Method for rapidly processing graphical surface of ultralong grating ruler rolling die

A surface pattern and processing method technology, applied in the field of lithography, can solve the problems of high environmental condition dependence, high cost, low manufacturing efficiency, etc., and achieve the effect of reducing manufacturing cost, high production efficiency, and low external environment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

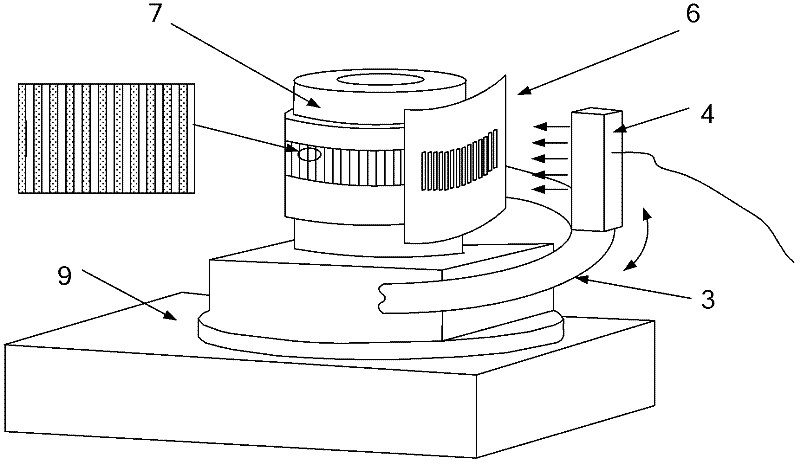

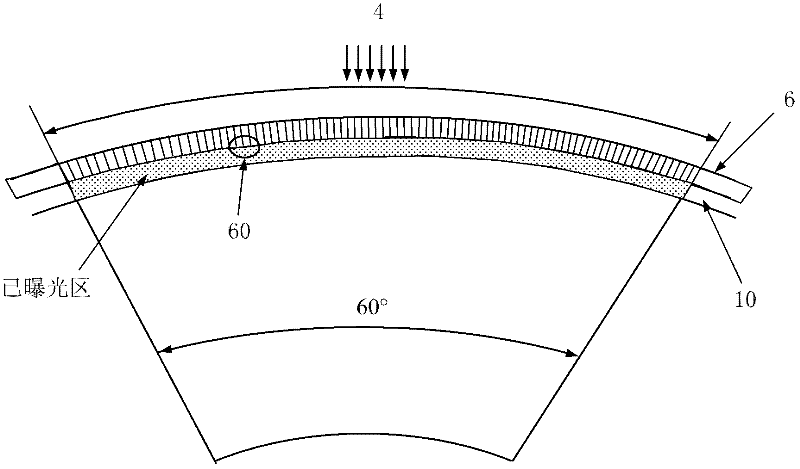

[0038] The present invention will be further described below through the accompanying drawings and specific implementation examples.

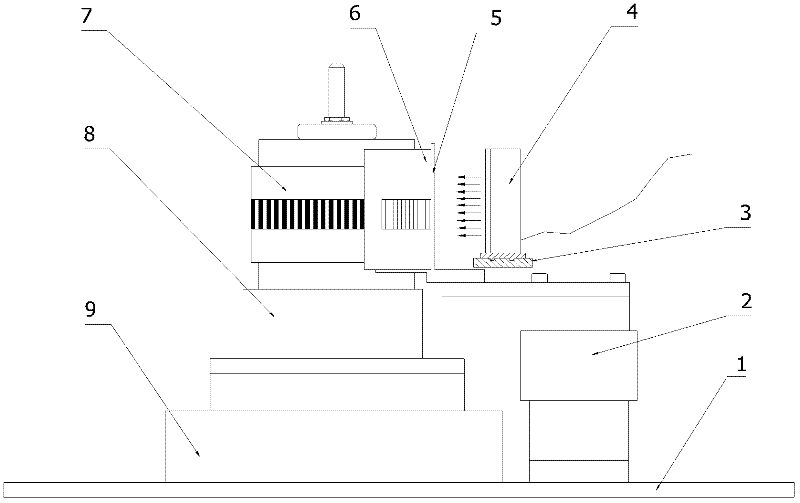

[0039] see Figure 1 to Figure 5 As shown, the specific implementation of the method for rapid processing of the surface patterning of the ultra-long grating scale rolling mold of the present invention is realized through the following steps. The method includes the following steps:

[0040] The first step is to select a suitable rolling die: choose cylindrical metal copper, Invar, etc. or choose non-metallic cylindrical quartz blank material as the material of rolling die 7; the diameter of rolling die 7 is Φ50mm~Φ500mm, and the length 50mm-500mm, after traditional mechanical turning, milling and grinding, the surface roughness Ra of the rolling mold 7 is less than 1.6, and the errors of roundness and cylindricity are less than or equal to 0.01mm;

[0041] The second step, cleaning of the surface of the rolling mold: first immerse the rollin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com