Mechanical ball adding machine

A ball adding machine, mechanical technology, applied in the direction of grain processing, etc., can solve the problems of inaccurate adding balls, ball jamming, and easy grinding ball jamming, etc., to achieve compact equipment structure, prevent ball jamming, and prevent jamming ball effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

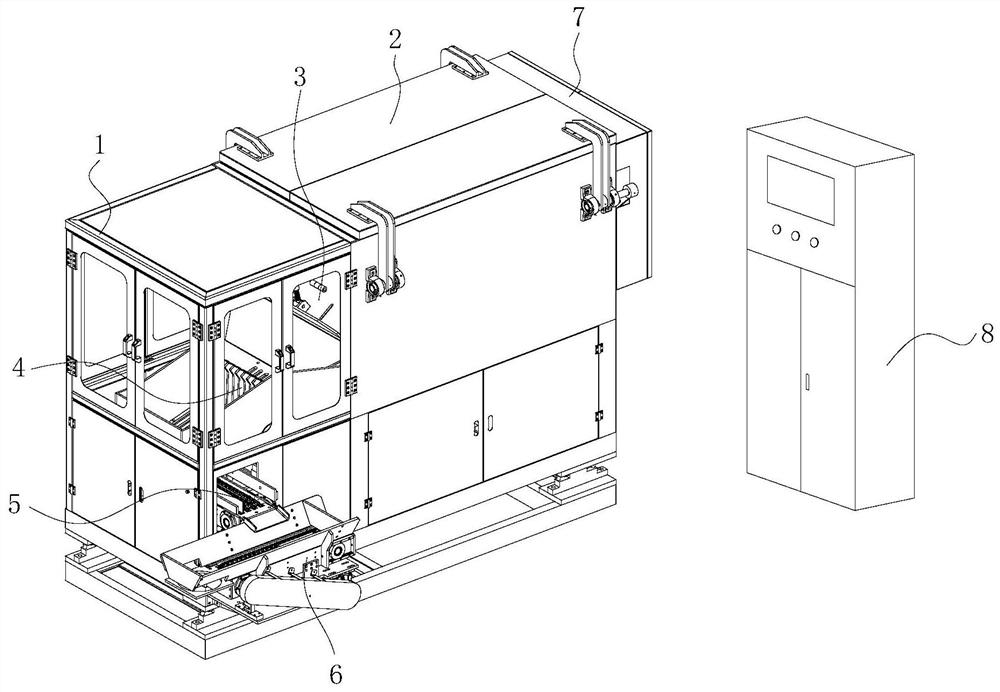

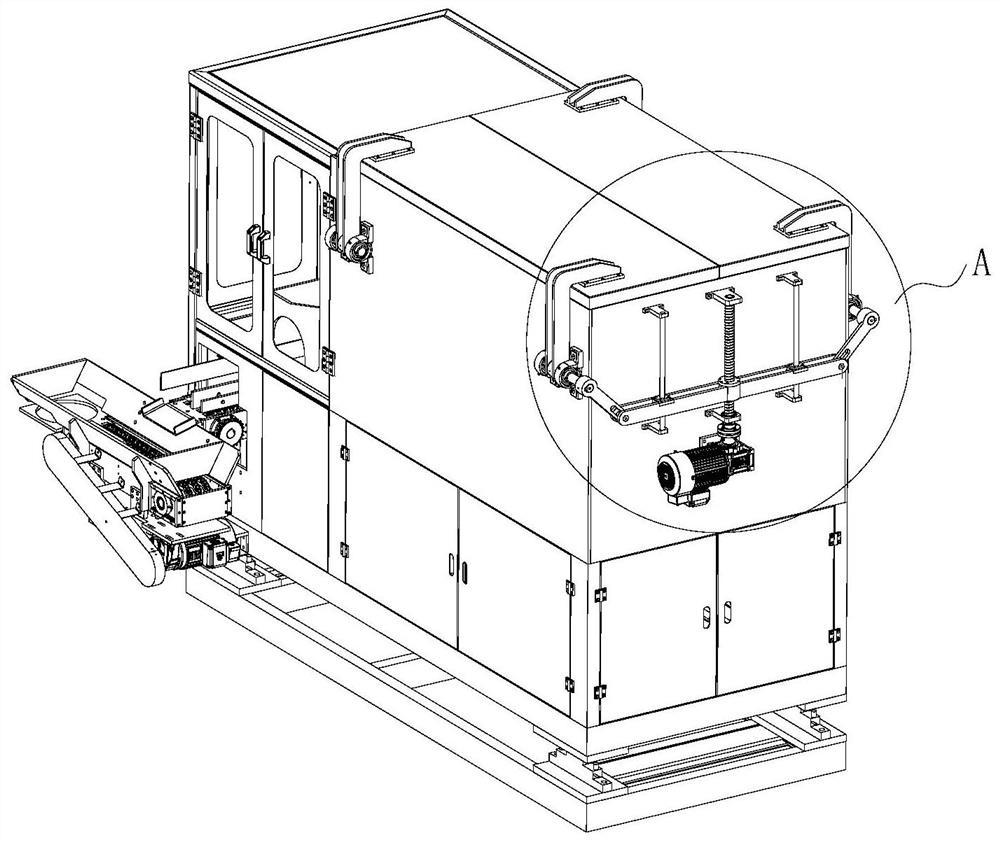

[0056] Please refer to figure 1 , figure 2 and Figure 4 As shown, the present invention discloses a mechanical ball adding machine, which includes a frame 1, a ball storage bin 2, a material door mechanism 3, a turning claw mechanism 4, a reversing conveyor belt 5, a weighing mechanism 6, and a door opening mechanism. Closing mechanism 7 and control host 8.

