Automatic grouting production system

A production system and monitoring system technology, applied in chemical instruments and methods, batching weighing instruments, mixing plants, etc., can solve the problems of increasing labor input costs, discontinuous pulping process, and low slurry proportioning accuracy. The effect of improving pulping efficiency, avoiding errors, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

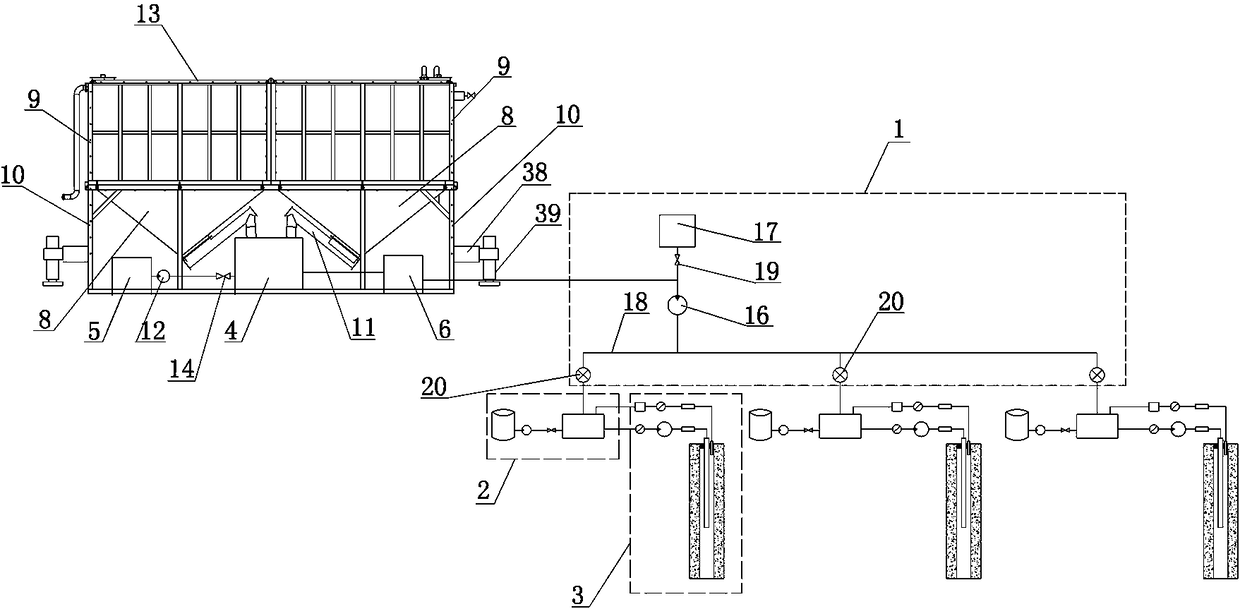

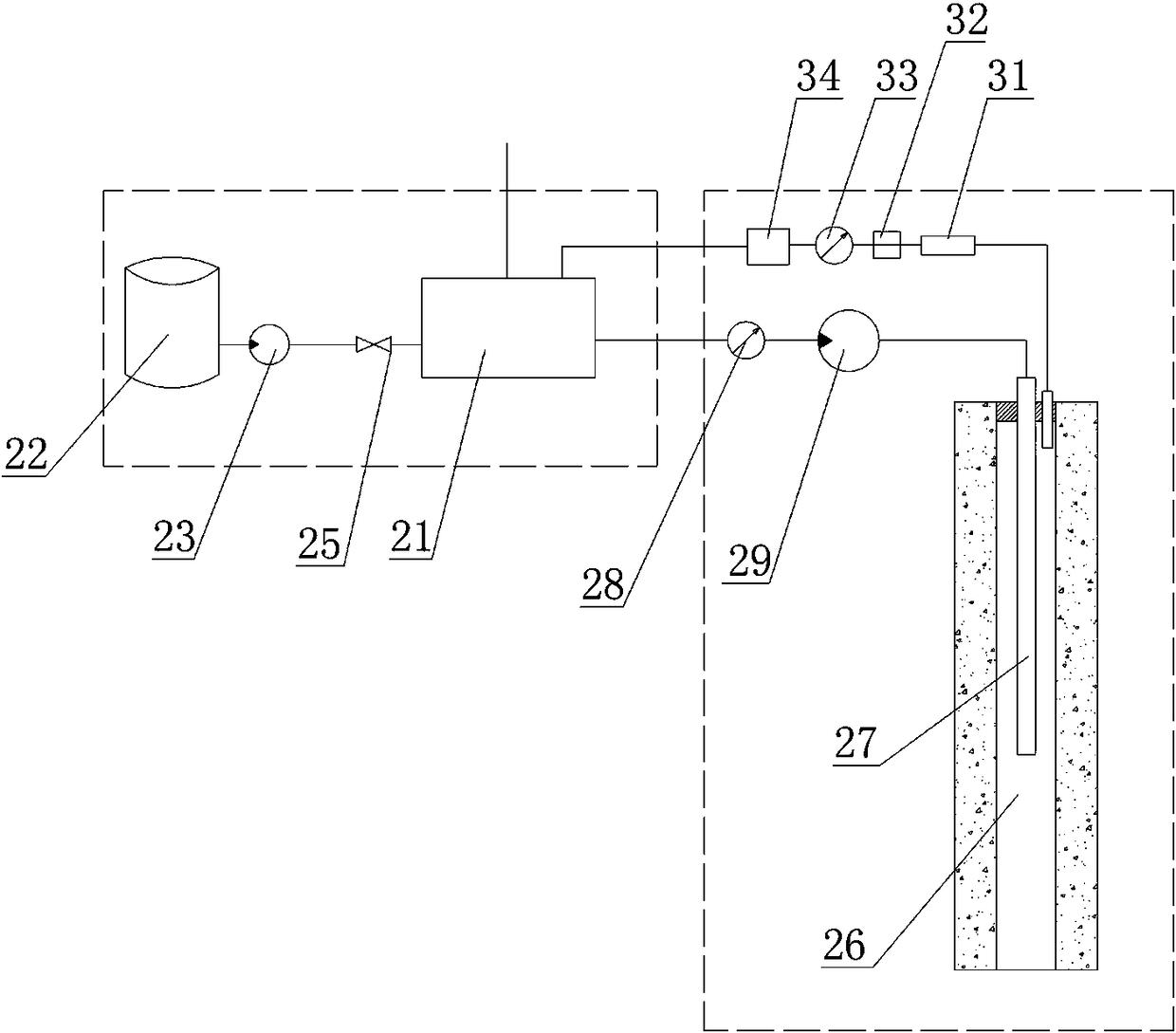

[0020] like Figure 1~3 As shown, a grouting automatic production system, which includes a control system, a pulping station, a slurry delivery system 1, a slurry mixing station 2 and a grouting monitoring system 3;

