Steel ball output device capable of adjusting specified number

A technology of output device and quantity, applied in the directions of transportation and packaging, packaging, packaging protection, etc., can solve the problems of wasting manpower, troublesome packaging, troublesome, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

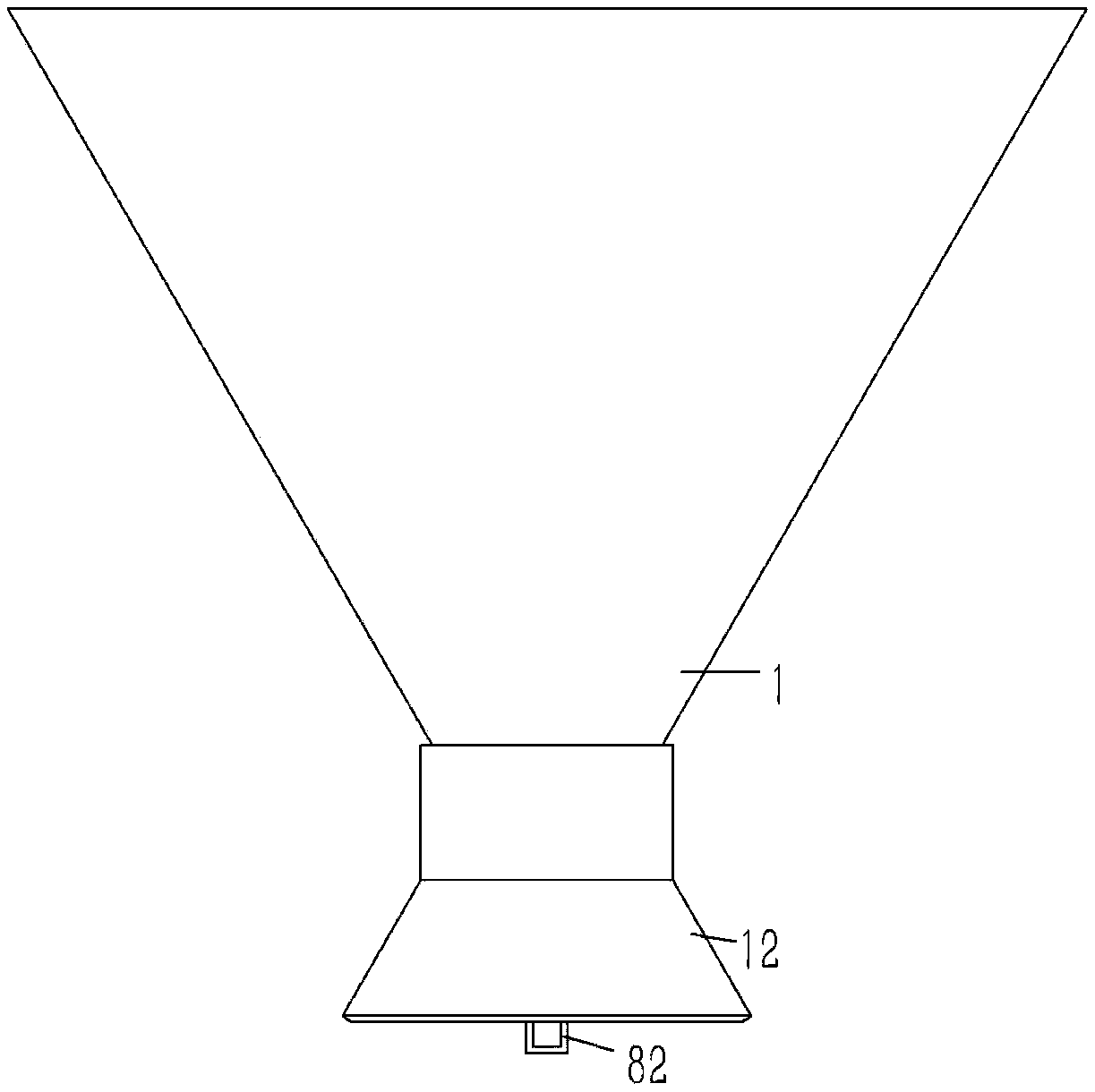

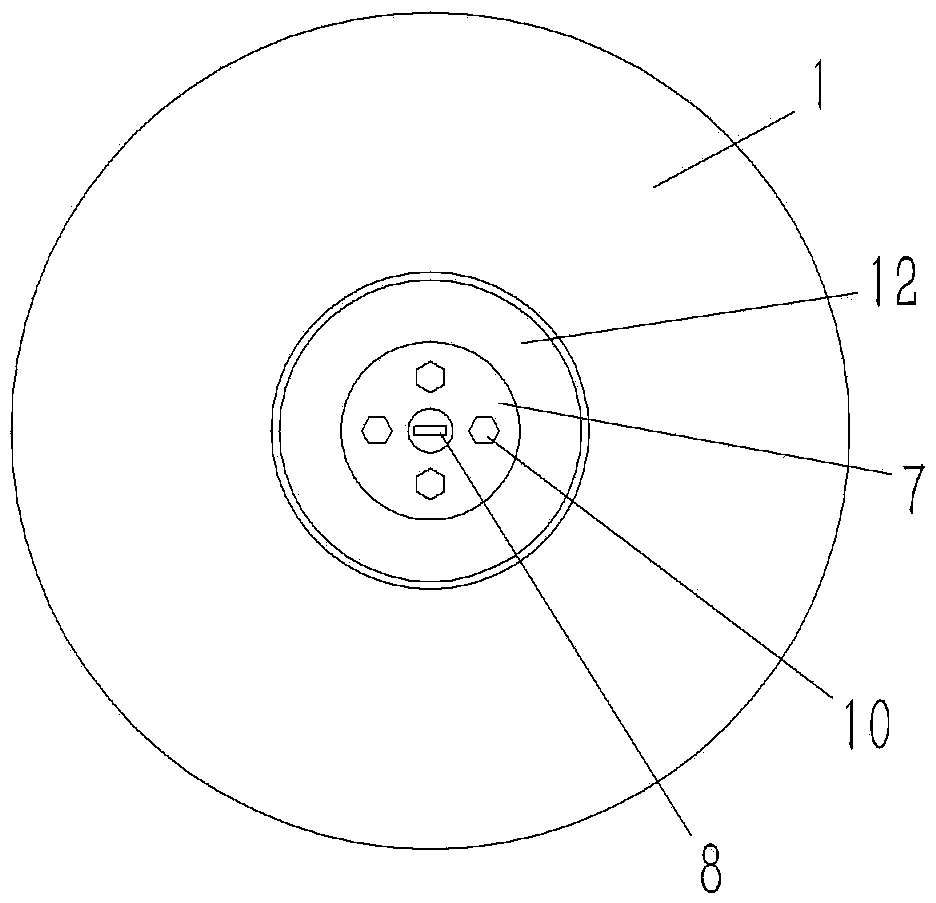

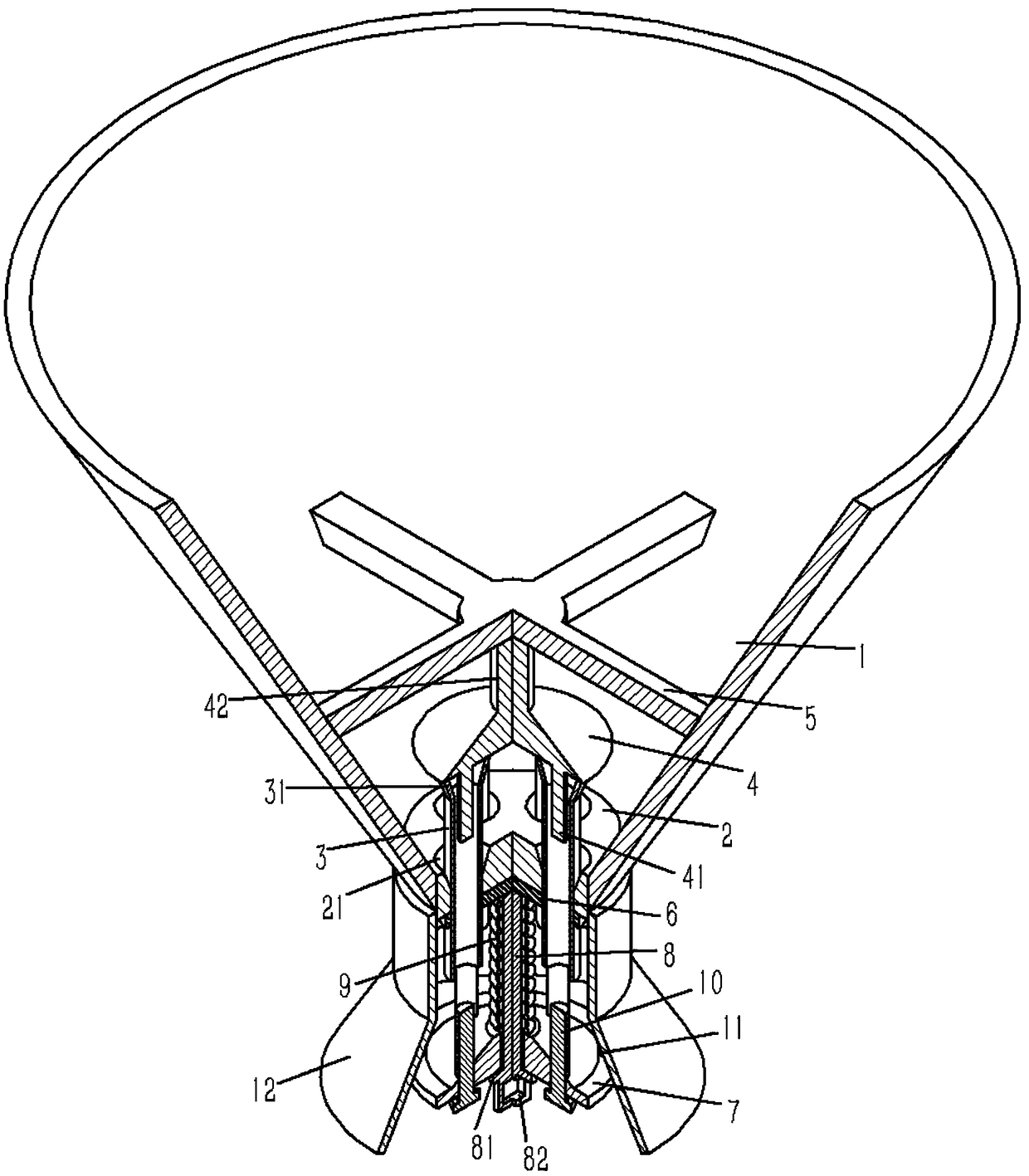

[0018] Example: see Figures 1 to 3 As shown, a steel ball output device with adjustable rated quantity includes a conical hopper 1, a positioning block 2 is inserted and fixed in the outlet of the lower end of the hopper 1, and a number of vertical pins are inserted and fixed on the positioning block 2. Metering tube 3, the metering tube 3 is evenly distributed on the positioning block 2 around the center of the hopper 1, the lower end of the metering tube 3 protrudes from the positioning block 2 and is plugged and fixed on the connecting bracket 6, and the lower side of the connecting bracket 6 is provided with a cone Shaped base 7, several upright posts 11 are fixed on the outer edge of base 7, and the upper end of upright post 11 is fixed on the positioning block 2; A baffle plate 81 is formed through the base 7, and a compression spring 9 is sleeved on the pull rod 8. The two ends of the compression spring 9 are respectively pressed against the connecting bracket 6 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com