Rain-night reflective bead mixing equipment

A technology of mixing equipment and reflective beads, which is applied in the field of marking paint, can solve the problems of inability to achieve precise bead ratio and different bead sizes, and achieve the effects of simple structure, improved product quality, and high linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

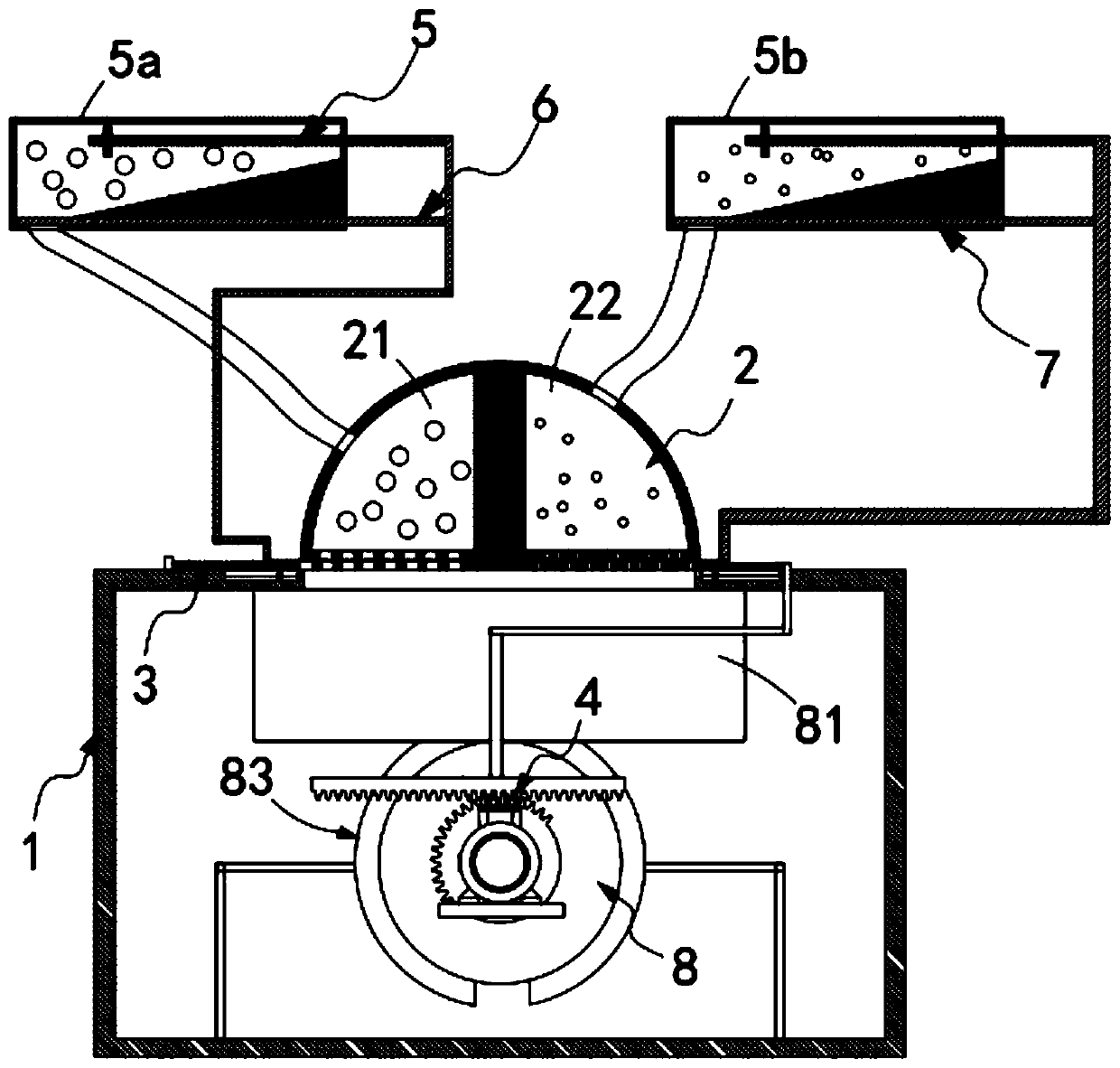

[0071] Such as figure 1 , figure 2 As shown, the rainy night reflective bead mixing equipment includes a reaction tank 1, a reflective bead storage box 2 arranged at the input end of the reaction tank 1, and also includes:

