Efficient and water-saving feed putting device for large ornamental fish culture box

A feeding device and breeding box technology, which is applied in the field of ornamental fish breeding, can solve the problems of large impact, feed accumulation, and increased work difficulty, and achieve the effects of increasing drying time, avoiding accumulation, and improving drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

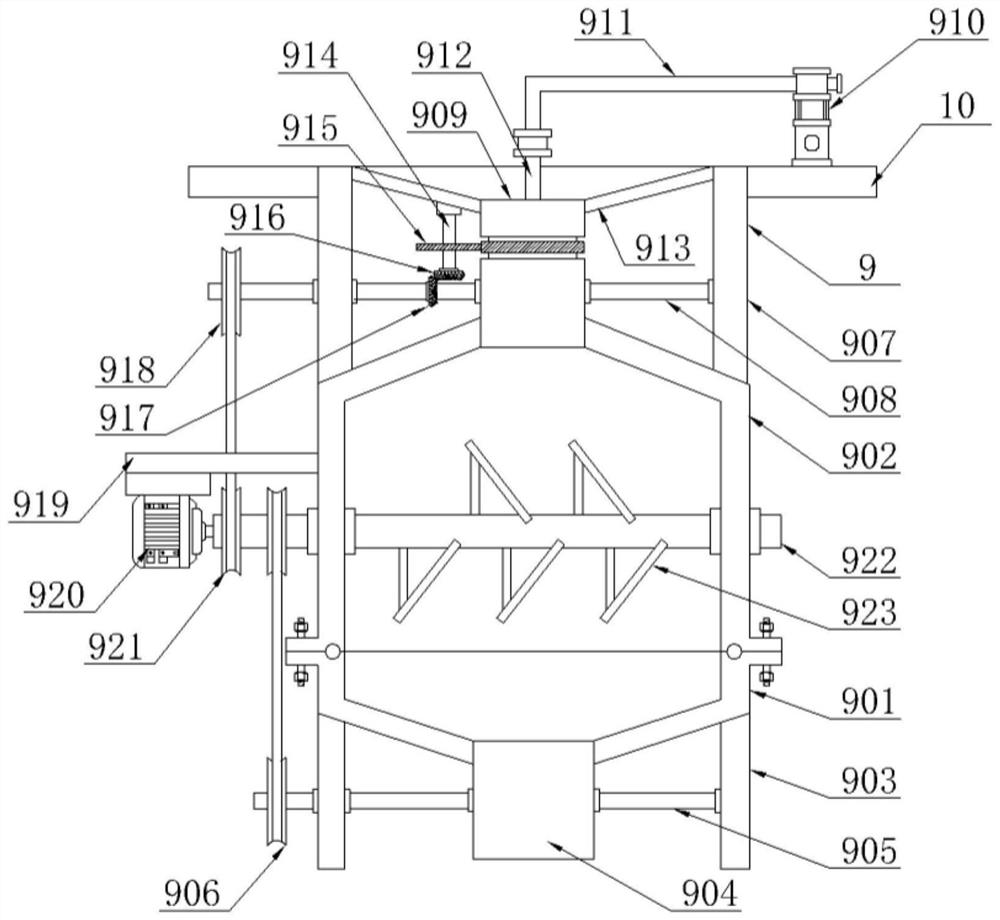

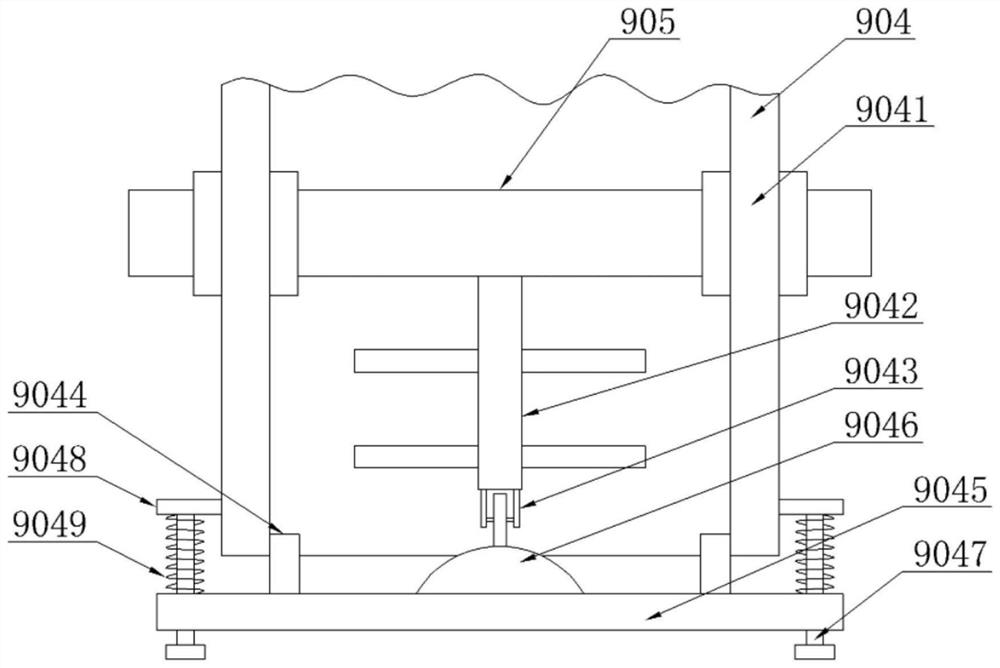

[0027]1) Feed preparation: First, pour the feed into the hopper 913. The feed leaks into the dry quantitative feeding device 909 through the hopper 913. Dry gas is injected through the pump body 910 to dry the feed to prevent the feed from being blocked by moisture and adhesion. After drying