Patents

Literature

213 results about "Glow discharge plasma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for atomic layer deposition using an atmospheric pressure glow discharge plasma

InactiveUS20100255625A1Comparable and good performanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPlasma generatorProduct gas

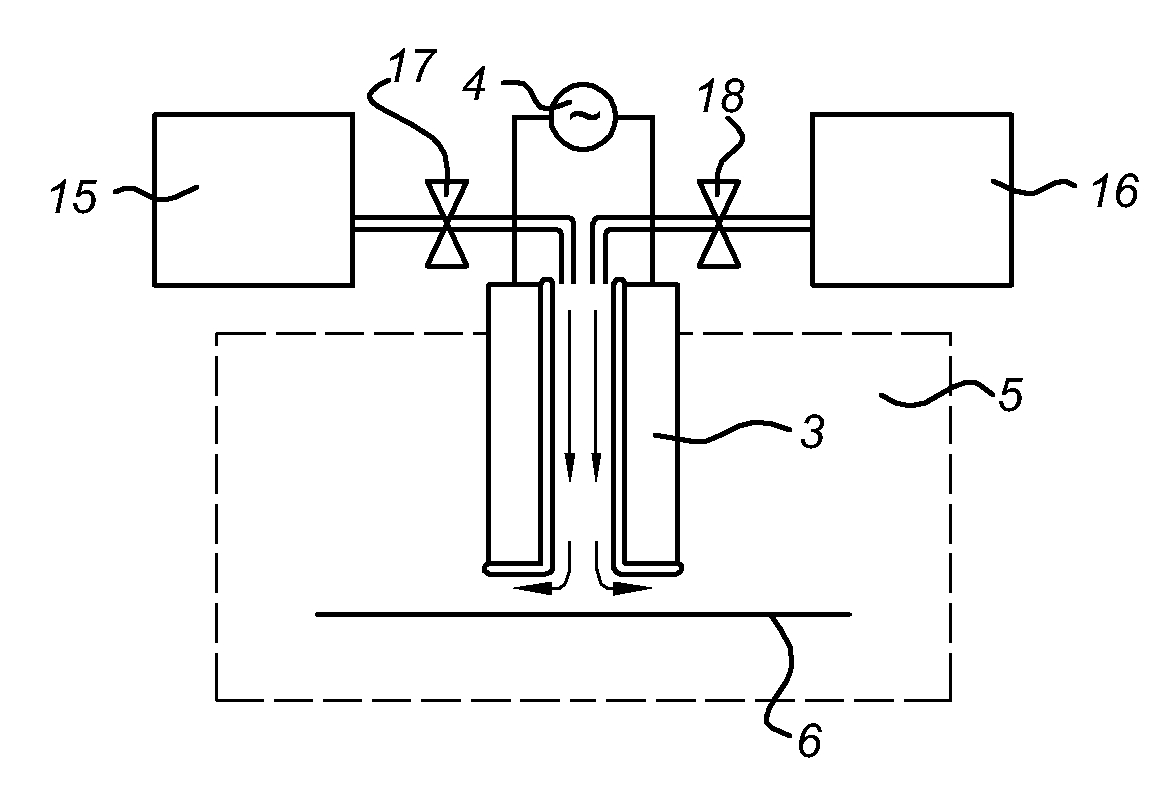

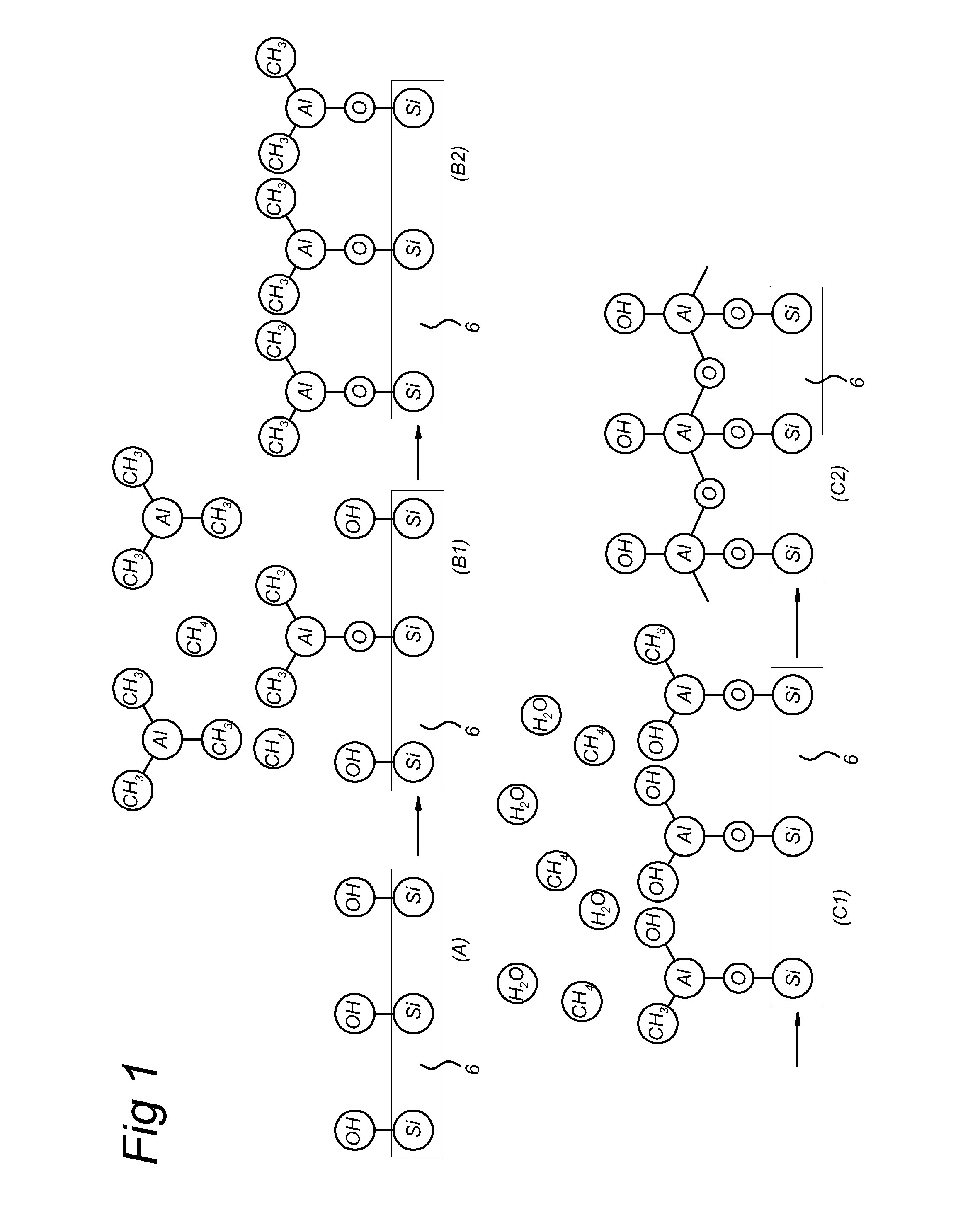

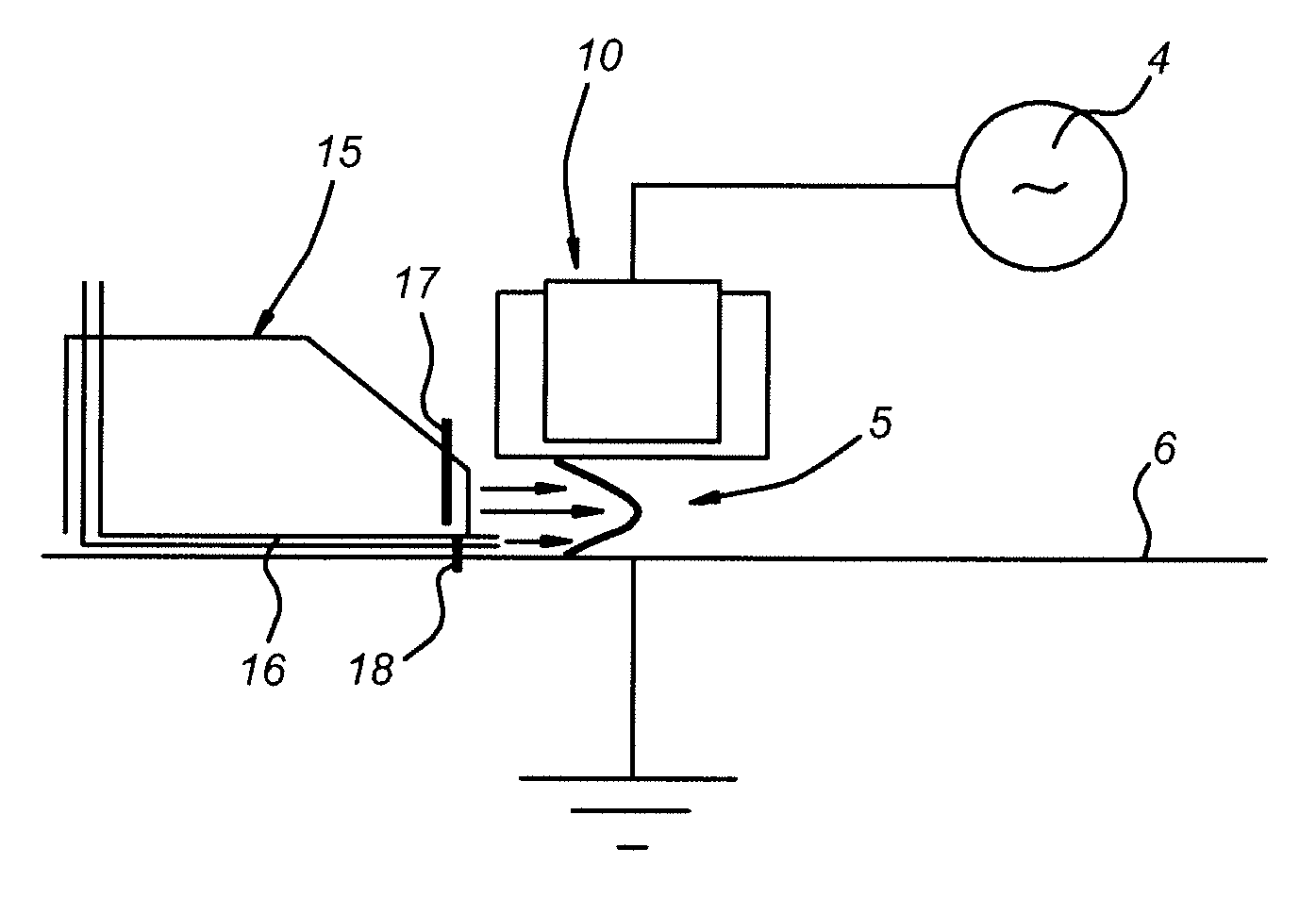

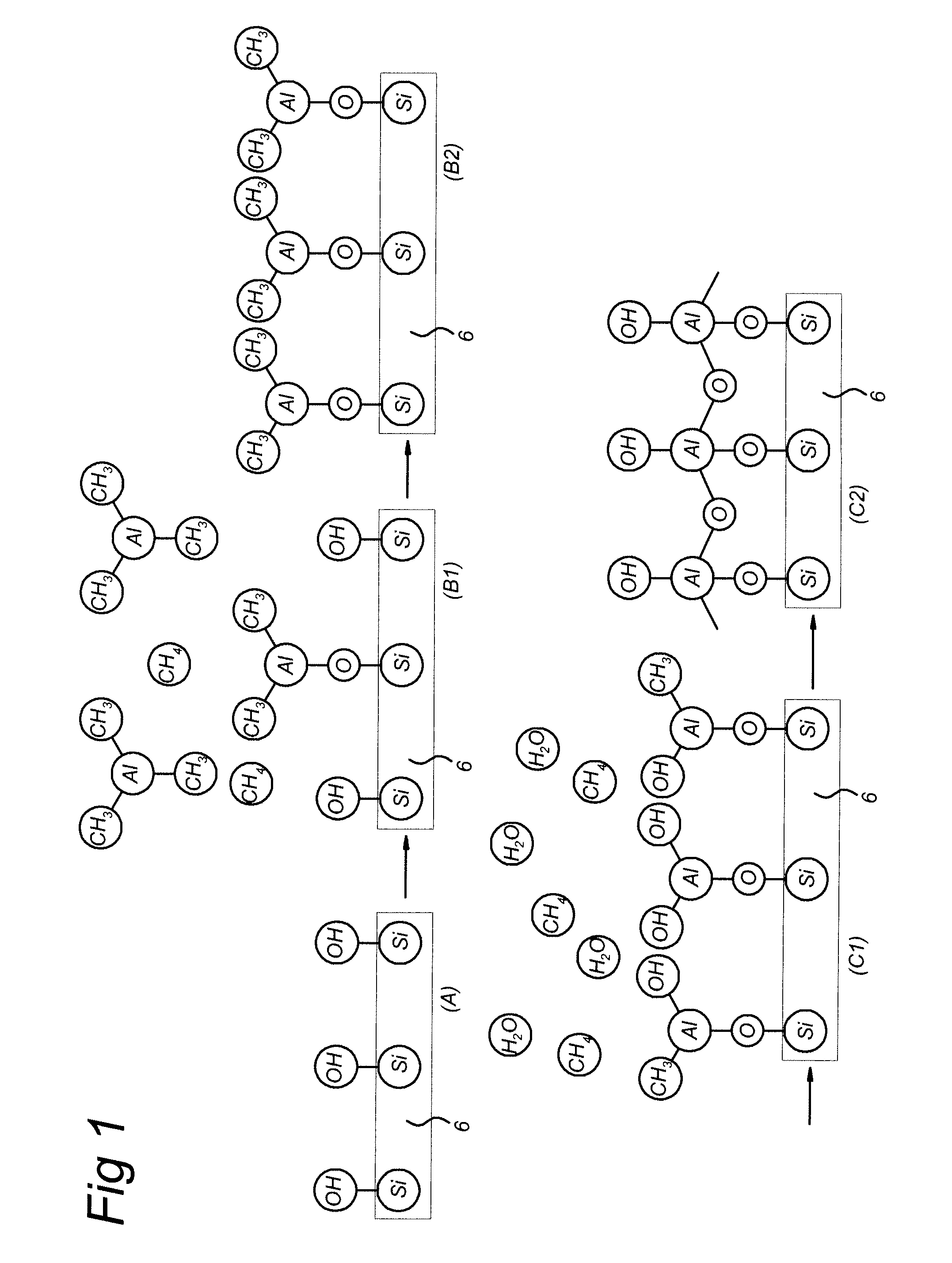

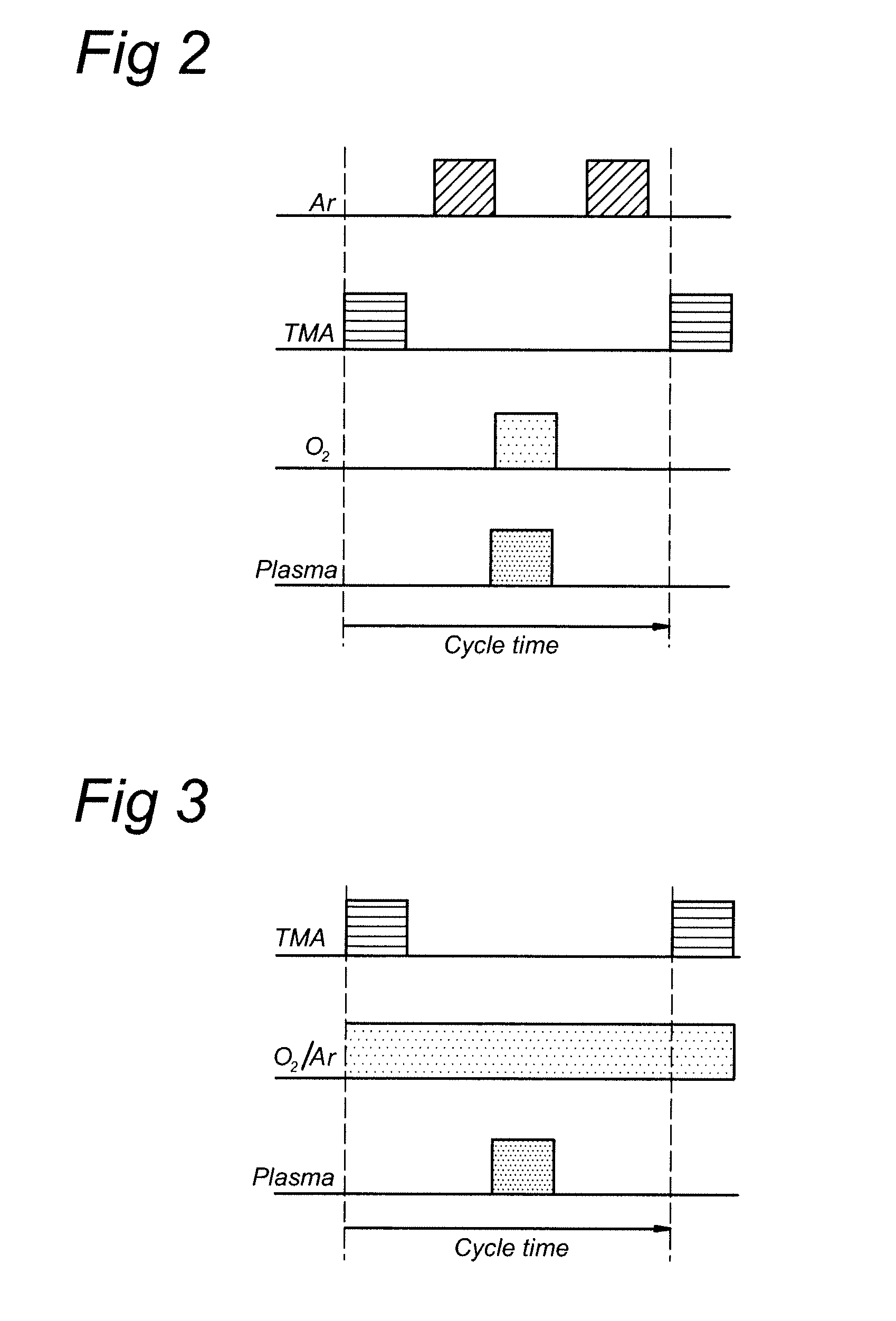

