On-site automatic preparation system for mixed injection slurry

An automatic grout preparation technology, applied in construction, infrastructure engineering, etc., can solve problems such as inaccurate and stable supply, increase construction costs, and reduce grouting efficiency, so as to improve economic and social benefits, avoid waste, and save materials. Measuring Accurate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

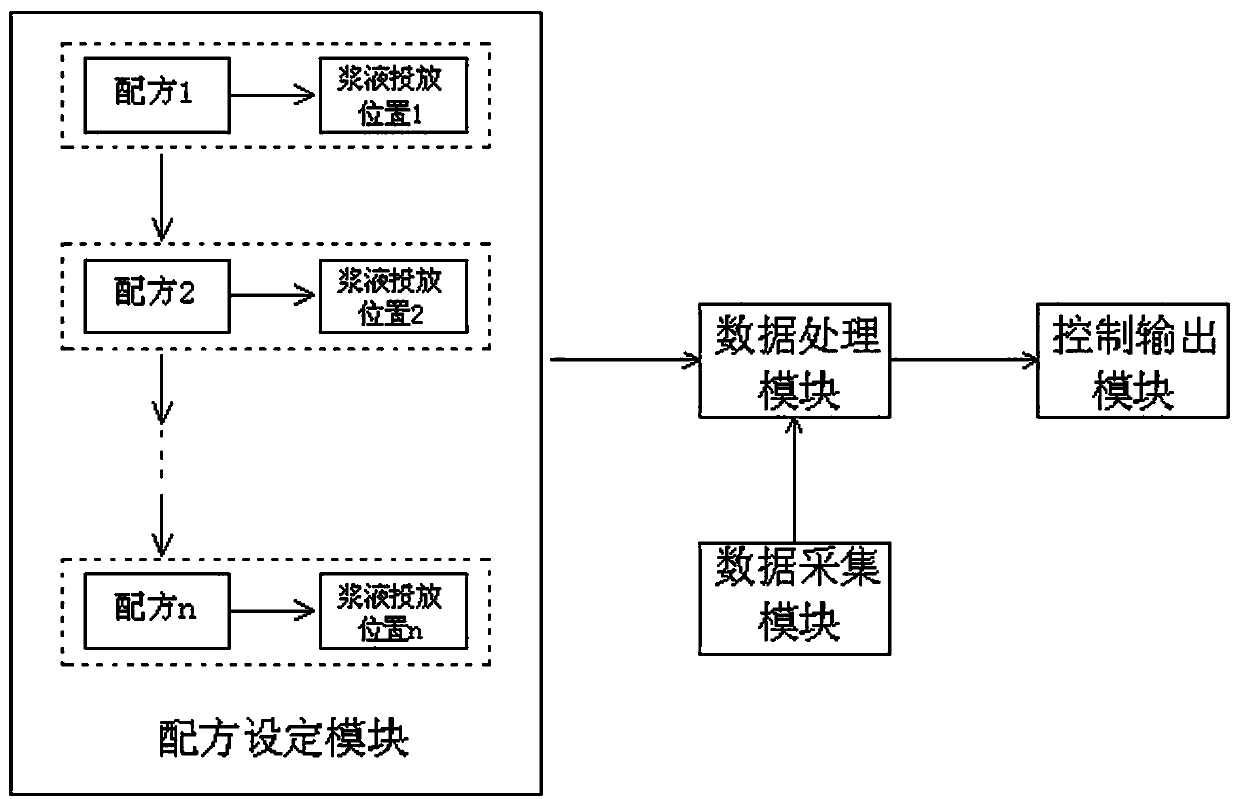

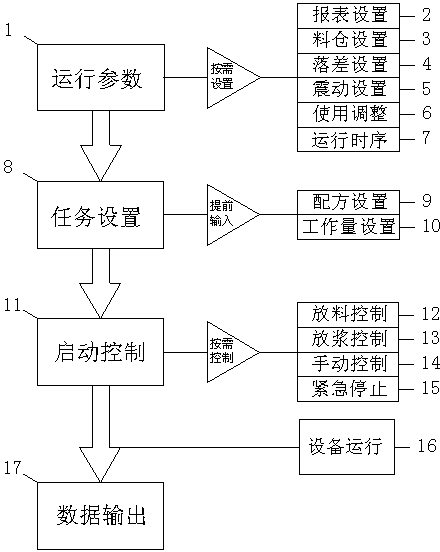

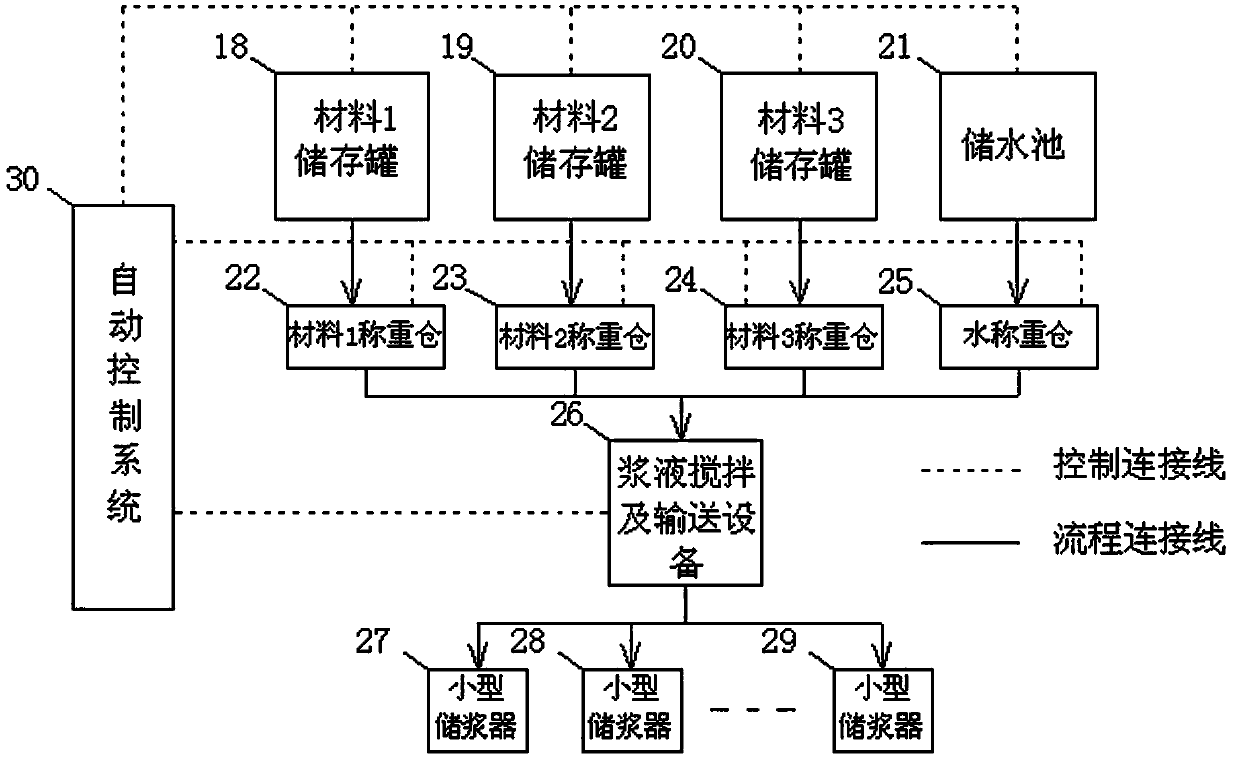

[0021] see figure 1 , figure 2 , image 3 , the computer software of the on-site automatic preparation system for the patented mixed grouting fluid of the present invention is composed of a formula setting module, a data acquisition module, a data processing module and a control output module. Silo setting, 4-drop setting, 5-vibration setting, 6-use setting, 7-running sequence, 8-task setting, 9-recipe setting, 10-workload setting, 11-start control, 12-discharging control , 13-pulp discharge control, 14-manual control, 15-emergency stop, 16-equipment operation, 17-data output.

[0022] Taking the cement-tailings sand-clay mixed slurry as an example to illustrate the working process of the present invention is as follows: the working requirement is to perform grouting for two holes at the same time, and two kinds of mixed slurry with different proportions are required. Set through the formula setting module, that is, 8-task setting: including 9-recipe setting and 10-workloa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com