Device for the production of spiral screens

一种螺旋筛、设备的技术,应用在造纸、应用、造纸机等方向,能够解决工艺技术不可行、螺旋圈品质损失等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

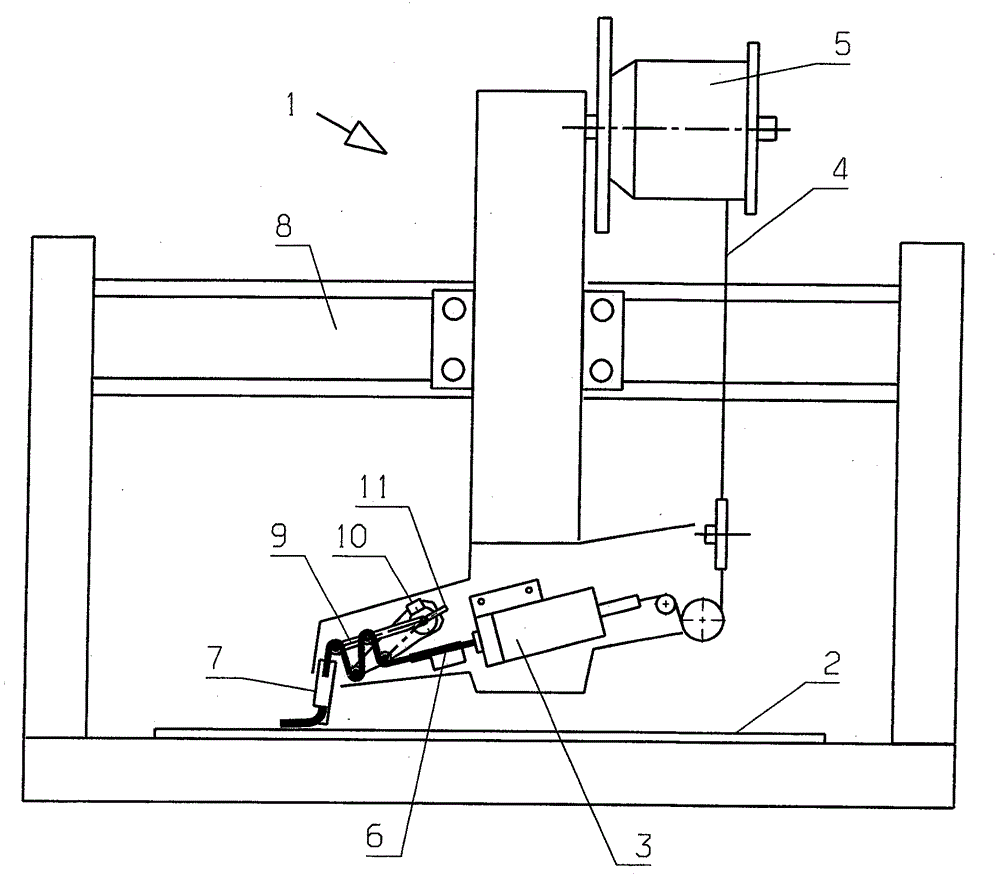

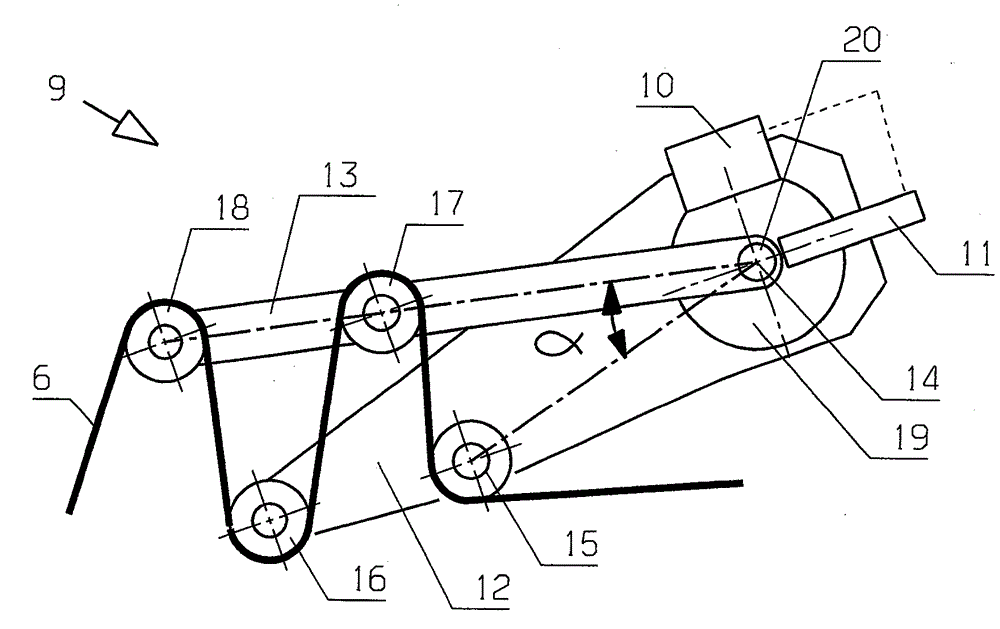

[0021] figure 1 A plant 1 for producing screw screens is shown very schematically with a working surface 2 and a coiling device 3 . The winding device 3 draws a plastic thread 4 (for example a plastic monofilament) from a reel 5 and thereby produces a helical coil 6 which is placed on the working surface 2 by means of a placement device 7 . To achieve this, the roll-forming device 3 can travel together with the depositing device 7 at a portal 8 . The drivers provided for this are not described in detail.

[0022] However, it can also be realized that only the placement device 7 travels above the working surface 2 while the lap forming device 3 remains stationary or travels at another speed relative to the working surface.

[0023] In the present exemplary embodiment, the placement device 7 deposits the coils 6 from the left side of the working surface 2 to the right side of the working surface 2 . The helical coil 6 is then severed. The placement device 7 travels from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com