Patents

Literature

231results about How to "Realize continuous preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing graphene by using supercritical fluid

ActiveCN102115078AThe process is simpleLow costBulk chemical productionSingle layer grapheneCvd graphene

The invention discloses a method for preparing graphene by using a supercritical fluid, which relates to the technical field of novel nano materials. The graphene is prepared by repeatedly and circularly treating and cooling graphite powder dispersion liquid. Graphene of less than eight layers, prepared by the method, accounts for 90-95 percent and single-layer graphene accounts for over 10 percent; meanwhile, continuous operation is performed, so that mass production can be realized, and the graphene has the advantages of simple process, nontoxicity and lower cost.

Owner:SHANGHAI JIAO TONG UNIV

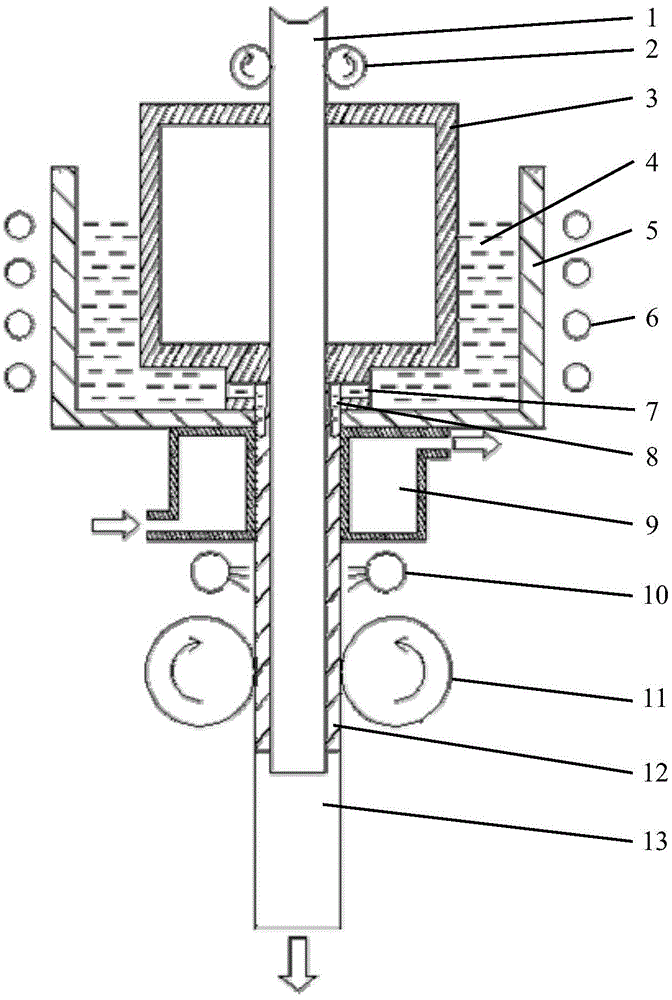

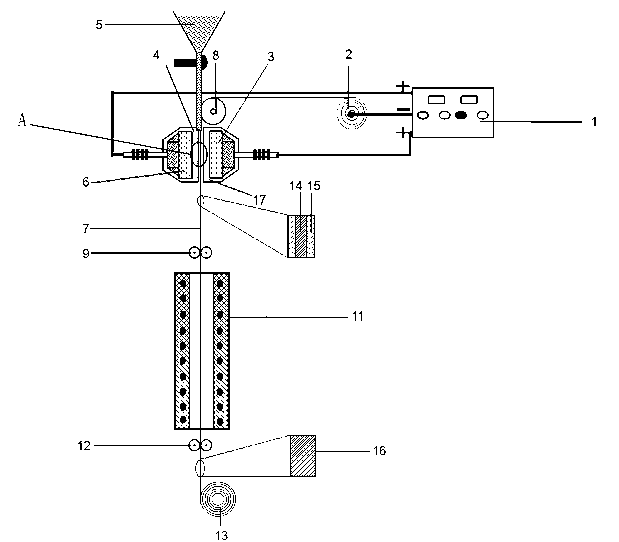

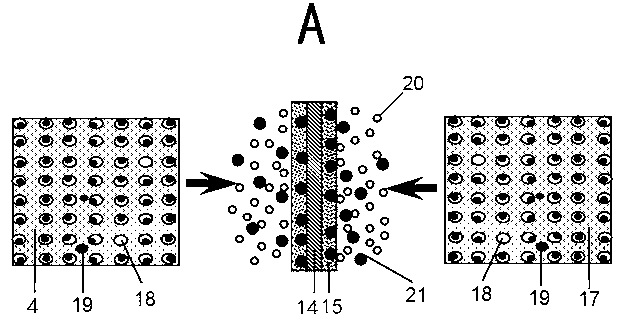

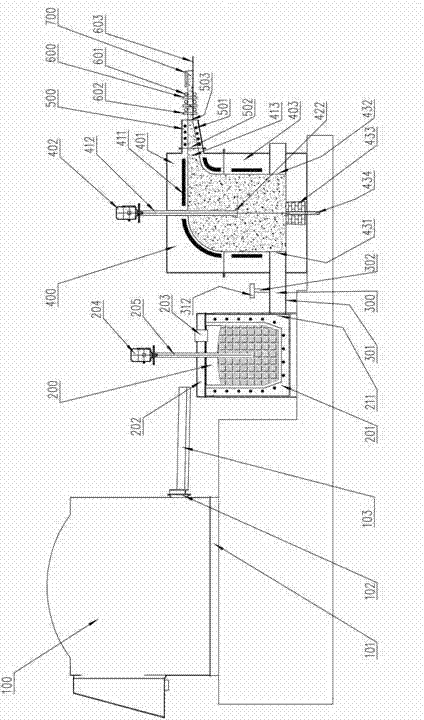

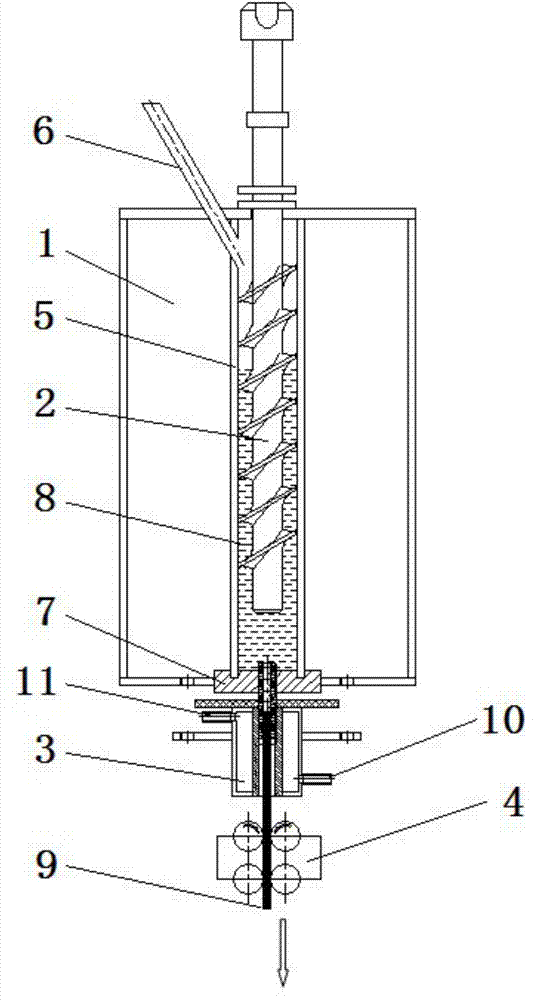

Clad material solid/liquid composite dual-solidification continuous casting and forming equipment and method

The invention belongs to the technical field of clad material continuous casting, in particular to clad material solid / liquid composite dual-solidification continuous casting and forming equipment and method. The clad material solid / liquid composite dual-solidification continuous casting and forming equipment and method are characterized in that inversion solidification and forward solidification continuous casting and forming are combined, the measures that core materials are not heated in advance, an inversion solidification device with small capacity is designed, the core materials are prevented from penetrating through clad layer melt metal for a long time, the melt metal flows out from the bottom of a crucible by relying on self-weight, and the size of the inversion solidification device and the size of a water-cooled crystallizer are controlled effectively are taken, the high quality clad materials of needed shapes and sizes are formed through continuous casting, and the equipment and the method are especially suitable for continuous casting forming of the high quality clad materials with the melting point of the clad layer metal lower than that of the core material metal. The equipment and method have the advantages that the equipment is simple in structure, parts are easy to replace, operation and maintenance are convenient to carry out, layout is reasonable and compact, investment is small, industrialized application and popularization are facilitated, the procedure of the forming process is short, energy is saved, environment is protected, cost is low, the combination freedom of the clad layer metal and the core material metal is large, and the prepared clad materials are good in quality and performance.

