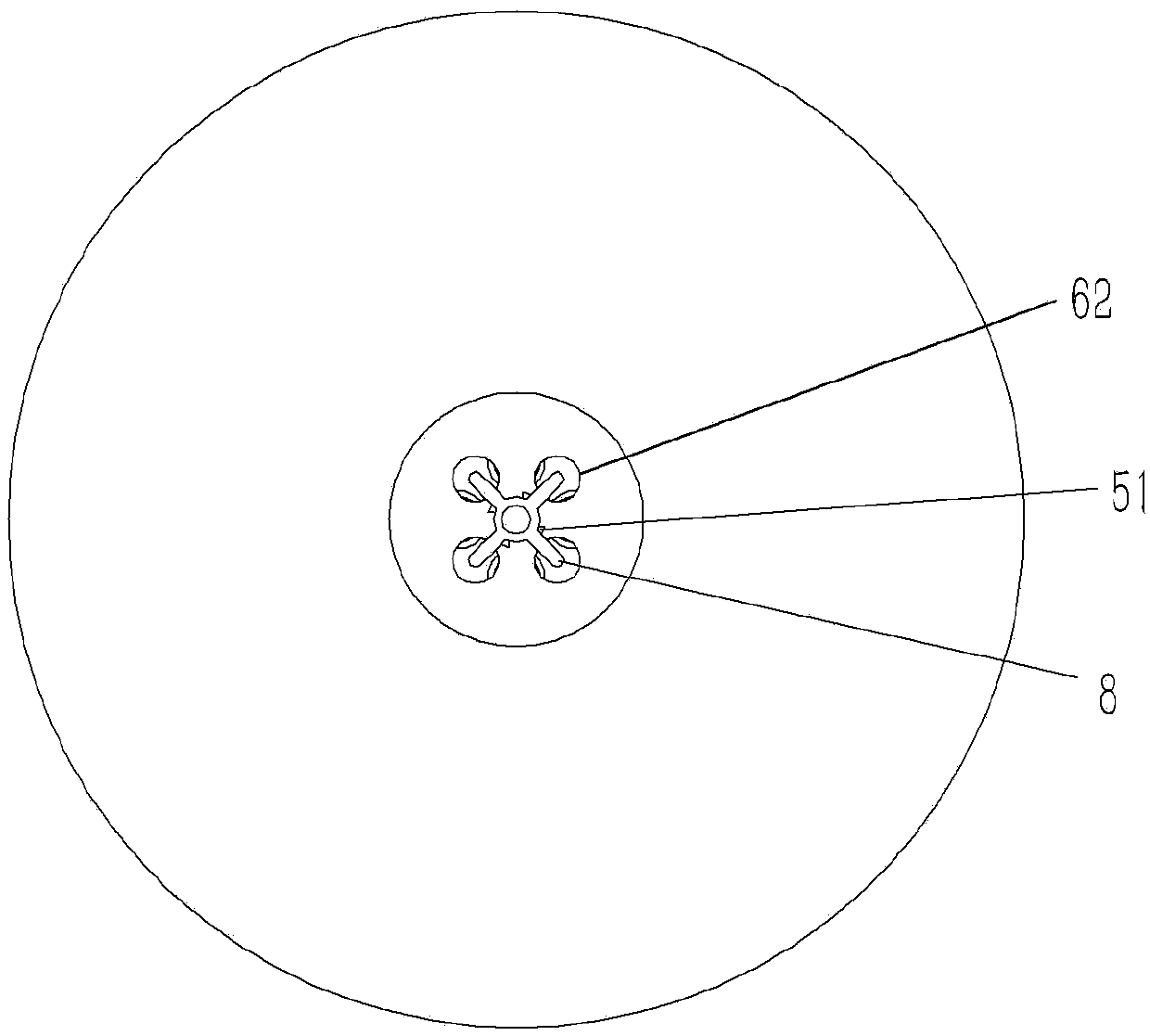

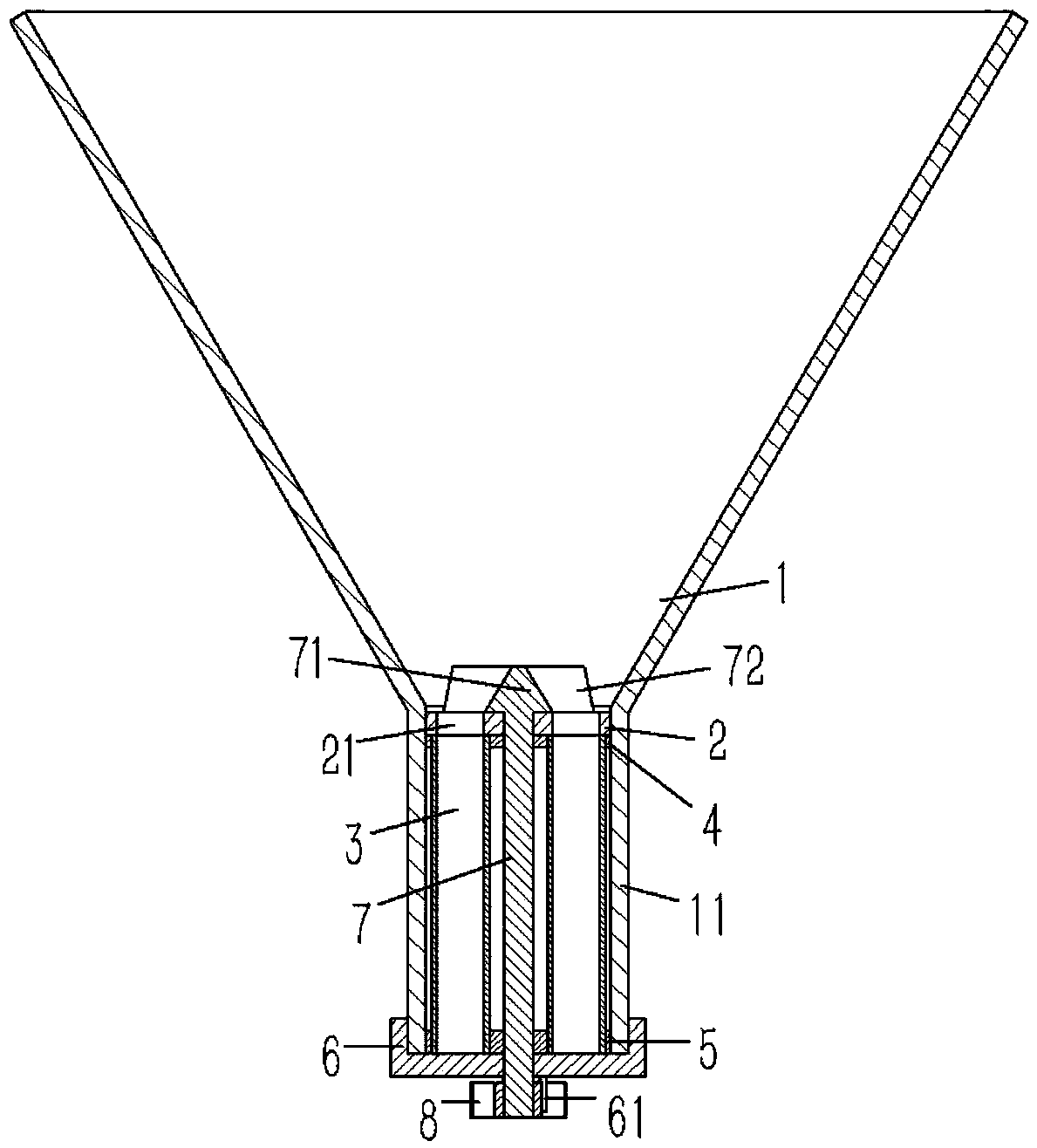

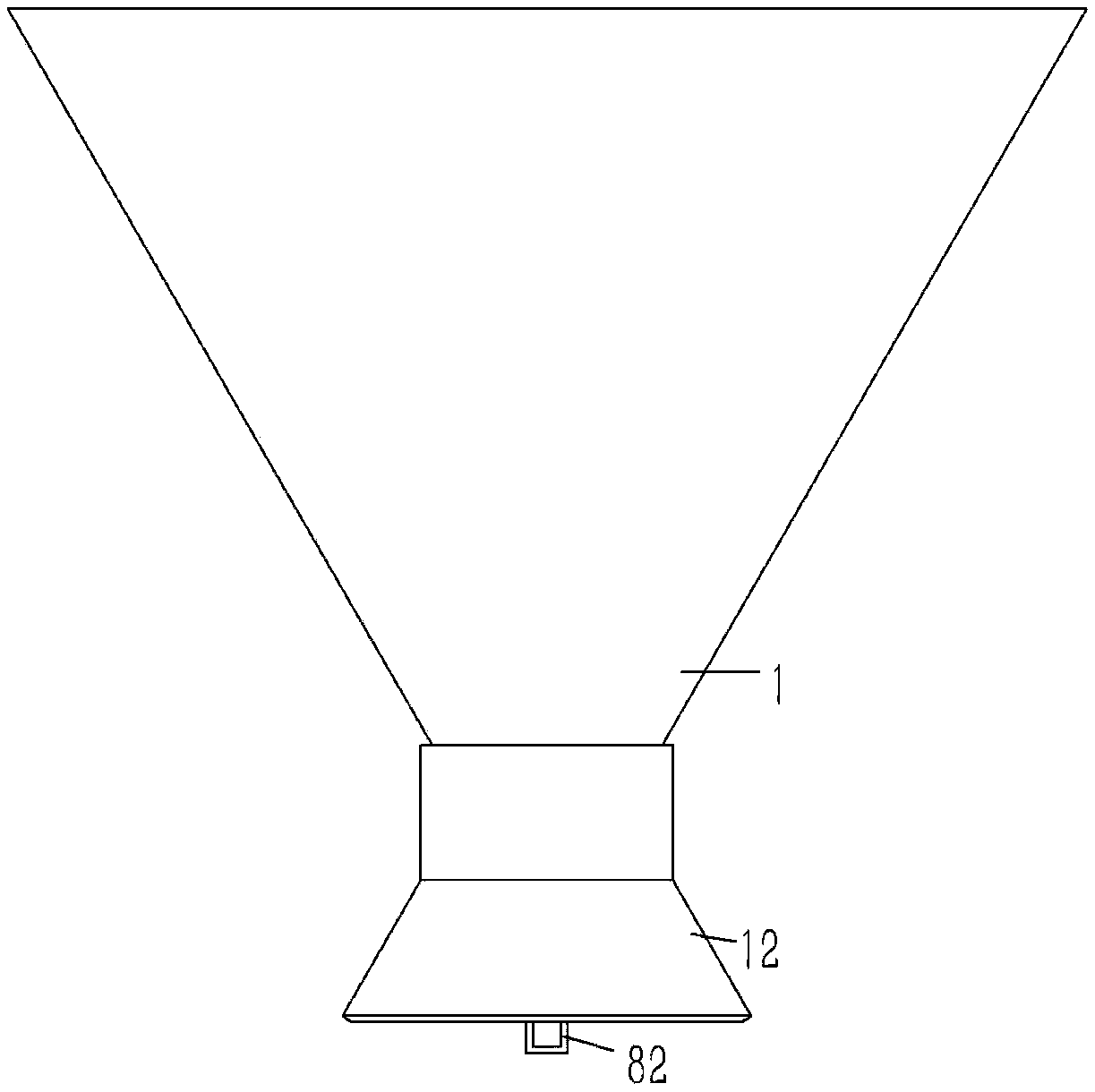

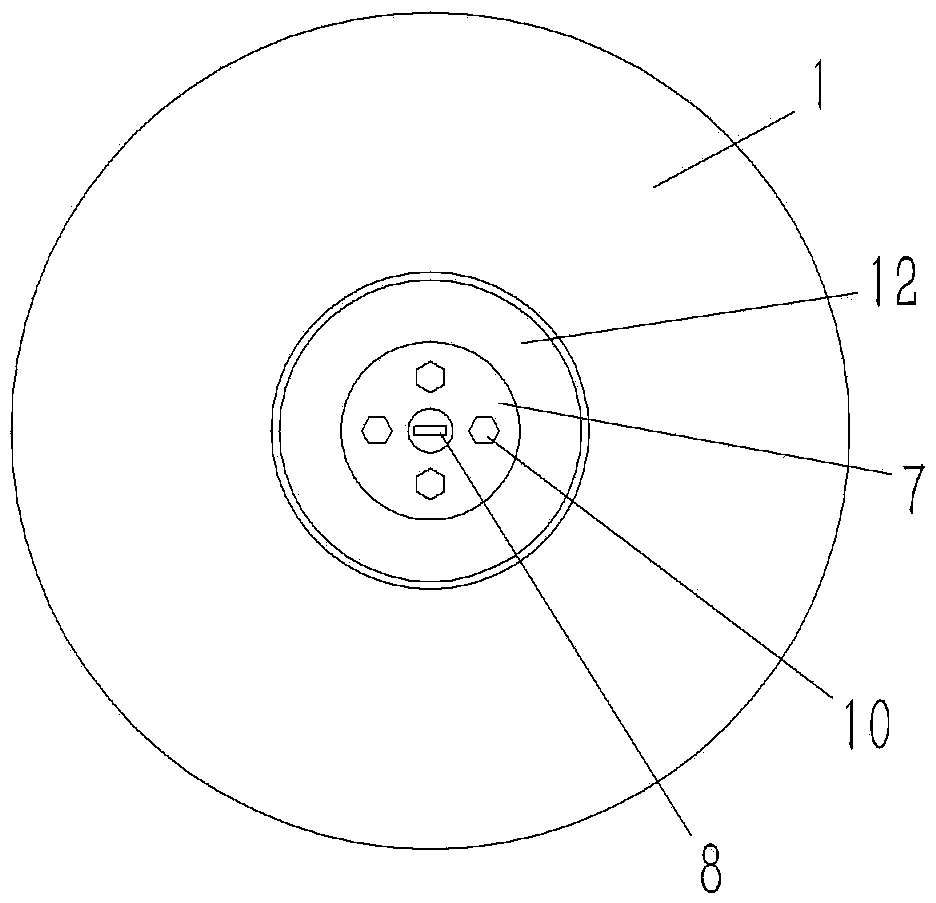

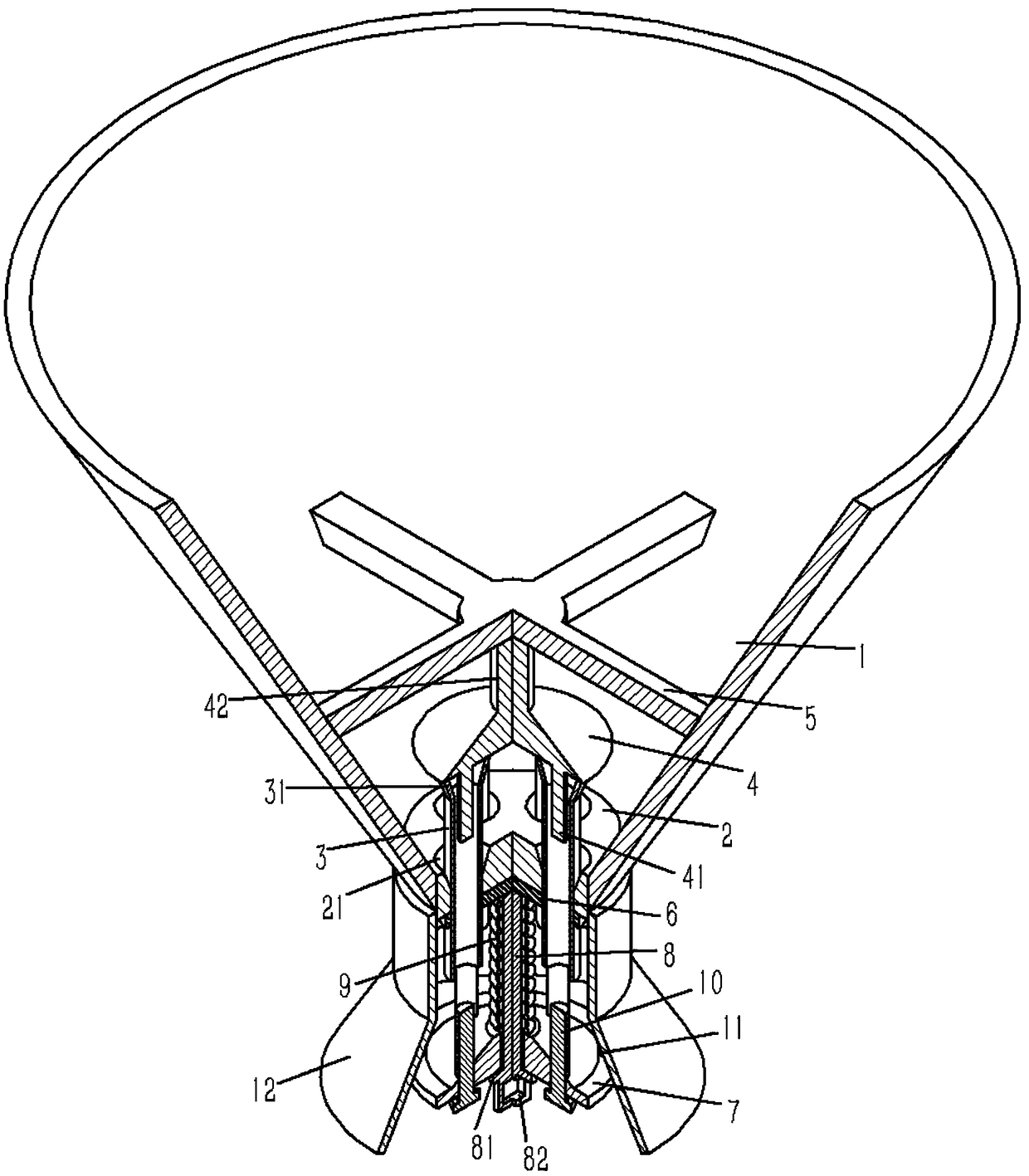

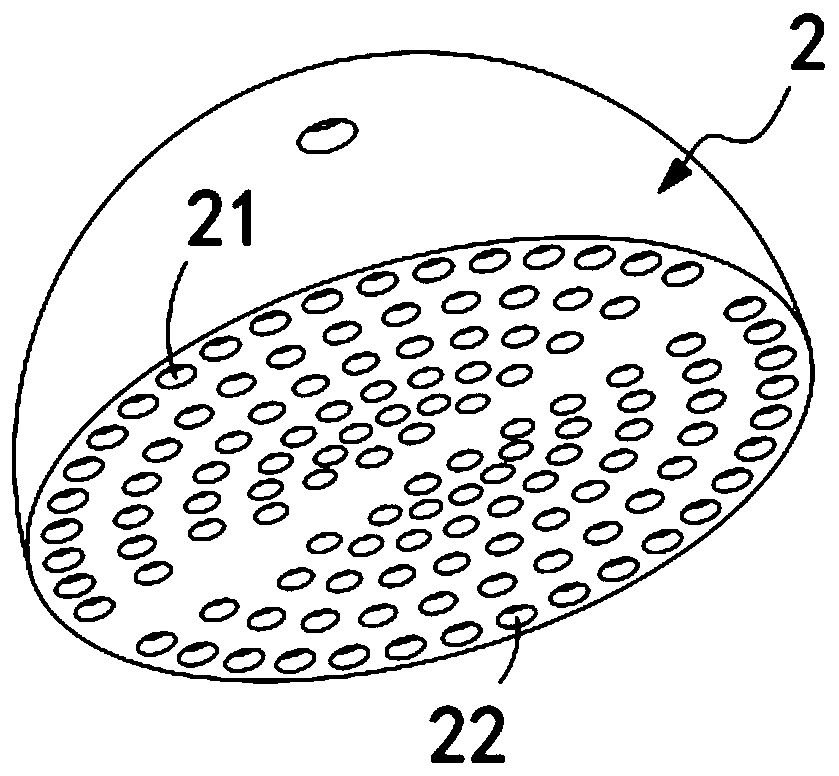

Steel ball quantitative output device for packaging

InactiveCN109515783ARealize quantitative outputIncrease productivitySolid materialArchitectural engineeringHoneycomb

The invention discloses a steel ball quantitative output device for packaging. The steel ball quantitative output device comprises a tapered material holding hopper, wherein a vertical honeycomb ductis molded at the lower end of the material holding hopper, and a positioning plate is fixed on the inner wall of the upper end of the honeycomb duct; a plurality of through holes are formed in the positioning plate and are annularly and uniformly distributed around a central axis of the positioning plate; a plurality of metering tubes opposite to the through holes in the positioning plate are inserted to the honeycomb duct on the lower side of the positioning plate; the upper