Fungi for improvements of wood and pulp appearance and qualities

a technology of appearance and quality, applied in the field of fungi for improving the appearance and quality of wood and pulp, can solve the problems of loss of value in timber products, detrimental properties of wood products, and timber industry derives from staining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0097] Results

[0098] Surprisingly not all of the albinos had the same effect for prevention of stain. This was an unexpected and unobvious result as previously it was considered that any albino or white fungus, or almost albino would constitute a biocontrol effect on wood, and prevent staining fungi from staining the wood, Successful competitive albino fungi were judged as those with less than 0.5 stain score on their own, and that maintained a stain score when challenged with one of the staining fungi, in this example Leptographium or Diplodia (Sphaeropsis sapinea) of 1 or less than 1. As shown in the results, the preferred organisms were F71, F80, F93 (all albinos, with regard to hyphae but not with regard to synnemata, of Ophiosotoma floccosum), OPC 703, 422 (albinos, with regard to hyphae but not with regard to synnemata, of the species Ophiostoma piceae) and 3410 and 7073 (albinos, with regard to hyphae but not with regard to synnemata, of the species Ophiostoma pluruanulatum)....

example 2

[0101] Results

[0102] There is a variety of responses of the albino fungi to these diagnostic tests. Not all the albinos have the same characteristics.

Example 3

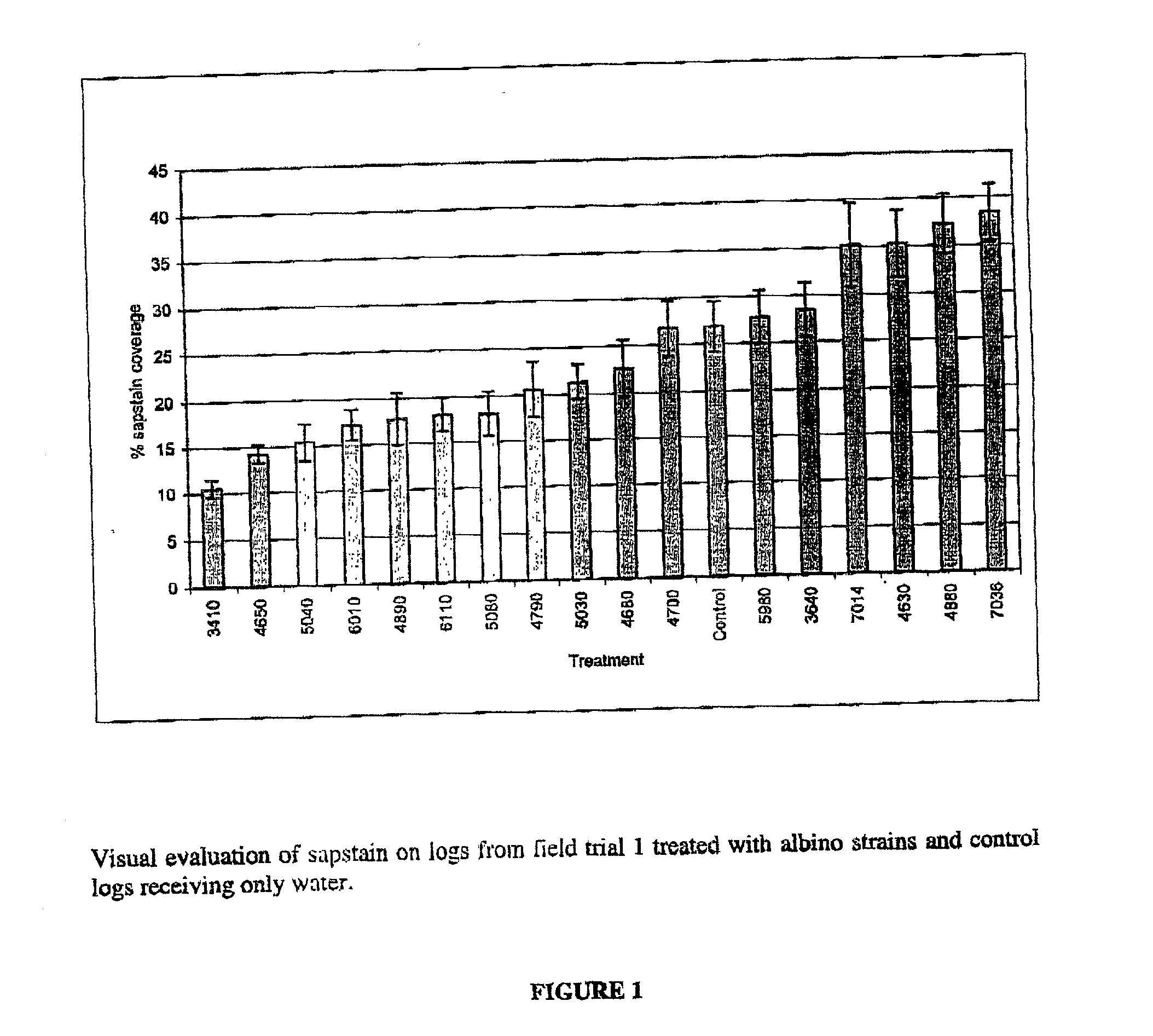

[0103] Field Results on Solid Logs with Albino Inoculation

[0104] Albino fungi were grown in liquid cultures of growth media consisting of sufficient carbon, nitrogen and trace elements and vitamins to promote cell biomass accumulation (standard and non-standard mycological media are acceptable), either used in the spent growth media, or harvested by centrifugation and resuspended in water or buffer, with or without washing, were sprayed onto radiata pine logs, Either a pure single strain or more than one strain can be used simultaneously or consecutively. The typical cell concentration of the fungus in spent media, water or buffer was from 10e2 to 10e6 colony forming units per millilitre. The fungal cell suspensions were applied onto the logs by back-pack spray systems, or commercial sprayers, either variety such as used by co...