Owner:UNIV OF SCI & TECH BEIJING

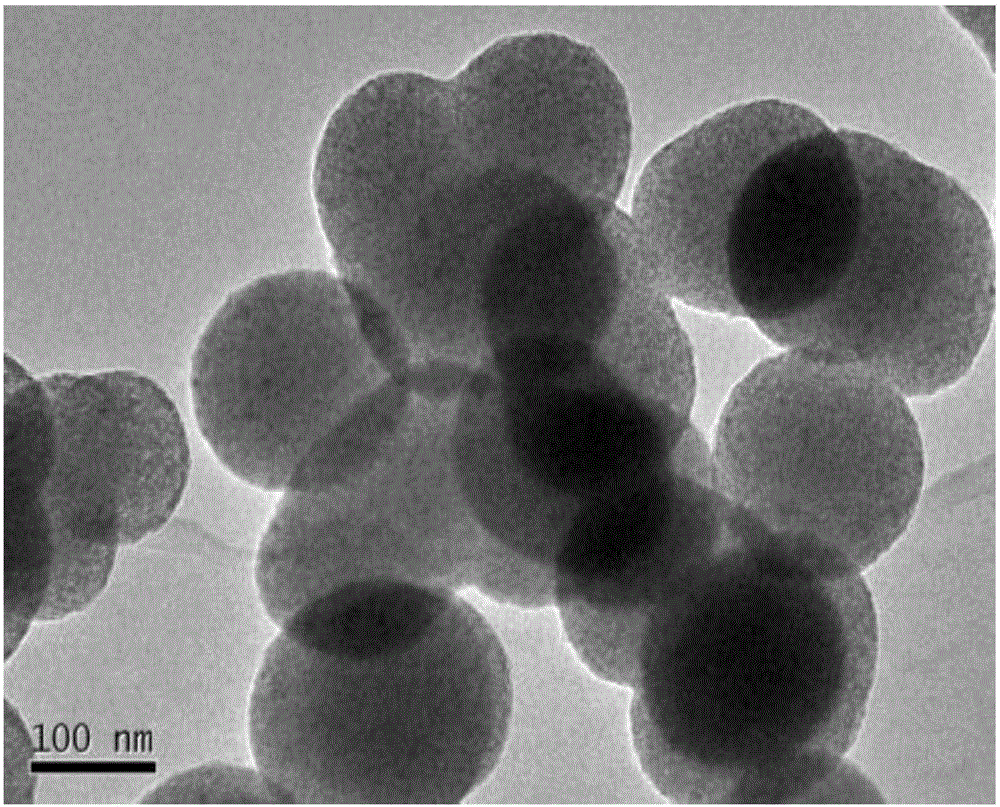

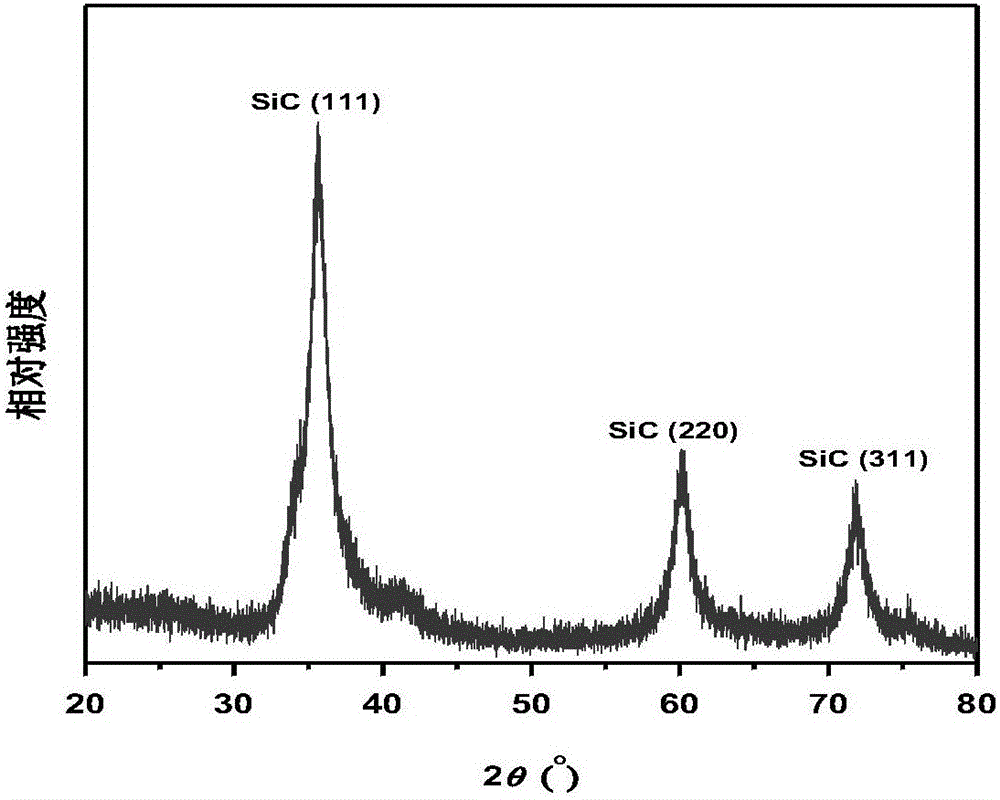

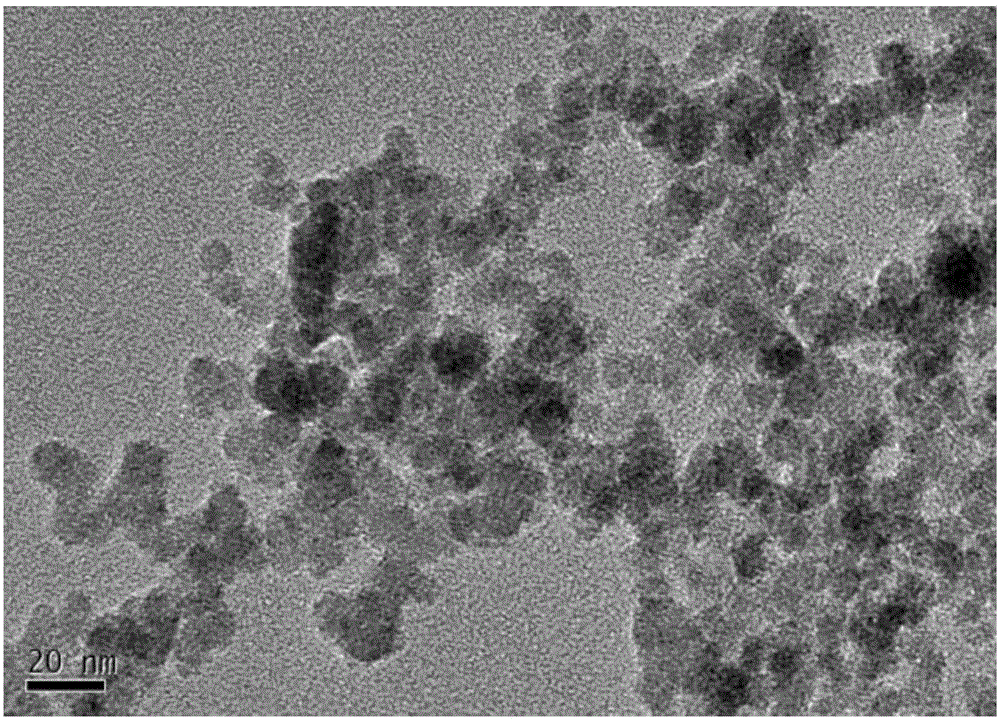

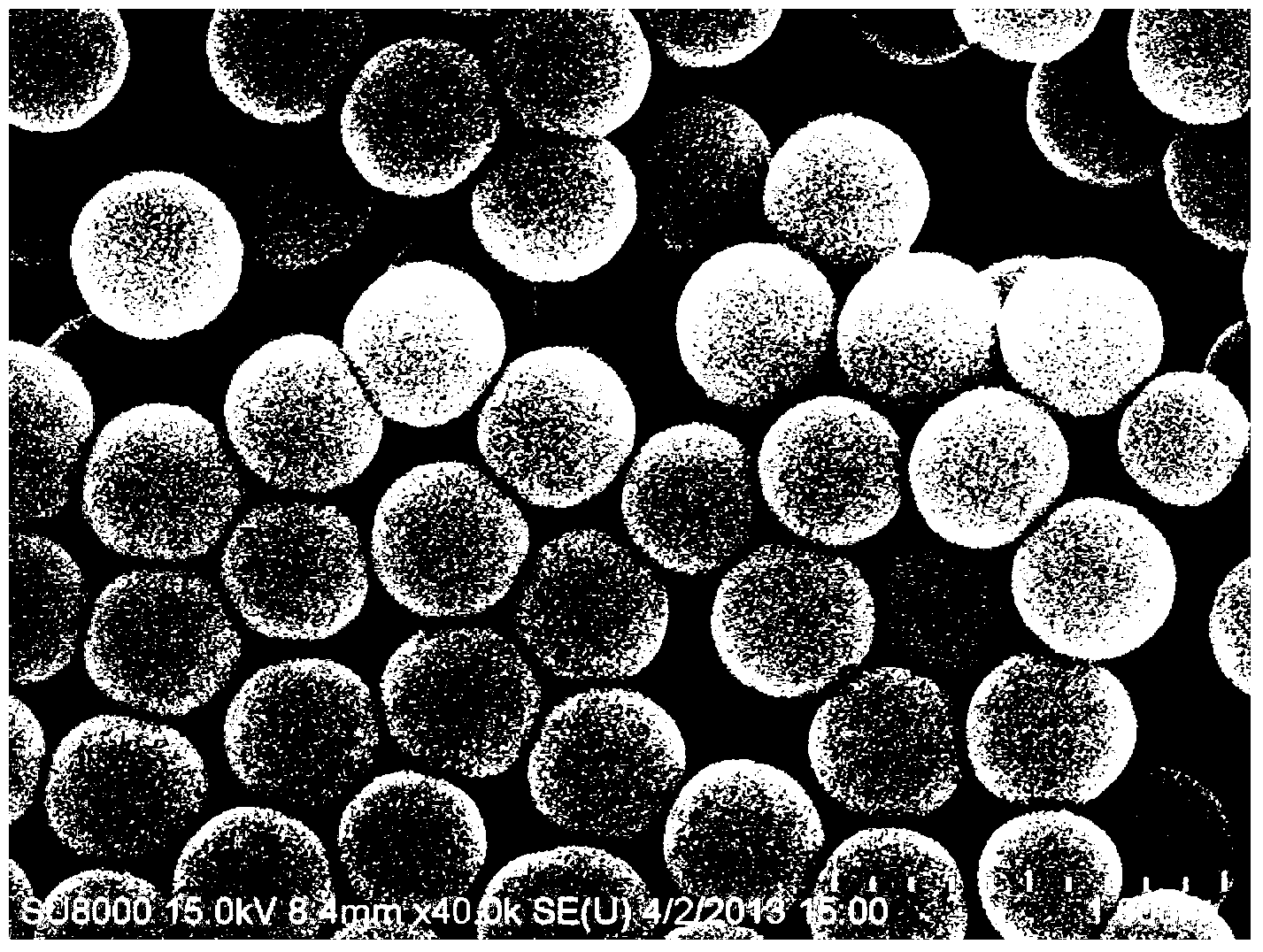

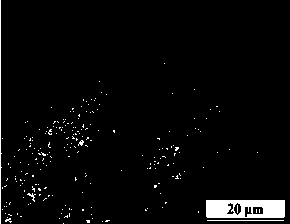

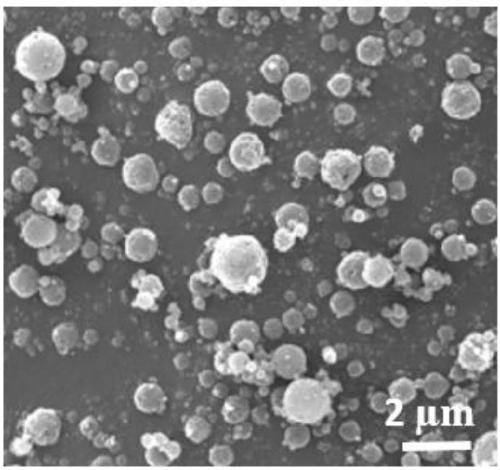

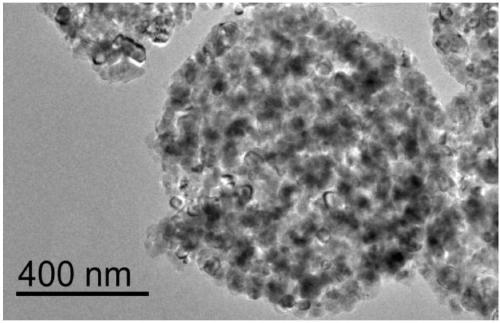

Fluidized bed chemical vapor deposition preparation method of silicon carbide nanoparticle

InactiveCN106082227ANarrow particle size distributionLower sintering temperatureNanotechnologyDisilaneGas phase

The invention relates to a fluidized bed chemical vapor deposition preparation method of silicon carbide nanoparticles. The fluidized bed chemical vapor deposition preparation method comprises the following steps: by using a fluidized bed chemical vapor deposition method, heating a precursor material hexamethyl disilane to generate vapor, and feeding the vapor into a fluidized bed reactor in a gas carrying manner; implementing pyrolytic reaction on the precursor vapor in a high-temperature zone so as to form silicon carbide nanoparticles; conveying the nanoparticles to the upper part of the fluidized bed reactor under the action of a fluidization gas, sucking out by using a negative-pressure device, and collecting so as to obtain silicon carbide nano powder; in the presence of an inert atmosphere, implementing high-temperature thermal treatment, thereby obtaining well-crystallized silicon carbide nanoparticles. The silicon carbide nanoparticles are cubic-phase silicon carbide, are sphere-shaped and are narrow in particle size distribution, and the sizes of the particles are 5-300 nanometers and are adjustable. By adjusting the reaction atmosphere, particles of pure silicon carbide and silicon-enriched or carbon-enriched silicon carbide can be prepared. The fluidized bed chemical vapor deposition preparation method is simple in process procedure, convenient and rapid in process operation, low in cost and beneficial to industrial production.

Owner:TSINGHUA UNIV

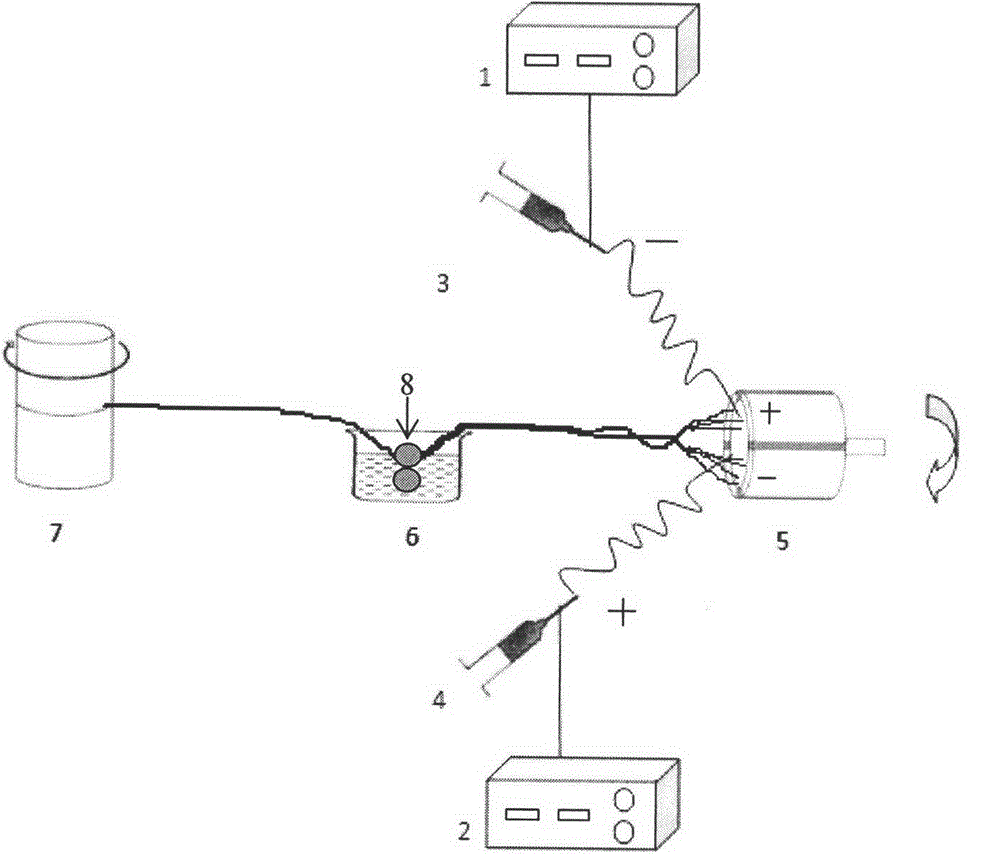

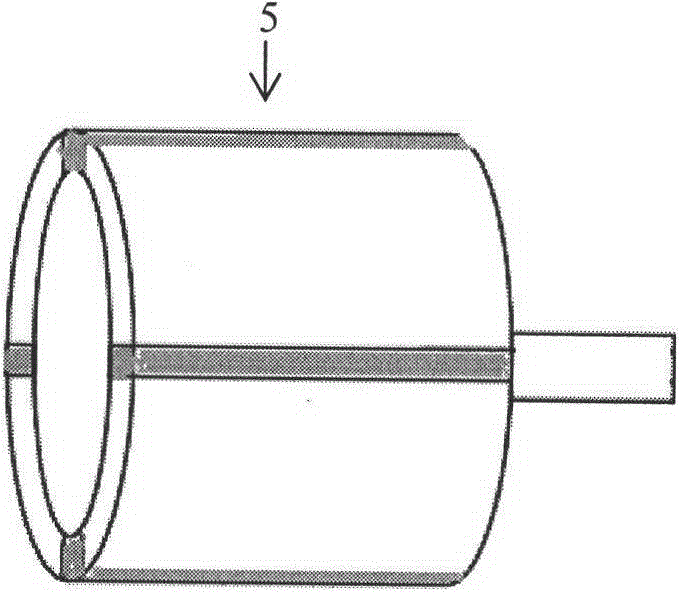

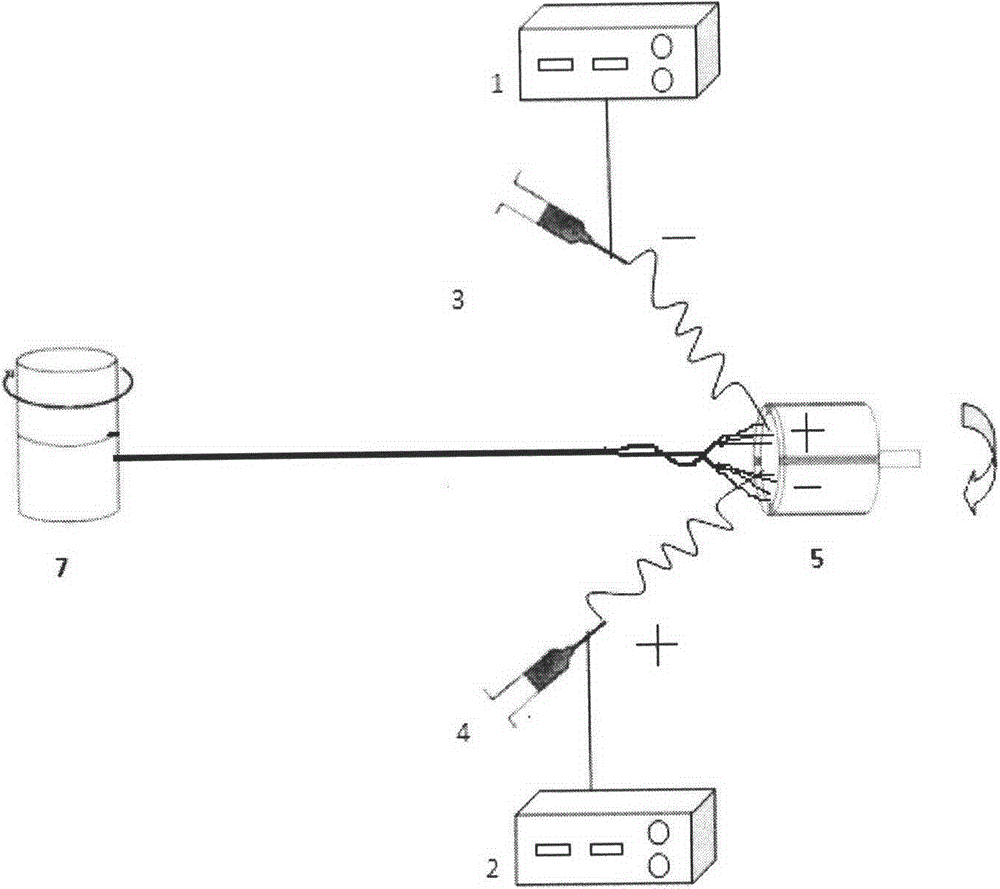

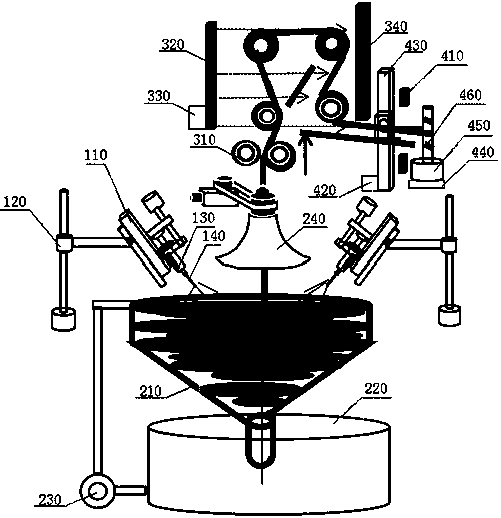

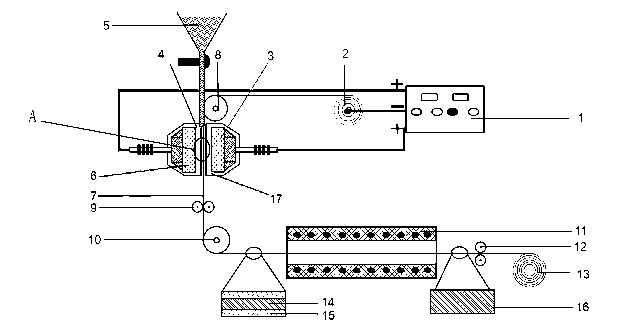

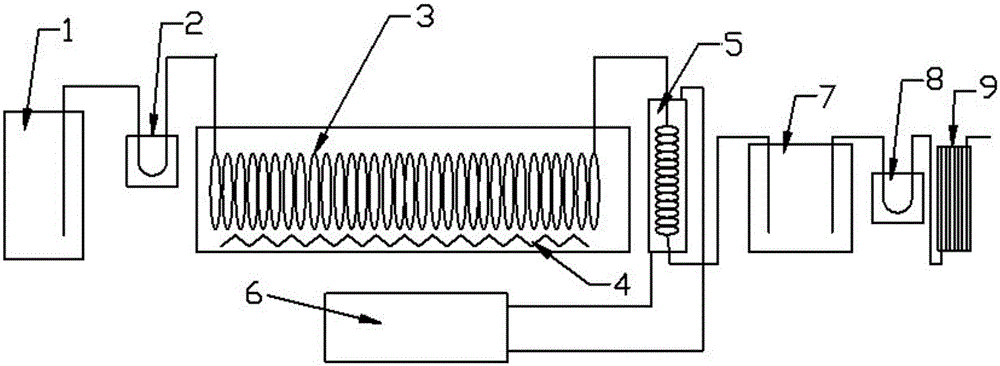

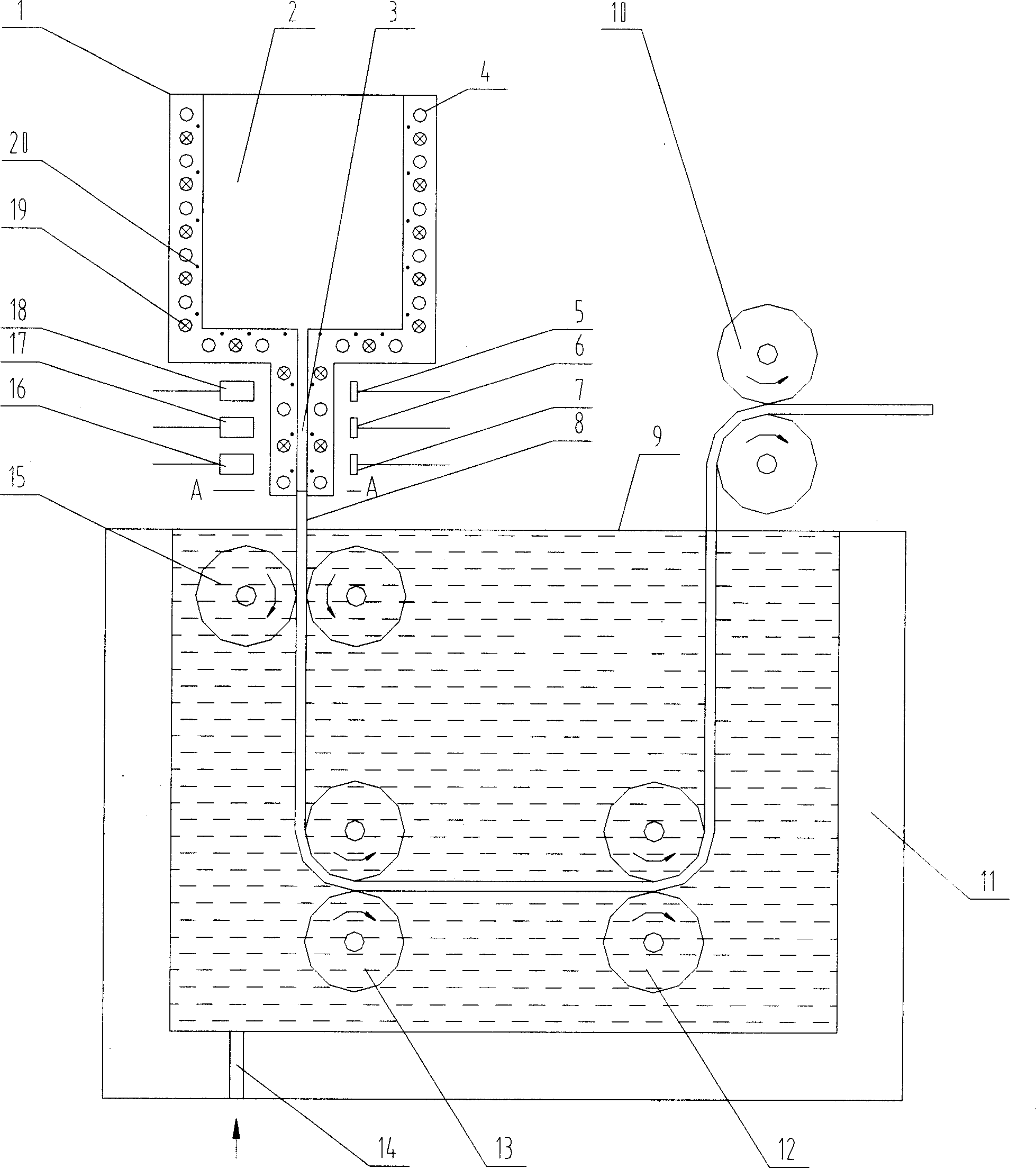

Production method and device for continuous nano-fiber yarn

ActiveCN104060355ARealize continuous preparationImprove mechanical propertiesArtificial thread manufacturing machinesFilament/thread formingYarnSpinning

The invention discloses a production method and device for a continuous nano-fiber yarn. The production method comprises the following processing steps: (1) preparing a polymer solution; (2) performing nano-jet injection and forming fibers; (3) forming the continuous nano-fiber yarn. The production device is designed according to the production method provided by the invention and mainly comprises a spinning system, a twisting system and a winding system, wherein the spinning system comprises an injection pump, an injector, a spinning nozzle and a high-voltage power supply; the twisting system comprises a controller and a turntable; the winding system comprises a solution tank, a roller and a controller. Compared with the prior art, the production method and device provided by the invention are characterized in that the continuous nano-fiber yarn is prepared by rotating and twisting two nano-fiber bundles which are formed by controlling the polarity of the turntable by an electric brush; the continuous preparation of the nano-fiber yarn is realized; the mechanical property of the yarn is increased; the twisting of the yarn is uniform; the yarn levelness is good; the hairiness is less; the application value is huge.

