System for treatment of fly ash from waste incineration

A waste incineration fly ash and treatment system technology, applied in the direction of solid waste removal, etc., can solve the problems of low efficiency, low degree of automation, and inaccurate dose control of fly ash, and achieve convenient and safe equipment operation, high degree of automation, The effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

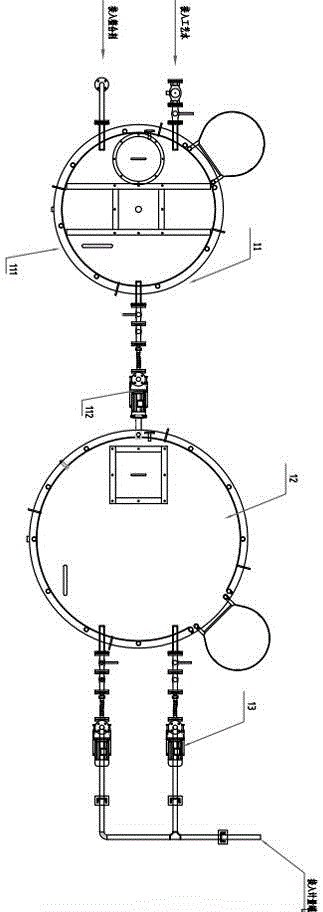

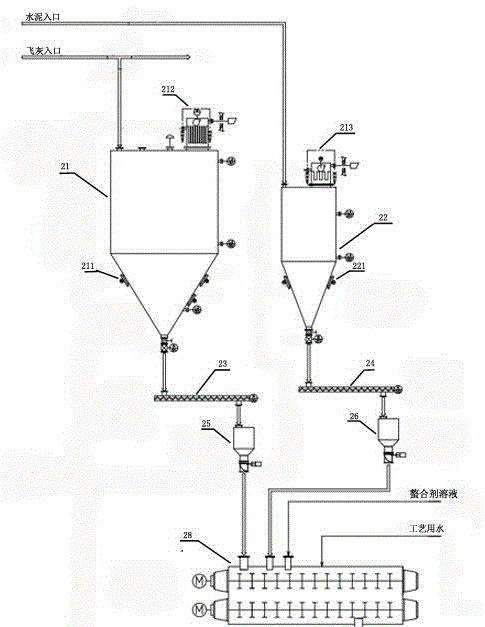

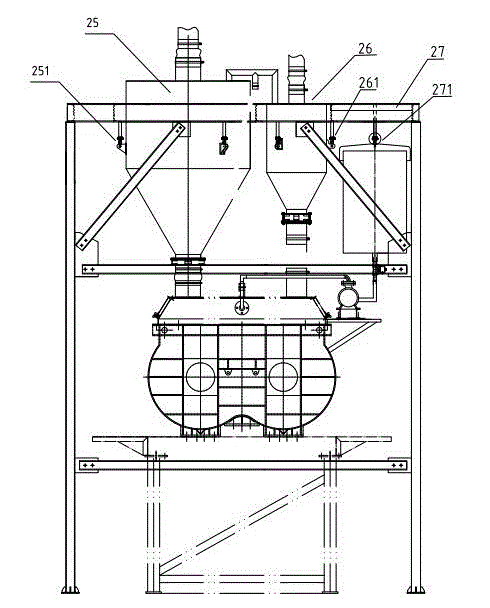

[0030] Such as figure 1 Shown is a chelating agent preparation system, comprising a chelating agent preparation device 11, a chelating agent storage tank 12, a chelating agent delivery pump 13, and the chelating agent preparation device 11 is used to dilute the chelating agent into a certain concentration solution; the chelating agent storage tank 12 stores the chelating agent The solution prepared by the mixture preparation tank; the chelating agent delivery pump 13 completes the delivery of the chelating agent solution;

[0031] The chelating agent preparation device comprises a chelating agent stirring tank 111 and a chelating agent solution pump 112, and the substances added in the chelating agent stirring tank 111 are chelating agent and process water. The source of process water comes from the tap water pipe network of the factory.

[0032] The filling chelating agent is added to the chelating agent dosing pump, sent to the chelating agent stirring tank to be stirred wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com