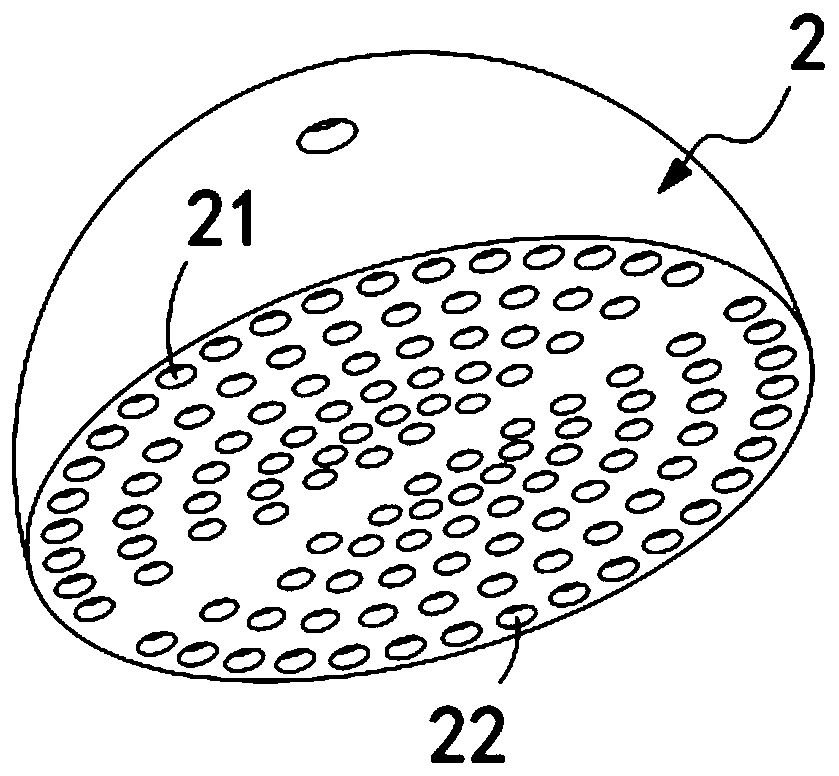

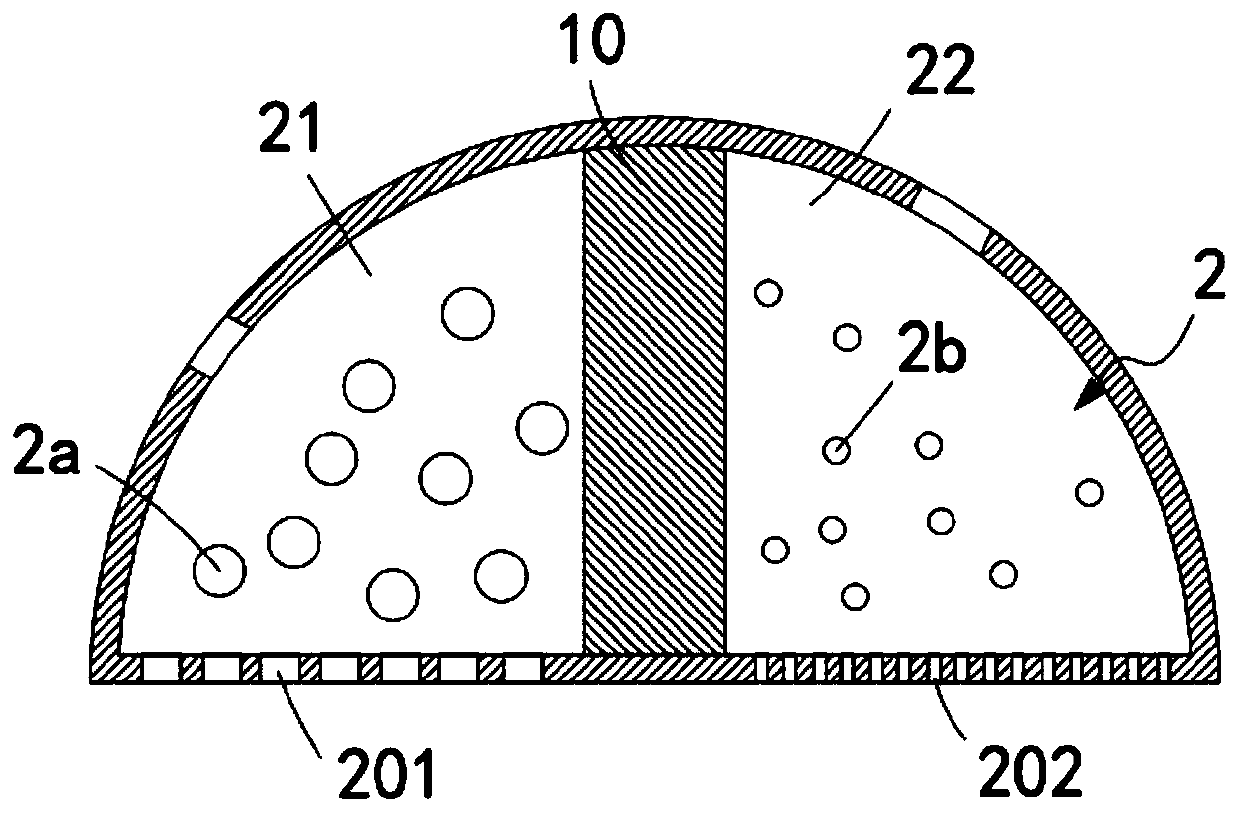

[0072] A discharge assembly 3, the discharge assembly 3 is attached to the output end of the reflective bead storage box 2, and the reflective bead storage box 2 is a semi-disc structure, which includes a rainy night reflective mother-of-pearl storage space 21 and rainy night reflective beads bead storage space 22;

[0073] a drive assembly 4, the drive assembly 4 drives the discharge assembly 3 to reciprocate and circulate in the horizontal direction;

[0074] Replenishment assembly 5, which includes a first storage bin 5a and a second storage bin 5b located above the reflective bead storage box 2, the first storage bin 5a and the reflective bead The rainy night reflective mother-of-pearl storage space 21 of the storage box 2 is connected and arranged...

Embodiment 2

[0125] Such as Figure 18 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0126] further, such as Figure 18 As shown, the upper end of the reaction tank 1 is provided with a first opening 11, and the diameter of the first opening 11 is R1, and the diameter of the lower surface of the reflective bead storage box 2 is R2, and R1≥R2.

[0127] In this embodiment, by setting R1≧R2, the rainy night reflective mother-of-pearl beads 2a and rainy night reflective beads 2b in the reflective bead storage box 2 are completely dropped into the reaction tank 1 .

[0128] work process:

[0129] First start the driving motor 41, utilize the rotation of the driving motor 41 to drive the driving tooth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com