Owner:TIANJIN POLYTECHNIC UNIV

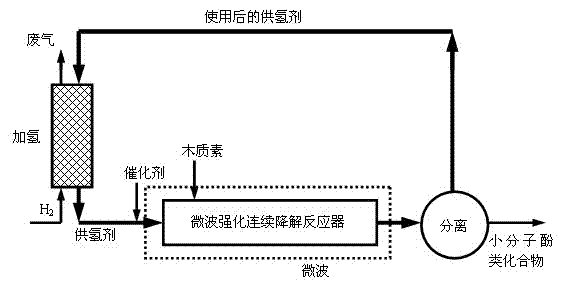

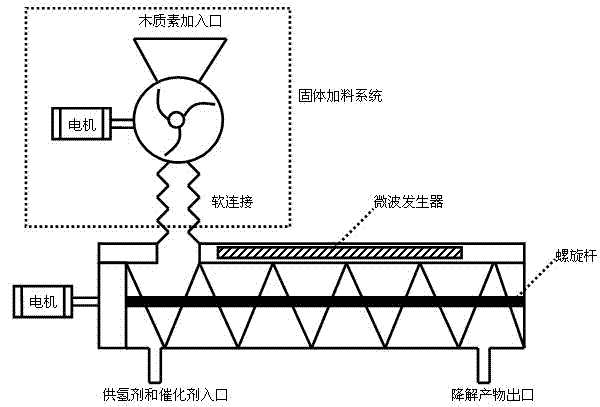

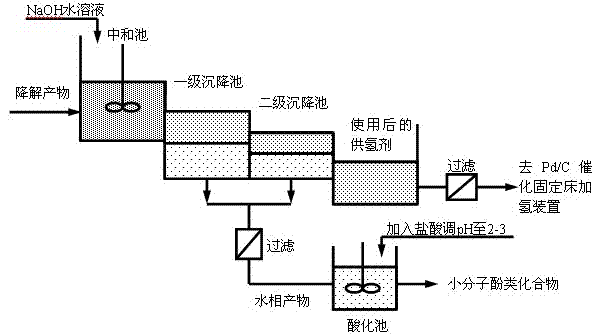

Technology for preparing micro-molecular phenolic compound through microwave reinforced continuous degradation of lignin in hydrogen donor

InactiveCN103073395ARealize continuous preparationIncrease reaction rateOrganic compound preparationCarbonyl compound preparationHydrogenMicrowave

The invention discloses a technology for preparing a micro-molecular phenolic compound through the microwave reinforced continuous degradation of lignin in a hydrogen donor. The technology comprises the following steps: 1, continuously adding lignin to a microwave reinforced screw rod continuous degradation reacting device through a solid charging system, continuously adding the hydrogen donor and a catalyst to the continuous degradation reacting device through pumps, and carrying out a continuous degradation reaction of lignin at 150-200DEG C for 10-40min; 2, neutralizing degradation products in a neutralization pool in a degradation product separation device with an aqueous solution of NaOH, allowing the neutralized degradation products to enter a primary settling pool and a secondary settling pool, mixing lower-layer products of the primary settling pool and the secondary settling pool, filtering to obtain a water-phase product, using hydrochloric acid in an acidifying pool to adjust the pH to 2-3 in order to obtain the micro-molecular phenolic compound; and 3, filtering a used hydrogen donor which is the upper-layer product of the secondary settling pool, and regenerating in a Pd / C catalytic fixed bed hydrogenation device to obtain a regenerated hydrogen donor for cycle use. The technology which adopts continuous operation enables the treatment amount to be large and is suitable for the large-scale industrial application.

Owner:ZHEJIANG UNIV

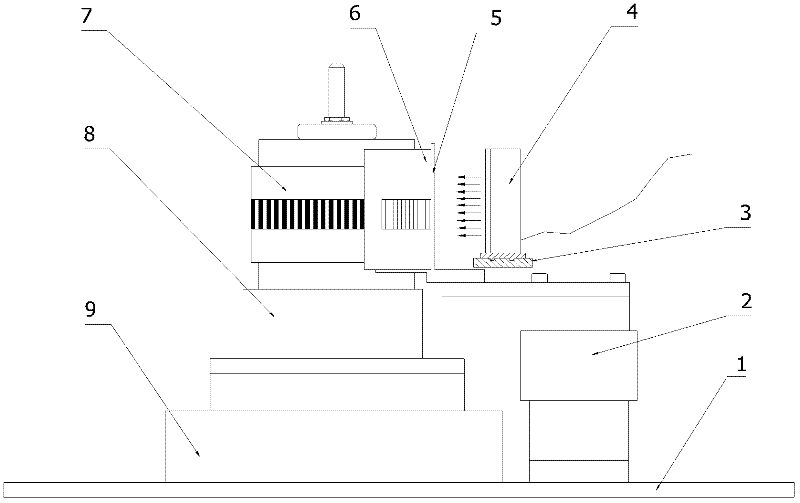

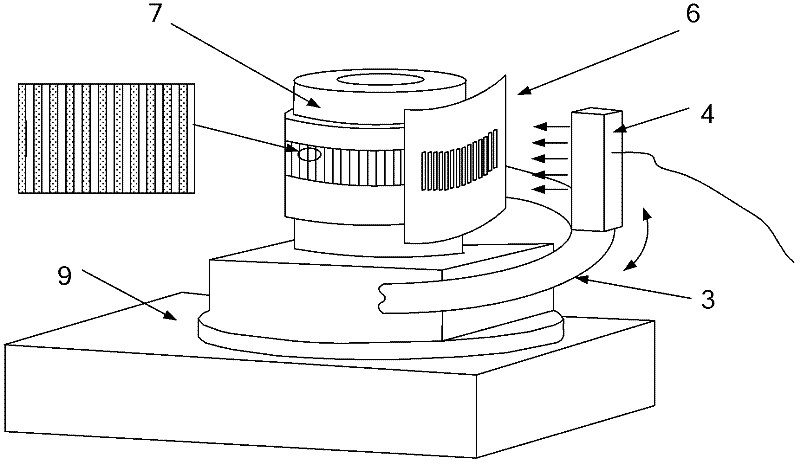

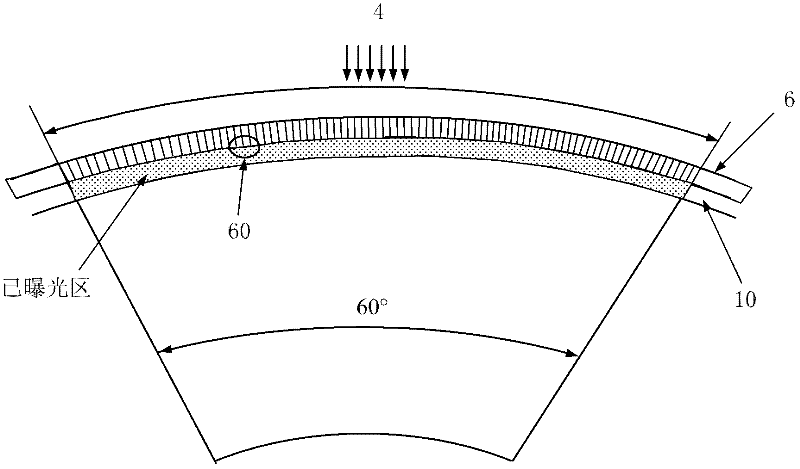

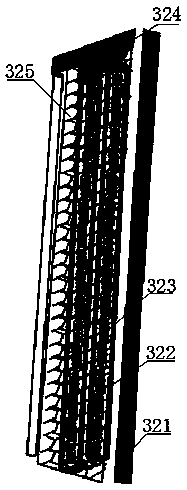

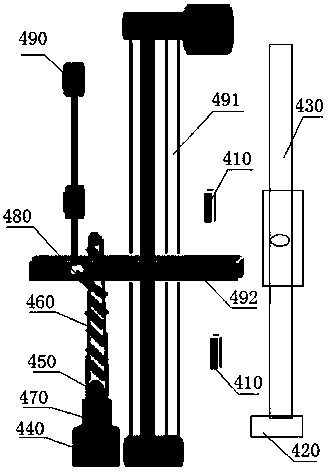

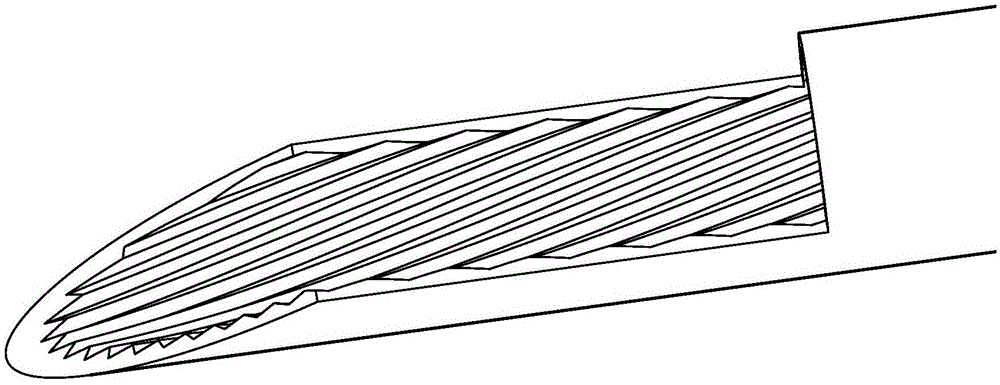

Method for rapidly processing graphical surface of ultralong grating ruler rolling die

InactiveCN102566260AContinuous manufacturingLow external environment requirementsPhotomechanical exposure apparatusMicrolithography exposure apparatusPhotoresistMicrostructure

The invention discloses a method for rapidly processing a graphical surface of an ultralong grating ruler rolling die. The method comprises the following steps: 1) selecting a rolling die; 2) cleaning the rolling die; 3) carrying out gluing on the surface of the rolling die; 4) carrying out pre-baking treatment on the rolling die; 5) fixing the rolling die; 6) selecting and adjusting a mask; and 7) carrying out exposure. According to the invention, through adopting a rotational exposure technique for exposure splicing, a graph of a grating microstructure on the mask is transferred to a photoresist on the surface layer of the rolling die, and after an operation of development is performed, a graphical grating-structure masking layer is formed on the surface of the rolling die; through using an etching or electroforming method, the graphical masking layer is copied to the surface of the rolling die; and through the application of the die, the grating microstructure on the surface of the die can be continuously copied to a grating ruler blank by using a rolled printing or inverted rolled printing method so as to realize the continuous manufacturing of an ultralong grating ruler. The method has low requirements on the external environment and is high in production efficiency, thereby effectively reducing the manufacturing cost of the grating rule.

Owner:XI AN JIAOTONG UNIV

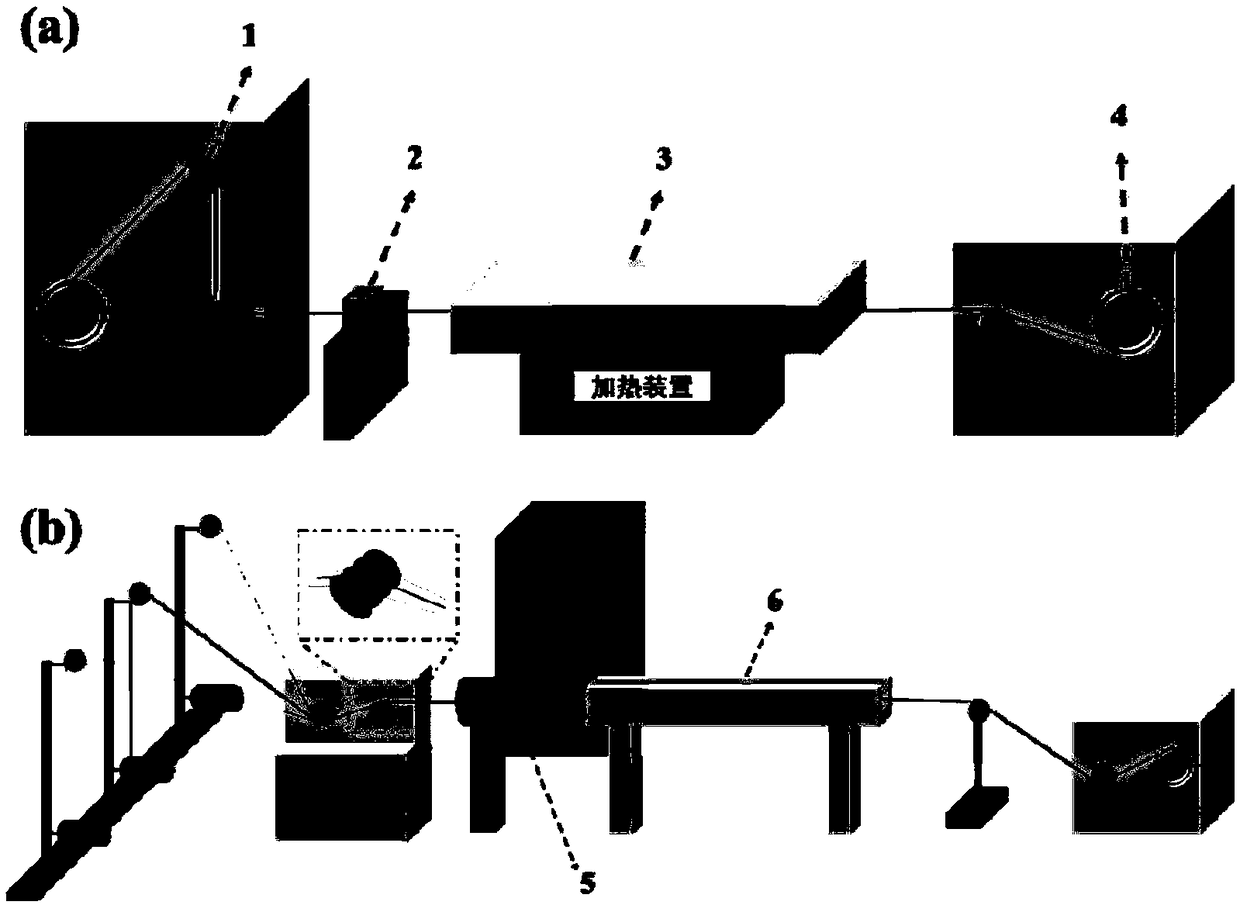

Method for preparing single-walled carbon nanotube fiber and composite fiber thereof

The invention relates to the field of carbon nanotube fiber and composite fiber thereof, in particular to a method for preparing single-walled carbon nanotube fiber and composite fiber thereof. A single-walled carbon nanotube prepared through a floating catalyst chemical vapor deposition method is adopted as a base material, an amphipathy surface active agent is used for dispersing the single-walled carbon nanotube and extruded into a condensation bath to form the fiber, and continuous preparation of the high-strength and high-conductivity fiber is achieved. A material with the good compatibility is added into a fiber stock solution, the composite fiber is obtained, and more functions are given to the fiber. According to the method, consumption of strong acid in the existing wet method spinning technology is avoided, and safety risk and environment problems in the production process are reduced; meanwhile, consumption of insulativity polymer adhesives is avoided, the conductivity of the fiber prepared through wet method spinning is improved, the problems that in the existing carbon nanotube composite fiber preparation technology, the function material is distributed in the fiber not uniformly, and the carrying amount cannot be increased easily are solved, and uniform distribution of the high-load functional material in the fiber base is achieved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