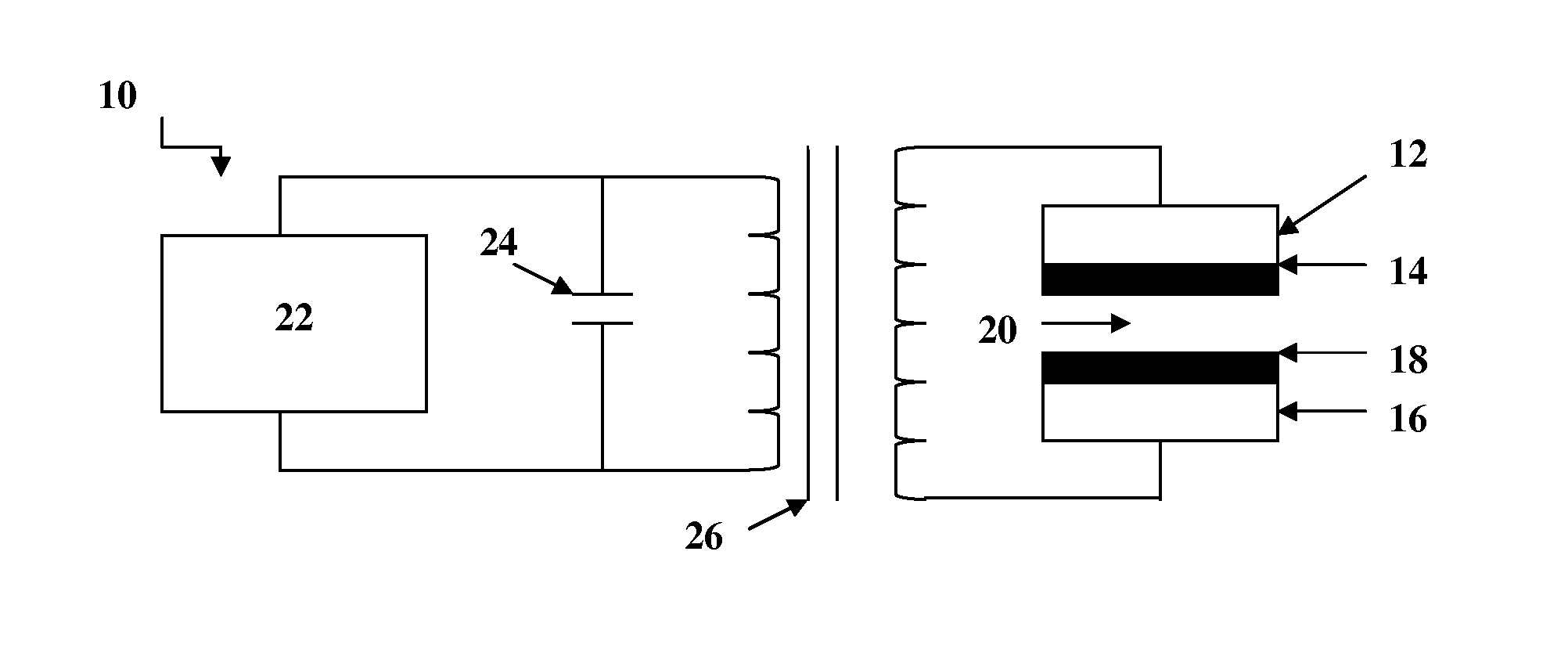

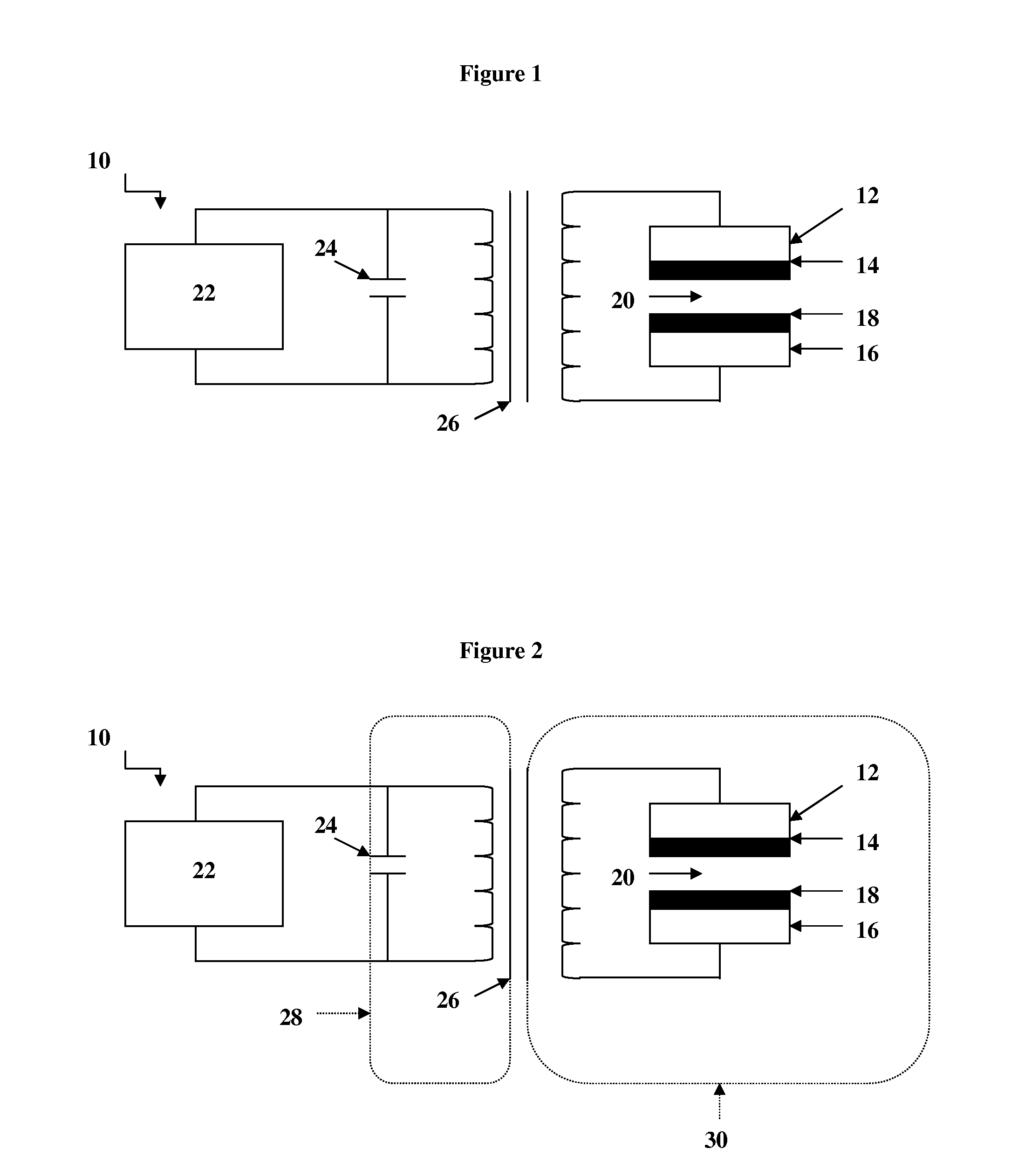

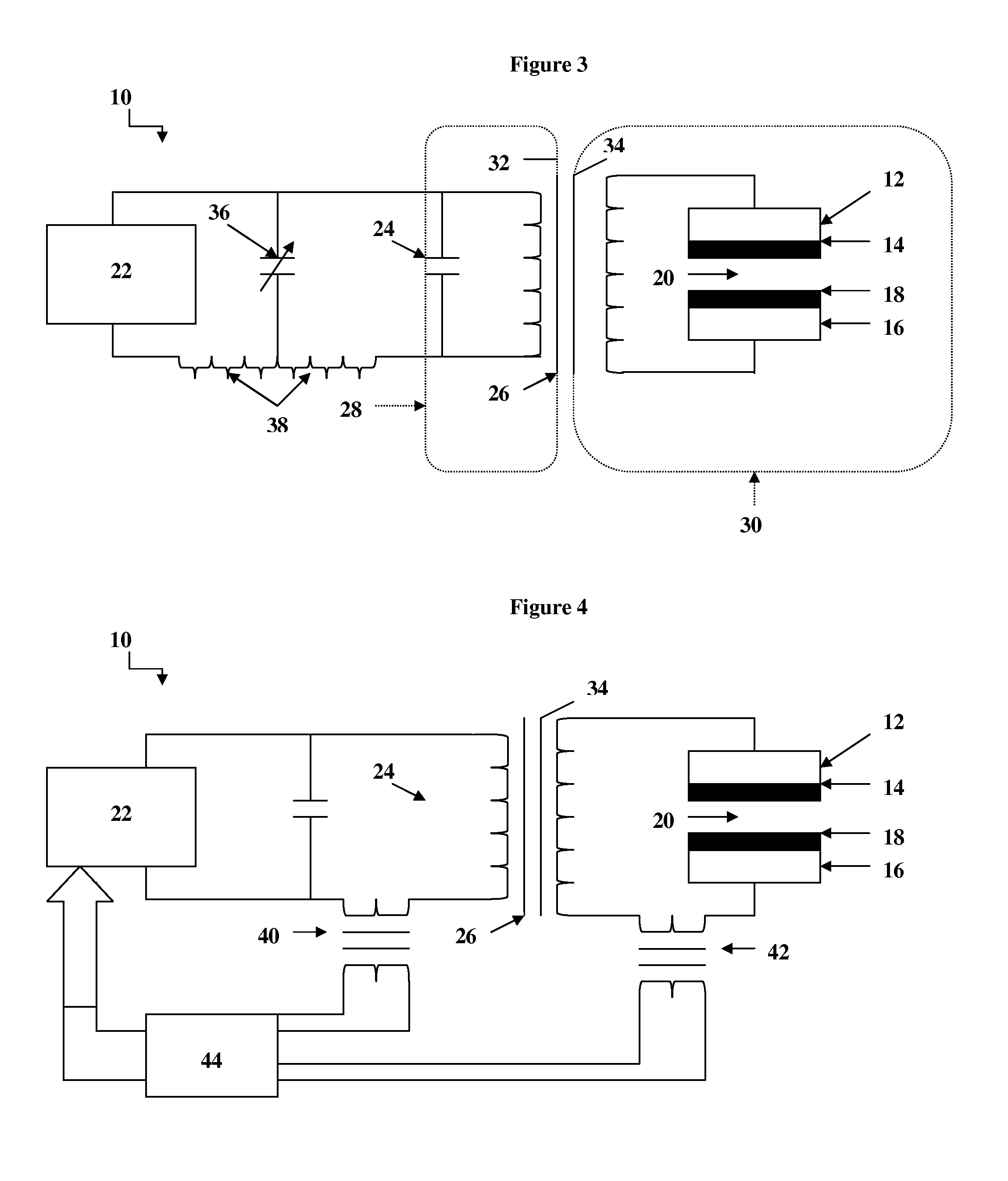

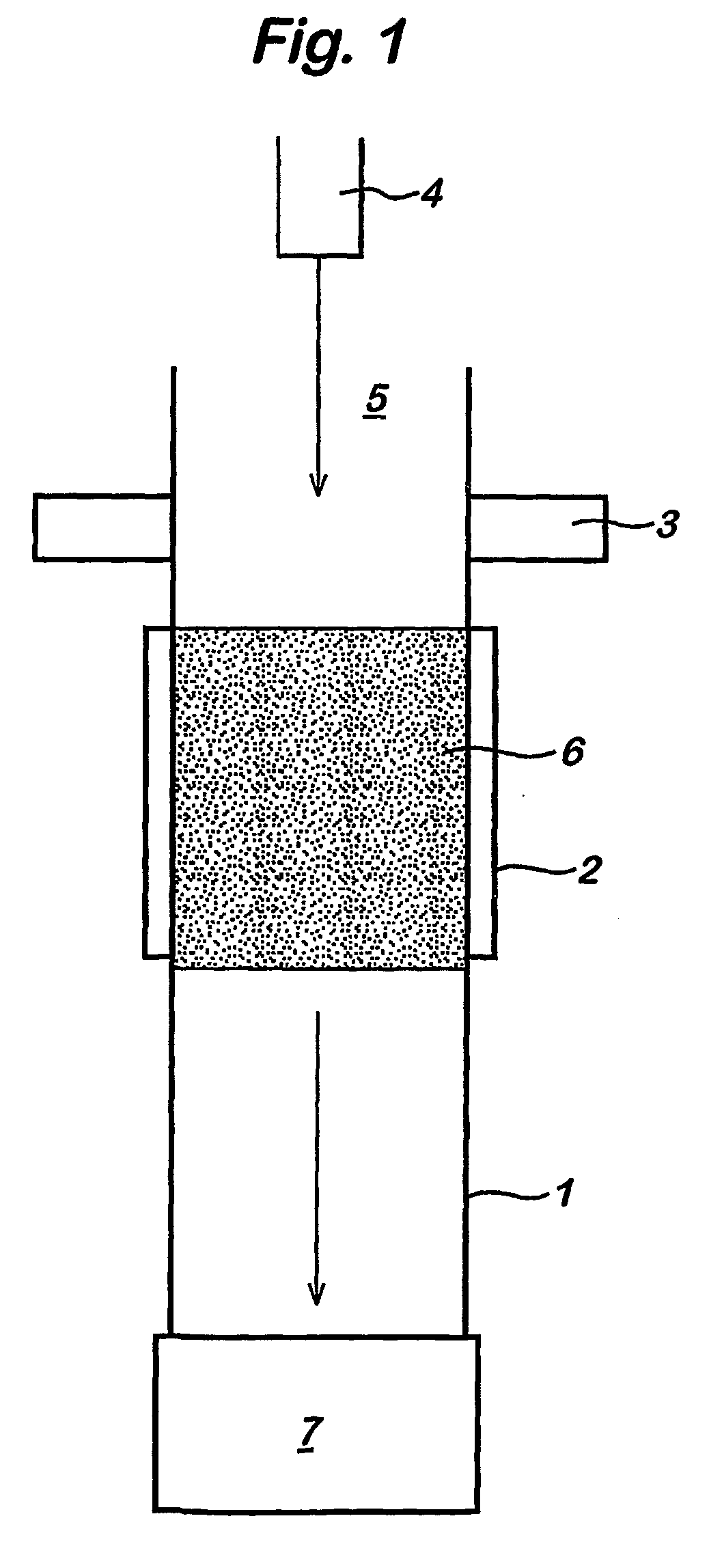

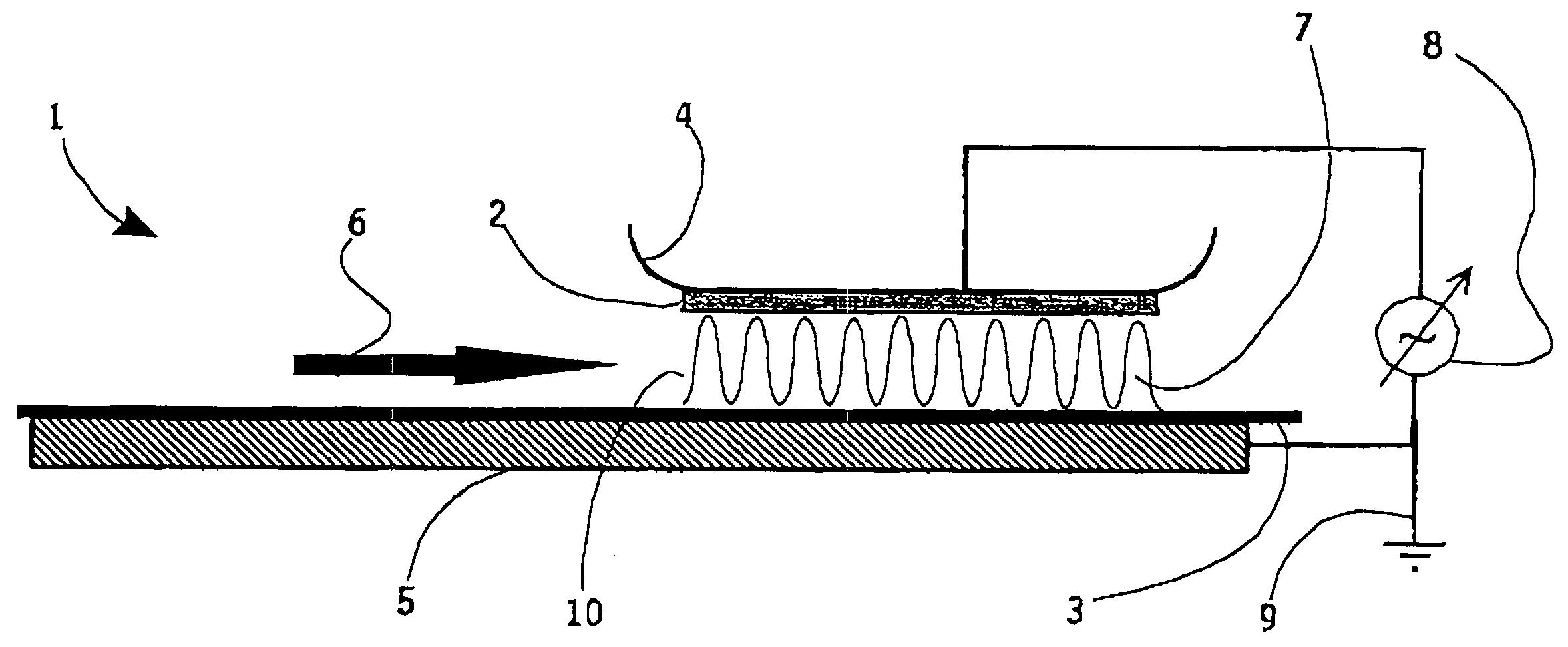

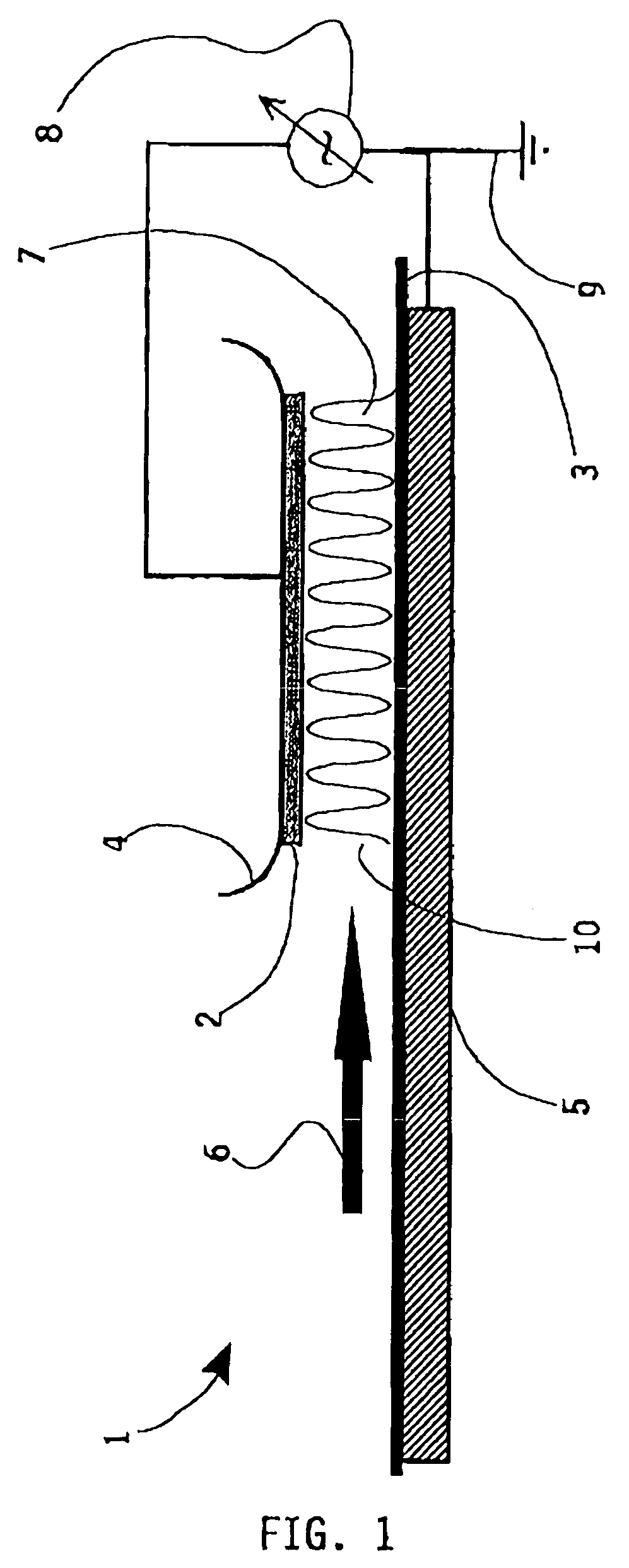

Apparatus and method for atomic layer deposition on a surface of a substrate (6) in a treatment space. A gas supply device (15, 16) is present for providing various gas mixtures to the treatment space (1, 2). The gas supply device (15, 16) is arranged to provide a gas mixture with a precursor material to the treatment space for allowing reactive surface sites to react with precursor material molecules to give a surface covered by a monolayer of precursor molecules attached via the reactive sites to the surface of the substrate. Subsequently, a gas mixture comprising a reactive agent capable to convert the attached precursor molecules to active precursor sites is provided. A plasma generator (10) is present for generating an atmospheric pressure plasma in the gas mixture comprising the reactive agent, the plasma generator being arranged remote from the treatment space (1, 2).