end of each of the metering tubes is inserted and fixed on an upper turntable; the upper end of the upper turntable abuts against the lower end face of the positioning plate and abuts against the inner wall of the honeycomb duct; the lower end of each of the metering tubes is inserted and fixed on a lower turntable; the lower turntable abuts against the inner wall of the honeycomb duct and also abuts against an end cover; the end cover is fixed on the lower end face of the honeycomb duct; and vertical rotary shafts are inserted and fixed in the center of the upper turntable and the center of the lower turntable. According to the steel ball quantitative output device, the quantitative output of a steel ball canbe conveniently and rapidly realized to replace a weighing way to package the steel ball, and then the production efficiency is effectively improved.

Owner:周志泉

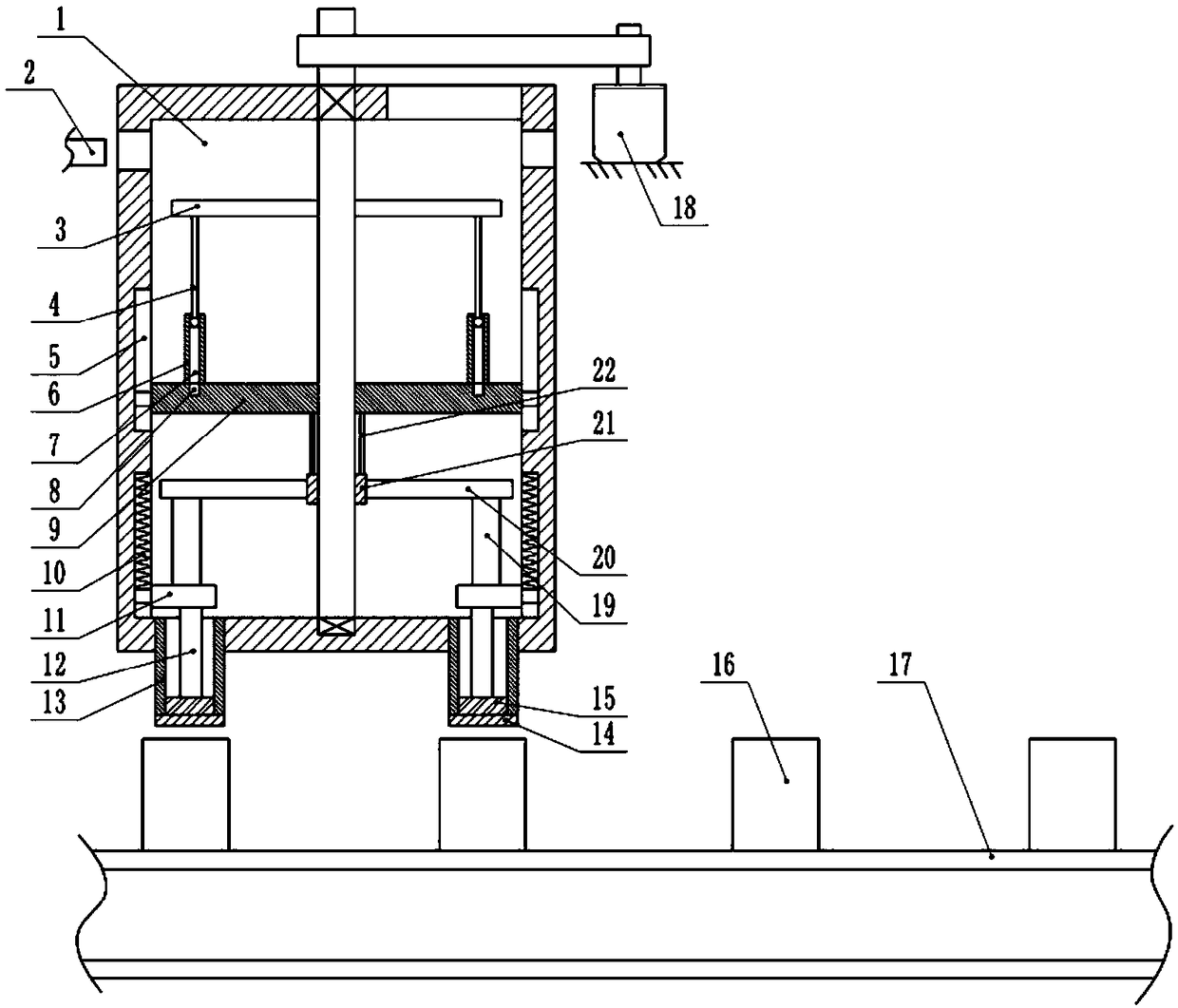

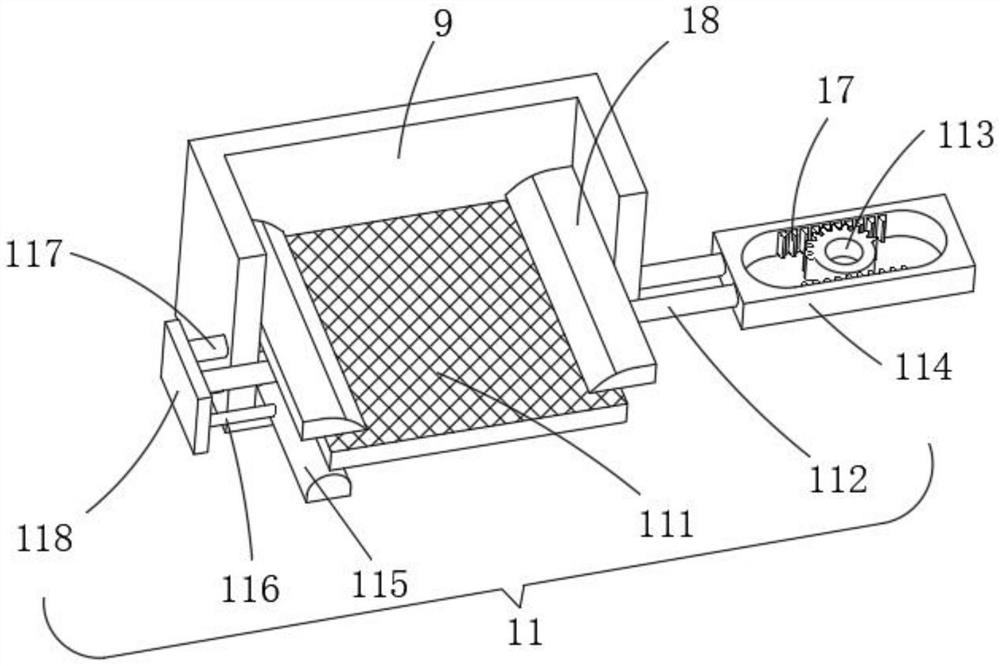

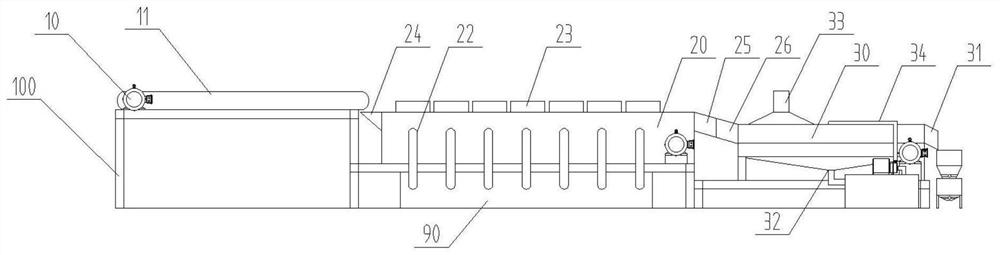

Equipment specially used for filling seedling growing plate of salt-tolerance rice with mud