for a period of time, start the rotating motor 920, the rotating motor 920 drives the rotating shaft 922 to rotate, the rotating shaft 922 drives the upper rotating rod 908 to rotate, the cylinder 9092 is driven to rotate, so that the feed can only be discharged through the groove 9093, and the rotation can be controlled. The rotation speed of the motor 920 realizes quantitative feeding. The function of the stirring gear 923 is to agitate the feed in the upper feeding box 902, and after the feed is broken up, it is discharged through the anti-blocking quantitative discharge device 904;

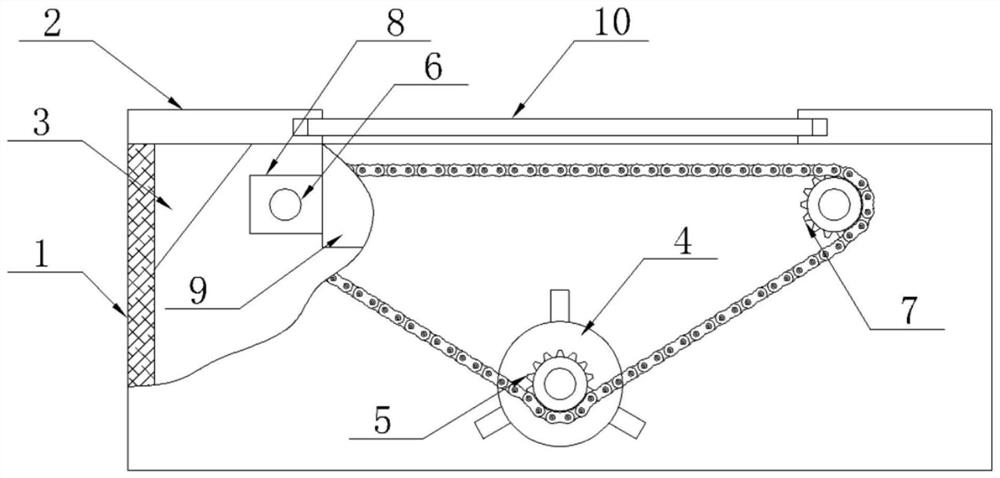

[0028]2) Feed feeding: the drive motor 4 drives the gear 5, the transmission gear 7 and the screw rod 6 to rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com