A tension-compression process for special-shaped materials using pmi foam sandwich

A technology of profiled material and foam core, applied in the direction of coating, etc., to achieve good connection effect, enhance overall stability, and achieve the effect of designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

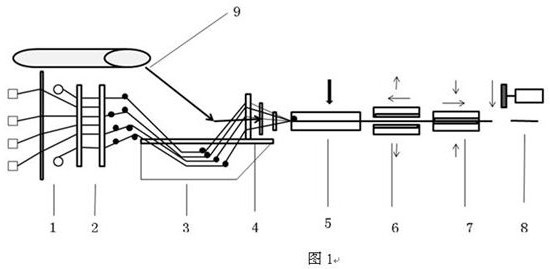

Image

Examples

Embodiment 1

[0029] A kind of special-shaped bar tension-compression process that adopts PMI foam sandwich, is characterized in that, comprises the steps:

[0030] Step (1) impregnation, impregnation of multiple fibers or rovings with resin, the resin impregnation process can be realized in an impregnation tank;

[0031] Step (2) preforming, after the fiber material is impregnated with resin, it is preformed by using mold tooling;

[0032] Step (3) Curing molding, impregnating the fiber material with resin to realize the curing of the resin in the molding mold to form a covering material, and at the same time, the PMI foam core is fed synchronously and continuously to realize the coating and the final molding of the product; to ensure the uniform temperature inside the mold It is characterized in that the PMI foam core is sprayed with a kind of gallium thulium doped on the surface of the PMI foam core before feeding. surface treatment agent;

[0033] Step (4) cutting, at the end of the e...

Embodiment 2

[0046] A kind of special-shaped bar tension-compression process that adopts PMI foam sandwich, is characterized in that, comprises the steps:

[0047] Step (1) impregnation, impregnation of multiple fibers or rovings with resin, the resin impregnation process is realized by pressing in the forming tool;

[0048] Step (2) preforming, after the fiber material is impregnated with resin, it is preformed by using mold tooling;

[0049] Step (3) Curing molding, impregnating the fiber material with resin to realize the curing of the resin in the molding mold to form a covering material, and at the same time, the PMI foam core is fed synchronously and continuously to realize the coating and the final molding of the product; to ensure the uniform temperature inside the mold It is characterized in that the PMI foam core is sprayed with a kind of gallium thulium doped on the surface of the PMI foam core before feeding. surface treatment agent;

[0050] Step (4) cutting, at the end of t...

Embodiment 3

[0063] A kind of special-shaped bar tension-compression process that adopts PMI foam sandwich, is characterized in that, comprises the steps:

[0064] Step (1) impregnating, impregnating multiple fibers or rovings with resin, the resin impregnating process is realized in the impregnating tank;

[0065] Step (2) preforming, after the fiber material is impregnated with resin, it is preformed by using mold tooling;

[0066] Step (3) Curing molding, impregnating the fiber material with resin to realize the curing of the resin in the molding mold to form a covering material, and at the same time, the PMI foam core is fed synchronously and continuously to realize the coating and the final molding of the product; to ensure the uniform temperature inside the mold It is characterized in that the PMI foam core is sprayed with a kind of gallium thulium doped on the surface of the PMI foam core before feeding. surface treatment agent;

[0067] Step (4) cutting, at the end of the equipme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com