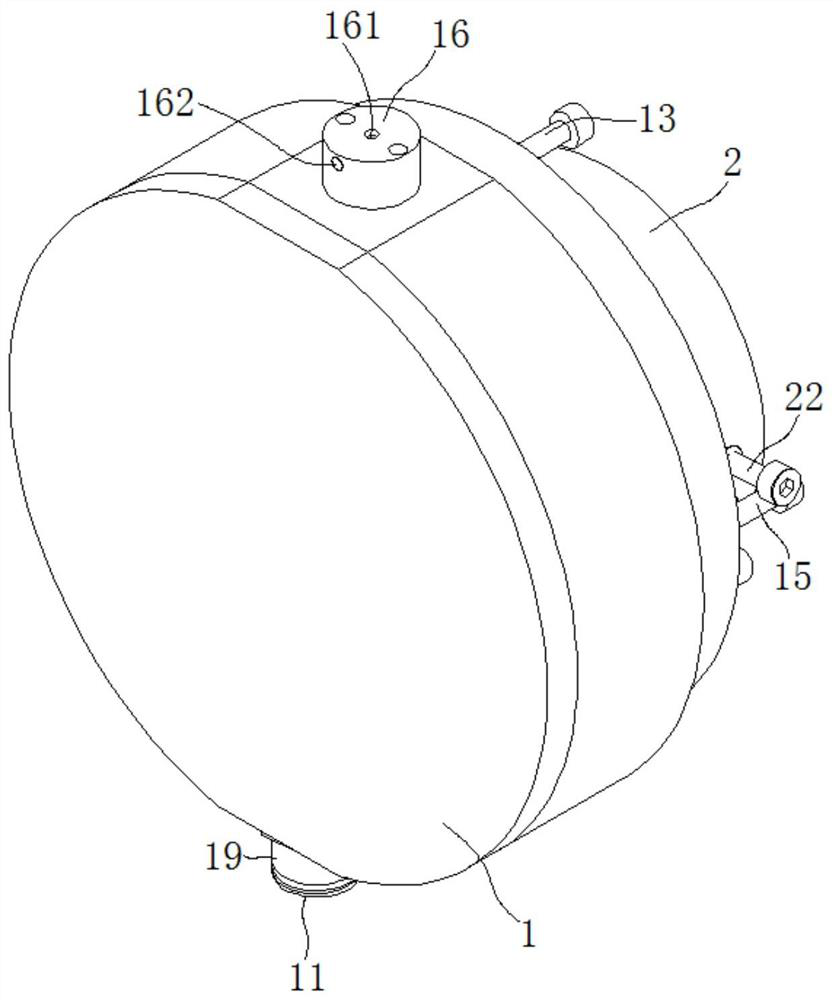

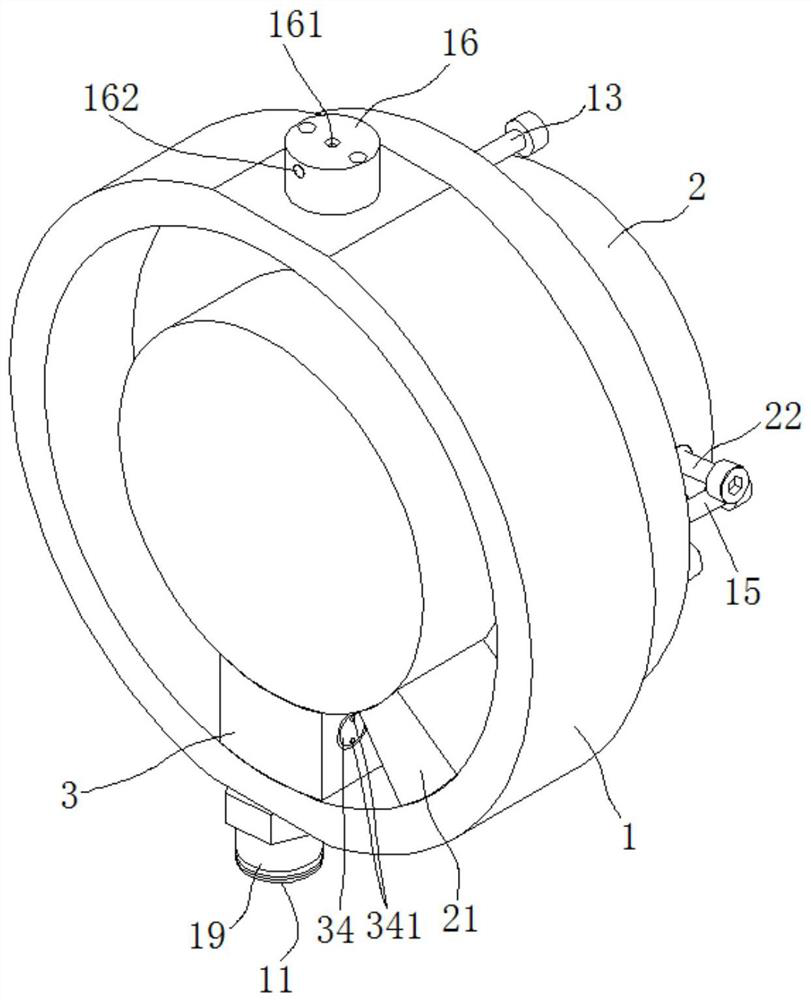

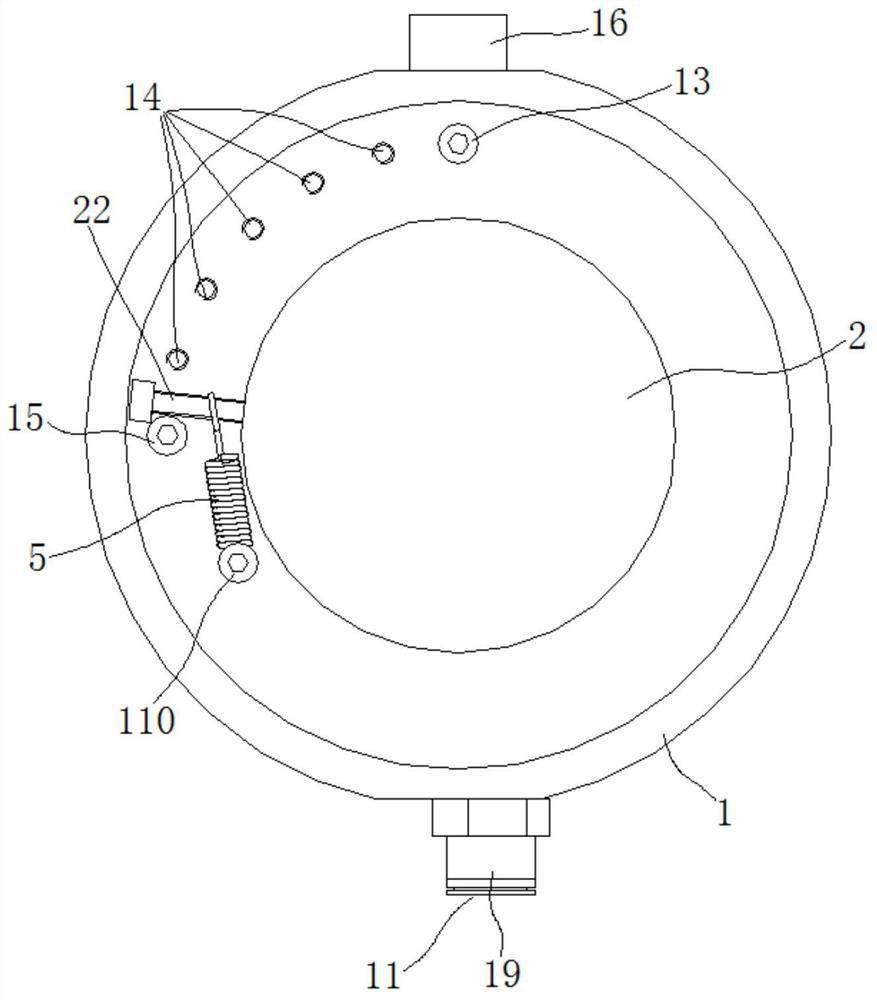

Distributor and main shaft

A distributor and seat technology, which is applied in distribution devices, engine components, engine lubrication, etc., can solve the problem of difficult quantitative transportation of oil bodies, inability to supply different oil quantities, and inability to adjust the oil output of quantitative oil and gas distributors, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Preferred embodiments of the present application will be described in detail below with reference to the accompanying drawings. Those skilled in the art will appreciate that these descriptions are only descriptive and exemplary, and should not be construed as limiting the protection scope of the present application.

[0045] First of all, it should be noted that the orientations of top, bottom, upward, and downward mentioned in this article are defined relative to the directions in each drawing, and they are relative concepts, and therefore can be It changes in different positions and different practical states. Accordingly, these or other orientations should not be construed as limiting terms. In addition, the "front" and "rear" in this embodiment are defined relative to the upstream and downstream of the oil passage, wherein the front end is near the upstream end, and the rear end is near the downstream end.

[0046] It should be noted that the term "comprising" doe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com