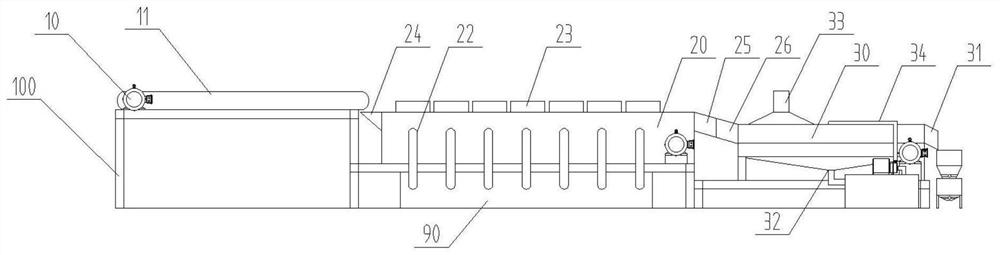

Horizontal rice steaming machine capable of recycling water resources and method

A rice steamer and water resource technology, applied in the field of yellow rice wine production, can solve the problems of low efficiency, poor sealing performance of the rice steamer, waste of heat, etc., and achieve the effects of improving the qualification rate of wine mother, improving the qualification rate of rice wine, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

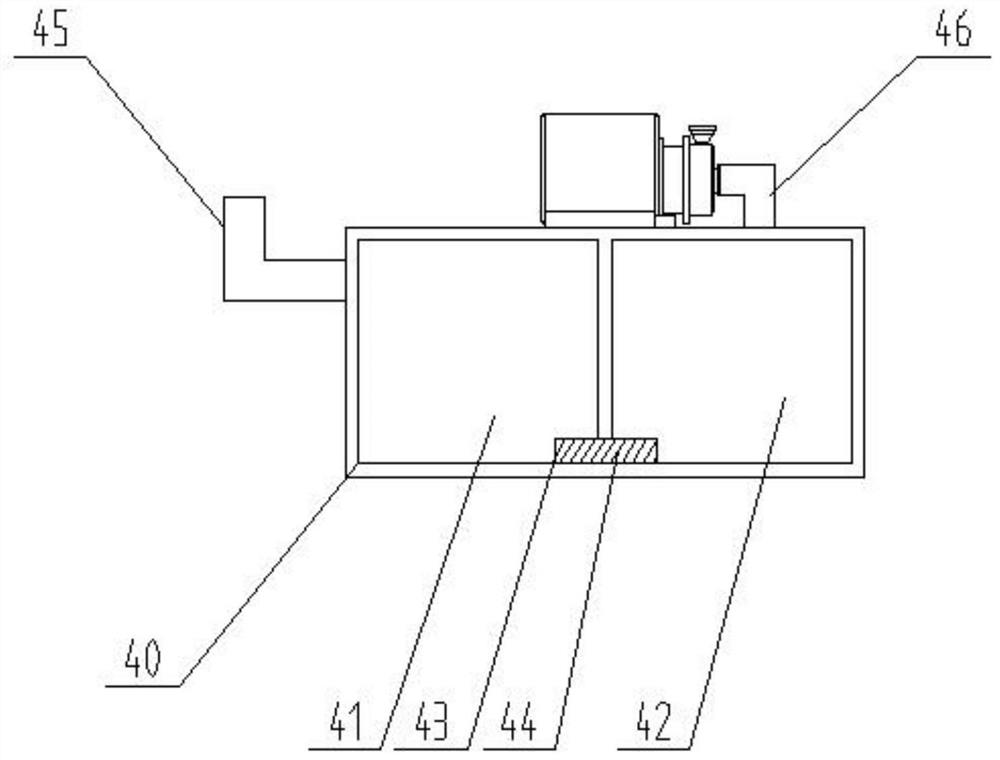

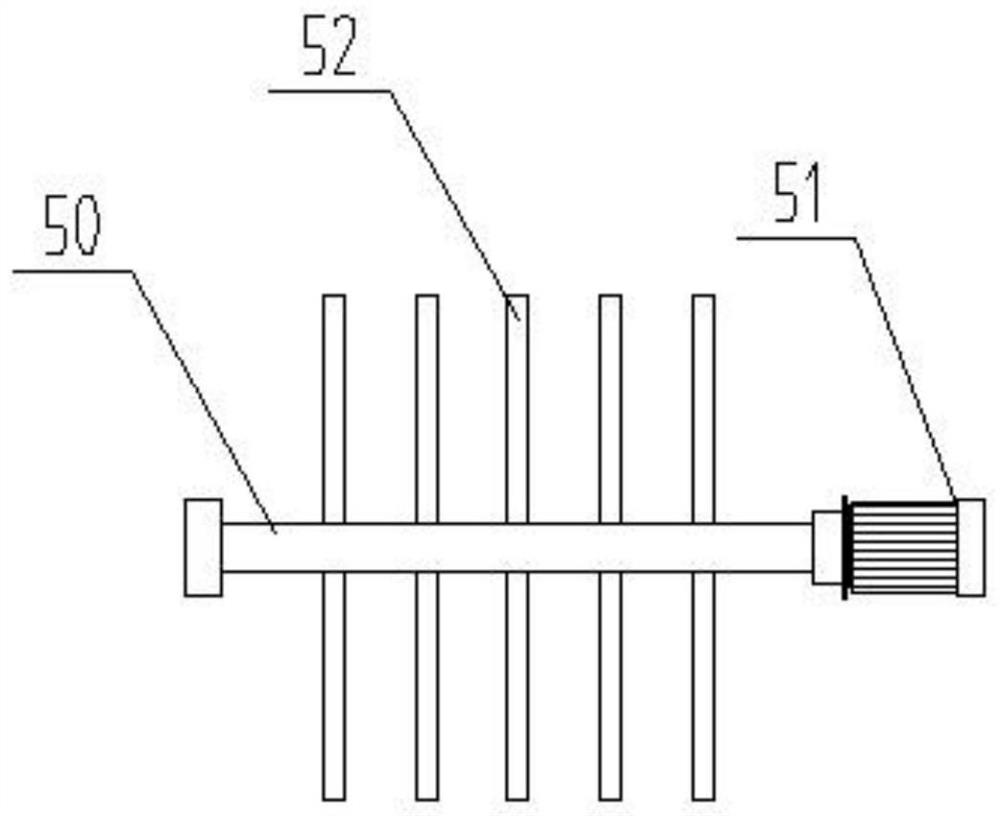

Method used

Image

Examples

Embodiment 1

[0119] a kind of rice wine

[0120] 1. After the dipping process, some raw rice slurry water will remain on the rice, and the rice will be taken to the rice steaming steel belt, and it will be cooked and cooled; 2. After the processing is completed, the equipment needs to be rinsed; 3. During processing, it is necessary to Cooling water used for cooling cooked rice. The collected physical and chemical indicators of circulating water are as follows:

[0121] Acidity (calculated as lactic acid): 0.1g / L; PH: 6.2; solids: 0.01g / L; 80% of water is used for feeding rice wine, and low pH value is beneficial to inhibit miscellaneous bacteria and improve the pass rate of rice wine; 20% of water It is used as the feeding water of rice wine and distiller's mother. The low pH value is beneficial to inhibit bacteria and improve the pass rate of distiller's mother.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com