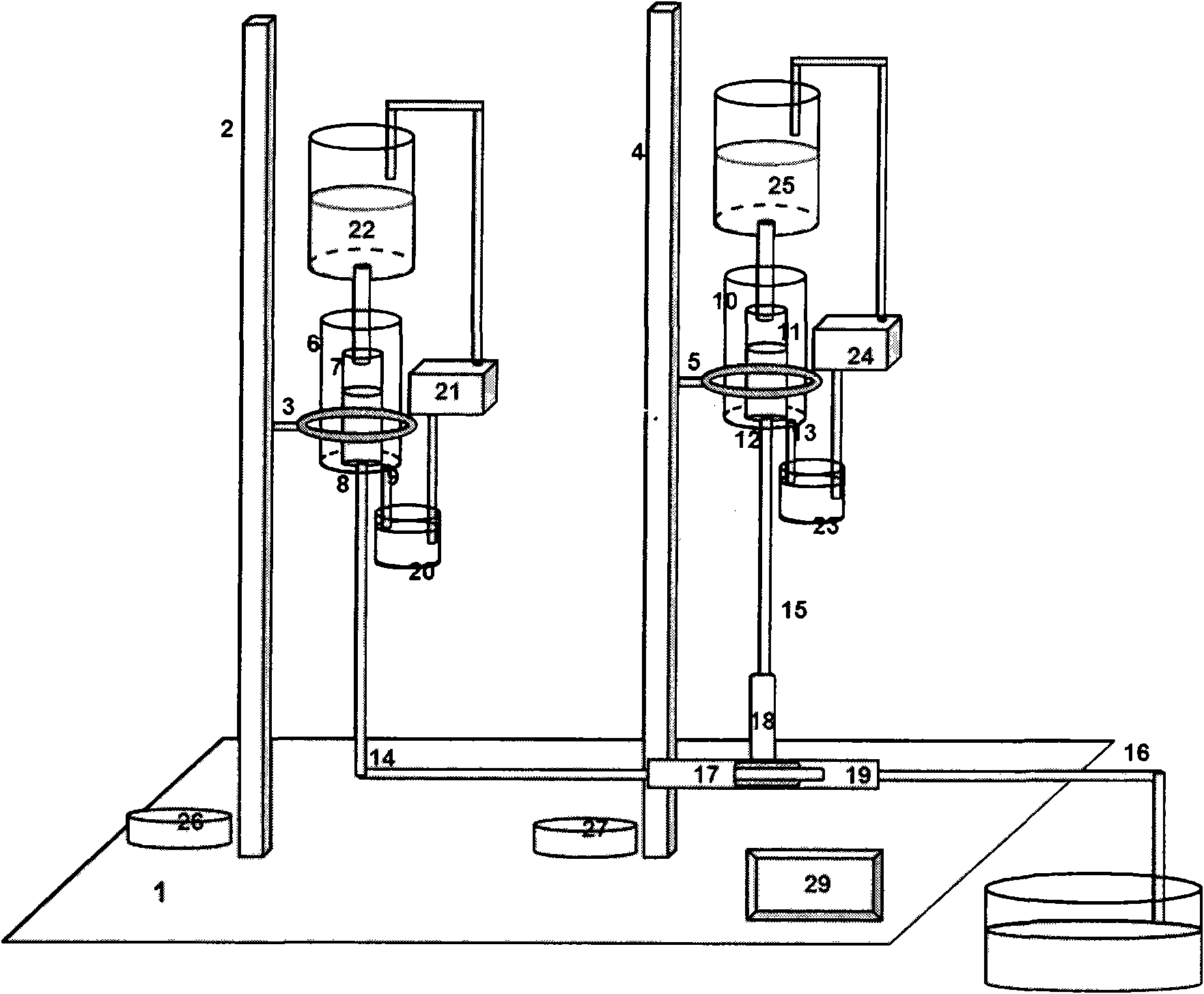

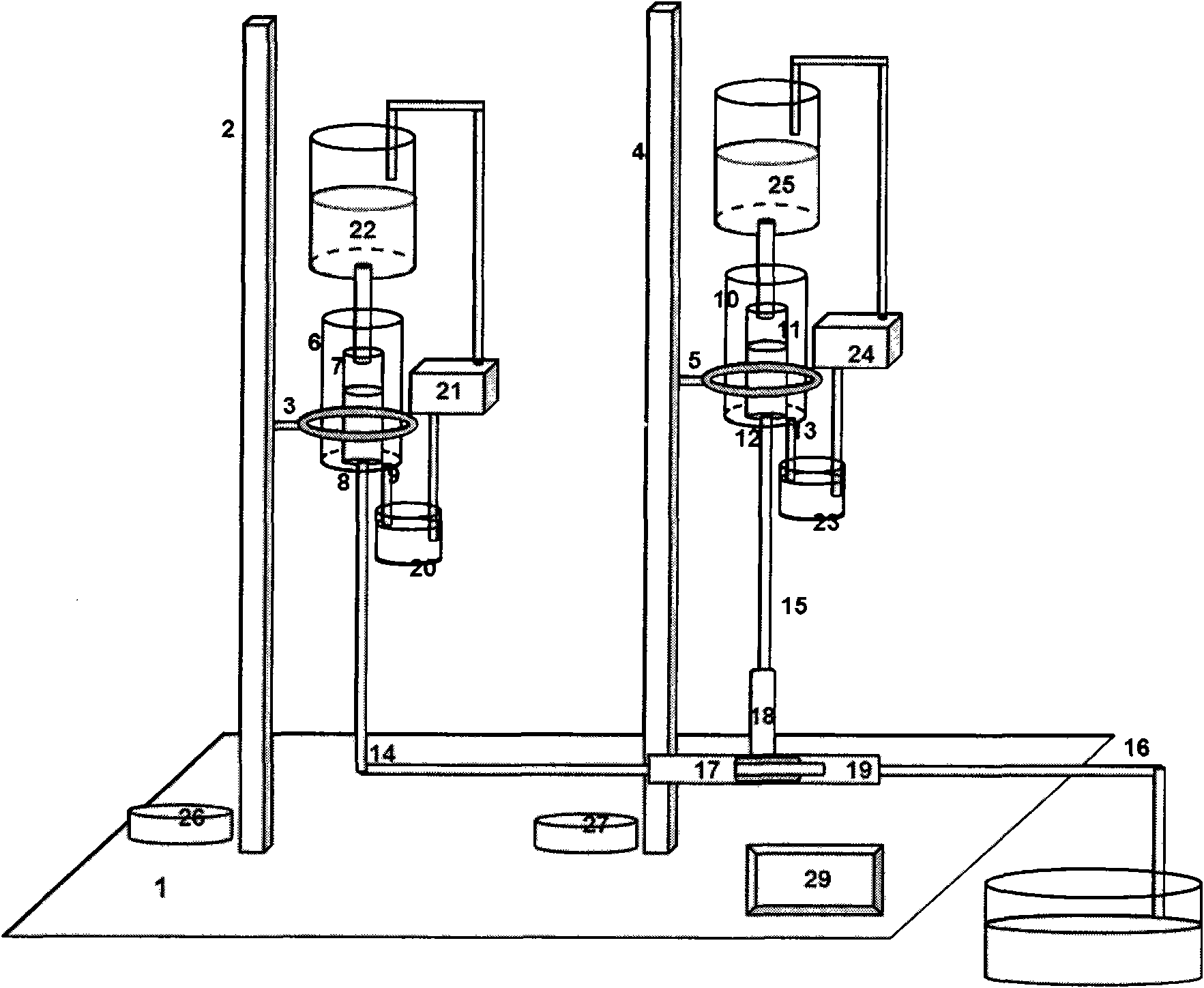

Gravity drive microfluidic device for preparing monodispersed emulsion and method thereof

InactiveCN101982229ACustomer service costCustomer service errorLaboratory glasswaresChemical/physical/physico-chemical processesEmulsionMicrofluidics

The invention relates to a gravity drive microfluidic device for preparing a monodispersed emulsion and a method thereof, which is characterized in that a microfluidic system is driven by utilizing the constant flow rate generated by means of the constant gravity action of fluid columns with different heights based on the microfluidic device; liquid drops with different and even volumes are formed by utilizing the action of a shearing force, the surface tension and the like of the continuous phase fluid to the dispersed phase fluid; and microspheres meeting the requirements on bioanalysis and carriers of proteins, genes, medicine screening and the like are formed by solidification, drying or ultraviolet irradiation polymerization. The device of the invention comprises a microfluidic control device support component, a constant sample introduction component, a fluid pipeline, a microfluidic control channel component and a continuous sample adding component, wherein the heights of two-phase liquid columns are automatically controlled by controlling a two-phase mechanical motor; the liquid columns with different heights drive the fluid to generate the constant speed; the continuous-phase fluid for driving the microfluidic control device is used for shearing the dispersed phase liquid to prepare the liquid drops with the different volumes; and the large-scale and continuous preparation of the liquid drops can be realized by the continuous sample adding component and the constant sample introduction component.

Owner:SOUTHEAST UNIV

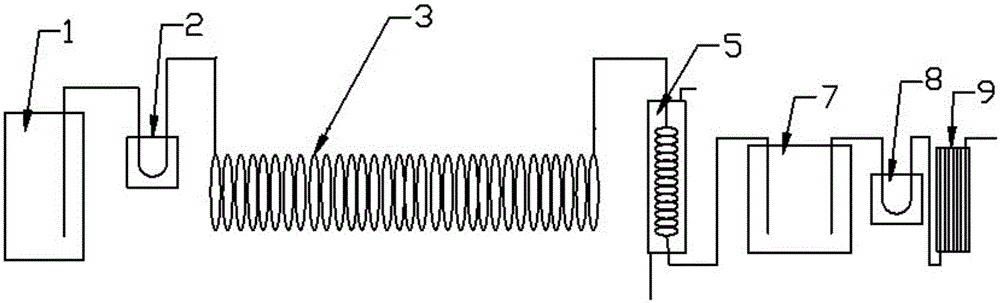

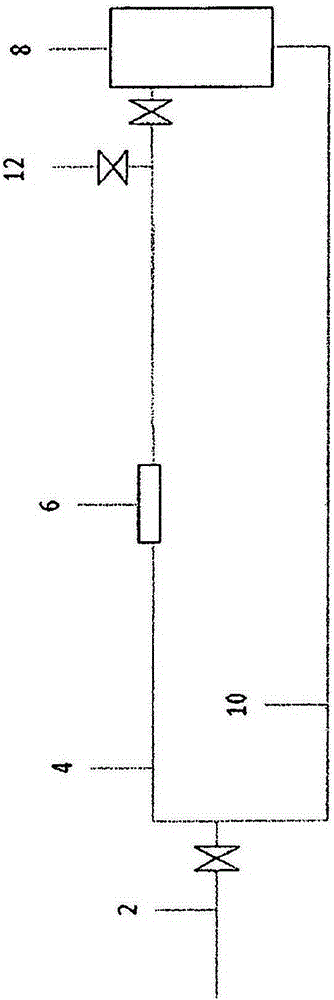

Method and device for preparing nanofiber yarn

ActiveCN109610021ARealize continuous preparationHigh yieldArtificial thread manufacturing machinesContinuous wound-up machinesFiberWater baths

The invention discloses a method and a device for preparing nanofiber yarn, and relates to the technical field of nanofiber yarn. According to the method and the device for preparing the nanofiber yarn, provided by the invention, the nanofiber yarn is prepared through water bath eddy reverse yarn forming, and continuous preparation of the nanofiber yarn can be realized; the height and angle of a spinning nozzle can be adjusted at random through the adjustment of a first adjusting screw and a second adjusting screw on a support, and the operation is simple and convenient; the spinning nozzle isused for ejecting nanofiber into a liquid eddy of an upper liquid groove, so that the air pollution caused by solvent evaporation can be reduced; the nanofiber rotates and is collected under the effect of the liquid eddy, and simultaneously the fiber is further orientated through the upward drafting of the yarn and the downward drafting of the eddy, so that the uniformity is higher; the nanofiberrotates and is twisted under the effect of the liquid eddy, the nanofiber is stable and controllable, and the mechanical property of yarn forming is excellent; and after the nanofiber is formed through drying, the mechanical property of the yarn can be further strengthened, and the adhesion among the yarns is reduced.

Owner:JIAXING UNIV

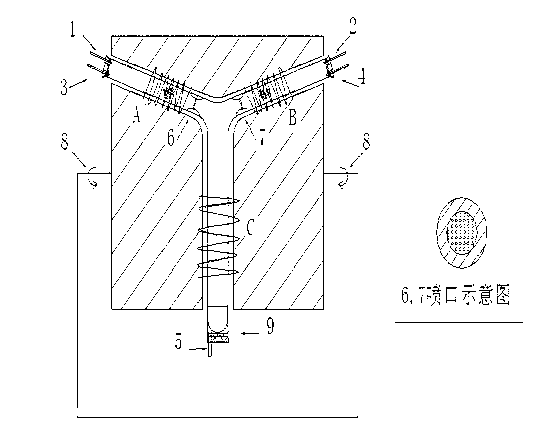

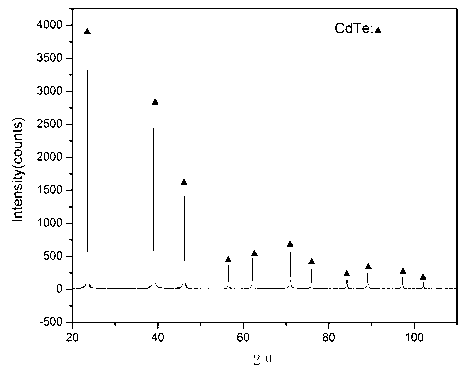

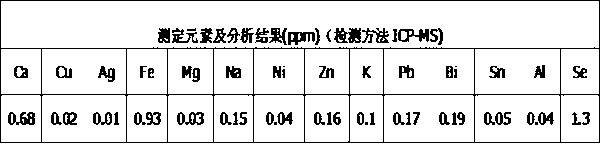

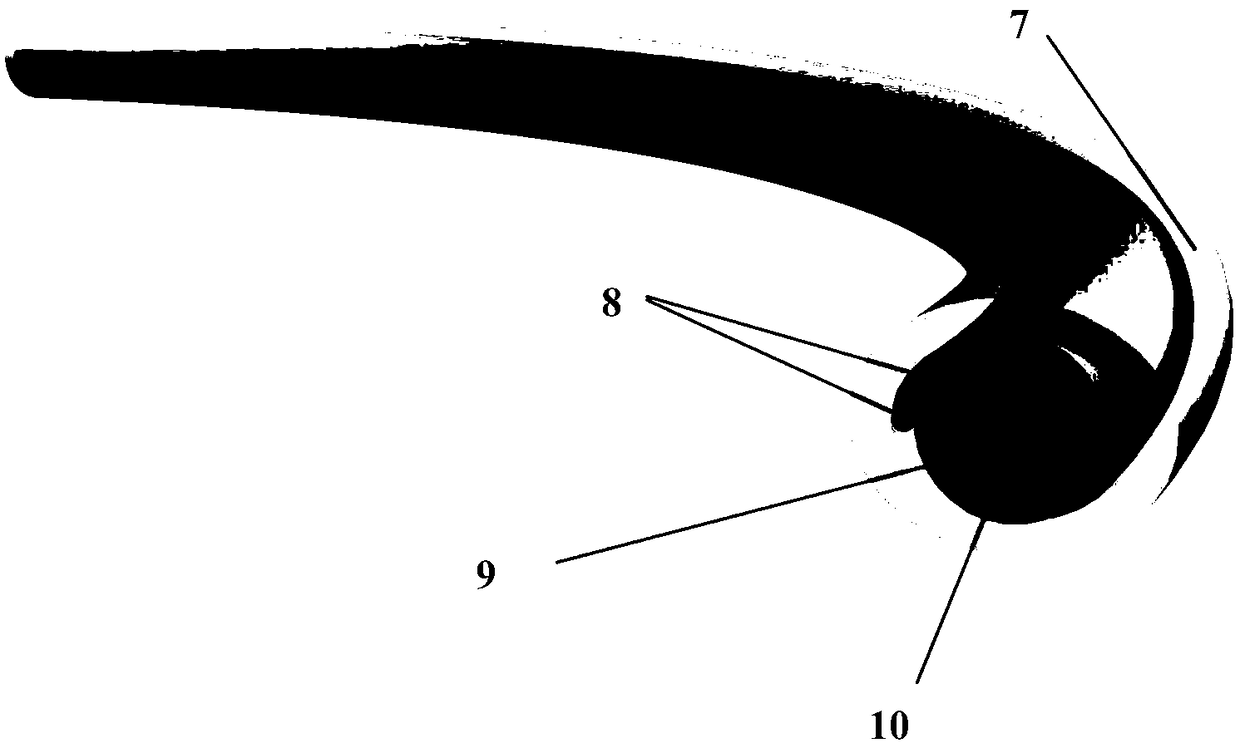

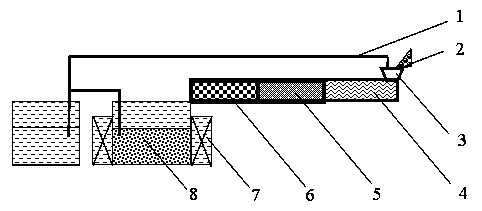

High-temperature liquid-phase synthesis method of cadmium telluride powder

ActiveCN102849693ASafe workmanshipEfficient process methodBinary selenium/tellurium compoundsBreatherSynthesis methods

The invention discloses a high-temperature liquid-phase synthesis method of cadmium telluride powder, which comprises the following steps: respectively containing cadmium blocks and tellurium blocks in the end A and the end B of a Y-shaped tube according to a mol ratio of 1:1; horizontally placing the Y-shaped quartz tube in an open / close type Y-shaped furnace chamber performing three-section heating; then vacuumizing the quartz tube to 1*10<-3>-1*10<-4> Pa; respectively heating the section A, the section B and the section C of the Y-shaped quartz tube to 350-400 DEG C, 480-600 DEG C and 600-1100 DEG C, and keeping the temperature until the test is finished; when the tellurium and the cadmium are molten into liquids, vertically arranging the open / close type furnace performing three-section heating through a bracket 8; then closing vacuum valves 1 and 2, opening breather valves 3 and 4 and a bleed valve 5, and introducing Ar gas of 0.01-1 MPa, so that the tellurium and cadmium liquids are respectively sprayed out from nozzles 6 and 7 and atomized, the high-purity cadmium telluride powder can be synthesized through the contact of the atomized tellurium and cadmium liquid drops, and the cadmium telluride powder scatters on the bottom of the end C of the Y-shaped quartz tube; and after the atomization process is finished, stopping heating, cooling to room temperature, opening an end cover 9 at the end C, and collecting the high-purity cadmium telluride powder.

Owner:SICHUAN UNIV

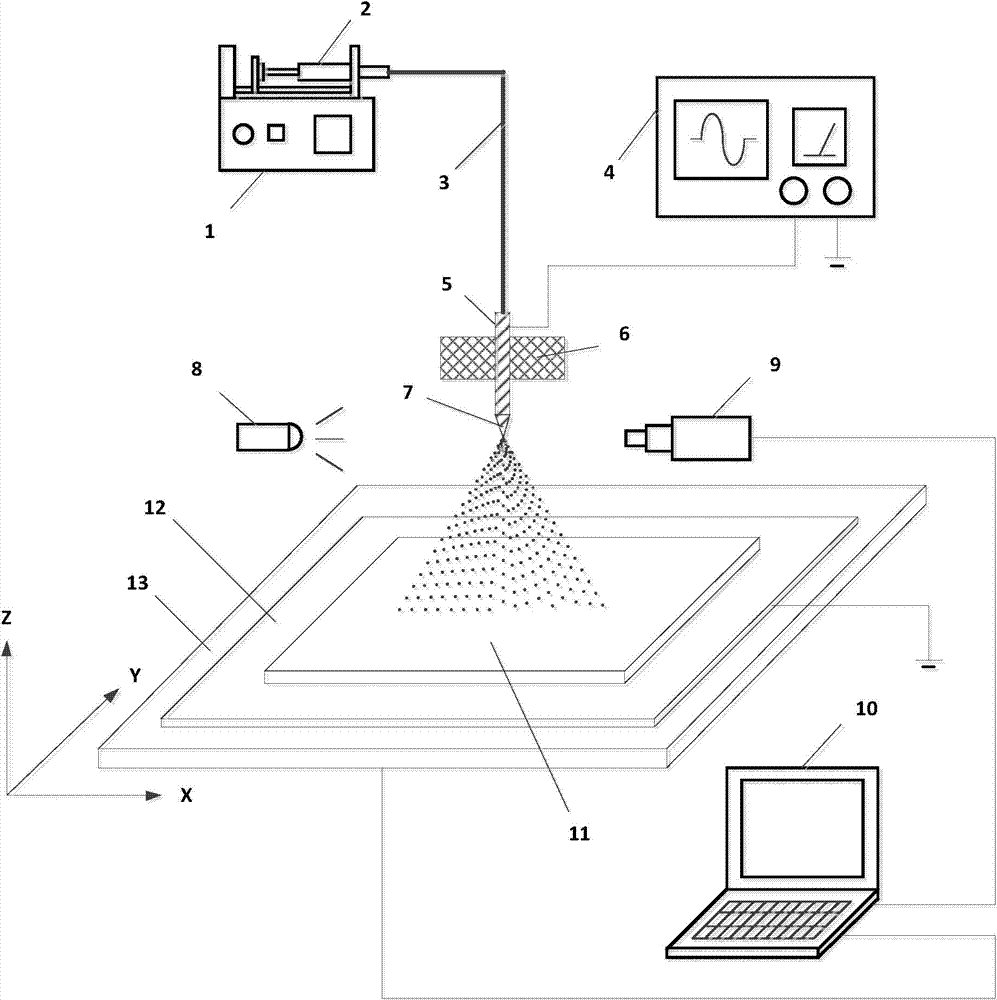

Electrospray device, method of producing solar cell anti-reflection layer by electrospray, and solar cell

ActiveCN103586154AImprove photoelectric conversion efficiencyRealize continuous preparationPhotovoltaic energy generationSpray discharge apparatusEngineeringHigh pressure

The invention discloses an electrospray device and a method of producing a solar cell anti-reflection layer by electrospray. According to the principle of electrospray, an anti-reflection layer in an inverted nano-bowl microstructure and in an inverted approximate hemisphere shape is produced on a transparent conductive film; controlling the shape and size of the inverted 'nano-bowl' by adjusting the parameters such as flow speed of spray, diameter of a nozzle, voltage of a high voltage generator, and spacing between the metal nozzle and the transparent conductive layer; controlling density of the nano-bowl by using a PC control unit to adjust X-directional and Y-directional motion speeds of a moving platform. The anti-reflection layer is produced by the electrospray technology, process environmental requirements are low, the whole process is digitally controlled, and process parameters are easy to control. Through the application of the produced anti-reflection layer, surface reflection of the solar cell can be reduced effectively, light permeability is improved, and photoelectric conversion efficiency of the solar cell is effectively improved in a certain wavelength range.

