Patents

Literature

666results about How to "Precise ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Premixing mortar with high moisture retention and production method thereof

The invention discloses pre-stirring mortar with high moisture retention and a production method thereof. The premixing mortar comprises the following components by weight ratio: 100 parts of cement with the high moisture retention, 1 to 900 parts of fine aggregate and 30 to 200 parts of water, wherein the cement with the high moisture retention contains a cellulose ether component and has the moisture retention above 90 percent; and the fine aggregate is natural sand or artificial sand obtain through screen sizing or removing harmful components, and has the maximum grain diameter of 1.18 mm to 2.36 mm. The production method comprises the following steps: arranging a mortar stirring machine on a construction site or nearby; adopting the cement with the high moisture retention and the fine aggregate to automatically meter and stir, enable mortar to be usable while stirring, and the like to ensure the mortar quality; and adopting a closed stirring mode, a dust-collecting mode and the like to reduce dust raise. The pre-stirring mortar can effectively improve and ensure the qualities of the mortar buildings, obviously improves the construction environment, greatly decreases the production cost of the pre-stirring mortar and solves the difficult problems that the prior pre-stirring mortar has over-high cost and are difficult to popularize and apply.

Owner:SOUTH CHINA UNIV OF TECH

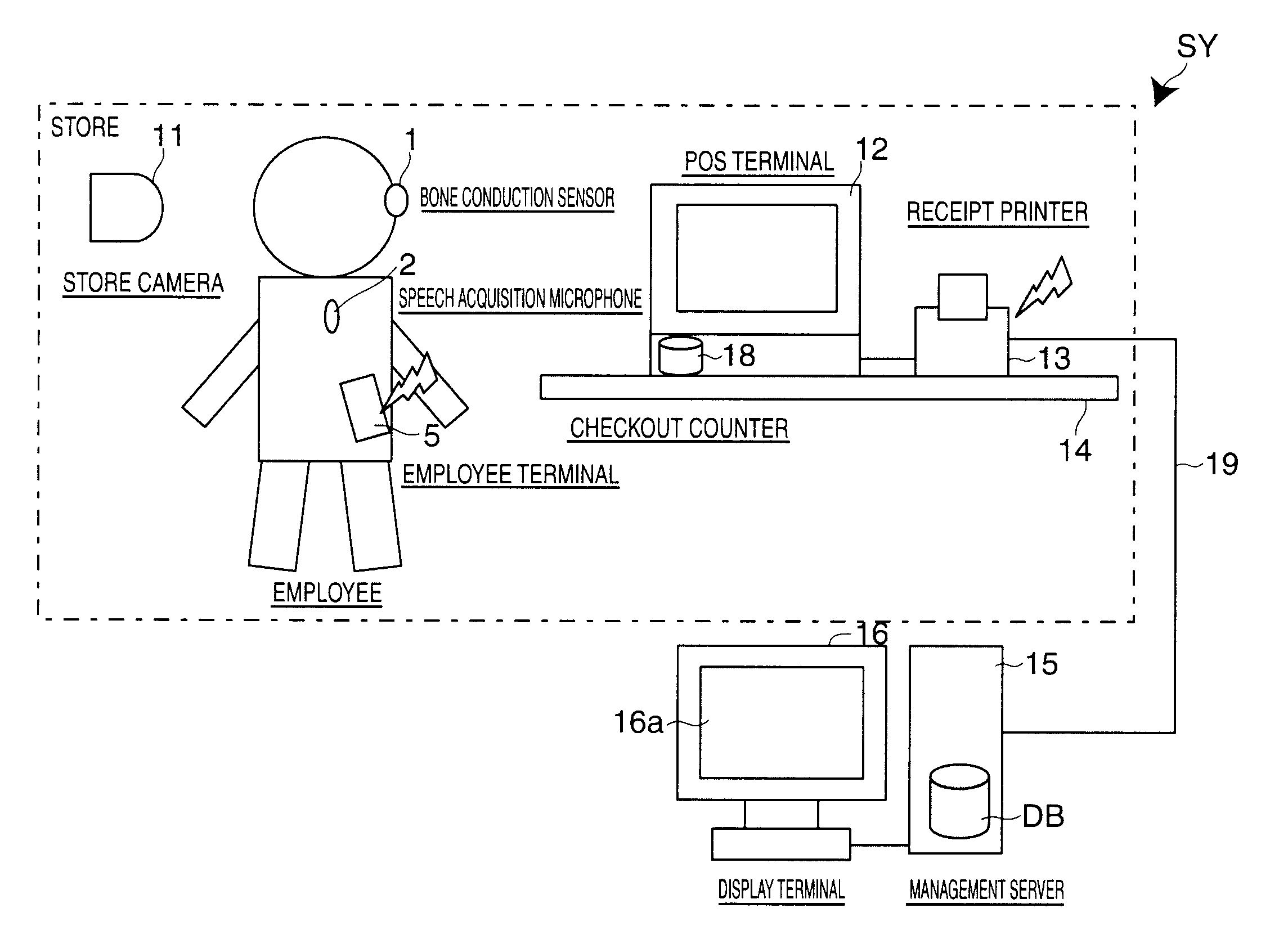

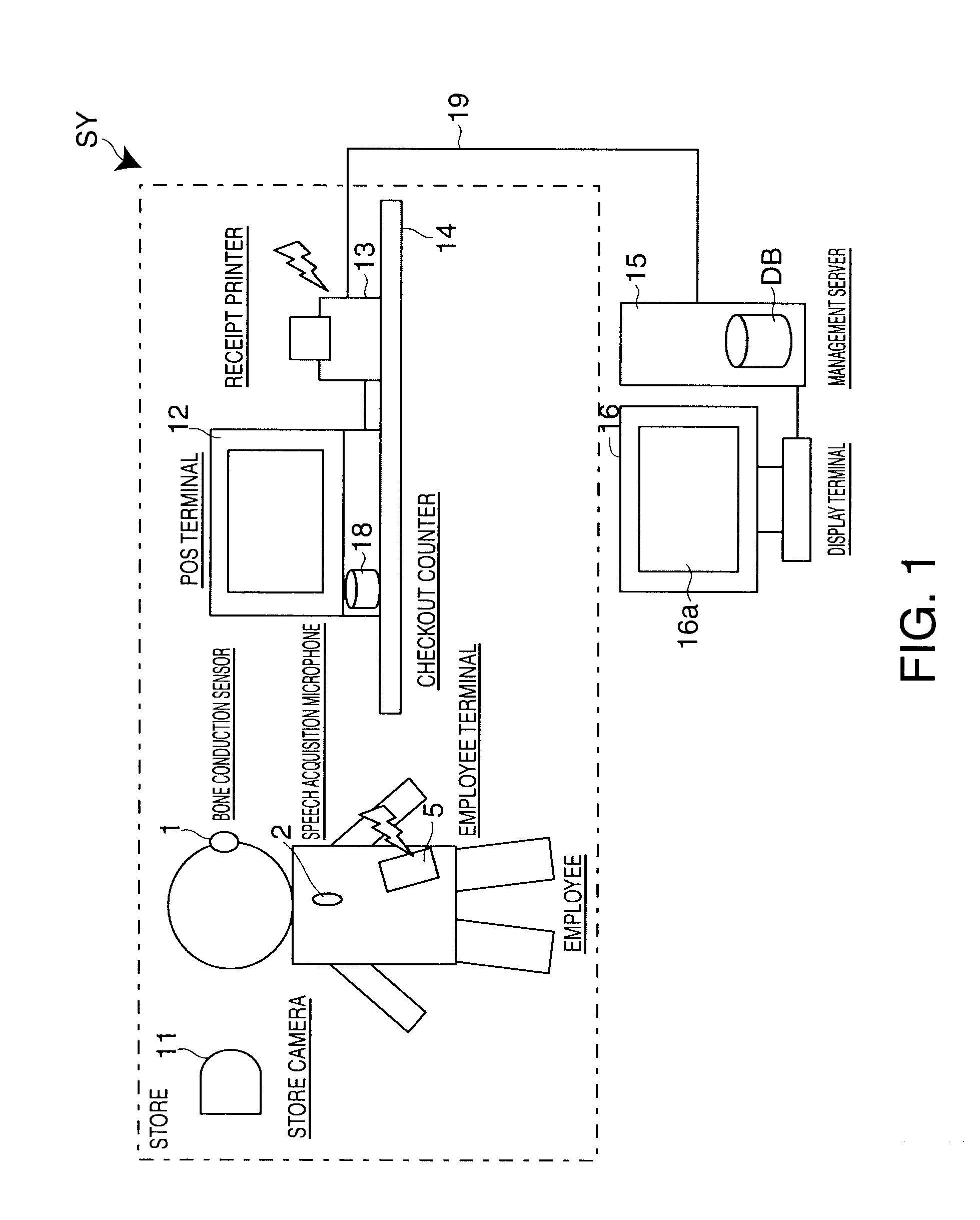

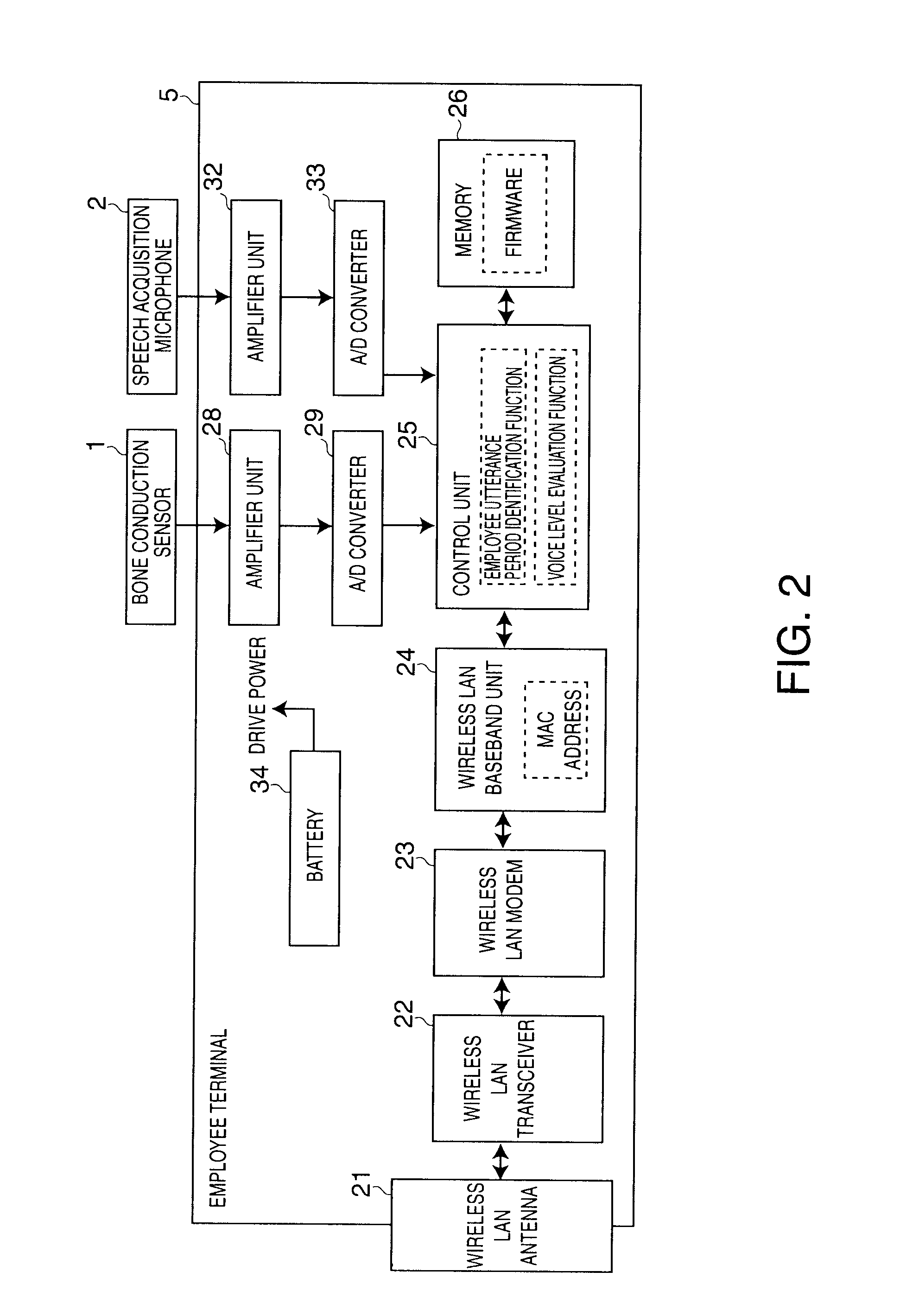

Customer Service Data Recording Device, Customer Service Data Recording Method, and Recording Medium

InactiveUS20110282662A1Improve conversation skillsAccurately identify employee and customer speechSpeech recognitionData recordingSpeech sound

To enable determining the correlation between customer satisfaction and employee satisfaction, a speech acquisition unit 102 acquires conversations between employees and customers; an emotion recognition unit 155 recognizes employee and customer emotions based on employee and customer speech in the conversation; a satisfaction calculator 156, 157 calculates employee satisfaction and customer satisfaction based on the emotion recognition output from the emotion recognition unit 155; and a customer service data recording unit 159 relates and records employee satisfaction data denoting employee satisfaction and customer satisfaction data denoting customer satisfaction as customer service data in a management server database DB.

Owner:SEIKO EPSON CORP

Preparation of original bamboo fiber by bioenzyme method

The invention discloses a method to make bamboo origin fiber that the process includes following steps: cutting the bamboo and dissecting into sheet, adding to boiling water, taking out and crushing, hammering to filament, adding into pressure cooker to boil, dipping the processed bamboo filament into solution that contains biology enzyme to gain fibrin fiber, cleaning, whitening, oil pumping, softening, shredding the fibrin fiber, the bamboo origin fiber would be gained.

Owner:苏州市利飞纺织品有限公司

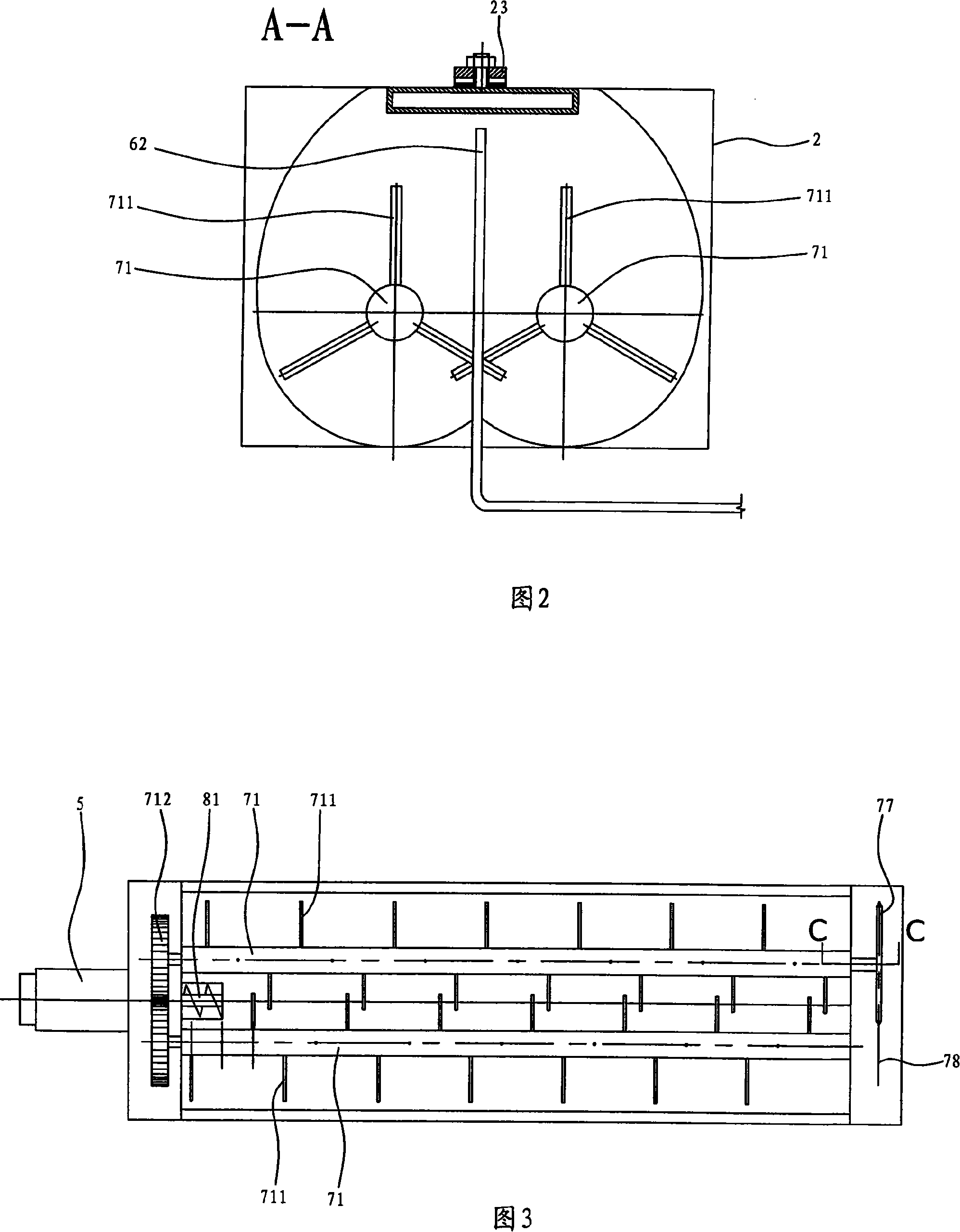

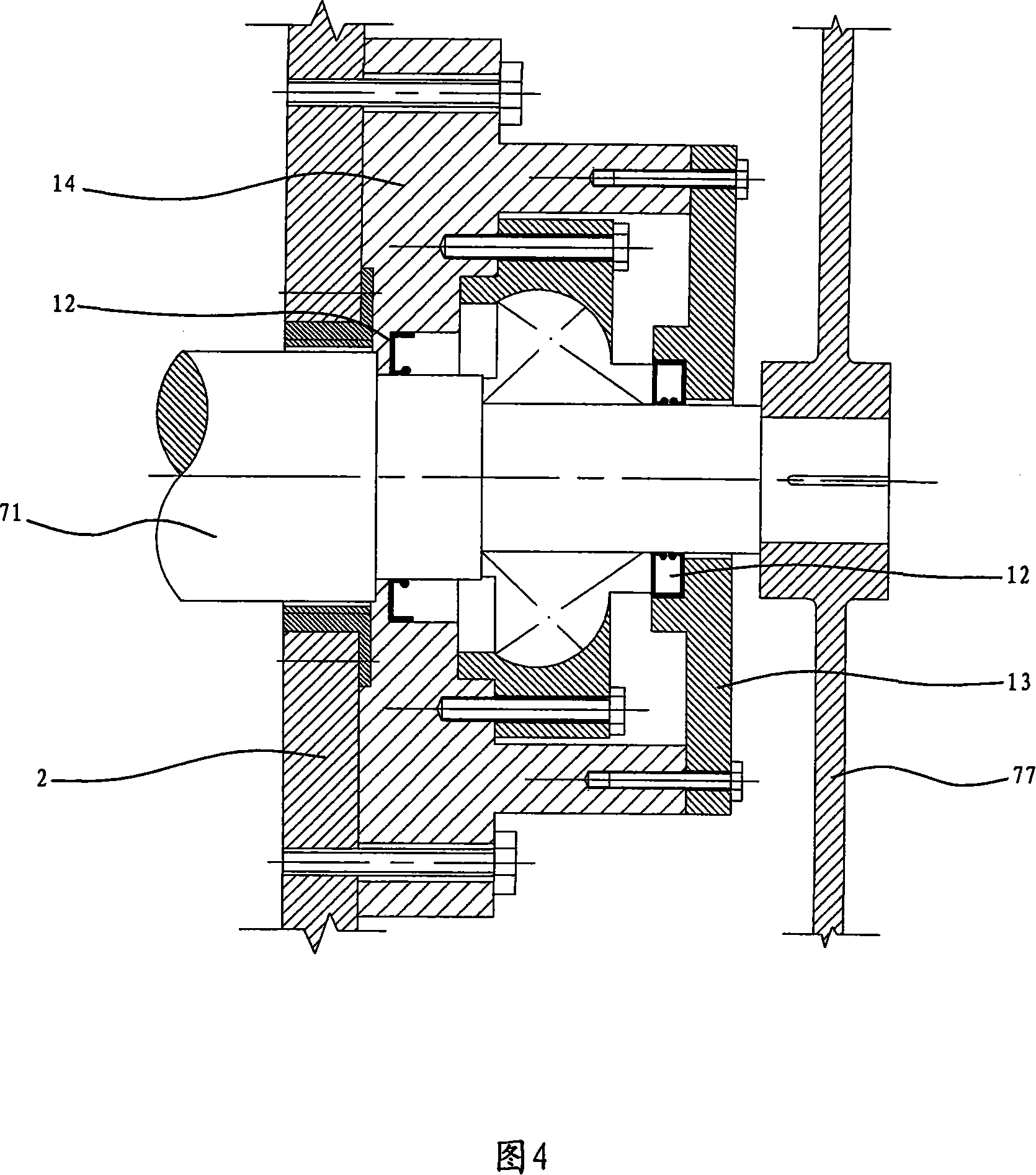

Continuous vacuum dough mixing machine and noodle producing equipment with the same

ActiveCN101147500AReduce labor intensityIncrease productivityRotary stirring mixersTransportation and packagingContinuous/uninterruptedControl circuit

The present invention relates to a continuous vacuum kneading machine and a noodles production equipment with said kneading machine. Said continuous vacuum kneading machine includes the following several portions: machine frame, kneading container, flour-conveying device, water-supplying device and control circuit. Said kneading container is equipped with a dough-discharging device. Besides, it also includes an evacuating device and a stirring-feeding device. Said invention also provides the working principle of said kneading machine and its concrete operation method.

Owner:山东江泷机械有限公司

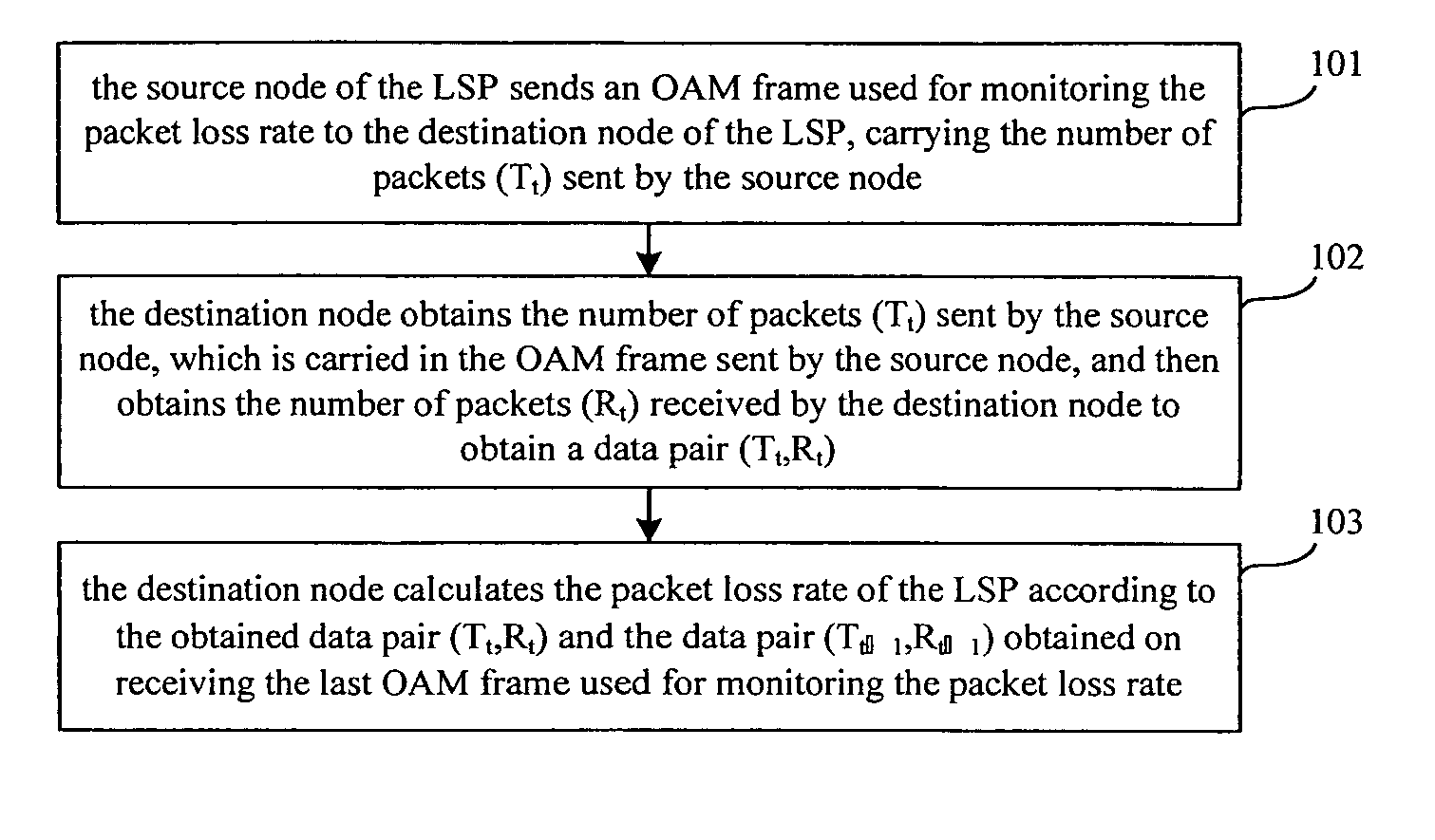

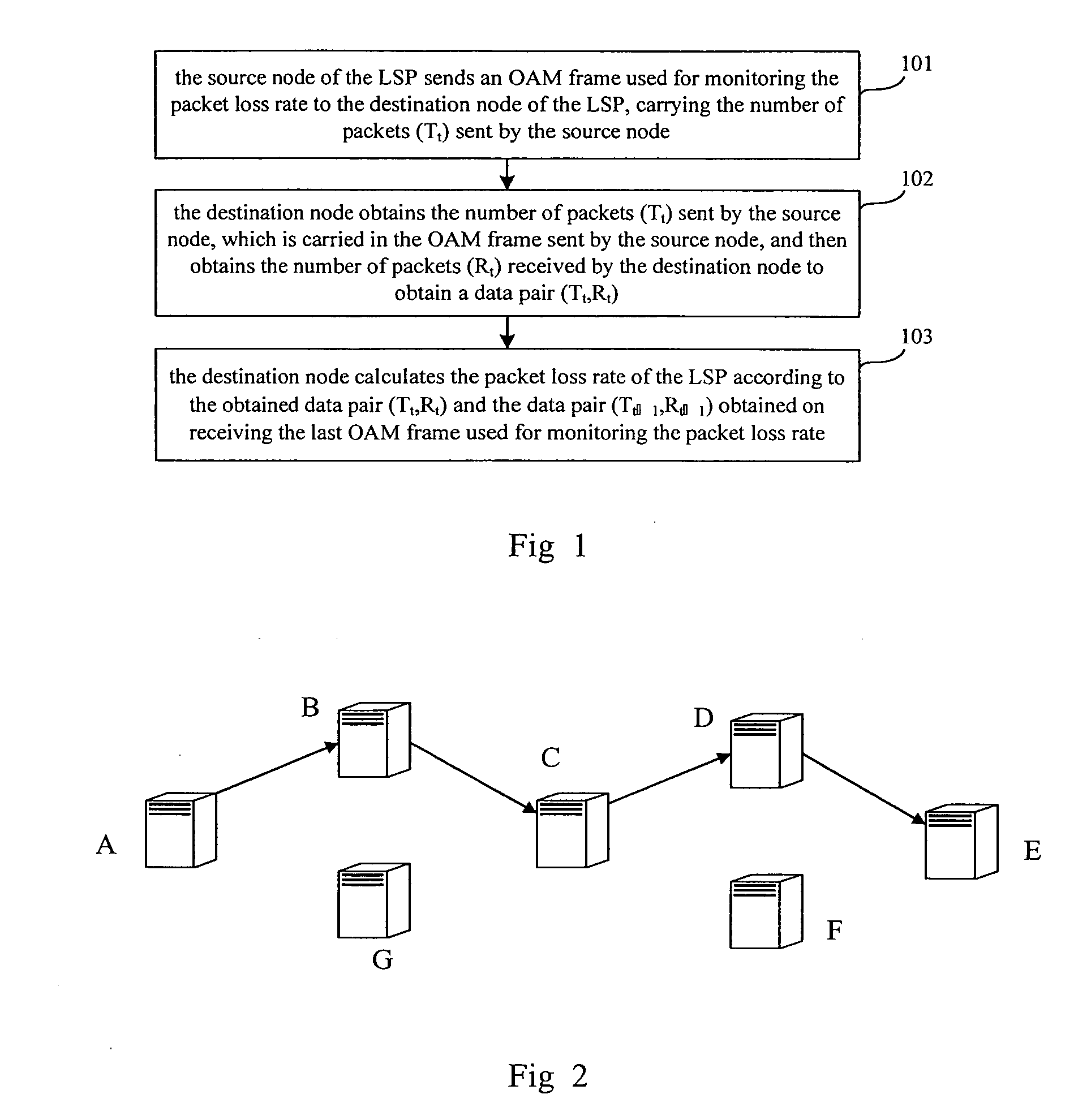

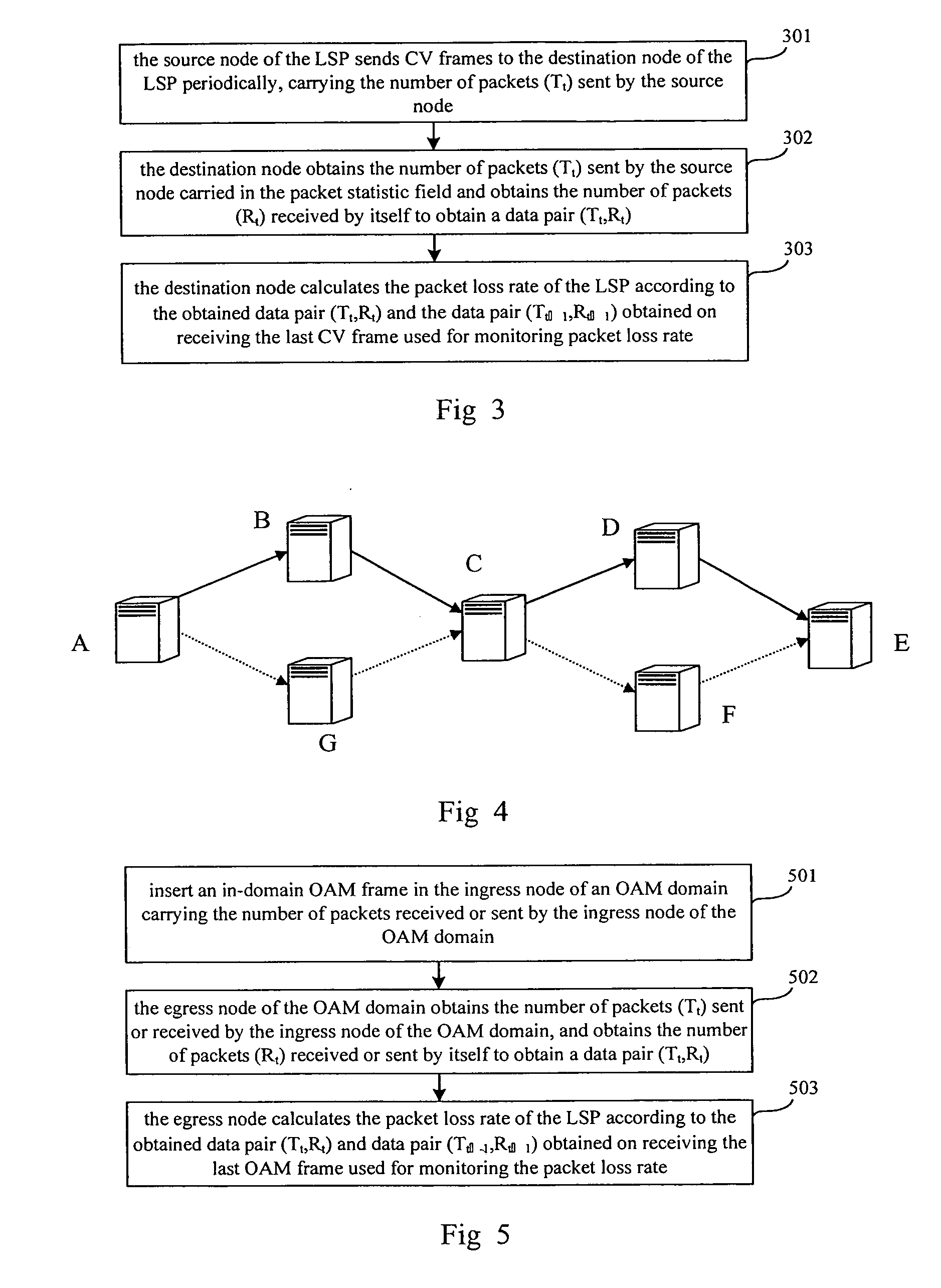

Method for monitoring packet loss ratio

InactiveUS20070064611A1Easy to implementSecurity of partError preventionTransmission systemsPacket lossExchange network

A method of monitoring the packet loss ratio in a label switching network is disclosed, in which an OAM frame carrying packet statistical information used for monitoring the packet loss ratio is sent by the source node to the destination node of an LSP such that the current packet loss ratio could be calculated upon receiving the OAM frame by the destination node according to the packet statistical information. The present invention also discloses a method for monitoring the packet loss ratio in a multi-domain label switching network. By the method for monitoring the packet loss ratio described in the present invention, the packet loss ratio can be monitored and obtained timely and accurately. The method is simple to realize while few modifications have to be made on the existing label switching network.