PendingCN110278811ARealize batchRealize industrializationCultivating equipmentsFlower-pot fillingEngineeringMechanical engineering

The invention discloses equipment specially used for filling a seedling growing plate of salt-tolerance rice with mud. The equipment comprises a mixing cylinder, a first conveying mechanism, a second conveying mechanism and a third conveying mechanism; a feeding port is formed in the upper end of the mixing cylinder, and a discharging port is formed in the bottom of the mixing cylinder; the first conveying mechanism is located at the lower side of the discharging port, the third conveying mechanism is located at the upper end of the feeding port, the second conveying mechanism is aslant arranged, one end of the second conveying mechanism is located at the upper end of the feeding port, a smashing mechanism is arranged at the portion, close to the feeding port, of the mixing cylinder, and a mixing mechanism and a water inlet pipe are arranged in the middle of the mixing cylinder. According to the equipment, the design of mechanical filling of the mud is adopted, labor is effectively replaced, and batched, industrialized and quantified work is achieved; through a gap spacing mechanism, gap discharging of the mud is achieved; meanwhile, through the further utilization of a quantitative discharging mechanism, the mud quantitatively discharged, and then the seedling growing plate is filled with sufficient and quantitative mud.

Owner:辽宁省水稻研究所

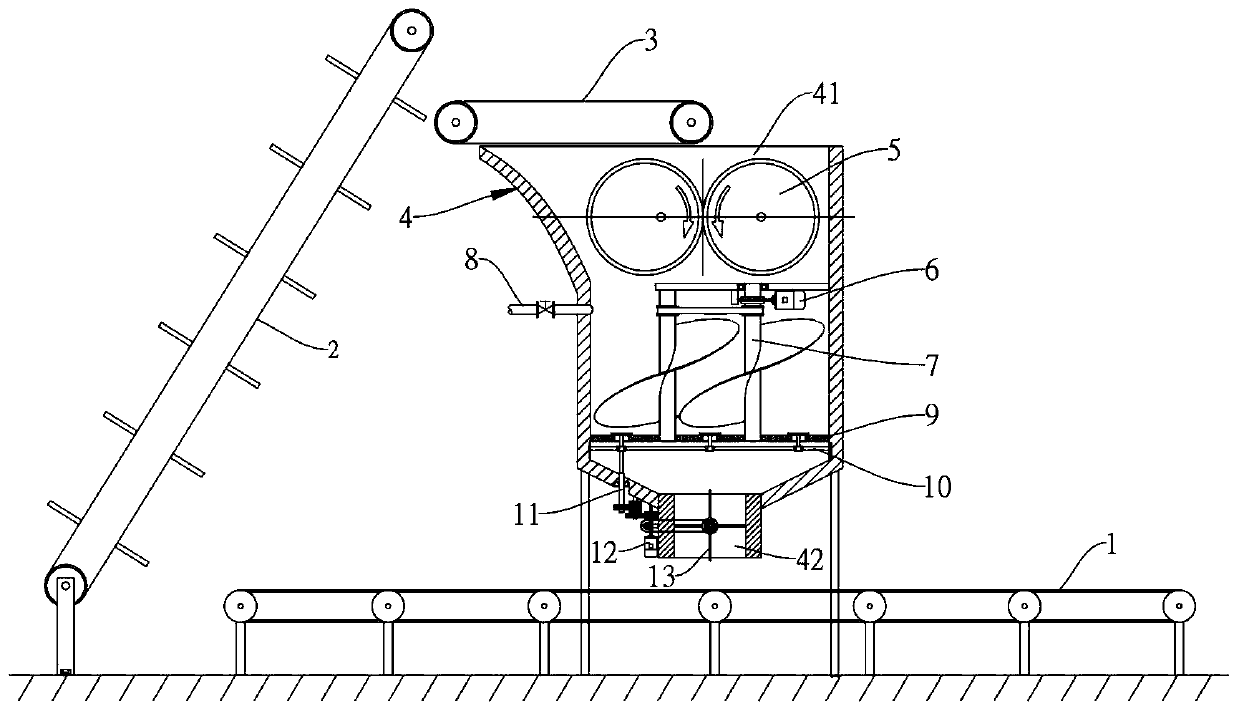

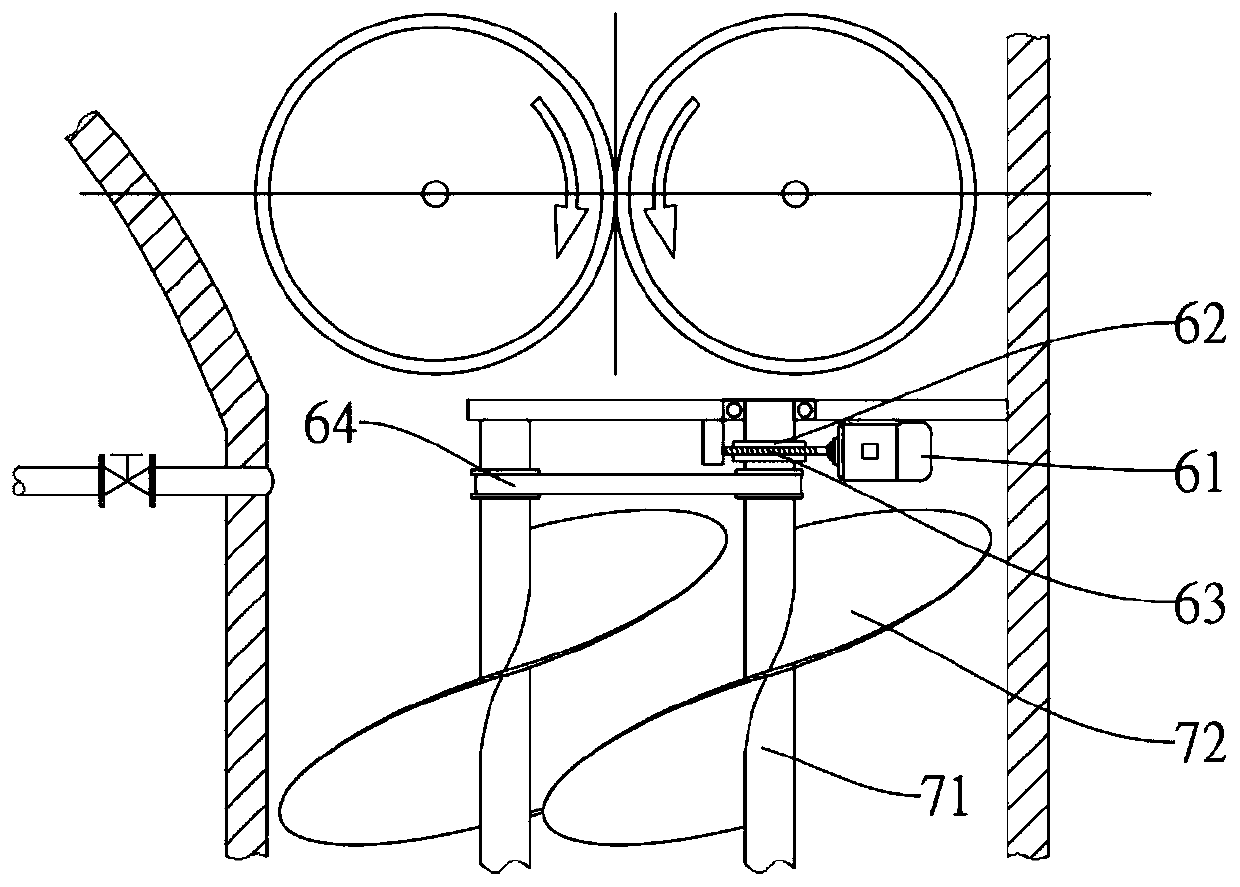

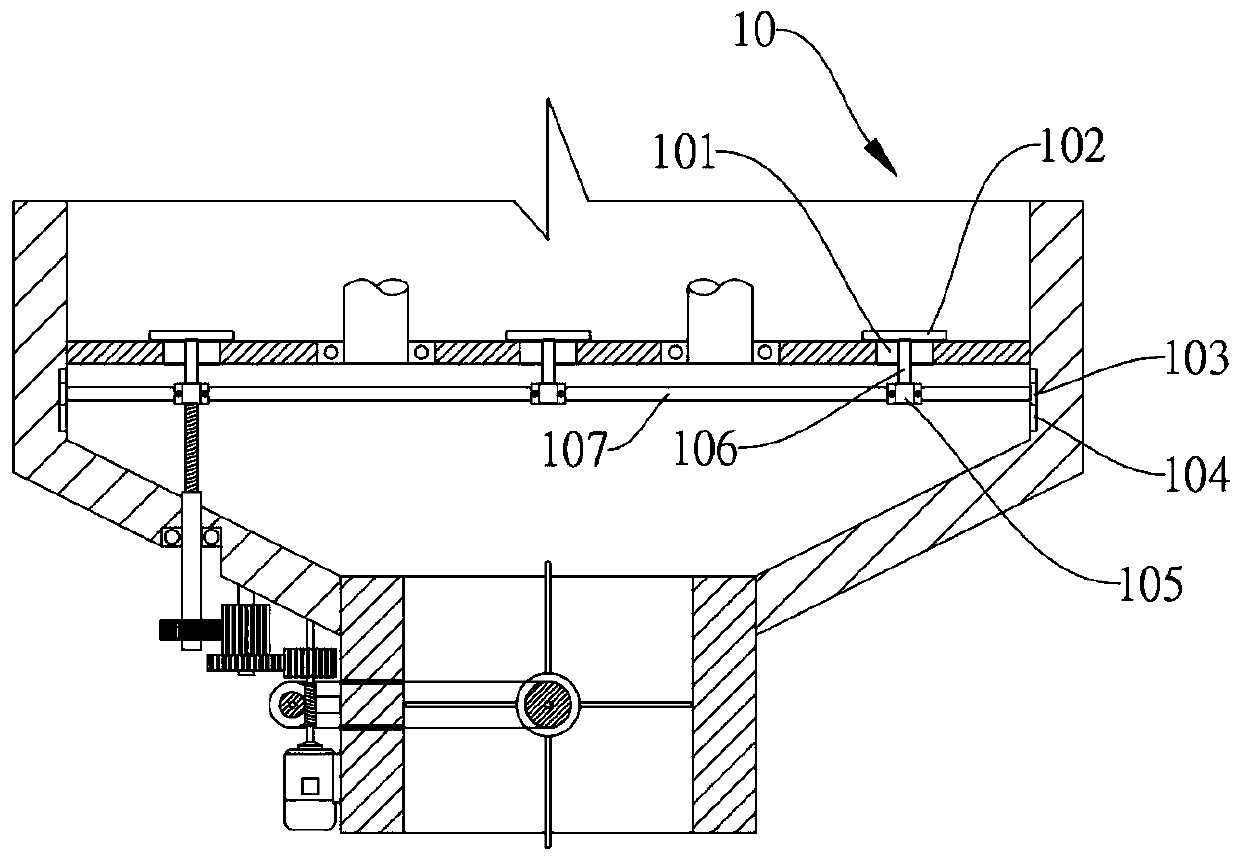

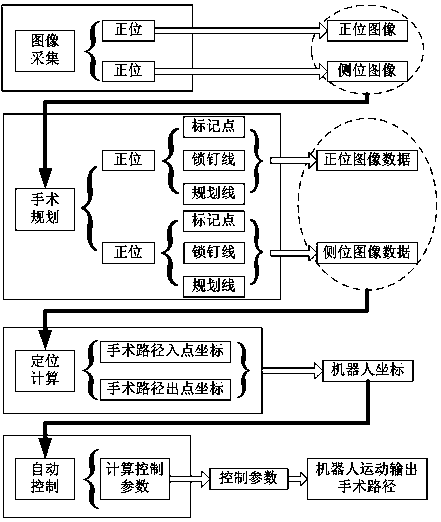

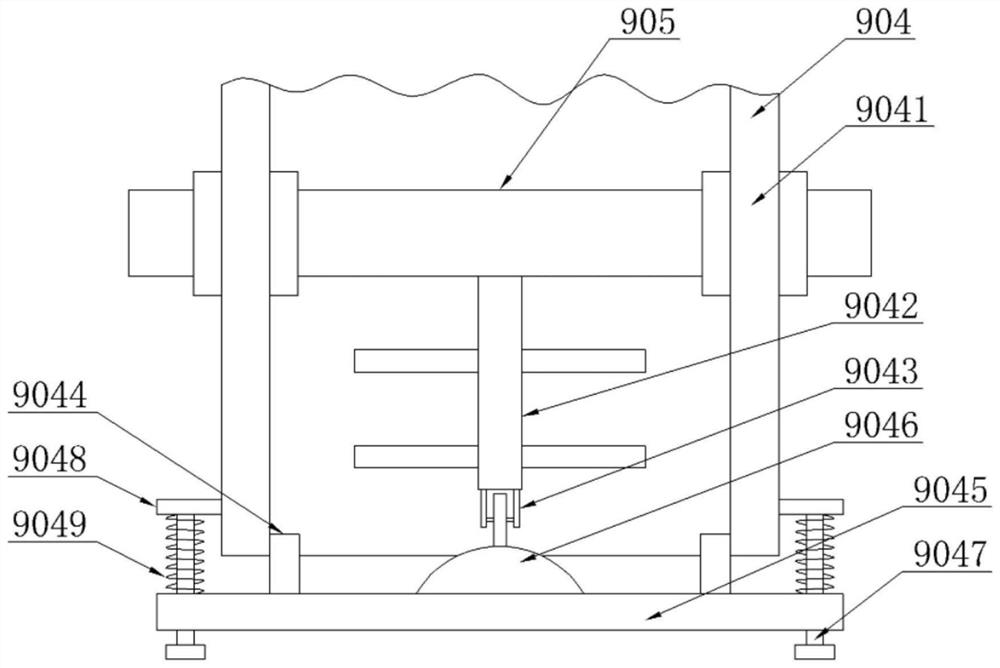

Robot navigation method of collum femoris hollow rivet implanting operation based on perspective vision

InactiveCN108066011ARealize quantitative outputSurgical navigation systemsSurgical robotsSimulationX ray image

The invention aims at providing a robot navigation method of a collum femoris hollow rivet implanting operation based on perspective vision. The technical purpose is to use a robot to conduct the remote collum femoris hollow rivet implanting operation. The method comprises the following steps that 1, C-shaped arm X-ray image obtaining equipment is utilized to shoot front pictures and side picturesof operation positions; 2, a doctor plans an operation path according to the front pictures and the side pictures; 3, calculating spatial coordinates of the operation path through a locating algorithm, and converting the spatial coordinates into a robot coordinate system; 4, converting the spatial coordinates of the operation path in the robot coordinate system into actual control parameters andtransmitting the parameters to a robot controller to control the robot to move and output the operation path.

Owner:广州键佳科技有限公司

Packaging production method of water-soluble film product

ActiveCN113086259ARealize opening and closingRealize quantitative outputWrapper twisting/gatheringSolid materialSoluble FilmElectric machinery

The invention discloses a packaging production method of a water-soluble film product. The packaging production method comprises the following steps that powder is put into a quantitative discharging mechanism; a driving shaft drives a rotating plate to rotate along a rotating groove through an opening and closing mechanism, so that a pair of electric heating plates conduct opening and closing movement, and after the electric heating plates are attached, a bottom transverse opening and side openings of a packaging bag strip are subjected to heat sealing; a motor drives the driving shaft to rotate to enable the electric heating plates to seal the bottom and the side walls of the packaging bag strip, the quantitative discharging mechanism intermittently and quantitatively puts powder into a hopper, and the hopper guides the powder into the packaging bag strip with the sealed bottom and the sealed side edges; the electric heating plates separate and loosen the packaging bag strip, meanwhile, the driving shaft drives a conveying mechanism to pull the packaging bag strip in a linkage manner, the filled powder moves to the bottoms of the electric heating plates, the electric heating plates are closed again to seal the packaging bag strip at the top of the powder, and the multiple products are continuously and hermetically packaged on the packaging bag strip; and the conveying mechanism conveys and enables the packaged products to enter a cut-off mechanism, and the driving shaft drives the cut-off mechanism to cut off packaging bag strips between the adjacent products in a linkage manner.

Owner:干将新材料有限公司

Quantitative material conveying device applied to packaging of particle bags

InactiveCN109533415ARealize quantitative outputImprove packaging efficiencySolid materialEngineeringMechanical engineering

The invention discloses a quantitative material conveying device applied to packaging of particle bags. The quantitative material conveying device comprises a vertical discharge pipe, wherein a bafflewhich extends downwards and is in an arc shape is formed on the rear side of the lower end of the discharge pipe, the lower end of the discharge pipe is sleeved with an arc-shaped positioning casingpipe, the rear side of the lower end of the positioning casing pipe is provided with a cutting groove, and the lower end of the discharge pipe abuts against a valve plate; a vertical support plate isformed at the front end of the valve plate, a plurality of T-shaped first guide rods are inserted in the support plate, a first pressure spring is sleeved with each first guide rod, one end of each first pressure spring is pressed against the head of the corresponding first guide rod, and the other end of each first pressure spring is pressed against the support plate; the lower end face of the valve plate abuts against a measuring cylinder, and a T-shaped positioning pin is fixed to an outer wall opposite to the measuring cylinder and inserted into the lower end of the positioning casing pipe; an adjusting plate is inserted into the measuring cylinder, and adjusting bolts are fixed to the lower end face of the adjusting plate and are in threaded connection with the measuring cylinder. Thequantitative material conveying device can quantitatively output granular articles to be packaged and improve the packaging efficiency.

Owner:SHENZHEN SENSELEADER TECH DEV CO LTD

A preparation device for emulsified oil compound agent for hydraulic support

ActiveCN111871268BImprove solubilityImplement addRotary stirring mixersTransportation and packagingElectric machineryEngineering