Owner:HUAZHONG UNIV OF SCI & TECH

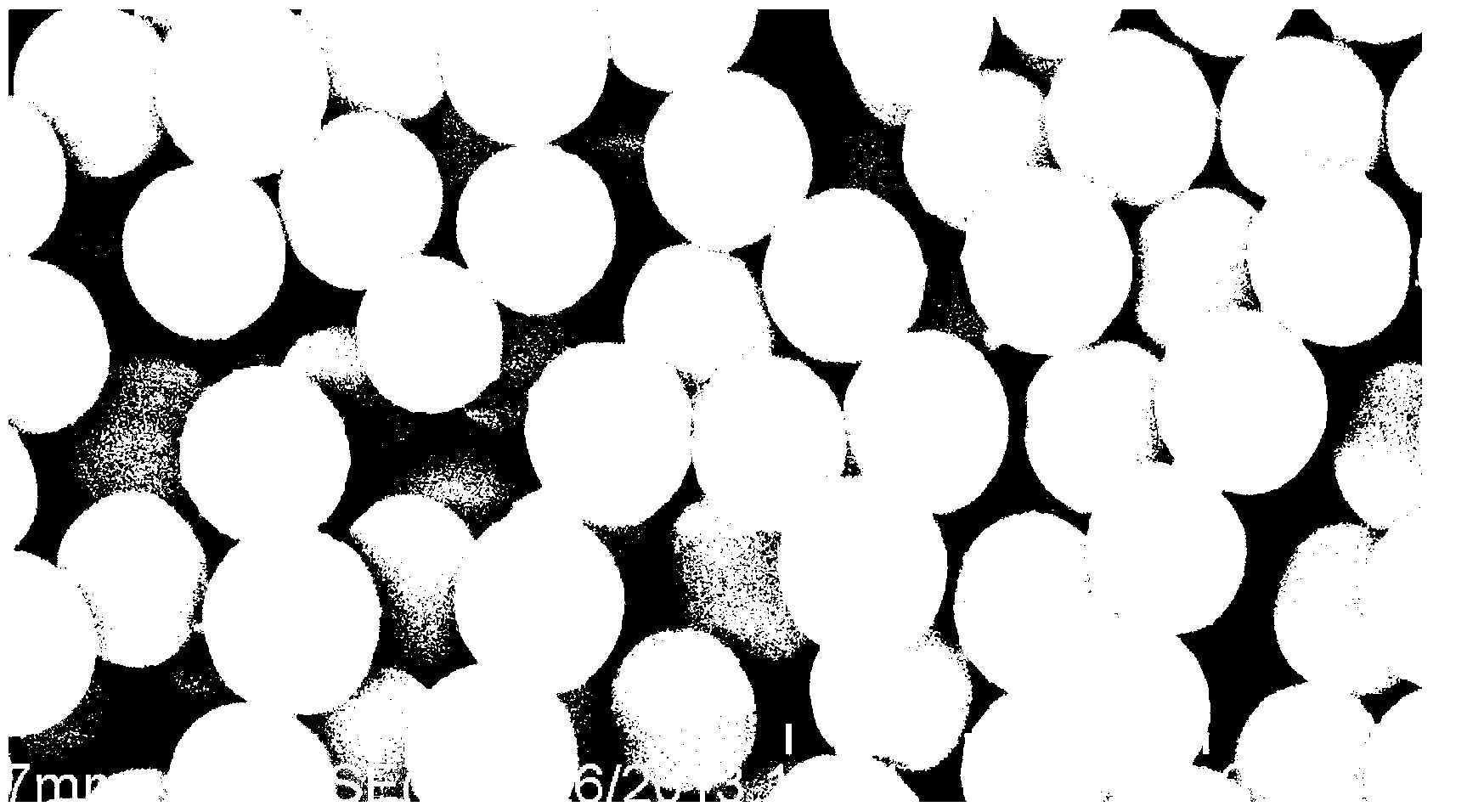

Control method of grain sizes of monodisperse silicon dioxide pellets

The invention discloses a control method of the grain sizes of monodisperse silicon dioxide pellets, relating to a method for controlling the grain sizes of the monodisperse silicon dioxide pellets and aiming at solving the problems that an existing control method of the grain sizes of the monodisperse silicon dioxide pellets cannot realize continuous preparation and the prepared silicon dioxide pellets have small grain sizes. The control method comprises the following steps: 1, preparing a mixed liquor of absolute ethyl alcohol and ammonium hydroxide; 2, preparing a mixed liquor of TEOS (tetraethoxysilane) and absolute ethyl alcohol; and 3, dropwise adding the mixed liquor of TEOS and absolute ethyl alcohol into the mixed liquor of the absolute ethyl alcohol and ammonium hydroxide, reacting for 3 hours, then measuring the gain sizes of the silicon dioxide pellets in the solution by using a laser analysis meter, and adding the TEOS and water in batch according to a formula until the gain sizes of the silicon dioxide pellets reach the targeted gain size. According to the control method disclosed by the invention, the silicon dioxide pellets do not need to take out from a reactor, so that the continuous preparation can be realized and the silicon dioxide pellets with large gain sizes can be prepared; and the gain size of each silicon dioxide pellet is less than or equal to 5%.