Owner:HUAWEI TECH CO LTD

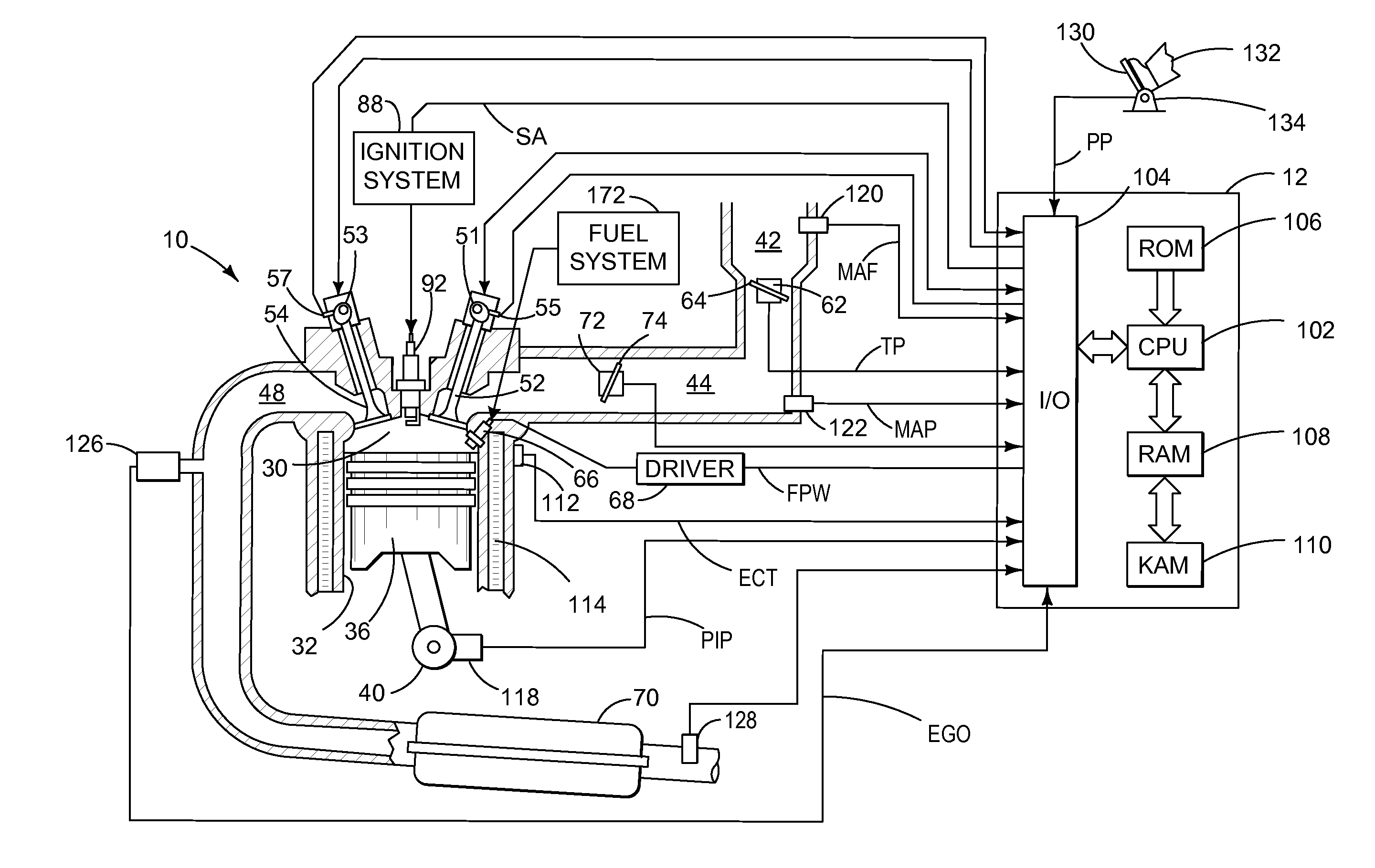

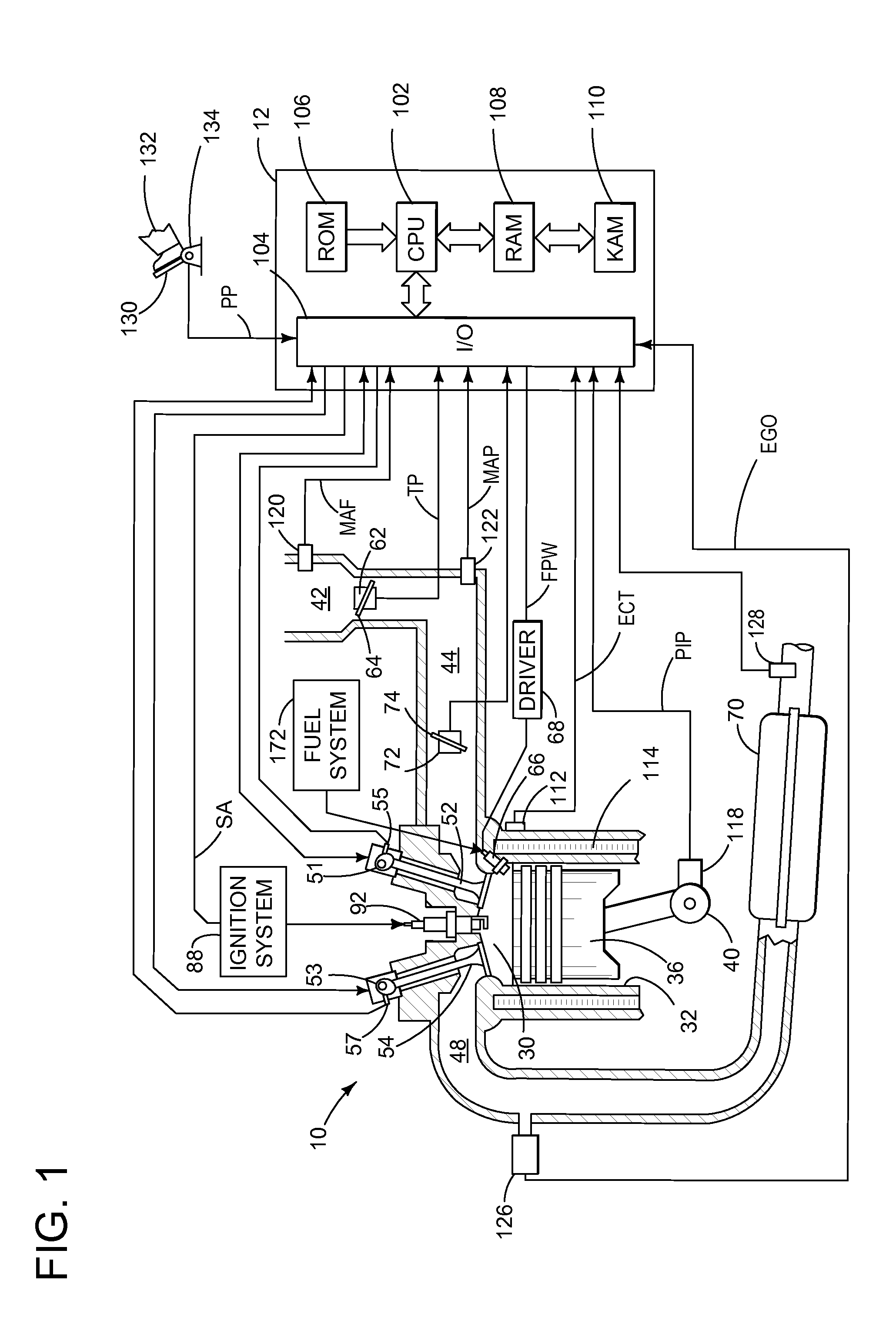

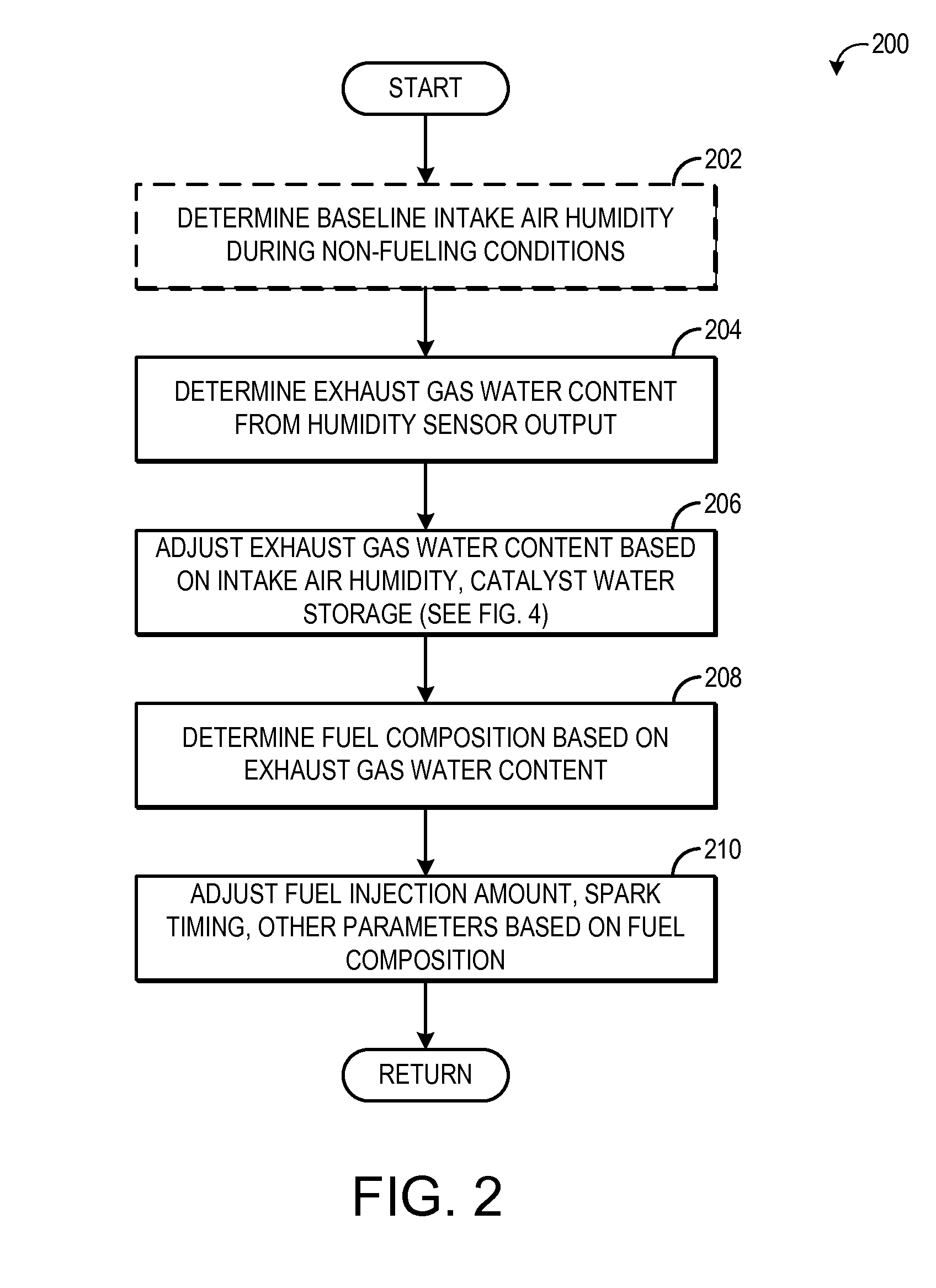

Exhaust humidity sensor

ActiveUS20140156172A1Reduce evaporationWithout compromising engine air-fuel ratio controlAnalogue computers for vehiclesElectrical controlEngineeringMoisture sensor

Embodiments for adjusting engine operating parameters based on output from an exhaust humidity sensor are provided. One example method for an engine comprises based on a dew point of exhaust gas, adjusting an exhaust gas sensor heater configured to heat an exhaust gas sensor disposed in an exhaust passage of the engine, the dew point based on output from a humidity sensor disposed in the exhaust passage.

Owner:FORD GLOBAL TECH LLC

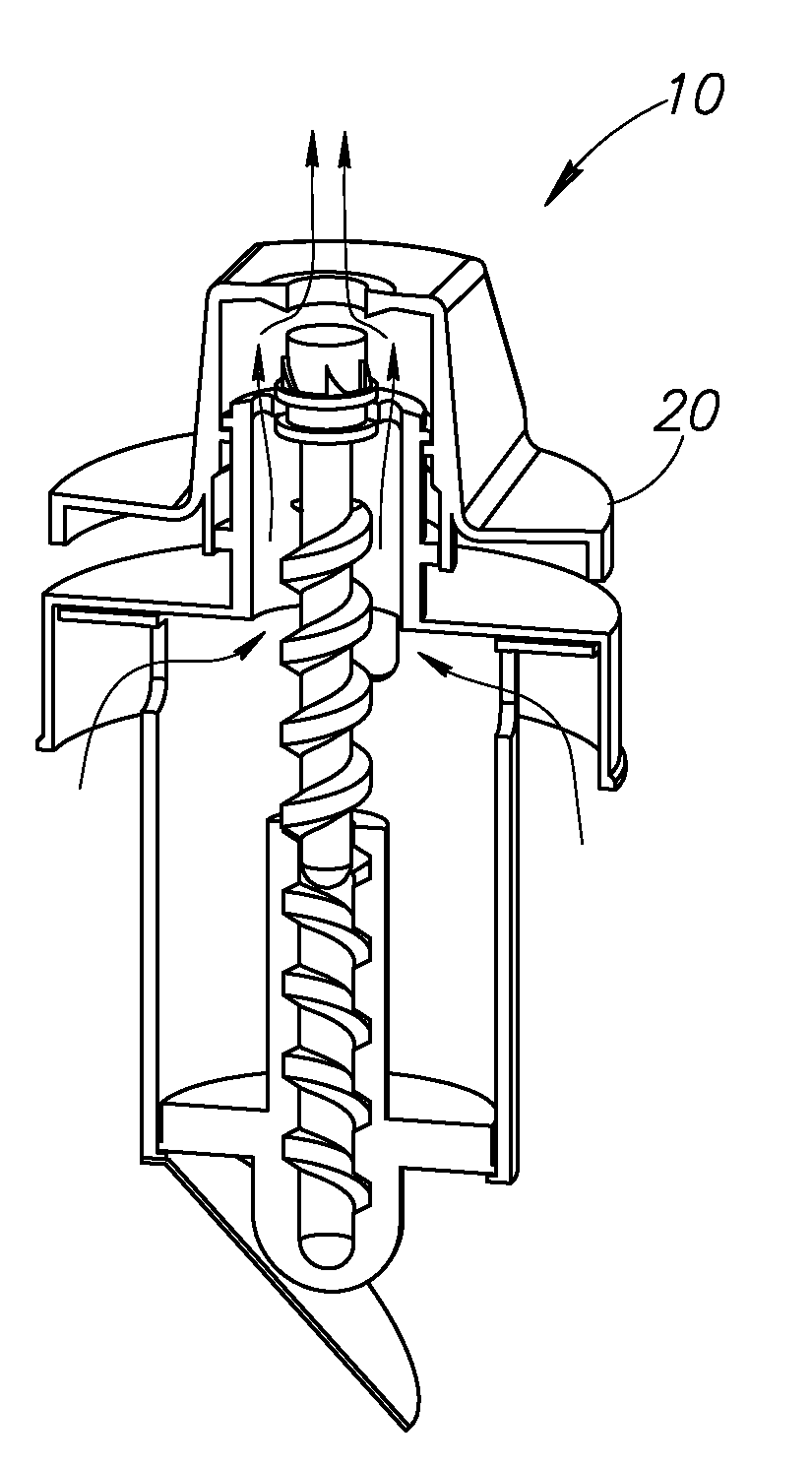

Double-component glue automatic glue mixer

InactiveCN102240514AImprove securityIncrease productivityRotary stirring mixersMixing methodsAutomatic controlReciprocating motion

The invention aims to provide a double-component glue automatic glue mixer with high safety performance, high production efficiency and good finished product quality. The automatic glue mixer comprises a glue storage mechanism, a glue transporting mechanism, a glue mixing mechanism, a reciprocating sizing mechanism, a heating insulation mechanism, a vat glue providing mechanism and a liquid level detection and electric control system. The glue storage mechanism employs a double glue storage barrel sealed structure. The glue transporting mechanism employs a structure of two motors connecting with the electric control system to ensure that an output glue proportion equals to a required glue proportion. The glue mixing mechanism employs a pneumatic performer to control two glues to enter into a mixing tube simultaneously and to mix fully through a double-spiral structured mixing core rod. The reciprocating sizing mechanism employs an automatic back-and-forth reciprocating motion apparatus. The heating insulation mechanism employs a multi-position heating to realize constant temperature of glue during an output process, so that an output proportion is more accurate. The vat glue providing mechanism realizes glue injection into the two glue storage barrels through the electric control system. The liquid level detection and electric control system realizes automatic control on an integral machine operation and controls glue proportion in a digitization approach with accurate proportion; besides the system can provide glue continuously to adapt high-speed automation production. The automatic glue mixer can ensure production efficiency, quality and safety; and compared with prior equipment, the automatic glue mixer is more convenient for operation, has a more reasonable structure and a more beautiful appearance.

Owner:SINOMECH CORP

Preparation of bamboo protofibre for weave by biological enzyme

The present invention discloses a bio-enzyme method preparing textile bamboo fibril and the method need not any chemical processing, has simple operation, short processing time and stabilizing product quality. The process is as follows: first of all, cutting bamboo and subdividing bamboo into bamboo strip, then boiling them in boiled water till they are soft, putting out, crushing and hammering into filament, then boiling in pressure cookers, immersing the treated bamboo filament in the solution containing bio-enzyme in order to the lignin, hemicellulose and pectin in bamboo filament can be dissociated by bio-enzyme and preparing the cellulose fiber in bamboo; then washing, bleaching, oiling, softening and opening the bamboo cellulose fiber dissociated by enzyme, then the bamboo fibril to be used for weaving is prepared. The invention solves the problem of stable product quality without any chemical treatment which is to be solved and has not been resolved.

Owner:苏州市圣竹家用纺织品有限公司

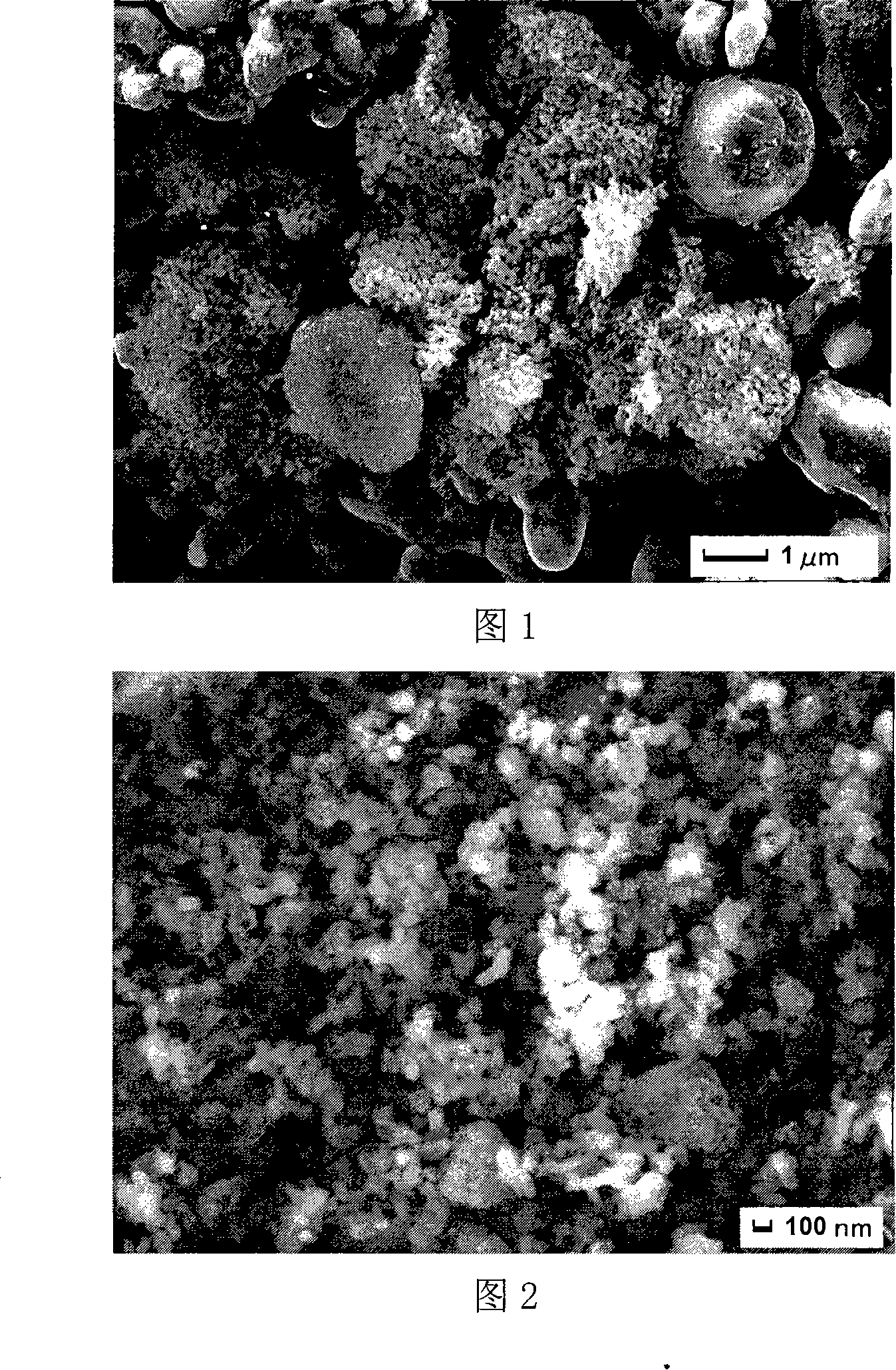

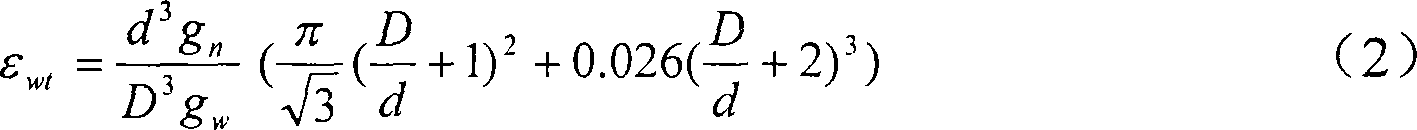

Mechanical process of preparing composite nanometer ceramic and micron metal powder

The present invention discloses mechanical process of preparing composite nanometer ceramic / micron metal powder. The composite nanometer ceramic / micron metal powder is prepared with marketable micron and nanometer powder as material, and through establishing the theoretical model of the weight ratio between the micron powder and the nanometer powder, preparing stable suspension of nanometer ceramic powder, mixing the nanometer suspension and the micron powder, and mechanical compounding. The process has simplicity, short treating time, easy control, continuous production and other features, and is suitable for engineering application.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

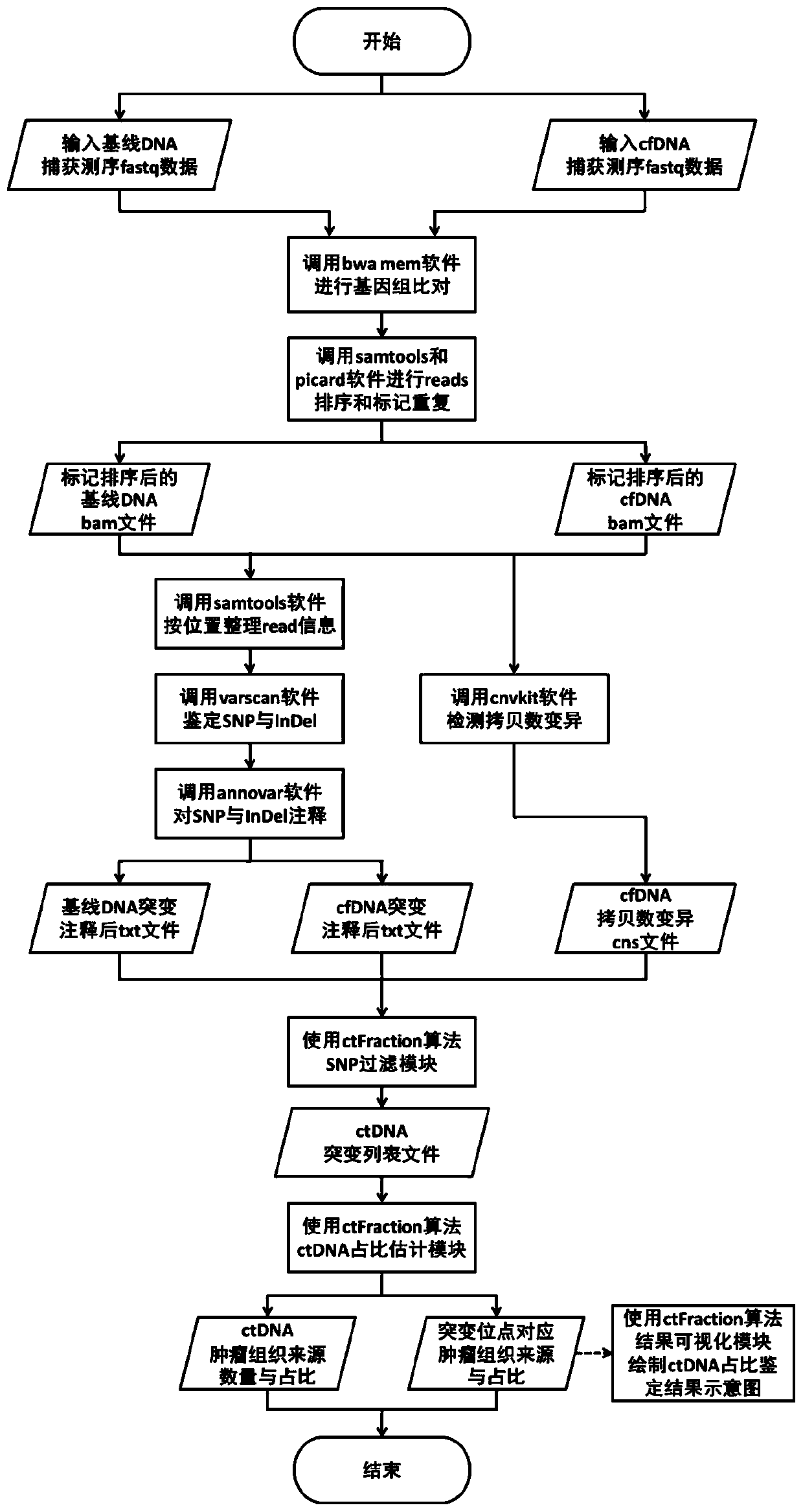

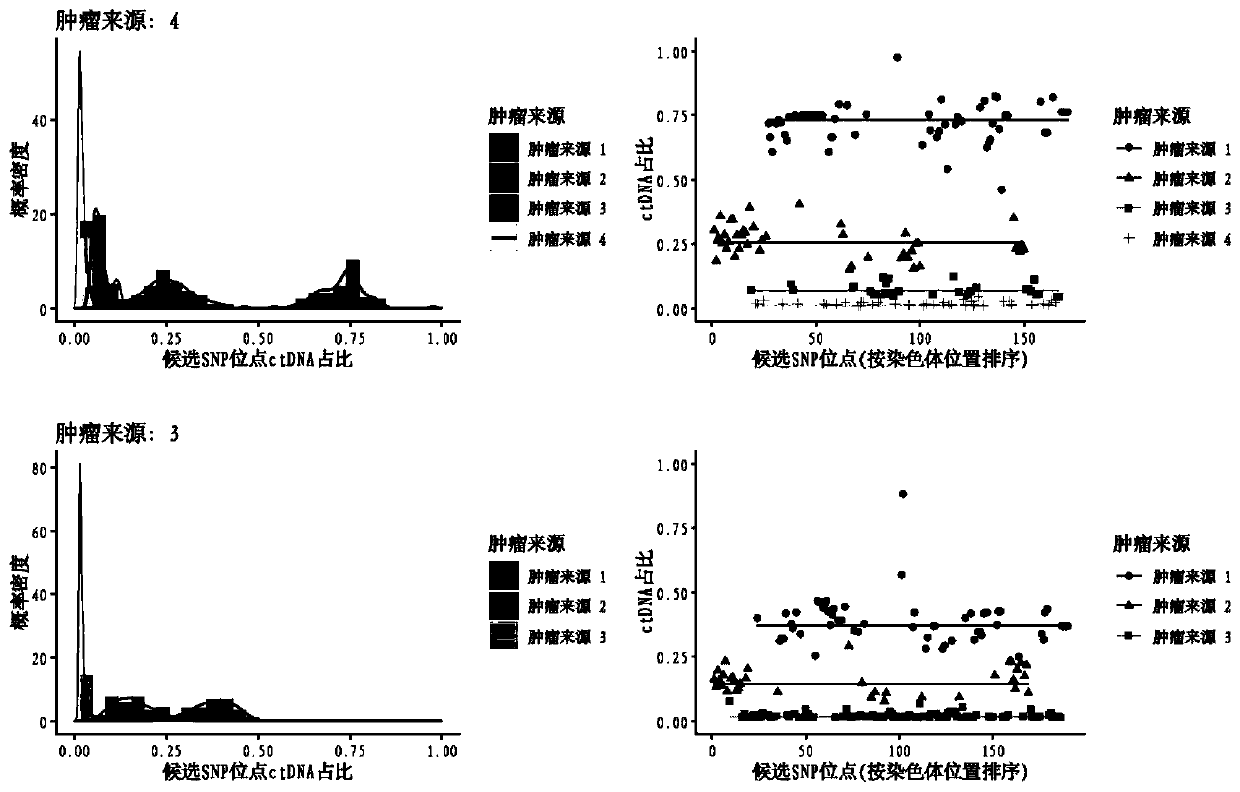

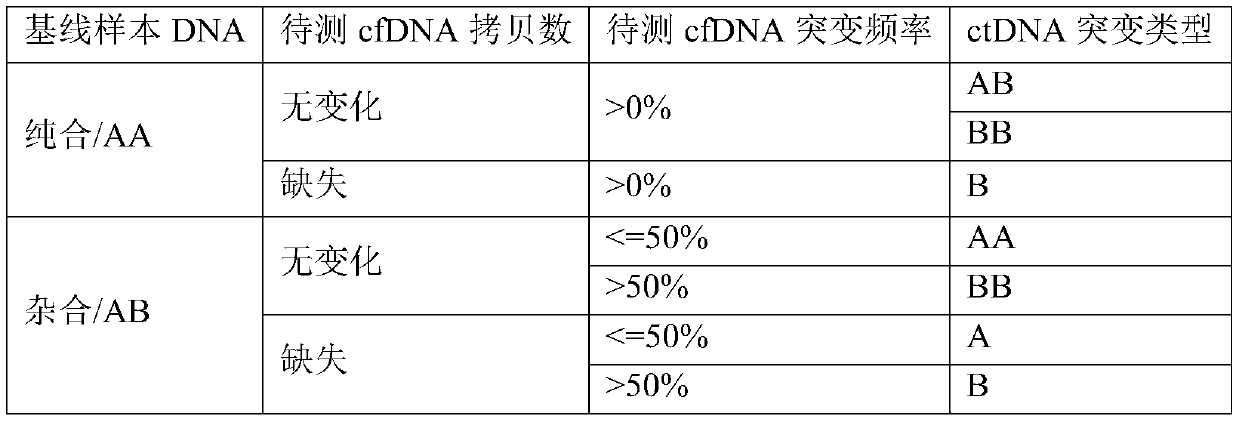

Detection method and detection device for ctDNA proportion based on capture sequencing

The invention discloses a detection method and detection device for ctDNA (circulating tumor DNA) proportion based on capture sequencing. The detection method includes the following steps: S1, obtaining baseline sample DNA and gene data of capture sequencing of cfDNA (circulating cell-free DNA) to be tested; S2, using the homozygous and heterozygous sites in the baseline sample DNA at the same time, and selecting the sites on which the mutation frequency between the baseline sample DNA and the cfDNA to be tested is significantly different and the predetermined filtering conditions are satisfied as candidate SNP (Single Nucleotide Polymorphisms) sites; S3, determining a mutation type of the candidate SNP sites of normal cell DNA and ctDNA, in combination with the situation that copy numbervariation occurs in the region where the candidate SNP sites are located; and S4, establishing a probability model by using a maximum likelihood method, and obtaining ctDNA proportion by calculation through the probability model. The application of the technical scheme of the detection method and detection device for ctDNA proportion based on capture sequencing can improve the sensitivity and accuracy of CNV (copy number variation) detection of plasma ctDNA at the same time from various aspects.