Owner:淮北金岭石化有限公司

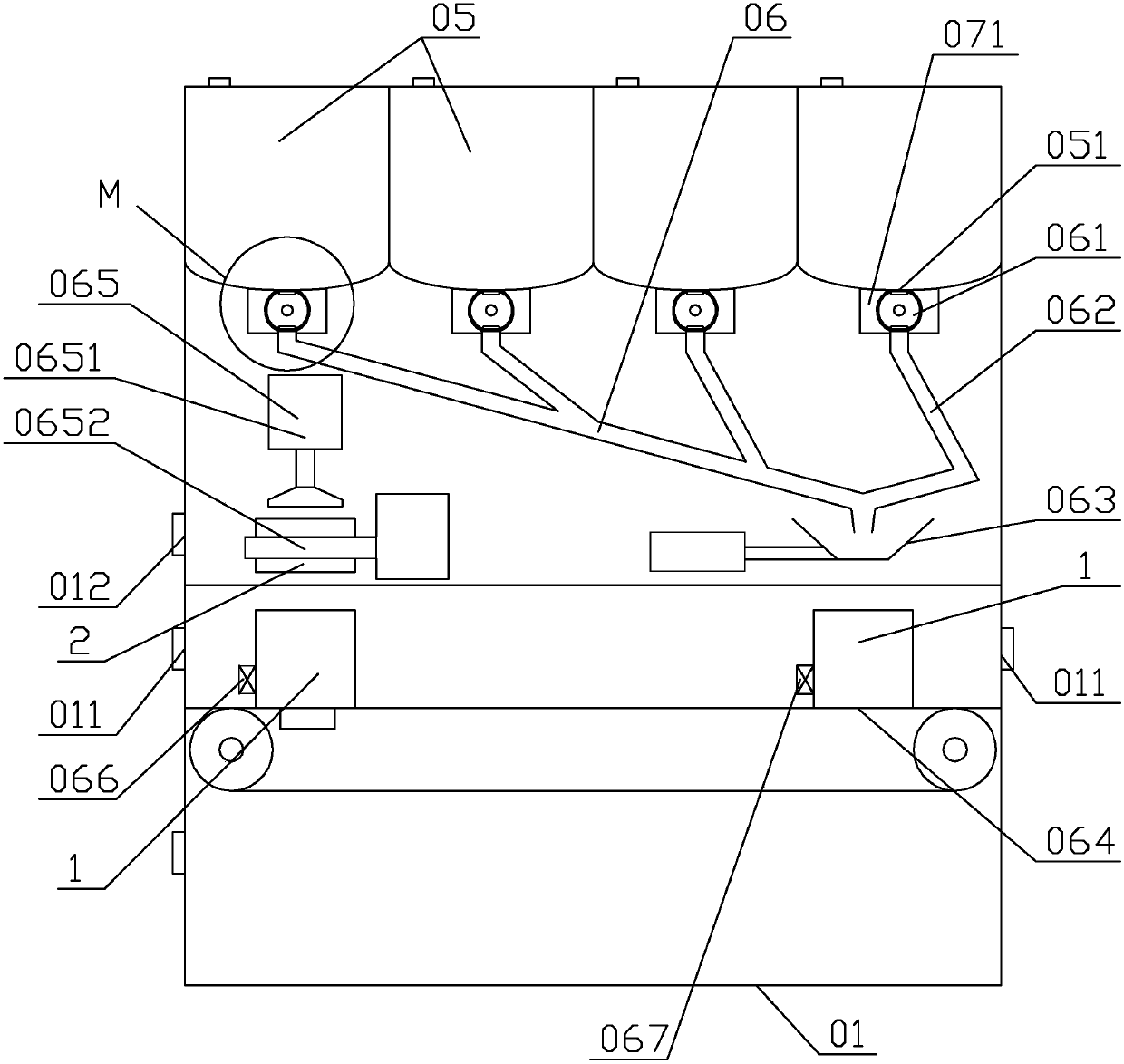

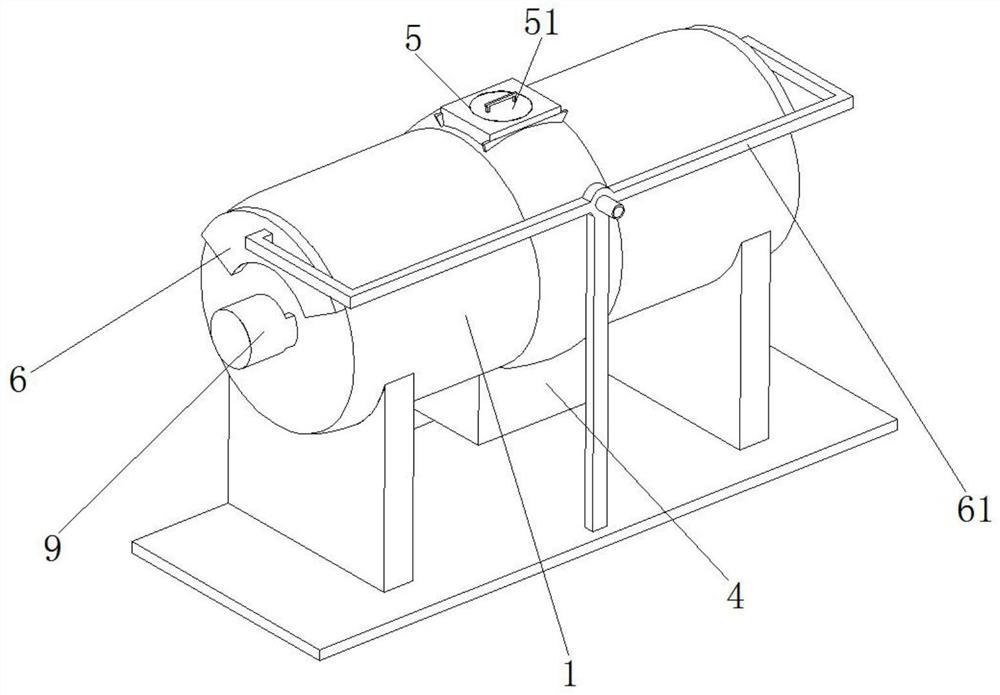

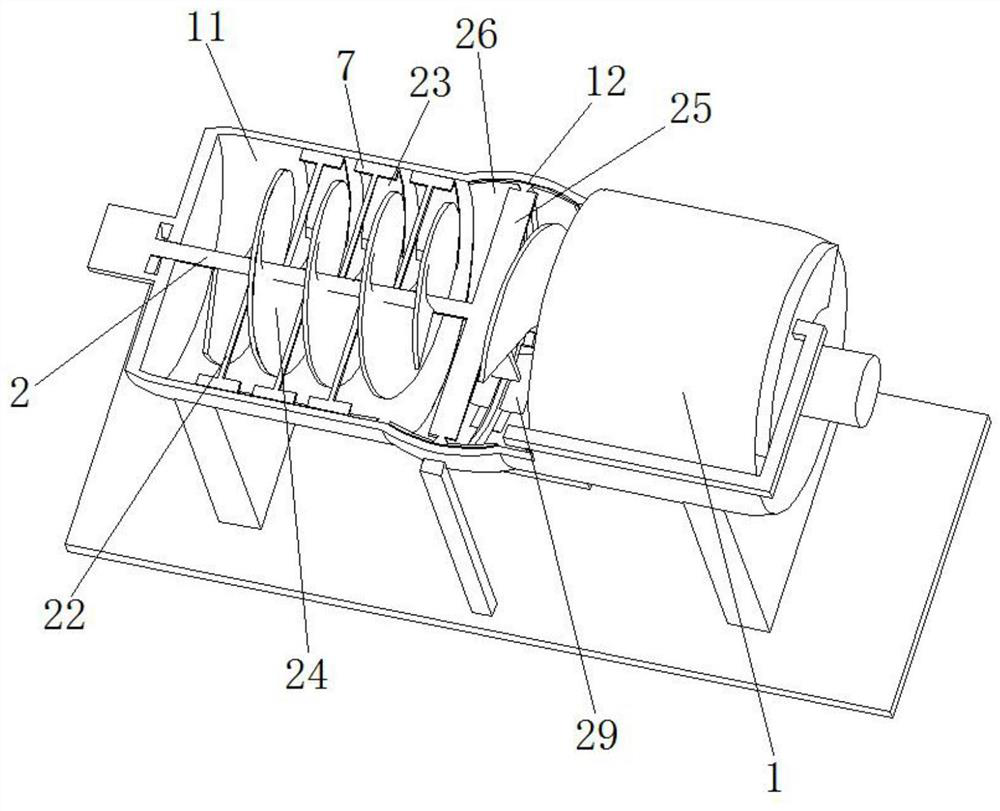

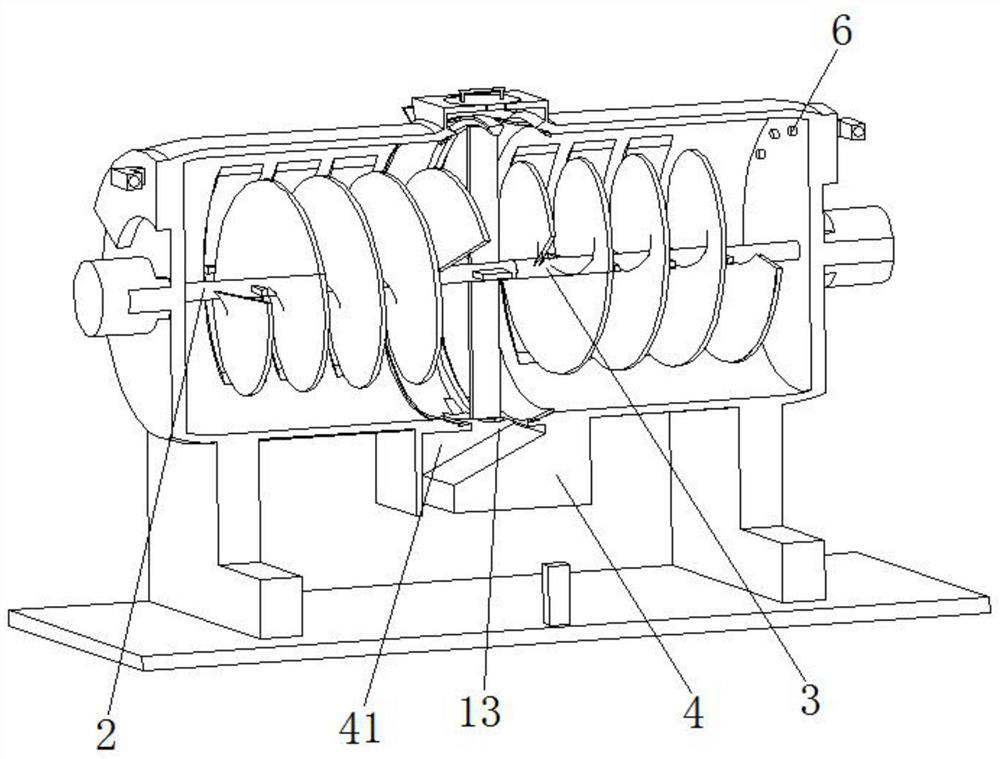

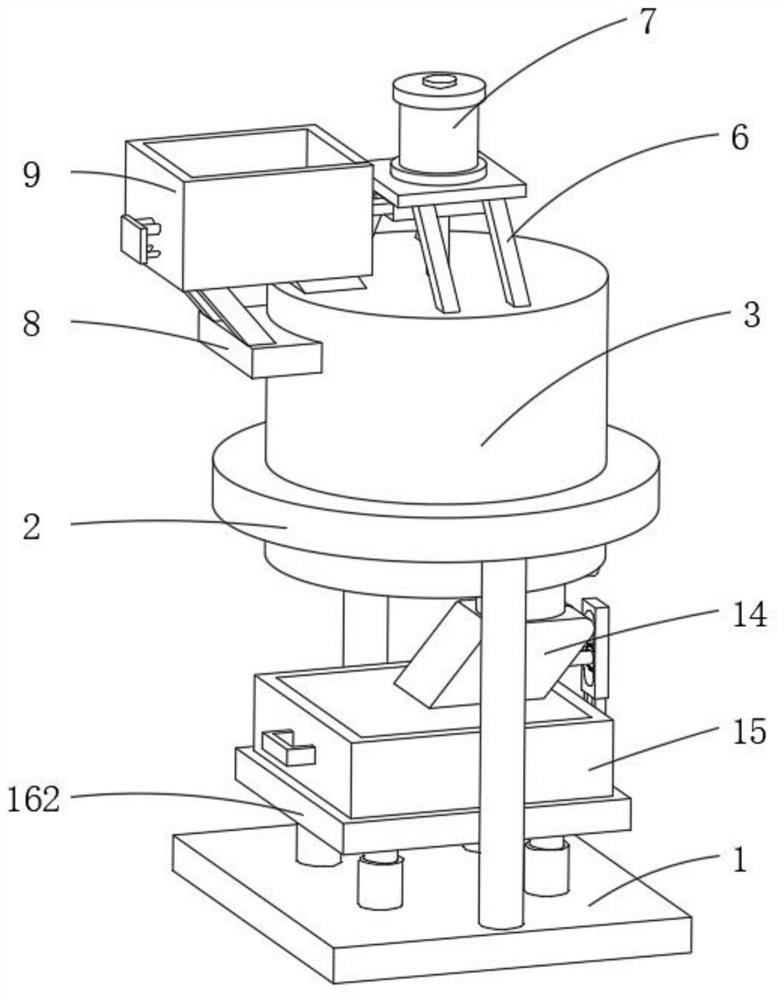

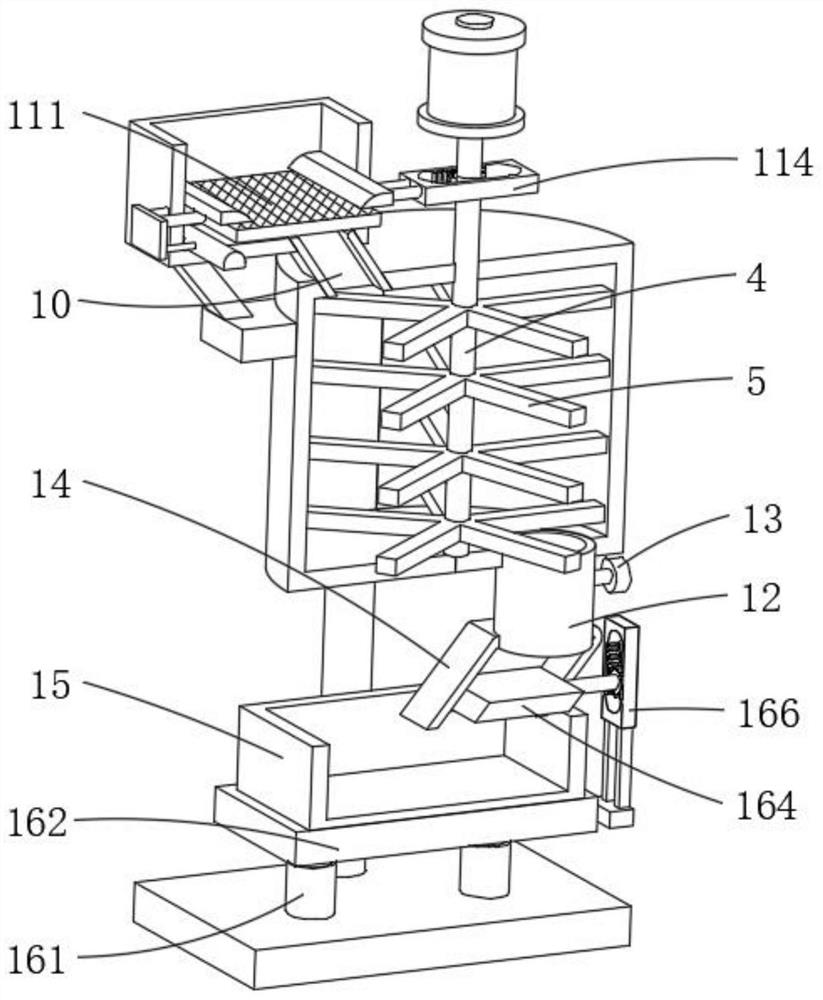

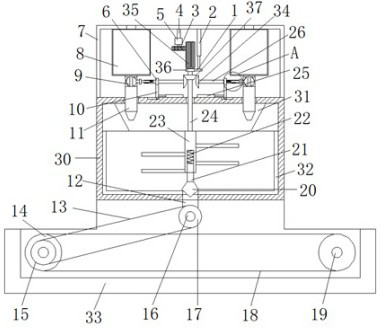

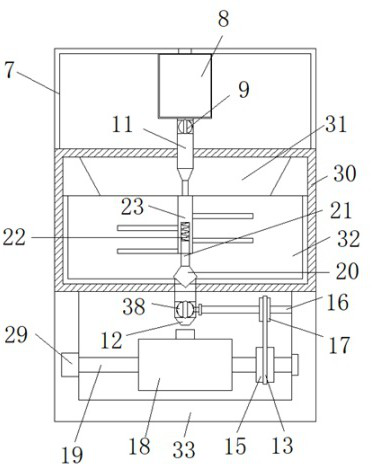

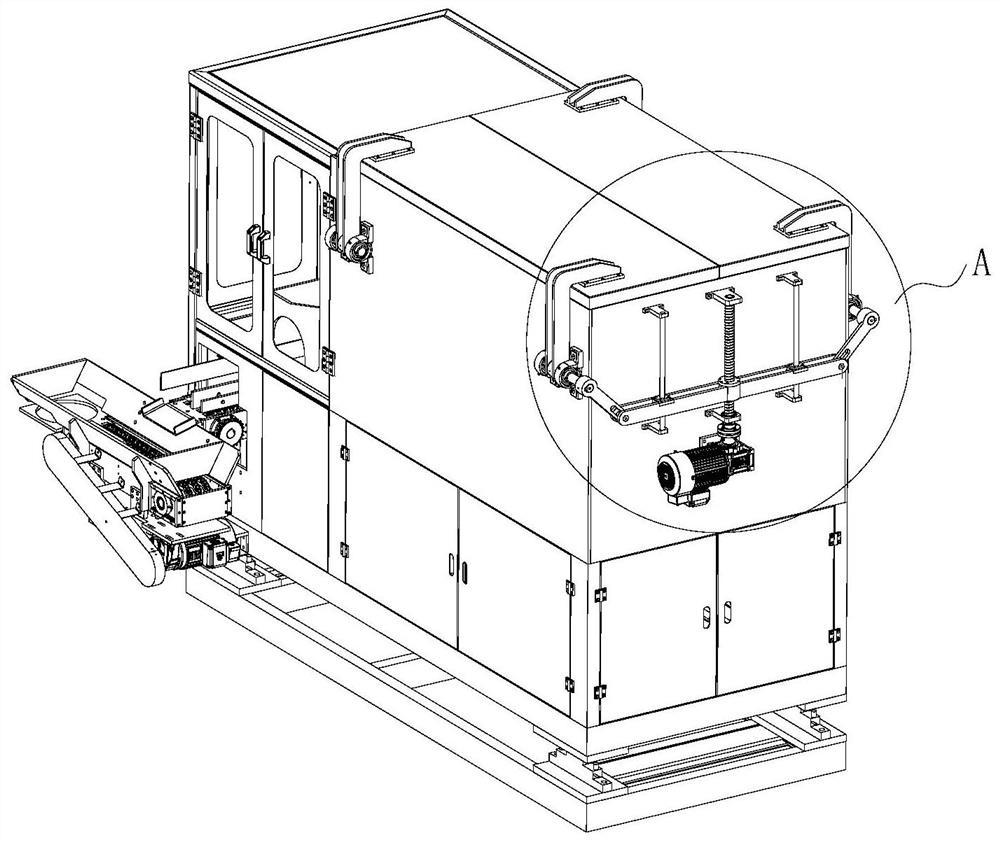

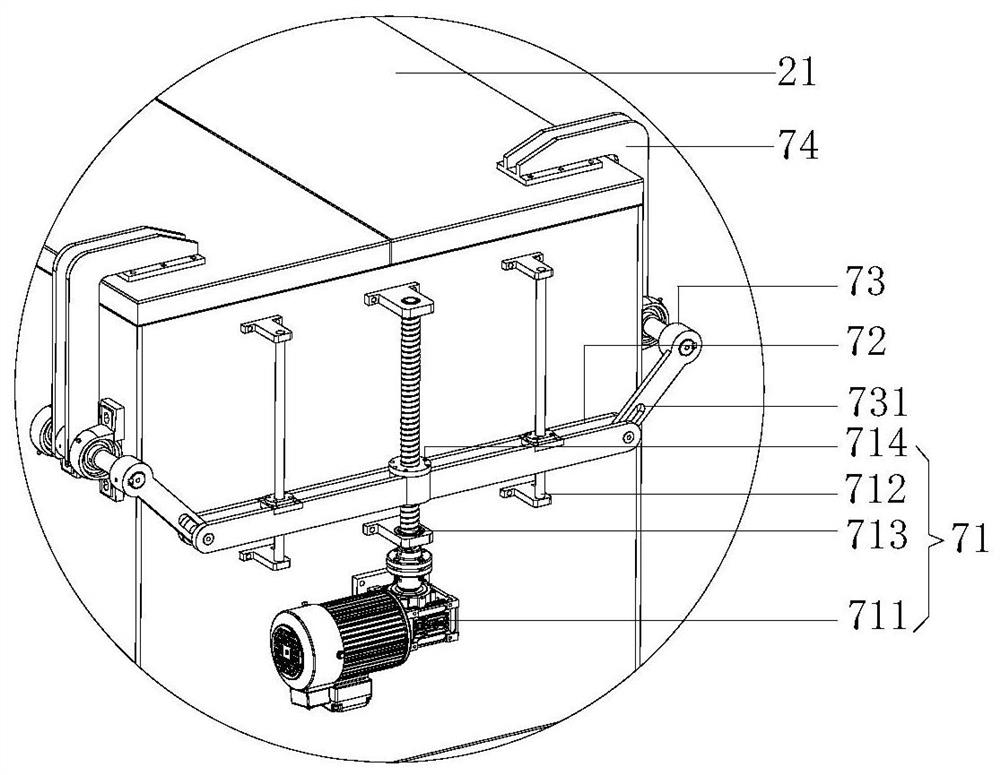

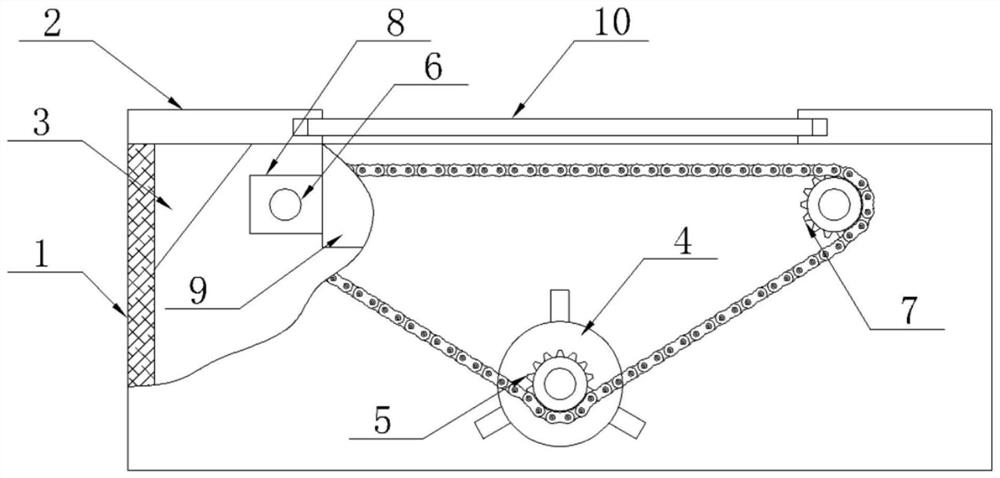

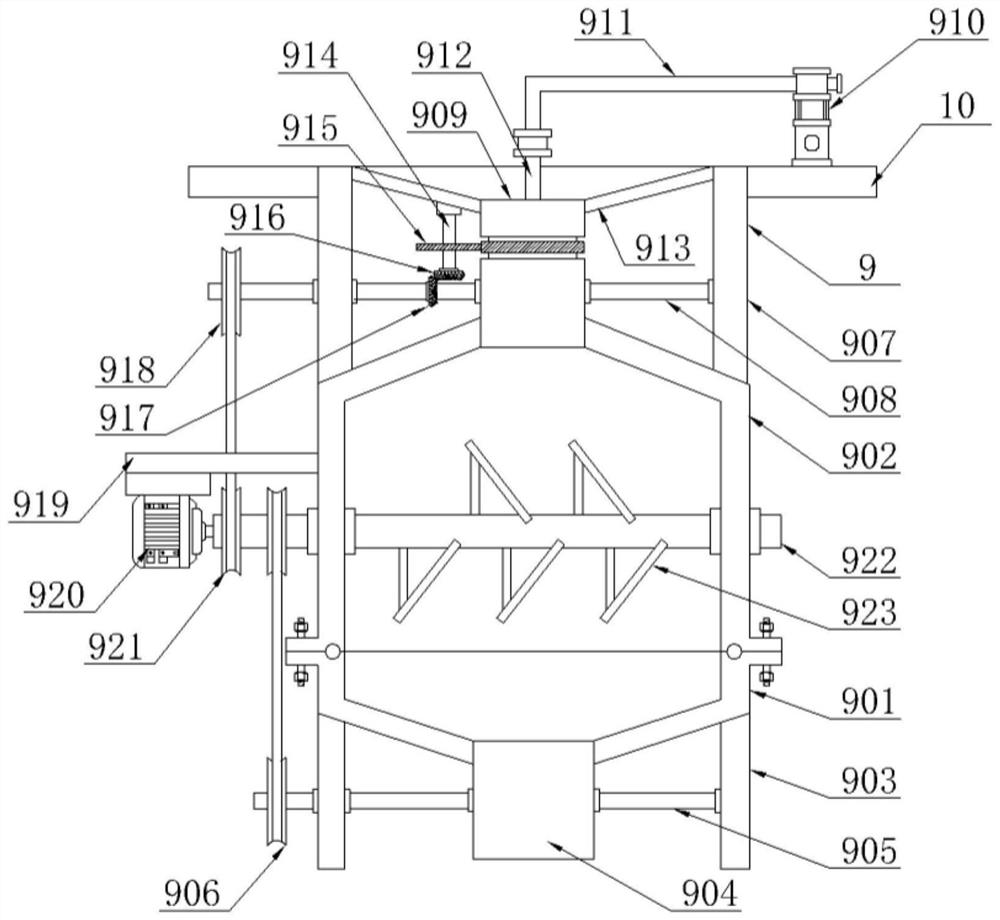

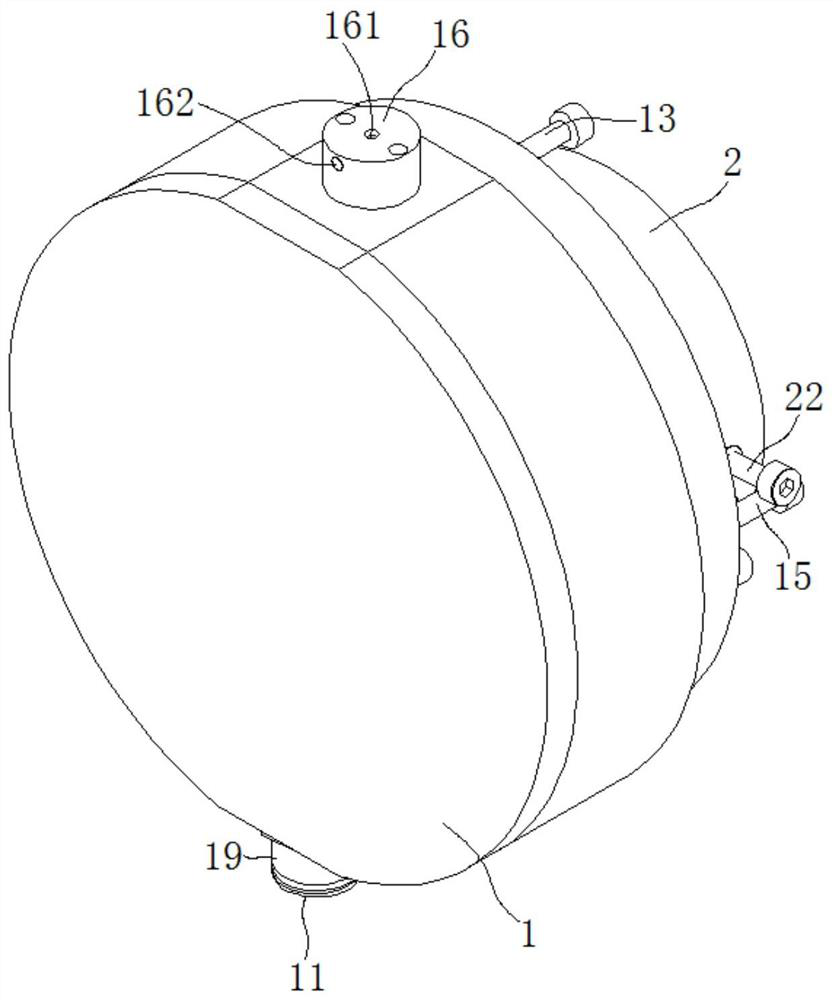