example 3

[0105] Results

[0106] Some albinos can have a positive effect on wood quality, biocontrol and keep wood from staining, better than the commercial fungus and better than commercial anti-sapstain chemicals. Some albinos have detrimental effects and increase the amount of stain, therefore not all white fungi behave in the same manner with regard to their effect on wood.

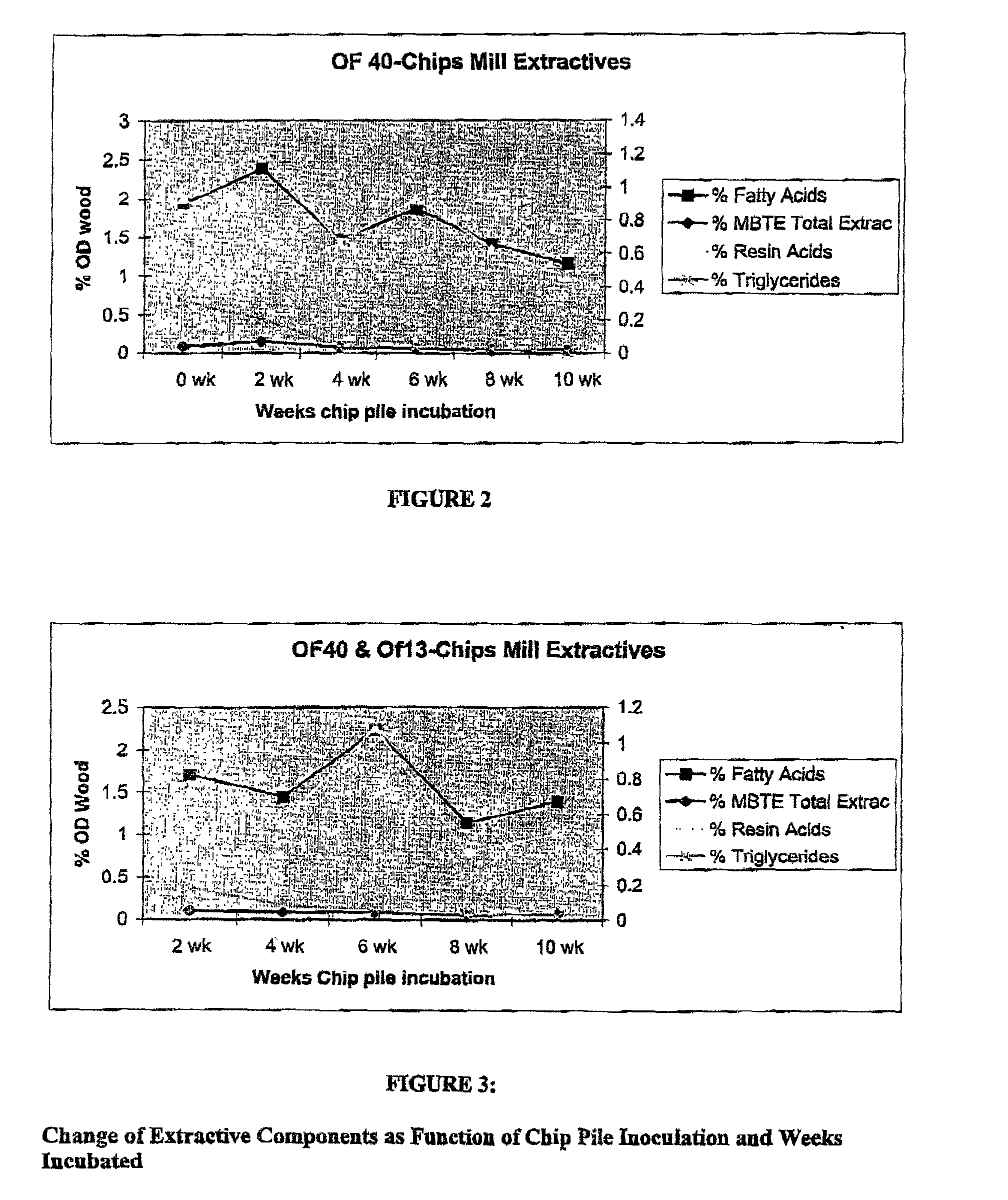

EXAMPLE 4

[0107] Resin Component Degradation

[0108] Solid wood or wood chips, either previously sterilised by gamma irradiation or some other method, or non-sterilised, was treated with more than two dozen albino fungi, a bacteria (for example Pseudomonas resinovorans) or the commercial product Cartapip 97. The inoculated wood was either left to stand at ambient temperature or incubated from 0 degrees Centigrade to plus 65 degrees Centigrade. The wood was analysed anytime from 2 days to 16 weeks, most typically between 1-8 weeks) for full extractive analysis.

[0109] Extractives Analysis

[0110] The wood extractives content of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| OD | aaaaa | aaaaa |

| OD | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com