Patents

Literature

189results about How to "Improve pulping efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

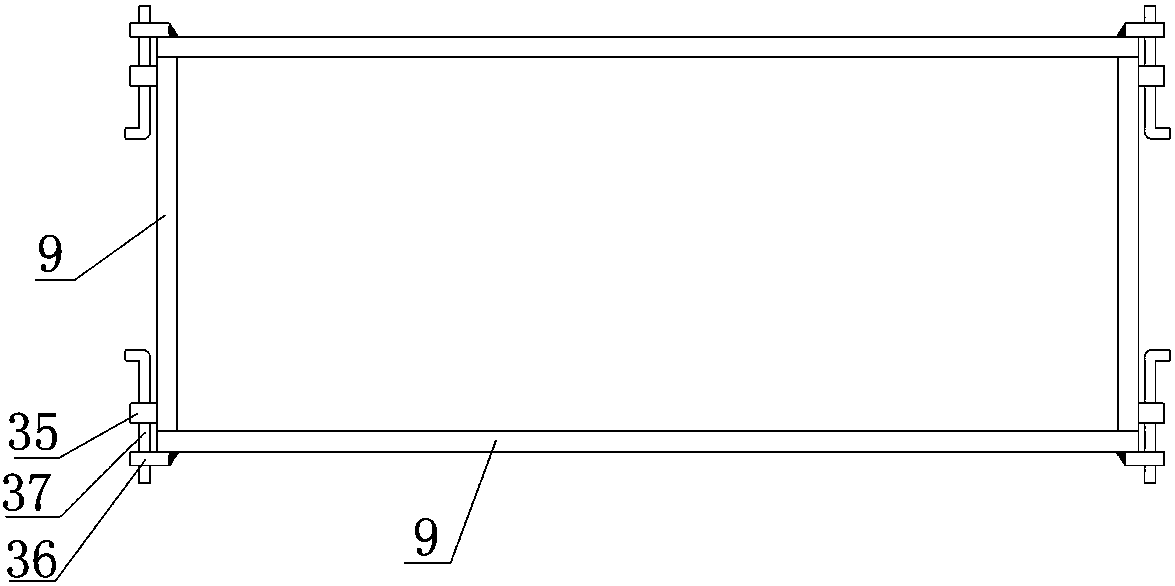

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

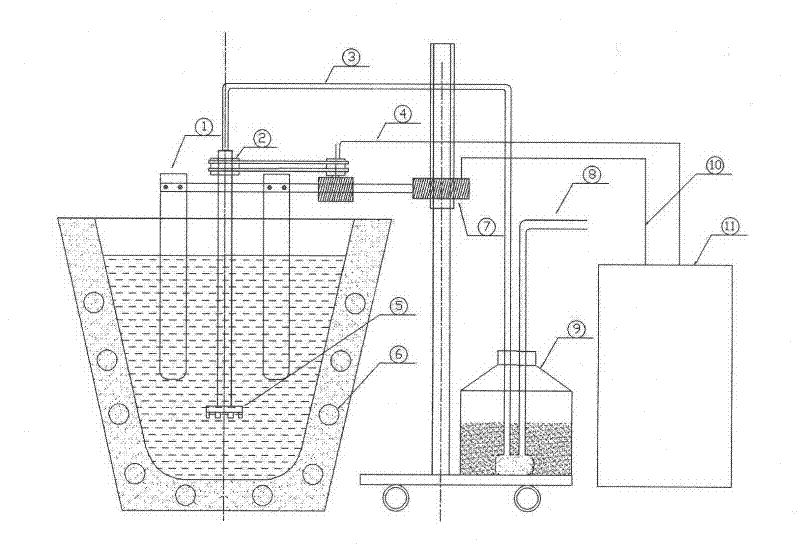

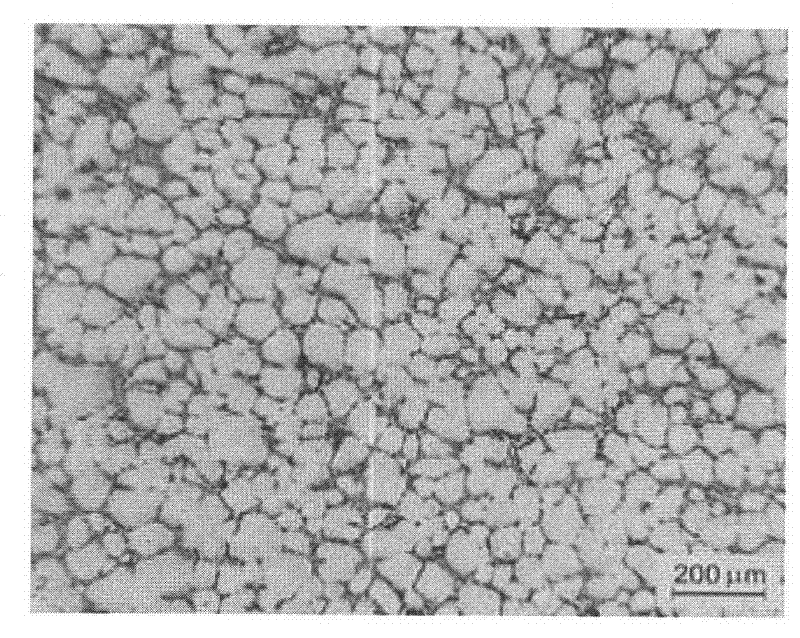

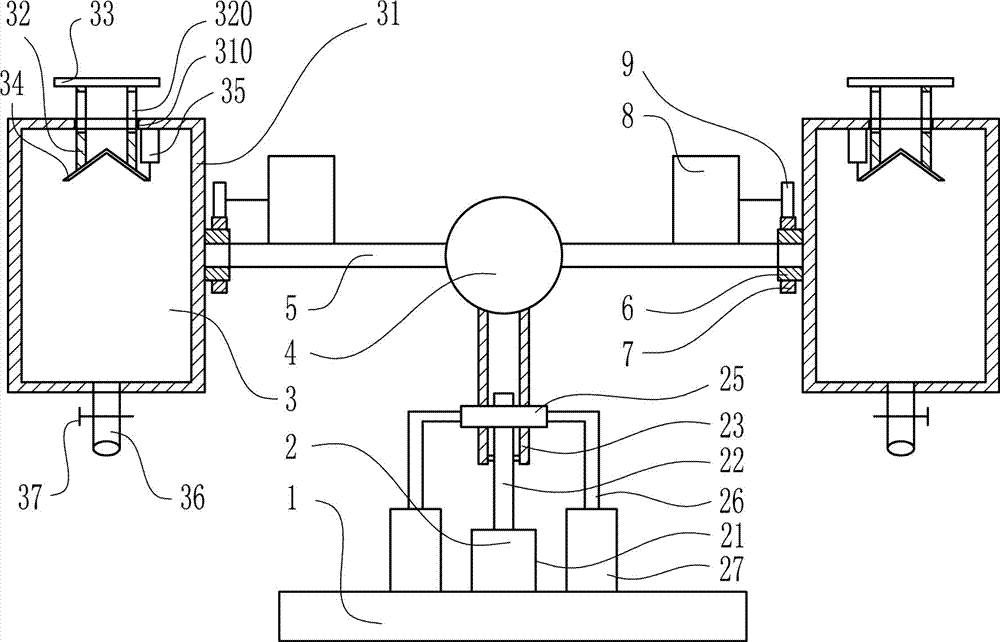

Method and apparatus for preparing semisolid slurry for automobile aluminium wheel through compound modification refinement and electromagnetic stirring

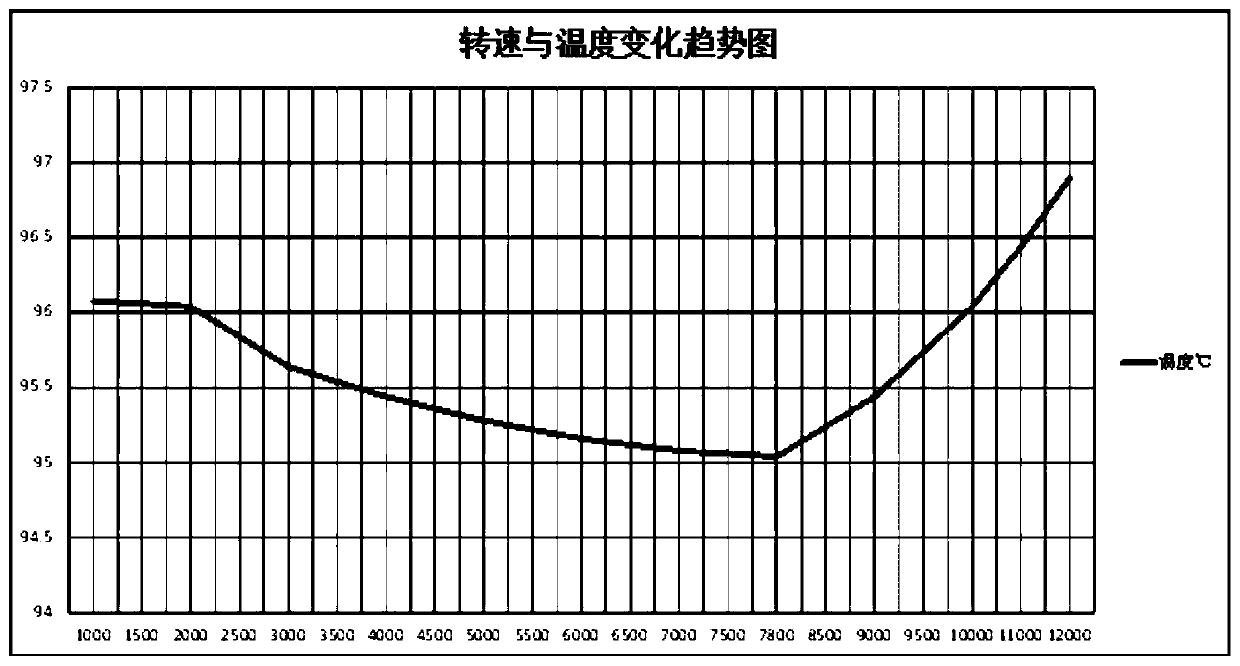

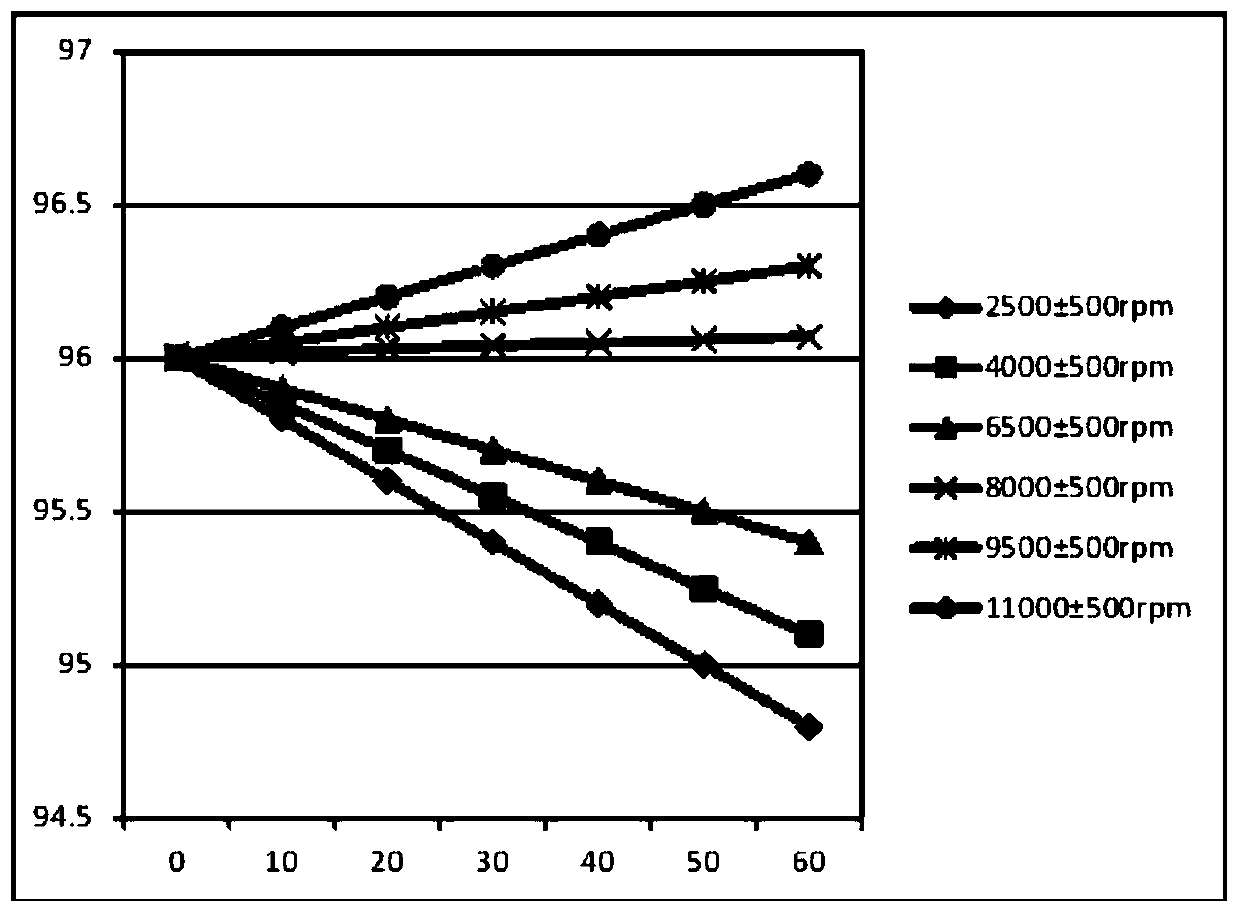

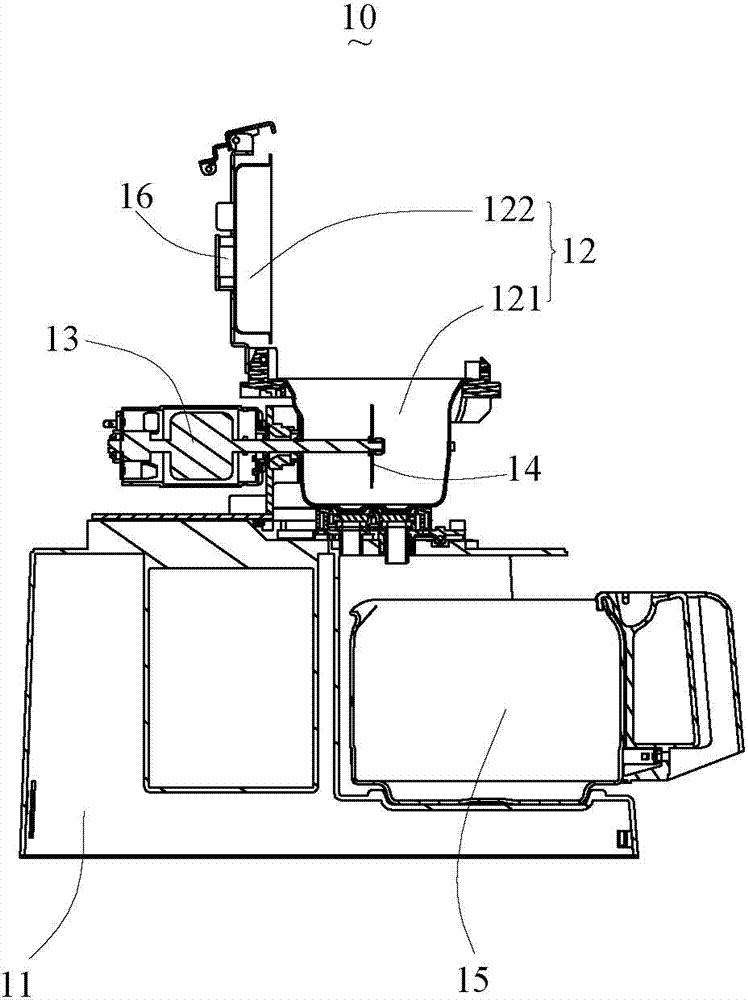

A method and an apparatus for preparing a semisolid slurry for an automobile aluminium wheel through compound modification refinement and electromagnetic stirring. The method comprises steps of: transferring alloy with degree of superheat of 100-120 DEG C into a transit bag, adding a refinement modification agent with high purity nitrogen by an injecting device, wherein the refiner is Al-Zr-B-O intermediate alloy with a granularity of 150-200 um, and the alterant is Al-Sr-RE complex alloy with a granularity of 200-2505 um; standing for 5-8 min, pouring into an electromagnetic stirring crucible when a temperature is 40-50 DEG above a liquidus, putting the crucible in an electromagnetic stirrer, and carrying out composite stirring through a crucible peripheral stirrer and central stirrer, wherein the peripheral stirrer has a frequency of 10-20 Hz, a power of 12 kw, a rate of 300-500 rmp and a time of 2-3 min, and the central stirrer has a frequency of 5-15 Hz, a power of 1-2 kw, a rate of 300-800 rmp and a time of 2-3 min; stopping stirring, when a melt temperature drops to 10-15 DEG C below the liquidus, to obtain a near sphaerocrystal structure semisolid aluminium alloy slurry. The method solves problems of nonuniform slurry and low pulping efficiency.

Owner:JIANGSU KAITE AUTO PARTS

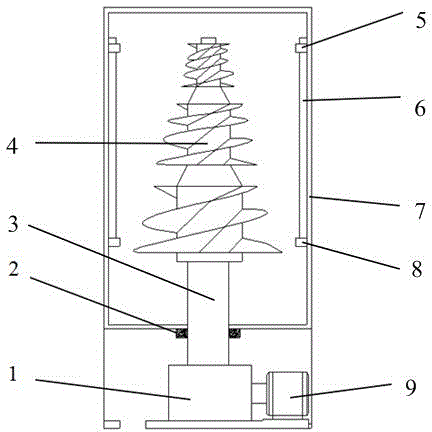

Pulper low in power consumption and noise

The invention provides a pulper low in power consumption and noise. The pulper mainly comprises a cylinder wall, a motor, a reducer, a seal device, a spindle, a spiral blade rotor, upper vortex board grooves, lower vortex board grooves and vortex boards. The pulper is characterized in the motor provides power, and the power is transmitted to the spiral blade rotor sequentially through the reducer and the spindle. By the inner and outer crescent arc transitions of the upper and lower vortex board grooves and the crescent cylindrical four-side arc structures at the inner edges of the vortex boards, flows can stably generate four vortexes at the four-side arcs of the vortex boards, vortex kinetic energy pulping is achieved, and low power consumption is achieved. Due to the fact that the hollow holes in two sides of the upper and lower vortex board groove retaining plates and in the middle portions of the vortex boards can be filled with damping and sound absorbing materials, fluid exciting force and solid noises can be absorbed, and low noise is achieved.

Owner:UNIV OF JINAN

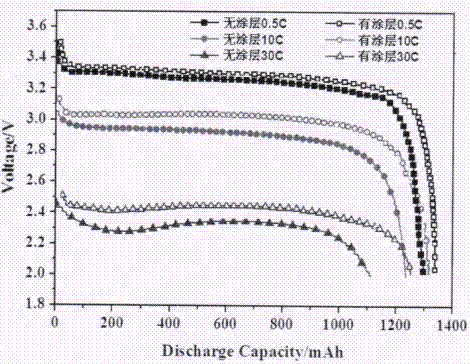

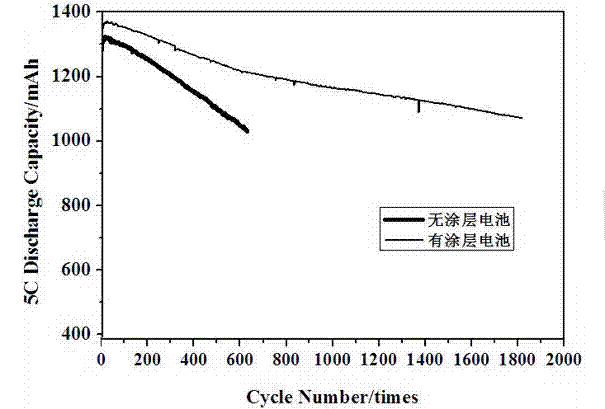

Lithium ion battery anode functional coating and preparation method thereof

ActiveCN102757700AReduce the presence of air bubblesEasy to processCell electrodesElectrically-conductive paintsLow speedSlurry

The invention provides a lithium ion battery anode functional coating and a preparation method thereof. A dispersing agent NMP (N-methyl-pyrrolidone) is stirred by a planetary stirrer at a high speed till the temperature reaches 40 to 50 DEG C; a certain proportion of a binding agent PVDF (Polyvinylidene Fluoride) is added to enable the solid content of a binding agent solution to be 1.2 to 3.5 percent; low-speed revolution is performed and then high-speed rotation is started; cold circulating water is received to control the temperature of the slurry below 50 DEG C; stirring is preformed for 2 to 6 h; a carbon black conductive agent (conductive carbon) is added to enable the solid contend of the slurry to be 20 to 30 percent; stirring is performed for 2 to 4 h; the slurry is transferred into a high-efficiency dynaflow ultrasonic slurry mixer to be subjected to ultrasonic dispersion for 1 to 2 h; after the preparation is finished, the slurry passes through a 200-mesh screen stencil and is sprayed through a spraying machine, wherein the spraying thickness is controlled within 3 to 5 Mum; and after the spraying is finished, a coated pole piece is baked for 12 to 14 h at 110 plus or minus 3 DEG C, wherein dry nitrogen is filled for replacement once each two hours, so as to obtain the lithium ion battery anode functional coating. The replacement of a current collector with an anode aluminium foil material by a current collector with the functional coating can greatly improve the electrochemical properties of lithium ion batteries.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