Owner:HARBIN INST OF TECH

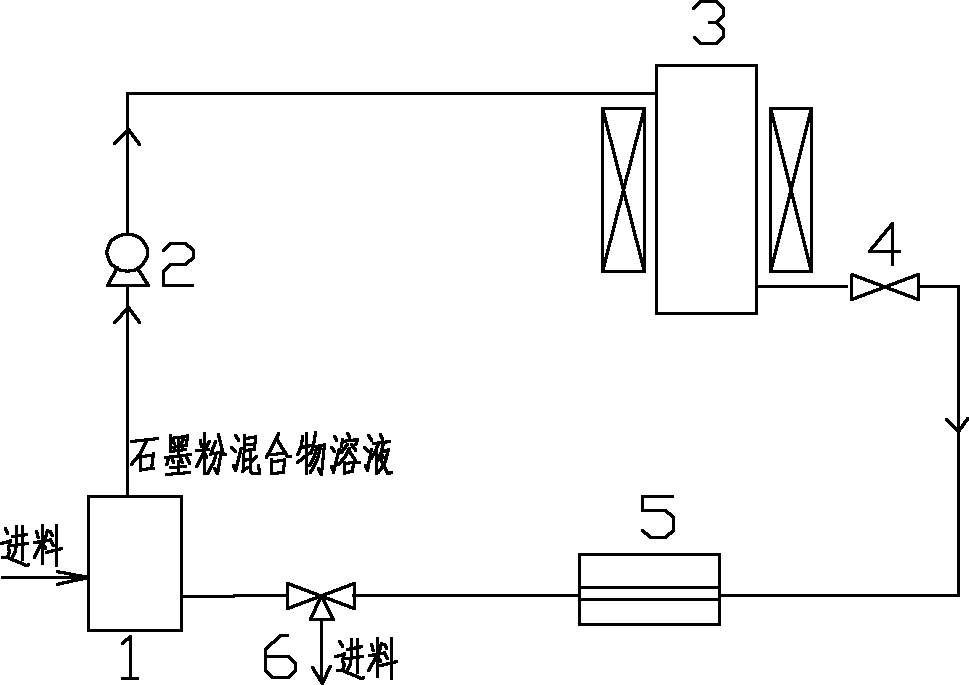

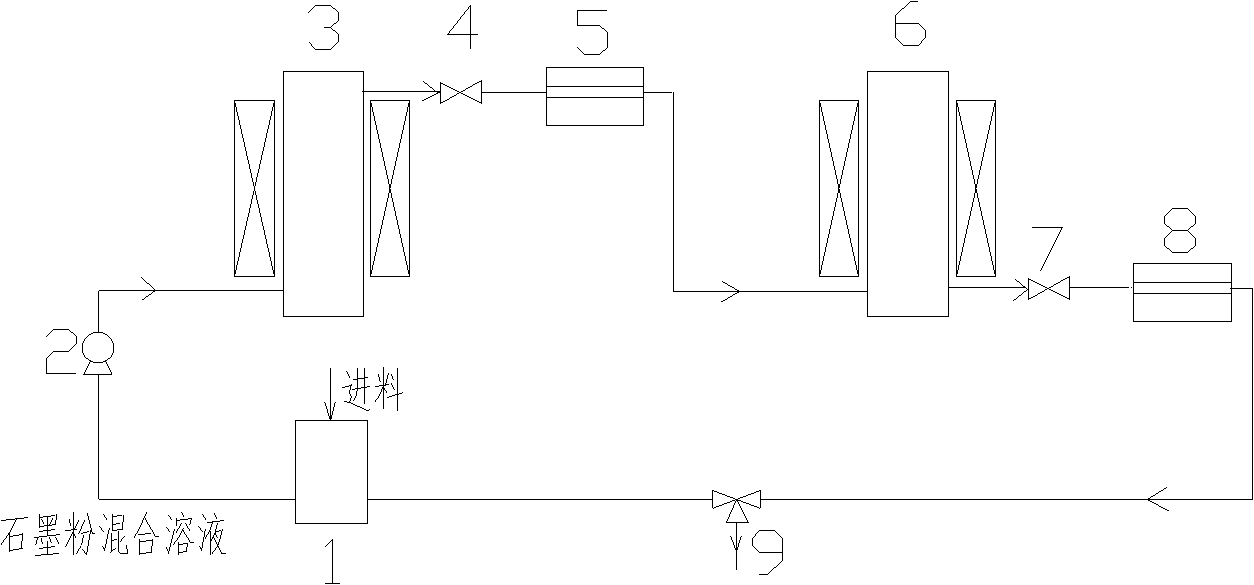

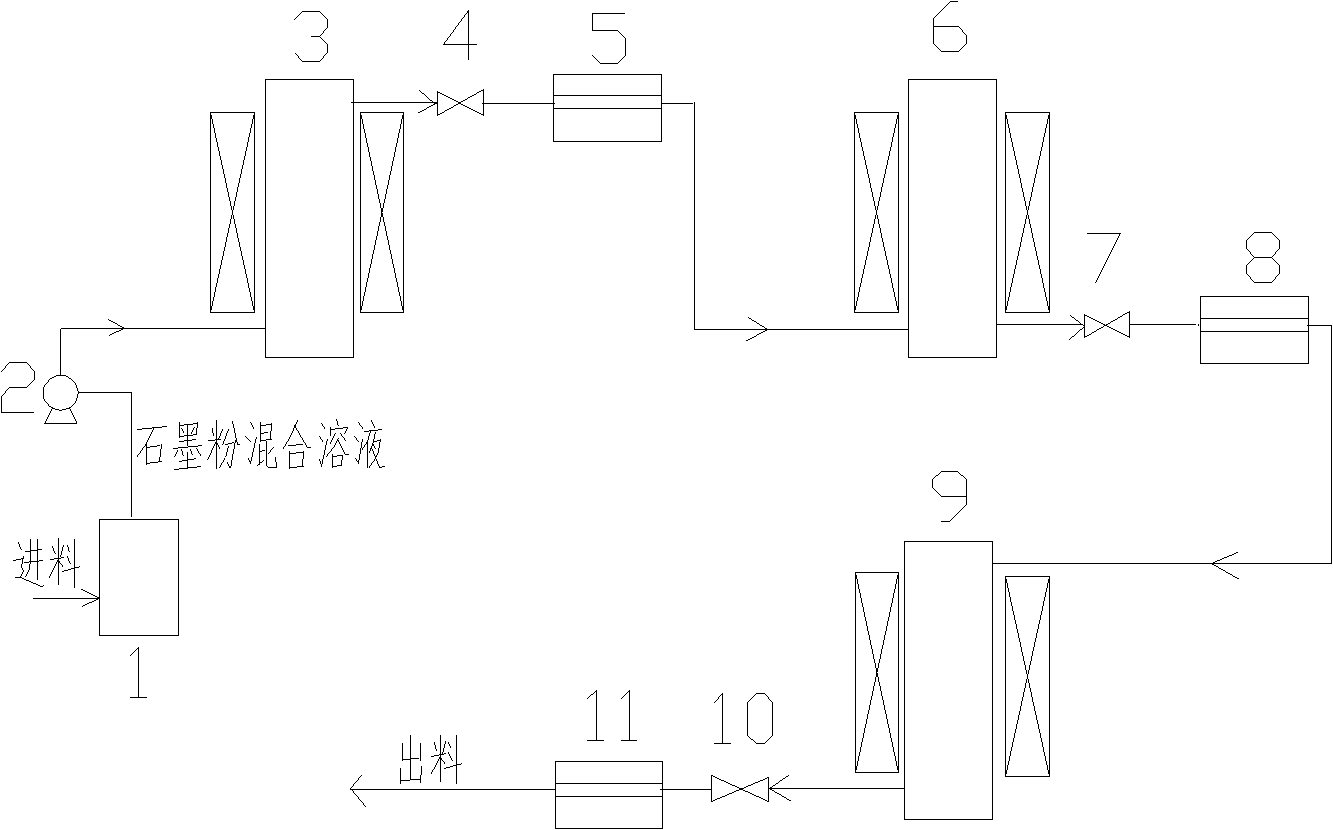

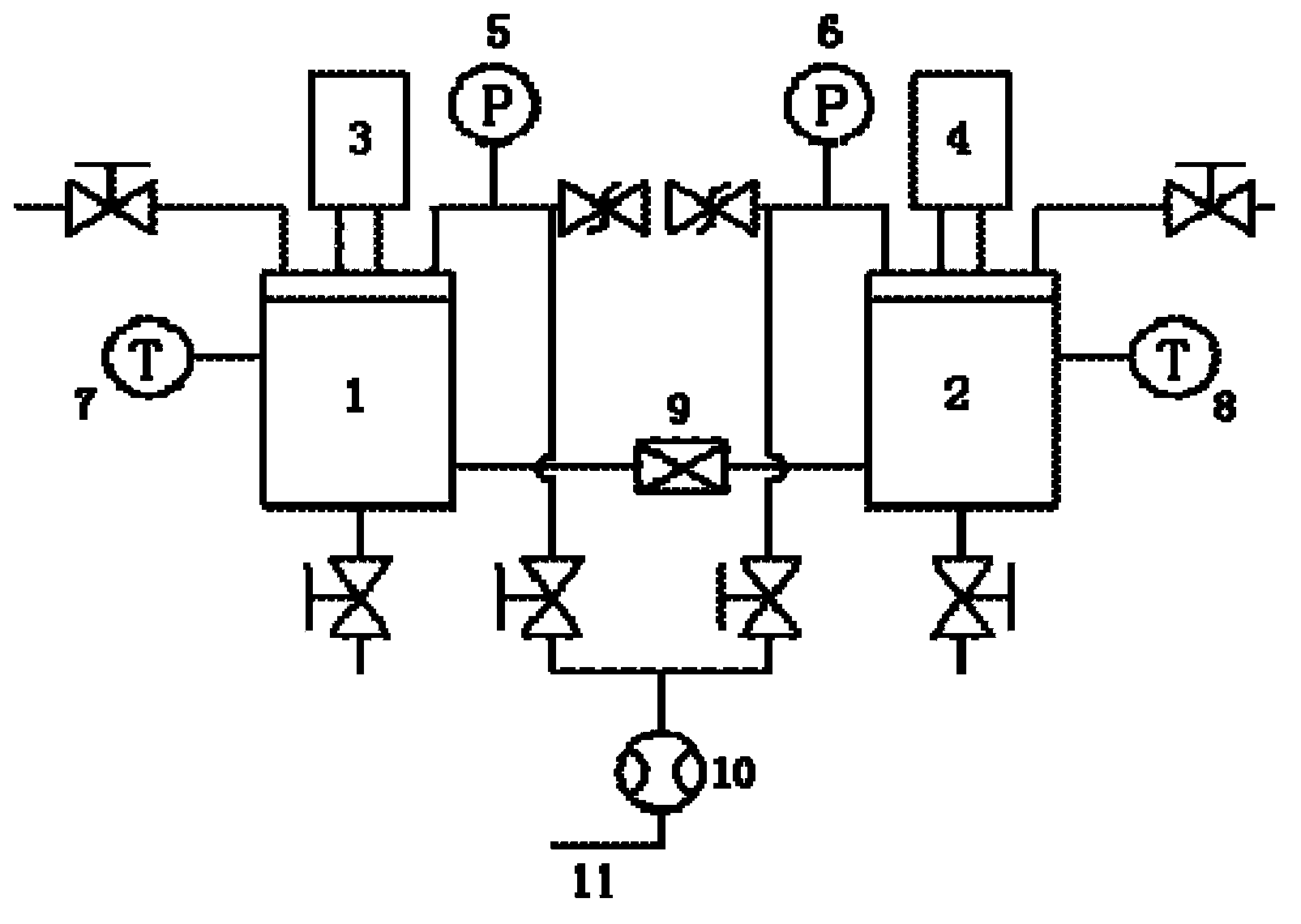

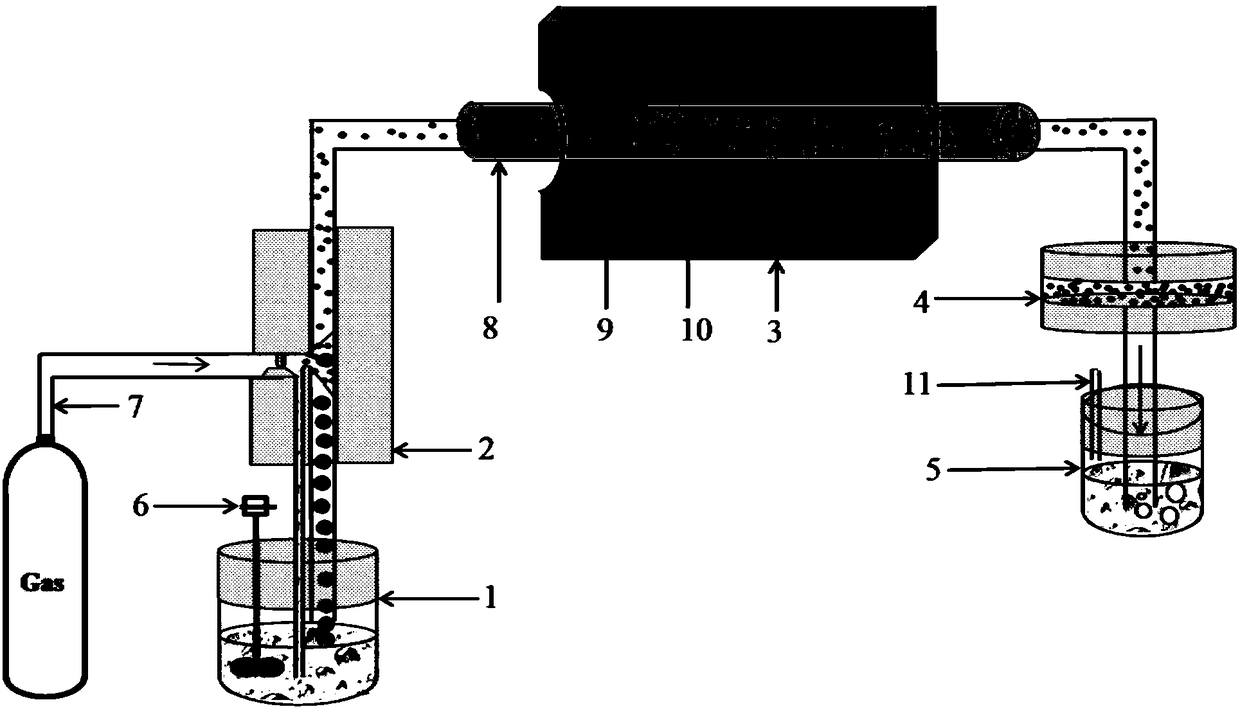

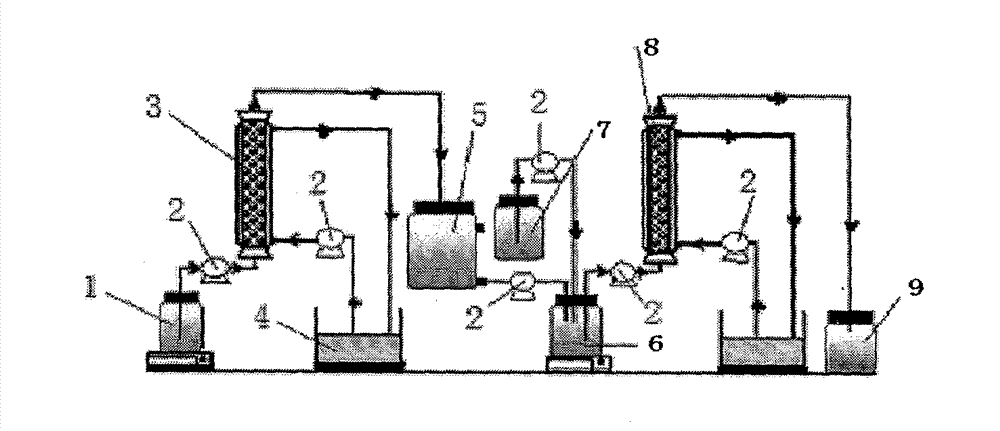

Preparation apparatus and preparation method for graphene

ActiveCN103435030AHigh yieldImprove stripping efficiencyGrapheneBulk chemical productionOscillatory reactionPneumatic valve

The invention provides a preparation apparatus and a preparation method for graphene. The apparatus comprises a first reaction vessel, a second reaction vessel, a first stirrer, a second stirrer and a pneumatic valve. The method comprises the following steps: introducing graphite powder and a dispersant into the first reaction vessel; introducing a reaction medium into the first reaction vessel, allowing the reaction medium to form a supercritical fluid, and allowing the graphite powder to undergo a reaction so as to obtain graphite powder reacted in the first reaction vessel; adjusting the pneumatic valve to allow the graphite powder reacted in the first reaction vessel and the dispersant to enter into a second reaction vessel with a normal pressure, introducing the reaction medium into the second reaction vessel, allowing the reaction medium to form a supercritical fluid, allowing the graphite powder to undergo a reaction so as to obtain graphite powder reacted in the second reaction vessel and repeating the previous steps several times so as to obtain a crude graphene product; and cleaning and drying the crude graphene product so as to obtain graphene. The preparation method for graphene utilizes performance of the supercritical fluid and the characteristics of a dual-reaction vessel oscillatory reaction so as to prepare high quality and high yield graphene.

Owner:江苏华永烯科技有限公司

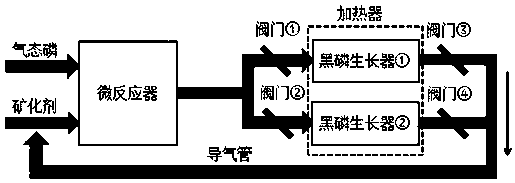

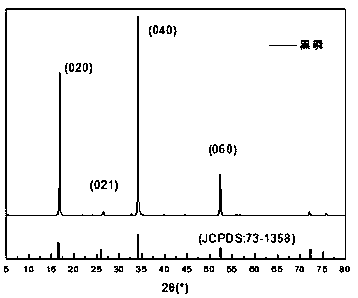

Continuous preparation method of black phosphorus

The invention discloses a continuous preparation method of black phosphorus, and belongs to the technical field of phosphorus chemical industry. The method disclosed by the invention comprises the following steps: introducing gaseous phosphorus and a mineralizer into a microreactor in which the temperature is 550 to 750 DEG C, after sufficiently mixing the reactants inside the microreactor to react sufficiently, further introducing obtained gaseous products into a black phosphorus grower in which the temperature is 200 to 500 DEG C, growing black phosphorus inside the black phosphorus grower,simultaneously separating the mineralizer from black phosphorus in a gaseous state, and mixing with an initial mineralizer for continuous utilization. According to the preparation method, high-purityblack phosphorus can be prepared, and continuous preparation of black phosphorous can be realized, so that the device is low in cost, simple and easy to operate, the device can be engaged with production equipment of yellow phosphorous and red phosphorous in industrial engineering at present, and the production cost is reduced.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing high-silicon steel ribbon through using electric brush composite plating method and continuous silicon steel ribbon preparing device

ActiveCN103320842AAvoid adverse effectsHigh cell voltageElectrolytic coatingsCarbon steelSilicon particle

The invention discloses a method for preparing a high-silicon steel ribbon through using an electric brush composite plating method. The method is characterized in that a pure iron ribbon, a low-carbon steel ribbon or a low-silicon steel ribbon is used as a cathode plating piece ribbon, an electric brush plating anode plate is used as an anode, a layer of iron-silicon iron particle composite plating layer is coated on the cathode plating piece ribbon through using an electric brush composite silicon plating process, a composite plating layer steel ribbon adopting a steel-ribbon substrate as a core part is formed, then the uniform dispersion heat treatment is carried out, silicon-contained particles in the iron-silicon iron particle composite plating layer are uniformly dispersed into the steel ribbon substrate of the core part, and the high-silicon steel ribbon can be continuously prepared. The invention also discloses a continuous silicon steel ribbon preparing device which comprises an unreeling guide device, a conveying device, an electroplating device, a dispersion heat treatment device and a rolling device. The high-silicon plating layer is electrically plated on the cathode plating piece ribbon, then the high-silicon steel ribbon with an excellent magnetic conduction performance is obtained through using a heat treatment process, the simplicity in operation can be realized, characteristics such as high efficiency and continuity in preparation can be achieved, and the preparation cost also can be greatly reduced.

Owner:SHANGHAI UNIV

Continuous production equipment for foam aluminum alloy

ActiveCN103667765AReduce labor intensityImprove production efficiency and product qualification rateIntermediate frequencyContinuous production

The invention relates to continuous production equipment for a foam aluminum alloy. The continuous production equipment comprises a smelting heat-preserving furnace, a molten aluminum thickening furnace, a continuous foaming furnace, a rolling device and a cooling system, wherein the molten aluminum thickening furnace comprises an intermediate frequency furnace body I, a movable furnace cover and a stirring device; the intermediate frequency furnace body I is used for receiving molten aluminum flowing out of a chute; one side of the bottom of the intermediate frequency furnace body I is provided with a conveying valve bank which is connected with the continuous foaming furnace and is used for conveying thickened molten aluminum to the continuous foaming furnace; the conveying valve bank comprises a ceramic conveying tube, a high-temperature adjusting valve and an executing mechanism; the continuous foaming furnace comprises an intermediate frequency furnace body II, a furnace cover and a stirring device; the bottom of the intermediate frequency furnace body II is provided with a ventilation brick; a gas supplying device is arranged on the ventilation brick; one side of the upper part of the intermediate frequency furnace body II is provided with a foam aluminum alloy outflow port which is connected with at least two groups of movable furnace nozzles; molten aluminum foam in the furnace is conveyed to the rolling device through the movable furnace nozzles for molding by rolling. According to the continuous production equipment, the foam aluminum alloy is produced by adopting a continuous foaming and casting way, and foam aluminum sections of various sizes and various section specifications can be prepared.

Owner:岳阳钟鼎热工电磁科技有限公司

Electrochromic fiber and preparing method and application thereof

ActiveCN108873539ASimple structureRealize long-term constructionNon-linear opticsFiberElectrochromism

The invention relates to an electrochromic fiber and a preparing method and application thereof. The preparing method includes the steps that a metal wire is used as an electrode, the surface of the metal wire is coated with a viologen electrochromic electrolyte solution through fiber continuous construction equipment, heating solidifying is carried out, then external electrodes and a protection layer are prepared on the outer side, and the electrochromic fiber is obtained. The electrochromic fiber prepared with the method has good flexibility and discoloration performance, electrochromic fibers of 100 m or above can be continuously prepared, the problems that the electrochromic fiber is complex in structure, and cannot be continuously prepared are solved, and the electrochromic fiber hasgood application prospects in the field of intelligent garments.

Owner:DONGHUA UNIV

Metal casting blank continuous manufacturing device and method capable of providing pressure casting function

The invention discloses a metal casting blank continuous manufacturing device capable of providing the pressure casting function. The device comprises a hollow melting furnace. A hollow furnace cavity is formed in the melting furnace. A feeding port is formed in the side wall of the furnace cavity. A threaded rod is arranged in the furnace cavity. One end of the threaded rod extends out of the furnace cavity. A crystallizer communicated with the furnace cavity is connected into the lower end of the furnace cavity. A water outlet and a water inlet are sequentially formed in the side wall of the crystallizer from bottom to top. The crystallizer is used for cooling metal casting blanks. A dragger used for dragging the metal casting blanks is further arranged below the crystallizer. The invention further provides a metal casting blank continuous manufacturing method. Through the device and method, the problems that metal casting blanks are loose, uneven in components, large in grain and poor in quality in the prior art are solved.

Owner:JIANGXI UNIV OF SCI & TECH

Method for continuous preparation of aluminum-base in-situ composite material

The invention relates to an aluminum-base composite material, and in particular relates to a method for continuous preparation of an aluminum-base in-situ composite material. The method is characterized by comprising the steps of mixing a pre-heated solid reactant with an aluminum alloy at near-liquidus temperature through a spiral rheological extrusion device, implementing chemical reaction in a high-temperature area after extrusion, continuously feeding a high-temperature aluminum-base composite material obtained from the reaction into a composite material melting bath; simultaneously, introducing an aluminum alloy melt which is at a relatively low temperature to the melting bath, electromagnetically stirring to mix the melt, reducing temperature of slurry of an aluminum-base in-situ composite material to normal pouring temperature of the base alloy so as to guarantee uniformity, molding through a conventional pouring method, and cooling to obtain an aluminum-base in-situ composite material ingot or casting. The method disclosed by the invention, which effectively integrates advantages of the prior art, is mature in core technology, easy to implement and convenient for industrial application.

Owner:JIANGSU UNIV

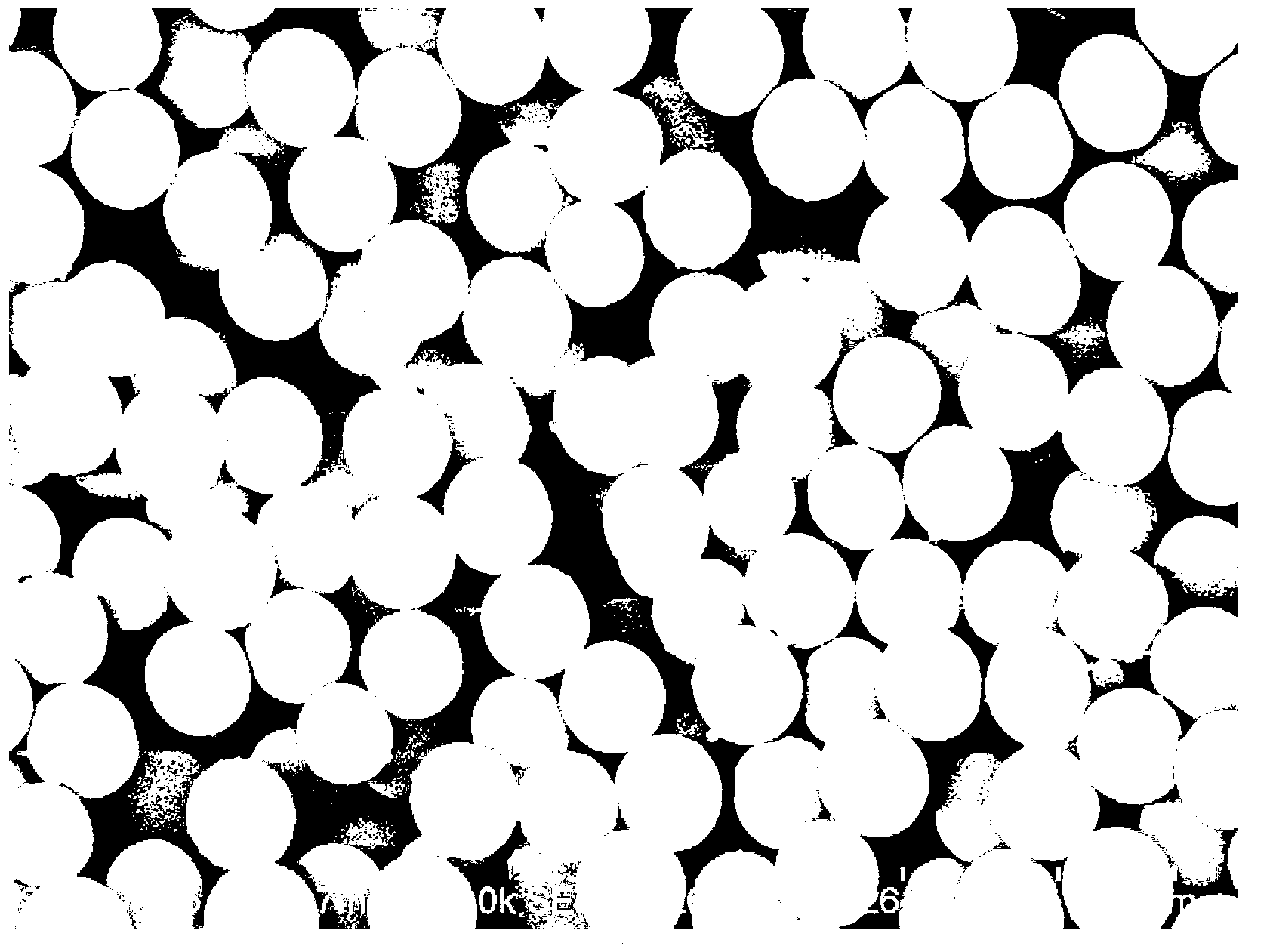

Preparation method, device and application of spherical magnesium oxide

ActiveCN108975360ASimple and fast operationCause secondary pollutionOther chemical processesDisinfectantsMagnesium saltPhysical chemistry

The invention provides a preparation method, device and application of spherical magnesium oxide, and belongs to the technical field of inorganic chemical industry. The method comprises the steps thata magnesium salt solution and an auxiliary solution are mixed and are prepared into a precursor solution or sol under the stirring condition; and the precursor solution or sol passes through a reaction device through carrier gas, and solid powder is collected and calcined so as to obtain a spherical magnesium oxide product. Magnesium oxide particles prepared through the method are controllable inmorphology, uniform in particle size and capable of realizing continuous preparation. The prepared spherical magnesium oxide can be used for metal ion adsorption and can also be used in the field ofantibacterial materials.