Owner:ZHENYUE BIOTECHNOLOGY JIANGSU CO LTD

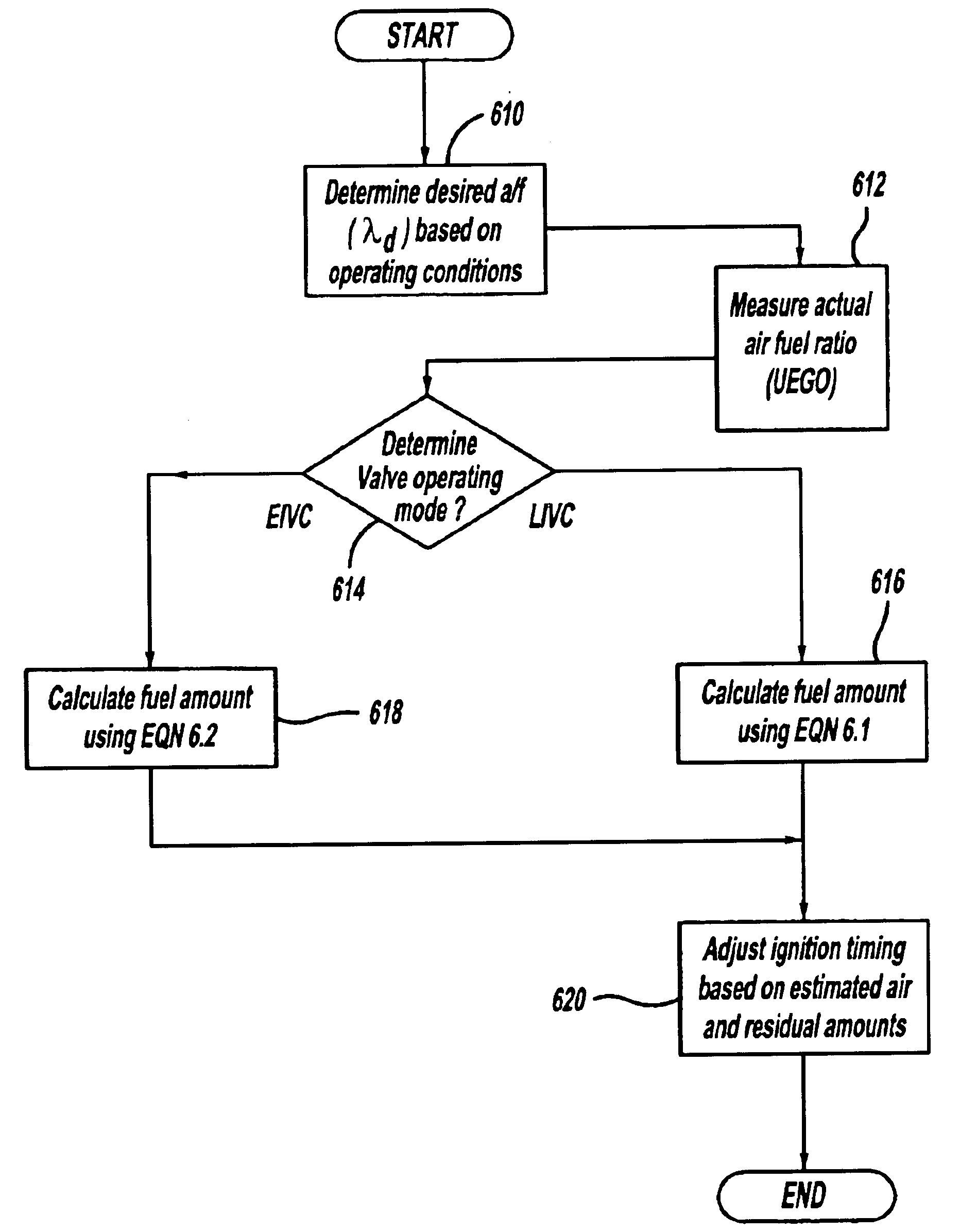

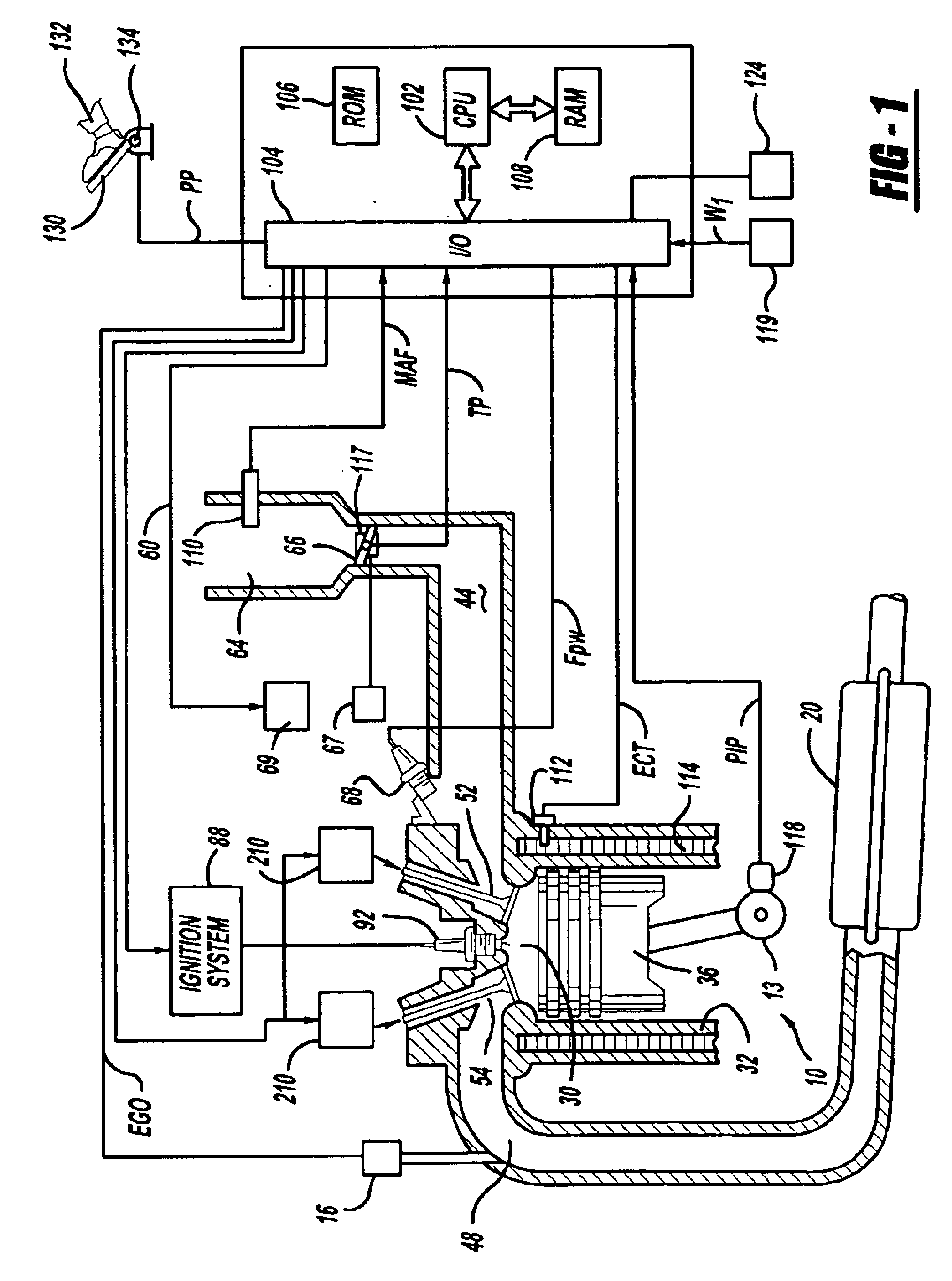

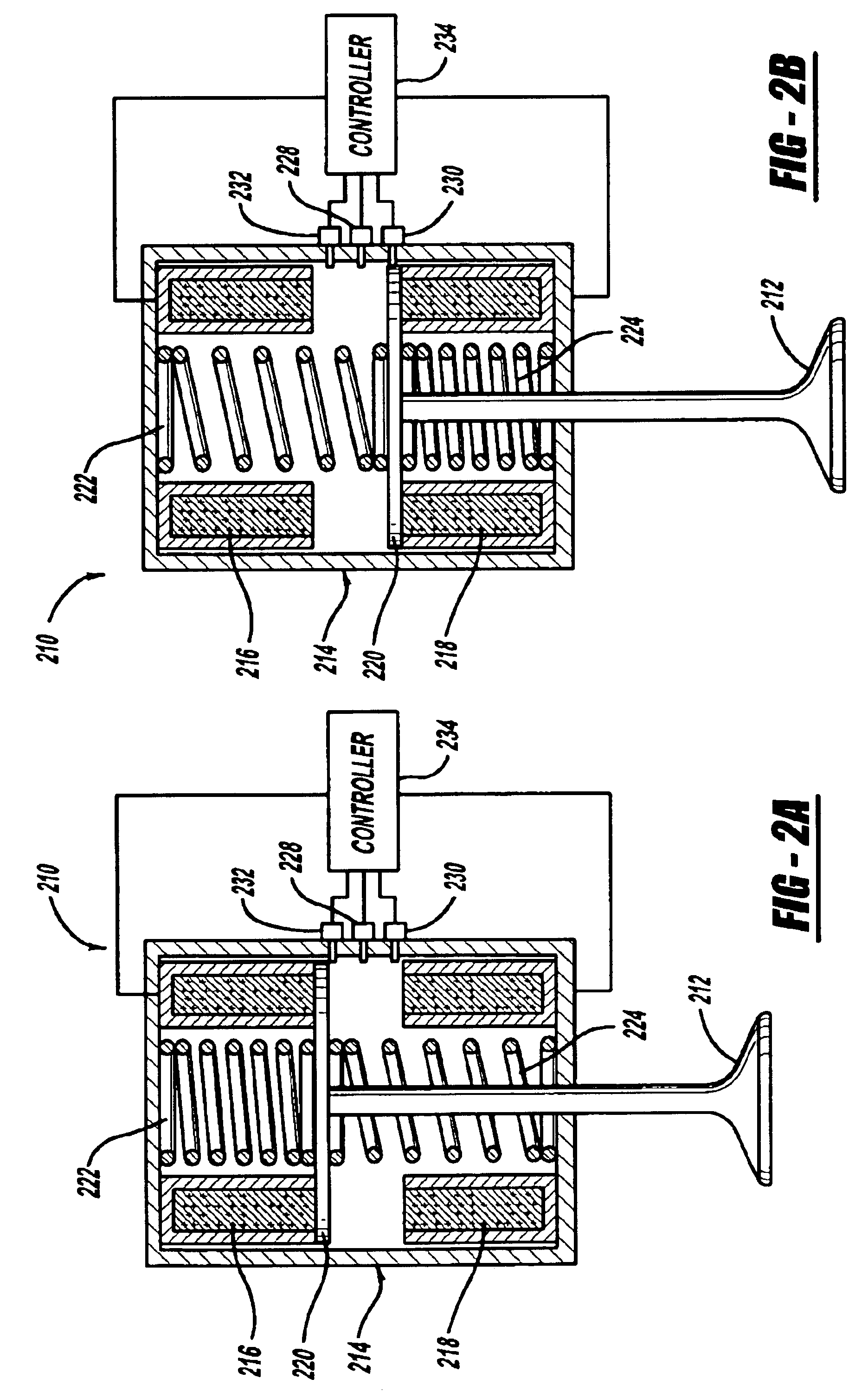

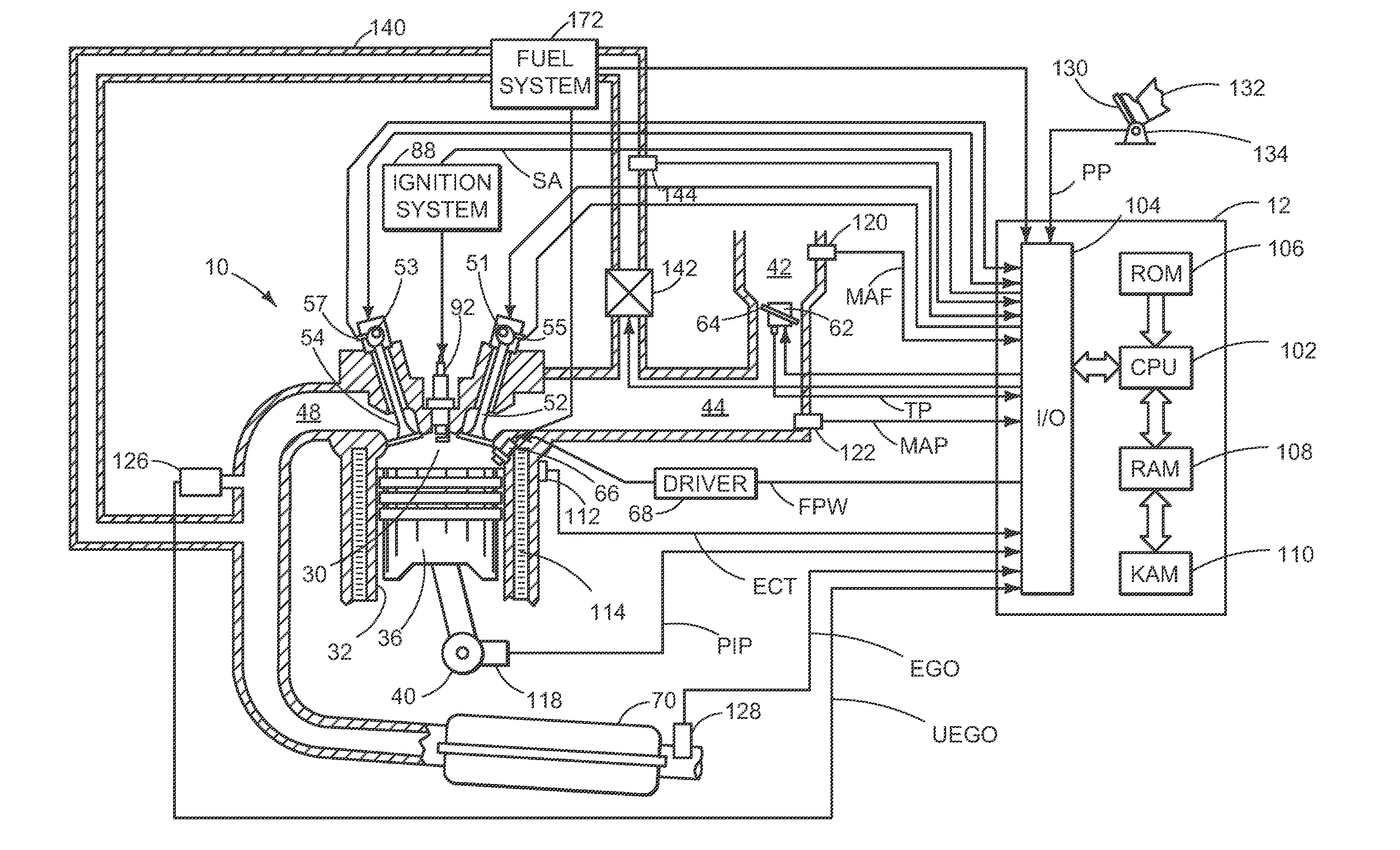

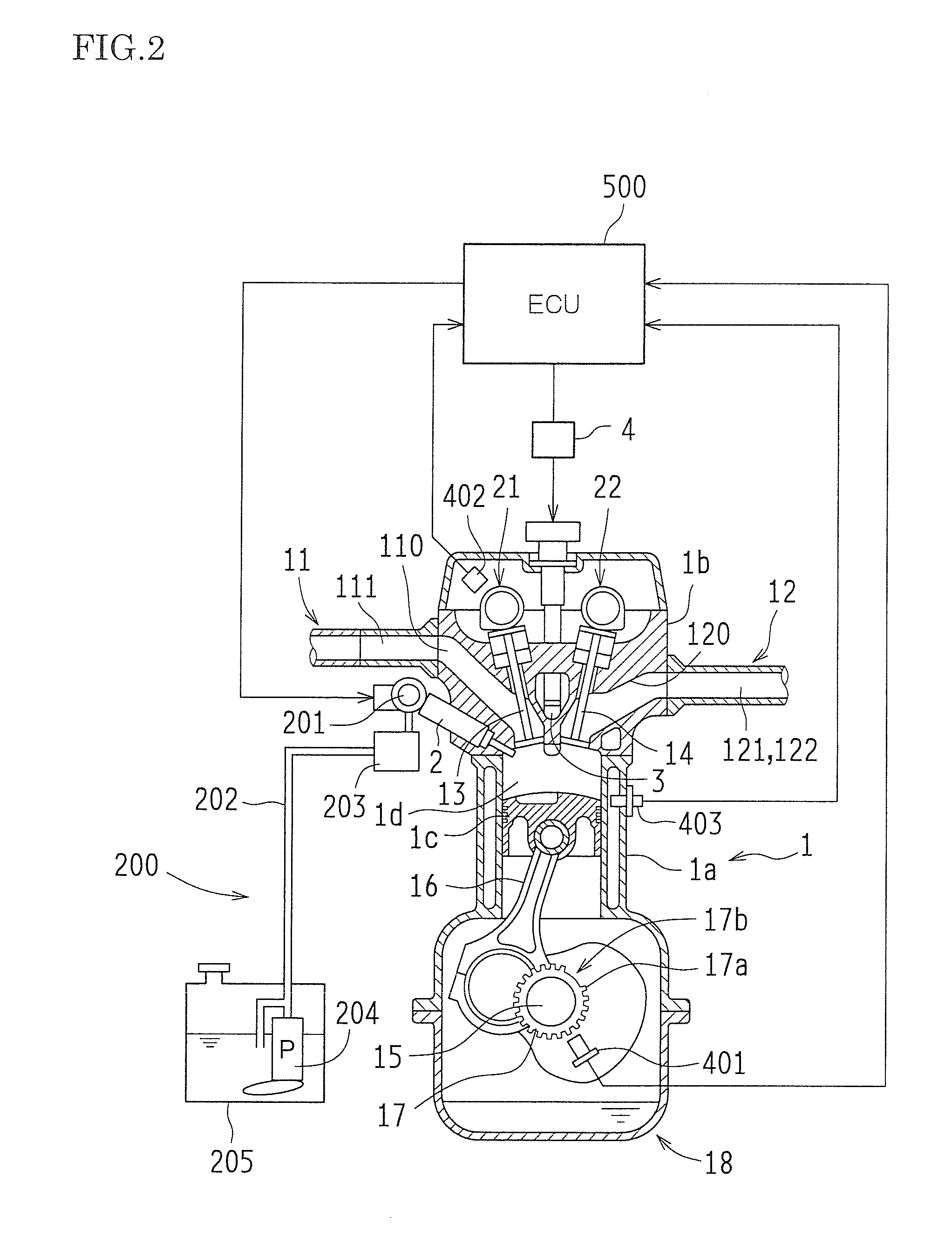

Computer controlled engine valve operation

InactiveUS6959692B2Reducing exhaust air-fuel ratio errorAccurately maintaining overall exhaust gas air-fuel ratioElectrical controlNon-fuel substance addition to fuelOxygen sensorInlet valve

An electronic valve actuation system and control method is described. The valve timing is changed between early and late intake valve closing depending on engine operating conditions. Further, valve timing is adjusted to control engine airflow or engine torque. Finally, air-fuel ratio is adjusted based on feedback from an exhaust gas oxygen sensor as well as an estimate of air, fuel, and residual exhausted from cylinders operating with late valve closing (after bottom dead center) timing.

Owner:FORD GLOBAL TECH LLC

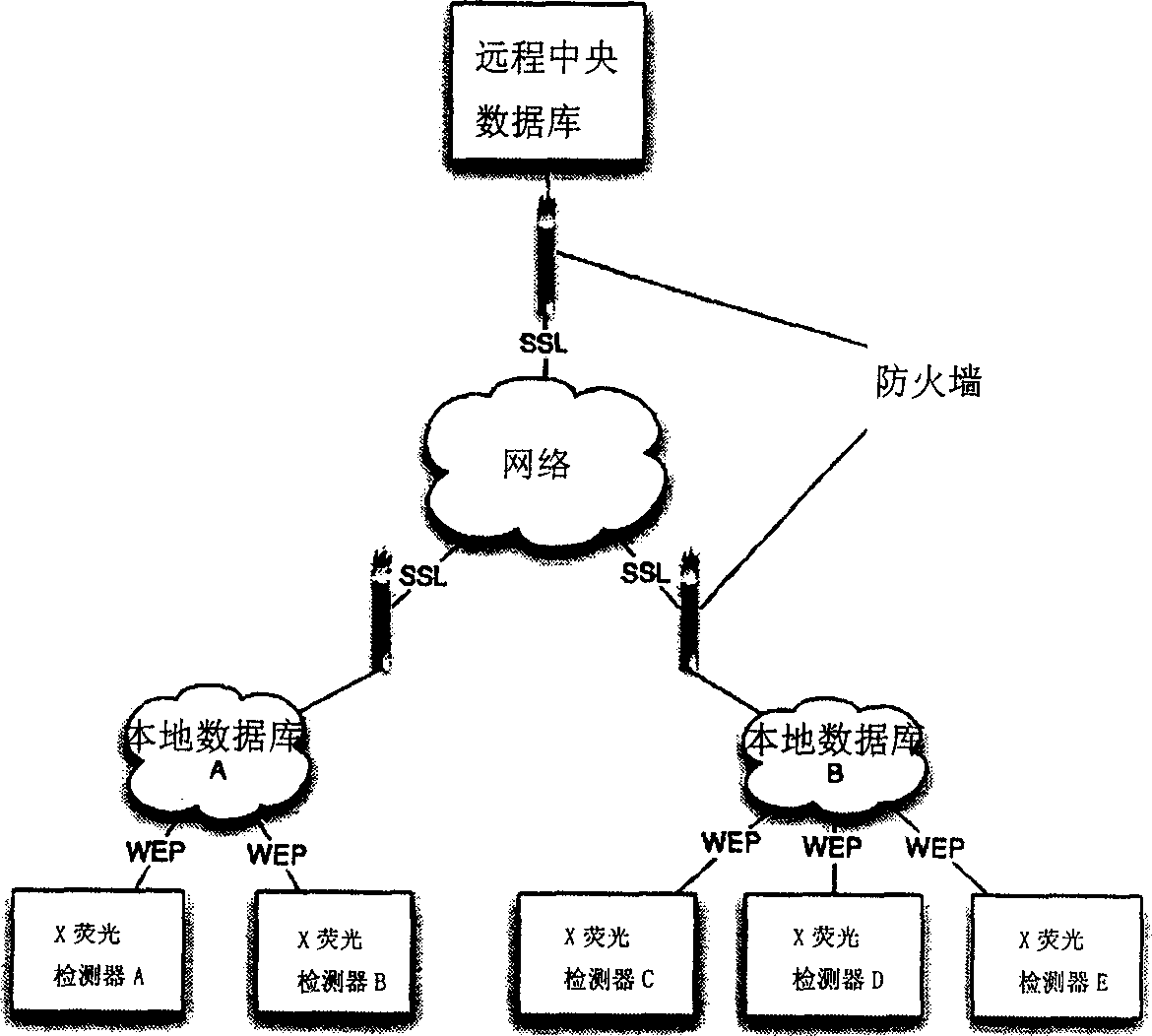

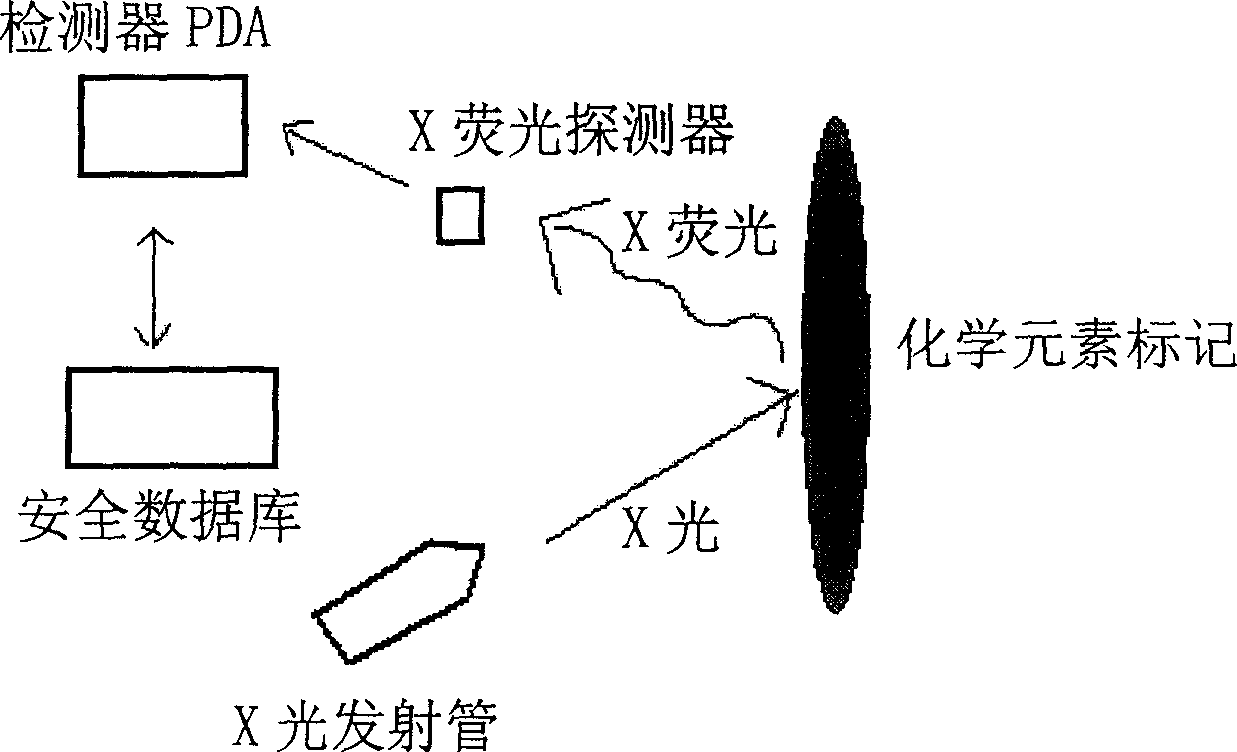

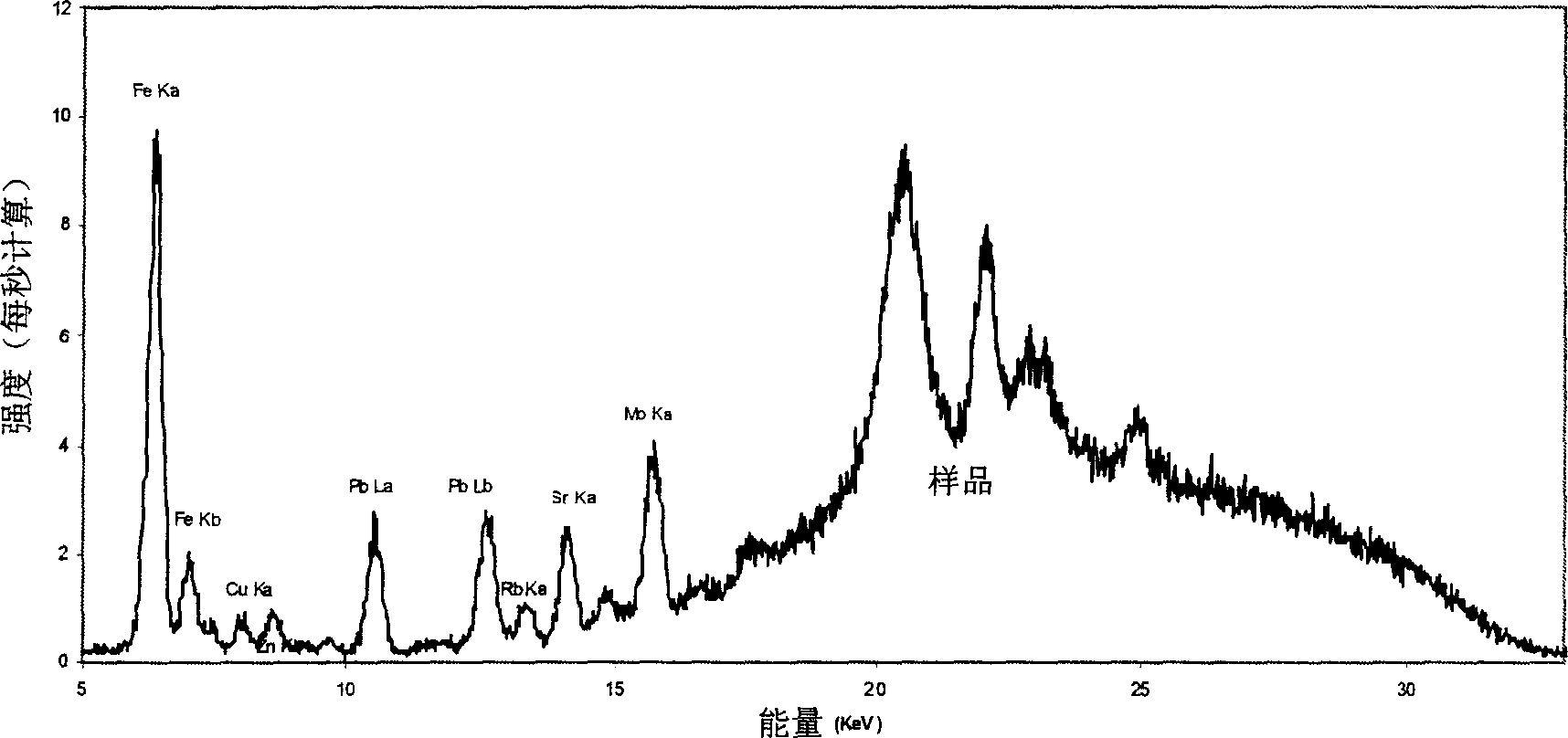

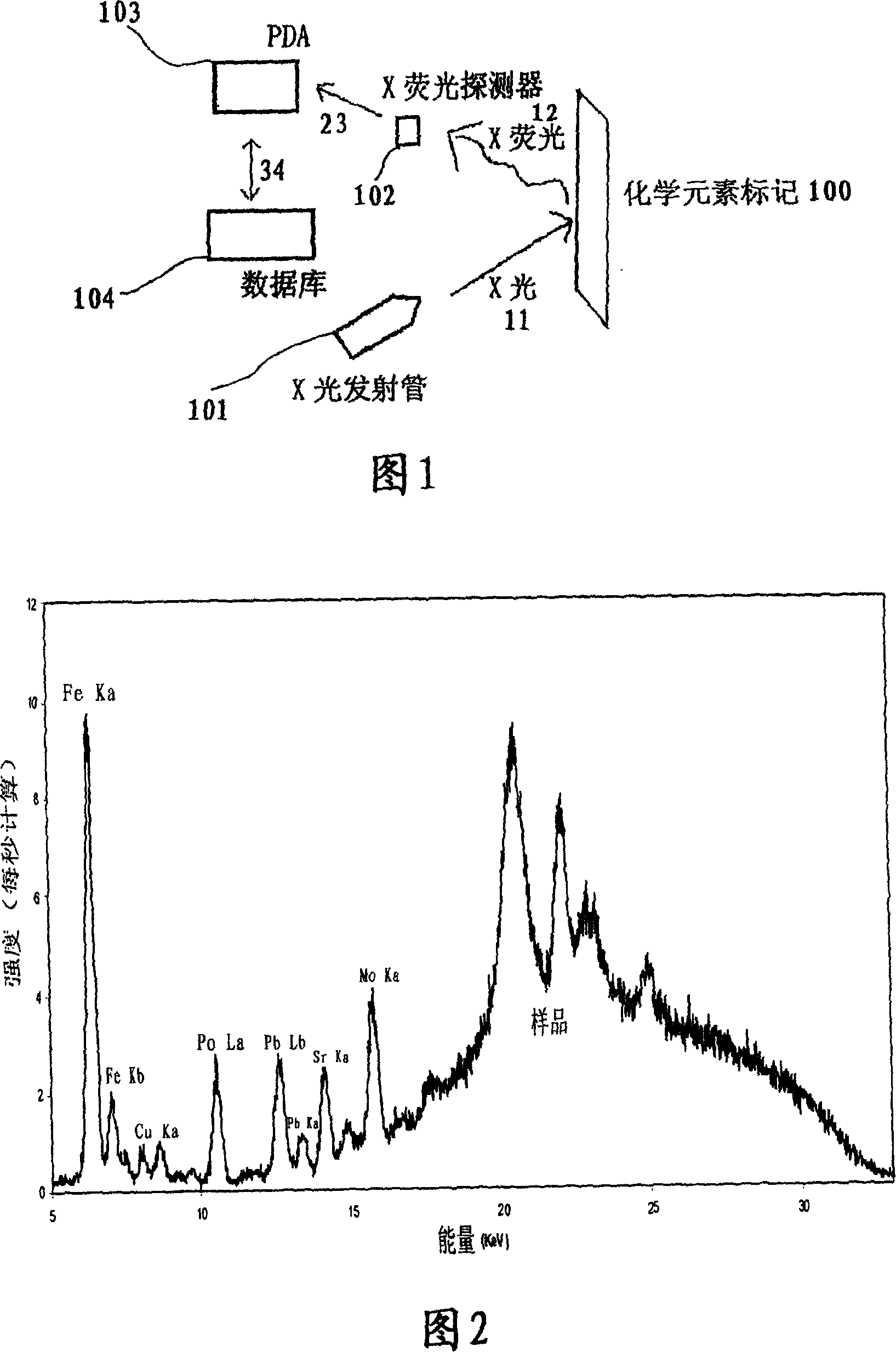

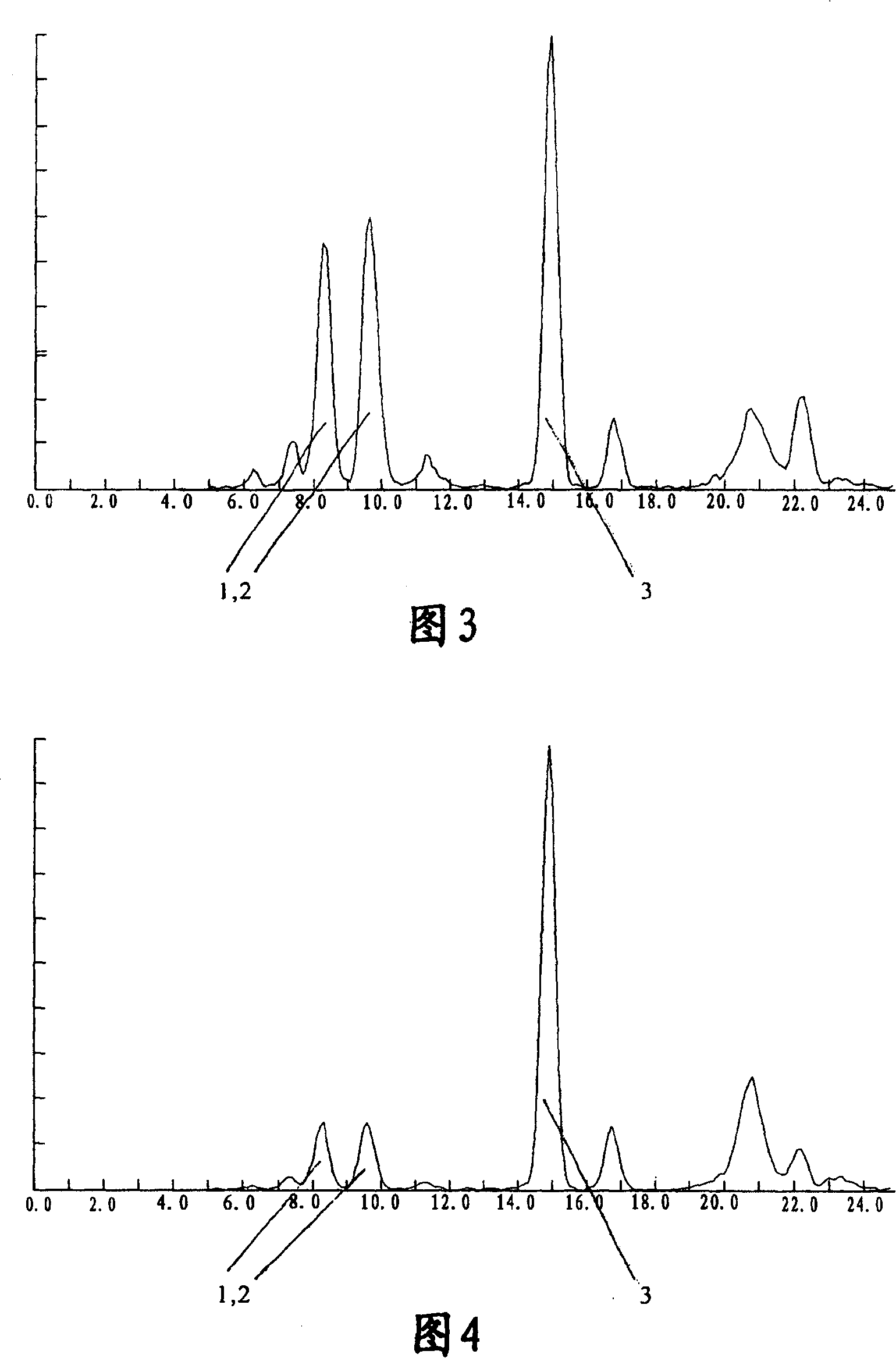

Mark method adopting chemical elements, device thereof and chemical elements marking

InactiveCN1908957AProtect personal safety and healthPrevent Recipe DuplicationDigitally marking record carriersMaterial analysis using wave/particle radiationFluorescenceLight spectrum

The disclosed chemical element labeling method comprises: setting chemical element label included one or more elements with atomic number more than 22 on target, detecting the nominal spectrum data of label by X fluorescence detector to compare with detected data in security database. This invention does not dissolve general organic or inorganic solvent, has well stability, and introduces well detection accuracy without damage to target surface.

