Control method for making soybean milk of soybean milk machine

A control method and technology for a soymilk machine, which are applied in the directions of preventing overflow, household appliances, and applications, can solve the problems of soymilk machine overflow, high motor power and heat generation, and high energy consumption of the whole soymilk machine, so as to reduce power consumption and reduce overall consumption. The effect of machine energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

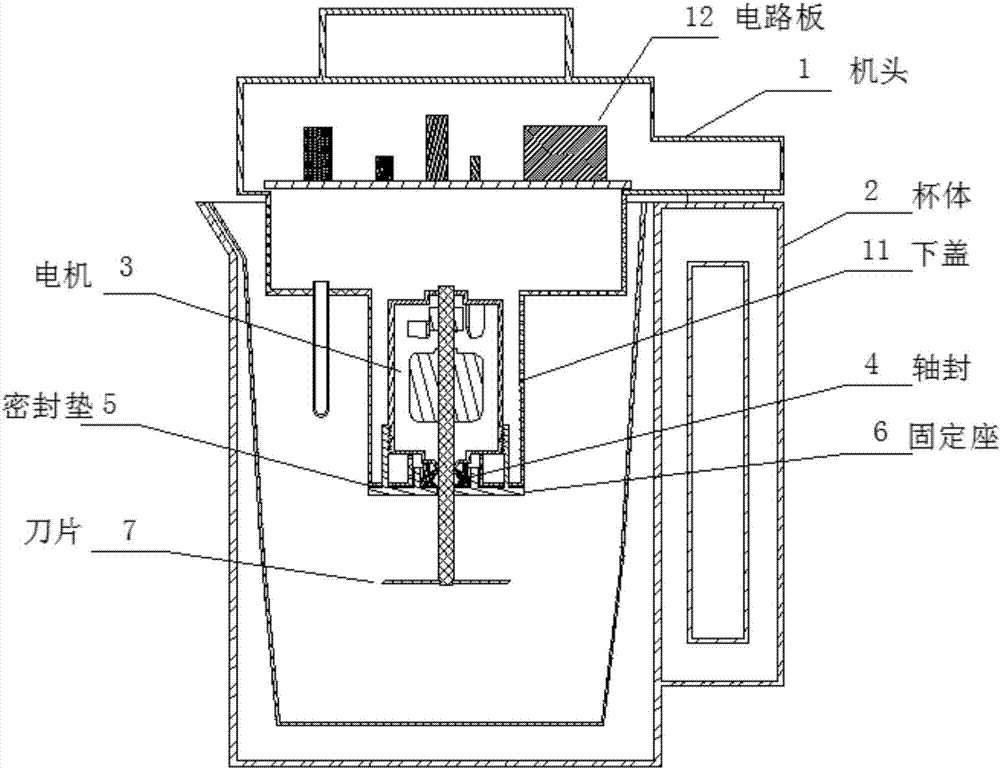

[0065] A pulping control method for a soymilk machine, such as figure 1 As shown, the soybean milk machine can include a head 1 and a cup body 2, the head 1 includes: a lower cover 11 and a circuit board 12, and the lower cover 11 of the head 1 is provided with a motor 3, a shaft seal 4, a gasket 5, Blade 7; a fixed seat 6 is arranged under the motor 3, and the fixed seat 6 is located on the outer surface of the machine head and can directly contact the slurry. The pulping process includes: preheating stage, pre-crushing stage, crushing stage and boiling stage; The working stages include: pre-crushing stage and crushing stage, such as figure 2 As shown, the method includes step S101:

[0066] S101. Adjust the speed of the motor according to different stages in the pulping process to control the heating of the motor, and transfer the heat generated by the heating of the motor to the slurry through the fixing seat, so as to heat the slurry during the working stage of the motor...

Embodiment 2

[0087] This embodiment provides the specific control scheme of the pre-grinding stage in the first embodiment.