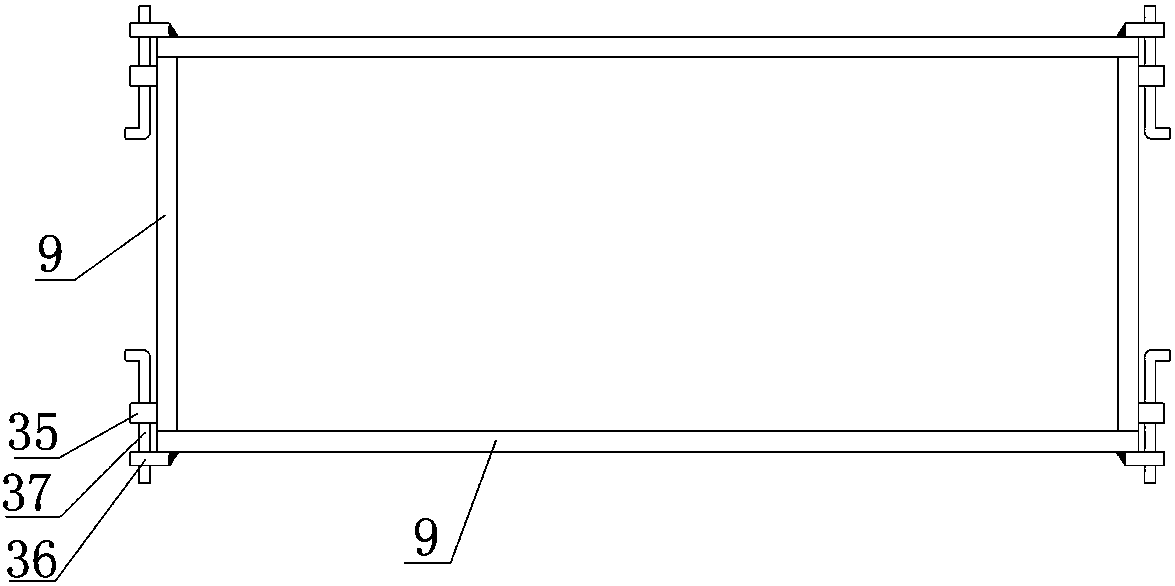

[0021] The pulping station includes a storage tank, a pulping tank 4 arranged below the storage tank, a water tank 5 and a pulp storage tank 6. The storage tank consists of a funnel 8, a shroud 9 and two support frames 10, and the funnel 8 is located at Between the two supporting frames 10, a screw conveying device 11 is arranged between the funnel 8 and the pulping barrel 4, and the four sides of the funnel 8 are hinged with a coaming plate 9 via a hinge seat 40, and the top of the coaming plate 9 is hinged with a cover plate 13, a locking device is provided between two adjacent coami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com