Owner:TRUE PROD ID TECH BEIJING

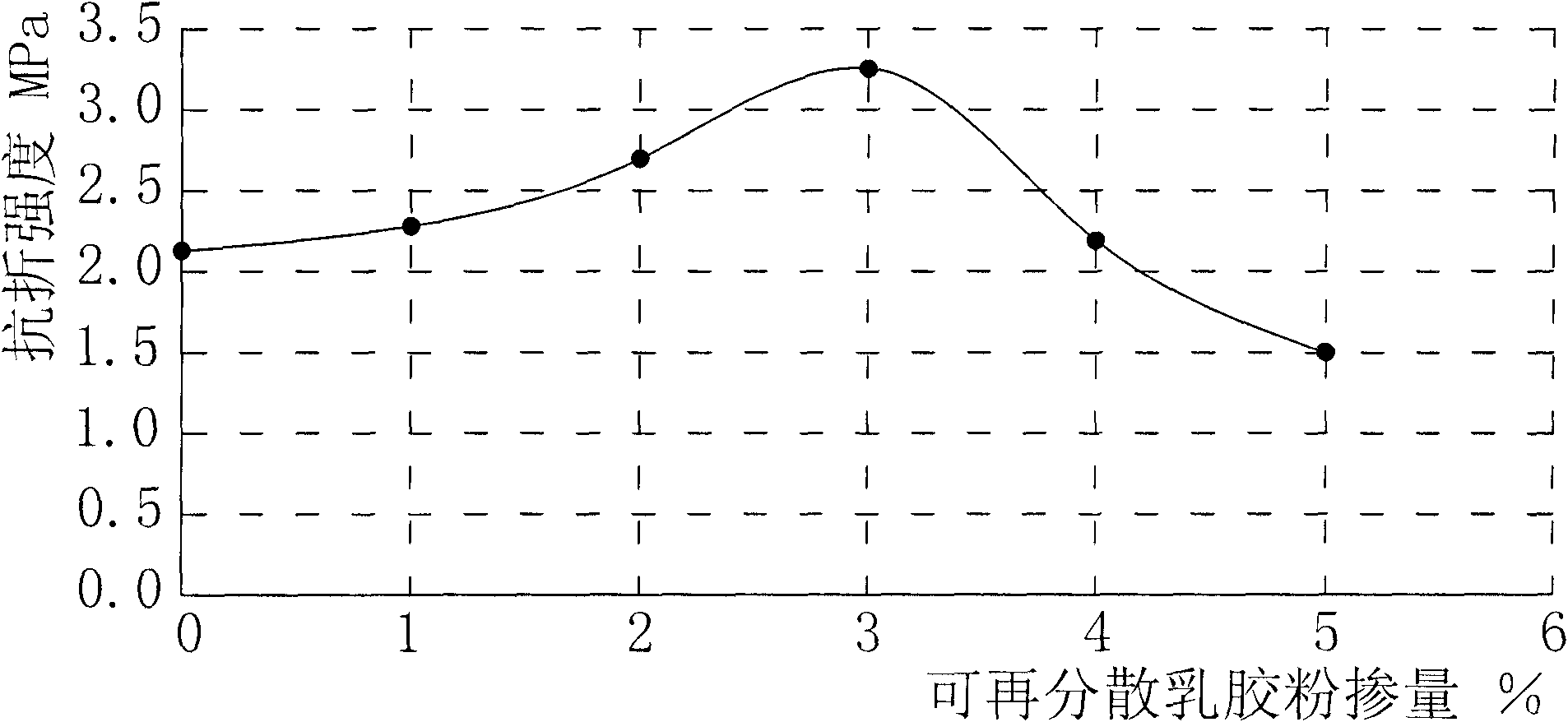

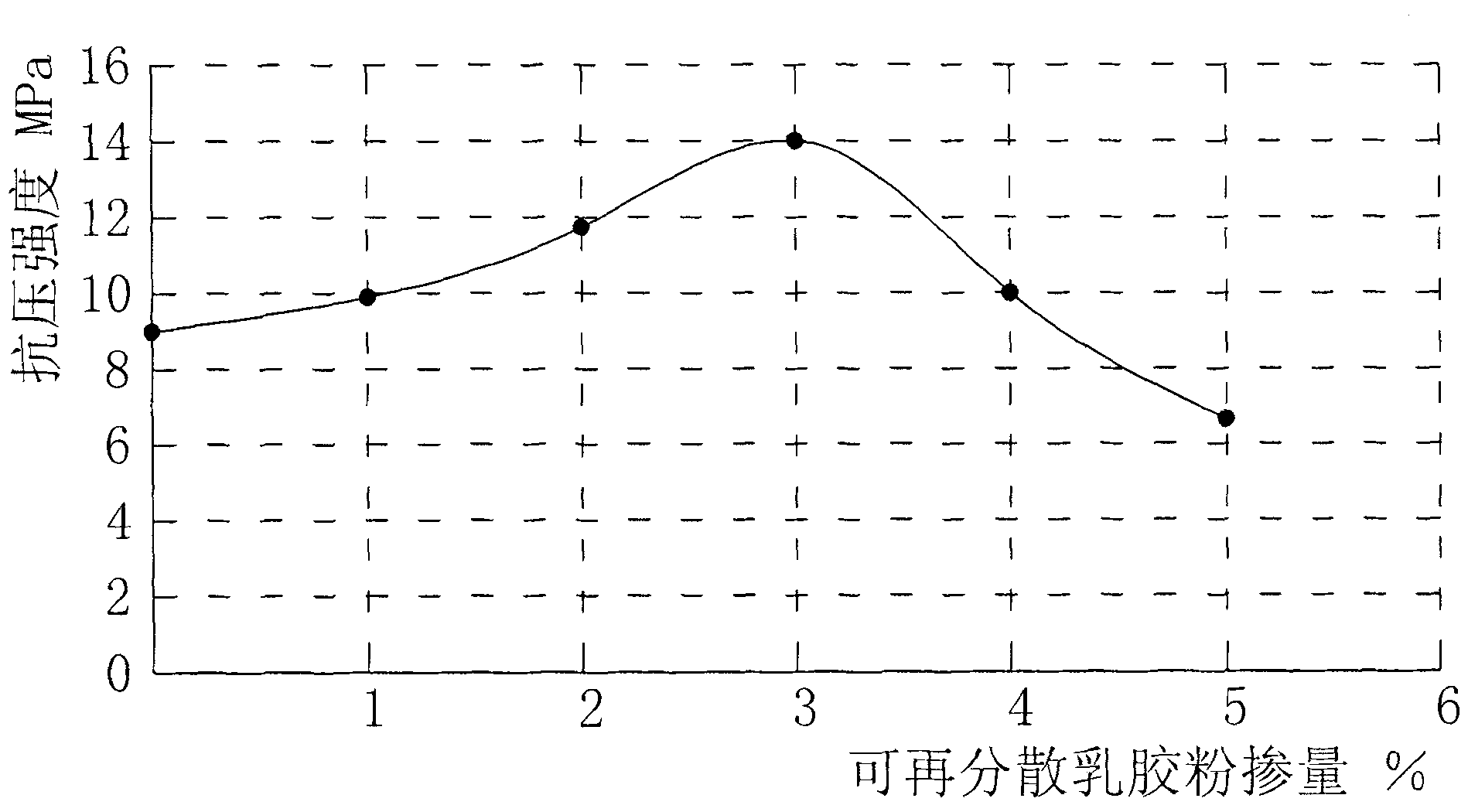

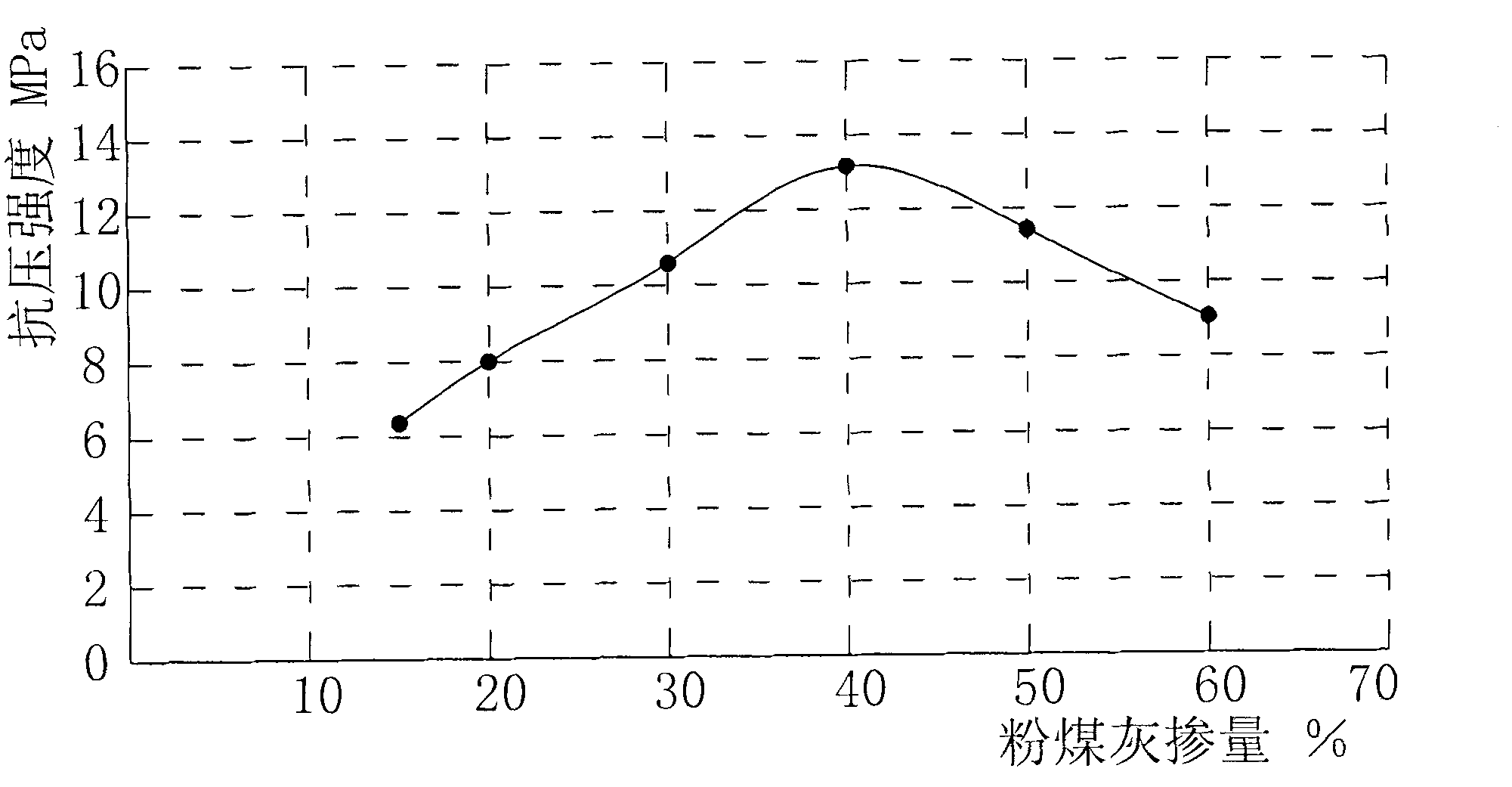

Light-weight dry-mixed masonry mortar

The invention discloses light-weight dry-mixed masonry mortar. The light-weight dry-mixed masonry mortar comprises the following components in percentage by weight: 200 to 300 percent of concrete, 80 to 120 percent of pulverized fuel ash, 400 to 1,400 percent of aerated concrete gains, 80 to 140 percent of vitrified beads, 0.8 to 1.6 percent of PP fibers, 2 to 12 percent of latex powder, and 3 to 15 percent of compound air entraining agent. The mortar has the advantages of avoiding field stirring and mixing, reducing construction dusts and noise pollution and reducing space occupation, along with precise mixing ratio, small concrete use amount, low cost, only need of adding water and mixing uniformly during construction, small material consumption and waste, convenient storage and transport and use, high binding strength, low shrinkage, high freezing resistance durability, low conductivity, good heat preservation, good workability, convenient construction, and the like; by substituting the aerated concrete gains for sand and using the pulverized fuel ash, the light-weight dry-mixed masonry mortar has the characteristics of industrial waste utilization, environmental protection, and low cost.

Owner:JIANGSU RONGNENG GROUP

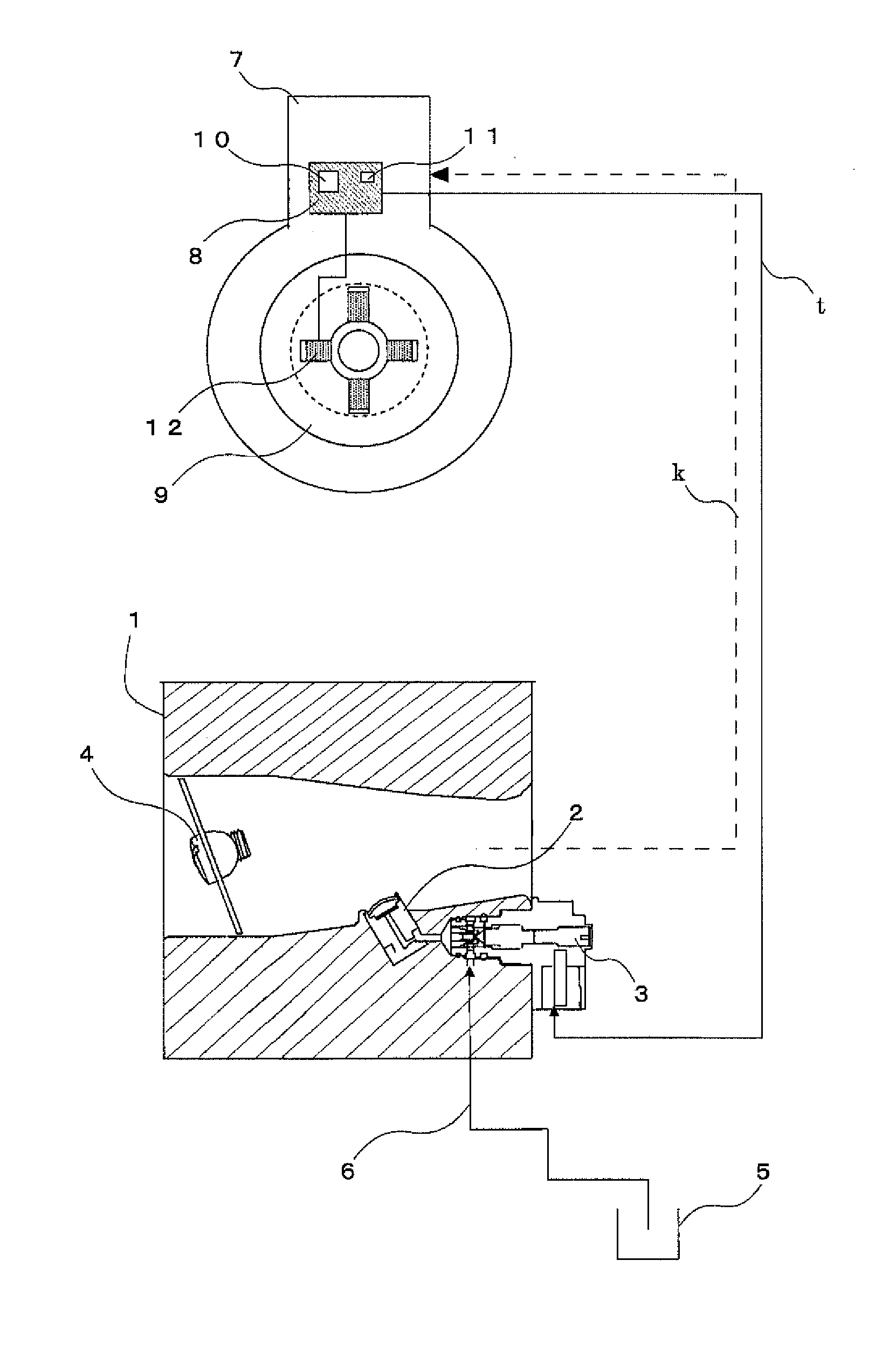

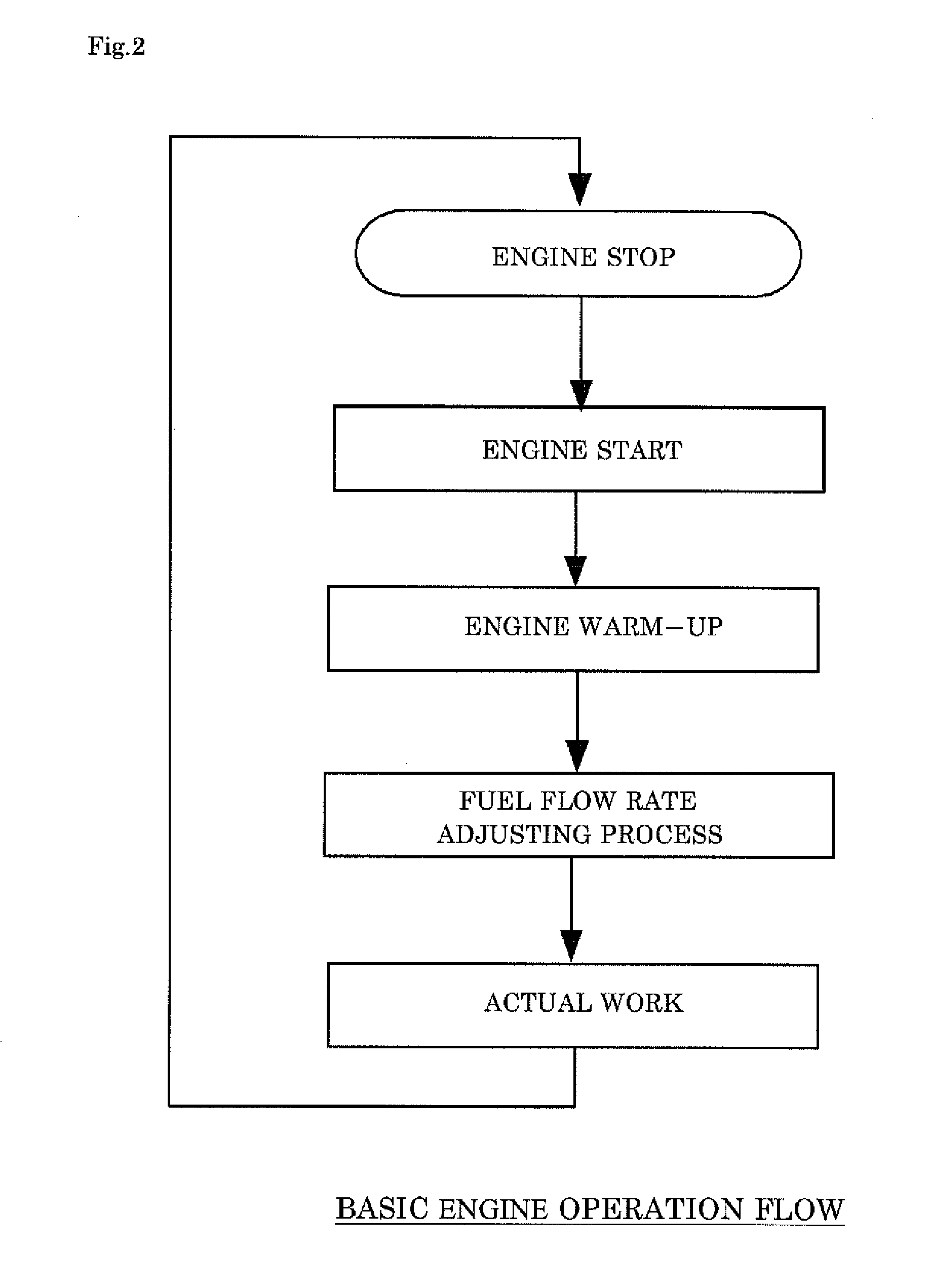

Fuel control method for hand-carried engine-driven working machine

ActiveUS20130255629A1Guaranteed uptimeGuaranteed stable operationElectrical controlIdling devicesSolenoid valveHand held

The opening of a solenoid valve is automatically adjusted after an engine is started and before actual work is performed for an appropriate air-fuel ratio, whereby it is possible to attain a good and stable driving of the engine without any delay even for an abrupt change in load.After the engine is started, when a rotation speed enters a “fuel flow rate adjusting rotation speed range” in which a definite load is applied to the engine in a working rotation speed range of the engine in which a throttle valve is opened to a definite opening, a detected rotation speed is fed back to a target rotation speed, and the opening of the solenoid valve is controlled to adjust a fuel flow rate, so that the combustion state in the engine is optimized at the valve opening so determined.

Owner:IIDA ELECTRIC IND +1

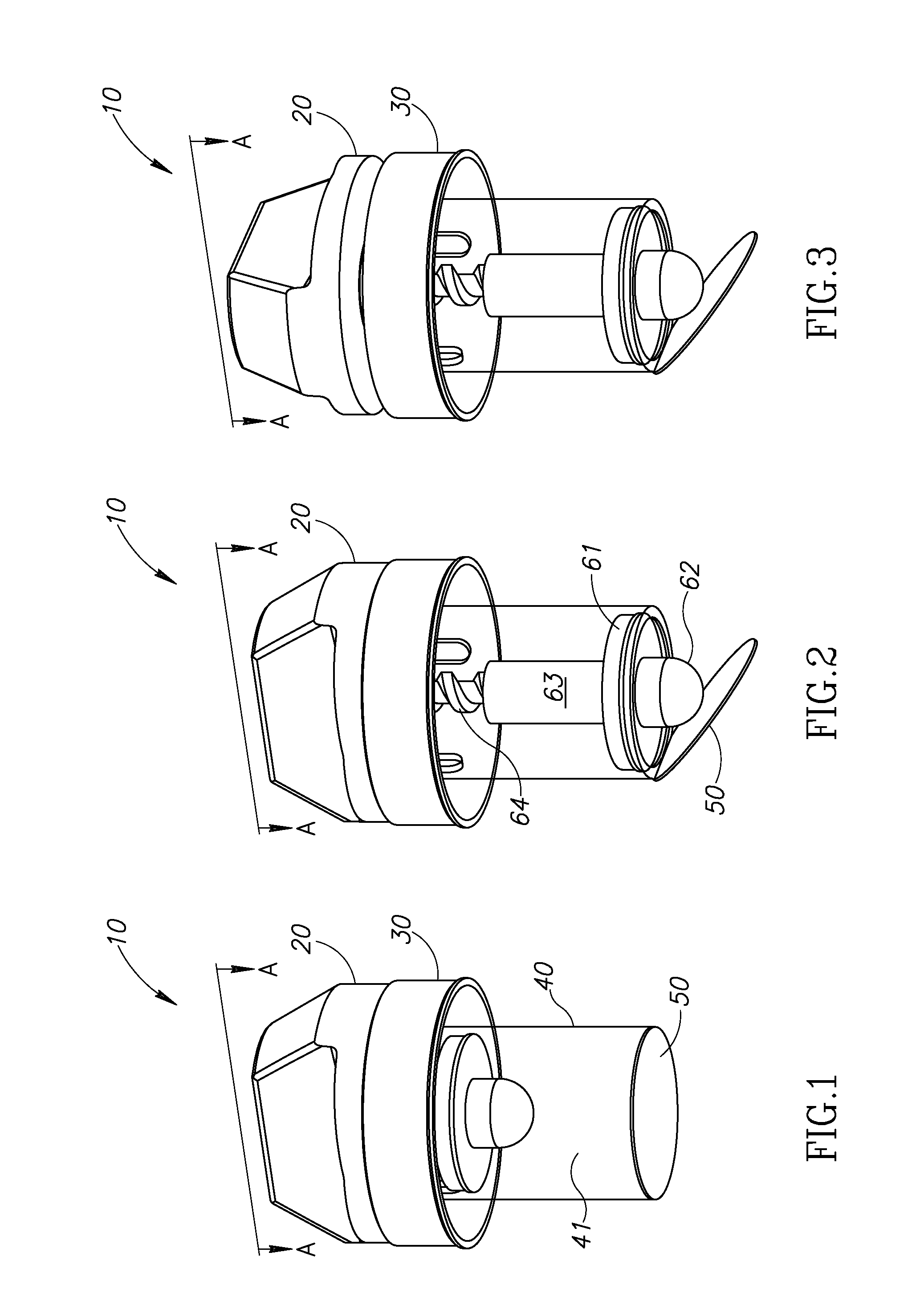

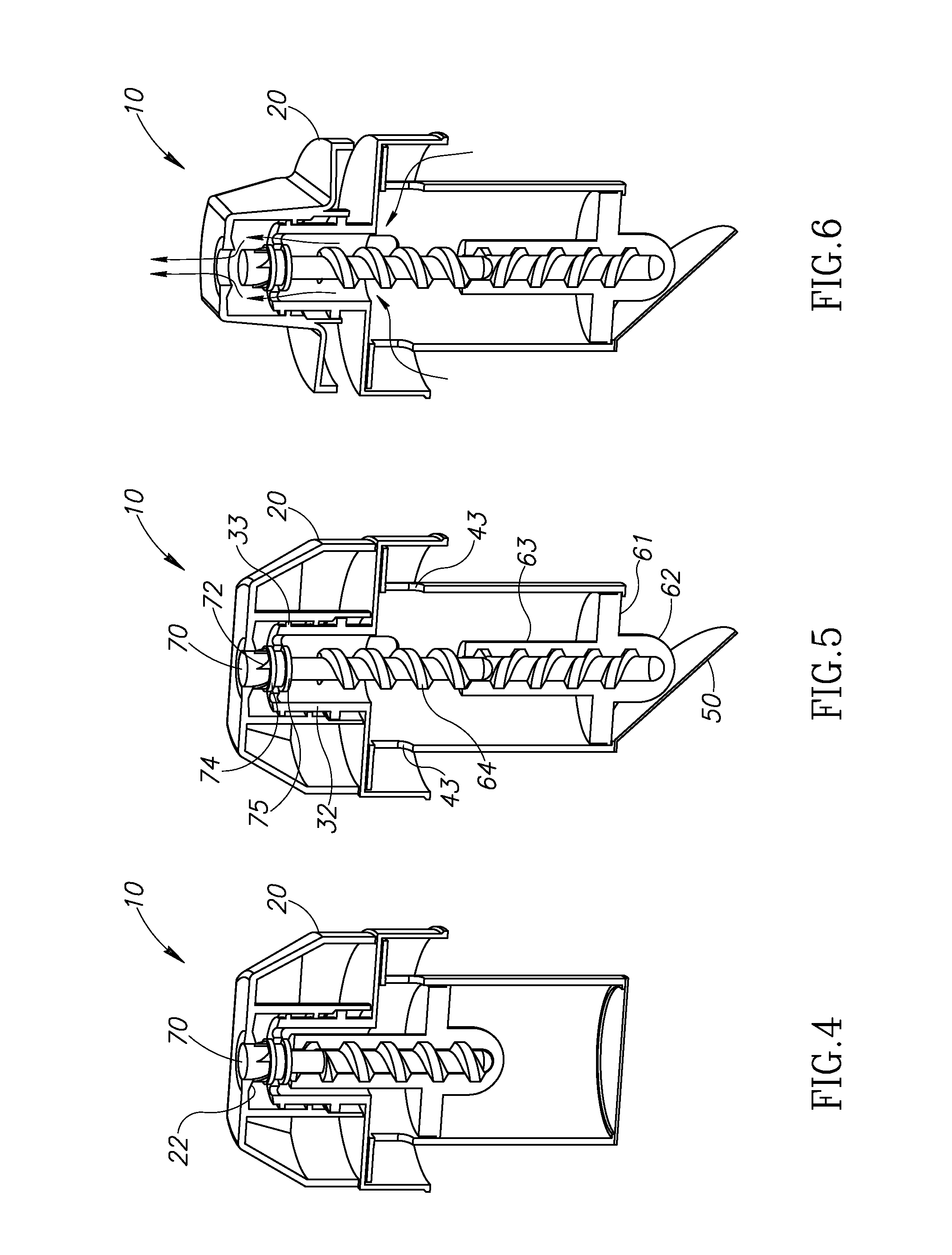

Multi-purpose cap for drink containers

InactiveUS20080099487A1Precise mixture to water ratioEnsure dry environmentClosuresInternal framesEngineeringMechanical engineering

The present invention provides a multi-purpose cap for drink containers to facilitate mixing an additive with a liquid such as water. The cap includes a chamber for housing the additive and a mouthpiece from which the liquid can be consumed. The cap is preferably configured to mate with the mouth of a standard water bottle. In some examples of the invention, twisting a mouthpiece in a first direction urges a plunger downward and against a seal, breaking the seal to spill the contents of the chamber into the water. Openings in a housing forming the chamber allow water to flow through the mouthpiece even while the additive remains sealed within the chamber.