Owner:DALIAN UNIV OF TECH

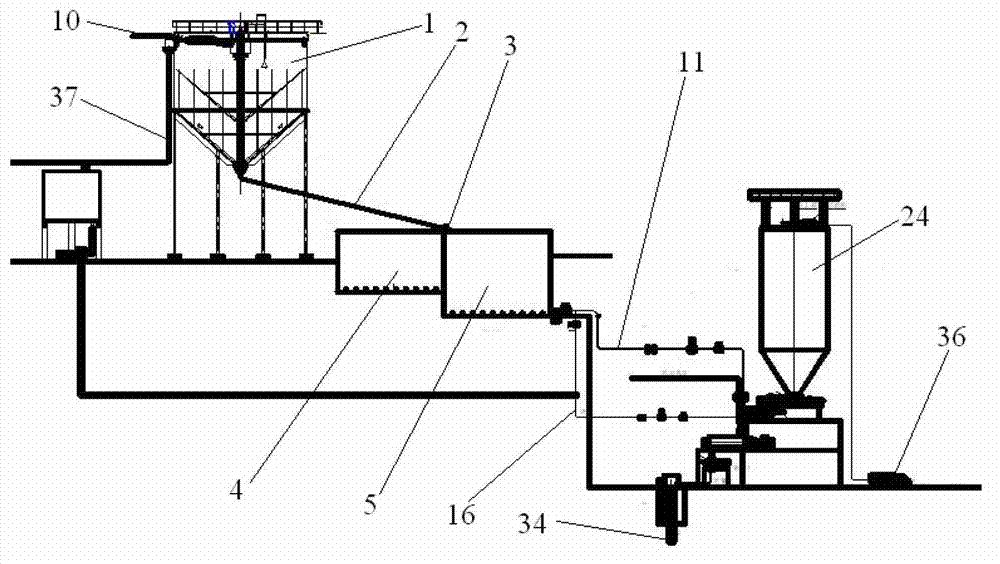

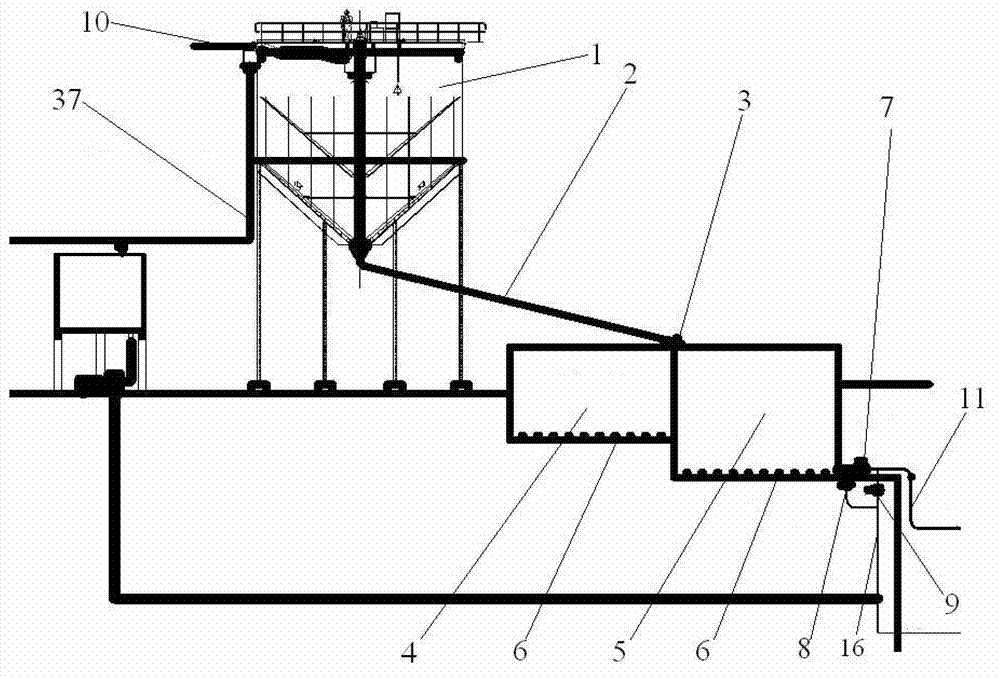

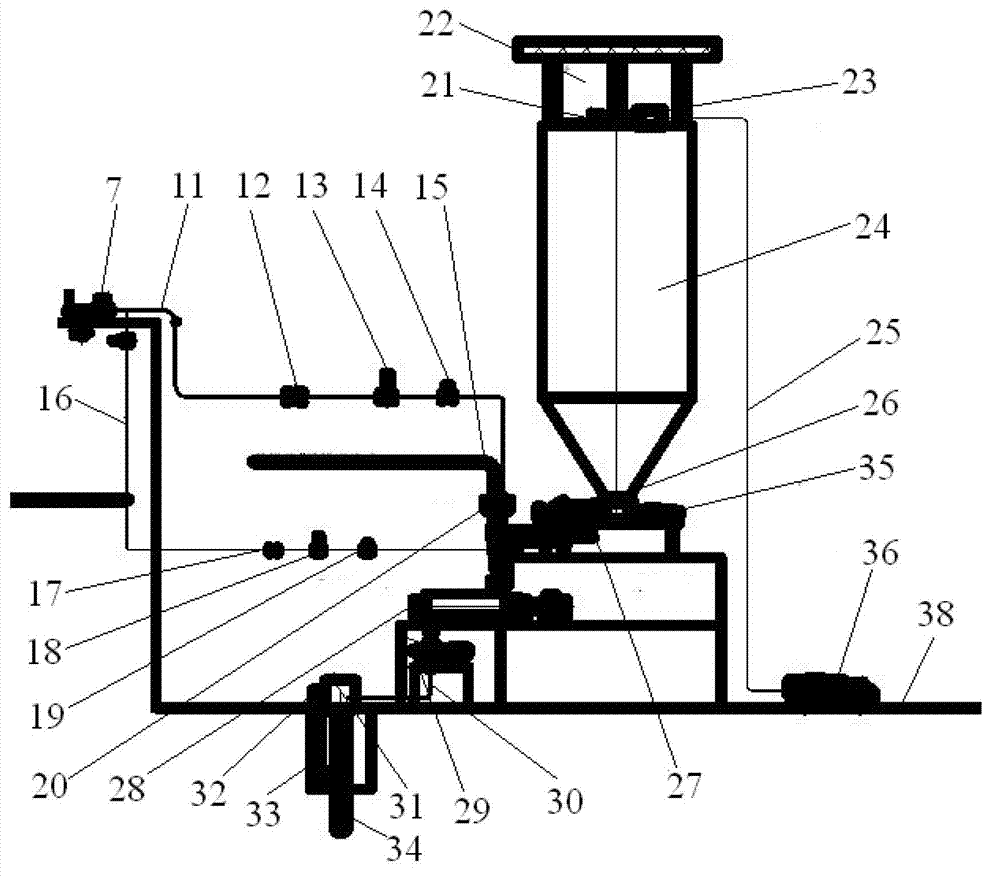

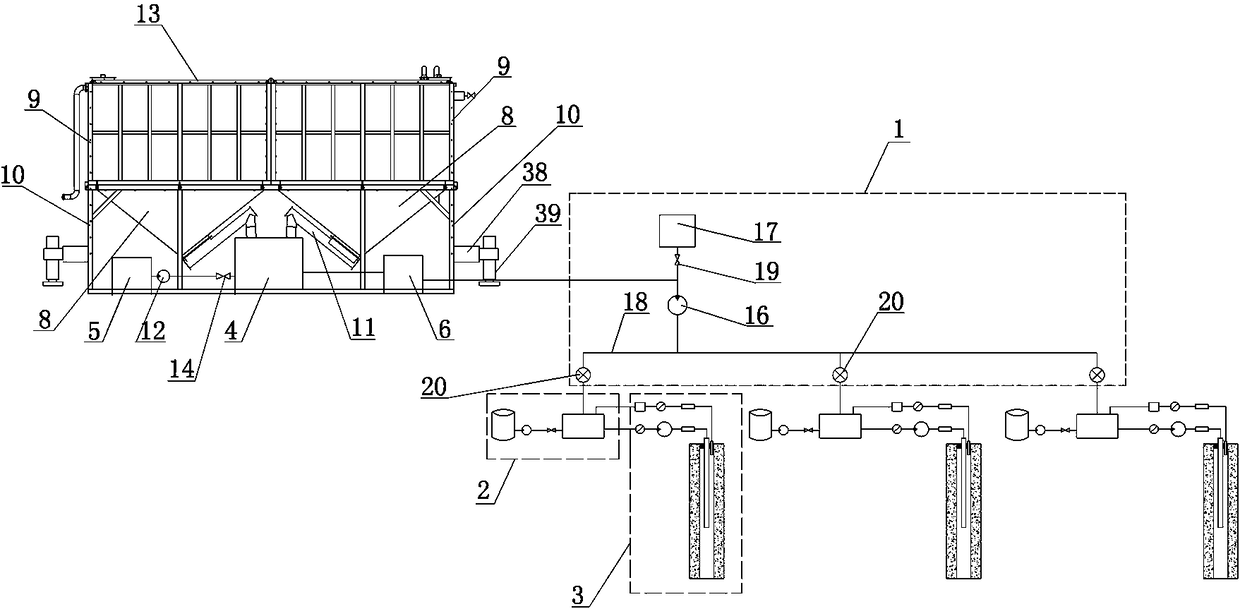

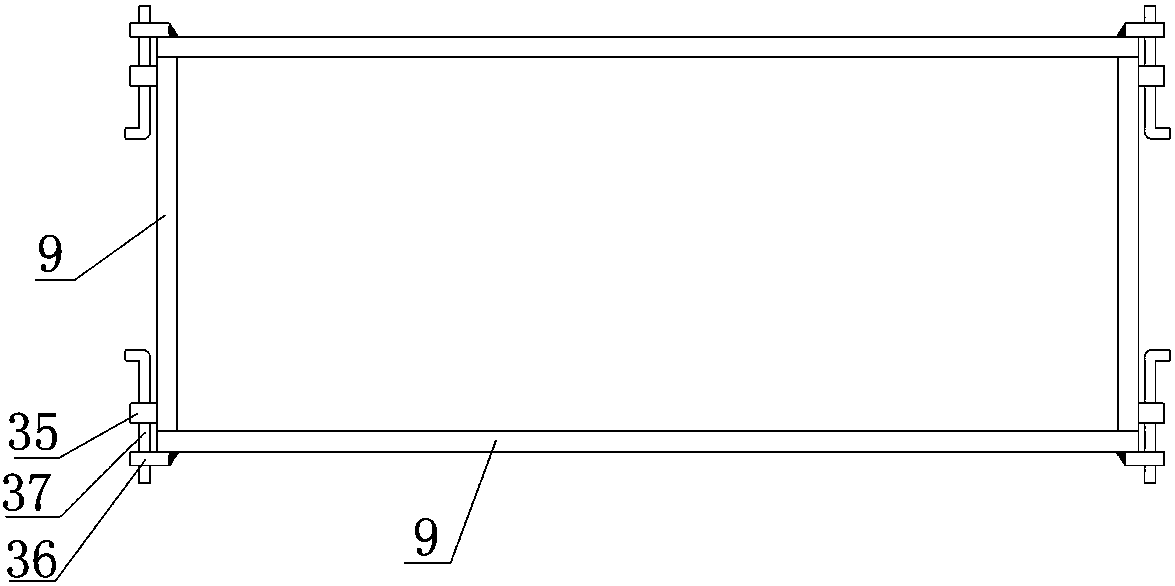

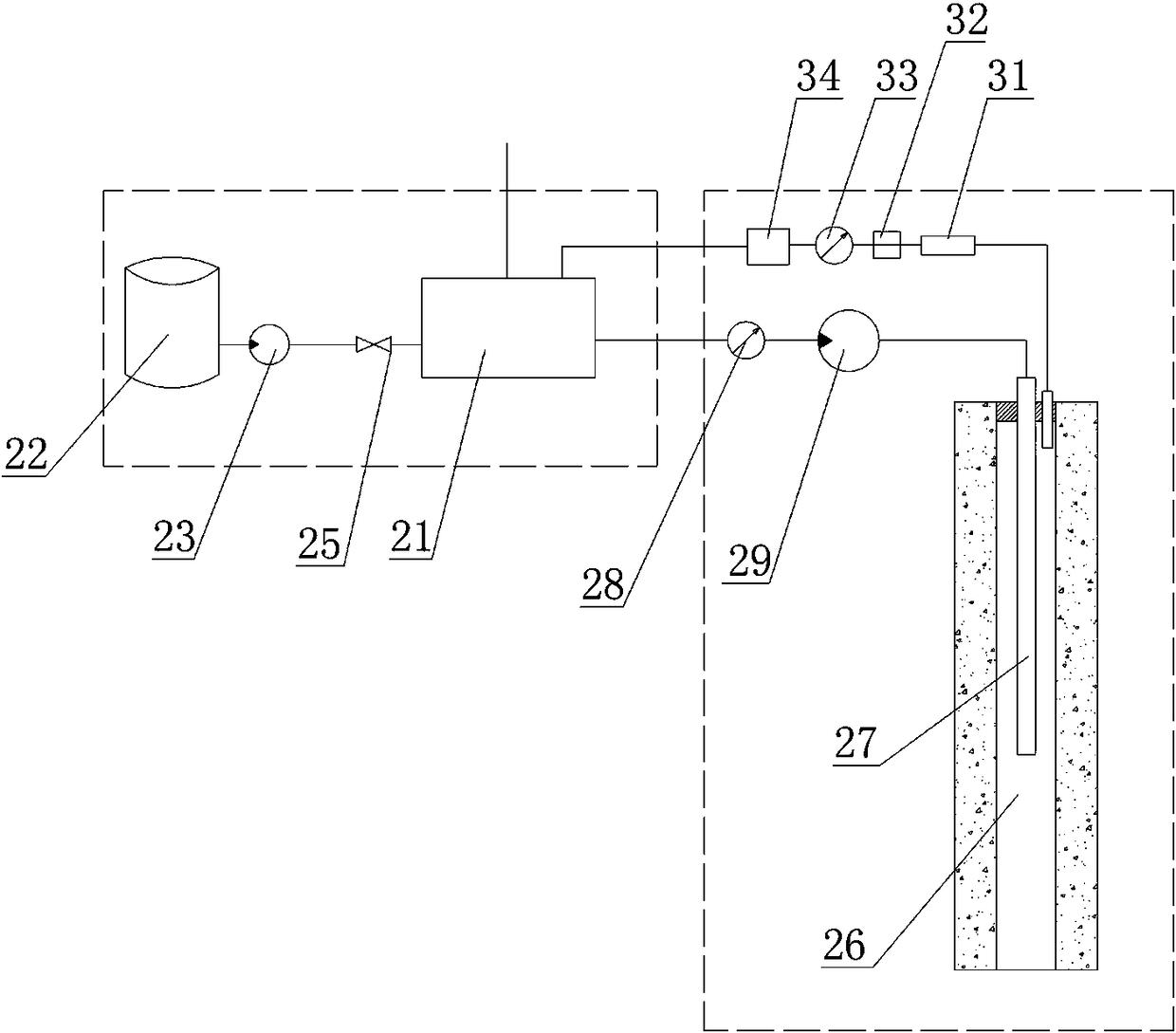

Preparation and production equipment for unclassified tailing filling material and preparation process

ActiveCN103086625ARealize continuous preparationRealize automatic controlAutomatic controlWater quality

The invention discloses preparation and production equipment for an unclassified tailing filling material. The preparation and production equipment comprises a high condensation product thickener (1), wherein the upper part of the high condensation product thickener (1) is connected with a concentrating mill thickener bottom flow pipe (10), and the bottom part of the high condensation product thickener (1) is connected with a sand tank through a thickener bottom conveying pipeline (2); the sand tank is connected with a coagulating, stirring and filling system through a sand discharging pipe (11); and the high condensation product thickener (1) is high efficiency and deeply conical, namely the bottom part of the high condensation product thickener (1) is a conical surface. Furthermore, the invention also discloses a preparation method adopted by the preparation and production equipment. Through the technical scheme, the novel efficient deep-cone thickener is used for preparing the full-fraction filling tailings, so that a continuous preparation of the filling material and an automatic control of the filling process are achieved; and the preparation and production equipment guarantees that overflow water quality meets the demand of recycling use of a concentrating mill.

Owner:安徽马钢矿业资源集团姑山矿业有限公司 +1

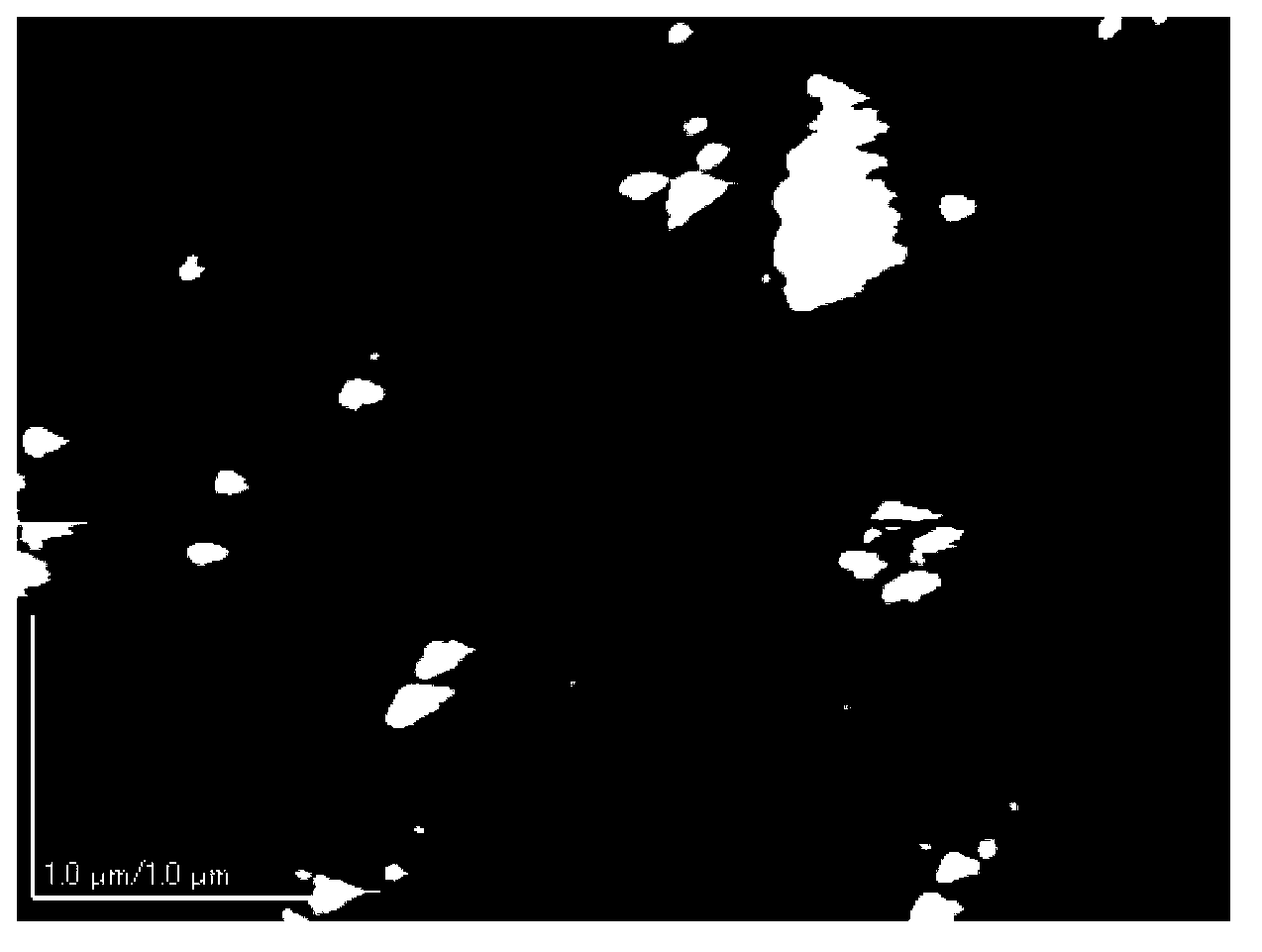

Self-supported graphene hydrogel membrane and preparation method thereof

The invention discloses a self-supported graphene hydrogel membrane and a preparation method thereof. The preparation method comprises the following steps: 1) mixing 1 part of graphene oxide and 50-200 parts of water, and carrying out ultrasonic dispersion to obtain an aqueous dispersion of the graphene oxide; 2) extruding the aqueous dispersion of the graphene oxide obtained in the step 1) into solidified liquid in a horizontal die device at the extrusion speed of 10-1,000mL / h, and solidifying to form a graphene oxide hydrogel membrane; and 3) carrying out chemical reduction on 1 part of graphene oxide hydrogel membrane obtained in the step 2) by using 1-200 parts of a reducing agent, and cleaning by water to obtain the self-supported graphene hydrogel membrane. The self-supported graphene hydrogel membrane is simple and convenient in method, simple in process, low in energy consumption, green and environment-friendly; the obtained self-supported graphene hydrogel membrane is good in toughness, high in strength, adjustable in thickness and size, and regular in microstructure, and can be applied to the fields such as biological drug loading and catalysis.