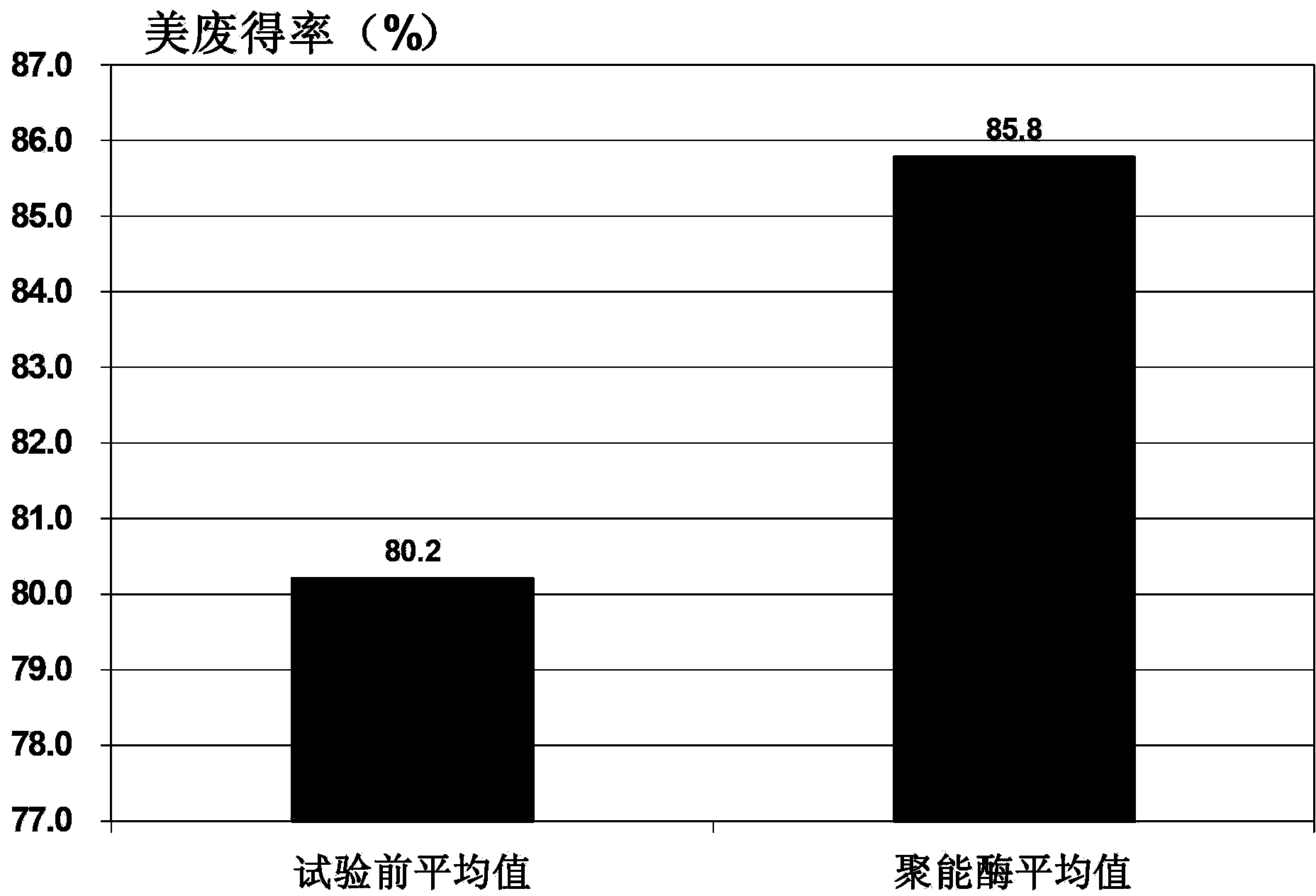

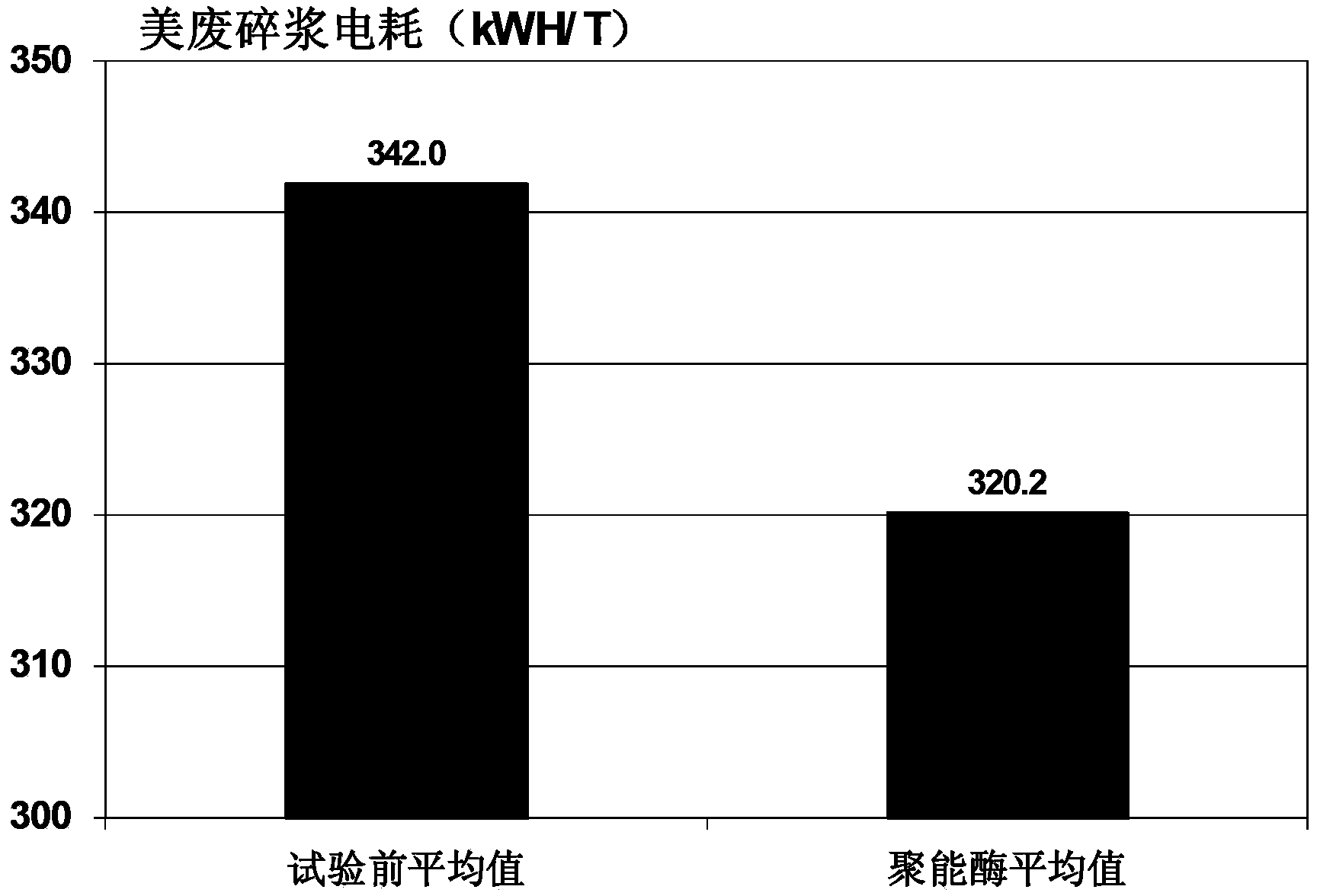

Wet-strength waste paper pulping method

ActiveCN103835174AAccelerate run upImprove permeabilityPaper recyclingWaste paper working-upFiberPapermaking

The invention discloses a wet-strength waste paper pulping method. The pulping method comprises the following steps: putting wet-strength waste paper in water and evenly mixing to obtain waste paper pulp; adjusting the pH value of the waste paper pulp to 3-10 and adding a biological enzyme for enzymolysis to obtain enzymatically degraded pulp, wherein the addition amount of the biological enzyme is 0.05-20kg per ton of wet-strength waste paper, the temperature of enzymolysis is 20-80 DEG C and the time of enzymolysis is 2-600 minutes; and pulping the enzymatically degraded pulp in a pulper to obtain paper pulp. According to the method, a wet-strength agent is selectively degraded by the biological enzyme, so that the combination between the wet-strength agent and fibers is destroyed, the moistening of the fibers is accelerated, and the pulping efficiency and the yield of fibers are enhanced; the pulping method is environmental friendly and safe since only biological enzyme needs to be added; all waste water during production can be recycled, and is not discharged to external, so that no environment pollution is caused; with the paper pulp produced by the method, the paper quality and the papermaking efficiency can be remarkably enhanced.

Owner:RISINGSTAR BIOTECH GUANGZHOU

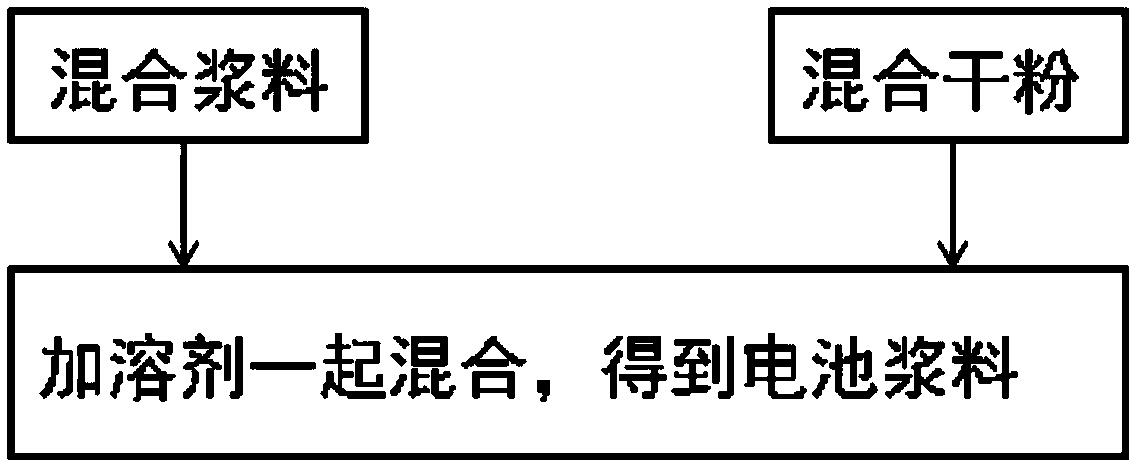

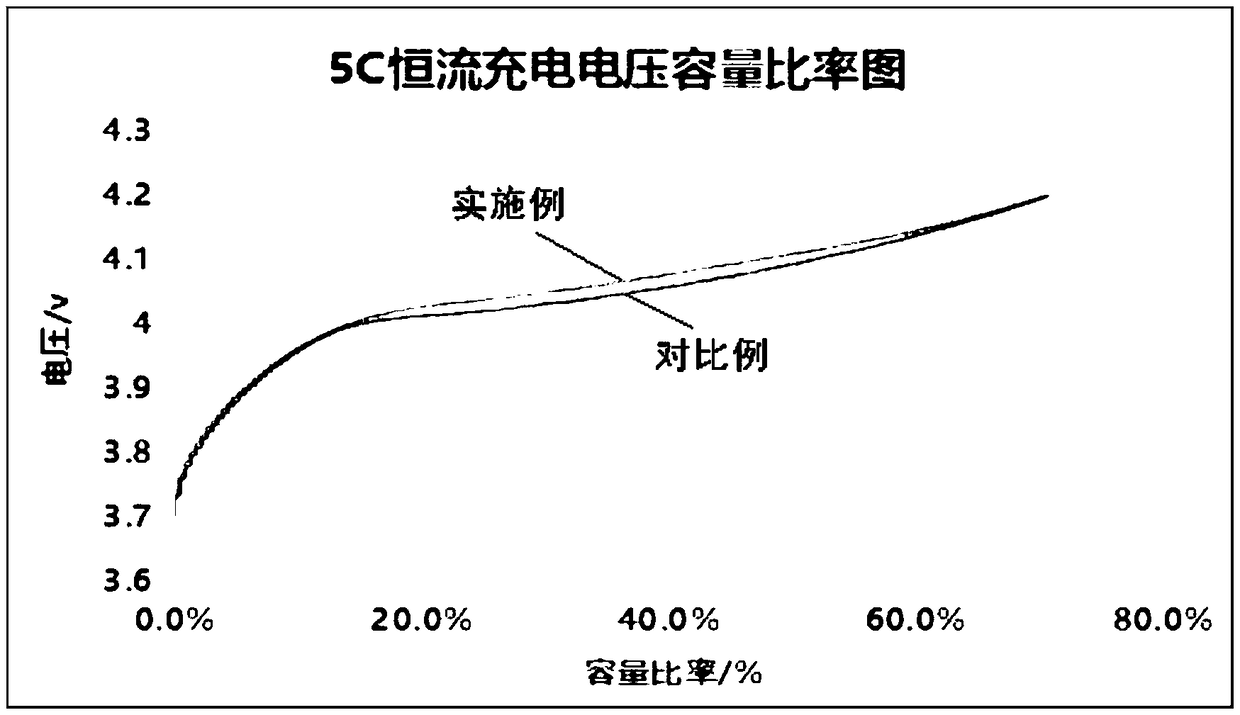

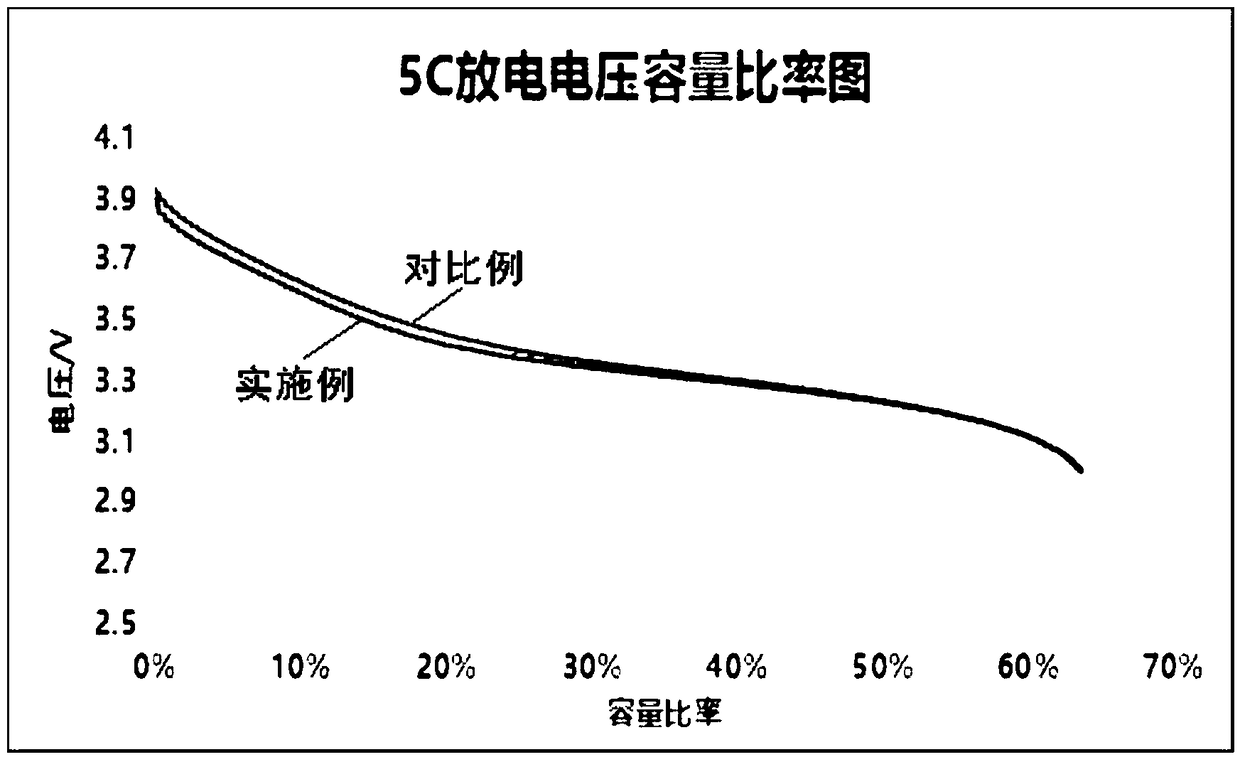

Preparation method of high-rate lithium ion battery slurry

InactiveCN109326779AStrong suction functionImproved magnification performanceTransportation and packagingMixing methodsHigh rateSlurry

The invention provides a preparation method of high-rate lithium ion battery slurry. The method comprises the following steps of (a) slurry mixing: uniformly stirring bonding agents and conductive slurry to prepare a slurry mixture; (b) dry powder mixing: uniformly stirring active substances and conductive dry powder to obtain a dry powder mixture; (c) solvent adding and stirring: mixing the slurry mixture and the dry powder mixture; adding solvents; performing uniform stirring to obtain the high-rate lithium ion battery slurry. The bonding agent with the dispersing function and difficult-to-disperse conductive slurry are stirred, mixed and dispersed in advance to obtain a first mixture; particular solid active substances and conductive dry powder which can be easily mixed are mixed together to obtain a second mixture; then, the first mixture and the second mixture are combined and subjected to stirring and mixing together with solvents. By using the method, the prepared lithium ion battery positive electrode slurry can be favorably, sufficiently and uniformly dispersed; the mixing and stirring efficiency is improved, so that the stirring is uniform; the time required by the stirring is reduced; in addition, the high-rate performance of the lithium ion battery positive electrode can be effectively improved.

Owner:桑顿新能源科技(长沙)有限公司

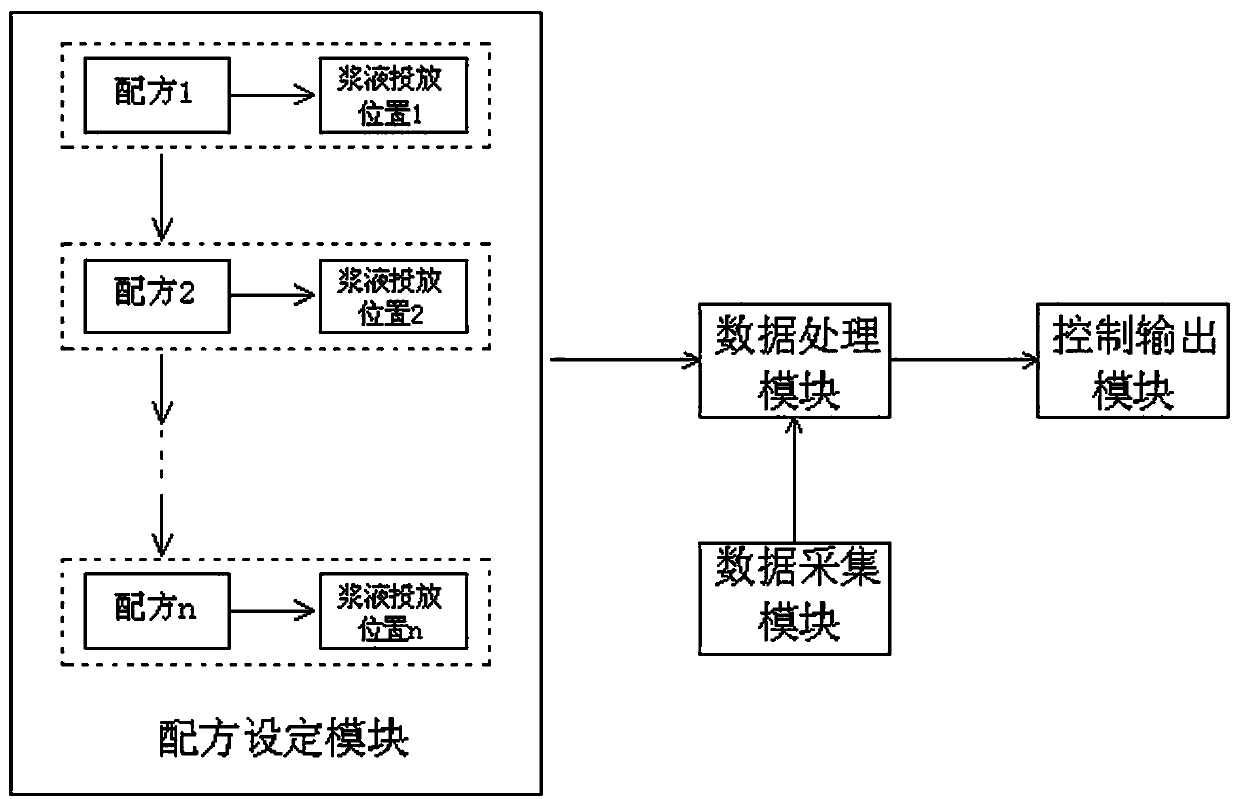

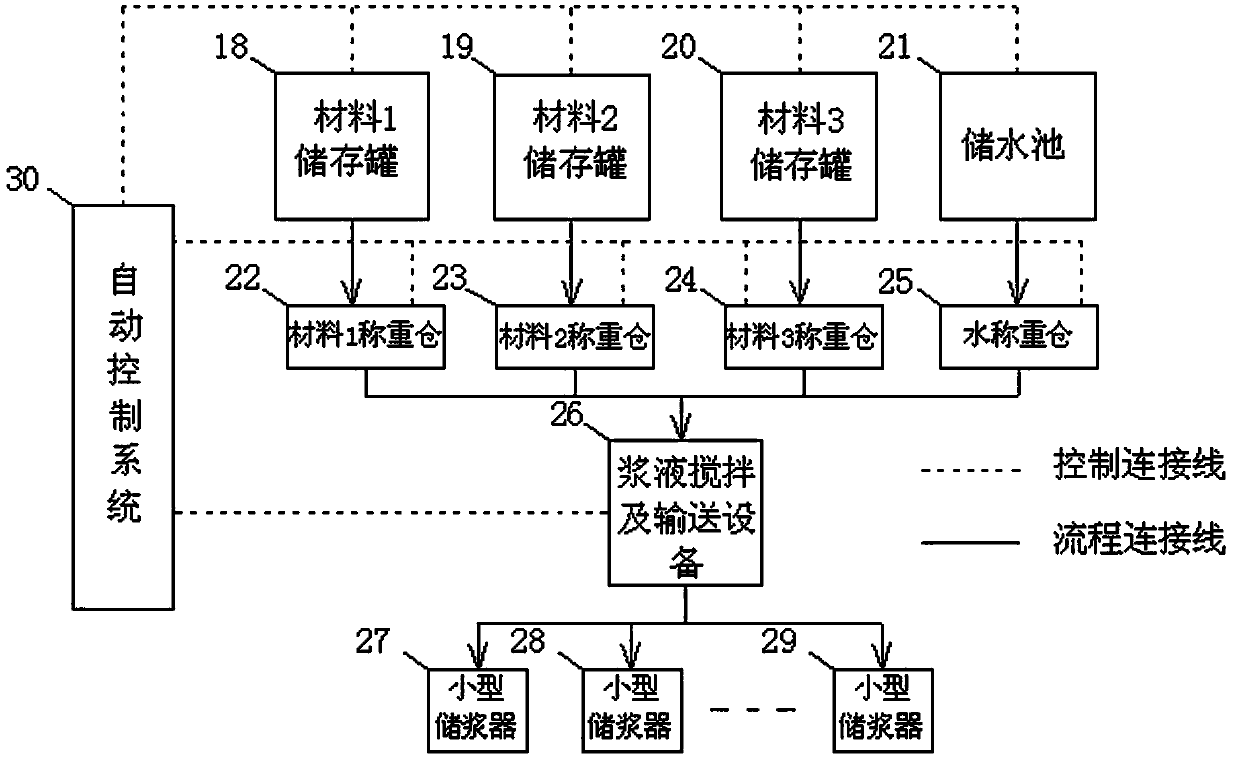

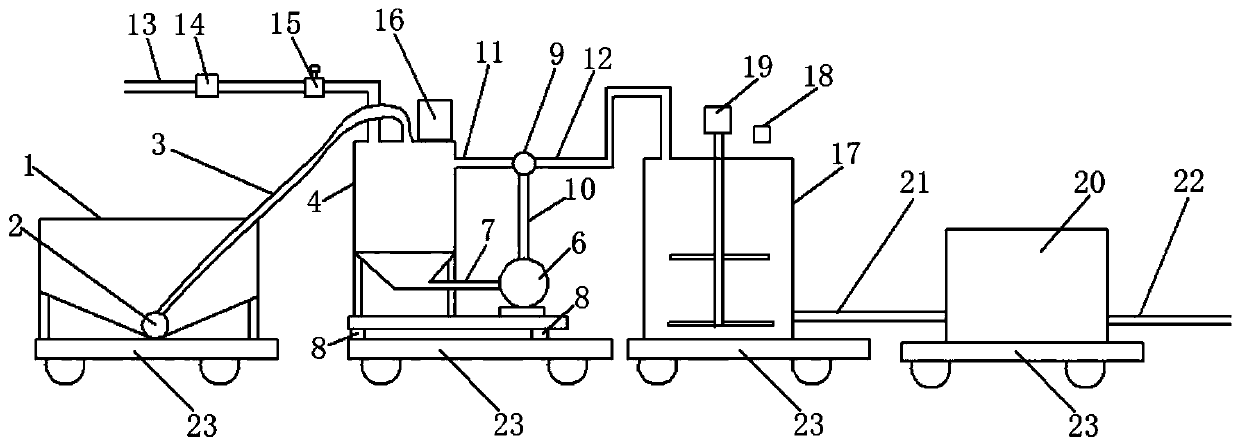

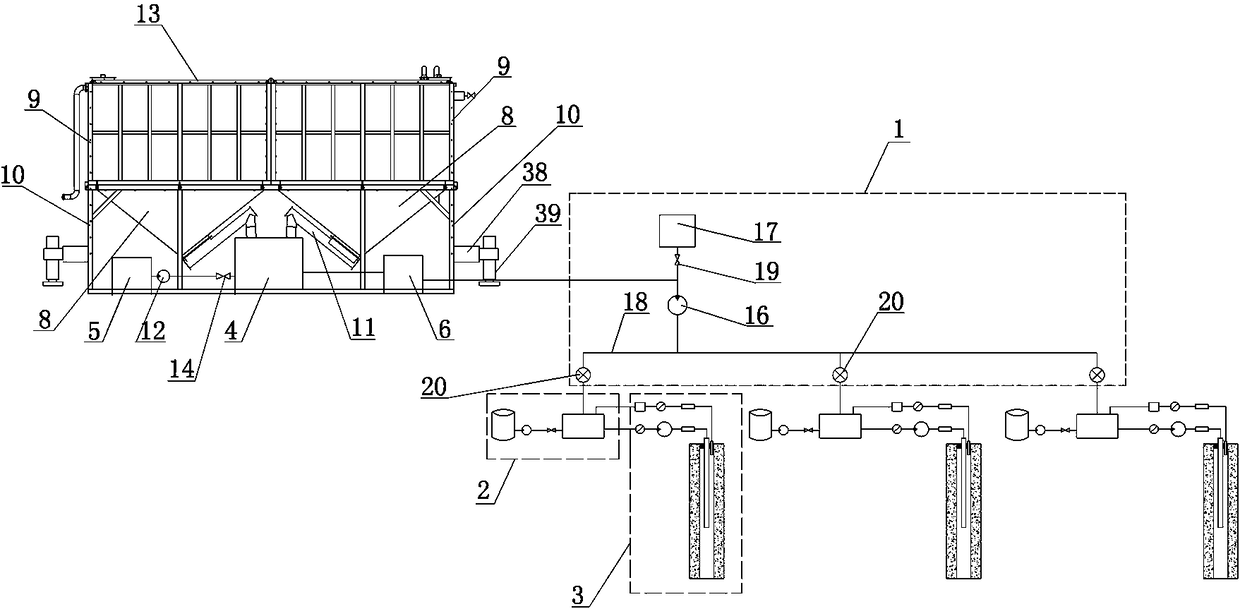

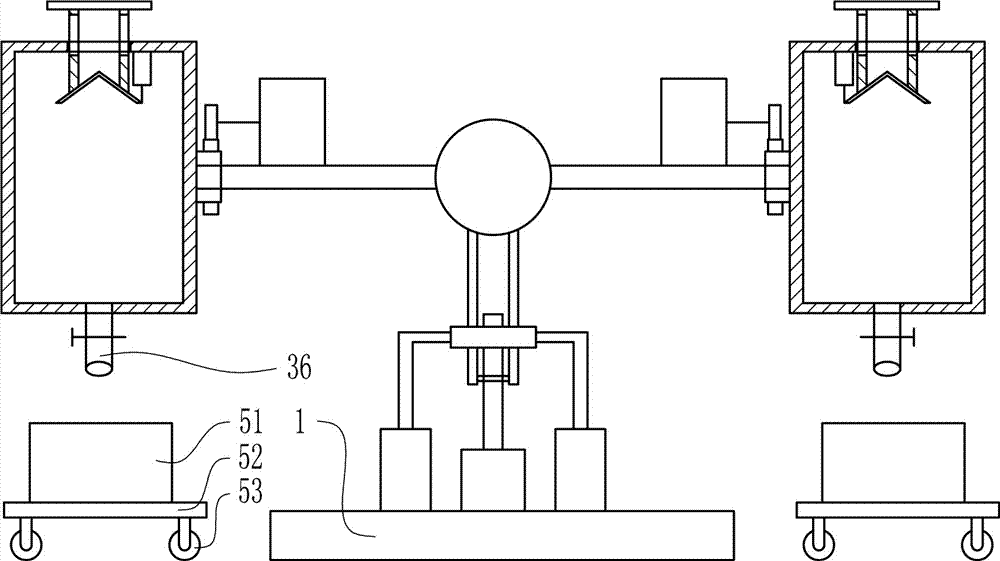

On-site automatic preparation system for mixed injection slurry

ActiveCN103806447APrecise ratioRealize ready-to-useFoundation engineeringSocial benefitsAutomatic control

The invention provides an on-site automatic preparation system for mixed injection slurry, and relates to the technical field of mine curtain slurry injection or water conservancy anti-seepage slurry injection. External hardware equipment comprises weighing and adding equipment, slurry stirring equipment and slurry conveying equipment, wherein the slurry stirring equipment structurally comprises a stirring tank, and a pumping and jet flow water pump is connected with an inner cavity of the stirring tank through a slurry inlet pipe and a slurry outlet pipe. The external hardware equipment is in communication connection with central control equipment, power distribution control enables signals to be transmitted accurately and achieves accurate control over the equipment, and a single worker can independently finish continuous preparation of the slurry. A computer of the central automatic control equipment sends control instruction signals to the external hardware equipment according to the needed preparation proportion of the slurry and a corresponding slurry storage device. The on-site automatic preparation system for the mixed injection slurry achieves the purpose that the slurry is used once being prepared, avoids waste of the slurry, is easy and convenient to operate, can be operated only by one worker, saves manpower and material resources, guarantees the quality of the slurry, and largely improves economic and social benefits.