Owner:WINN BRIAN J

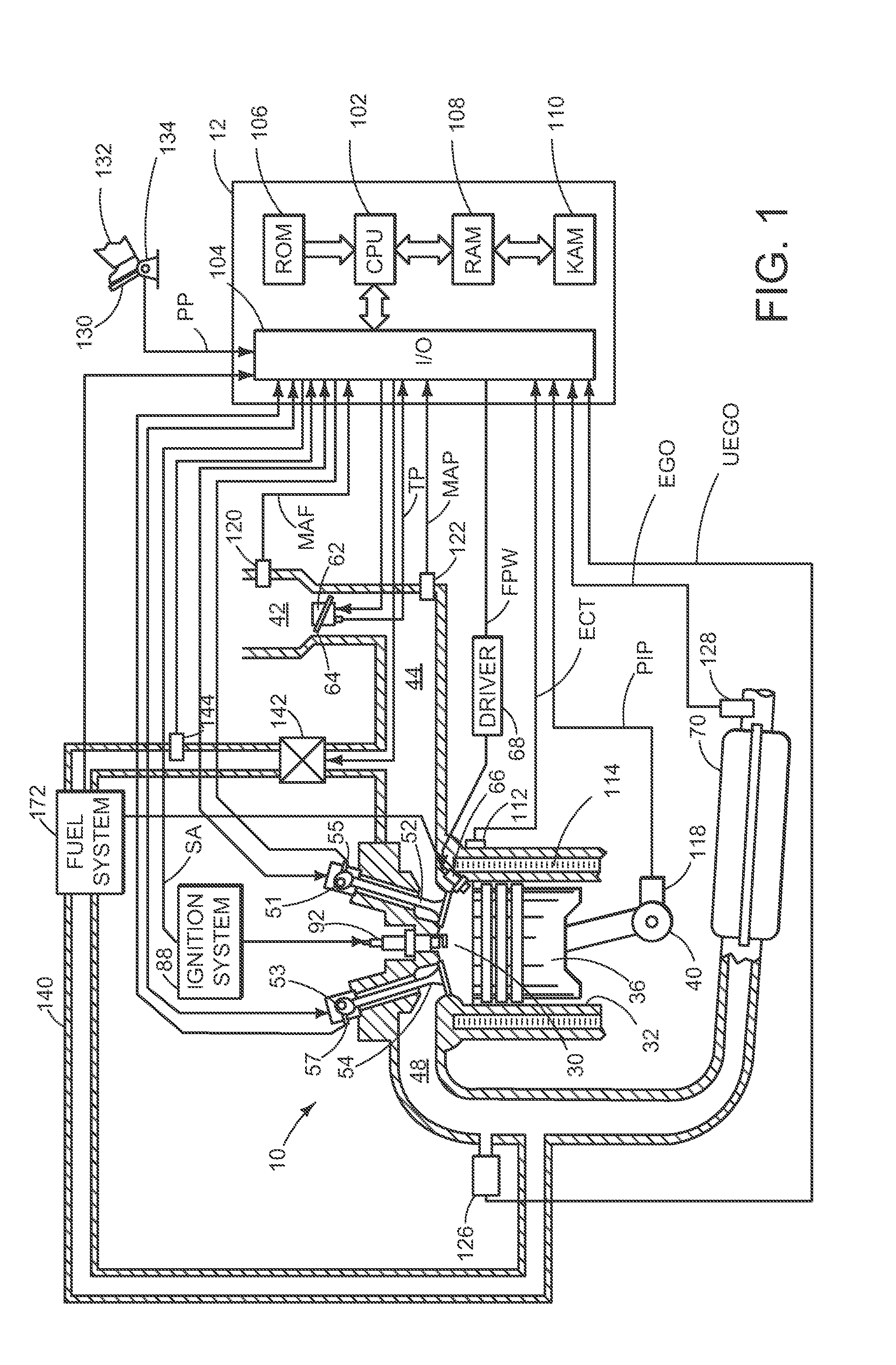

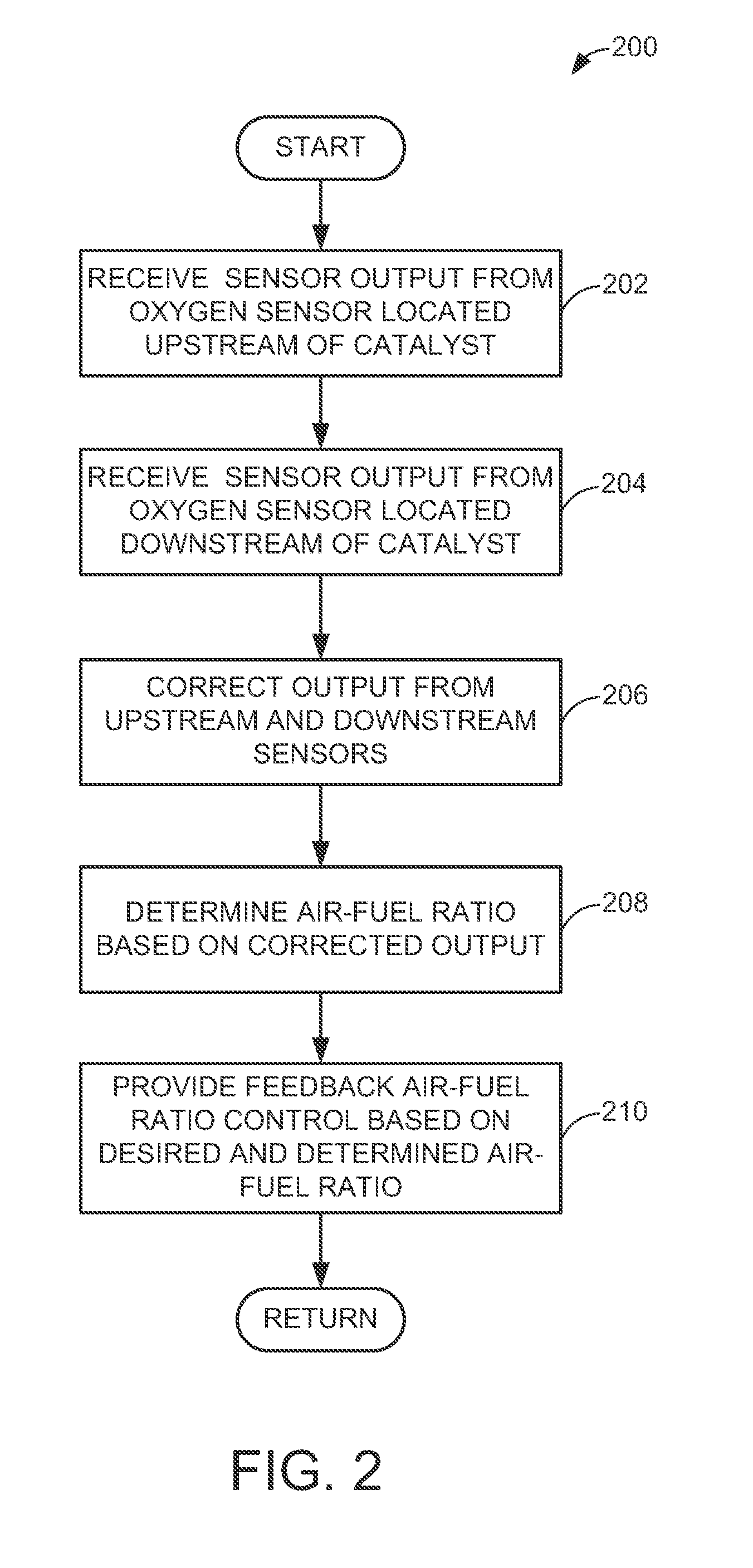

System and methods for controlling air fuel ratio

ActiveUS20120324864A1Precise ratioImprove fuel economyElectrical controlInternal combustion piston enginesEngineeringAromatic hydrocarbon

Methods and system for controlling air-fuel ratios in an internal combustion engine are disclosed. One embodiment comprises, adjusting a sensor calibration correction value of an exhaust sensor upstream of a catalyst based on an exhaust sensor downstream of the catalyst. The adjustment of the sensor calibration correction value takes advantage of the fact that certain aromatic hydrocarbons causing errors in the reading of the upstream sensor are not present at the downstream sensor due to sufficient catalytic activity of a catalyst positioned between the sensors.

Owner:FORD GLOBAL TECH LLC

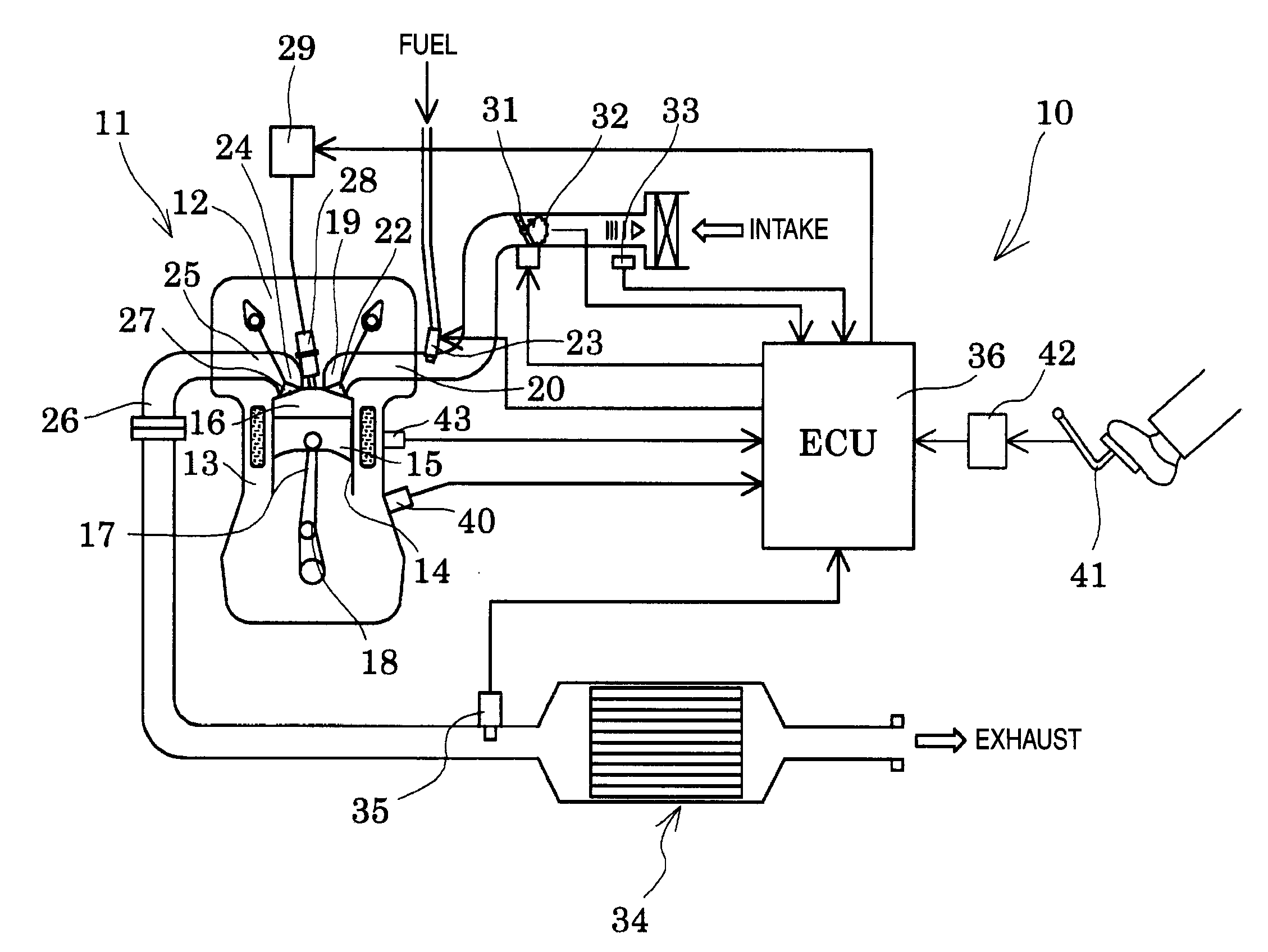

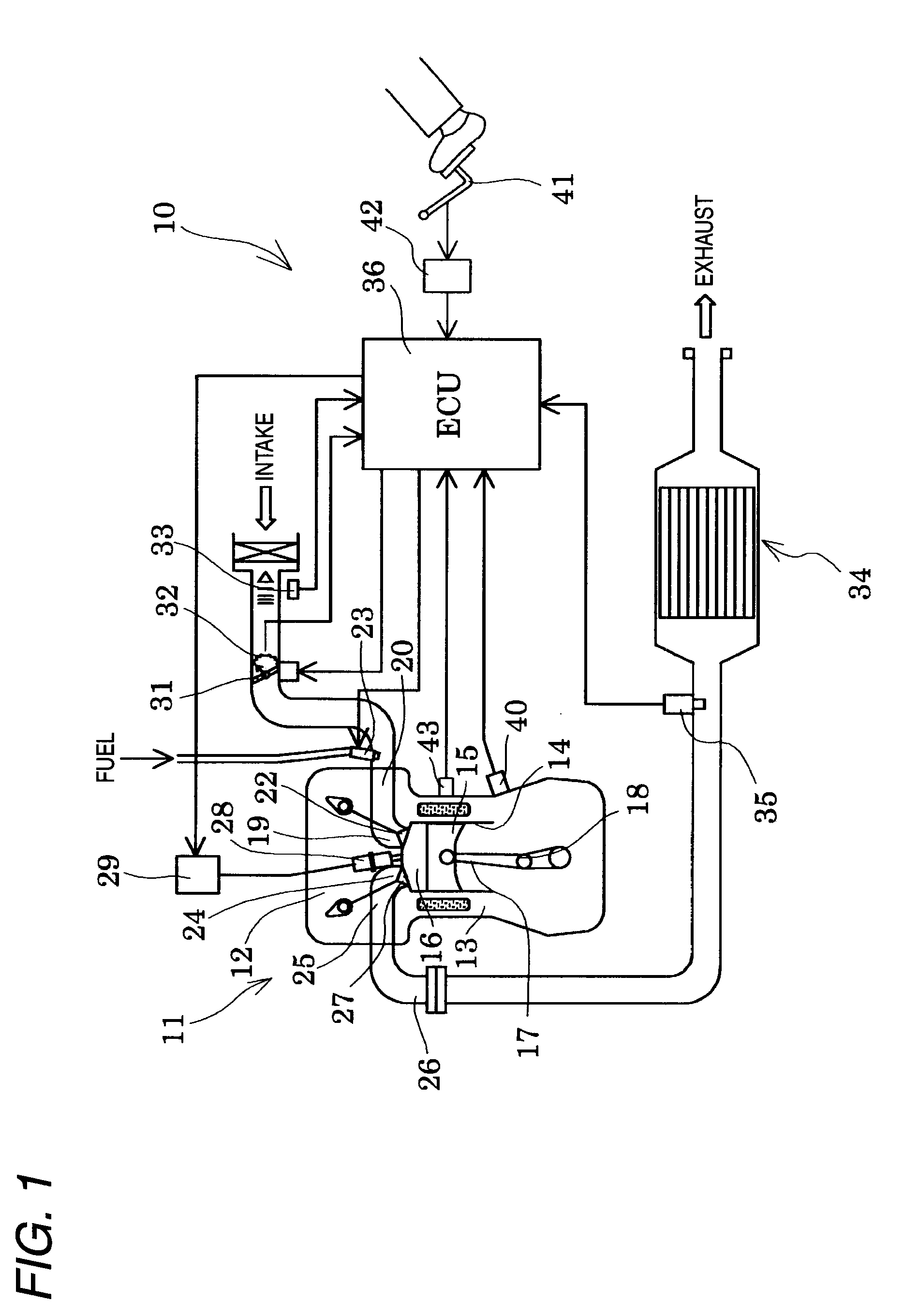

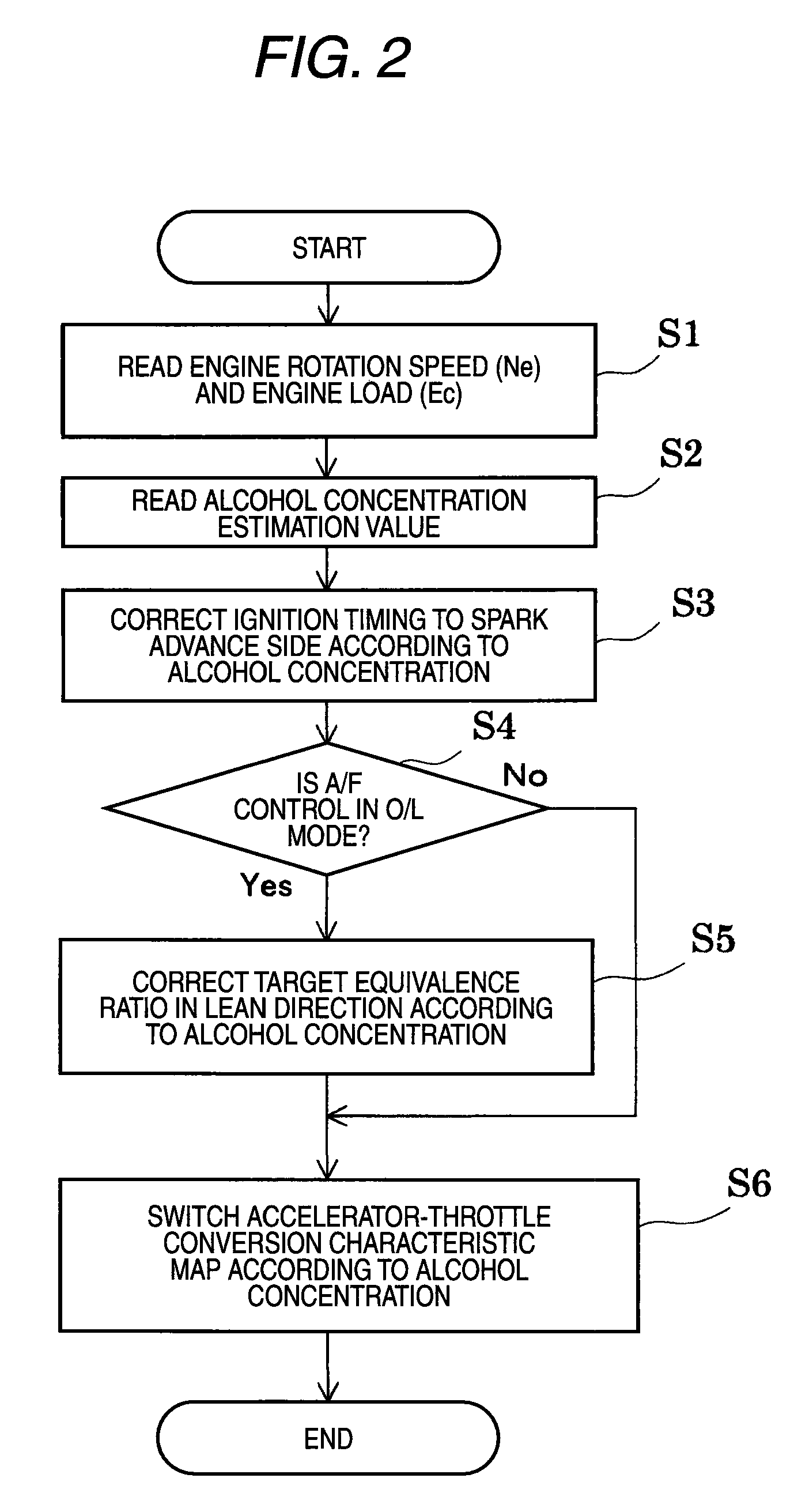

Controller of engine

InactiveUS20090205613A1Increase fuel consumptionHigh outputElectrical controlAutomatic controlEquivalence ratioHigh load

A controller of an engine that can use a blended fuel with alcohol blended therein, the controller includes: an ignition timing controller, operable to control an ignition timing of the engine; an exhaust air-fuel ratio detector, operable to detect an exhaust air-fuel ratio of the engine; a concentration detector, operable to detect concentration of the alcohol in the blended fuel; an operation state detector, operable to detect an operation state of the engine; and a corrector, when the operation state which is detected by the operation state detector is a high-speed, high-load operation state, as the concentration of the alcohol which is detected by the concentration detector is higher, operable to control an injection amount which is injected from a fuel injection valve to correct a target equivalence ratio more in a lean direction, and operable to correct the ignition timing which is controlled by the ignition timing controller more to a spark advance side.

Owner:MITSUBISHI MOTORS CORP

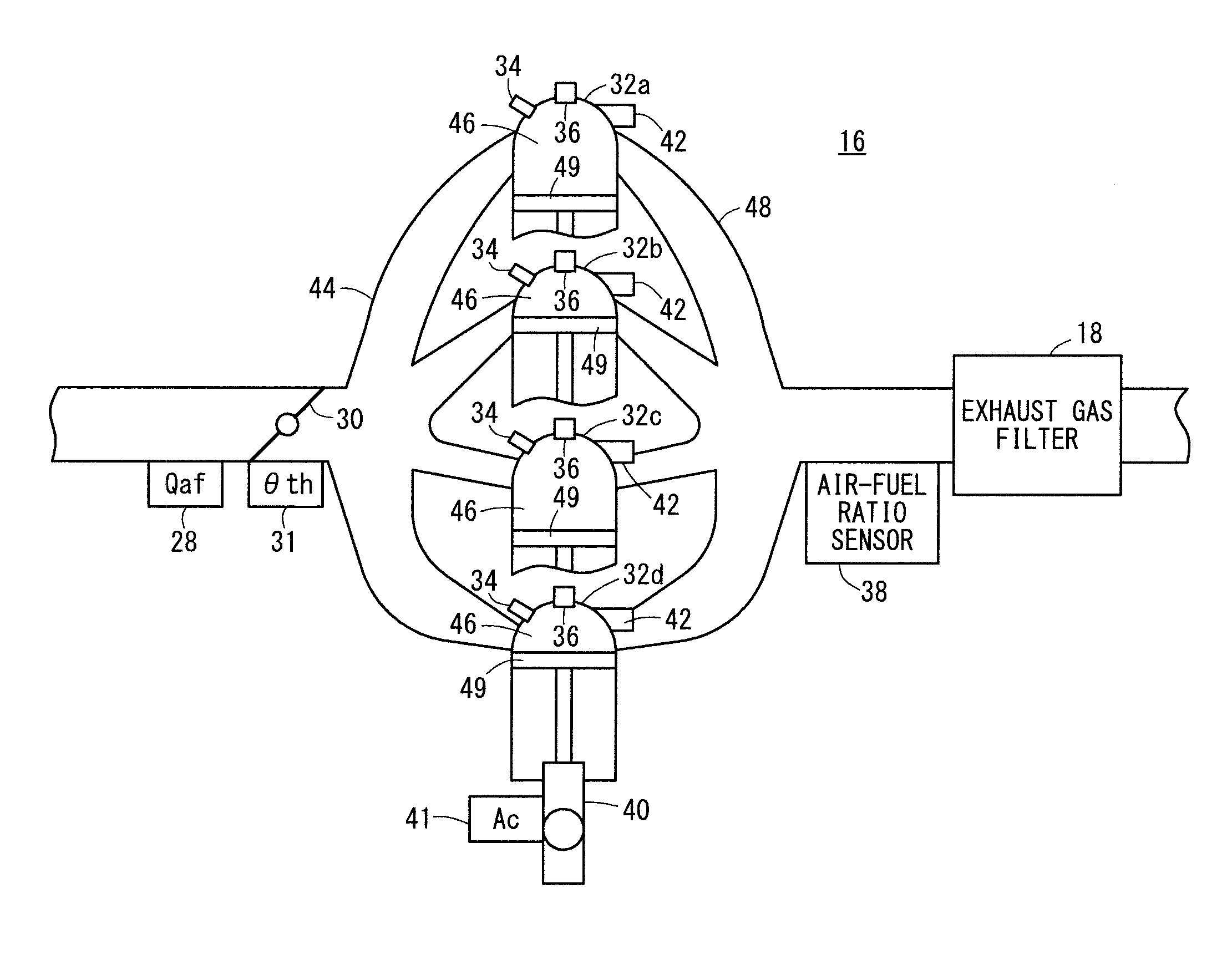

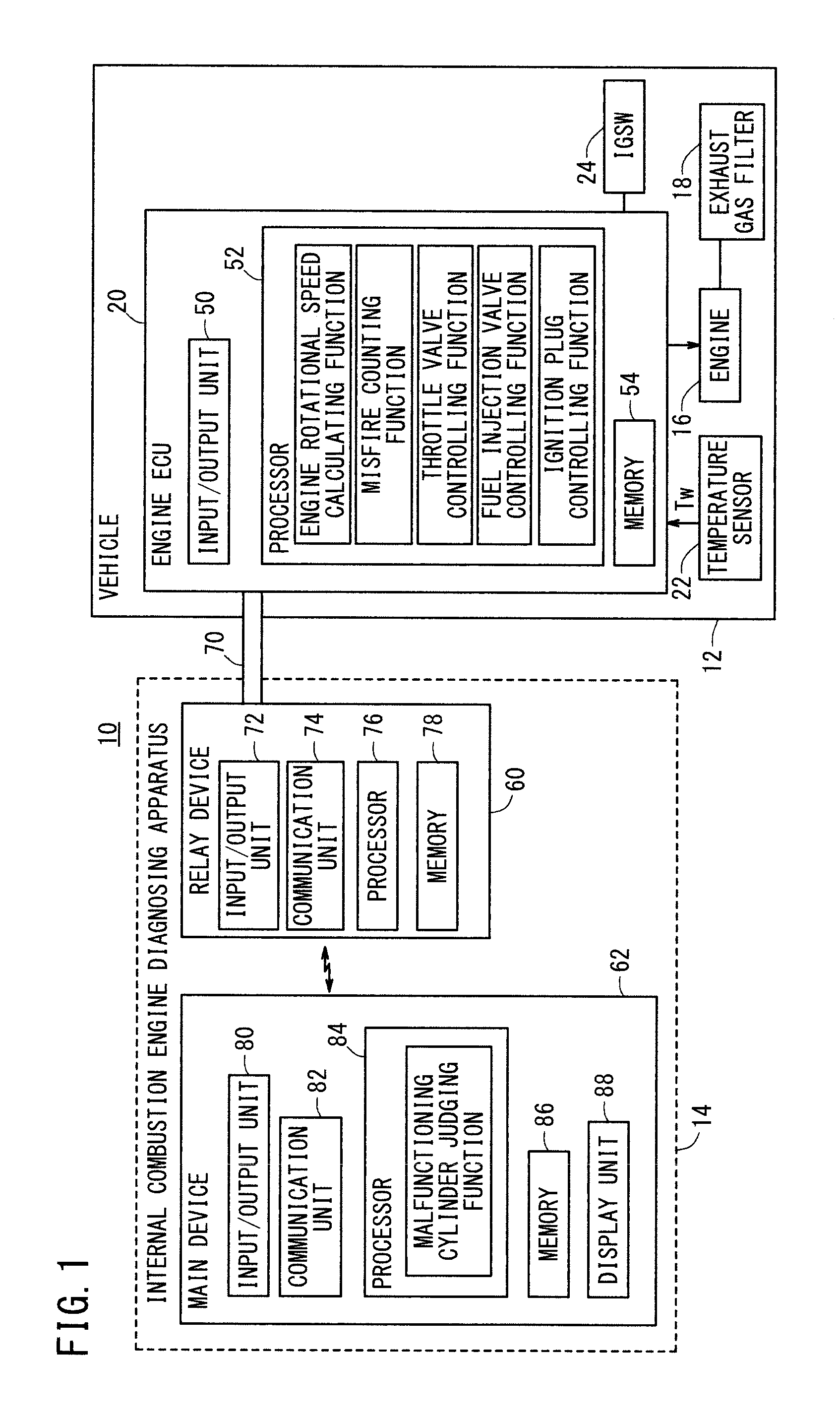

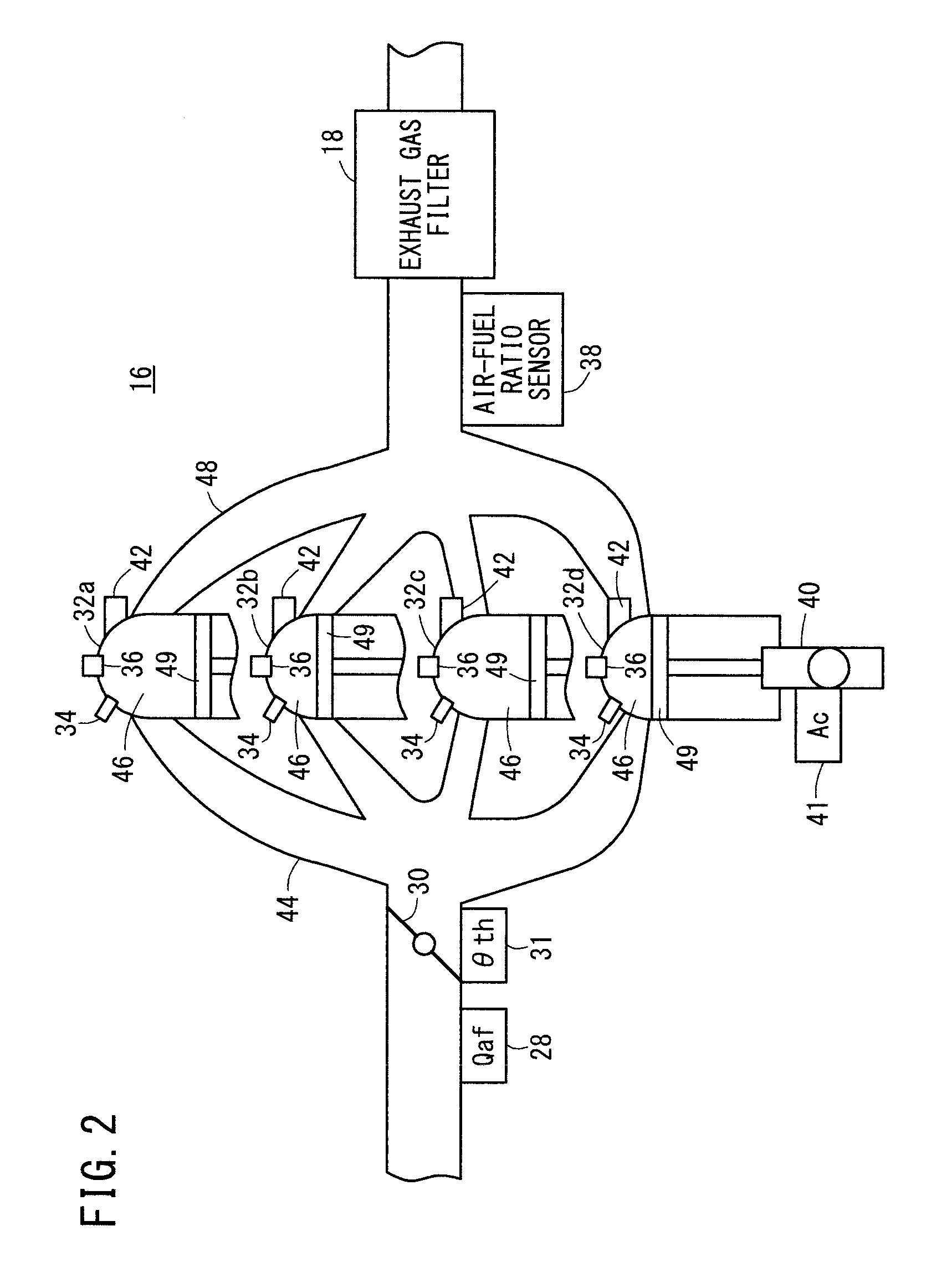

Internal combustion engine diagnostic device and internal combustion engine diagnostic method

ActiveUS20130158841A1Adversely affect durabilityAffect their durabilityElectrical controlInternal combustion piston enginesAir–fuel ratioFuel injection

An internal combustion engine diagnostic device and an internal combustion engine diagnostic method identify an abnormal cylinder having an abnormal air-fuel ratio among a plurality of cylinders during the operation of an internal combustion engine. The internal combustion engine diagnostic device comprises: an air-fuel ratio control unit for changing the air-fuel ratio in a stepwise manner by controlling a fuel injection amount adjusting means that adjusts the fuel injection amount of each of the plurality of cylinders; and an abnormal cylinder identification unit for identifying an abnormal cylinder on the basis of the relationship between each air-fuel ratio changed in a stepwise manner and the number of misfires occurring in the plurality of cylinders, the number being counted by a misfire counter for each air-fuel ratio changed in a stepwise manner.

Owner:HONDA MOTOR CO LTD

Zirconium-based alloy ingot and preparation method thereof as well as prepared zirconium-based amorphous alloy

The invention relates to the technical field of alloy ingots, and in particular relates to a zirconium-based alloy ingot and a preparation method thereof as well as a prepared zirconium-based amorphous alloy. The preparation method of the zirconium-based alloy ingot comprises two steps, namely, a vacuum arc melting method and a vacuum high frequency melting method, wherein the vacuum arc melting method comprises steps of mixing and melting Ni metal and a high melting point method Nb metal, thereby reducing the melting temperature; in addition, except the impurities in the raw materials in the vacuum arc melting method, no other impurities are mixed, so that the purity of the alloy is ensured; a mother alloy obtained by using the vacuum arc melting method is further mixed with the rest materials for secondary melting, thereby obtaining a five-element alloy ingot with accurate proportion. The zirconium-based alloy ingot is die-cast in a vacuum environment, a cooling speed expected by over-cooling is met so as to prevent the materials from crystallization, and the zirconium-based amorphous alloy with the thickness of 0.5-3mm can be manufactured.