Owner:FUJIFILM MFG EURO

Method and apparatus for atomic layer deposition using an atmospheric pressure glow discharge plasma

InactiveUS20090324971A1Increase response rateImprove productivitySynthetic resin layered productsChemical vapor deposition coatingPlasma generatorProduct gas

Apparatus and method for atomic layer deposition on a surface of a substrate (6) in a treatment space. A gas supply device (15, 16) is present for providing various gas mixtures to the treatment space. The gas supply device (15, 16) is arranged to provide a gas mixture with a precursor material to the treatment space for allowing reactive surface sites to react with precursor material molecules to give a surface covered by a monolayer of precursor molecules attached via the reactive sites to the surface of the substrate. Subsequently, a gas mixture comprising a reactive agent capable to convert the attached precursor molecules to active precursor sites is provided. A plasma generator (10) is present for generating an atmospheric pressure plasma in the gas mixture comprising the reactive agent.

Owner:FUJIFILM MFG EURO

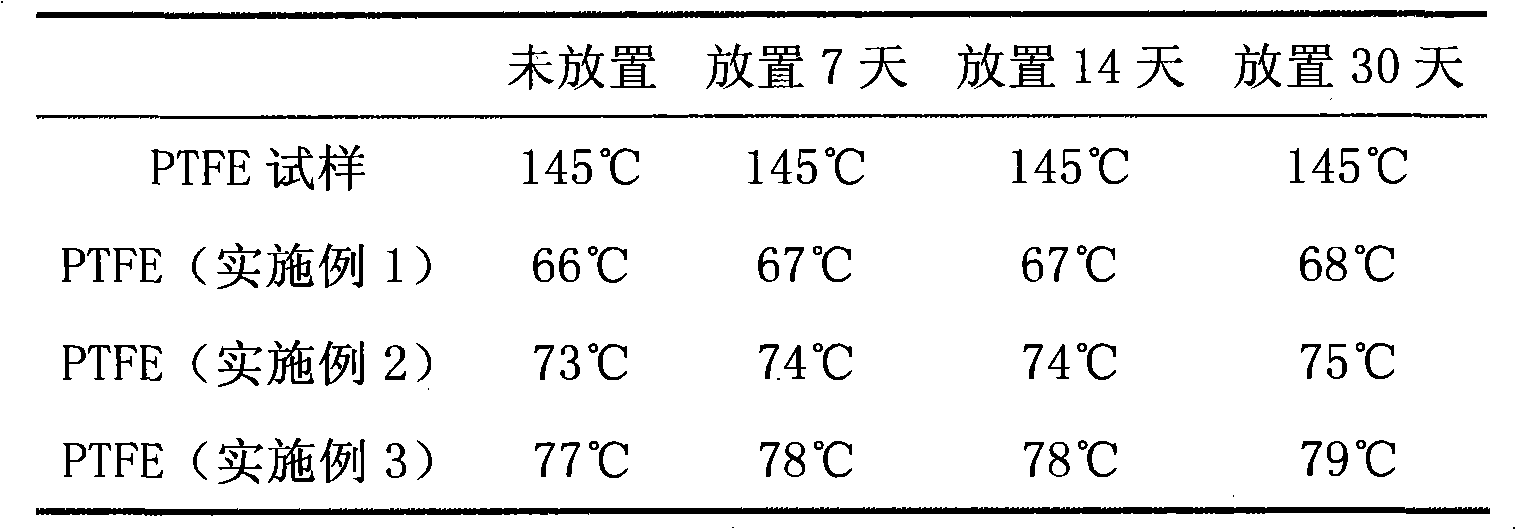

Surface hydrophilic modification method for polytetrafluoroethylene bulked membrane

InactiveCN101890314ASimple processEfficient treatment processSemi-permeable membranesWater layerLow pressure plasma

The invention relates to a surface hydrophilic modification method for a polytetrafluoroethylene bulked membrane, which is characterized by comprising the steps of: pretreating a polytetrafluoroethylene membrane by adopting low-pressure glow discharge plasma to make the surface of the polytetrafluoroethylene membrane generate active groups, and grafting acrylic acid to form a relatively stable hydrophilic layer. The method has the advantages that: the active groups are generated on the surface of the polytetrafluoroethylene membrane by low-pressure plasma treatment, and the relatively stable hydrophilic layer can be formed on the surface of the membrane by acrylic acid grafting treatment, so that the hydrophilicity of the polytetrafluoroethylene membrane is effectively improved, and the effect is lasting; and the polytetrafluoroethylene membrane is treated by the low-pressure plasma induction and acrylic acid grafting, so the treatment method is simple, high-efficiency, water and energy-saving, and suitable for industrialized production.