Owner:NORTH CHINA ENG INVESTIGATION INST

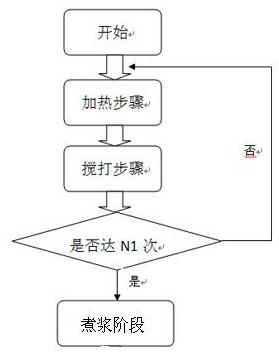

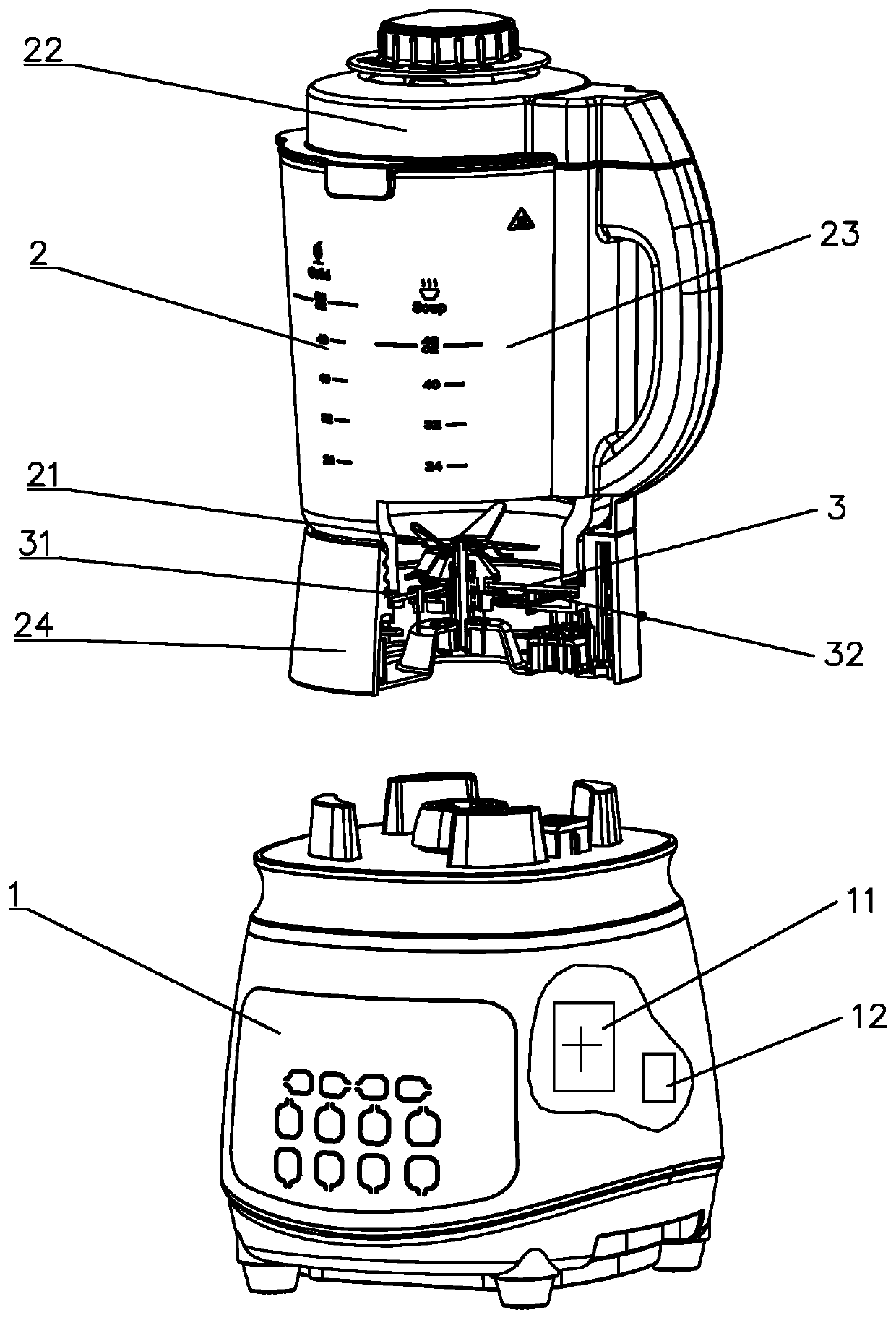

Milk making method of easy-cleaning soybean milk machine and soybean milk machine thereof

InactiveCN102326628ASimple cleaning processImprove efficiencyBeverage vesselsMilk substitutesNutrient contentEngineering

The invention discloses a milk making method of an easy-cleaning soybean milk machine. The soybean milk machine comprises a water tank, a crushing container, a water filling pipeline, a milk draining pipeline, a milk cooking cup, a crushing device, a first control switch and a second control switch. The method comprises the following steps of: controlling the second control switch to be switched on, introducing water of the water tank into the crushing container through the water filling pipeline, switching off the second control switch after a preset amount of water is filled, and starting the crushing device to crush materials in the crushing container; after crushing, controlling the first control switch to be switched on, draining milk into the milk cooking cup through the milk draining pipeline, and switching off the first control switch; and switching on the second control switch once again, adding a small amount of water into the crushing container, switching off the second control switch, starting the crushing device, draining water into the milk cooking cup after stirring, circularly performing the step for certain times, and ending milk making. The invention soybean milk machine has the advantages of convenience for cleaning, full absorption of residual nutritional ingredients of soybean milk and increase of milk making efficiency.

Owner:MIDEA GRP CO LTD

Mortar stirring machine

ActiveCN108032436AFacilitate other construction workEasy to operateCocoaCement mixing apparatusEngineeringMechanical engineering

The invention relates to the technical field of equipment for preparing mortar and mortar mixing materials, particularly to a mortar stirring machine. The mortar stirring machine comprises a motor, astirring barrel and a stirring paddle, wherein an output shaft of the motor is connected with the stirring paddle; the stirring barrel comprises a fixed barrel and a rotating barrel positioned in thefixed barrel; the stirring paddle is positioned in the rotating barrel; pawls are arranged on the stirring paddle; a ratchet ring matched with the pawls is arranged at the top of the rotating barrel;a grinding disc is arranged at the bottom of the rotating barrel; a feed inlet is formed in the top of the fixed barrel; a grinding chamber and a discharge opening which communicates with the grindingchamber are arranged at the bottom of the fixed barrel; the grinding disc is rotatably arranged in the grinding chamber; a communication hole which communicates with the grinding chamber and the interior of the rotating barrel is formed in the grinding disc; a control gate used for closing the discharge opening is arranged at the bottom of the discharge opening; and moving blocks used for intermittently opening the control gate are arranged on the grinding disc. Through the scheme, the situation that caked materials are generated or the discharge opening is blocked during the discharge process of mortar can be effectively prevented, and quality of output mortar is improved.

Owner:华汉致信(宁波)供应链管理有限公司

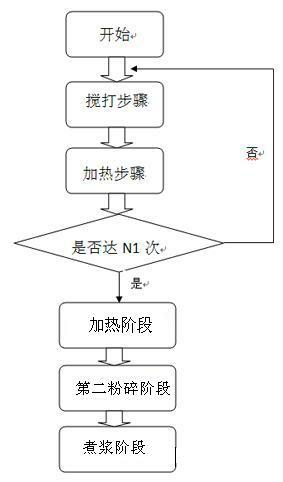

Originally ground soybean milk preparation method of soybean milk grinder and soybean milk grinder for preparing originally ground soybean milk

InactiveCN102144889ANot easy to burnImprove homogeneityBeverage vesselsMilk substitutesFlavorLiquid temperature

The invention relates to an originally ground soybean milk preparation method of a soybean milk grinder, which comprises: (a) a first grinding stage and (b) a boiling stage, wherein in the first grinding stage, materials for preparing soybean milk are ground by a grinding blade under the driving of an electric motor of the soybean milk grinder, and the liquid temperature during the first grinding stage is not more than 70 DEG C; and in the boiling stage, the soybean milk is heated by a heating component of the soybean milk grinder until the soybean milk is boiled up, and the heating component is used for persistently or interruptedly heating the materials in a cup during the first grinding stage. The soybean milk prepared according to the soybean milk preparation method has bean flavor and better mouthfeel.