Owner:WINTOP DONGGUAN INDAL TECH

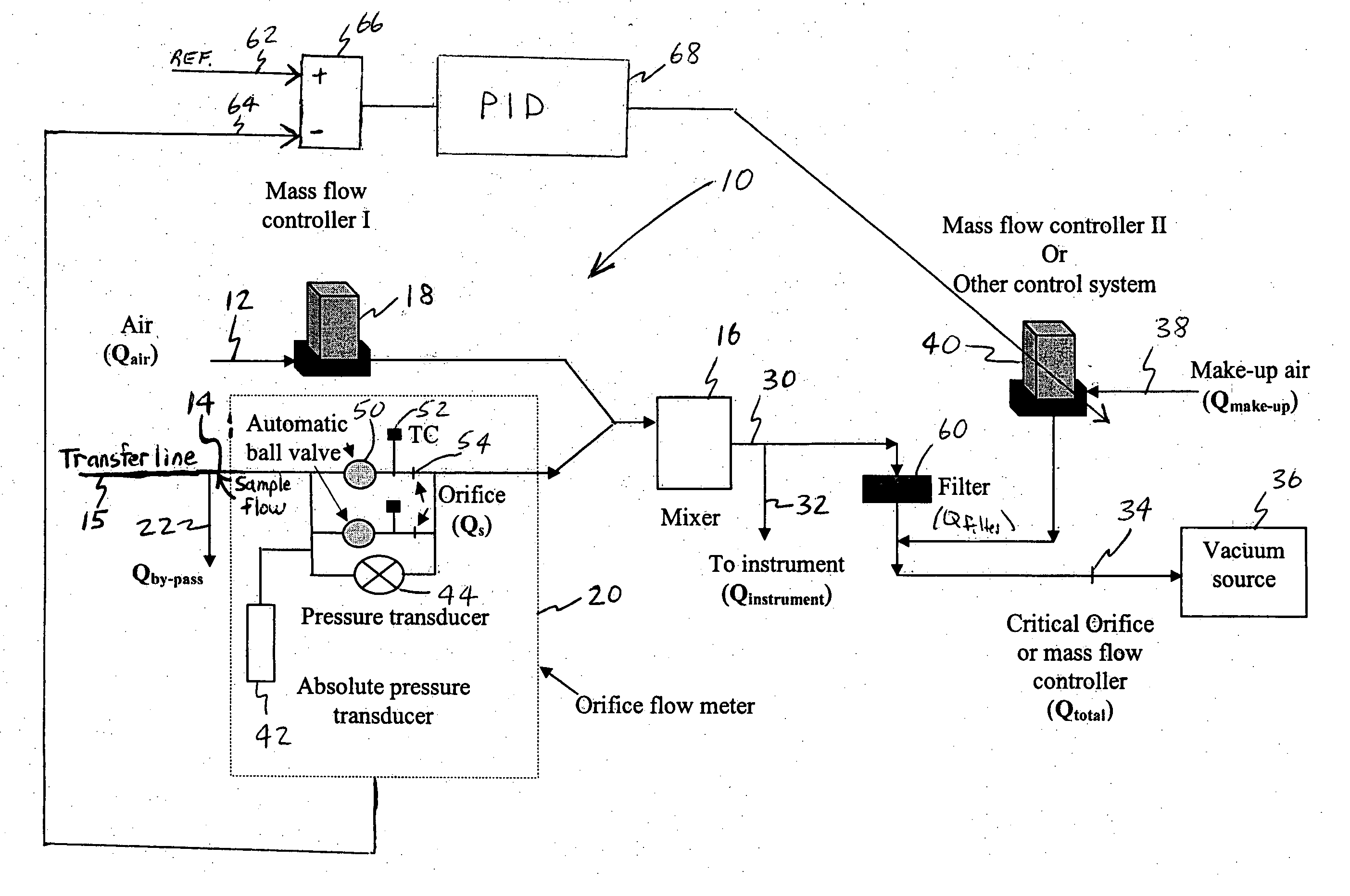

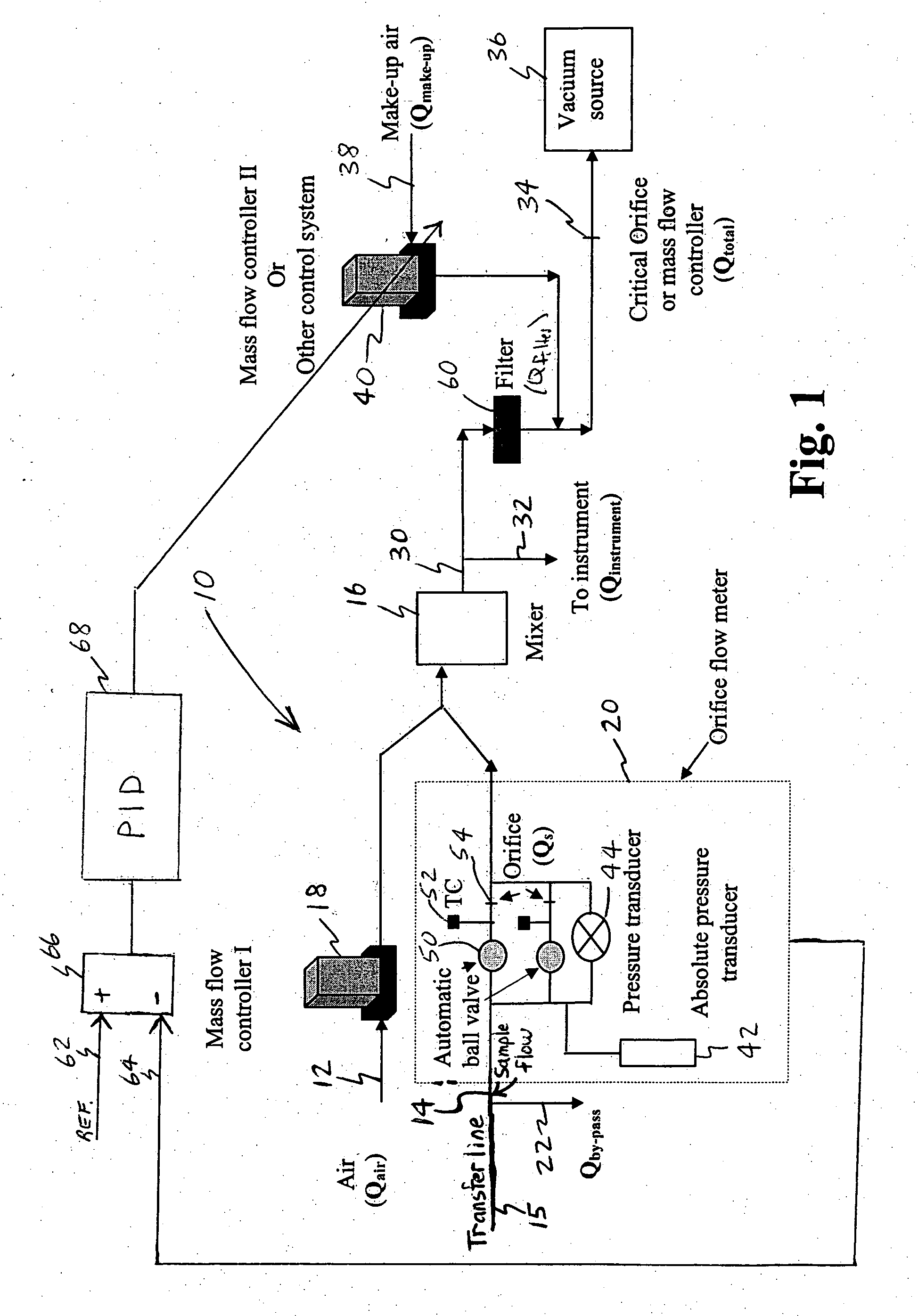

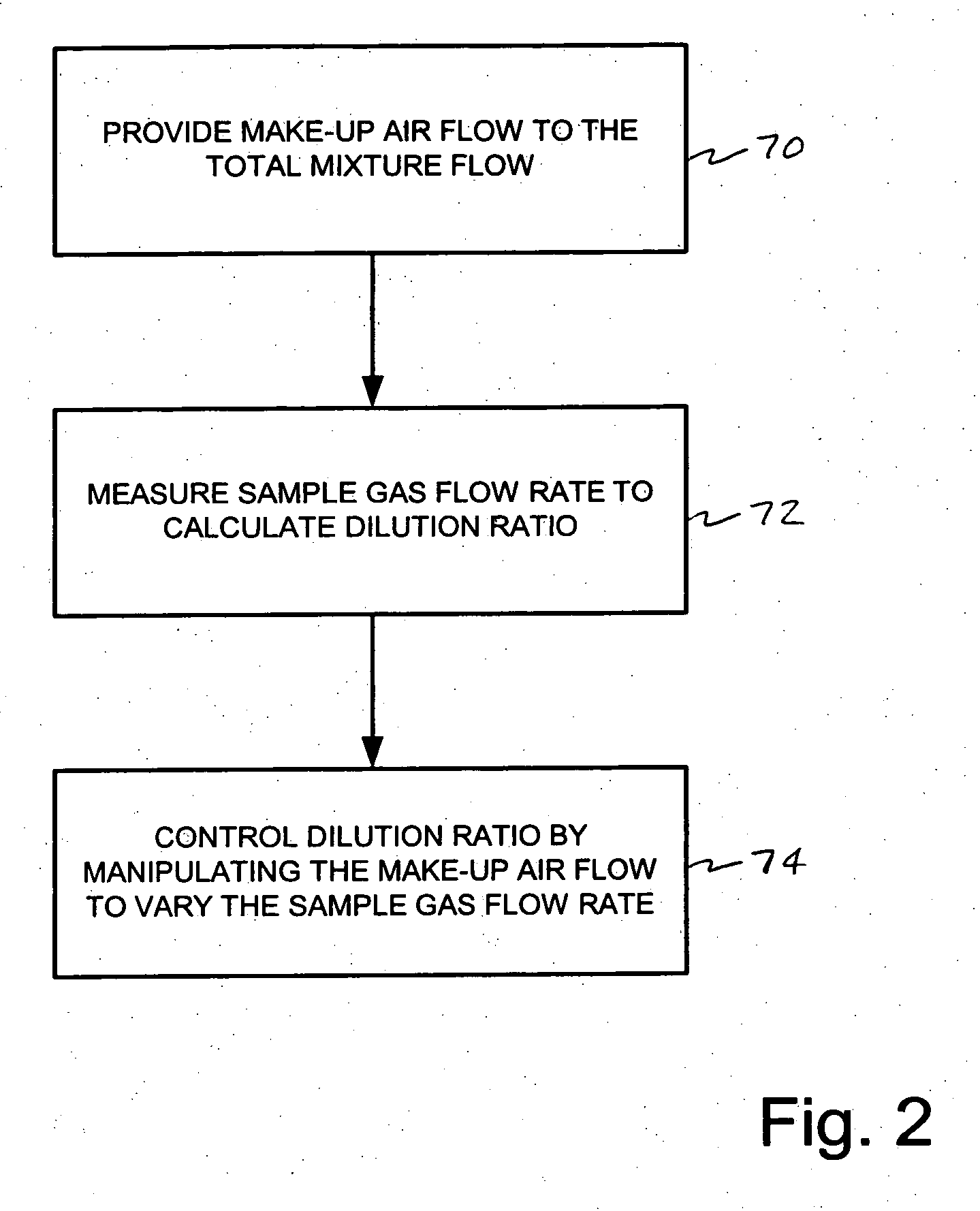

Wide range continuous diluter

ActiveUS20060179960A1Minimize small particle lossReduce residence time of flowAnalysing fluids using sonic/ultrasonic/infrasonic wavesWithdrawing sample devicesSmall particlesChemistry

A wide range continuous diluter for diluting gases that contain small particles to allow subsequent measurement of the diluted gases with an instrument is provided. A dilution gas inlet receives a dilution gas, and a sample gas inlet receives a sample gas. A flow meter measures the sample gas flow rate. A mixer receives and mixes the dilution gas and the sample gas at a dilution ratio. An instrument flow outlet provides a well-defined flow into the instrument from the mixture flow. A make-up gas inlet is arranged to provide make-up gas into the mixture flow at a controlled rate. Because the dilution gas flows at a controlled rate and the mixture flows at a controlled rate, changing the flow rate of the make-up gas causes a responsive change in the sample gas flow rate, thereby allowing continuous adjustment and control of the dilution ratio when desired.

Owner:HORIBA LTD

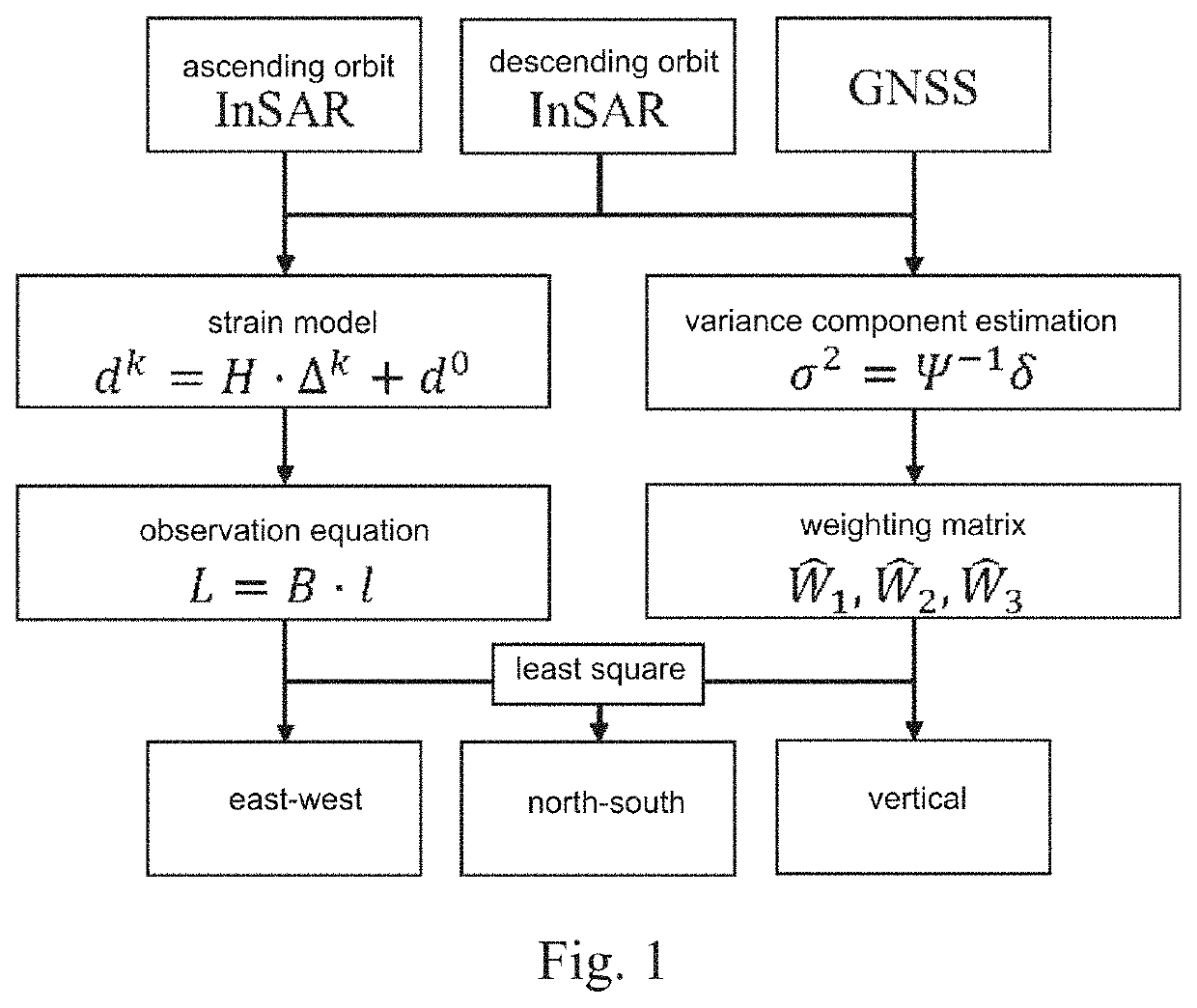

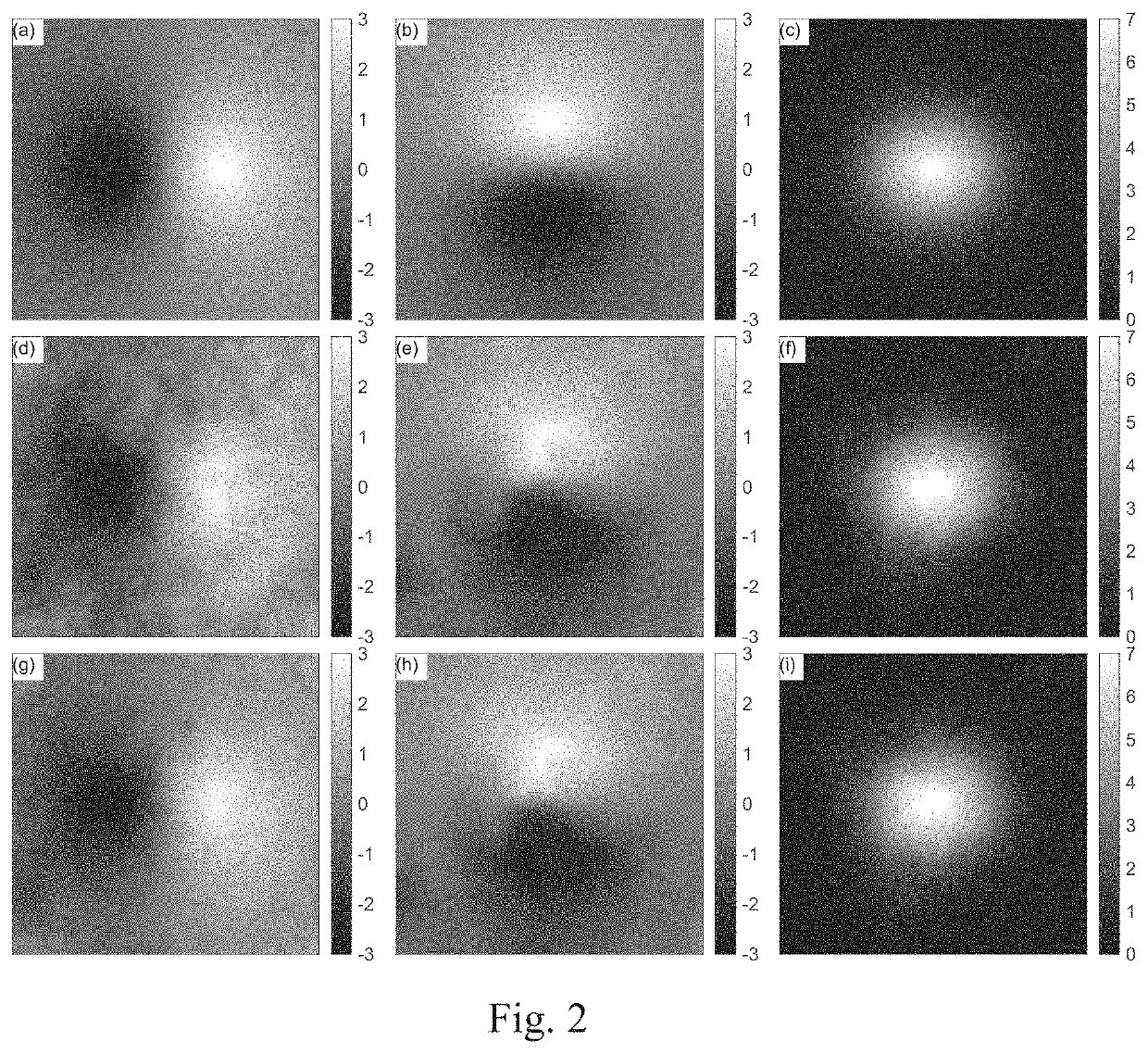

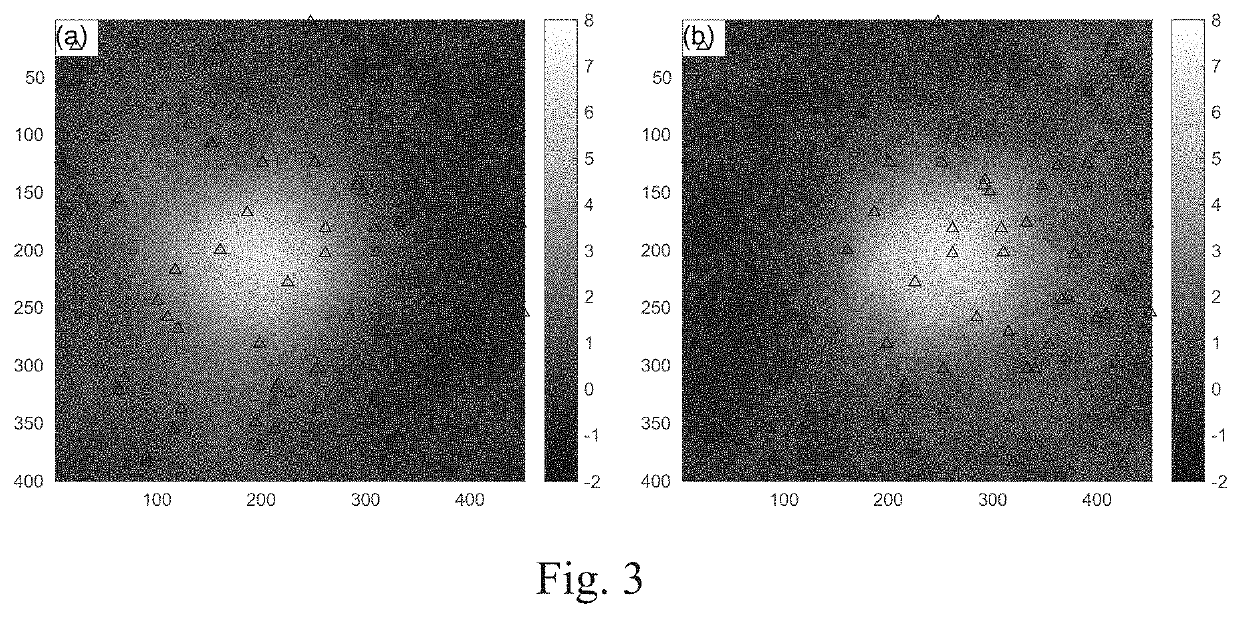

InSAR and GNSS weighting method for three-dimensional surface deformation estimation

PendingUS20210011149A1Accurately weight ratioImprove accuracySatellite radio beaconingUsing wave/particle radiation meansObservation dataComputational physics

An InSAR and GNSS weighting method for three-dimensional surface deformation estimation includes steps of: Step 1: establishing a functional relationship between three-dimensional deformation d0 of an unknown point and a certain amount of InSAR / GNSS data Li of surrounding points by using ascending and descending orbit InSAR data and GNSS data based on a strain model and observation imaging geometry: Step 2: performing relative weighting on Ki observation data in the InSAR / GNSS data Li, and determining an initial weight matrix Wi of various InSAR / GNSS observations; Step 3: determining accurate weight matrix Ŵi between the various InSAR / GNSS observations by variance component estimation, and solving the three-dimensional deformation d0 based on a least square method; and Step 4: performing the steps 1-3 for each surface point to estimate a high-accurate three-dimensional surface deformation field by fusing InSAR and GNSS.

Owner:CENT SOUTH UNIV

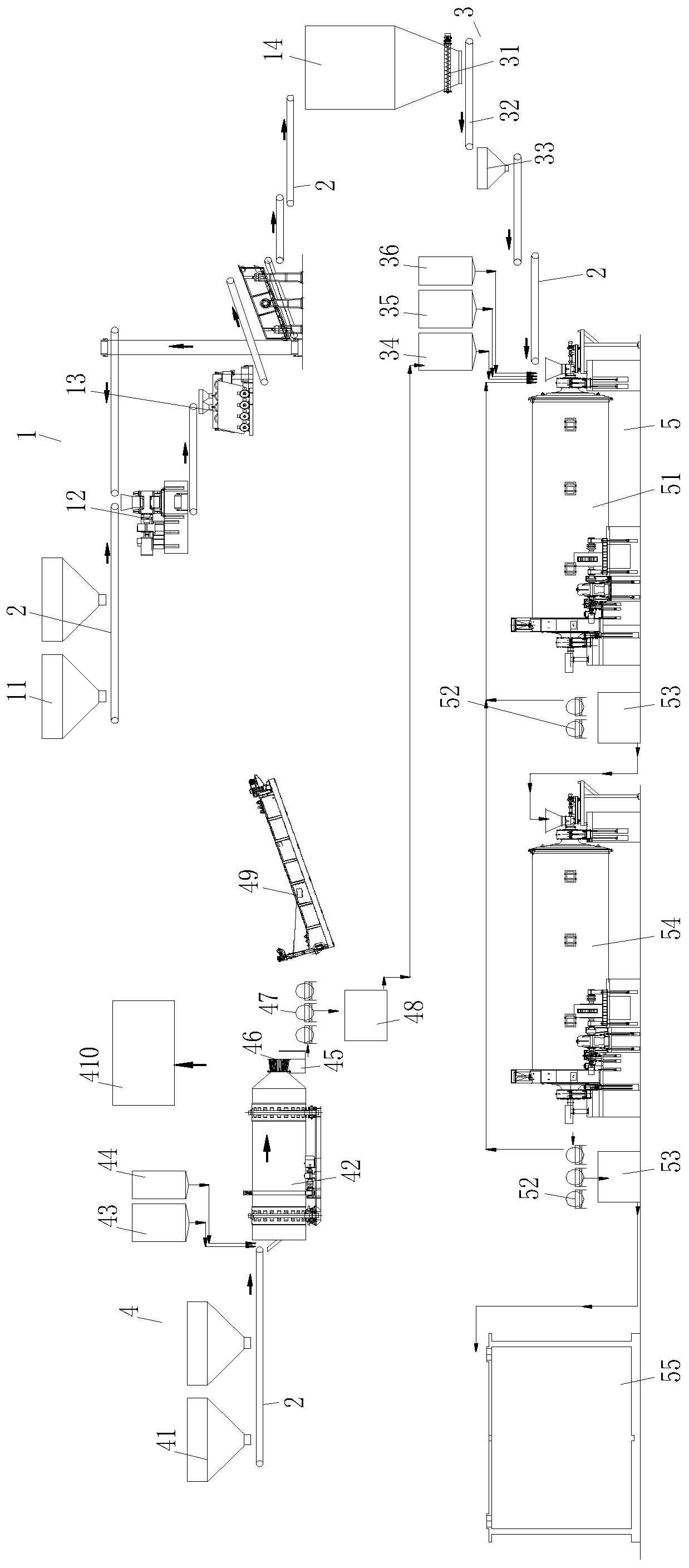

Intelligent wet powdering production technology for ceramic raw materials

InactiveCN110404657ARealize full automationIncrease production capacityGrain treatmentsNumerical controlProduction line

The invention relates to the technical field of ceramic raw material powdering and particularly relates to an intelligent wet powdering production line for ceramic raw materials. The intelligent wet powdering production line for ceramic raw materials comprises a raw material pre-crushing system, a belt conveying line, an automatic metering and batching system, a pug slurrying system and a continuous ball miller system. Transferring and conveying at the discharge end of the raw material pre-crushing system are carried out through a belt conveying line, the automatic metering and batching systemis located on the raw material pre-crushing system, the discharge end of the automatic metering and batching system is communicated with the feeding end of the pug slurrying system, and the other discharging end of the automatic metering and batching system is communicated with the continuous ball miller system. By means of the intelligent wet powdering production line for ceramic raw materials,the purposes of whole process automation, numerical control production and intelligent manufacturing of ceramic wet powdering technology are achieved, and thus the superior product rate and the production efficiency of ceramic products are improved; and besides, good mobility can be still ensured under the condition that the water content of slurry is low, and product defects are reduced.