Owner:ZHEJIANG TANGUSHANGXI MATERIAL SCI & TECH

Preparation method of jet-molded multi-gradient high-speed steel

InactiveCN104131211AImprove atomization efficiencyImprove deposition efficiencyPorosityChemical composition

The invention provides a preparation method of a jet-molded multi-gradient high-speed steel. The high-speed steel is composed of the following chemical components in percentage by weight: 1.5-2.0% of C, 4.5-5.0% of Cr, 4.5-5.5% of Mo, 7.0-7.5% of W, 3.0-3.8% of V, 0.6-1.0% of Nb, 0.2-0.5% of Ti, 0.5-1.0% of Si, 0.1-0.5% of Mn and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: blending materials, melting, carrying out jet molding, carrying out air cooling, annealing, carrying out hot forging and carrying out quench tempering. Due to the adopted method, the nebulization efficiency and deposition efficiency of the nozzle are improved and continuous preparation of a multi-layer composite material is realized. The preparation method of the jet-molded multi-gradient high-speed steel has the beneficial effects of low porosity (2-4%) of the deposited blank, fine and even structure (mean grain size ranging from 0.9 to 20 microns), excellent interfacial mechanical property and high material yield (72%-85%).

Owner:江苏飞达钻头股份有限公司

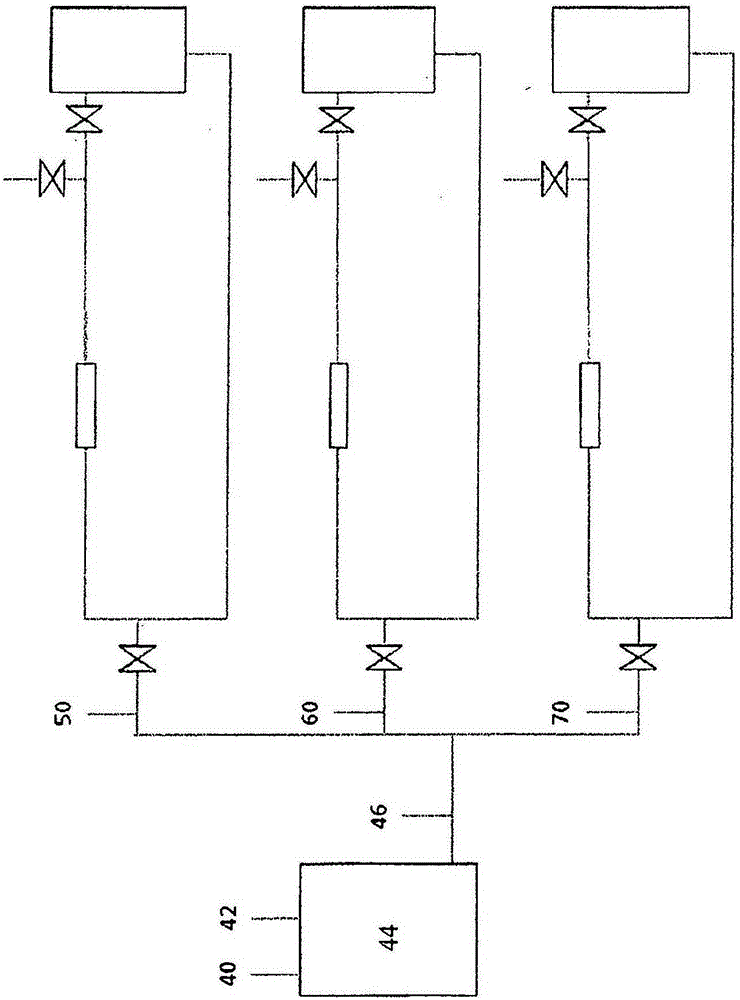

Millimeter channel type continuous preparation system

ActiveCN105080448AIncreased turbulenceEnhance heat and mass transferChemical/physical/physico-chemical processesUltrafiltrationEngineering

The invention provides a millimeter channel type continuous preparation system which can be used in preparation of various inorganic nonmetal nanocrystallines (such as oxides and sulfides). Compared with the prior art, the system has the advantages that 1, a millimeter channel type reaction pipe is adopted, and is internally provided with inner threads, so that turbulent flows are promoted to be generated in the channel, and heat and mass transfer is promoted effectively in the channel; 2, an ultrafiltration purification device is adopted for filtering out raw material molecules or ions which are subjected to non-complete reaction in a reaction mixed liquid, so that the continuous preparation of products is realized; 3, if a material tank is improved further, nitrogen can be introduced, so that the materials can be isolated from oxygen at the normal temperature, and channel type heat reaction is realized under an inert atmosphere. The millimeter channel type continuous preparation system can be used for the pilot plant test preparation of the nanocrystallines and high-molecular polymers, and can be used for effectively controlling the sizes or the molecular weight distribution of the materials.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

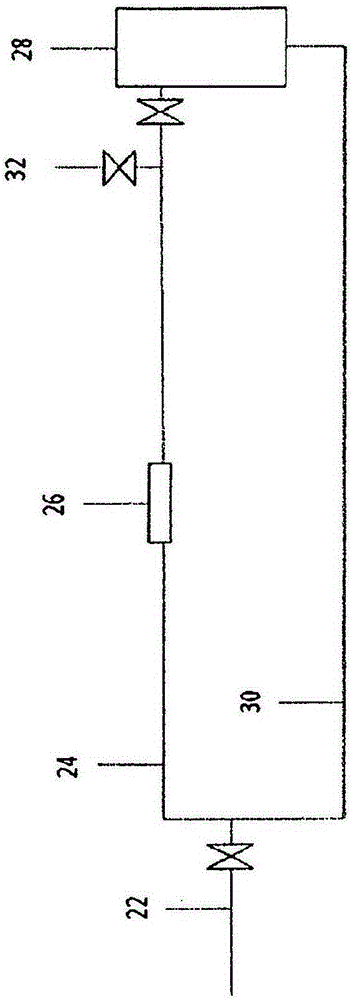

Multiple batch system for the preparation of a solution of calcium hydrogen carbonate suitable for the remineralization of desalinated water and of naturally soft water

InactiveCN105246838ARealize continuous preparationFlow mixersTransportation and packagingCalcium bicarbonateHydrogen

Owner:OMYA INT AG

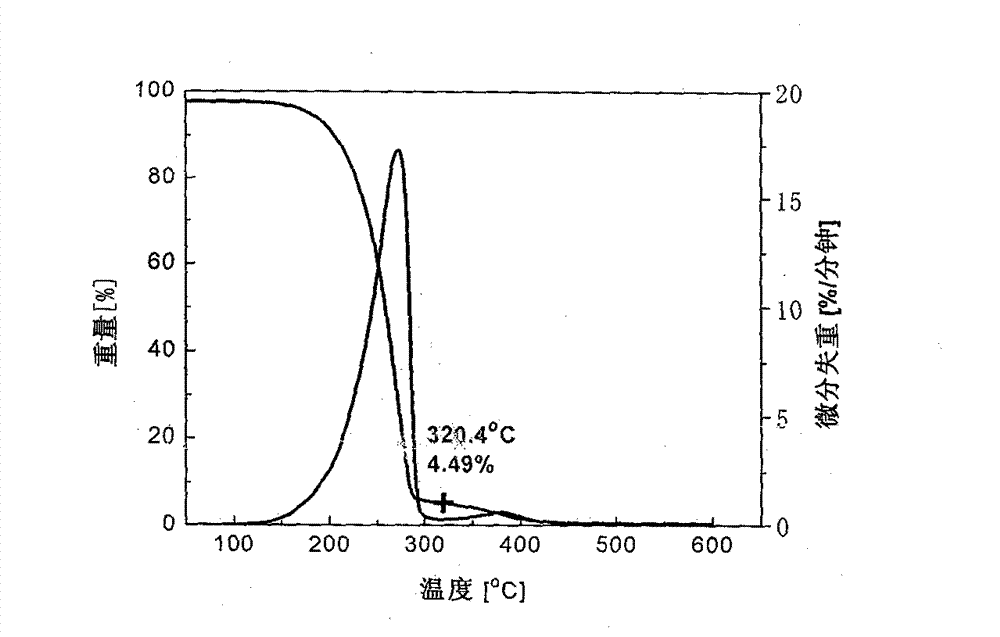

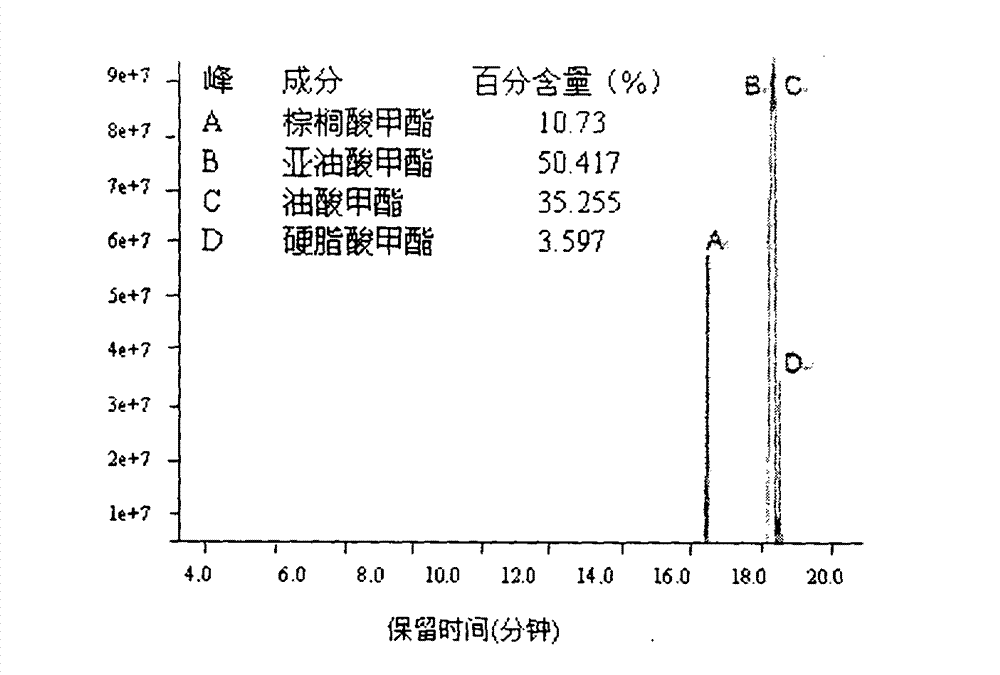

Continuous preparation method of biodiesel

InactiveCN102816645AAchieve separationRealize the transesterification reactionFatty acid esterificationBiofuelsEnvironmental resistanceOil and grease

The invention relates to a continuous preparation method of biodiesel, which uses waste animal and vegetable grease as the raw material and mainly comprises the following steps: (1) removing impurities and moisture in the raw material; (2) performing continuous esterification reaction in a cation exchange resin fixed bed reactor; (3) separating the esterification product; and (4) performing continuous ester exchange reaction and separation in an anion exchange resin fixed bed reactor. The invention overcomes the problems of severe equipment corrosion, difficult product separation, serious environmental pollution caused by waste acid liquid, failure to realize continuous preparation and the like in the homogeneous catalysis process, is low in cost, high in yield and friendly to environment, and has important market application prospects.

Owner:TIANJIN POLYTECHNIC UNIV

Method and equipment for successive co-orientation solidification casting and manufactured wire rod or plate and belt material

A casting method by continuous directional solidifying includes extending one end of drawing line or plate in crystallizing mouth, extending its another end is cooling liquid, preheating the crystallizer, pouring fluid material in the crystallizer, insulating for directional solidifying, and drawing said drawing line or plate to draw the solidified material in cooling liquid. Its apparatus is composed of crystallizer, drawing line or plate, cooling unit, drawing unit and check unit. Its product (wire or plate) features high quality and uniformity, and excellent performance.

Owner:周照耀

Automatic grouting production system

InactiveCN108705678ARealize continuous preparationEasy to controlMixing operation control apparatusFoundation engineeringControl systemMonitoring system

The invention discloses an automatic grouting production system. The automatic grouting production system comprises a control system, a grout making station, a grout conveying system, grout proportionstations and grouting monitoring systems. The automatic grouting production system has the advantages that the automation degree is high, the labor cost is saved, the operation is simple, the unmanned production or the flexible manpower line is realized, the proportion precision is improved, and the labor intensity is reduced.

Owner:XIYI AUTOMATION SYST ENG CHENGDU +1

Method for efficiently preparing sulphur-doped hollow carbon spheres

InactiveCN105293468ARealize continuous preparationImprove efficiencyMaterial nanotechnologyPeristaltic pumpPtru catalyst

The invention relates to a method for efficiently preparing sulphur-doped hollow carbon spheres. The method for efficiently preparing the sulphur-doped hollow carbon spheres comprises the following steps: firstly weighing a catalyst and a sulphur source, and mixing the catalyst with the sulphur source, wherein the catalyst is ferric acetylacetonate, the sulphur source is carbon disulfide, and the concentration of the catalyst in the sulphur source is 1-0.025g / ml; introducing the mixture into a tubular furnace, wherein temperature of the tubular furnace is 600-1350 DEG C; introducing inert gas as a carrier gas, inputting a reaction solution into an ejector inside the tubular furnace by virtue of a peristaltic pump, then spraying into a high-temperature region of the tubular furnace, and collecting products at the tail of the tubular furnace, so that carbon-coated iron nano core-shell particles are obtained; and putting the obtained carbon-coated iron nano core-shell particles into the mixed solution of hydrochloric acid and nitric acid, heating to 60-100 DEG C, carrying out magnetic stirring, filtering the obtained mixed liquor, adding deionized water for washing until filtrate is neutral, and immediately drying, so that the sulphur-doped hollow carbon spheres with high specific surface areas are obtained. The method for efficiently preparing the sulphur-doped hollow carbon spheres is easy to operate, simple in after-treatment, and applicable to industrial production.

Owner:SHANGHAI INST OF TECH

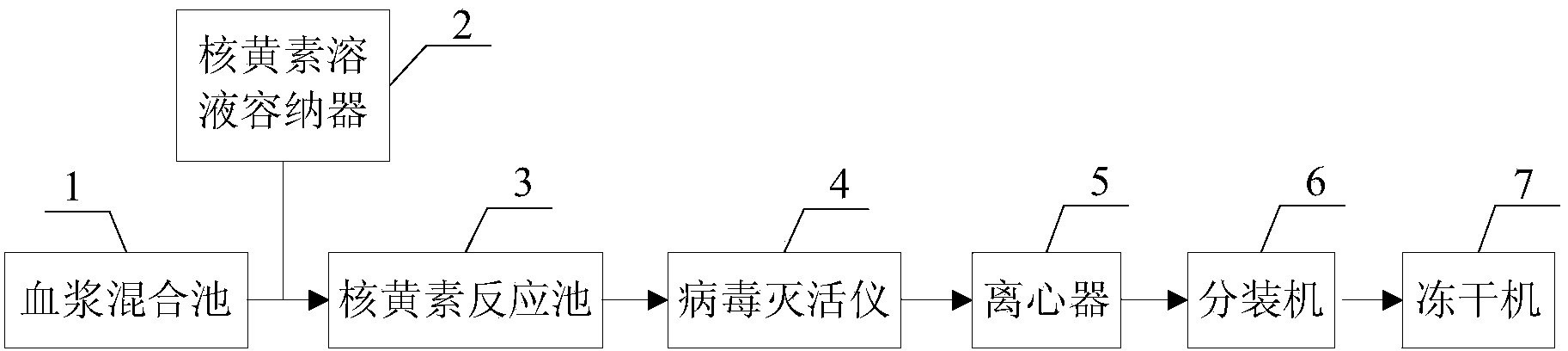

Preparation device and preparation method of universal virus inactivation blood plasma

InactiveCN104248643ARealize continuous preparationImprove production efficiencyMammal material medical ingredientsVirus inactivationTiter

The invention discloses a preparation device and a preparation method of universal virus inactivation blood plasma, the preparation device comprises a blood plasma mixing pool, a riboflavin solution container, a riboflavin reaction pool, a virus inactivation instrument and a centrifuge; the blood plasma mixing pool and the riboflavin solution container are connected with the riboflavin reaction pool by pipelines, and the riboflavin reaction pool is in turn connected with the virus inactivation instrument and the centrifuge. The preparation device and the preparation method can realize the continuous preparation of blood plasma, enhance the preparation efficiency of the blood plasma, can unify protein content specifications, improve the infusion efficiency, can reduce the titer of anti A and anti B two antibodies in the blood plasma, and inactivate all kinds of pathogens in the blood plasma and improve the safety of the blood plasma; and lyophilized powdery universal virus inactivation blood plasma is convenient in storage and transportation.

Owner:GENERAL HOSPITAL OF PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com