Owner:JOYOUNG CO LTD

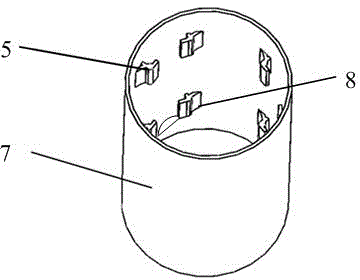

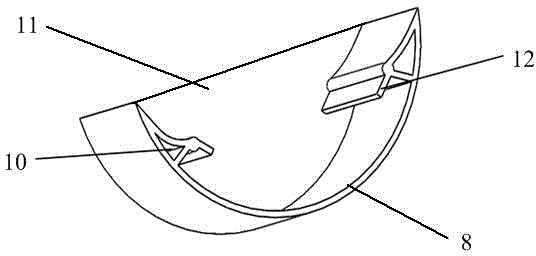

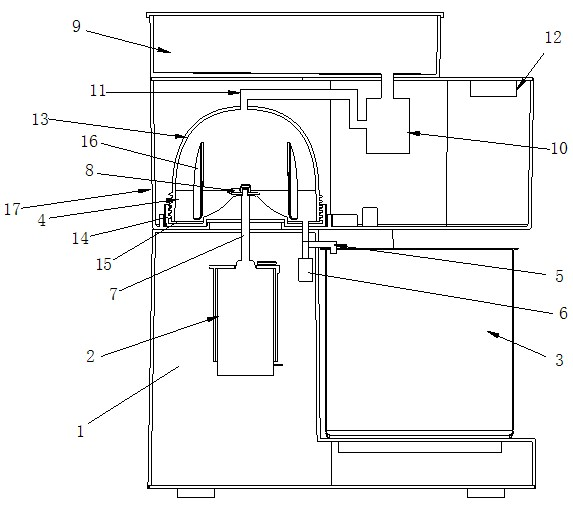

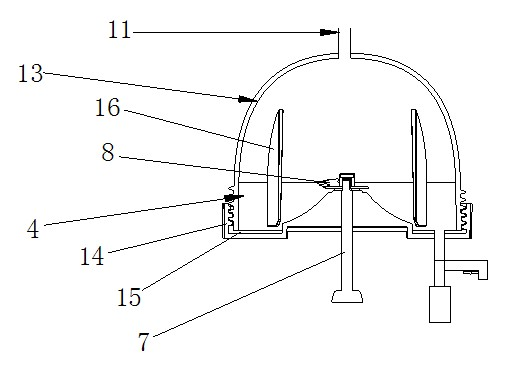

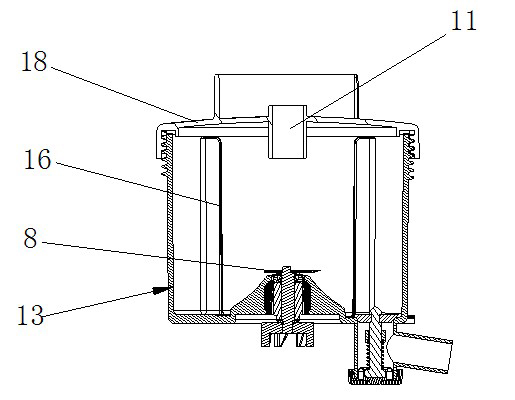

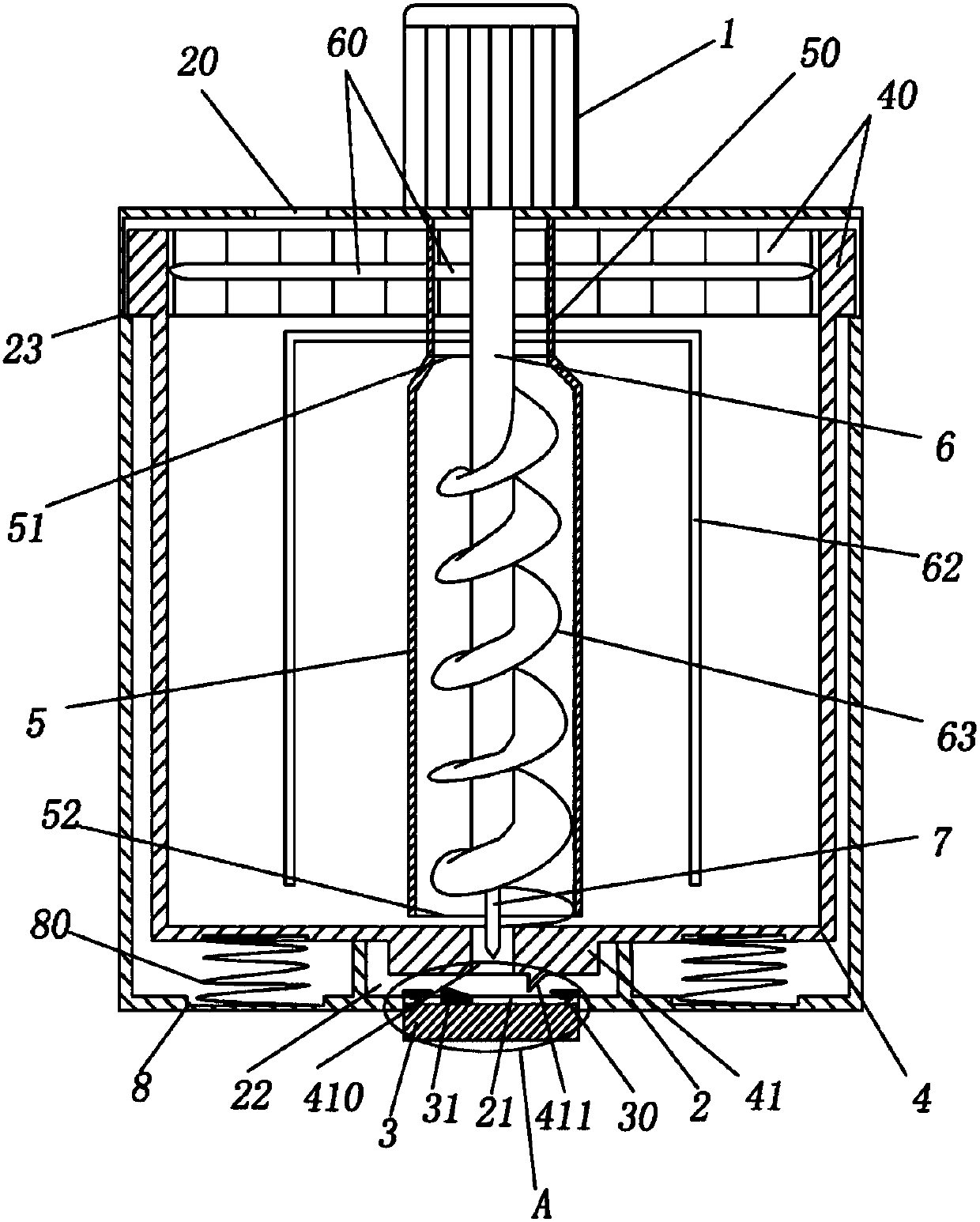

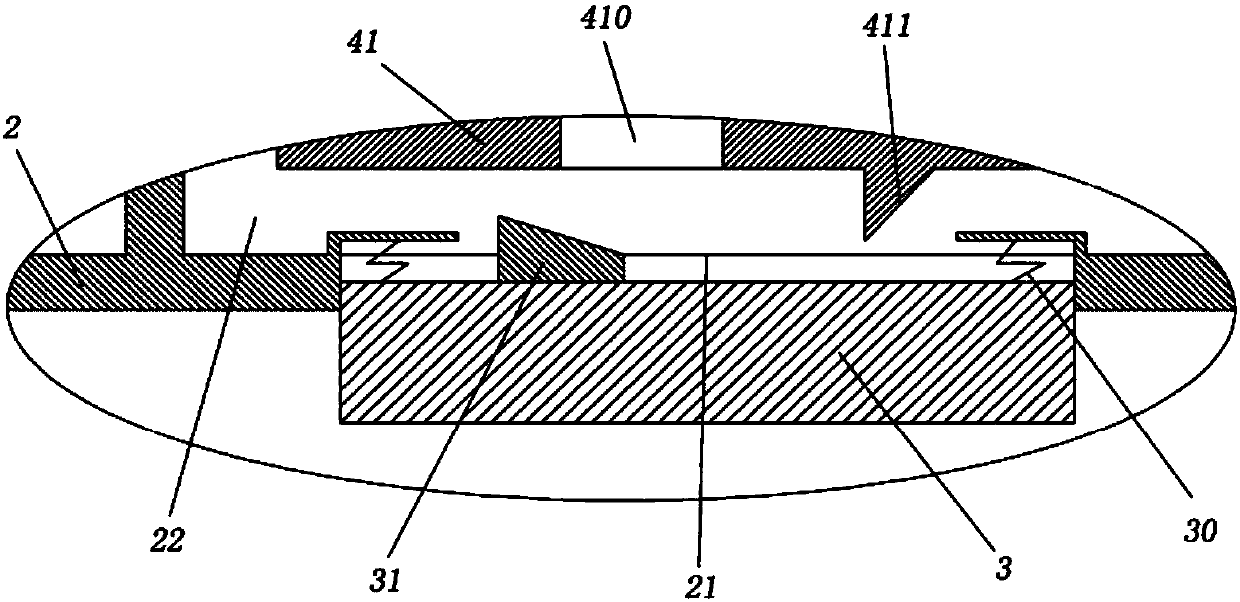

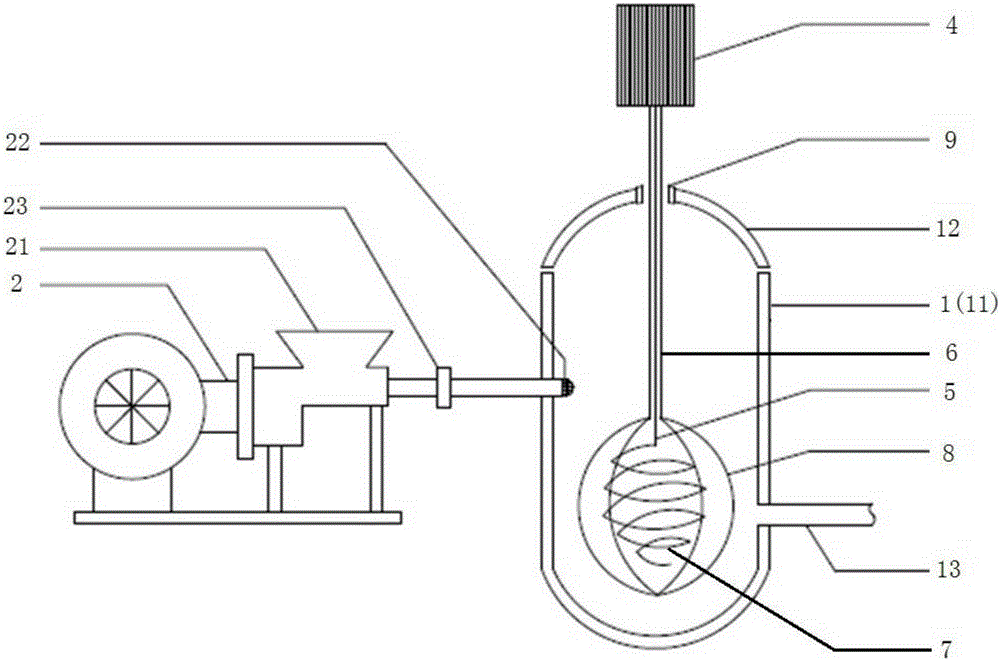

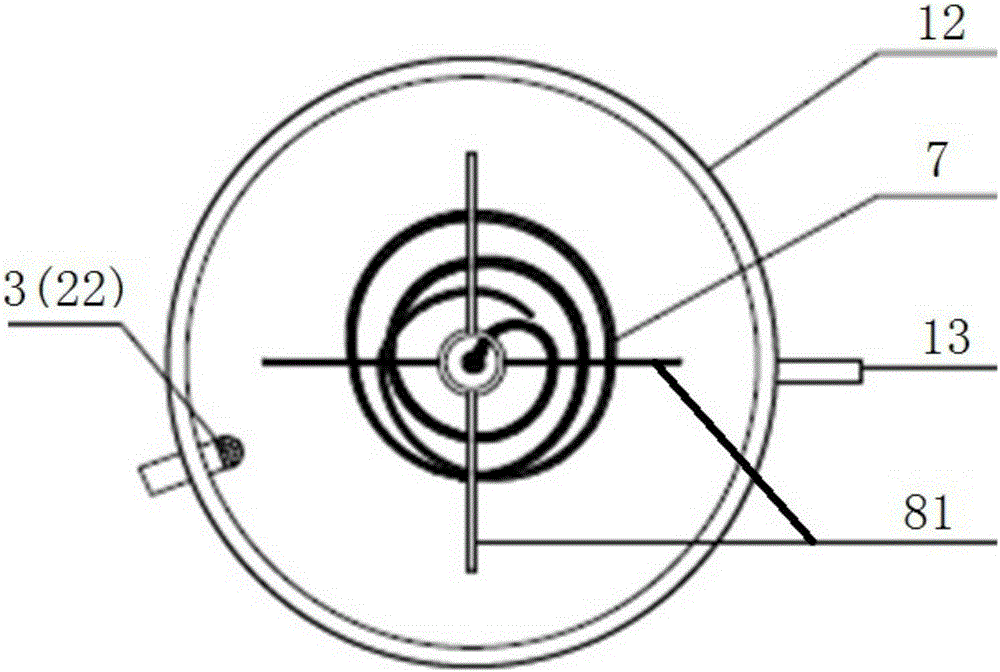

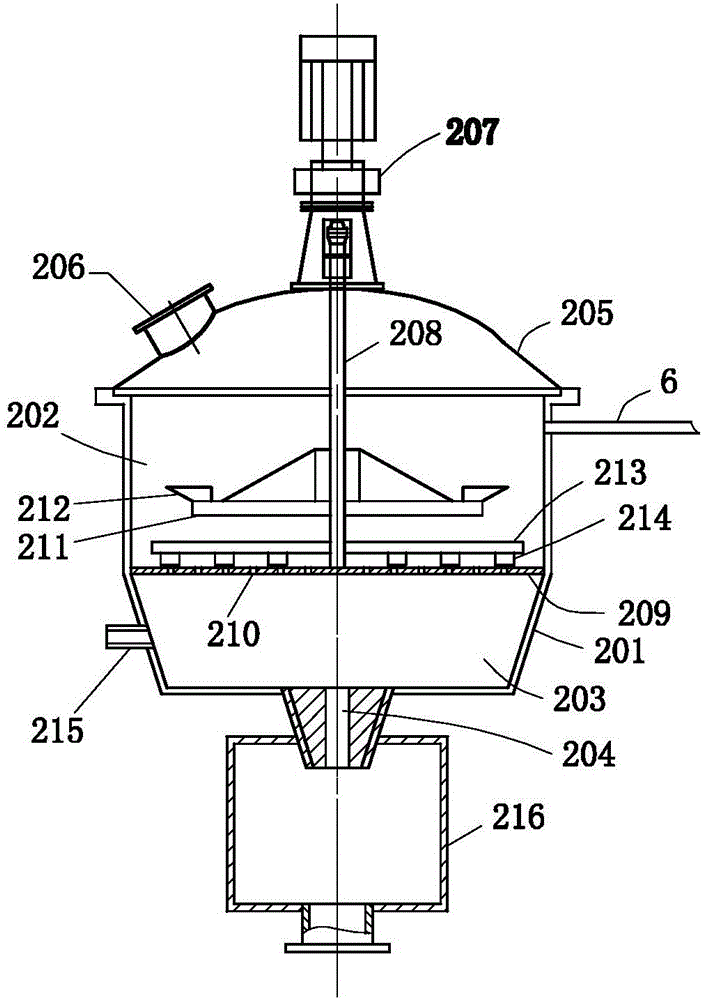

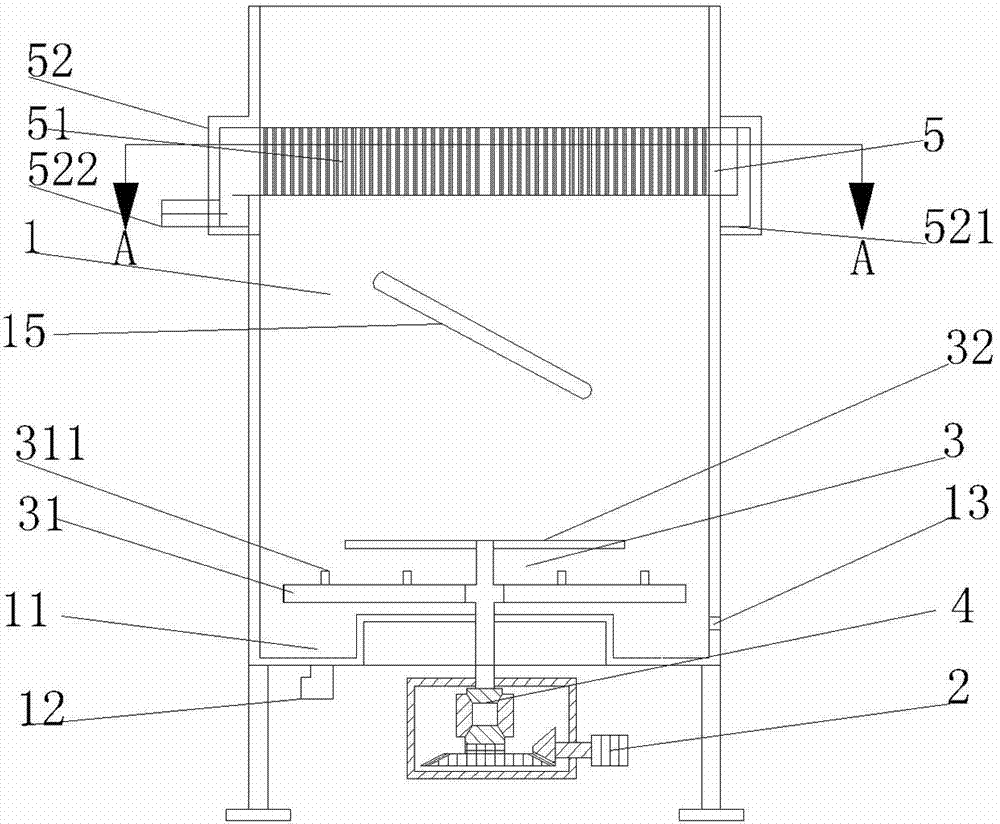

Filter cake slurrying device

The invention discloses a filter cake slurrying device including a beating tank (1) and a strip extruder (2), wherein the beating tank (1) is internally provided with stirring impellers; the end port of an extruding material outlet (22) of the strip extruder is provided with a screen (3) and extends into a tank body (11); a filter cake added from a feed inlet can be extruded into a filter cake extruded strip by the strip extruder; the extruded strip is dispersed via the screen at the extruding material outlet and then is further dispersed in the tank body via the water shearing force action, to form slurry under stirring of the stirring impellers. The stirring impellers can comprise a helical internal stirring impeller (7) and cage-shaped external stirring impellers (8), and the external stirring impellers radially alternately sleeve the exterior of the internal stirring impeller; a stirring motor (4) can respectively independently drive the internal stirring impeller and the external stirring impellers so as to achieve vertically lifting and falling, and can drive homonymous rotation or reverse rotation of the internal stirring impeller and the external stirring impellers. The filter cake slurrying device can fully crush the filter cake, has the advantages of good stirring effect and high slurrying efficiency, and can effectively relieve blocking of the discharge port and bottom deposition of the beating tank.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

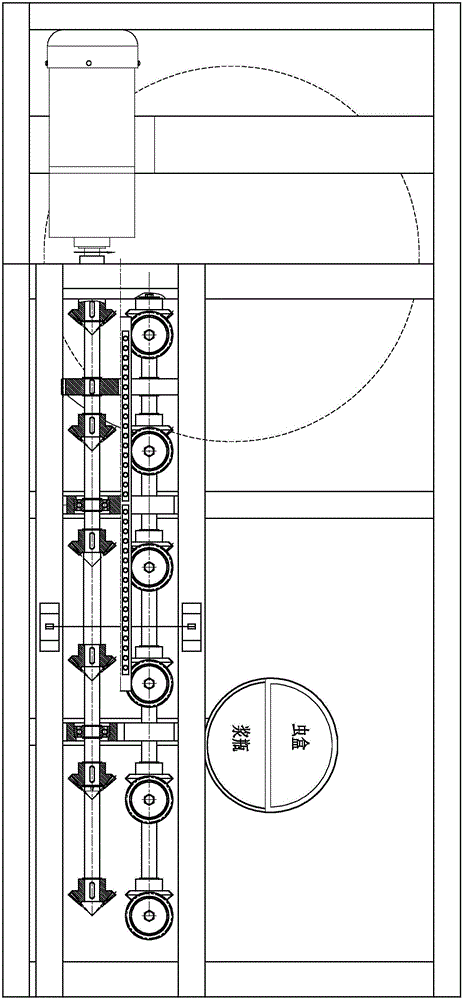

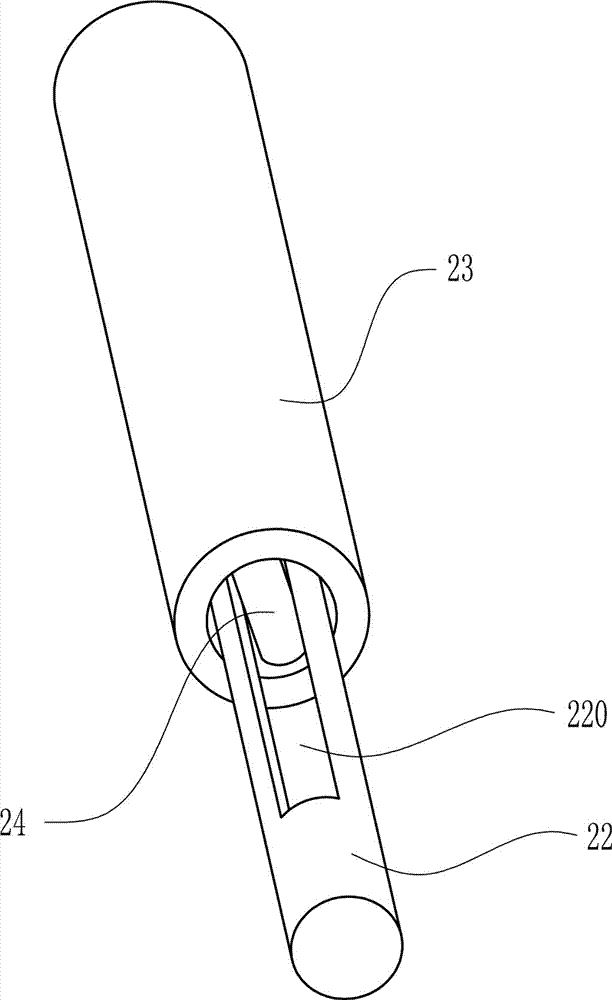

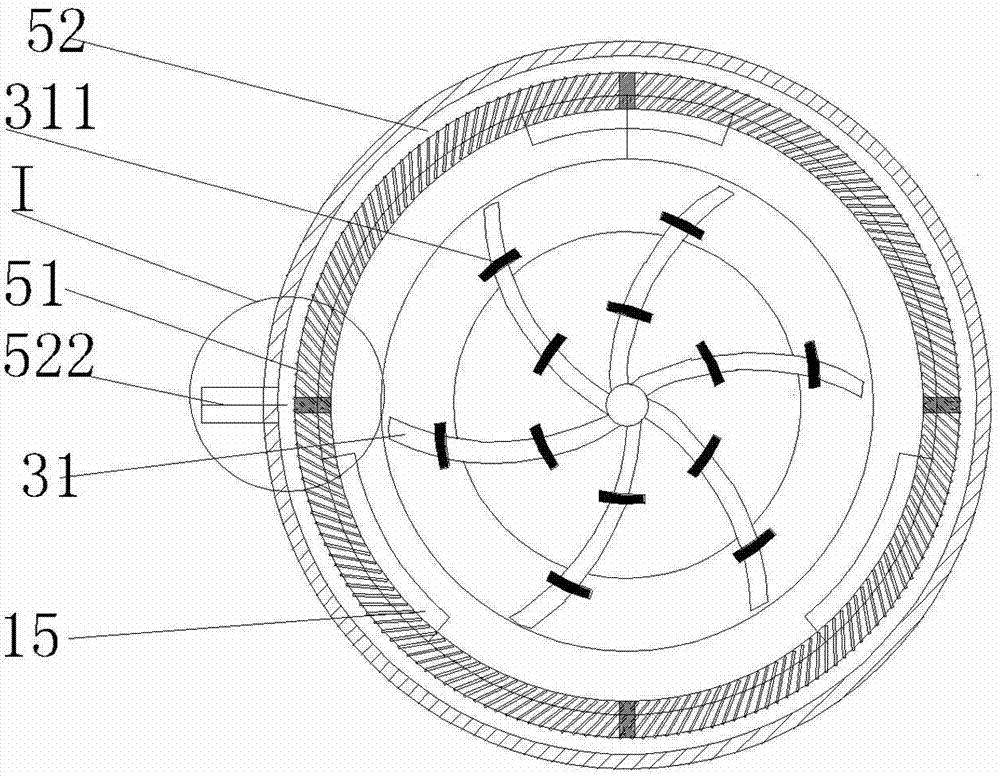

Pulping device of rare earth ore

ActiveCN107224905AUndamagedGood mixing and stirringTransportation and packagingRotary stirring mixersRare earthEngineering

The invention relates to a pulping device and particularly relates to a pulping device of rare earth ore. The pulping device of rare earth ore solves the technical problem of rare earth ore pulping. The pulping device comprises a stirring cylinder, a moving device, a stirring device, support legs, a discharge pipe and a discharge valve. The stirring device is arranged in the stirring cylinder. The stirring device is connected to the moving device. The support legs are welded to the bottom of the stirring cylinder. The upper end of the discharge valve is welded to the middle of the bottom of the stirring cylinder. The discharge pipe is provided with the discharge valve. A feeding hopper is welded to the middle of the top of the stirring cylinder. The feeding hopper is communicated with the stirring cylinder. Through combination of the moving device and the stirring device, the stirring device can move left and right in the stirring cylinder so that a stirring range is expanded.

Owner:连云港浩森矿产品有限公司

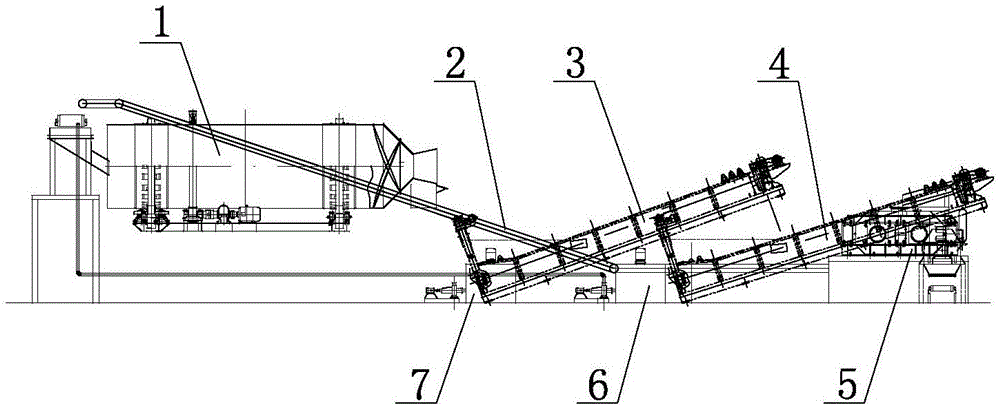

Ceramic raw material continuous pulping system and process

ActiveCN106391266AImprove pulping efficiencyReasonable process designGrain treatmentsParticulatesTransmission belt

The invention relates to a ceramic raw material continuous pulping system and a process, and belongs to the technical field of preparation of ceramic raw materials. The ceramic raw material continuous pulping system comprises a pulping machine, a classifier and a continuous ball milling machine; and a return transmission belt is arranged on one sides of the pulping machine and the classifier. The process comprises the following process steps: 1) the ceramic raw materials are fed in the pulping machine for pulping; 2) the ceramic raw materials are classified and screened; and 3) the classified fine materials are fed in the continuous ball milling machine; and the classified thick materials are crushed to feed in the pulping machine. The system and the process circularly grind and crush large particles through the pulping machine, pulp pugs accordant with the fineness requirements, apply the classified particles to the continuous ball milling machine, greatly improve the pulping efficiency of the ceramic raw materials, reduce the production energy consumption, and reduce the production cost.

Owner:广东鼎汇能科技股份有限公司

Automatic royal jelly acquisition device

ActiveCN106719109AReduce volumeEasy to carryFatty substance recoveryHoney collectionWaxTransfer procedure

The invention discloses an automatic royal jelly acquisition device. The automatic royal jelly acquisition device comprises an operation platform, jelly production strips, a transmission device, a bee wax cutting device, a blowing device, a jelly and larva separating device and a jelly and larva collection device. The transmission device is used for transmission of the jelly production strips, the bee wax cutting device is used for cutting bee wax on the jelly production strips in a transmission process, the blowing device is used for blowing royal jelly and larvae out of the jelly production strips after bee wax cutting, the jelly and larva separating device is used for separation of the larvae and the royal jelly, and the jelly and larva collection device is used for respectively collecting the royal jelly and the larvae after separation. By a mechanical feeding system for feeding the jelly production strips, the bee wax is cut by an electric heating wire device in a feeding process, and the problem of stickiness of the bee wax to cutters in a process of cutting the bee wax with the cutters is solved. By filtered clean large-flow air for blowing back holes of the jelly production strips, the royal jelly is blown into the jelly and larva separating device and vibrated and filtered through a filter screen to separate the royal jelly from the larvae, and accordingly a larva taking procedure is saved, jelly acquisition efficiency is greatly improved, and jelly output quality is guaranteed completely.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

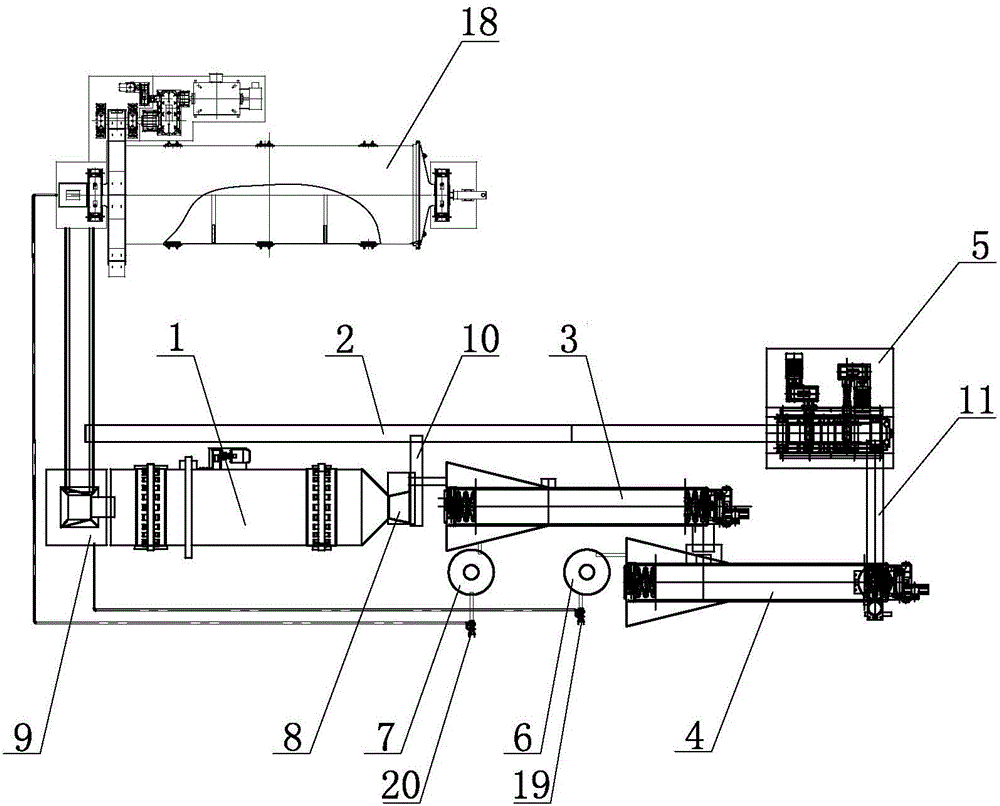

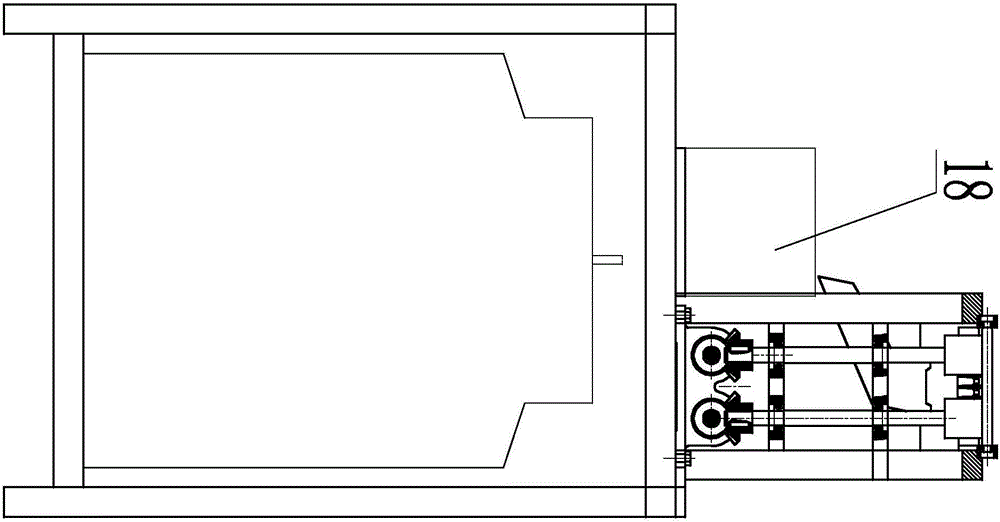

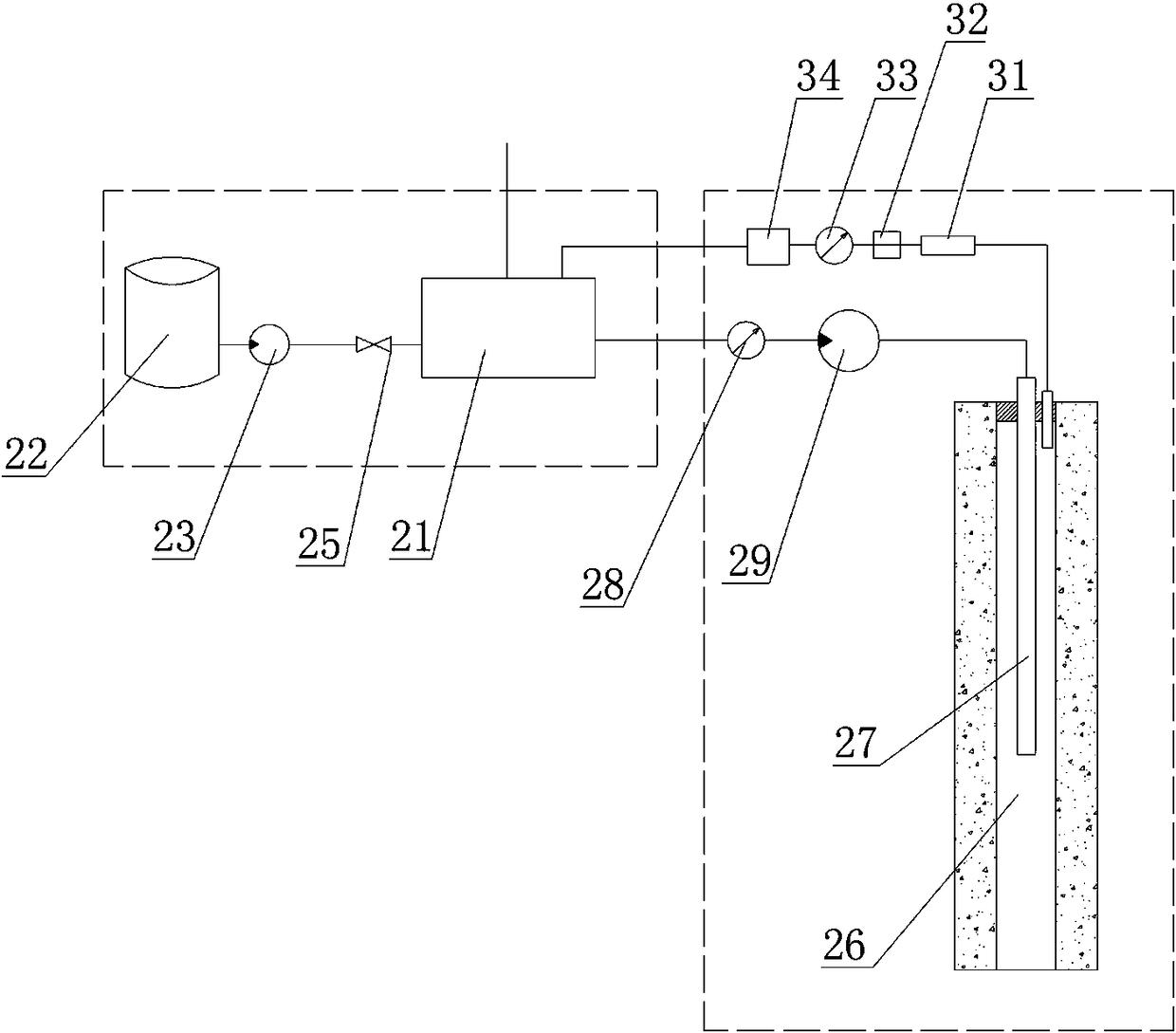

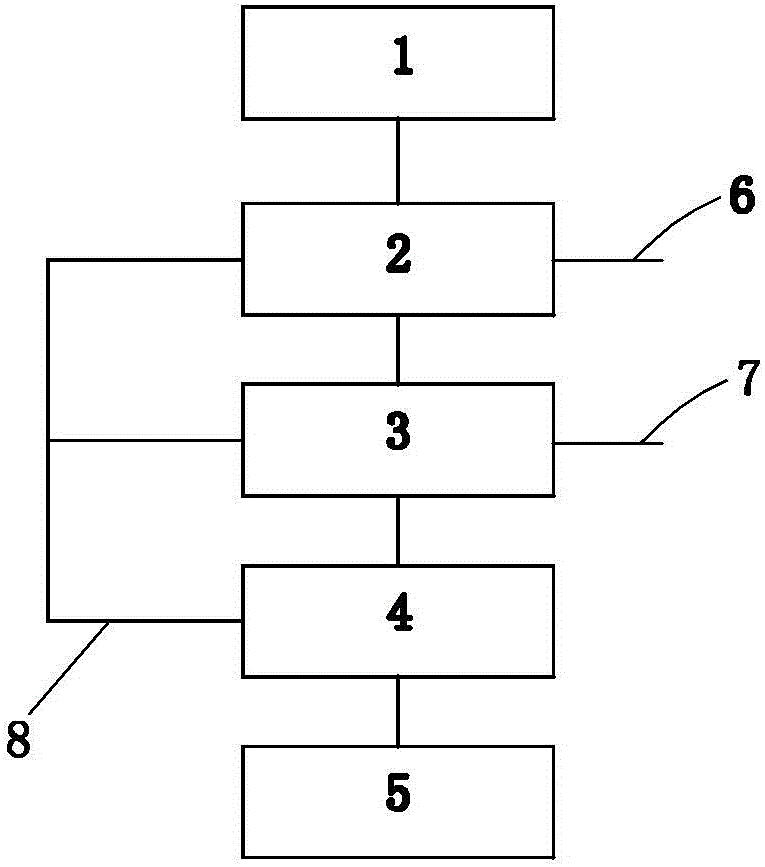

Underground coal mine movable type integrated automatic grouting system and use method

PendingCN111236981AGood effectImprove working environmentUnderground chambersDust removalDust controlWorking environment

The invention provides an underground coal mine movable type integrated automatic grouting system and a use method. The automatic grouting system comprises a powder conveying device, a grout making device, a grout storing device, a grouting device, a moving mechanism and a control device. The powder conveying device is used for conveying powder to the automatic grouting system, the grout making device is used for making the powder conveyed by the powder conveying device into grout, the grout storing device is used for storing the grout made by the grout making device, the grouting device is used for conveying the grout in the grout storing device, the moving mechanism is mounted on the bottom of the automatic grouting system, and can wholly move the grouting system, the control device is used for controlling the automatic grouting system to be started and stopped, when the powder enters a grout making bucket, dust removal is carried out, work environment is improved, for the position needing grouting, the system only needs to be wholly moved to the grouting point, labor intensity of a worker is reduced, device repeated dismounting and mounting can be avoided, the service life of the grouting system is prolonged, and the production cost is indirectly saved.

