Steel ball quantitative output device for packaging

An output device and packaging technology, applied in the direction of packaging, transportation and packaging, packaging item types, etc., can solve the problems of wasting manpower and troubles, and achieve the effect of improving production efficiency and convenient and quick quantitative output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

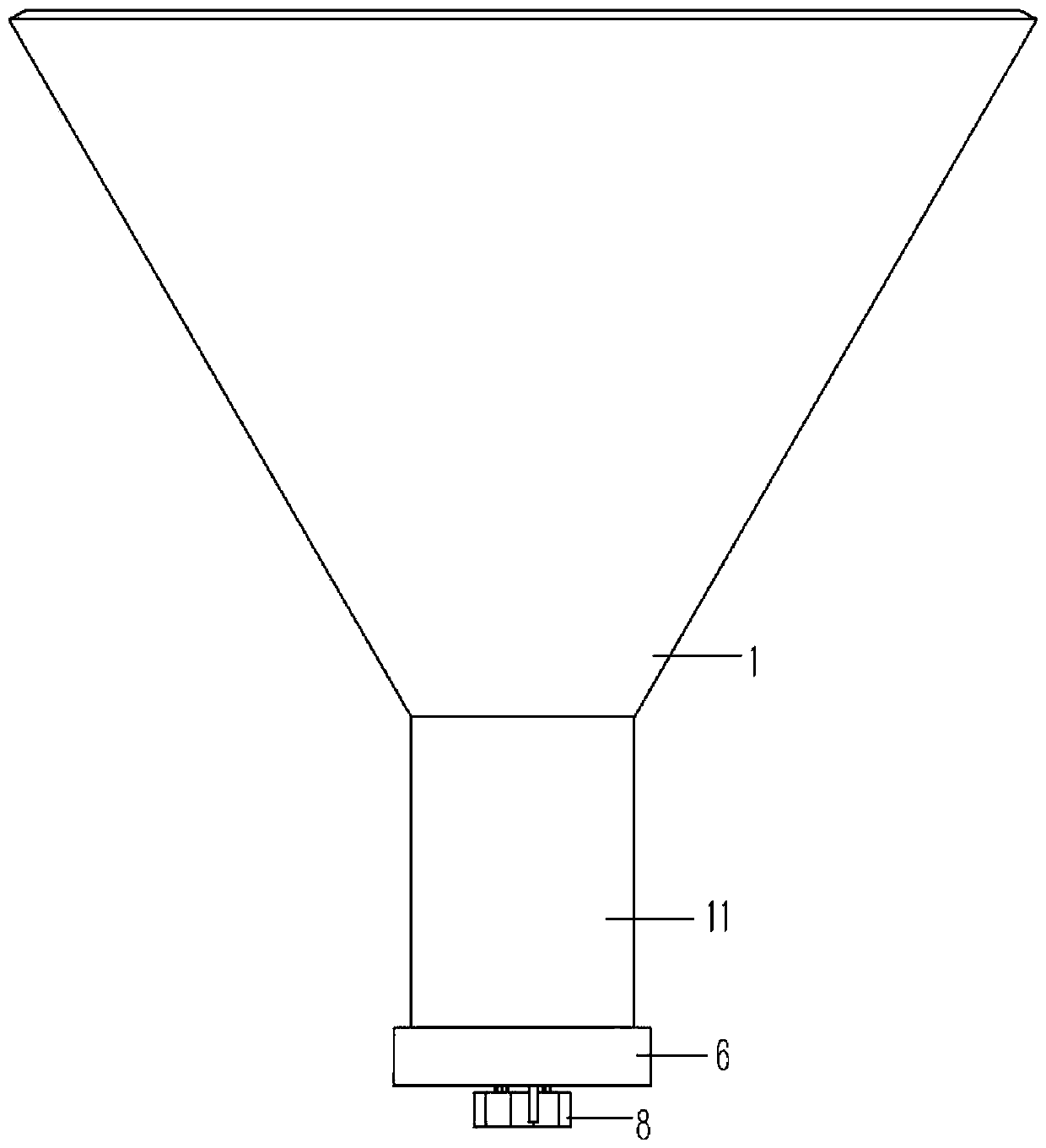

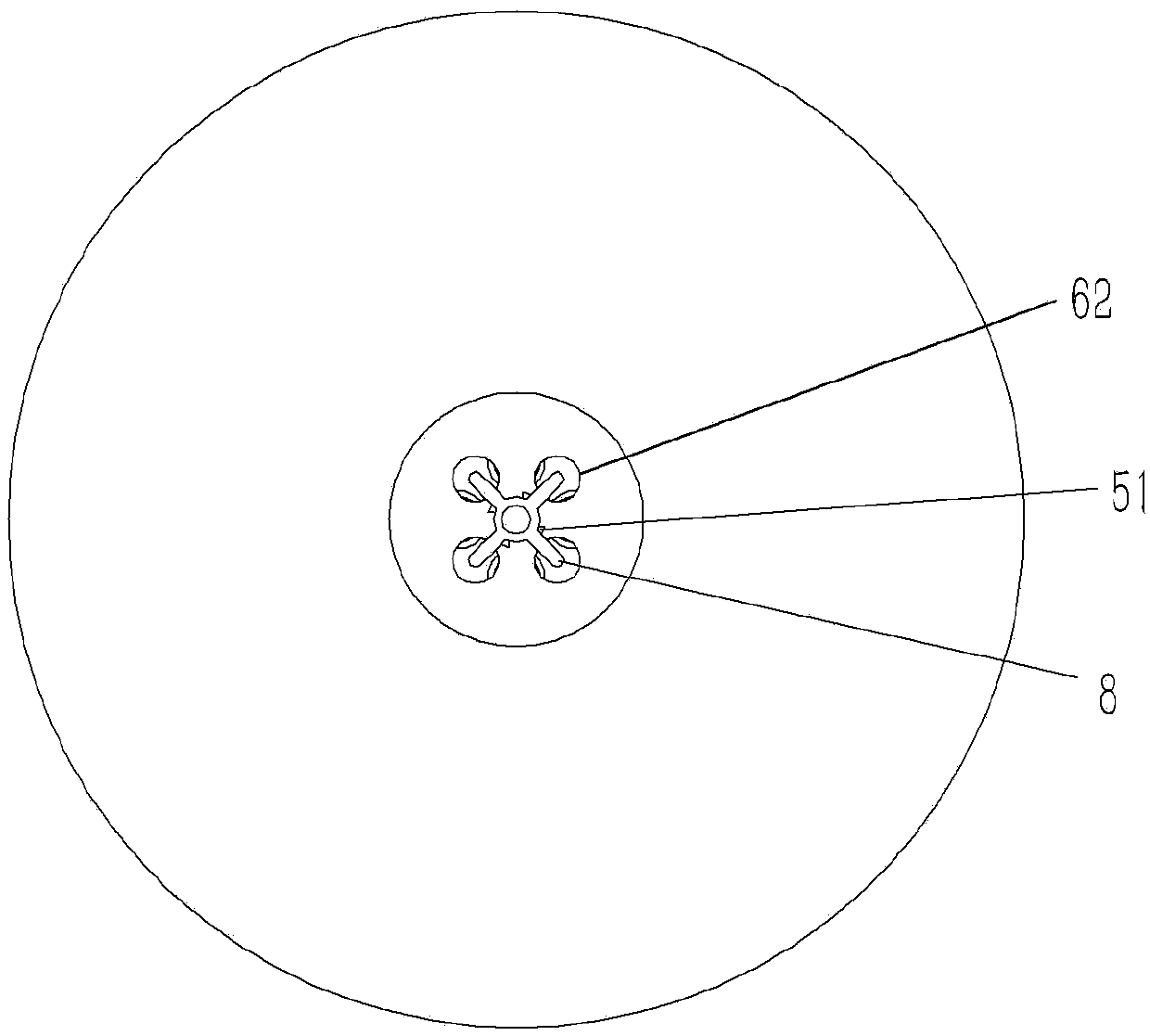

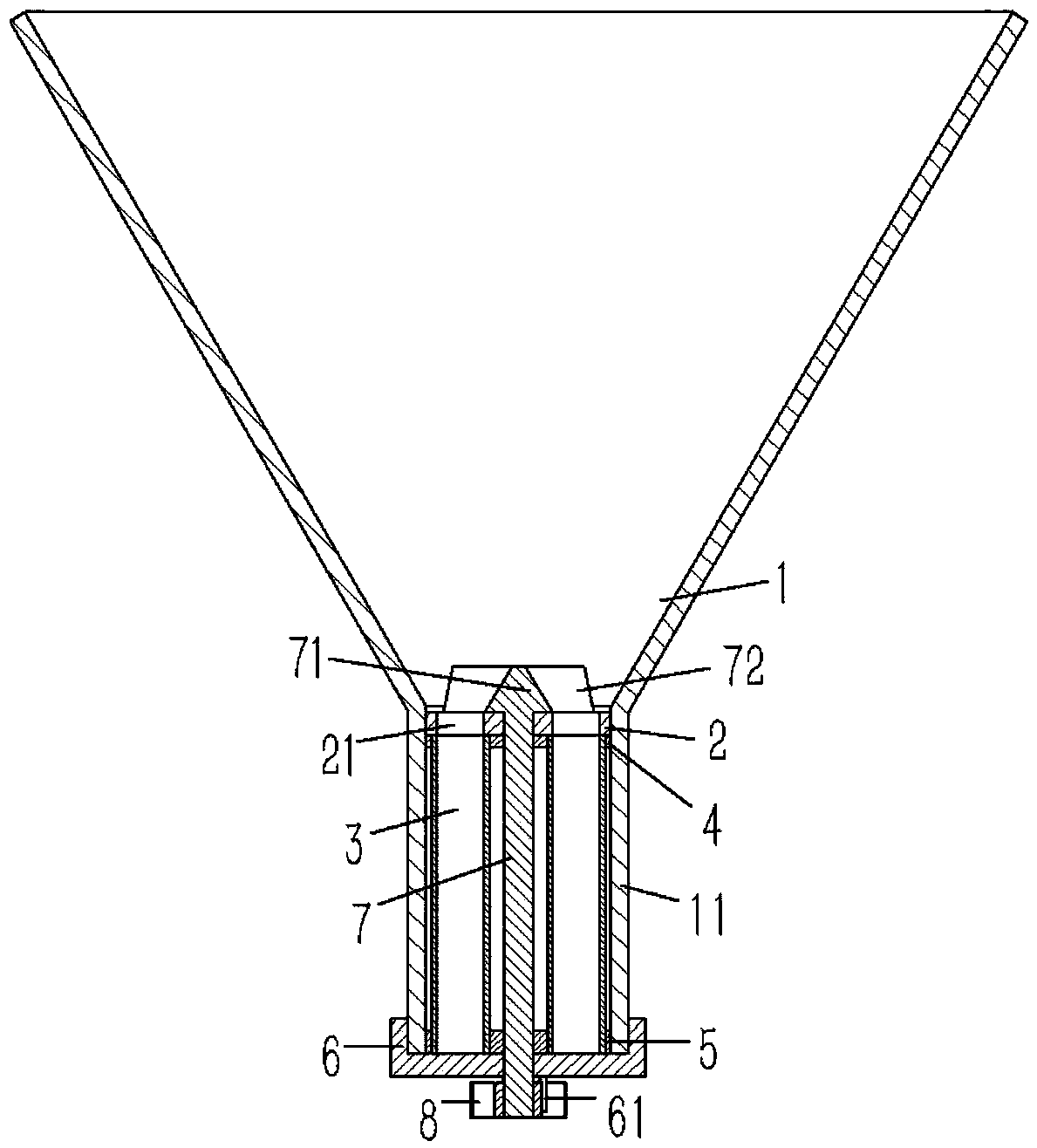

[0016] Example: see Figures 1 to 3 As shown, a steel ball quantitative output device for packaging includes a conical hopper 1, the lower end of the hopper 1 is formed with a vertical guide tube 11, and a positioning plate 2 is fixed on the inner wall of the upper end of the guide tube 11. A plurality of through holes 21 are formed on the positioning disc 2, and the through holes 21 are evenly distributed in a ring around the central axis of the positioning disc 2; The metering tube 3 opposite to the through hole 21, the upper end of the metering tube 3 is plugged and fixed on the upper turntable 4, and the upper end of the upper turntable 4 abuts against the lower end surface of the positioning plate 2 and against the inner wall of the draft tube 11; The lower end of the metering tube 3 is plugged and fixed on the lower turntable 5, the lower turntable 5 abuts against the inner wall of the draft tube 11 and against the end cover 6, and the end cover 6 is fixed on the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com