Owner:广东鼎汇能科技股份有限公司

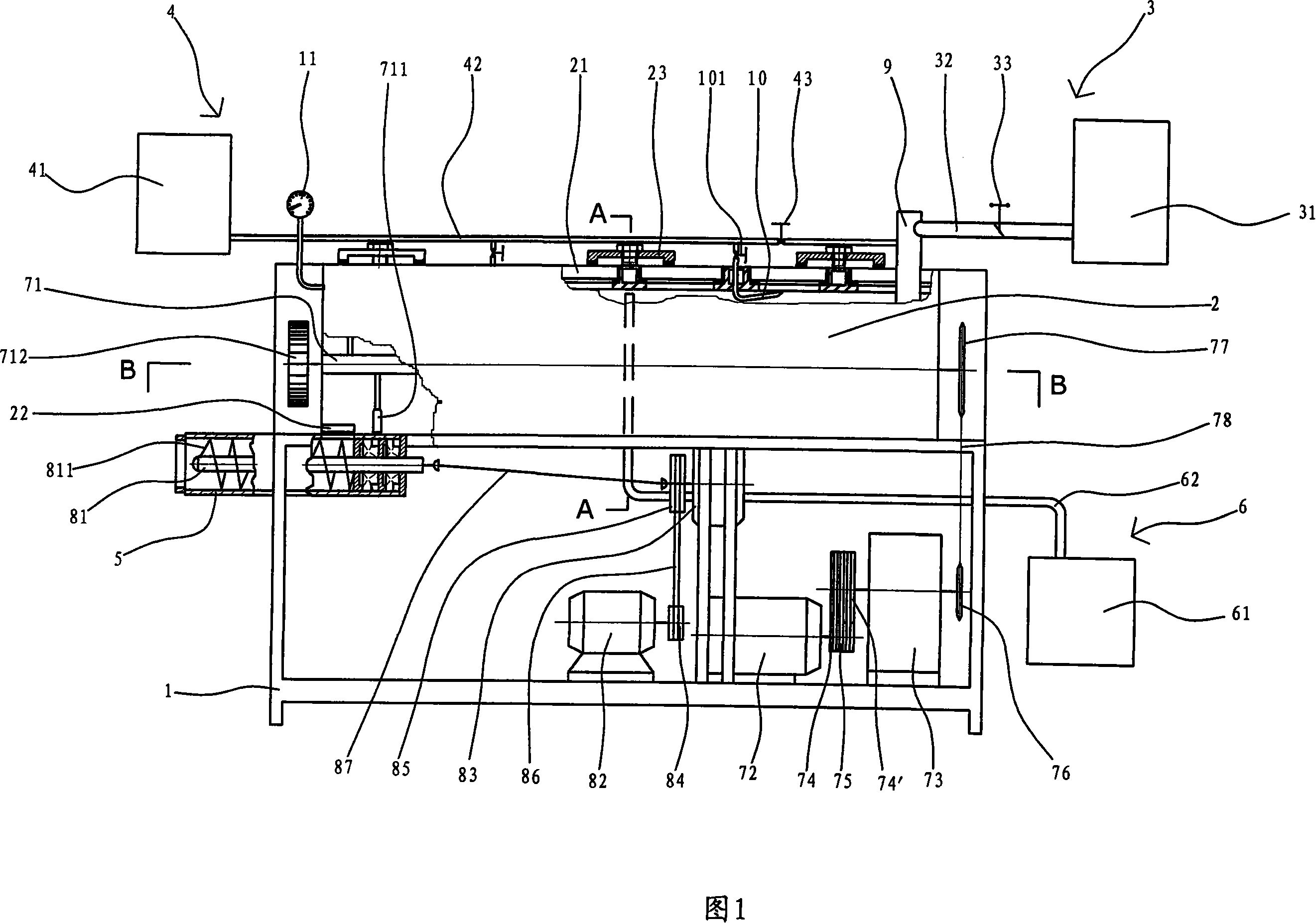

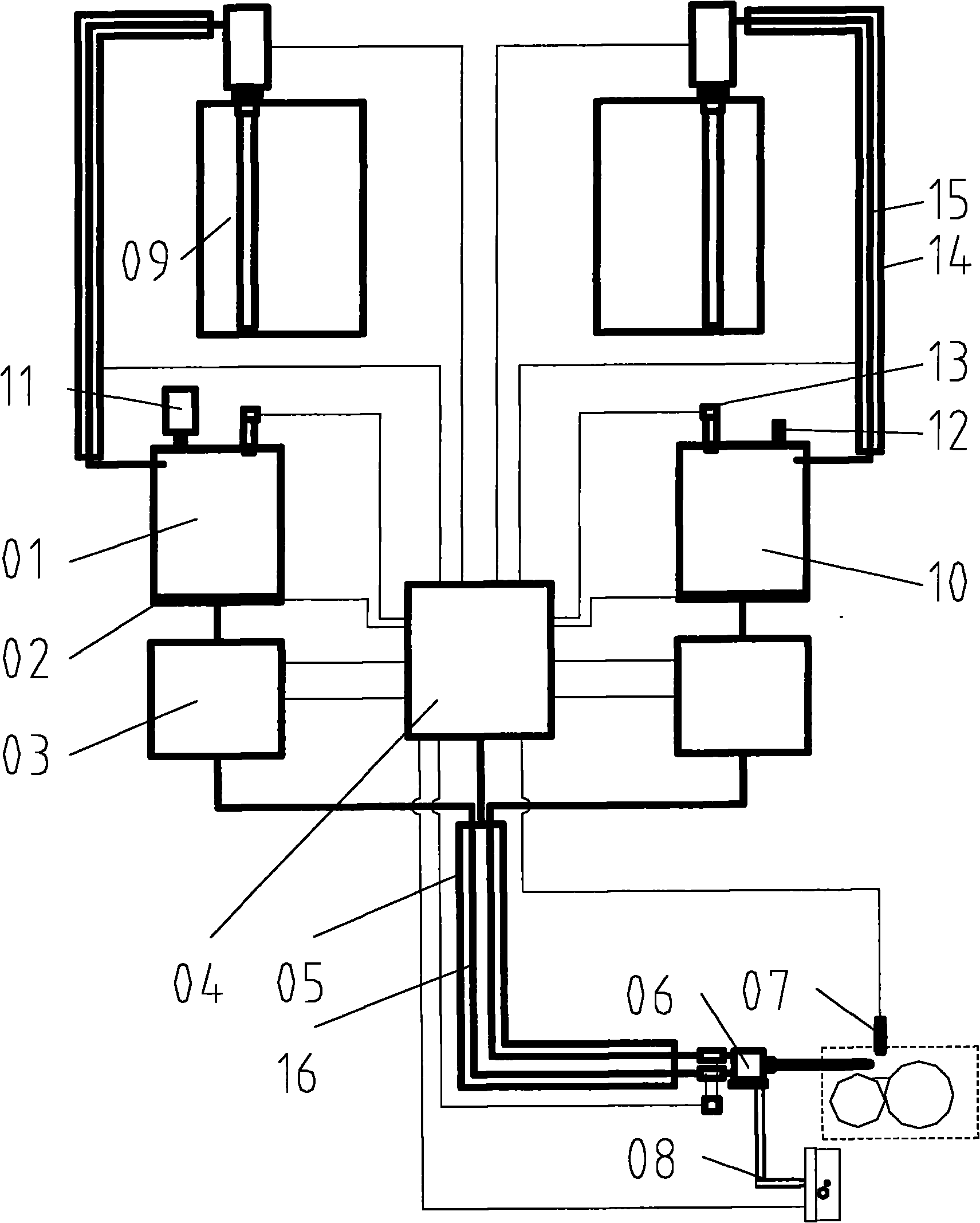

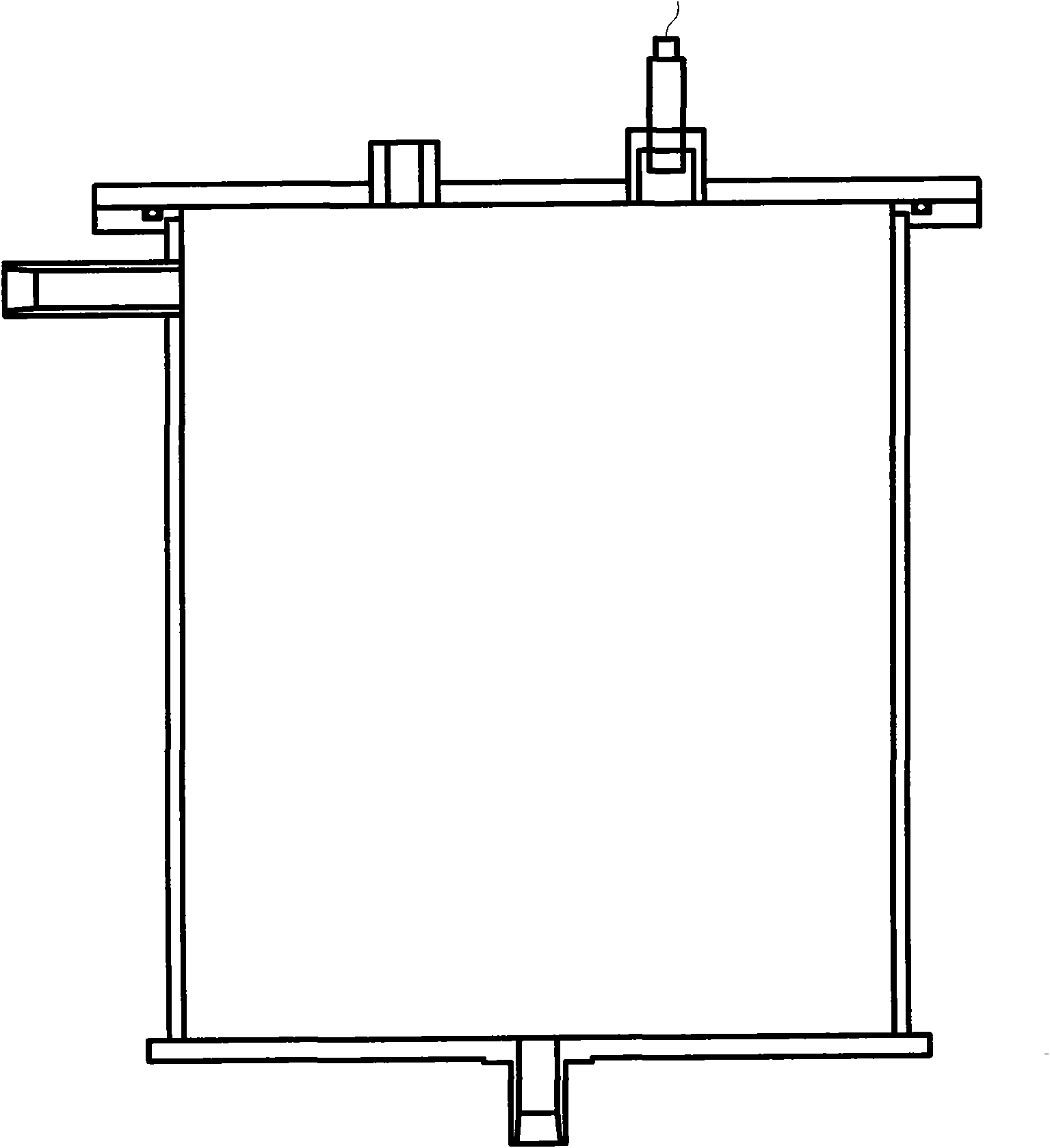

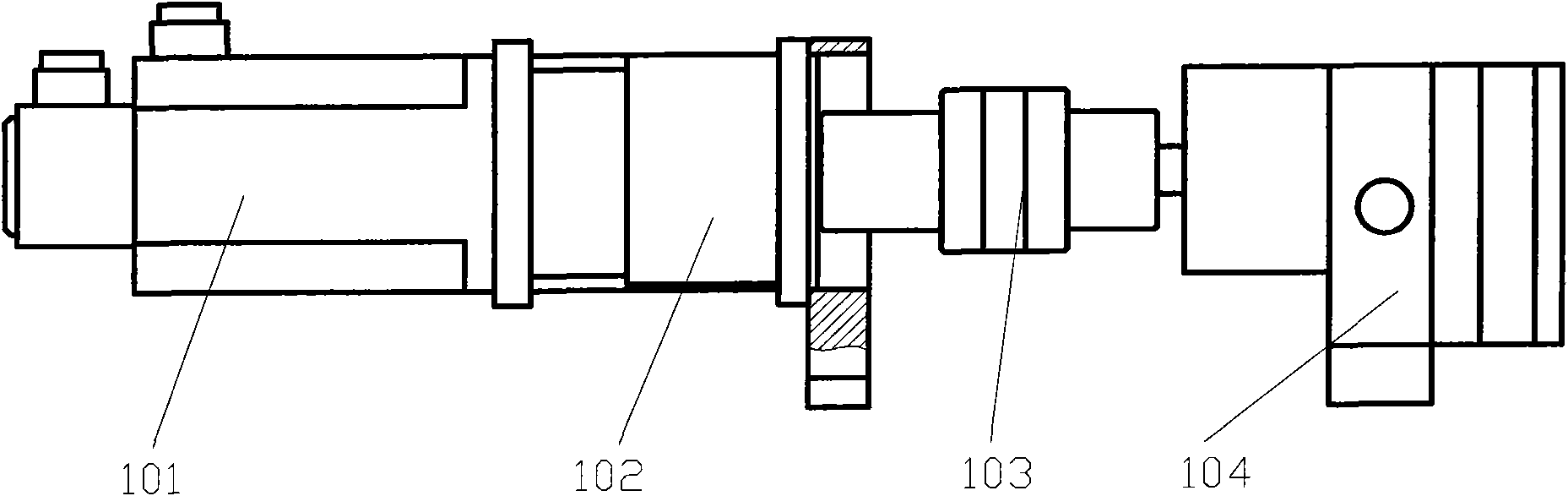

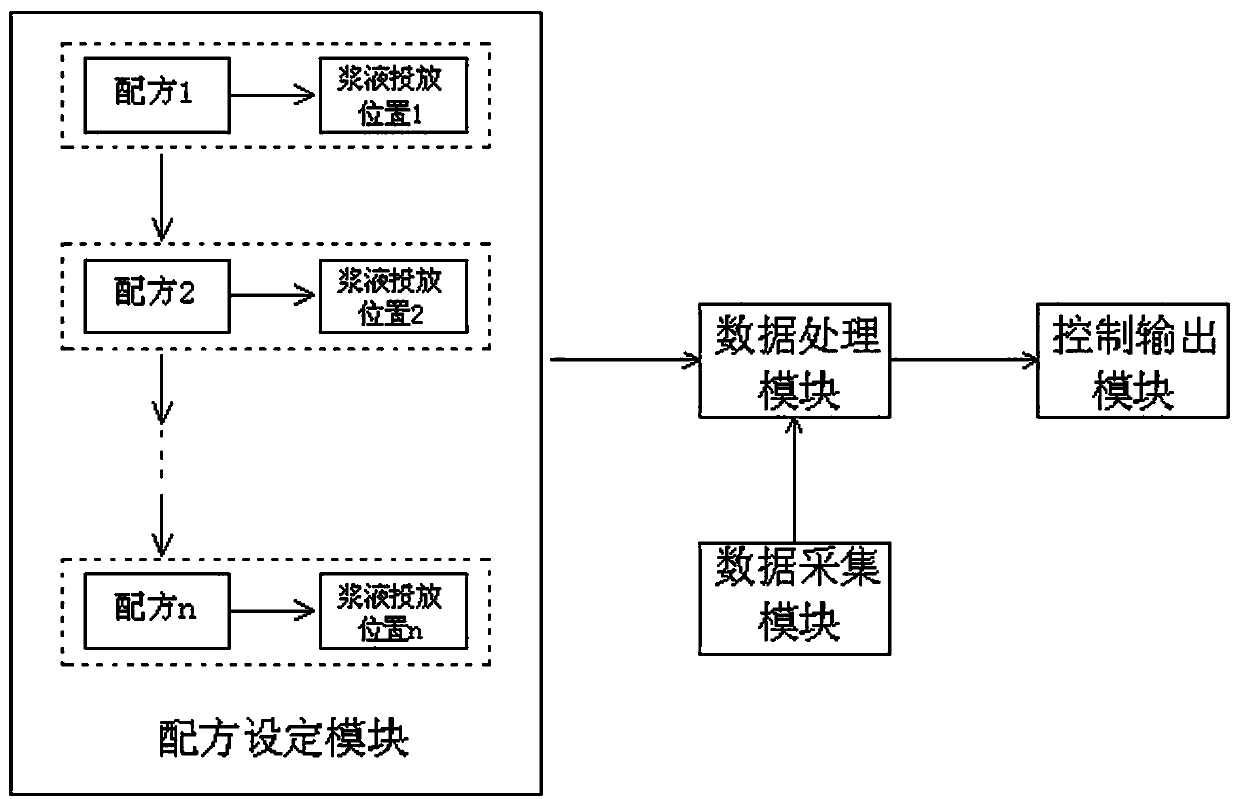

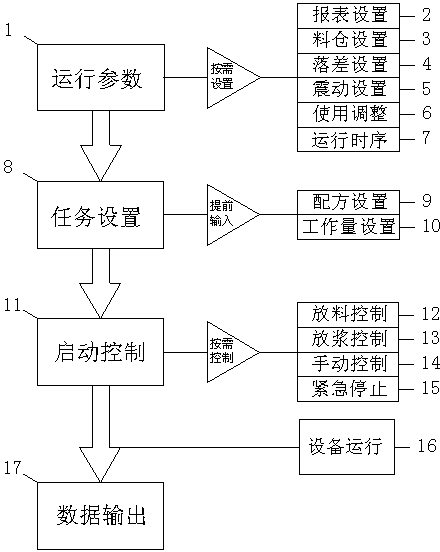

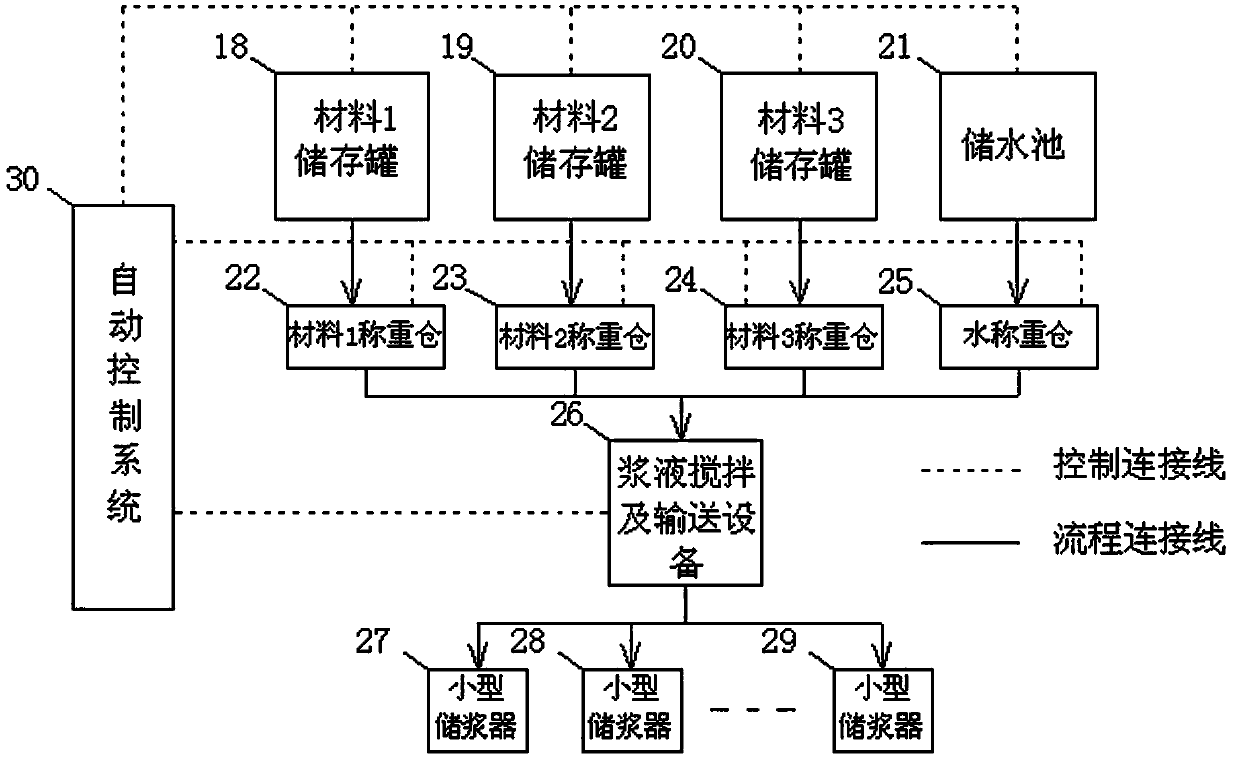

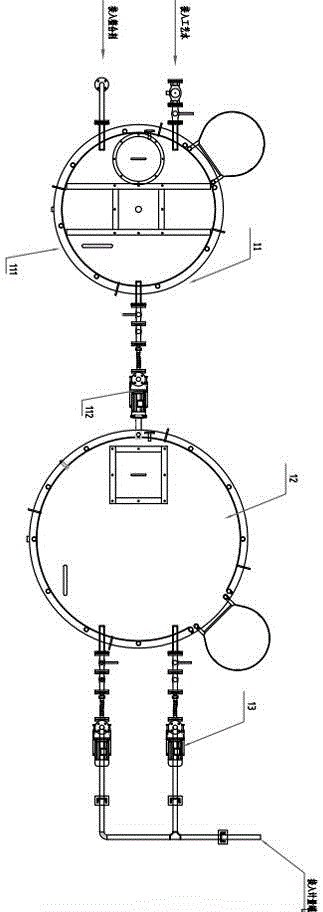

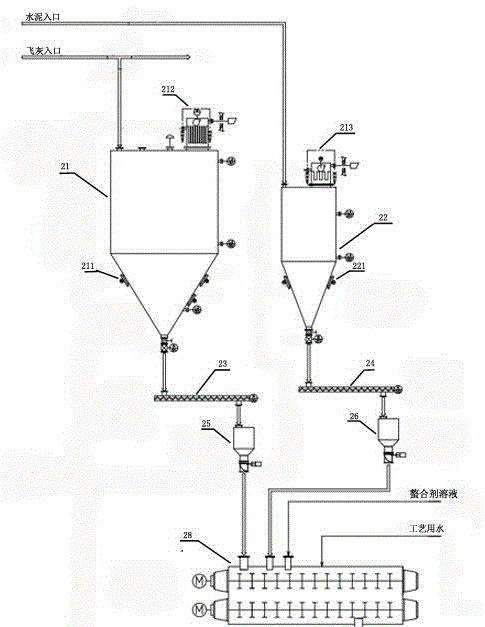

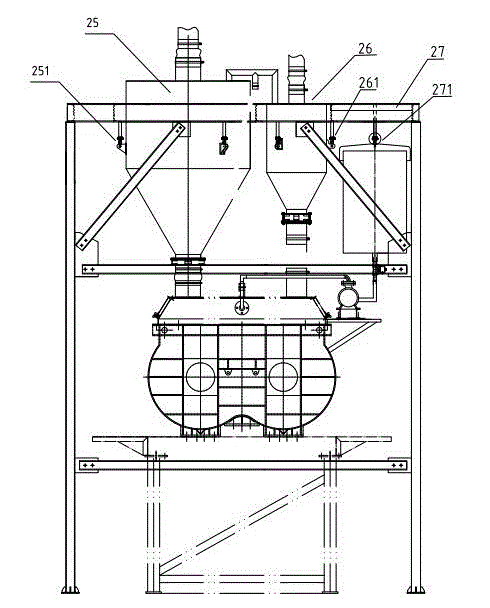

On-site automatic preparation system for mixed injection slurry

ActiveCN103806447APrecise ratioRealize ready-to-useFoundation engineeringSocial benefitsAutomatic control

The invention provides an on-site automatic preparation system for mixed injection slurry, and relates to the technical field of mine curtain slurry injection or water conservancy anti-seepage slurry injection. External hardware equipment comprises weighing and adding equipment, slurry stirring equipment and slurry conveying equipment, wherein the slurry stirring equipment structurally comprises a stirring tank, and a pumping and jet flow water pump is connected with an inner cavity of the stirring tank through a slurry inlet pipe and a slurry outlet pipe. The external hardware equipment is in communication connection with central control equipment, power distribution control enables signals to be transmitted accurately and achieves accurate control over the equipment, and a single worker can independently finish continuous preparation of the slurry. A computer of the central automatic control equipment sends control instruction signals to the external hardware equipment according to the needed preparation proportion of the slurry and a corresponding slurry storage device. The on-site automatic preparation system for the mixed injection slurry achieves the purpose that the slurry is used once being prepared, avoids waste of the slurry, is easy and convenient to operate, can be operated only by one worker, saves manpower and material resources, guarantees the quality of the slurry, and largely improves economic and social benefits.

Owner:NORTH CHINA ENG INVESTIGATION INST

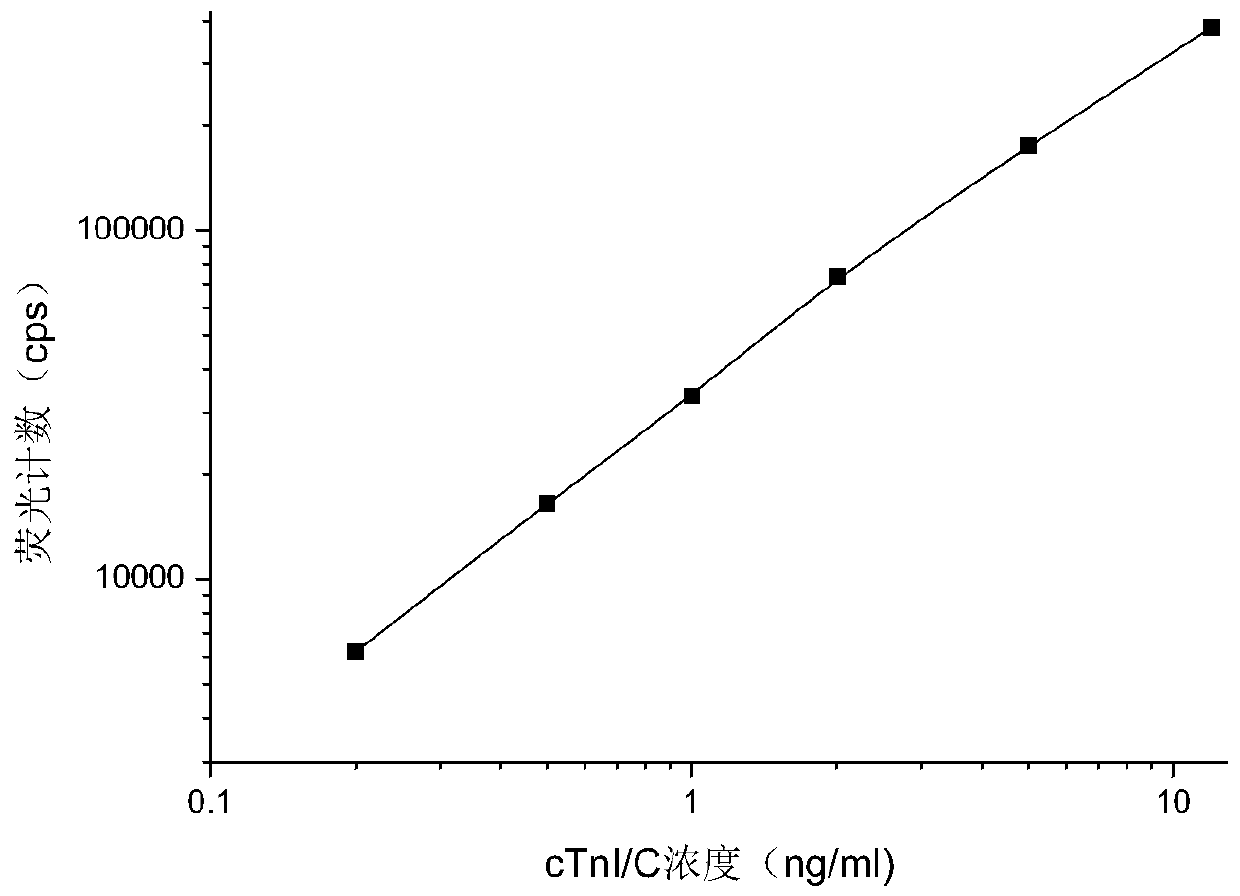

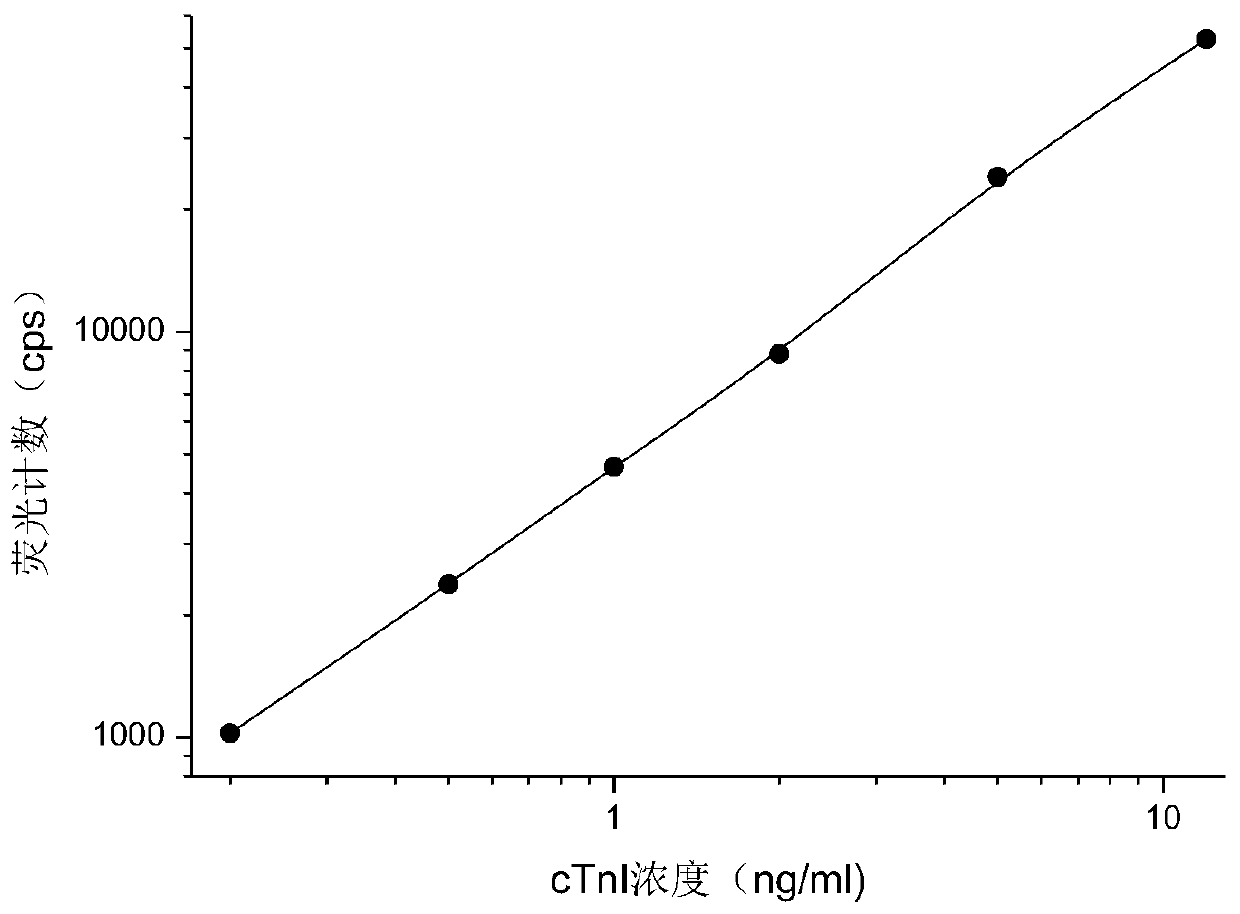

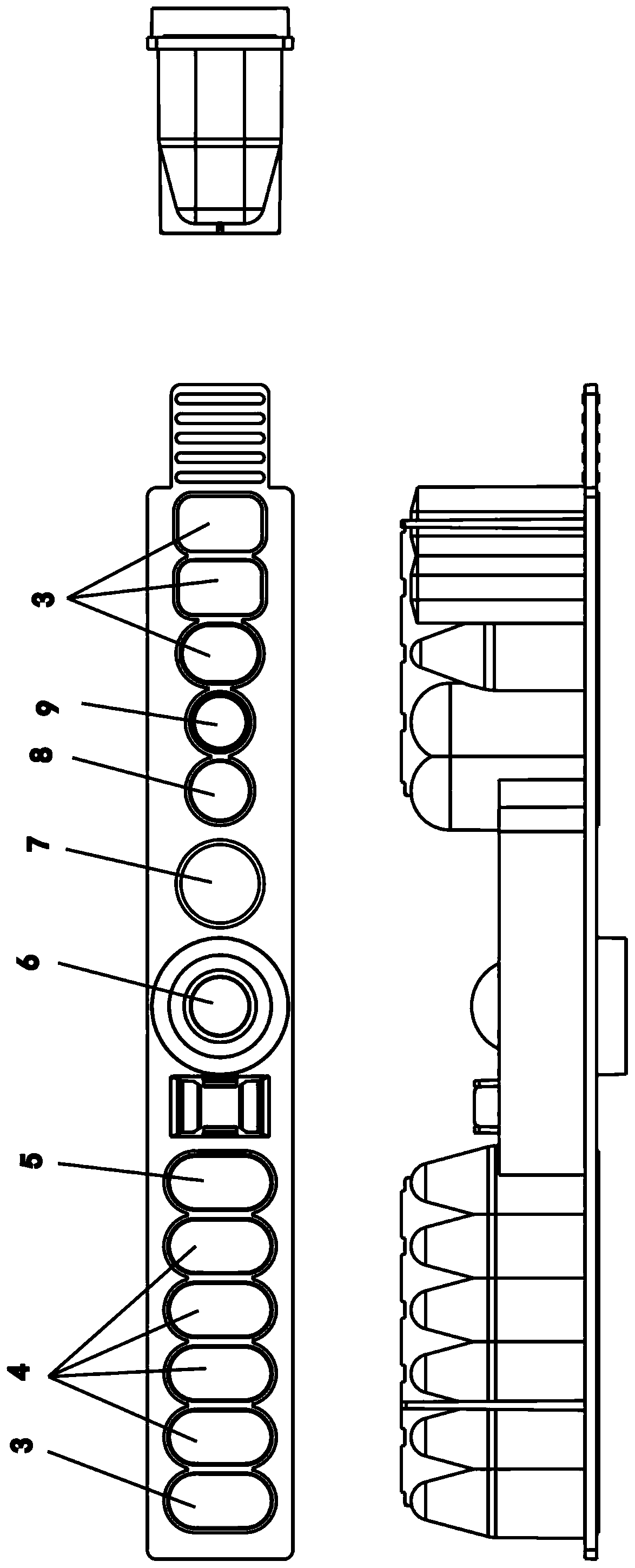

Double-labeling kit for detecting troponin (Tn) and compound and preparation and detection methods of double-labeling kit

The invention relates to a double-labeling kit for detecting troponin (Tn) and a compound and preparation and detection methods of the double-labeling kit, and belongs to the field of immunodetectionanalysis technologies and nano-biotechnologies. The kit comprises a reaction buffer solution integrated on a reagent strip, a cleaning solution, an enhancement solution, a magnetic particle solution coating a cTnI monoclonal antibody, a europium-labeled cTnC monoclonal antibody solution and a samarium-labeled cTnI monoclonal antibody solution and 2-6 bottles of additional freeze-dried calibrationproducts of natural cTnI antigens (containing cTnC) with different concentrations. The kit can provide a nearly-homogeneous double-labeling reaction system to ensure that the content of cTnI with complete fragments and the cTnI-C compound is detected simultaneously, the detection time is shortened, the efficiency is improved, and convenience is brought to clinical use.

Owner:浙江博实生物科技有限公司

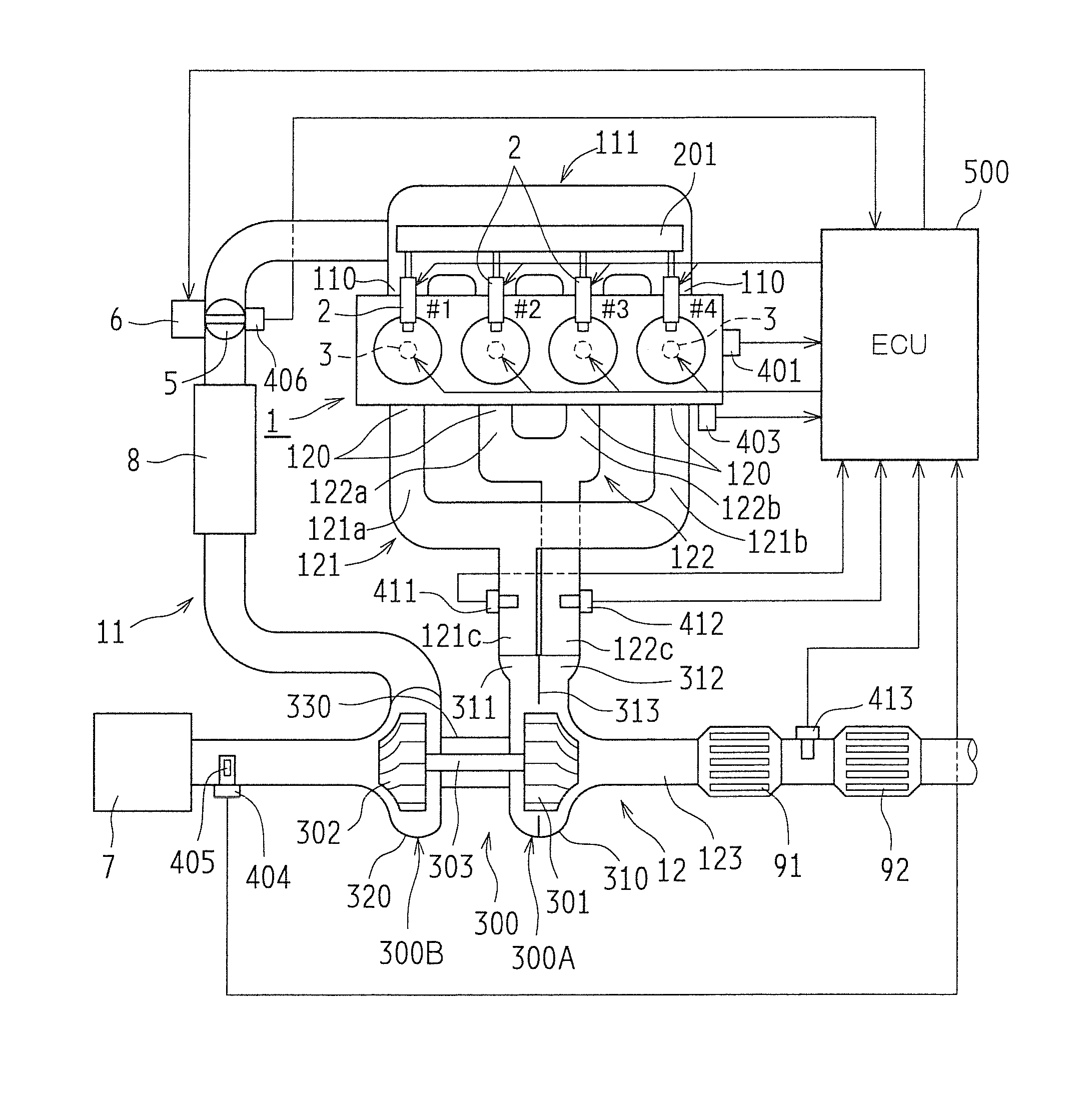

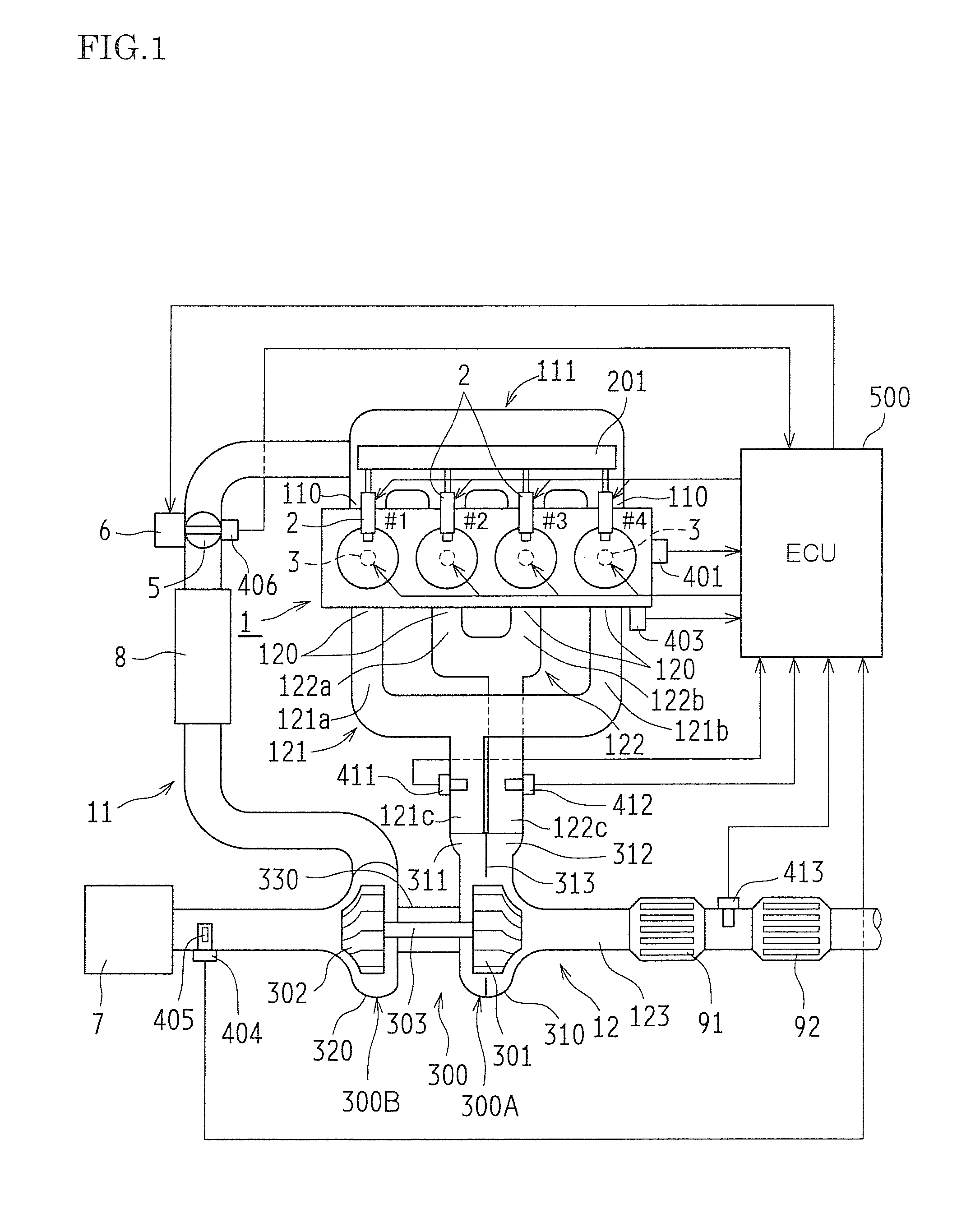

Supercharger-equipped internal combustion engine

ActiveUS20130283787A1Accurate detectionAccurate air-fuel ratioElectrical controlInternal combustion piston enginesTurbochargerAir–fuel ratio

In a multicylinder internal combustion engine including a turbocharger, the turbocharger employs a twin-entry turbo where a turbine includes two exhaust gas inflow ports. A first exhaust passage guides an exhaust gas discharged from a first cylinder group of the internal combustion engine to one exhaust gas inflow port of the turbocharger. A second exhaust passage guides an exhaust gas discharged from a second cylinder group of the internal combustion engine to the other exhaust gas inflow port of the turbocharger. An exhaust gas collecting portion of the first exhaust passage and an exhaust gas collecting portion of the second exhaust passage each include an air-fuel ratio sensor. This configuration allows efficiently contact of the exhaust gas on an element portion of the air-fuel ratio sensor, thus accurately detecting an air-fuel ratio of the exhaust gas at an upstream side of a catalyst for each cylinder.