Owner:河南力行科创矿山技术开发有限公司

Method for quickly making hot beverage by food processor

InactiveCN109770744APrevent splashPrevent overflowBoiling over preventionWarming devicesPulp and paper industrySlurry

The invention provides a method for quickly making a hot beverage by a food processor. The food processor comprises a machine base, a stirring cup arranged on the machine base and a stirring knife arranged in the stirring cup, wherein a motor and a control unit are arranged in the machine base. The food processor further comprises a heating device. The method comprises the steps: at the first heating stage, heating pulp in the stirring cup by full-power operation of the heating device; at the crushing stage, driving the stirring knife to rotate by the motor and stirring and crushing the pulp in the stirring cup; at the boiling stage, controlling the heating device to operate in a non-full power way by the control unit and boiling the crushed pulp in the stirring cup. The method further comprises the steps: at the stirring and cooling stage, controlling the motor to drive the stirring knife by the control unit to rotate at a rotating speed V1, and stirring and cooling the pulp, wherein2000 rpm <=V1 <= 7800 rpm, the stirring and cooling stage is set after the first heating stage and before the crushing stage, so that the heated pulp is rapidly cooled, and the pulp is prevented fromoverflowing in the high-speed crushing process.

Owner:JOYOUNG CO LTD

Soybean milk making method of rapid soybean milk maker

ActiveCN102771575AAvoid wastingReduce wasteBeverage vesselsMilk substitutesHigh concentrationWater resources

The invention relates to a soybean milk making method of a rapid soybean milk maker. The soybean milk making method at least comprises the steps: injecting the water of capacity V1 in a small-space smasher at a time, and heating the water in the small-space smasher through a heating device, draining the heated water to a milk receiving cup and mixing the milk in the milk receiving cup. Compared with the prior art, the residue of high-concentration milk / paste in the small-space smasher can be reduced, so that waste is avoided; furthermore, the water resources for cleaning at later stage can be effectively reduced, and the waste of water resources can also be reduced.

Owner:JOYOUNG CO LTD

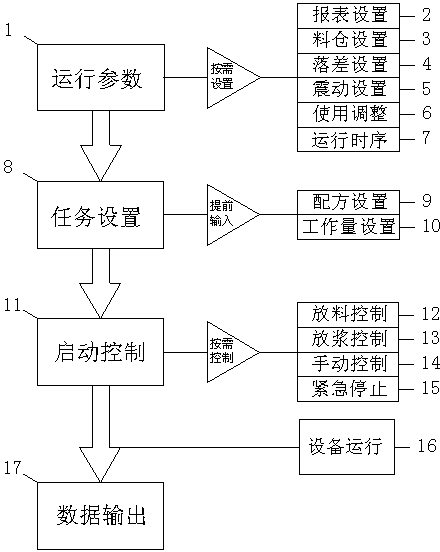

Automatic grouting production system

InactiveCN108705678ARealize continuous preparationEasy to controlMixing operation control apparatusFoundation engineeringControl systemMonitoring system

The invention discloses an automatic grouting production system. The automatic grouting production system comprises a control system, a grout making station, a grout conveying system, grout proportionstations and grouting monitoring systems. The automatic grouting production system has the advantages that the automation degree is high, the labor cost is saved, the operation is simple, the unmanned production or the flexible manpower line is realized, the proportion precision is improved, and the labor intensity is reduced.

Owner:XIYI AUTOMATION SYST ENG CHENGDU +1

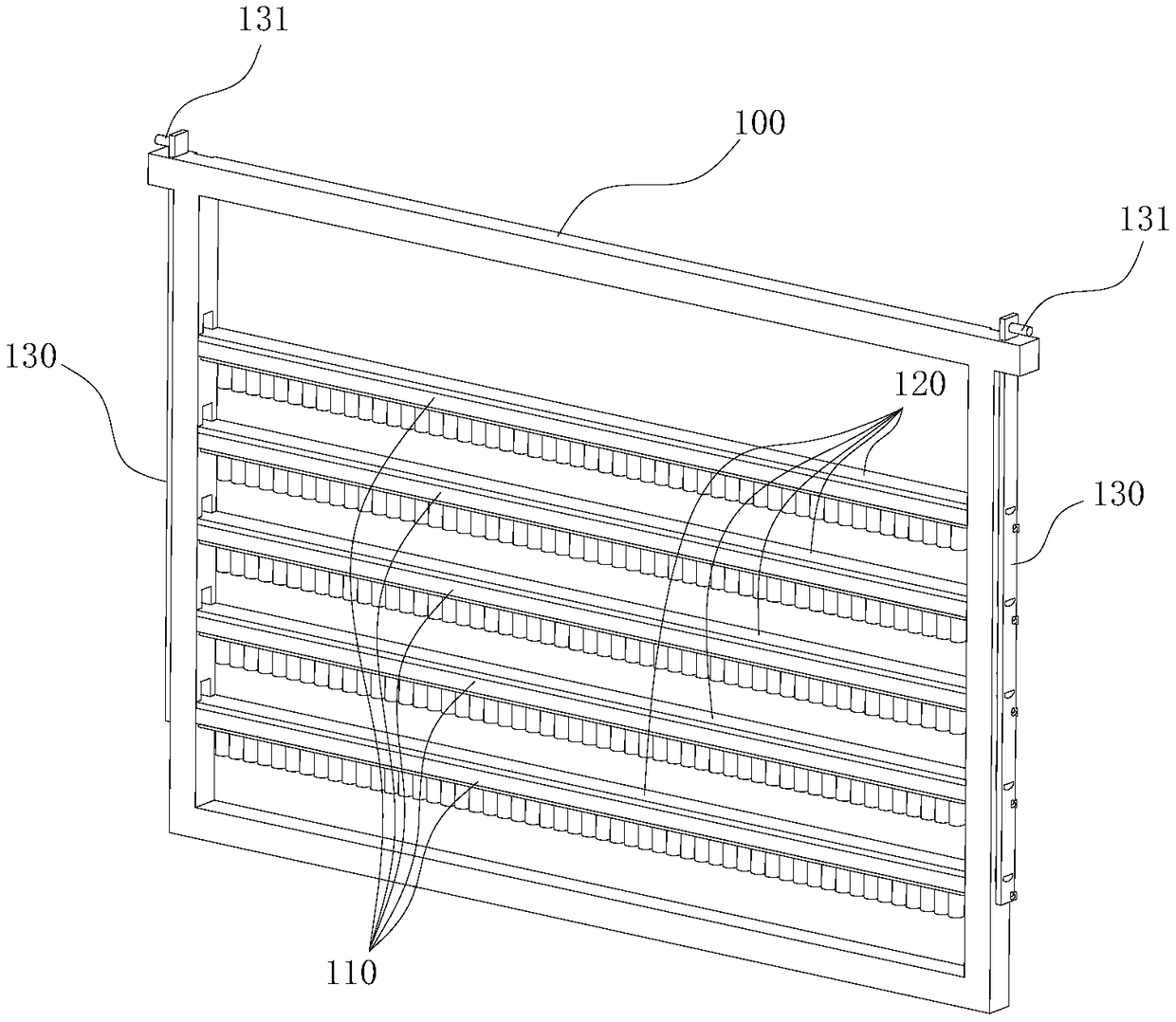

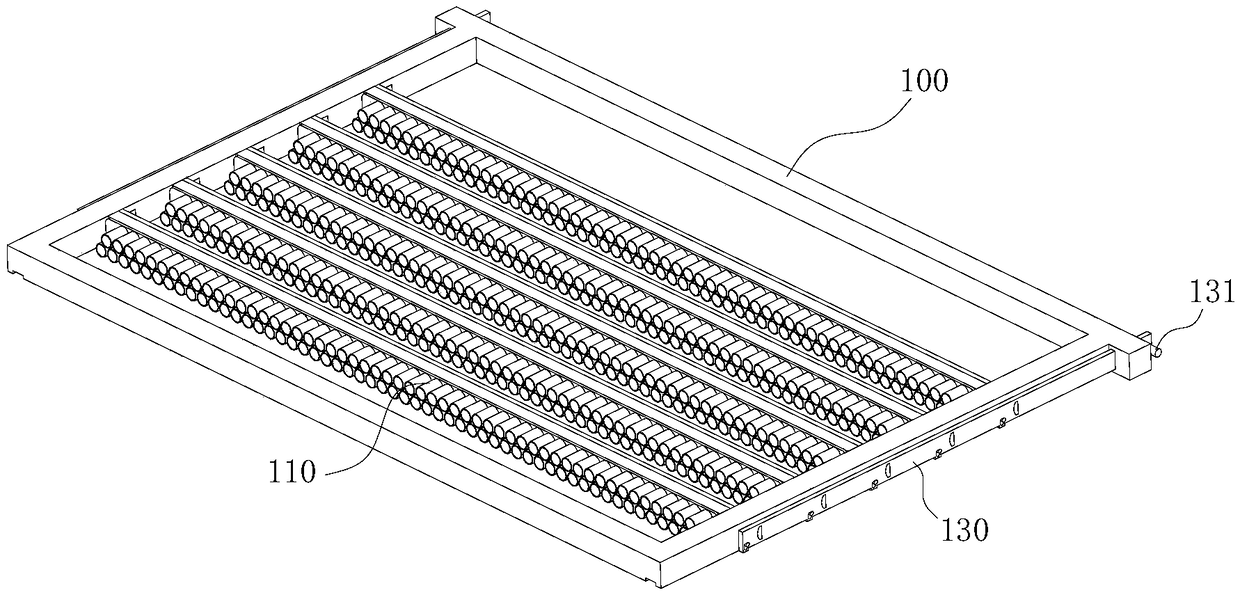

Royal jelly taking machine

The invention belongs to the technical field of royal jelly collection and processing and particularly relates to a royal jelly taking machine. The royal jelly taking machine comprises a royal jelly frame, a wax cutting device, a larva taking device and a jelly taking device. Royal jelly strips are rotatably arranged on the royal jelly frame, so that the royal jelly strips do not need to be dismounted from the royal jelly frame, the operation process is simplified, and improvement of the jelly taking efficiency is facilitated. In addition, royal jelly and larvae are firstly extruded towards aroyal table opening for a certain distance, so that the larvae are completely exposed outside a royal table, then a scraper is utilized to scrap off the larvae, the larvae always float on the surfaceof the royal jelly in the whole process and are prevented from being trapped in the royal jelly, the larva taking efficiency can be greatly improved compared with a traditional manual clamping mode adopting tweezers, and compared with a filtering mode of a larva taking device, a large amount of larvae can be prevented from being attached to royal jelly, the loss of the royal jelly is reduced, andthe purity of the royal jelly can be improved.

Owner:安徽智汇和科技服务有限公司

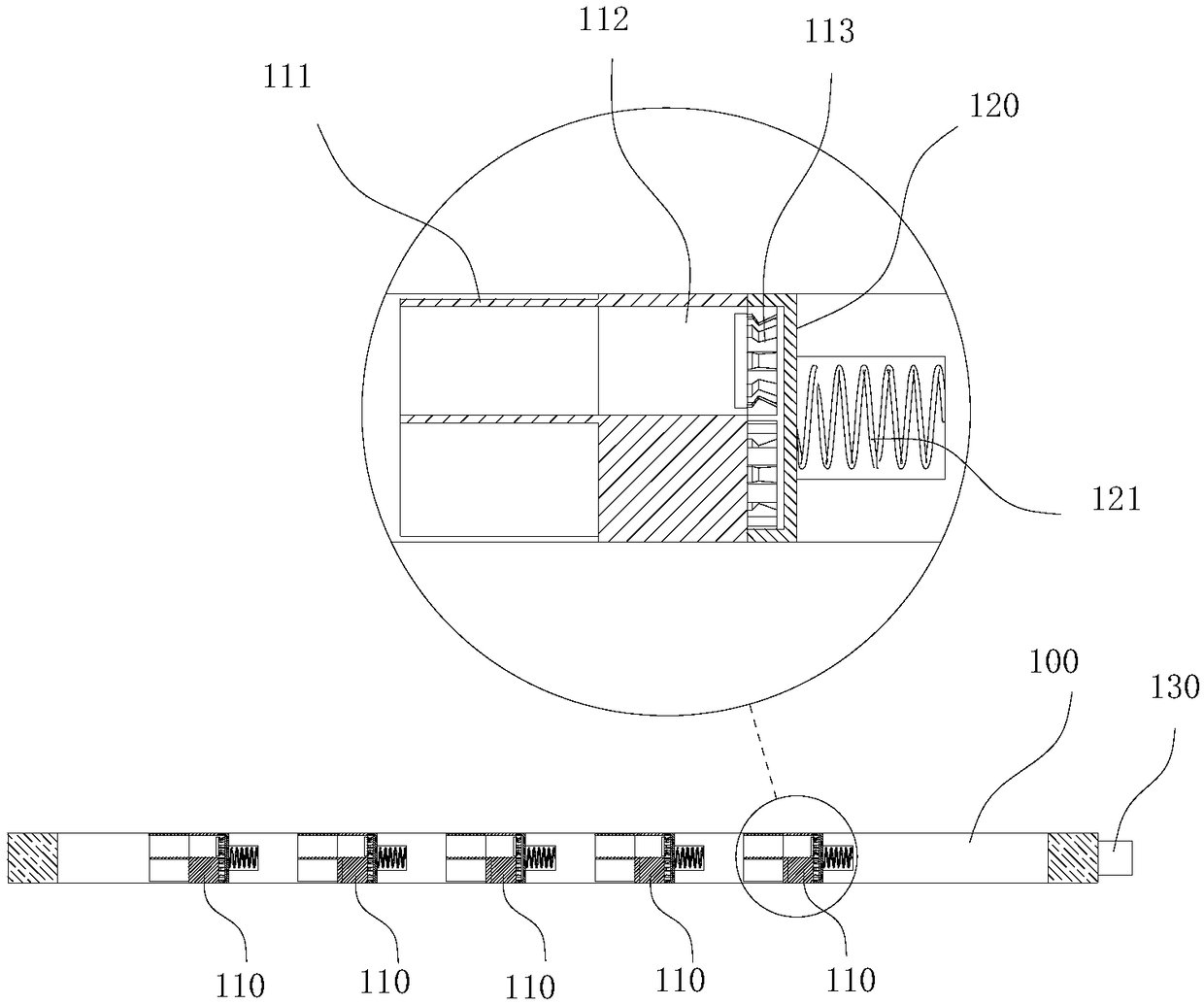

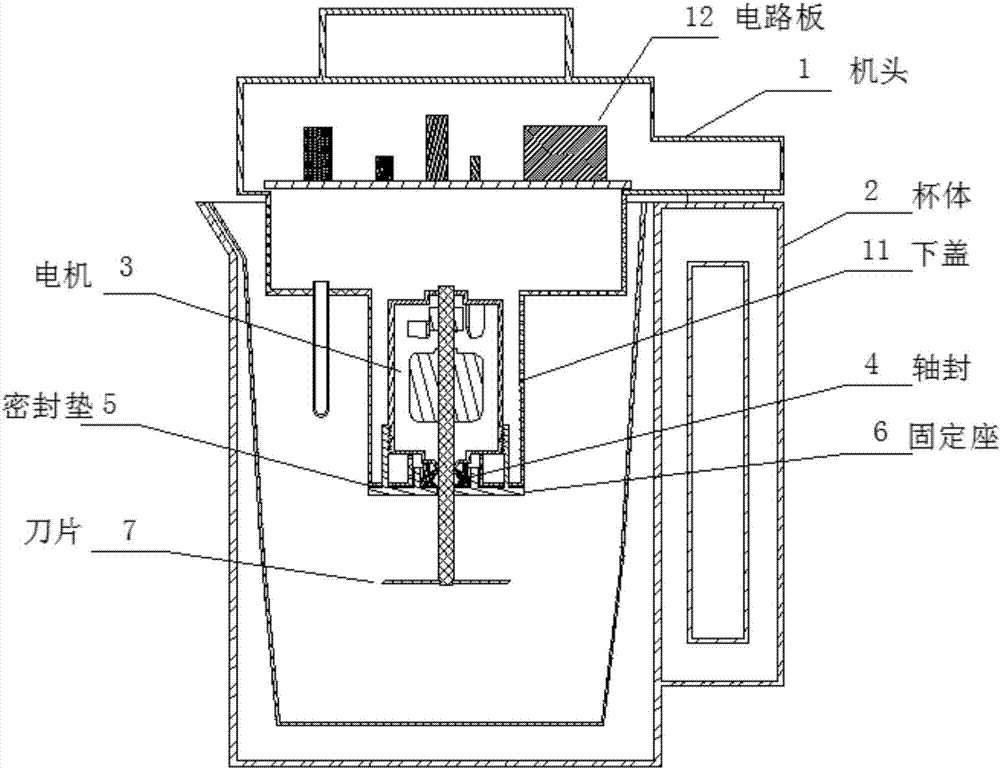

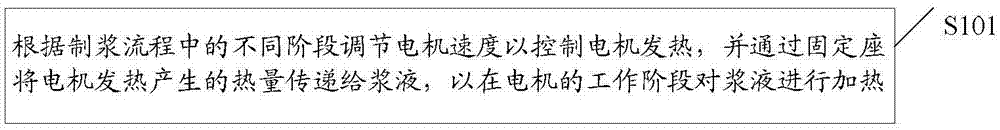

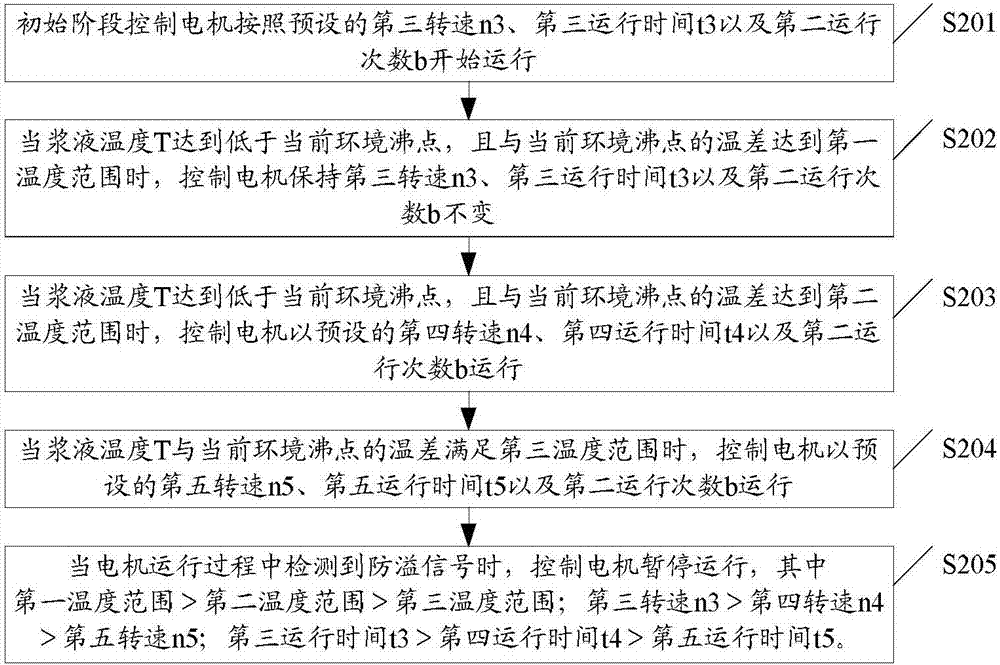

Control method for making soybean milk of soybean milk machine

The embodiment of the invention discloses a control method for making soybean milk of a soybean milk machine. The soybean milk machine comprises a machine head. A motor is arranged on the machine head. The process for making soybean milk comprises the following steps: a pre-heating phase, a pre-crushing phase, a crushing phase and a boiling phase. The working phases of the motor comprise a pre-crushing phase and a crushing phase. A fixing seat is arranged below the motor and located on the outer surface of the machine head. The fixing seat can directly contact soybean milk liquid. The method comprises the following steps: adjusting the speed of the motor in different phases of the process of making soybean milk in order to control the motor to emit heat, transferring the heat generated by heating of the motor through the fixing seat to soybean milk liquid such that the soybean milk liquid is heated in the working phase of the motor.

Owner:HONGYANG HOME APPLIANCES

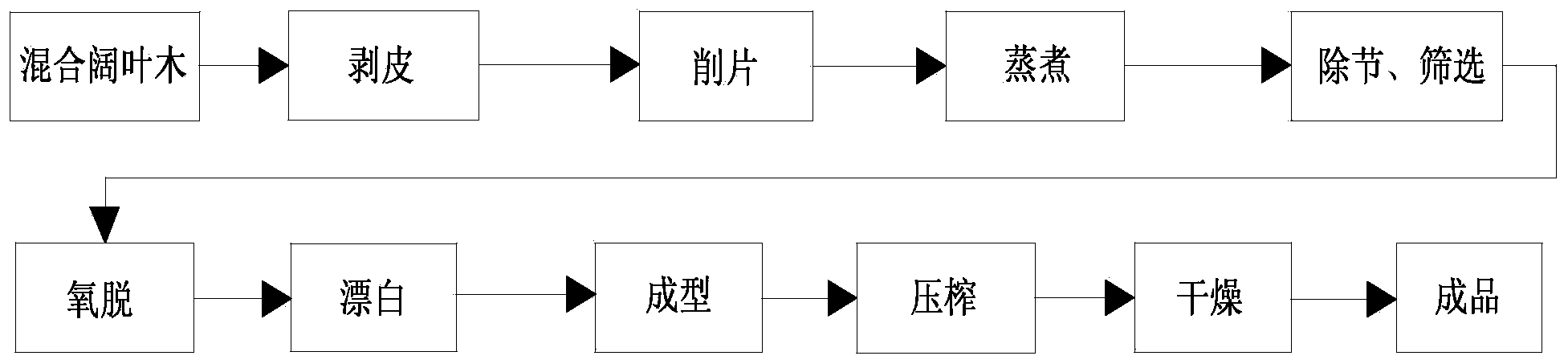

Method for pulping mixed broad-leaved woods

ActiveCN103981753AThe pulping method is simpleThe steps of the pulping method are simpleWashing/displacing pulp-treating liquorsPulp bleachingSulfatePulp and paper industry

The invention relates to a method for pulping mixed broad-leaved woods. The method comprises the following steps: (1) peeling cut mixed broad-leaved woods in different means according to different diameters; (2) chipping the broad-leaved woods, which are peeled in the step (1) and meet the requirement, by a chipping machine; (3) cooking the qualified wood chips, which are obtained by chipping the woods in the step (2), for certain time; (4) removing knots of pulp which is obtained by cooking the chips in the step (3); (5) performing enclosed primary three-section screening on the pulp subjected to knot removal in the step (4); (6) washing the pulp screened in the step (5); (7) performing two-section oxygen removal on the pulp washed in the step (6); (8) performing D1-EOP-D2 three-section bleaching on the pulp subjected to oxygen removal in the step (7); (9) mixing qualified bleached sulfate which is obtained by bleaching in the step (8) with the broad-leaved wood pulp for performing coarse pulp processing. The method is reasonable in steps, and convenient to carry out; the utilization rate of the broad-leaved woods is high, the energy consumption and the environment pollution can be reduced, the product quality is improved and the pulping efficiency is high.