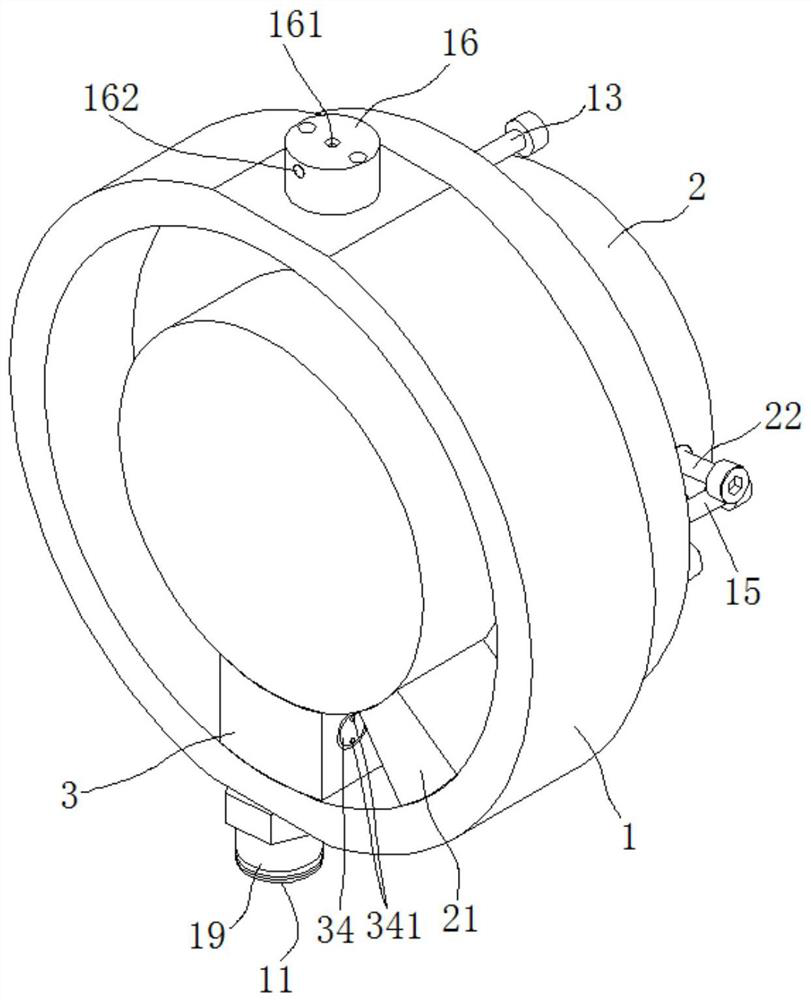

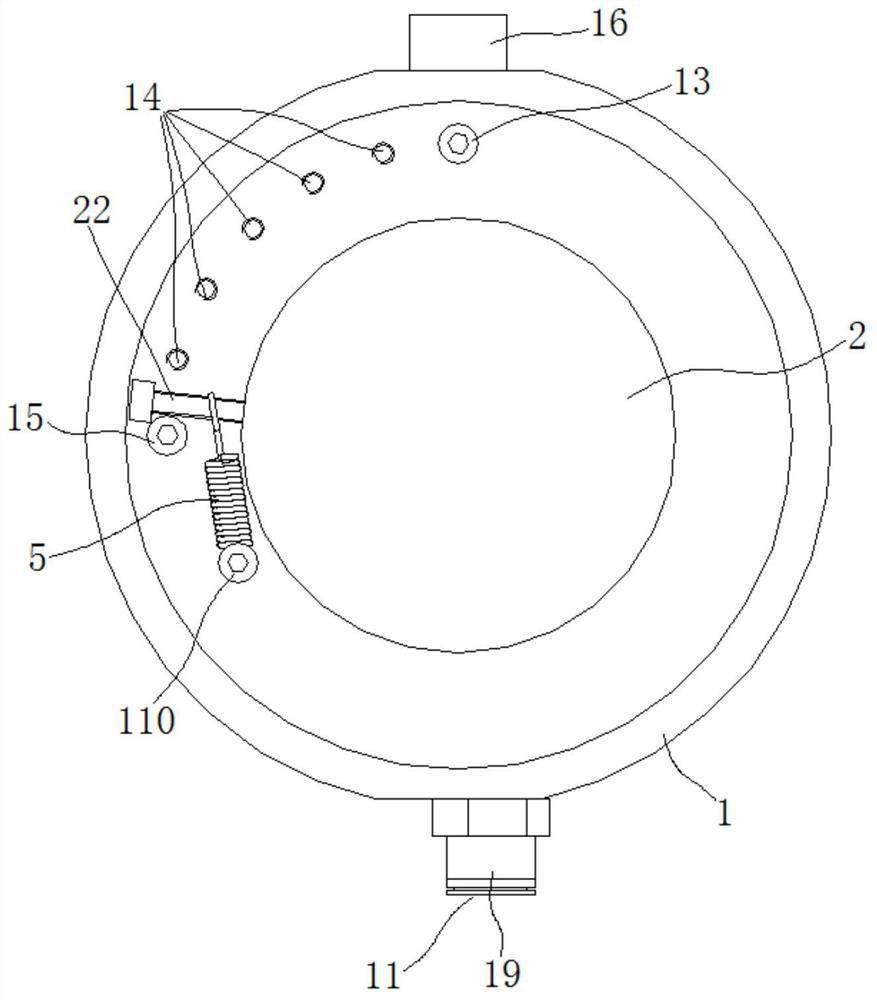

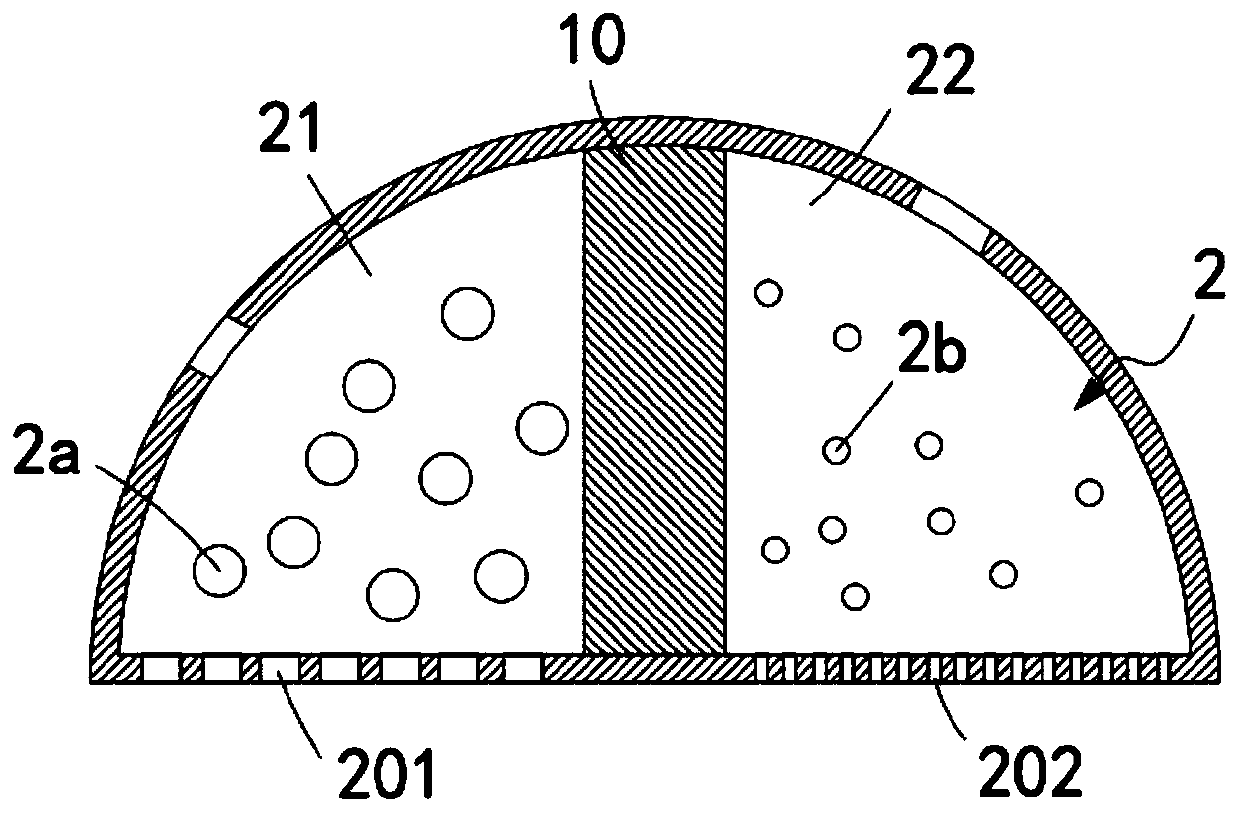

Blending device of emulsified oil complexing agent for hydraulic support

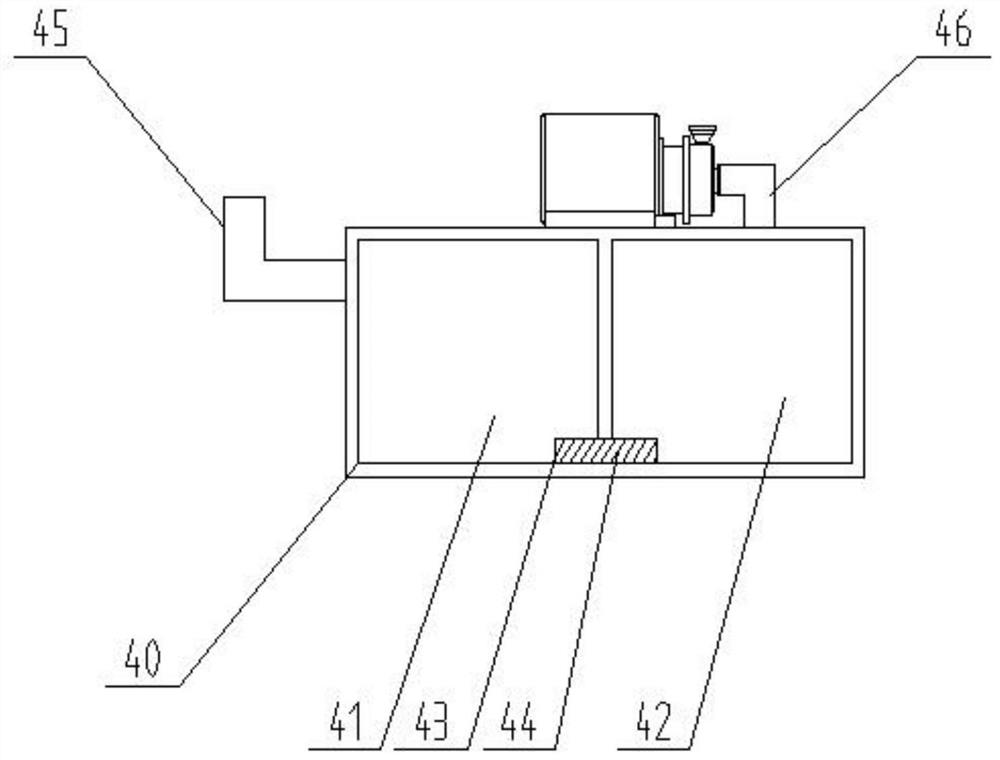

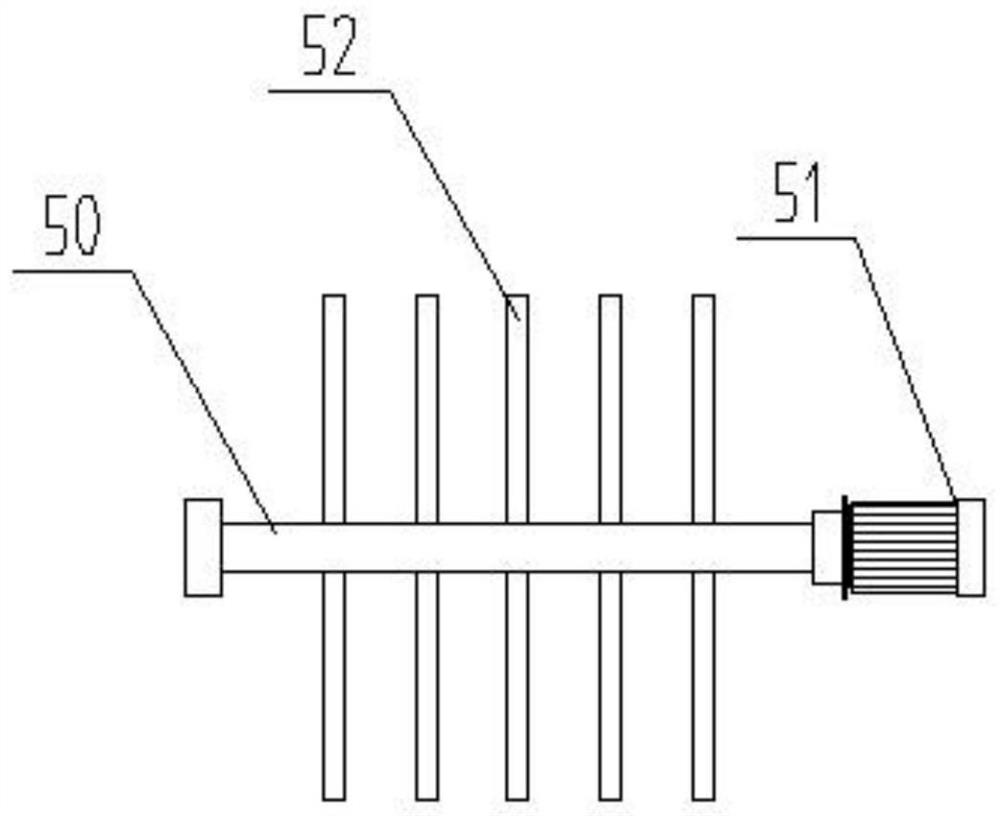

ActiveCN111871268AImprove solubilityImplement addRotary stirring mixersTransportation and packagingPhysical chemistryElectric machinery

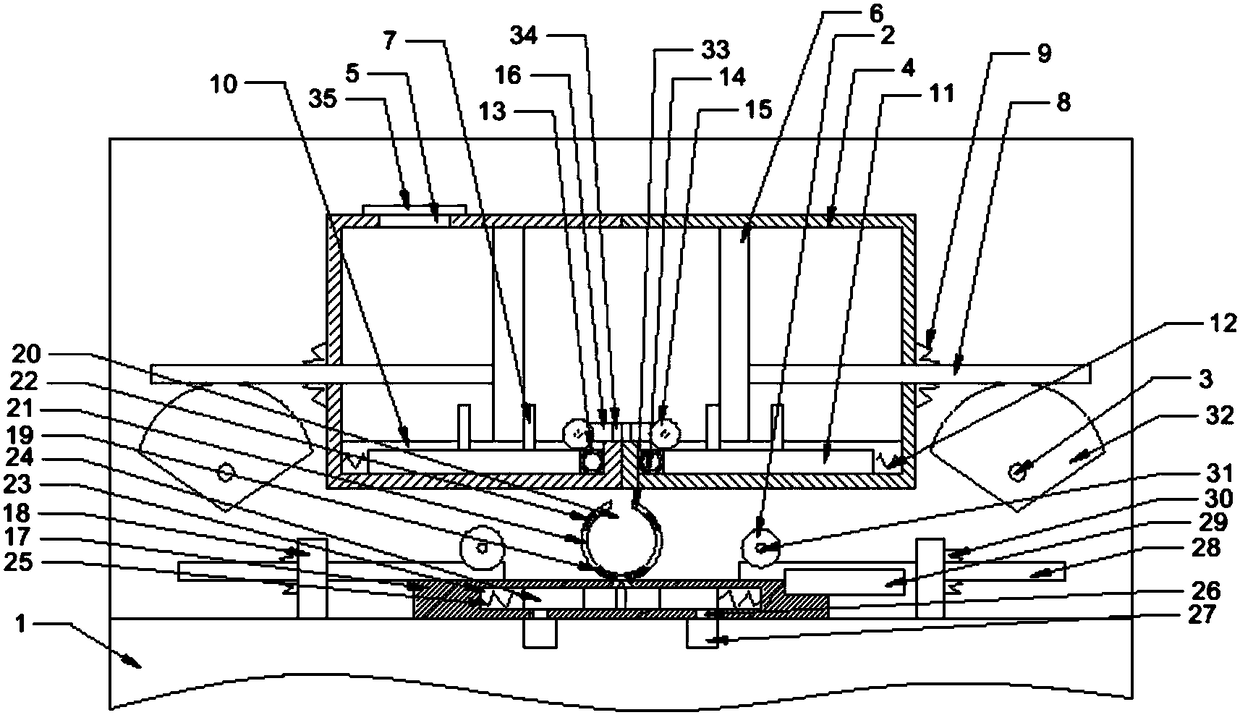

The invention discloses a blending device of an emulsified oil complexing agent for a hydraulic support, relates to the field of emulsified oil complexing agent blending, and provides the following scheme aiming at the problems that a traditional blending device of the emulsified oil complexing agent cannot quantitatively add raw materials and cannot quantitatively output preparation liquid. The blending device includes a base, wherein a first driving motor is fixedly connected to the interior of the base, an output shaft of the first driving motor is fixedly connected with a first rotating shaft, the exterior of the first rotating shaft is fixedly sleeved with a roller, the exterior of the roller is sleeved with a conveying belt, and the exterior of the first rotating shaft is fixedly sleeved with a first belt wheel; and a conveying belt is arranged outside the first belt wheel in a sleeving mode, and a second rotating shaft is rotatably connected into the base. According to the invention, quantitative addition of raw materials and automatic stirring of the preparation liquid can be automatically realized, dissolution is accelerated, quantitative output of the preparation liquid can be realized, and waste is avoided.