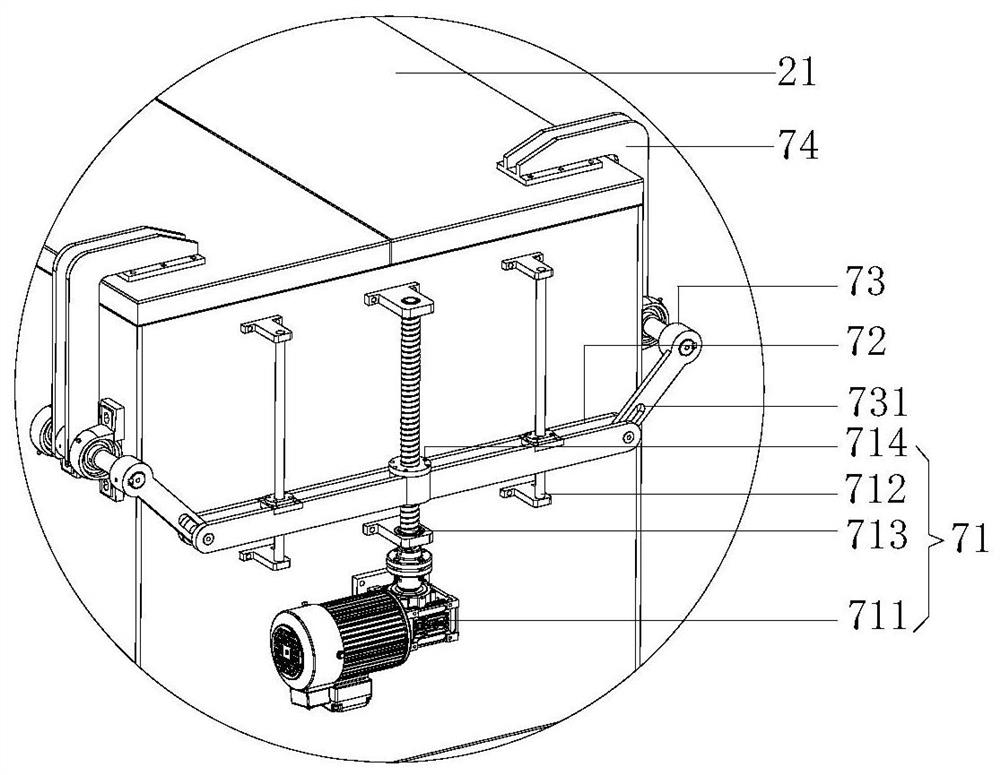

[0057] Please refer to image 3 As shown, wherein, the ball storage bin 2 is used for storing grinding balls. In order to realize the anti-theft of the grinding balls, preferably, the ball storage bin 2 is provided with a door 21. above the mouth to close the hatch.

[0058] The door opening and closing mechanism 7 includes a push-pull device 71 , a push block 72 , a pair of swing rods 73 and a pair of swing arms 74 . The push-pull device 71 pushes and pulls the push block 72 to go up and down. One end of a pair of swing arms 73 is respectively fixedly connected with the outer edges of a pair of bin doors 21 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com