Owner:YUNNAN YUNJING FORESTRY & PULP MILL

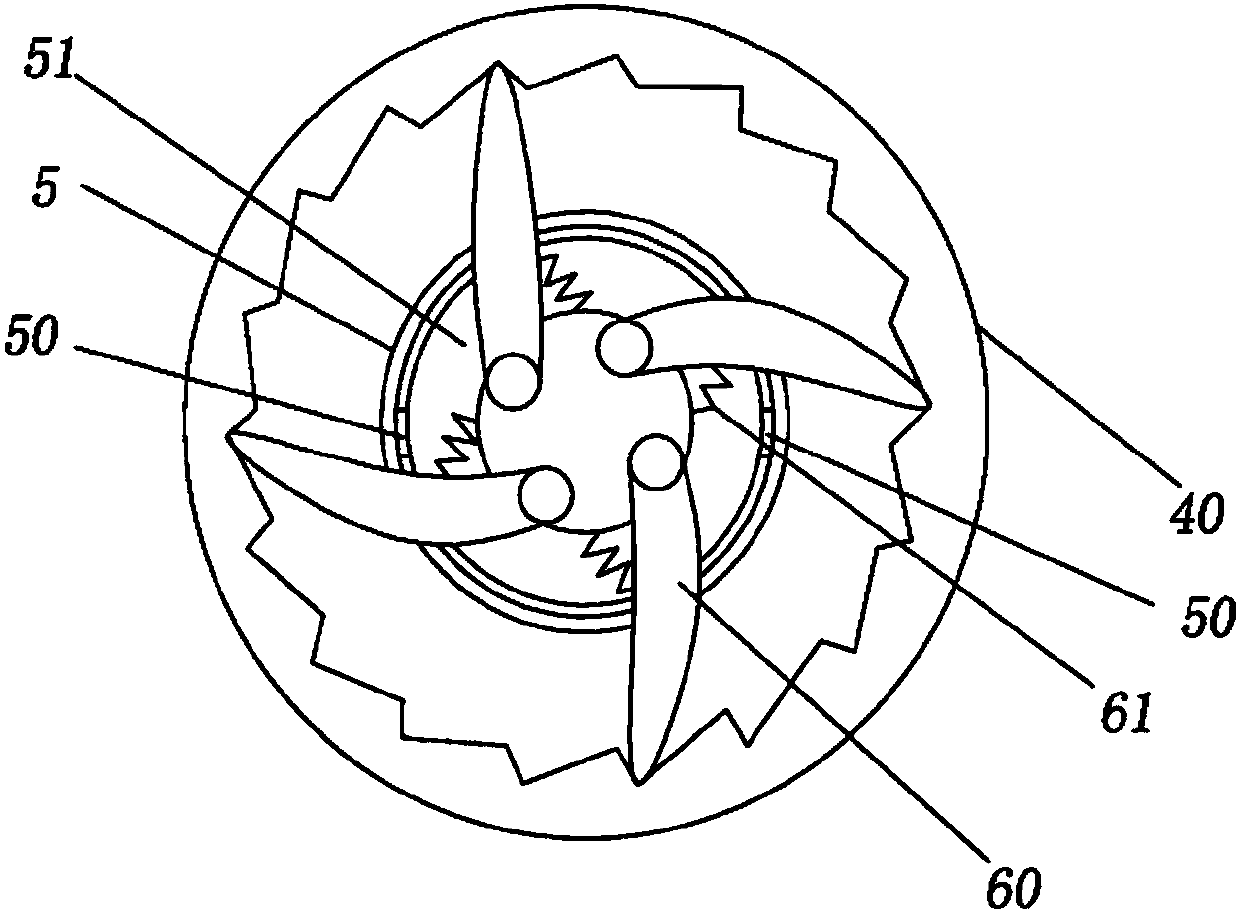

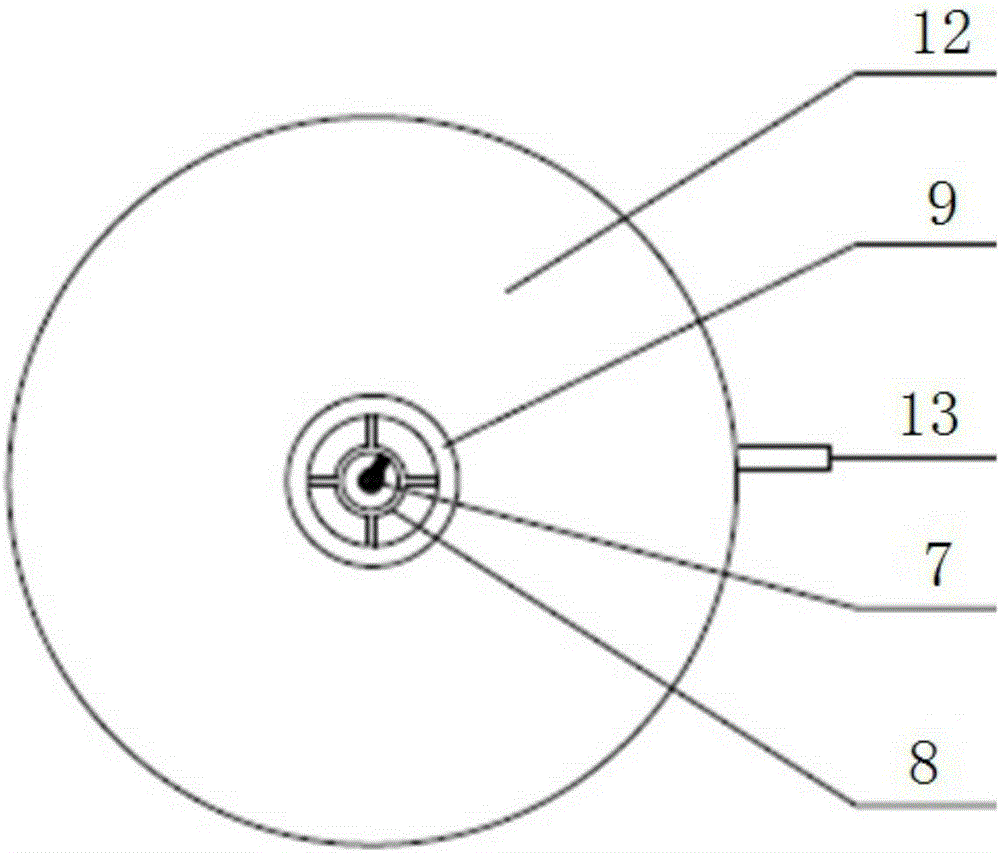

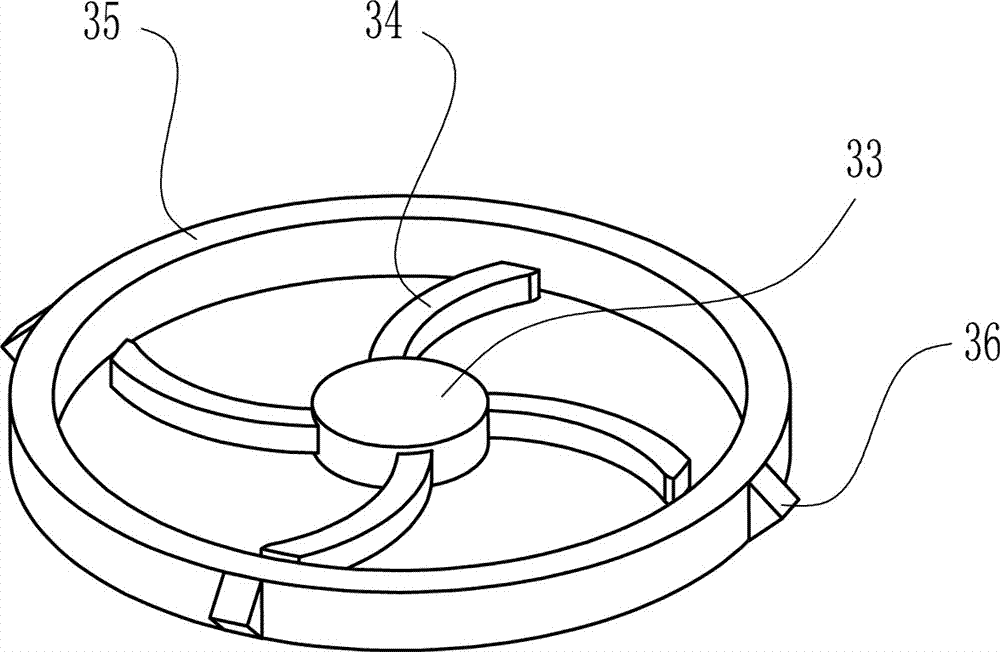

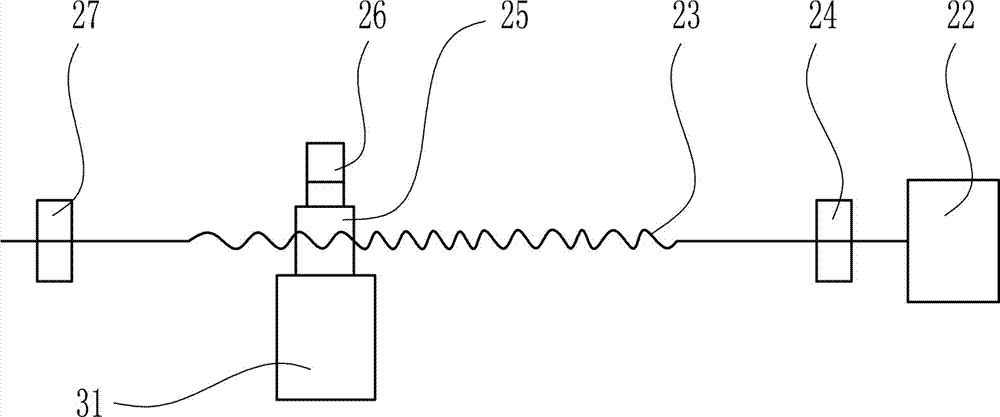

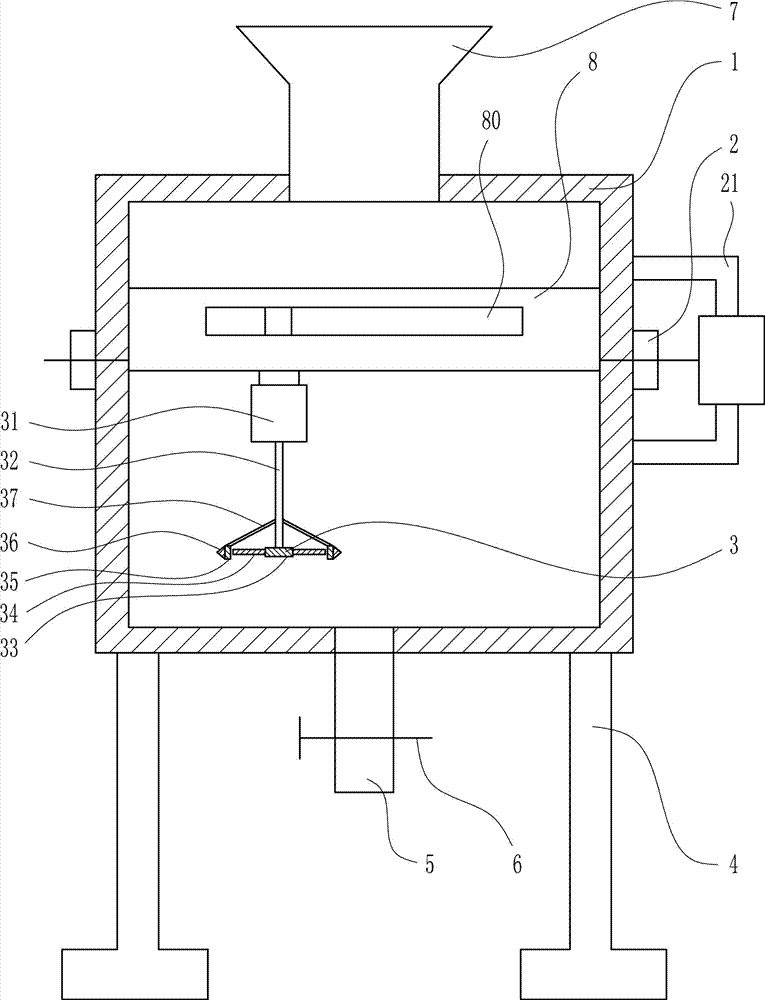

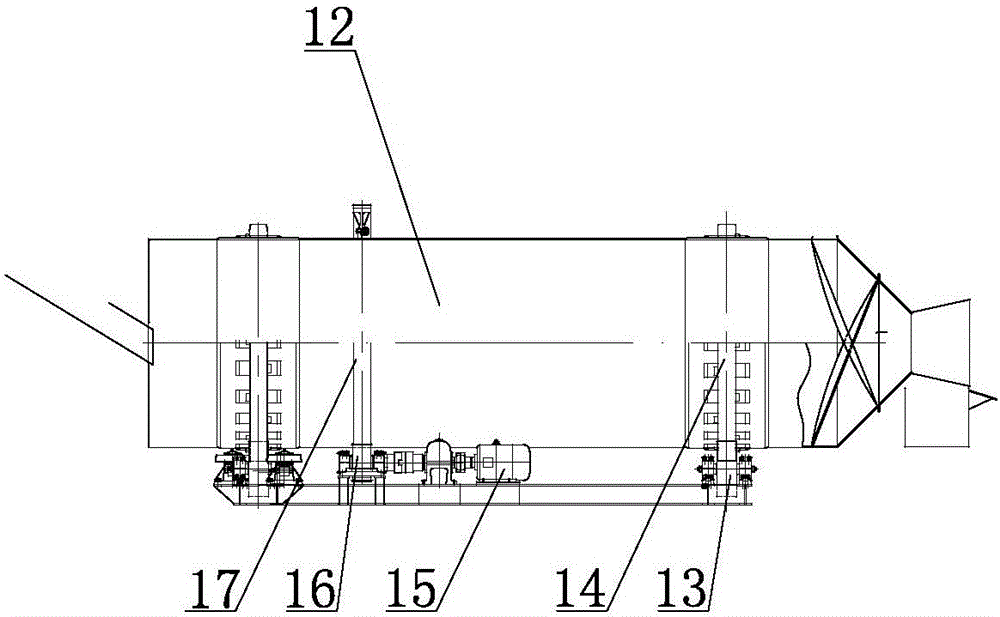

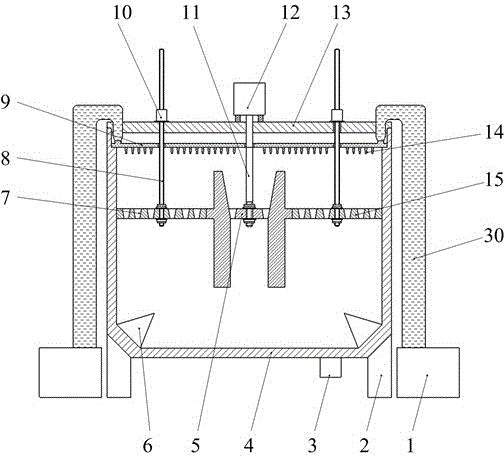

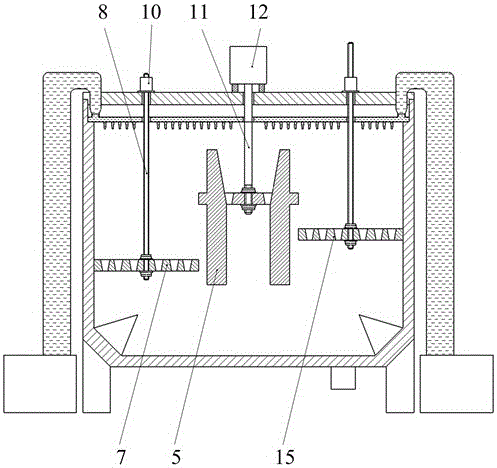

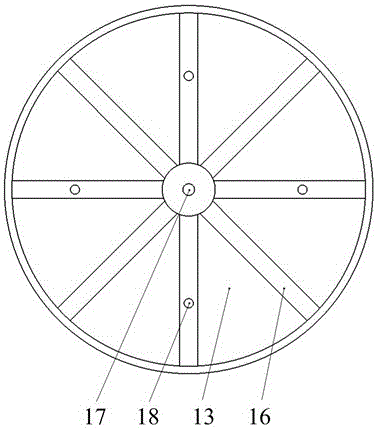

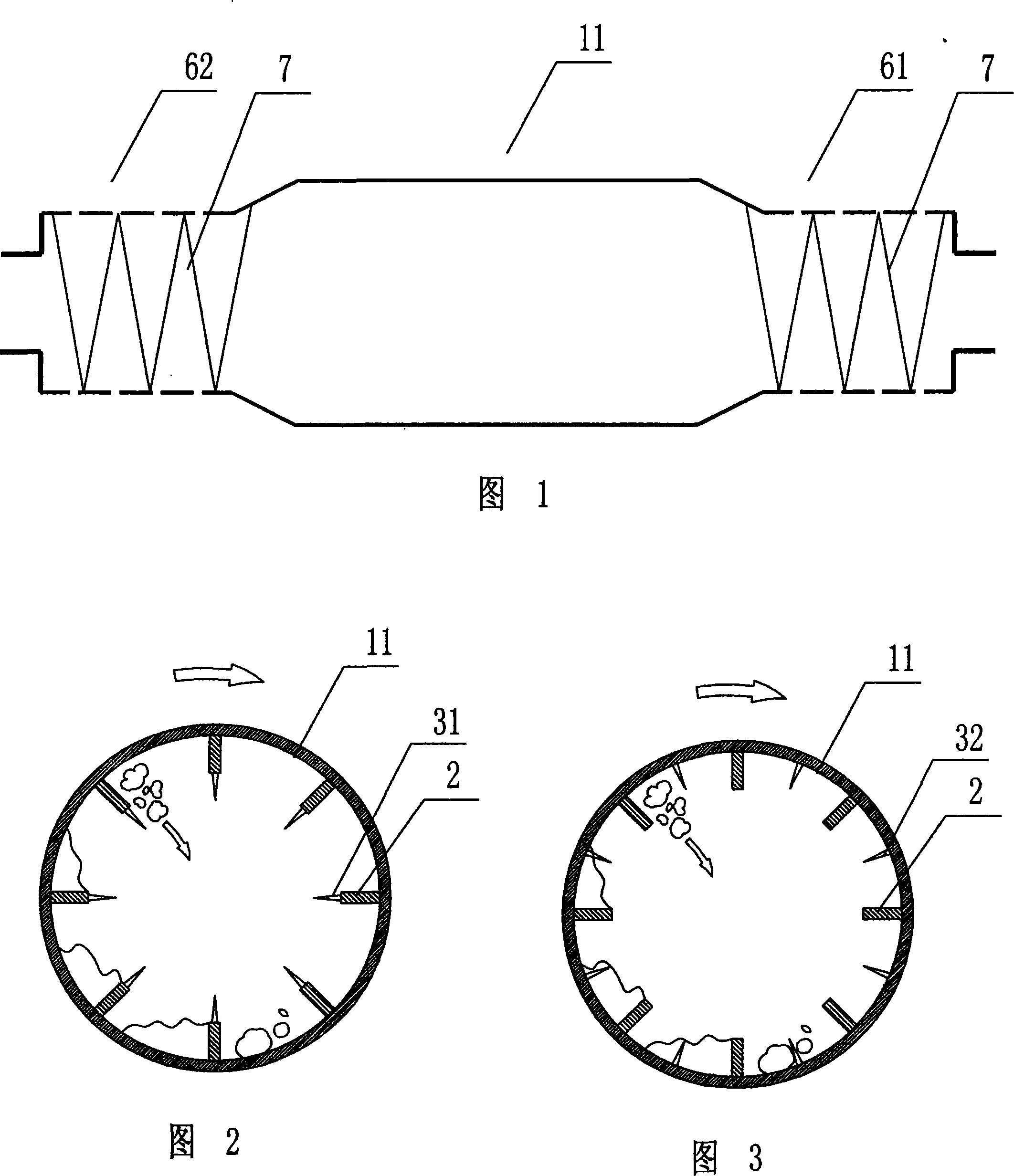

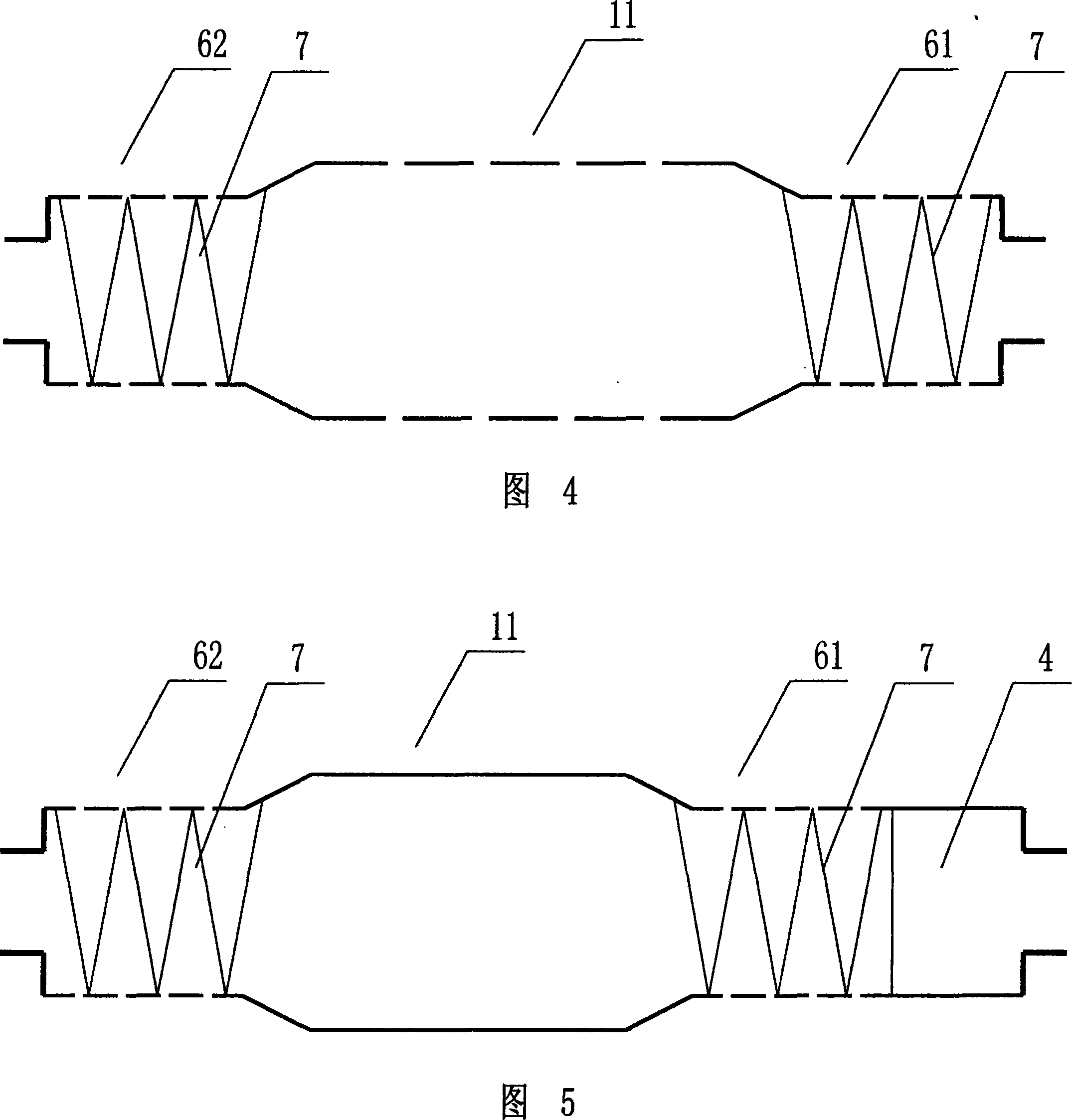

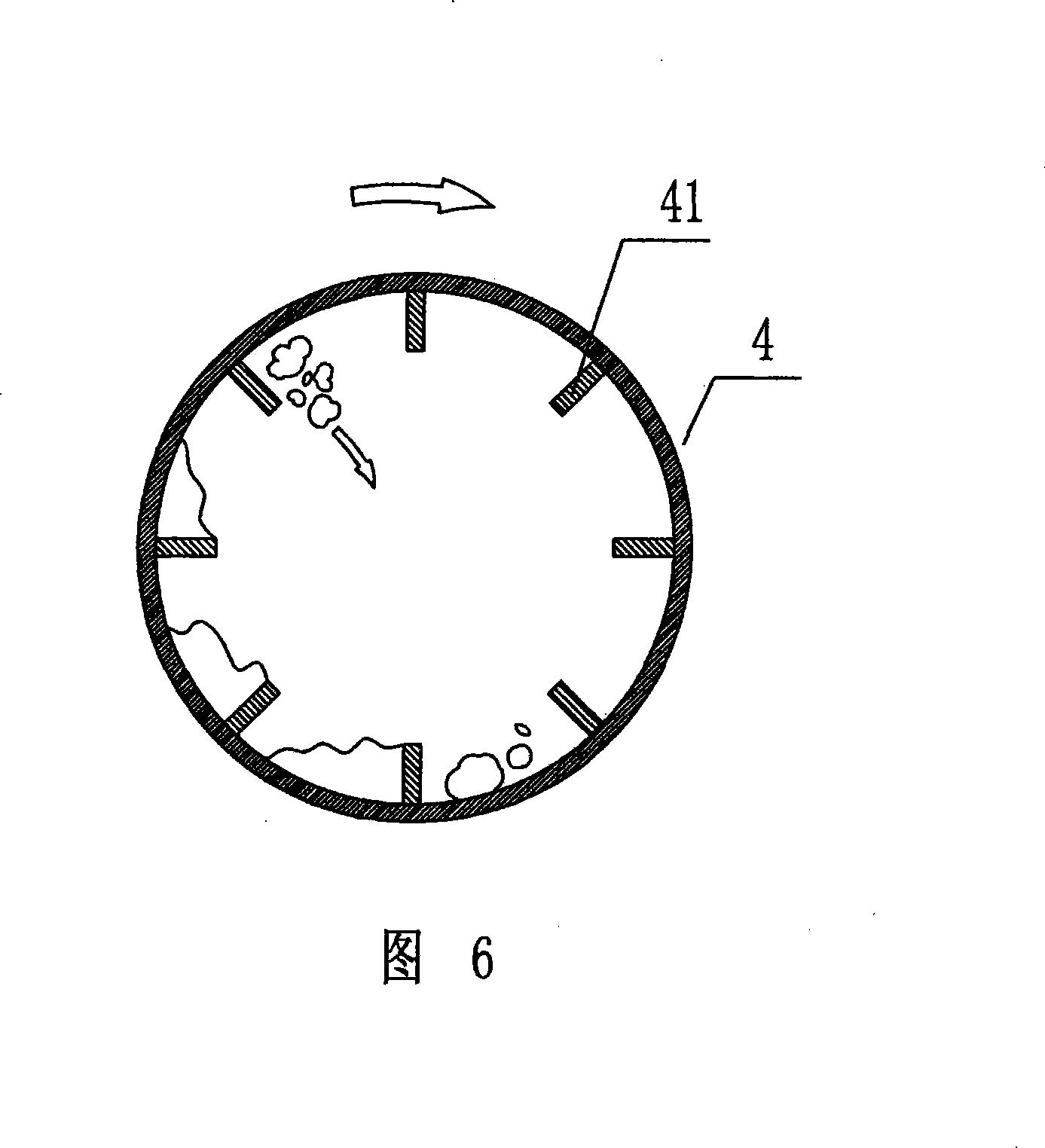

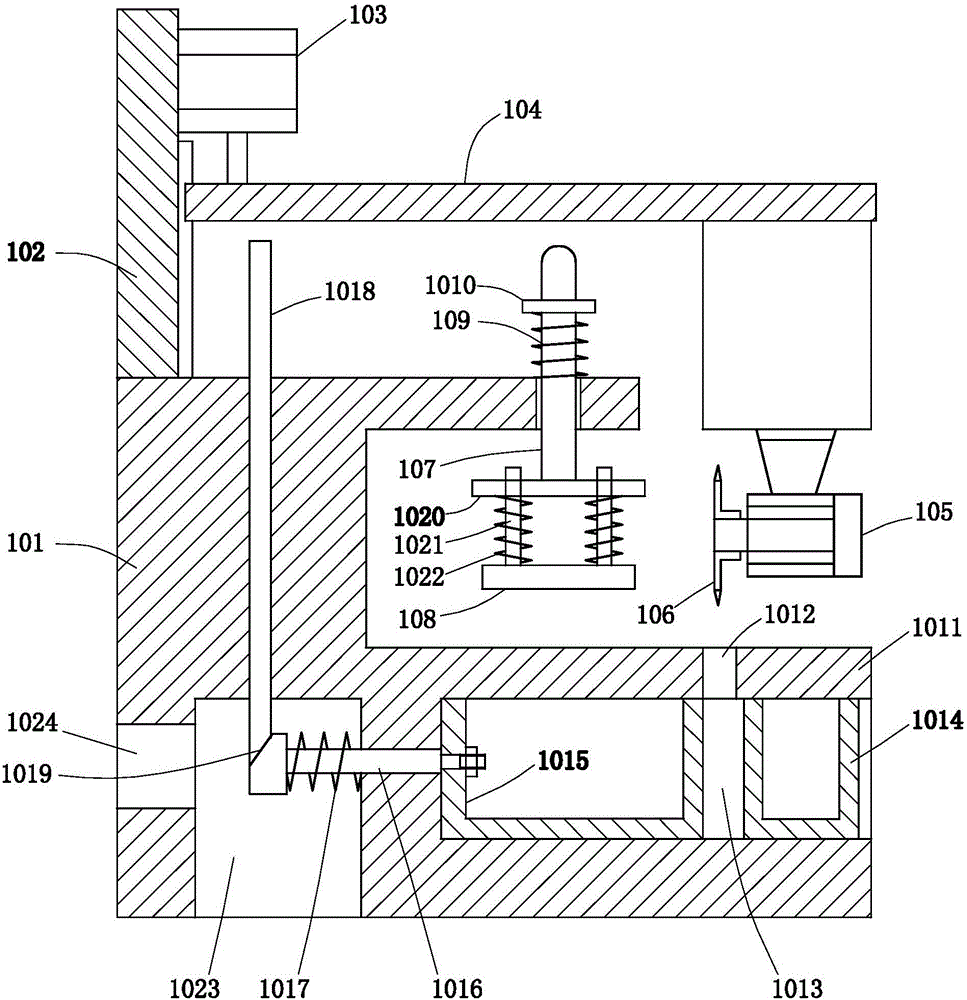

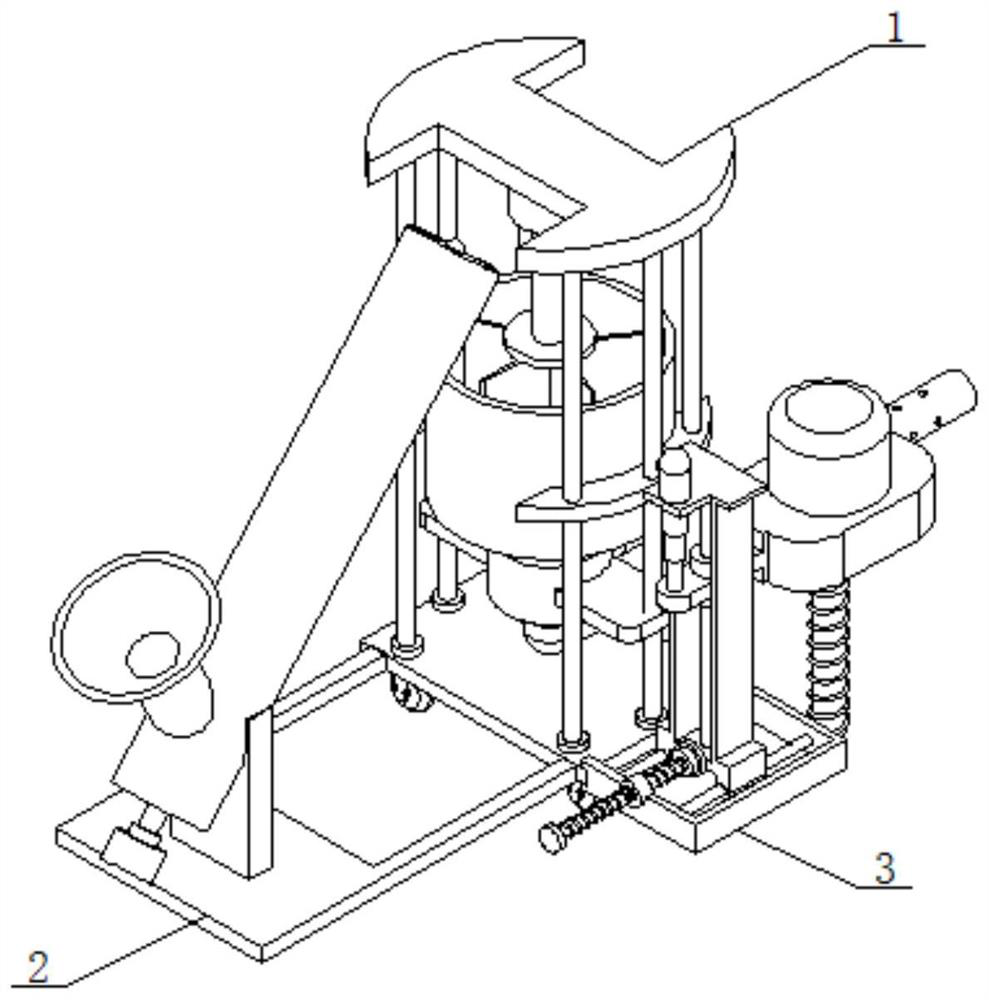

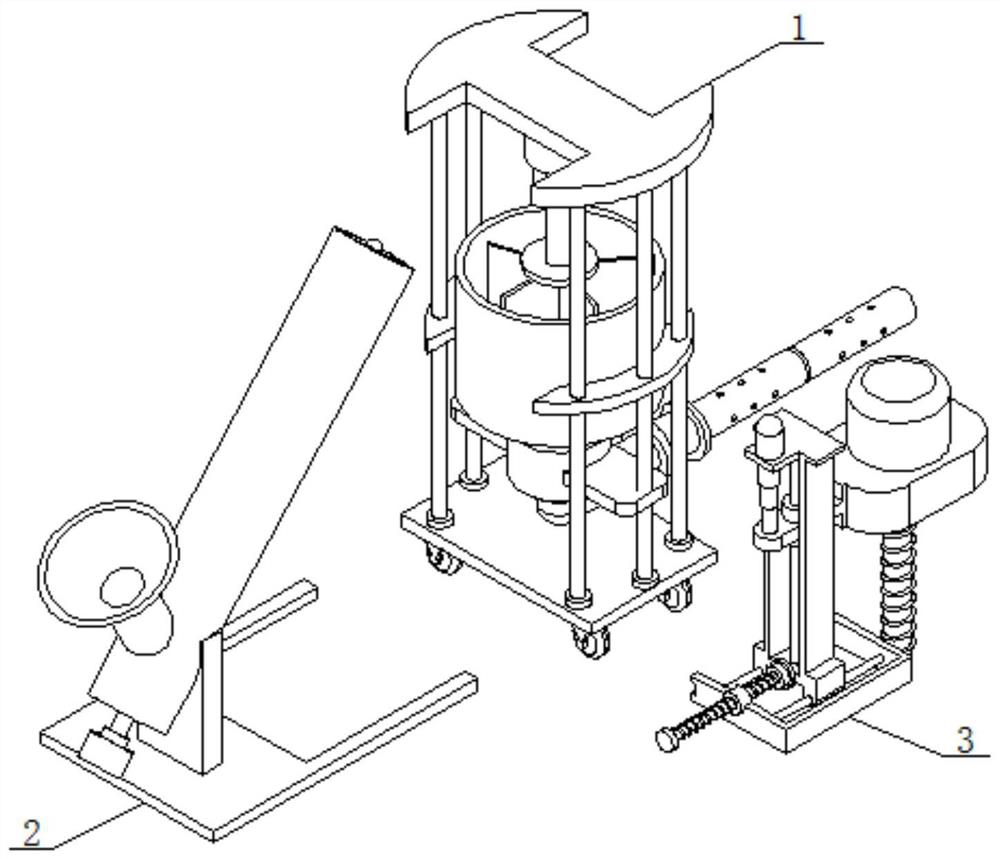

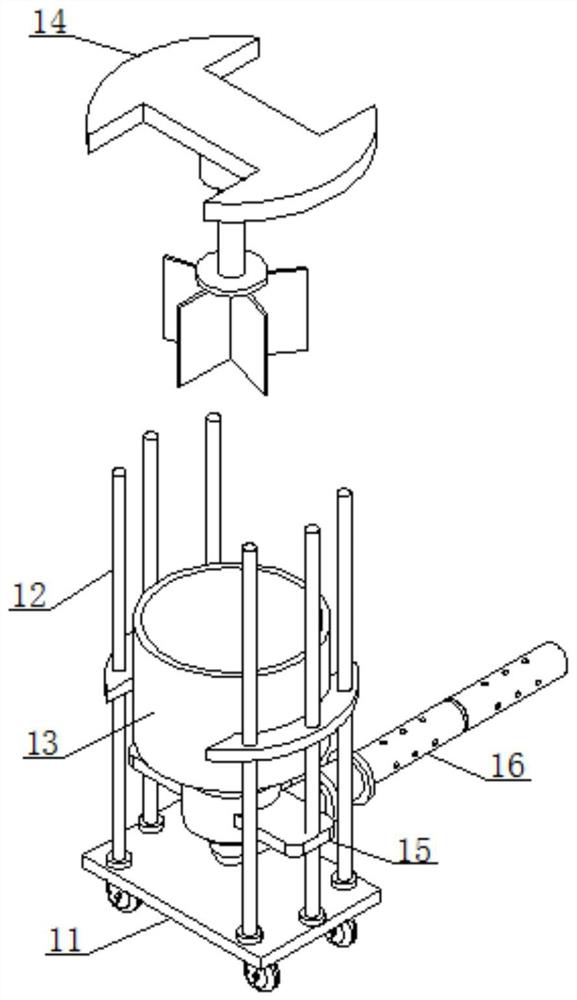

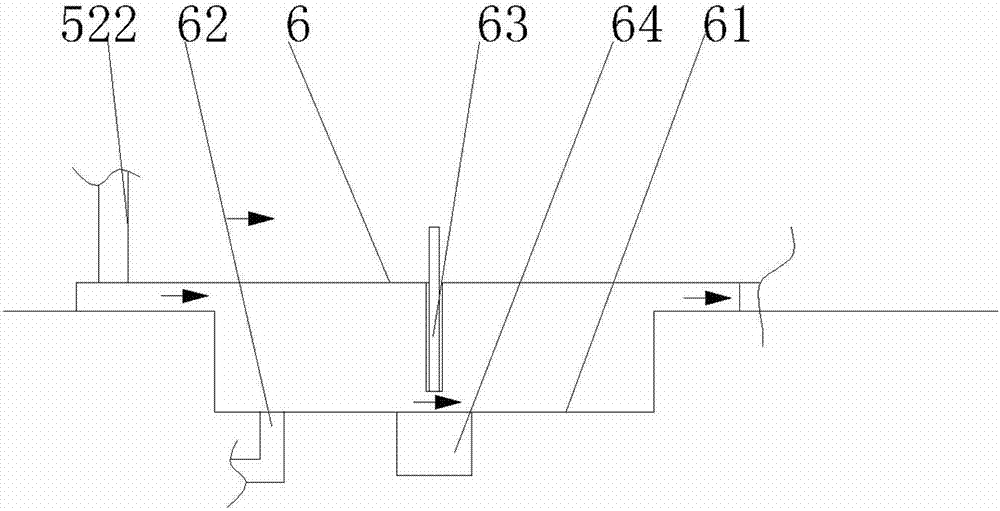

Pulping equipment based on high-pressure water jet and combined type rotor pulping

ActiveCN106522006AEasy to collectPromote fragmentationPaper recyclingRaw material divisionPulp and paper industryHigh pressure water

The invention provides pulping equipment based on a high-pressure water jet and combined type rotor pulping. The equipment mainly comprises a high-pressure water conveying device, a water jet pulping device, a combined rotor pulping device and a pulp generating device. The pulping equipment based on the high-pressure water jet and combined type rotor pulping is characterized in that preliminary pulping of the high-pressure water jet replaces a feed cylinder to inject water, and a mobile smashing knife in the combined rotor pulping device freely adjusts the height and assists in smashing feed. According to the pulping equipment based on the high-pressure water jet and combined type rotor pulping, a pulping blind area at the bottom of the feed cylinder and a 'rotary cake' phenomenon are eliminated through a triangular smashing knife, freely combined non-blind-area and efficient secondary pulp is achieved through the combined rotor pulping device, fast engagement and separation of the rotor and the mobile smashing knife are achieved through special structural teeth, and pulping efficiency is improved and uniform feed smashing is achieved through high-pressure exhaust pipes and conical holes which are distributed circumferentially evenly and in a dispersed mode of an arithmetic progression.

Owner:UNIV OF JINAN

Roller screening pulp kneader

The invention discloses a drum screening pulp kneader, which comprises a pulp kneader drum, and the pulp kneader drum is divided into a pulping area drum and a screening area drum, a baffle board is arranged on the inner wall of the pulping area drum, and the structure form of the pulping area drum comprises a first screening area drum, a pulping area drum which is fixedly connected with the first screening area and a second screening area drum which is fixedly connected with the pulping area drum in turn. When slurry which is primarily broken is untwined, the pulp is firstly screened by the first screening drum, and acceptable pulp fiber is screened out from raw material, and raw material which is not untwined gets into the pulping drum, a large amount of energy resource is reduced, and raw material which is not untwined is avoided from being coated by the acceptable pulp, and pulping efficiency is greatly improved.