Owner:TOYOTA JIDOSHA KK

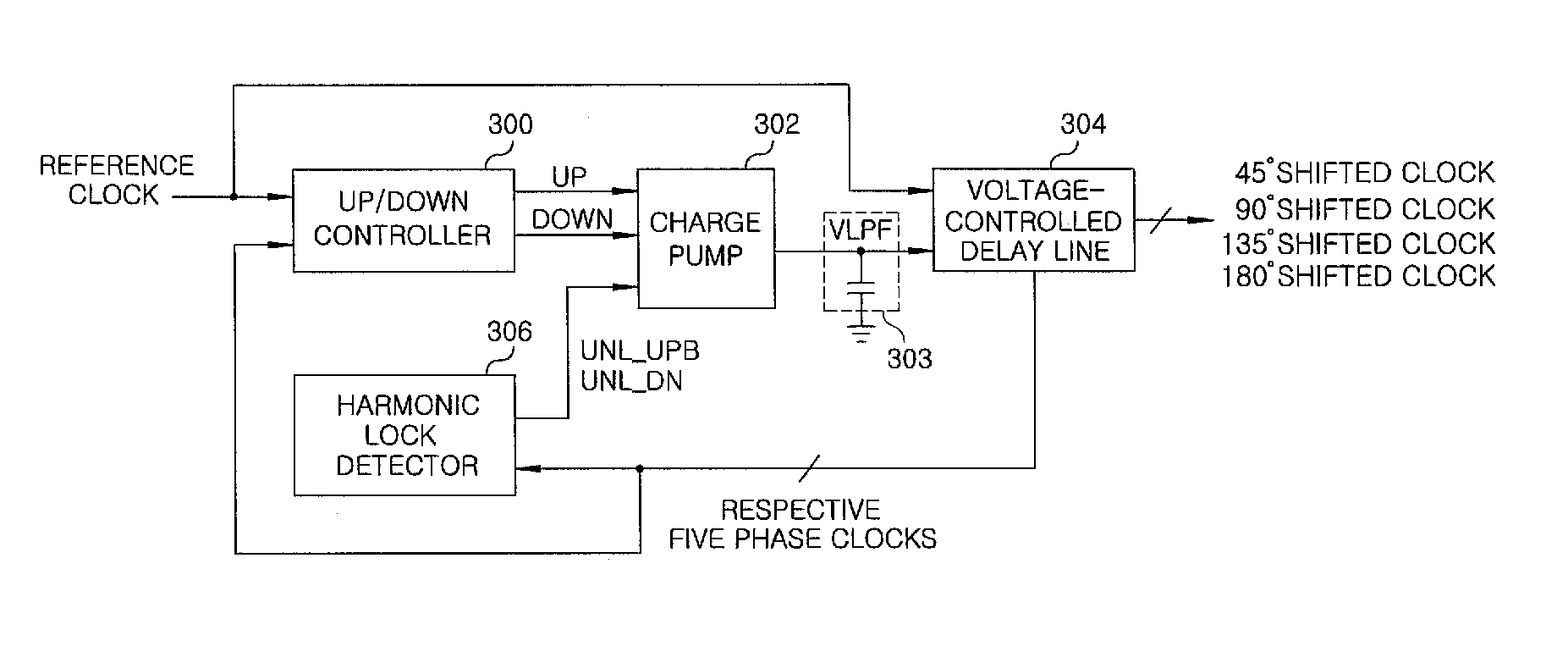

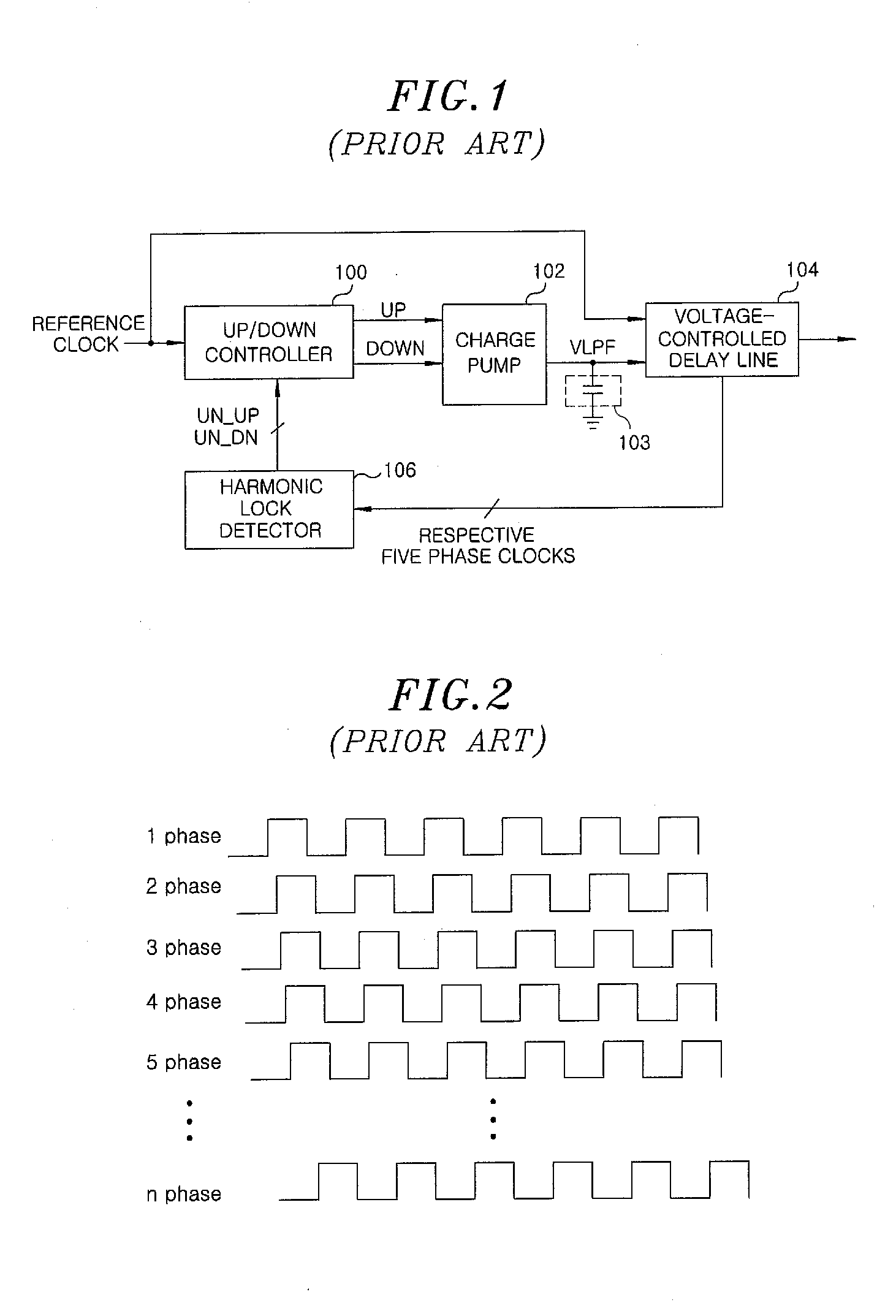

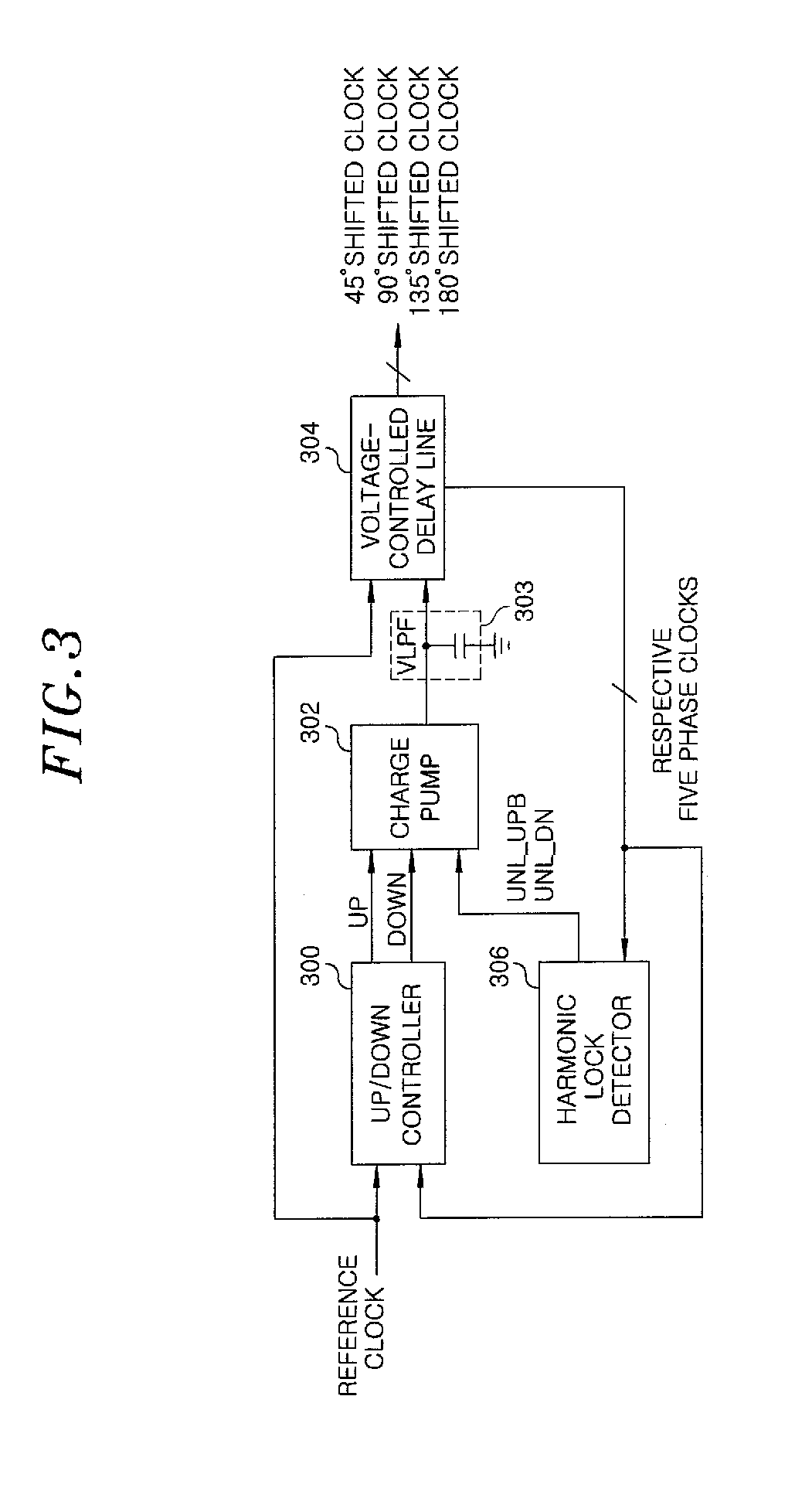

Delay-locked loop for timing control and delay method thereof

InactiveUS20090167387A1Stable operationAccurately duty ratioPulse automatic controlDelayed phaseDelay-locked loop

A delay-locked loop for timing control, includes a voltage-controlled delay line that delays a reference clock to generate a multi-phase clock comprising a plurality of delayed phase clocks; and an up / down controller that receives one of the delayed phase clocks as a feedback clock and generates a frequency up / down control signal based on whether a rising edge of the feedback clock coincides with a falling edge of the reference clock. The delay-locked loop further includes a charge pump that charges or discharges a loop filter connected to the voltage-controlled delay line according to a frequency up / down control signal from the up / down controller; and a harmonic lock detector that compares phases of multiple ones of the delayed phase clocks with a phase of the reference clock, and operates such that the multi-phase clock is locked within a first cycle of the reference clock.

Owner:DONGBU HITEK CO LTD

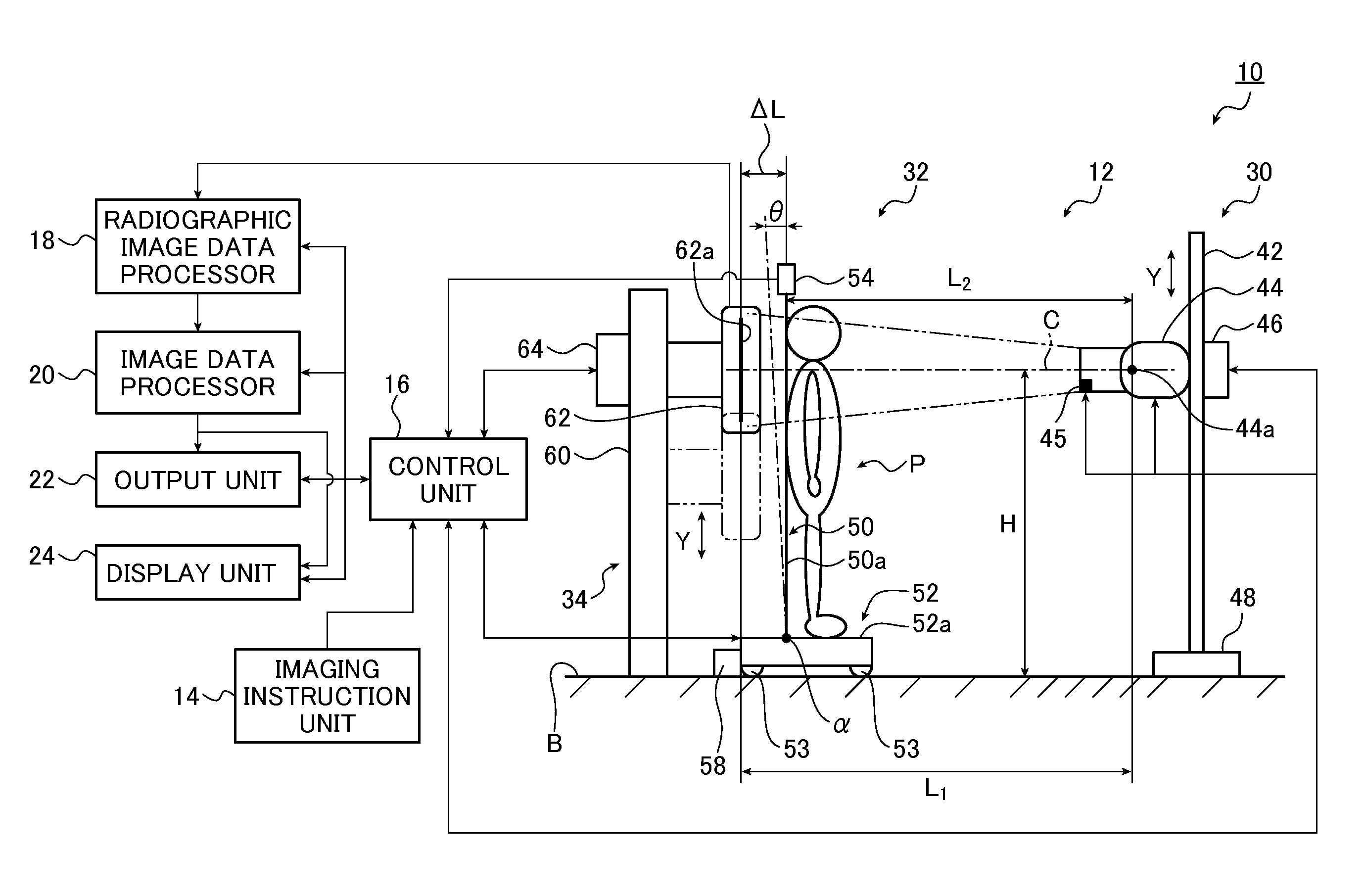

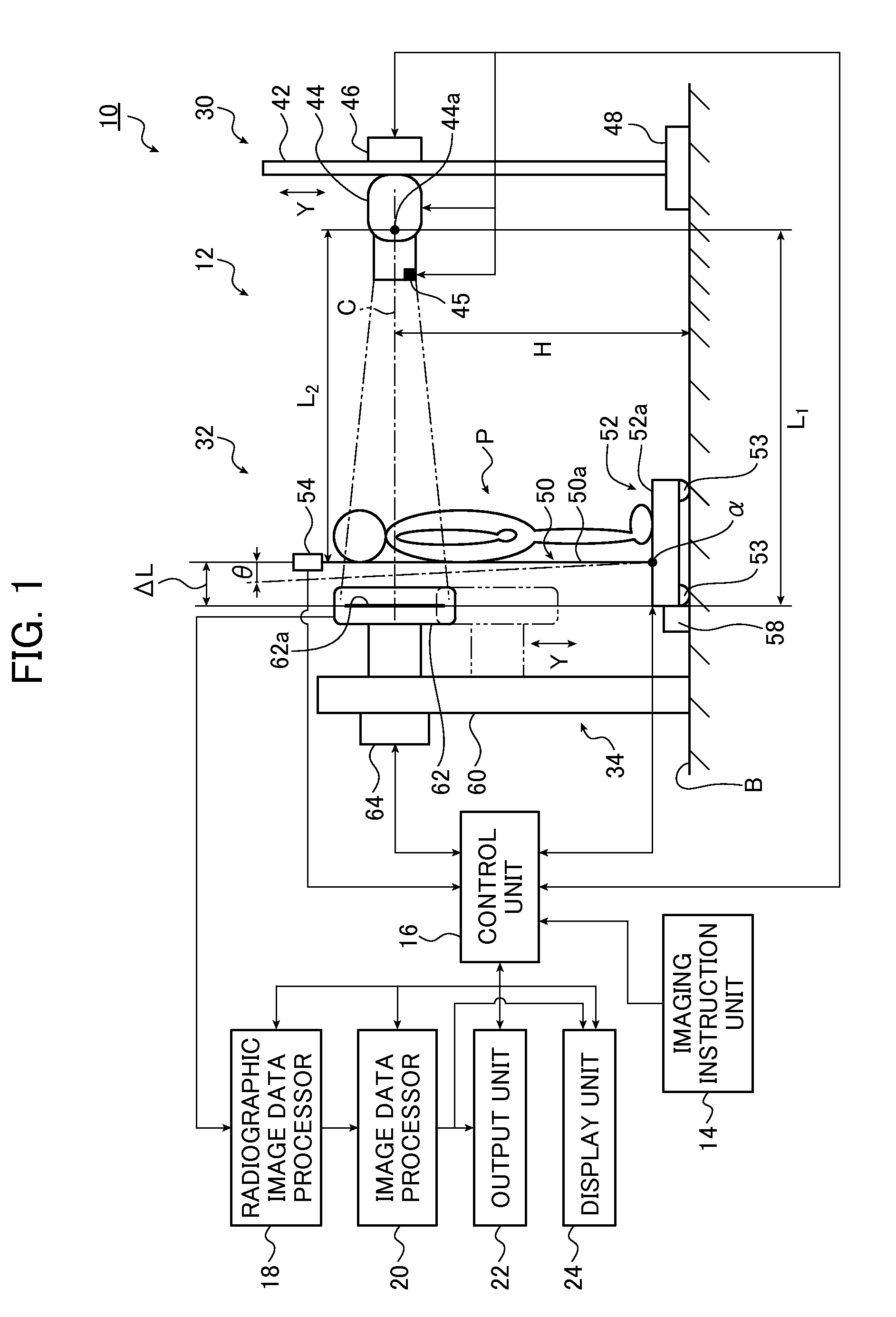

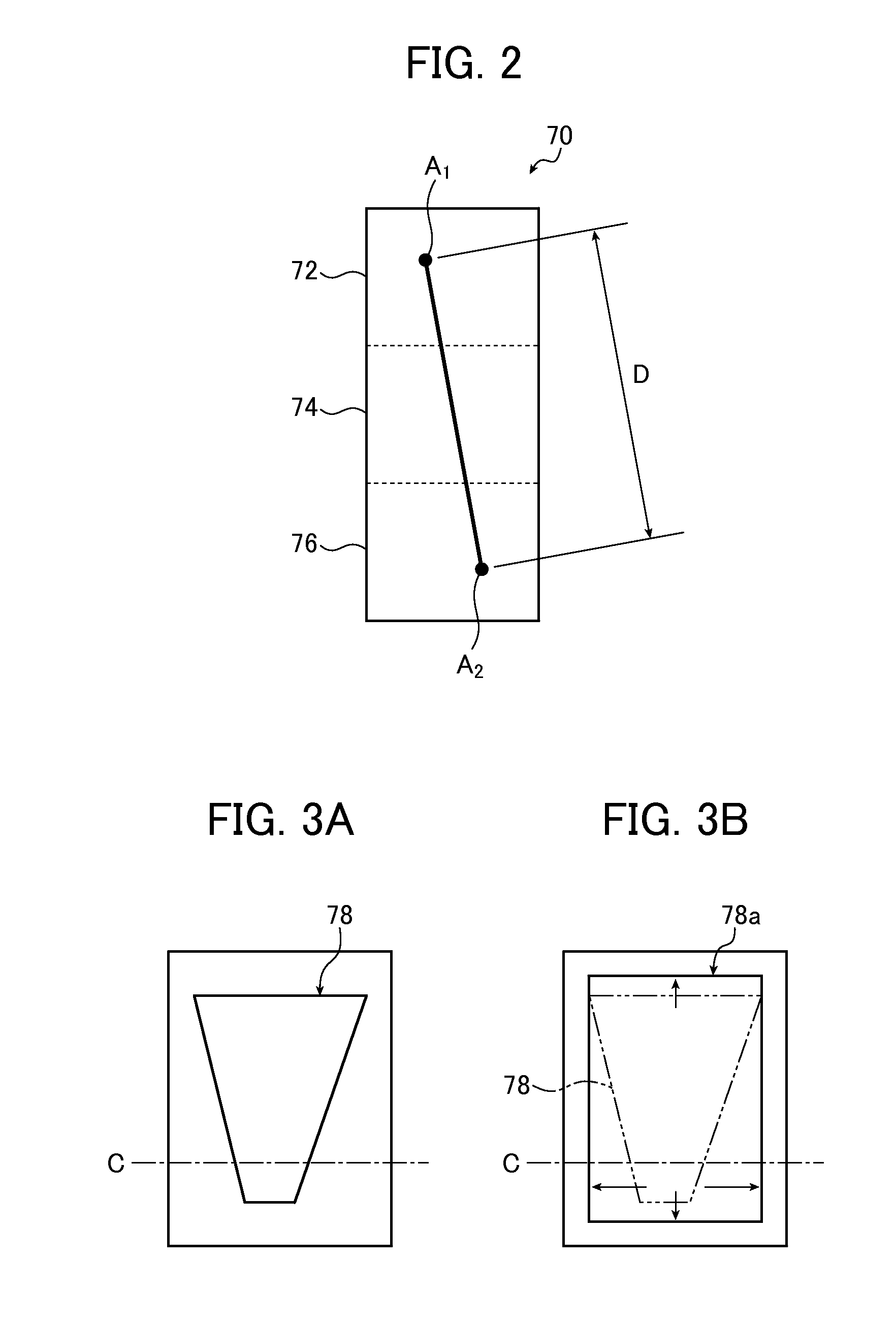

Radiographic imaging system and radiographic imaging method

InactiveUS8873709B2Precise ratioEasy to installPatient positioning for diagnosticsX-ray apparatusFluenceRadiography

A radiographic imaging system is capturing a radiographic image of a subject. The radiographic imaging system has a radiation detector that detects radiation from which the radiographic image is obtained, a radiation source that irradiates the radiation detector with the radiation, a partition that is disposed adjacent to the radiation detector and that locates the subject at a predetermined position relative to the radiation detector, a distance measuring unit that measures a distance between the partition and the radiation source, a tilt detecting unit that measures a tilt of the partition, and an image processor that corrects the captured radiographic image based on the distance between the partition and the radiation source obtained by the distance measuring unit and the tilt of the partition obtained by the tilt detection unit.

Owner:FUJIFILM CORP

System for treatment of fly ash from waste incineration

InactiveCN104874587AHigh degree of automationPrecise ratioSolid waste disposalVulcanizationAutomatic control

A system for treatment of fly ash from waste incineration comprises an electrical system and an automatic control system and further comprises a chelating agent preparation system, a fly ash stabilization system and a ton bagging machine system. The system has the benefits as follows: compared with the prior art, the system has the advantages that the degree of automation is high, fly ash captured in a flue dust remover (a bag-type dust remover) is fed into an fly ash storage tank which is designed according actual waste incineration quantity through a vulcanization bottom bin in an air cushion conveying manner, and treated into cured mixtures through a series automatic treatment during production, and the cured mixtures are transported out to be backfilled after bagging; according to the system, a measuring tank is adopted for controlling material usage, so that the ratio of used materials is accurate, the fly ash treatment efficiency is high, moreover, manpower is saved; equipment operation is convenient and safe; multiple controller are arranged to control middle processes, so that feedback in time and disposal in time are realized when one link in the system exceeds a preset specification.

Owner:SHISHI HONGFENG ENVIRONMENTAL PROTECTION BIOLOGICAL ENG

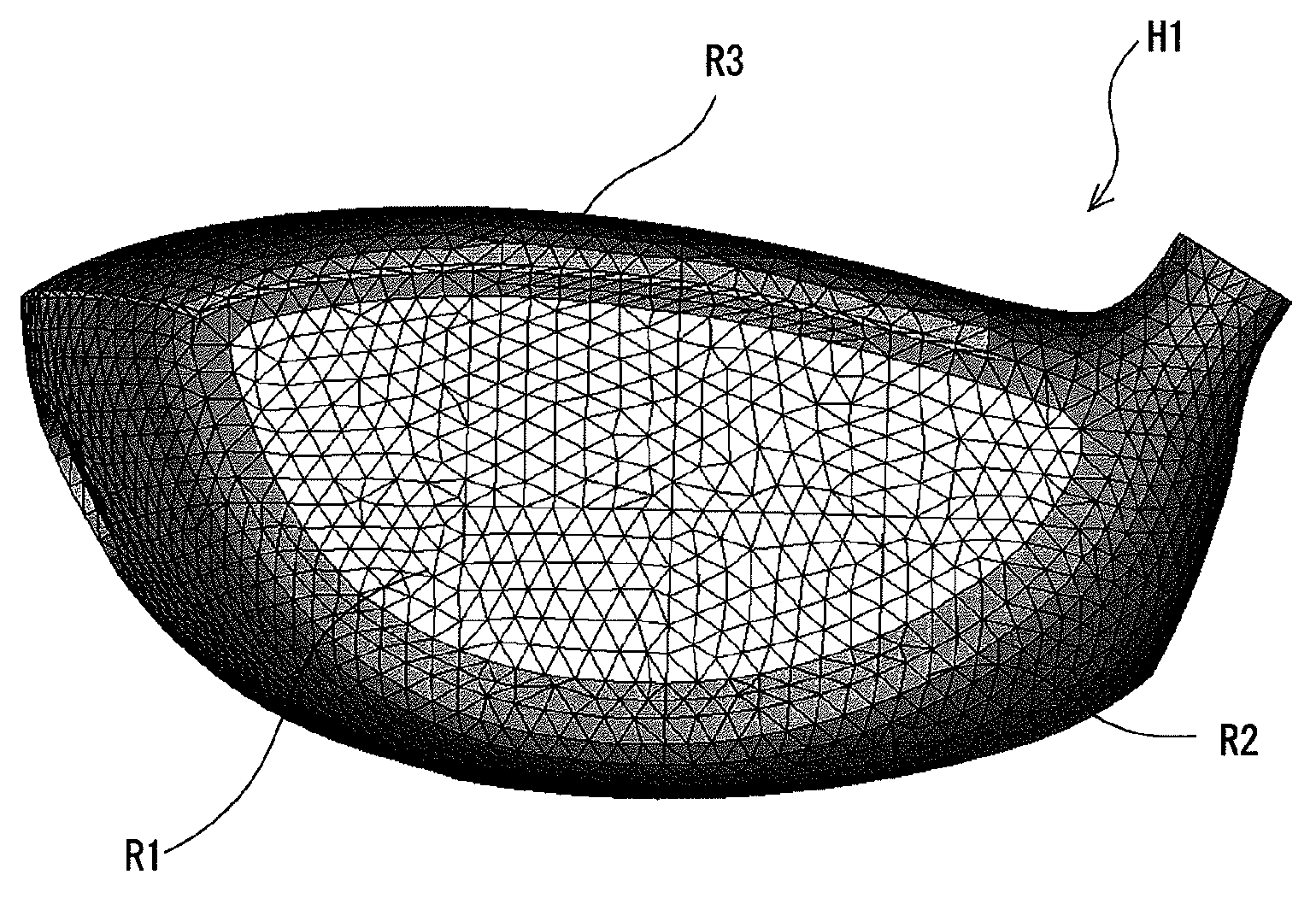

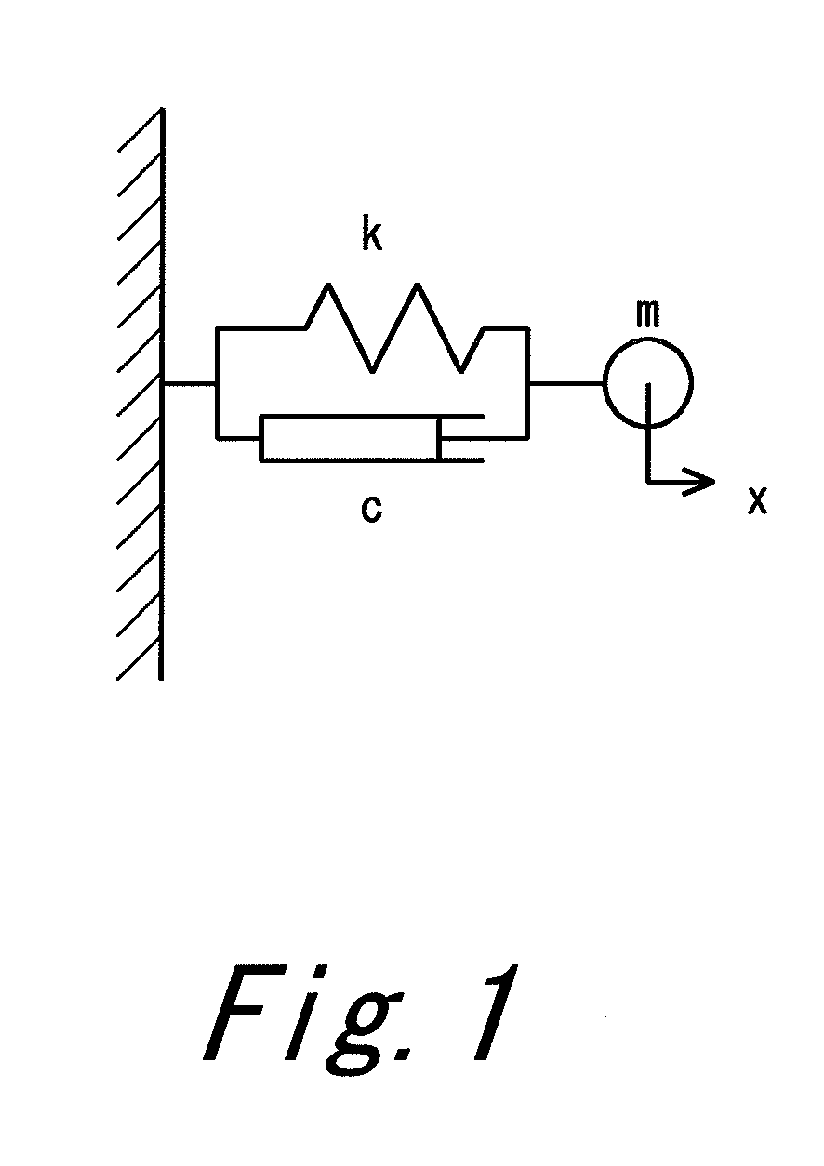

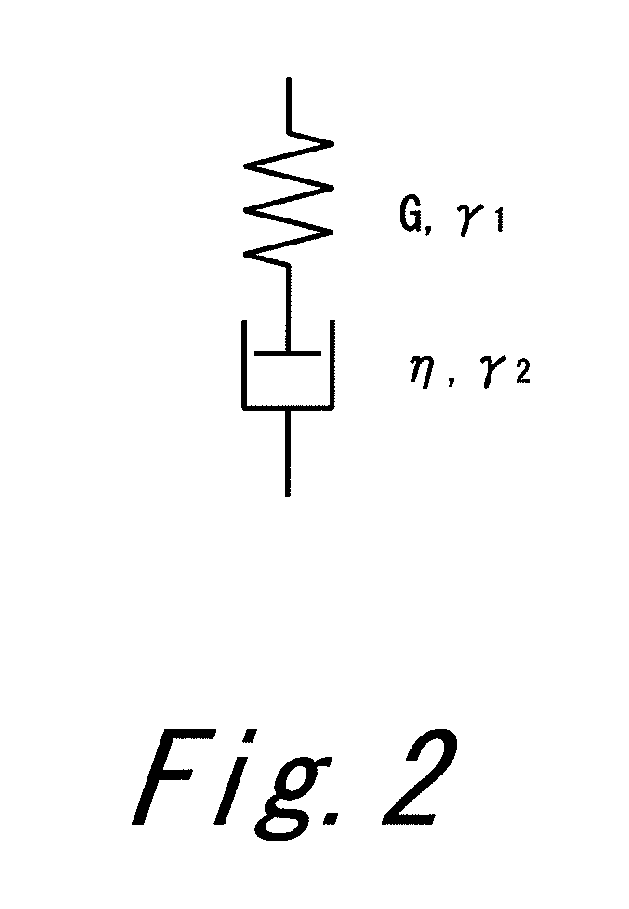

Method for predicting modal damping ratio of composite head

ActiveUS20120278048A1Precise ratioComputation using non-denominational number representationDesign optimisation/simulationMulti materialDamping ratio

A prediction method according to the present invention is a method for predicting a modal damping ratio of a composite head including two or more kinds of materials including a first material and a second material. The method includes the steps of: presuming at least a coefficient Px of a generalized Maxwell model M1 in the first material using a known material damping ratio ζ1; obtaining a calculation model of the head using the generalized Maxwell model M1; and calculating the modal damping ratio of the head based on analysis of the head using the calculation model. Preferably, the Maxwell model is further used also for the second material. Preferably, the method further includes the step of presuming a coefficient Py of a generalized Maxwell model M2 in the second material using a known material damping ratio ζ2.

Owner:SUMITOMO RUBBER IND LTD

Protection and detection for data image and data card

InactiveCN101154274AAvoid repetitionUniqueness guaranteedRecord carriers used with machinesComputer hardwareComputer science

A protective method for data image or data card comprises the following steps: a test mark for protecting the data image or data card is defined, and the mark comprises at least one chemical element selected from inherent chemical elements of the data image or data card and / or extra chemical elements; a database comprising the data of the mark is provided; the signal transmitted by the data image or data card is tested to generate test data which is compared with the data in the database; according to comparison results, scanning of the data image or data card goes on if the data image or data card to be tested is judged true according to the database, while the scanning of the data image or data card stops if the data image or data card to be tested is judged false according to the database. The invention also provides related equipment and systems.

Owner:TRUE PROD ID TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com