[0088] Optionally,

[0089] The first speed n1 satisfies: 1 / 3~1 / 2 of the rated speed;

[0090] The second speed n2 satisfies: 1 / 4~1 / 5 of the rated speed;

[0091] The first running times a includes: 3 to 5 times;

[0092] The first running time t1 includes: 15-20 seconds;

[0093] The time interval of each operation includes: 5-10 seconds.

[0094] In the embodiment of the present invention, the rotation speed of the motor in the pre-crushing stage is set according to the maximum rotation speed of the motor and the anti-overflow signal. In the pre-crushing stage, the motor is in the low-speed working stage, and the selection range of the first speed n1 of the motor can include 1 / 3 to 1 / 2 of the highest speed (rated speed) of the motor, and the low-speed work of the motor can be divided into 3-1 / 2. 5 runs, each running time can be 15-20 seconds, and run once every...

Embodiment 3

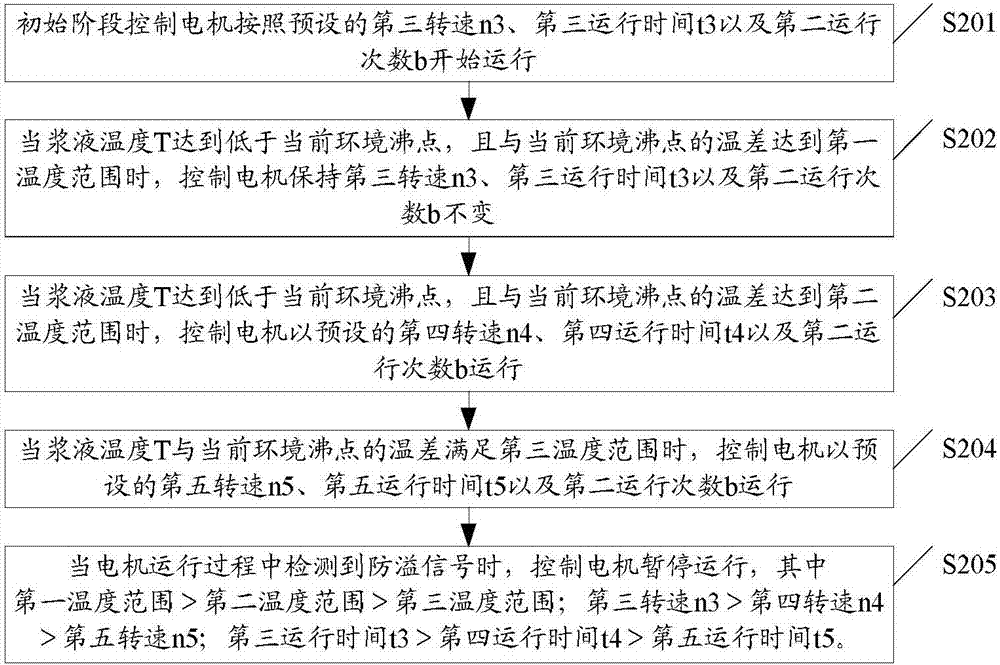

[0097] This embodiment provides the specific control scheme of the crushing stage in the first embodiment.

[0098] Optionally, the first temperature range includes: 3-5°C;

[0099] The second temperature range includes: 1-3°C;

[0100] The third temperature range includes: -1°C to 1°C;

[0101] The third rotational speed n3 includes the rated rotational speed;

[0102] The fourth speed n4 satisfies: 1000-3000 RPM below the rated speed;

[0103] The fifth rotational speed n5 satisfies: 1000-3000 RPM below the fourth rotational speed n4;

[0104] The third running time t3 includes: 15 seconds to 20 seconds;

[0105] The fourth running time t4 satisfies the following equation: Wherein, Δt3 is the time length during which the motor operates at the third rotational speed n3;

[0106] The fifth running time t5 satisfies the following equation: Among them, Δt4 is the length of time for the motor to run at the fourth speed n4;

[0107] The second running times b includes: 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com