Owner:李风宁

Treatment process and equipment of waste books

ActiveCN106149438AReduce power consumptionEmission reductionPaper recyclingPulp beating/refining methodsPulp and paper industryEnergy consumption

The invention discloses a treatment process and equipment of waste books and belongs to the technical field of waste paper recycling. The treatment process sequentially includes the steps, from top to bottom, of firstly, using an edge-cutting machine to cut off the edges, with glue or iron nails, of the waste books; secondly, using a hydrapulper to crush the waste books obtained after the first step, and using a ink-removing overflow pipe to discharge ink during the crushing; thirdly, using a pulping machine to make the crushed materials into pulp, performing ink removing while stirring during pulping, and discharging the removed ink through an ink discharge pipe; fourthly, using a concentrator to perform concentration; fifthly, storing the concentrated pulp in a pulp storage tank. The treatment process and equipment has the advantages that the process and equipment is simplified, energy consumption is lowered, the discharge of industrial waste liquid is reduced, the pulping efficiency and quality of the waste books are increased, and the process and equipment is widely applicable to waste paper treatment.

Owner:徐州市全鑫毛制品有限公司

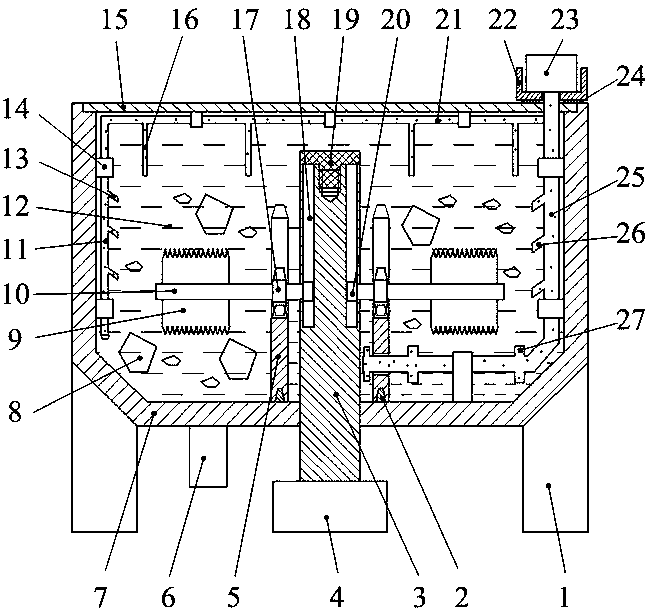

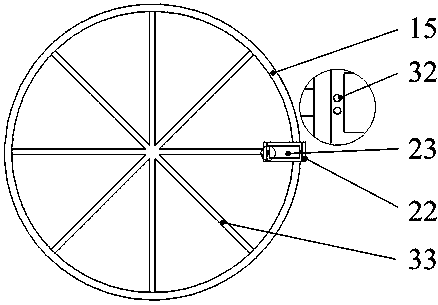

High-speed pulp making device for rare earth mine

ActiveCN107130107AReduce the burden onReduce manufacturing costRotating receptacle mixersShaking/oscillating/vibrating mixersRare earthEngineering

The invention relates to a pulp making device, in particular to a high-speed pulp making device for rare earth mine. The high-speed pulp making device for the rare earth mine comprises a base, an up-down moving device, a plurality of rotating devices, a rotating ball, a plurality of connecting rods, large bearings I, and the like; the rotating ball is arranged on the up-down moving device; the connecting rods are horizontally welded on the surface of the external circumference of the rotating ball; and the rotating devices are horizontally arranged in the external circumference direction of the rotating ball and correspond to the connecting rods. The high-speed pulp making device for the rare earth mine is provided with the up-down moving device and the rotating devices, water and the rare earth mine can be subjected to up-down shaking and rotation, so that high-speed pulp making on the rare earth mine is realized.