Owner:淮北金岭石化有限公司

Steel ball output device capable of adjusting specified number

InactiveCN109455369ARealize quantitative outputMeet needsPackaging automatic controlArchitectural engineeringEngineering

The invention discloses a steel ball output device capable of adjusting the specified number. The steel ball output device capable of adjusting the specified number comprises a tapered holding hopper,wherein a positioning block is inserted and fixed into an outlet of the lower end of the holding hopper; multiple vertical metering pipes are inserted and fixed onto the positioning block; the lowerends of the metering pipes are fixed onto a connecting support; a conical base is arranged on the lower side of the connecting support; multiple stand columns are fixed onto the outer edge of the base; the upper ends of the stand columns are fixed onto the positioning block; a vertical pull rod is fixed onto the connecting support; the lower end of the pull rod penetrates through the base so as toform a blocking plate; a compression spring is inserted onto the pull rod in a sleeving way; two ends of the compression spring are pressed against the connecting support and the base; the connectingsupport is pressed against the positioning block; the blocking plate is pressed against the base; a pull ring is formed on the lower end surface of the blocking plate; and vertical adjusting bolts are arranged right below the metering pipes and are screwed onto the base. According to the steel ball output device capable of adjusting the specified number provided by the invention, steel balls canbe conveniently and quickly output quantitatively, so that the production efficiency can be effectively improved; the setting output number can be adjusted; and the demands of packages with various specifications are met.

Owner:周志泉

Mechanical ball adding machine

The invention discloses a mechanical ball adding machine. The ball adding machine comprises a rack, a ball storage bin, a material door mechanism, an overturning ball claw mechanism, a reversing conveying belt, a weighing mechanism and a control host; the ball storage bin stores grinding balls; a ball outlet channel of the ball storage bin is formed between the material door mechanism and a ball storage bin bottom plate; the overturning ball claw mechanism is located at the ball outlet channel of the ball storage bin so as to grab the grinding balls; the reversing conveying belt is located atthe ball discharging end of the overturning ball claw mechanism so as to receive the grinding balls grabbed by the overturning ball claw mechanism, and the conveying direction of the reversing conveying belt is perpendicular to the ball discharging direction of the overturning ball claw mechanism; the weighing mechanism comprises a conveying belt and a first weighing sensor, the conveying belt isarranged below the ball falling end of the reversing conveying belt, the conveying direction of the conveying belt is perpendicular to the conveying direction of the reversing conveying belt, and thefirst weighing sensor bears the conveying belt; and the control host obtains the measured value of the first weighing sensor and calculates the ball outlet amount of the conveying belt.

Owner:FUJIAN JIANYANG YAHENG MACHINERY MFG

Efficient and water-saving feed putting device for large ornamental fish culture box

ActiveCN112273309AServe evenlyAvoid accumulationClimate change adaptationPisciculture and aquariaRotational axisWater saving

The invention discloses an efficient and water-saving feed putting device for a large ornamental fish culture box, and relates to the technical field of ornamental fish culture. The efficient and water-saving feed putting device comprises the culture box, a servo motor is mounted at the bottom of the front end surface of the culture box, a gear is mounted at the front end of the servo motor, a feed putting box is fixed in an inner cavity of a fixed frame, and movable blocks are welded to the bottoms of the left side and the right side of the feed putting box. Feed is evenly put in a manner that a driving motor drives the gear, a transmission gear and a lead screw to rotate, the lead screw rotates to drive the movable blocks and the feed putting box to move front and back to evenly scatterthe feed into the culture box, a rotating motor drives a rotating shaft to rotate, the rotating shaft drives a belt wheel and a lower belt wheel to rotate, at the moment, a lower rotating rod is driven to rotate to enable a stirring rod to rotate, when the stirring rod rotates to the bottom, a convex block and a blocking plate are pressed downwards, a spring is stretched, the feed is discharged through a gap between a discharging shell and the blocking plate, the feed is quantitatively scattered while the feed putting box moves forwards and backwards, and accumulation of the feed is avoided.

Owner:聊城市敏锐信息科技有限公司

Distributor and main shaft

PendingCN111765363ARealize quantitative outputProportioning devicesDistribution equipmentRotational axisOil pressure

The invention discloses a distributor and a main shaft. The distributor comprises a distributor base, a rotary shaft and an oil inlet assembly, wherein an oil inlet and an oil outlet are formed in thedistributor base; the rotary shaft is rotatably mounted in the distributor base through an elastic return part; an oil cavity which surrounds the rotary shaft is defined between the rotary shaft andthe distributor base; a baffle block is mounted on the rotary shaft; a limiting mechanism capable of limiting a rotation angle of the rotary shaft is arranged between the rotary shaft and the distributor base; the oil inlet assembly is mounted on the distributor base, and is arranged in an accommodating cavity by spacing the baffle block in a peripheral direction; the baffle block and the oil inlet assembly are used for dividing the oil cavity into an oil pressure cavity and an oil storage cavity; an oil path is arranged in the oil inlet assembly; the two ends of the oil path are separately anoil inlet end and an oil outlet end; the oil inlet end communicates with the oil inlet, and the oil outlet end communicates with the oil storage cavity; and a spring, a valve plug and an oil path converter are arranged in the oil path. The oil pressure cavity can be communicated while the oil inlet pumps high-pressure oil, and the oil storage cavity can be communicated while oil supply is disconnected. The distributor has the beneficial effect of being capable of realizing stable oil quantitative output.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

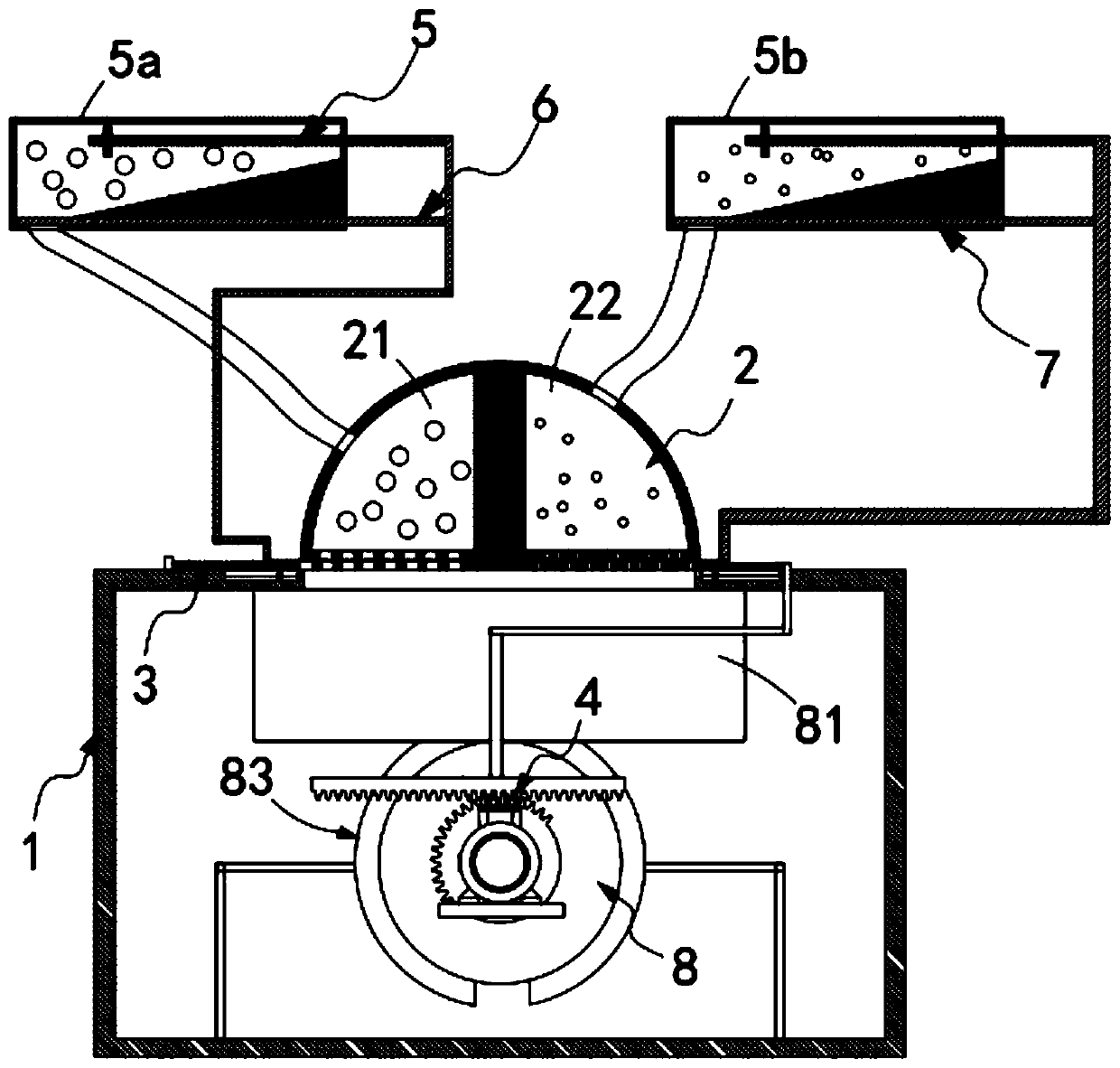

Rain-night reflective bead mixing equipment

InactiveCN111389286ARealize quantitative outputHigh degree of automationTransportation and packagingMixer accessoriesEngineeringMechanical engineering

The invention relates to rain-night reflective bead mixing equipment which comprises a reaction tank, a reflective bead storage box, a discharging assembly, a drive assembly, a supply assembly and a mixing assembly; the discharging assembly is attached to the output end of the reflective bead storage box, and the discharging assembly comprises a rain-night reflective bead mother bead storage spaceand a rain-night reflective sub-bead storage space; the supply assembly comprises a first storage bin and a second storage bin, the first storage bin is communicated with the rain-night reflective bead mother bead storage space of the reflective bead storage box, and a first control assembly is fixedly connected with one end of the discharging assembly and used for controlling discharging of thefirst storage bin; the second storage bin is communicated with the rain-night reflective sub-bead storage space of the reflective bead storage box, and a second control assembly is fixedly connected with the other end of the discharging assembly and used for controlling discharging of the second storage bin; the technical problem that two kinds of beads are different in size, and then accurate proportioning of the two kinds of beads cannot be achieved is solved.

Owner:ZHEJIANG ZHONGXIN NEW MATERIAL CO LTD

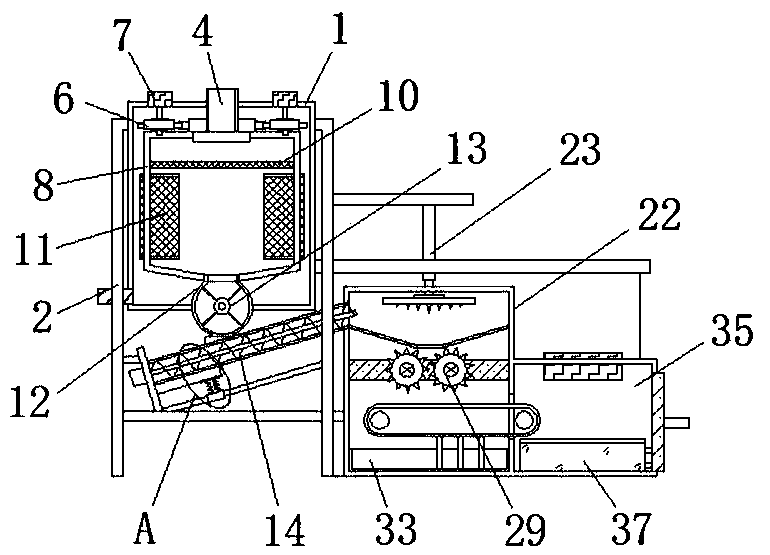

Horizontal rice steaming machine capable of recycling water resources and method

PendingCN114058466ARealize quantitative outputFacilitate subsequent production and processingAlcoholic beverage preparationYeastYield (wine)

The invention discloses a horizontal rice steaming machine method capable of recycling water resources, raw rice milk water and cooling water generated in the rice soaking and steaming process are collected to obtain feeding water with a low PH value, one part is used for yellow rice wine feeding, the low PH value is beneficial for inhibiting infectious microbes and improving the yield of yellow rice wine, and the other part is used for feeding water of yellow rice wine yeast. The low PH value is beneficial to inhibiting infectious microbes and improving the qualification rate of the distiller's yeast; according to the horizontal rice steaming machine capable of recycling water resources, raw rice milk water and cooling water generated in the rice steaming process can be collected to serve as feeding water.

Owner:ZHEJIANG JIASHAN RICE WINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com