Floating dock underwater assembly technology

A technology of floating docks and crafts, which is applied to ship components, ship construction, ships, etc. It can solve the problems of inability to close and launch, insufficient length and width, etc., and achieve the effects of balancing delivery, shortening the construction period, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

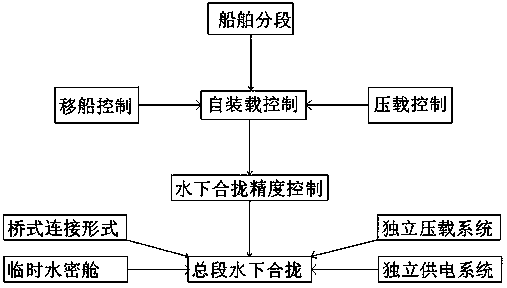

[0027] Such as figure 1 Shown is a floating dock underwater closing process, the specific process steps are as follows:

[0028] S1: Ship segmentation: divide the construction of the entire ship into multiple ship segments and assemble them into multiple general segments one by one, and meet the self-loading requirements;

[0029] S2: Launching: the ship is launched and undocked separately in sections or loaded in sections at both ends in the middle section;

[0030] S3: Self-loading control: use the unfinished sections of the floating dock to hold up other unfinished sections; in the state of floating on the water surface or in the dock, load multiple general sections to be assembled on the middle general section, Reduction of vessel loading size and required dock length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com