Owner:常熟东南高新技术创业服务有限公司

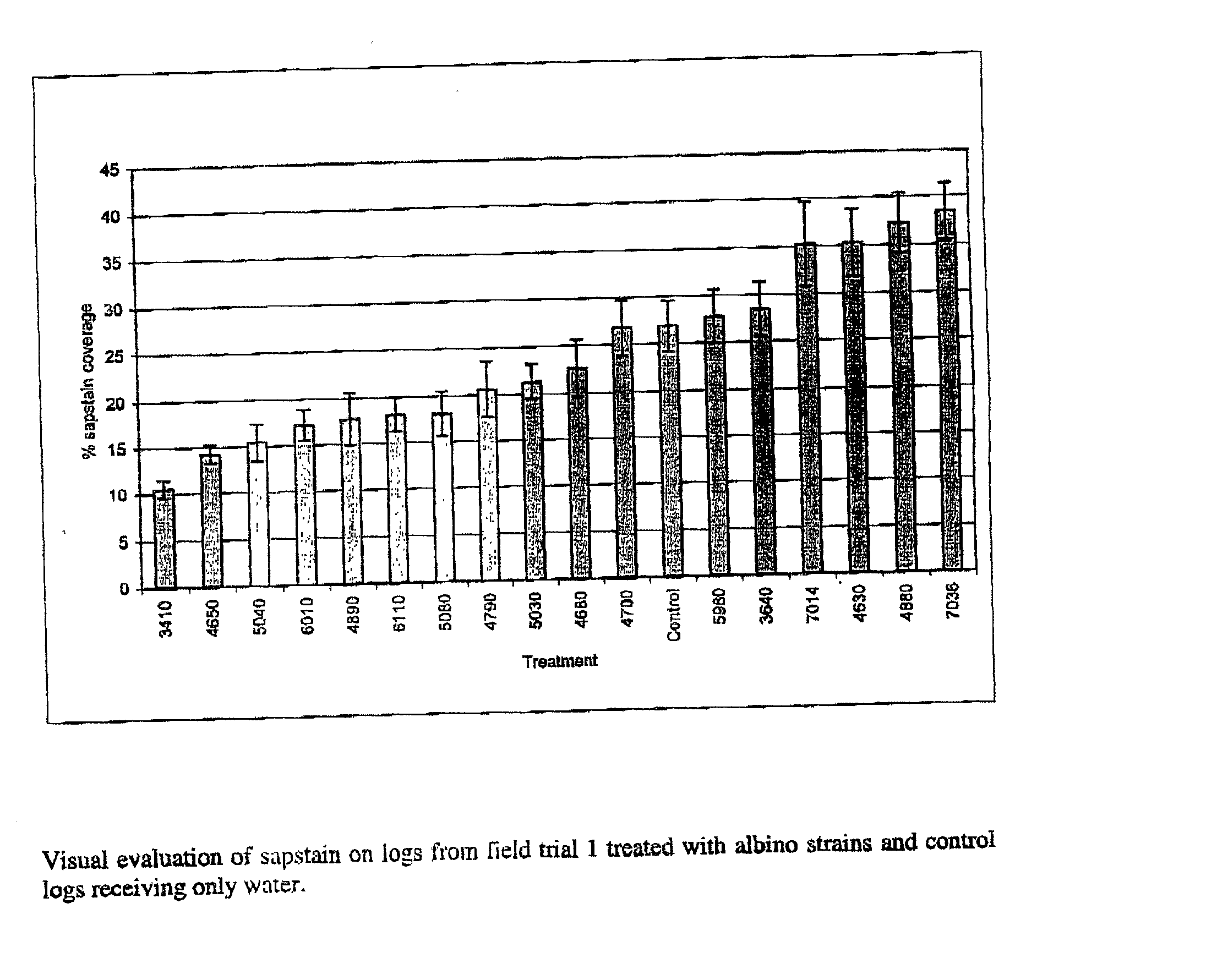

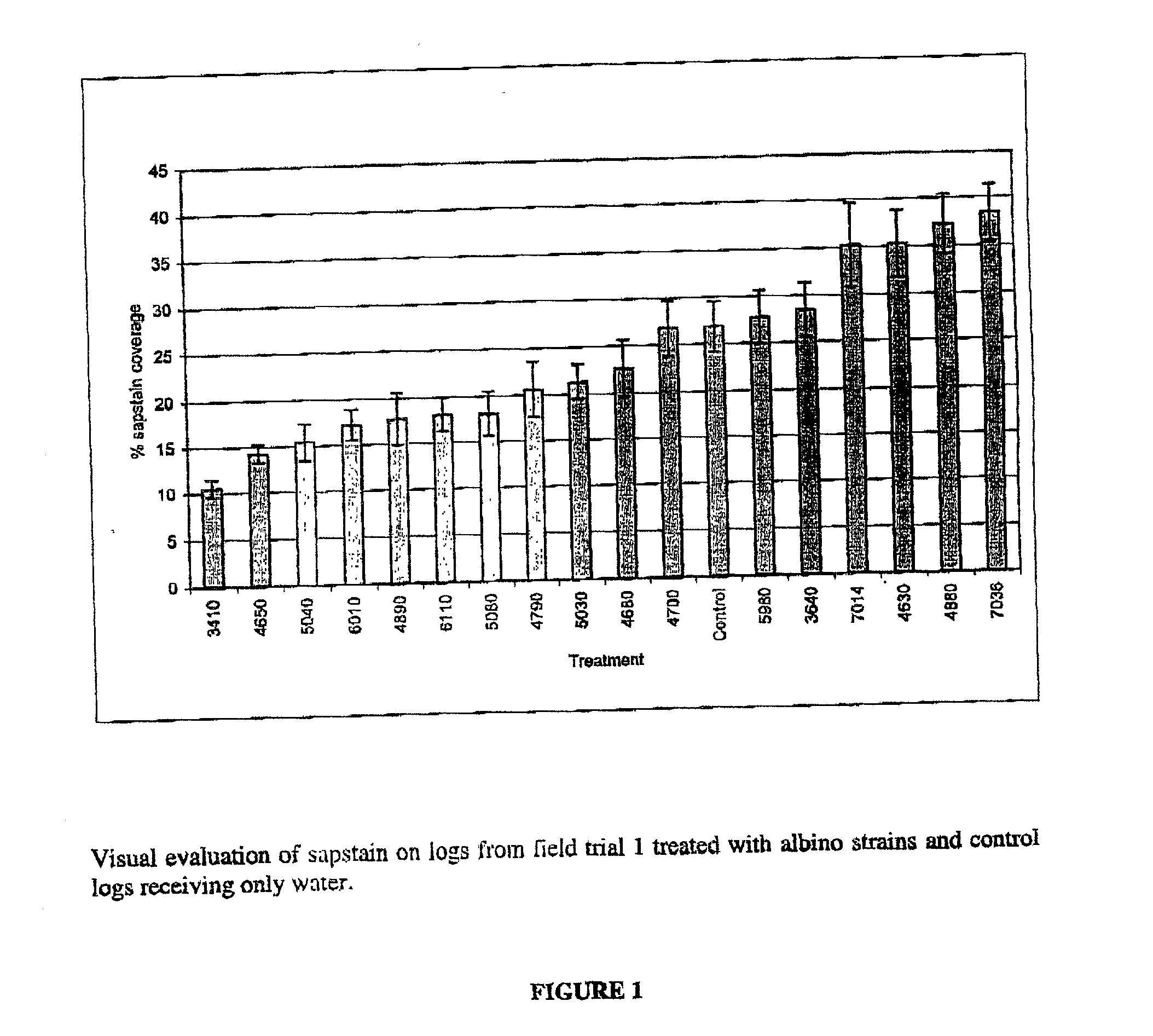

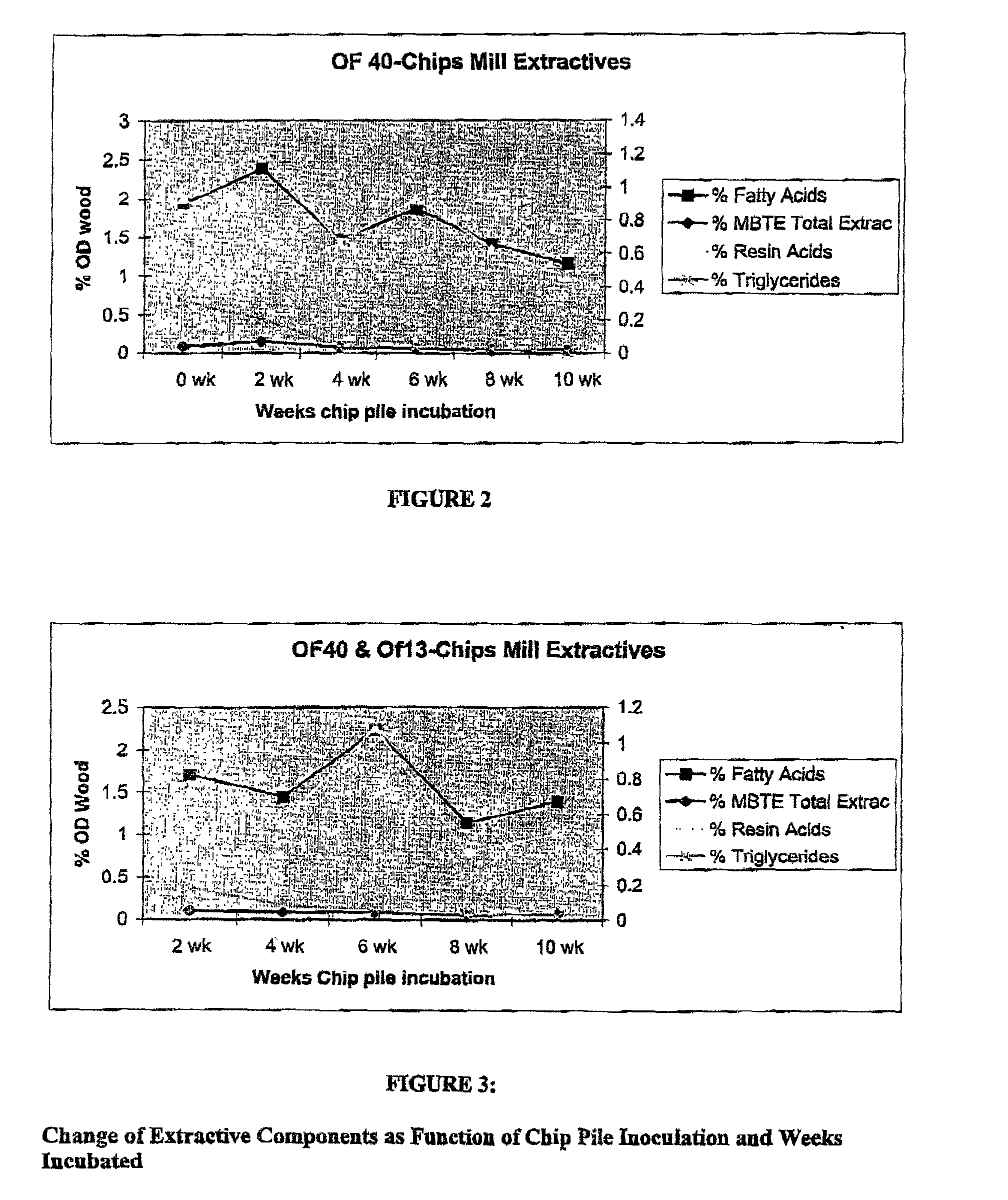

Fungi for improvements of wood and pulp appearance and qualities

InactiveUS20020096273A1Promote resultsIncrease brightnessFungi productsMicroorganismsOphiostoma floccosumBiology

The invention relates to the use of fungi stains of Ophiostoma floccosum, Ophiostoma piceae or Ophiostoma pluruanulatum, or mixtures on wood and pulp to improve chemical pulping processes and / or reduce cooking tie and / or improve brightness and / or decrease extractives.

Owner:UNIVERSITY OF WAIKATO

Geotechnical engineering grouting process and geotechnical engineering grouting device

PendingCN111810195AImprove pulping efficiencyReduce processConstructionsUnderground chambersSoil scienceDrilling machines

The invention discloses a geotechnical engineering grouting process and a geotechnical engineering grouting device. The geotechnical engineering grouting device comprises a grout producing structure,a conveying structure and a drilling structure, wherein the grout producing structure comprises a movable plate, a stirring structure, a grouting pump and a guide structure; supporting columns are vertically welded to the top face of the movable plate; a stirring barrel is vertically fixed among the supporting columns; the stirring structure is horizontally arranged on the top faces of the supporting columns; the bottom end of the stirring barrel is connected with the grouting pump in a penetrating mode through a guide pipe; the guide structure is installed at the discharge end of the groutingpump; the conveying structure is installed on one side, away from the guide structure, of the movable plate; and the drilling structure is installed on the front part of the side end face of the movable plate. The geotechnical engineering grouting device can integrate a drilling machine, the grouting pump, a conveying pipe and a grout nozzle, thereby facilitating grouting, reducing the grouting process and procedures and improving the grouting efficiency and effect.

Owner:福建岩土工程勘察研究院有限公司

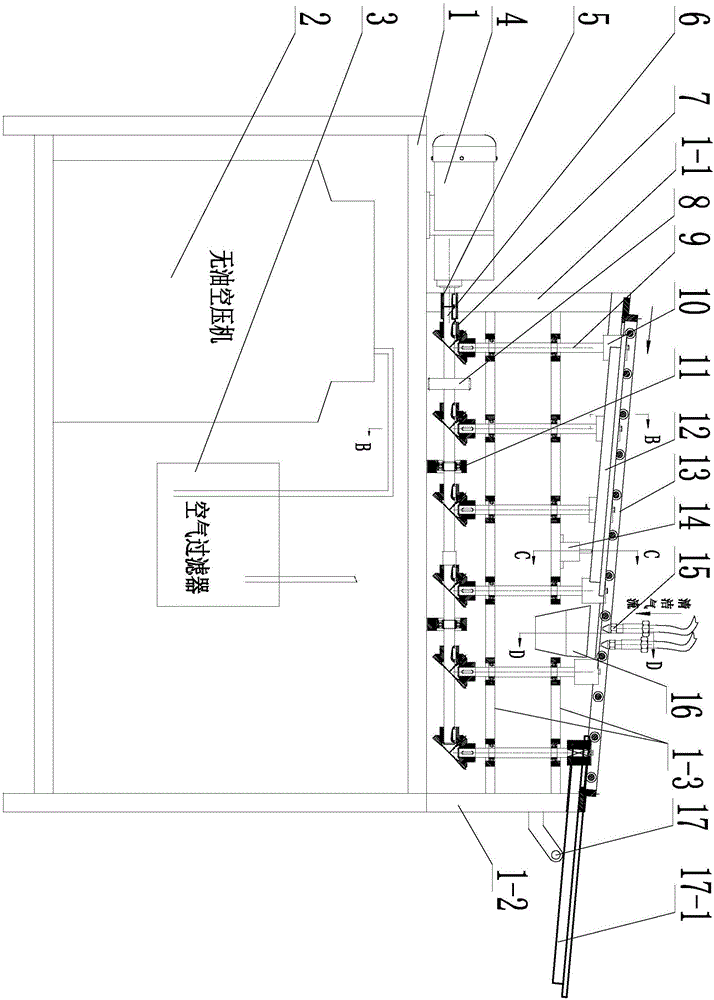

Pulper with automatic paper and plastic separating function

InactiveCN104711882AEasy to operateReduce resistancePaper recyclingRaw material divisionMolded pulpElectricity

The invention relates to a device for pulp repulping devices in the paper making industry, in particular to a pulper with an automatic paper and plastic separating function. The pulper with the automatic paper and plastic separating function conducts repulping on poor-quality paper in the papermaking process and is characterized by comprising a cylinder, a motor arranged below the cylinder, a stirring cutter device arranged at the bottom of the cylinder and a reduction gearbox arranged between a rotating shaft of the stirring cutter device and the motor, wherein an annular sediment settling groove is formed in the bottom of the cylinder and used for settling and collecting of heavy impurities, a sediment discharge port is formed in the bottom of the sediment settling groove, a water inlet is formed in the lower portion of the cylinder, the water inlet is located below the stirring cutter device, an annular feeding port is formed in the upper portion of the cylinder, multiple louver filtering and screening sheets are evenly distributed on the annular discharging port, and an annular material collecting bag is arranged outside the annular discharging port and connected with a light flotation device. By the adoption of the devices, the pulper with the automatic paper and plastic separating function can achieve automatic separation of paper and plastic and flotation of light impurities and is convenient to operate, small in resistance, high in pulping efficiency, small in power and free of electricity consumption.

Owner:侯俊民

Self-lifting rotary mixing and air flow impact type pulp breaking pulping equipment

InactiveCN108252139ARealize broken decompositionPlay a local stirring rolePaper recyclingRaw material divisionPulp and paper industryHigh pressure

The invention provides self-lifting rotary mixing and air flow impact type pulp breaking pulping equipment, which mainly comprises a pulp generating device consisting of a material cylinder and a cylinder cover, a self-lifting rotary mixing device, and an air flow impact pulp breaking device; the self-lifting rotary mixing device is composed of a gear cylinder, a spindle, a slide block, a cross rod, a gear and a flow disturbing plate; the air flow impact pulp breaking device is composed of a compressor, a branch pipe A, a branch pipe B and a branch pipe C; the self-lifting rotary mixing deviceand the air flow impact pulp breaking device are installed on the middle part and the inner wall of the pulp generating device. The pulping equipment is featured by that flow disturbing plate is rotated while vertically fluctuated and revolved to mix and pulp is broken by high pressure air impact. Through the gear cylinder and the flow disturbing plate of the self-lifting rotary mixing device, the all orientation mixing is realized; through the branch pipe A, the branch pipe B and the branch pipe C in the air flow impact pulp breaking device, the assistant impact breaking by air flow is realized.

Owner:UNIV OF JINAN

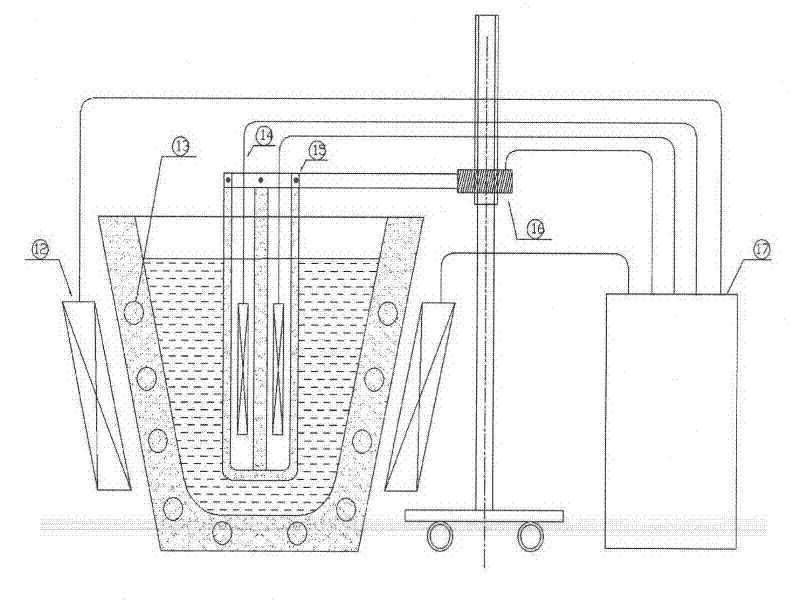

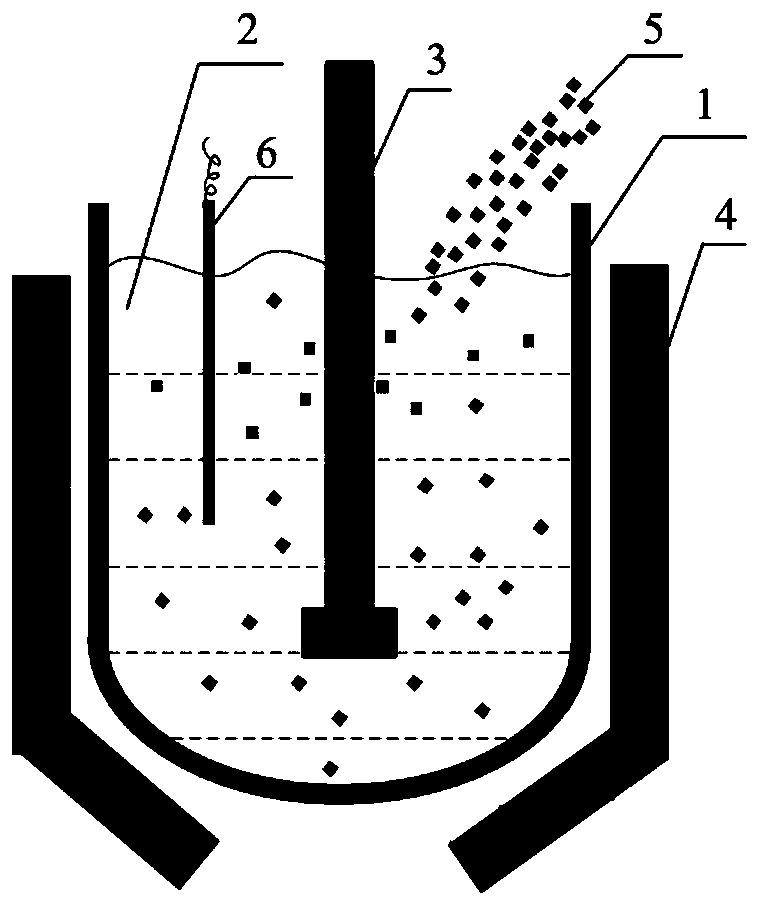

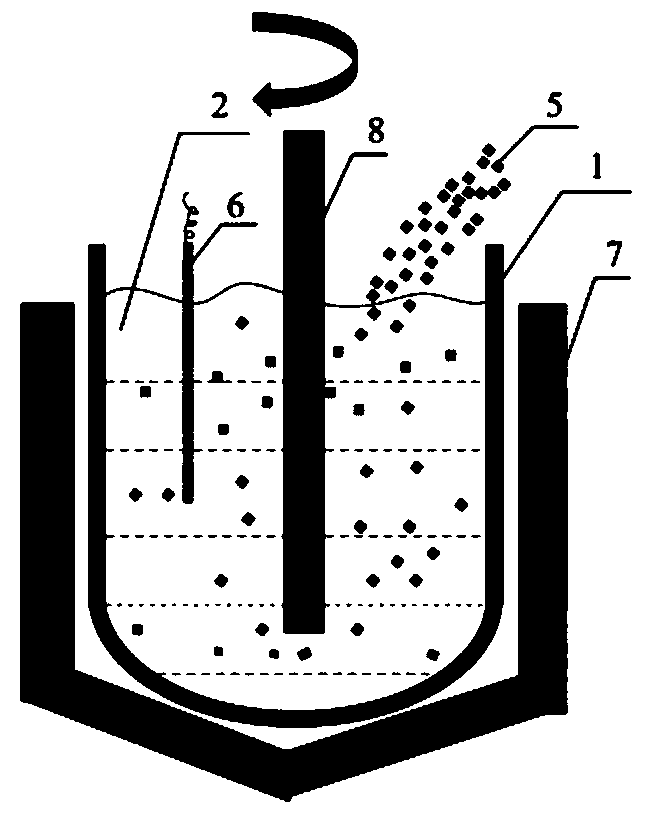

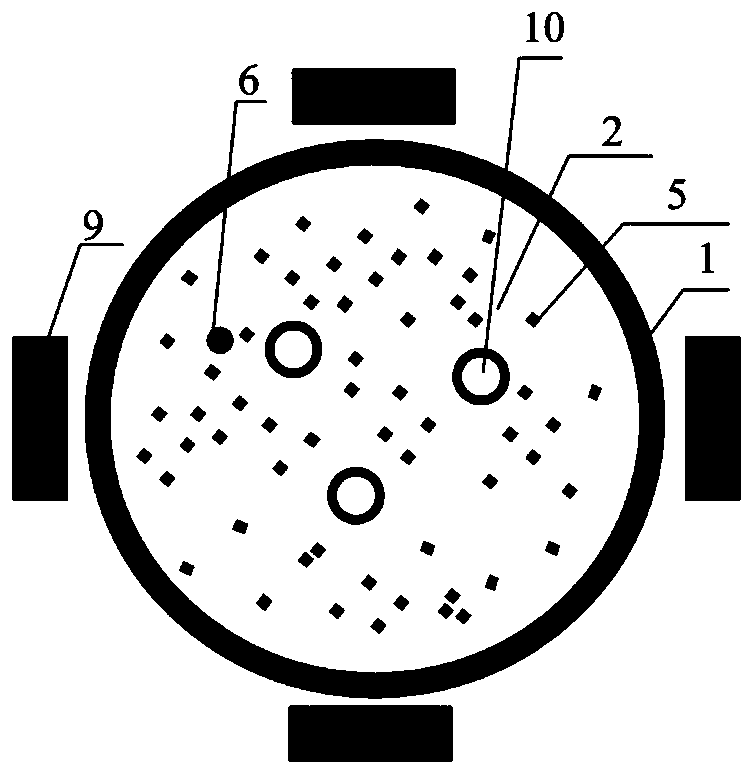

Method for efficiently preparing large-volume semi-solid thick liquid through compounding process

The invention relates to a method for efficiently preparing a large-volume semi-solid thick liquid through a compounding process. The method comprises the following steps that a large-volume alloy melt in a container is stirred, meanwhile, in order to enable the alloy melt of the edge part to be sufficiently stirred to avoid adhering materials and quickly cooling the melt, the melt disturbance andthe particles of the same alloy composition are added in the alloy melt on the outer wall of the container, so that the purpose of rapidly and uniformly melting a component field and a temperature field and rapidly cooling is achieved. According to the compounding process, when the melt falls to a preset semi-solid temperature, the treating is stopped, the large-volume semi-solid thick liquid with a solid phase rate of 20%-60% is obtained, and the thick liquid is sent to a forming device for rheoforming. The method solves the problem that when the large-volume semi-solid thick liquid is prepared by a single process, the structure is not uniform, the edge of a crucible is adhered due to insufficiently stirring or disturbing, and the cooling of the melt is slow; and the process is strong incontrollability and good in industrialization prospect, and is particularly suitable for preparing the large-volume semi-solid thick liquid with the weight of more than 10 kg.

Owner:UNIV OF SCI & TECH BEIJING

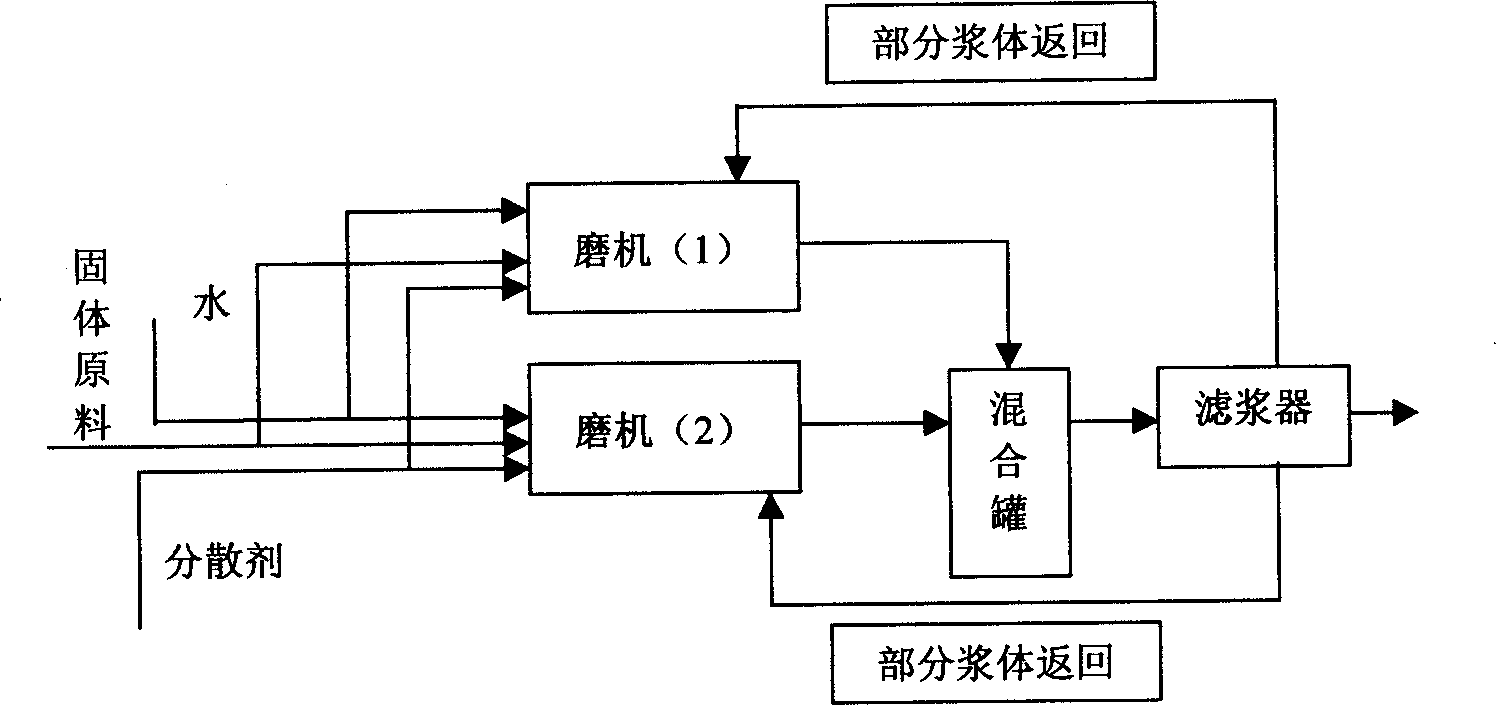

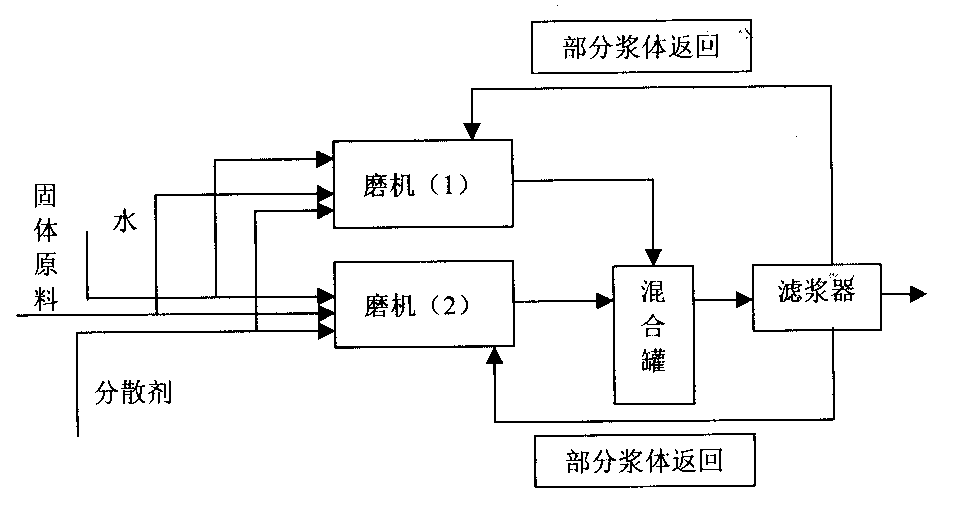

Process for preparing slurry with wide granularities distribution by parallel grinders

InactiveCN1356175AWide particle size distributionIncrease concentrationLiquid carbonaceous fuelsGrain treatmentsHigh concentrationGranularity

A process for preparing slurry with wide range of granularities by parally grinders includes pre-crushing raw solid material, proportionally mixing it with water, adding disperser, respectively grinding in vibration grinder and ball grinder, filtering the slurry discharged from vibration grinder, and mixing it with the slurry discharged from ball grinder. Its advantages include wide granularity distribution, and high concentration and stability.

Owner:SURFACE & INTERFACE CHEM ENG TECH RES CENT NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com