Owner:DONGHUA UNIV

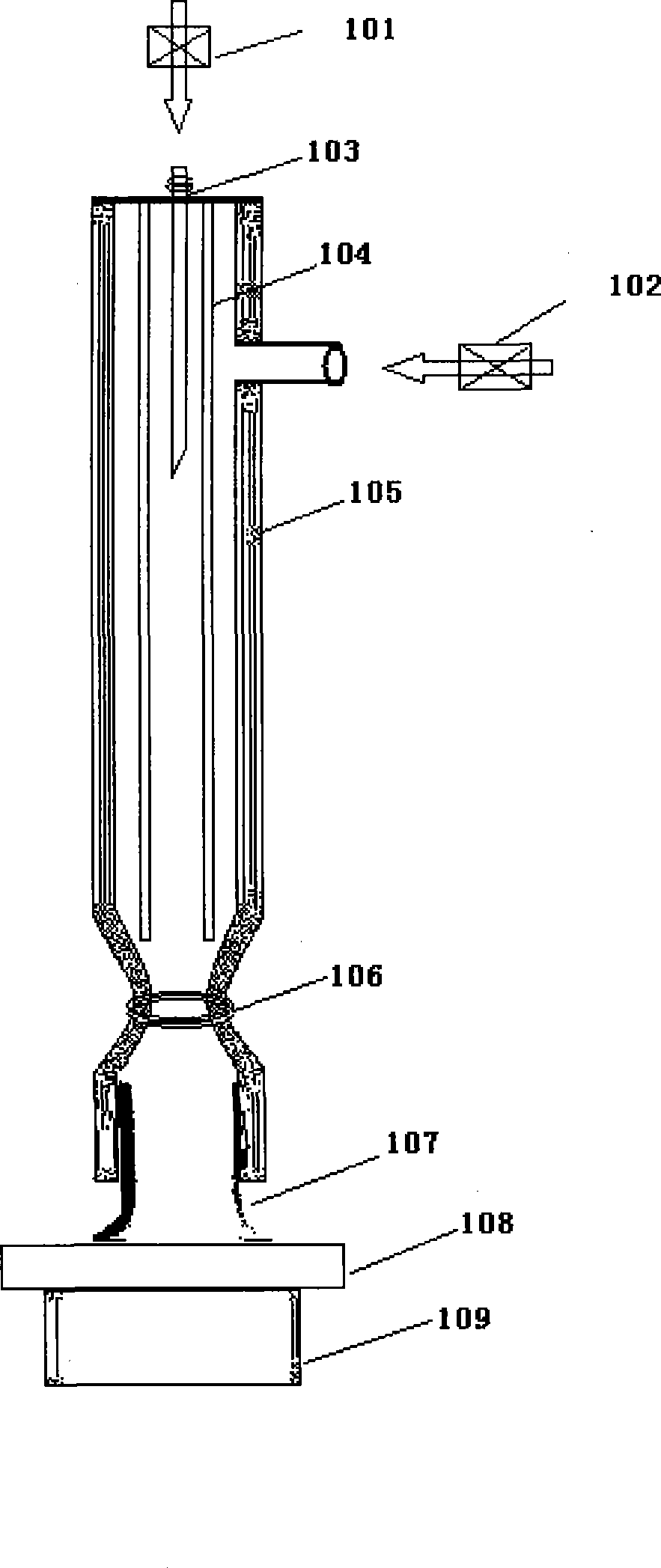

Preionization atmos low-temperature plasma jet generator

InactiveCN101466194AReduce breakdownIncrease discharge powerElectric discharge tubesPlasma techniquePlasma jetHigh concentration

The invention relates to an atmospheric pressure low-temperature plasma jet reactor with preionization structure, which belongs to plasma discharge reactor technical field, and the reactor is characterized in that: the device main body is a millimeter magnitude main silica tube with one open end; a part is arranged above the open end at the lower part with 15 to 25mm, and the part becomes the thinnest at 20mm part, and a ring-shaped electrode is wound on the part; a thin silica tube is connected at the closed end arranged in the inner part thereof through the closed end arranged at the upper part of the silica tube; and a needle electrode is arranged in the thin silica tube. An earthing electrode is arranged below the open end of the main silica tube; and the argon gas is filled into the needle electrode, and the oxygen gas is filled into the main silica tube. The needle electrode and the ring-shaped electrode can be exerted with the same high voltage; the needle electrode discharge can supply the seed electrons for the ring-shaped electrode discharge, and a stable glowing discharge plasma jet is arranged between the ring-shaped electrode and the earthing electrode. The reactor has the beneficial effects that the obtained plasma jet can generate high-concentration chemical activity species, and the reactor has practical value.

Owner:DALIAN UNIV OF TECH

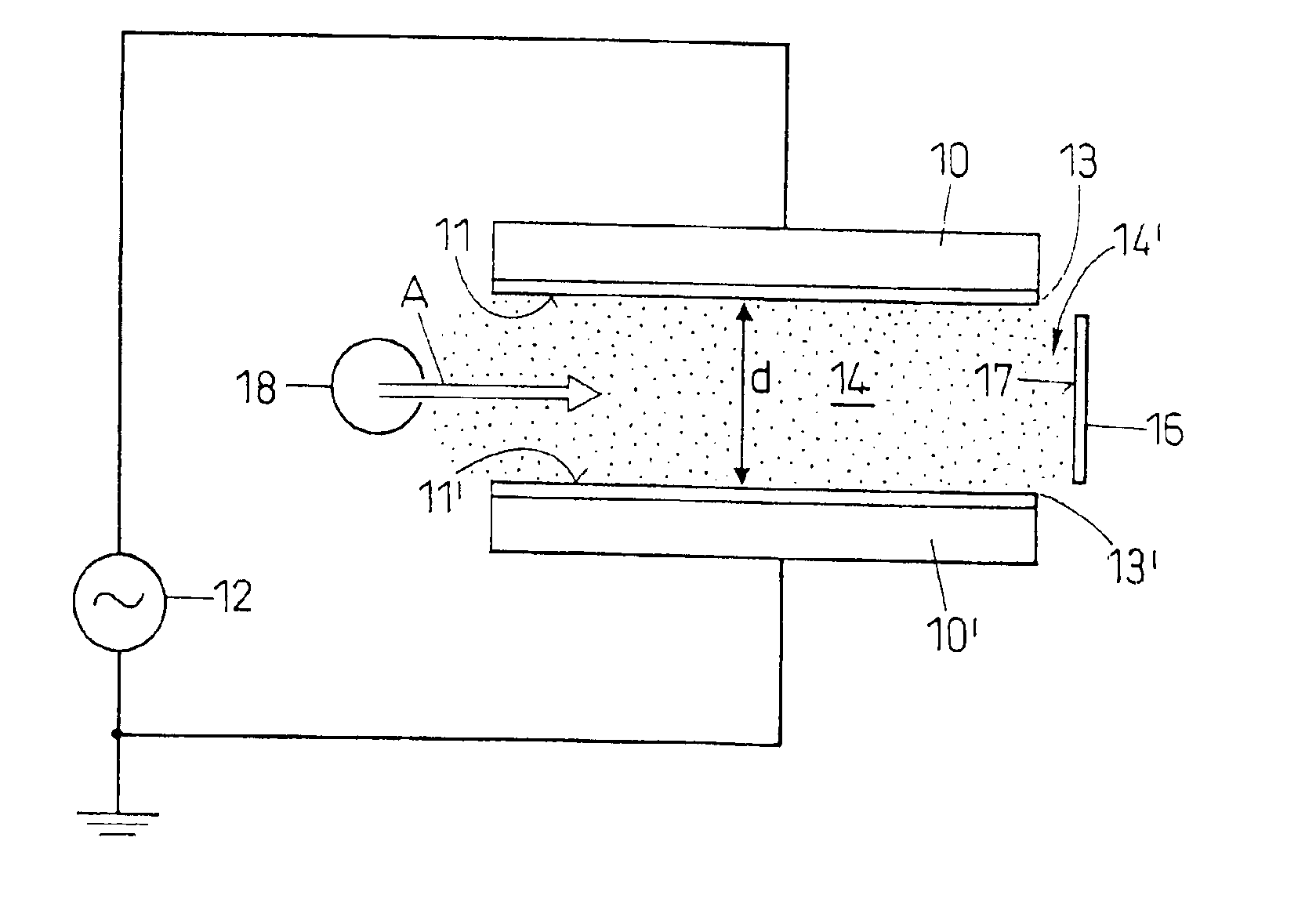

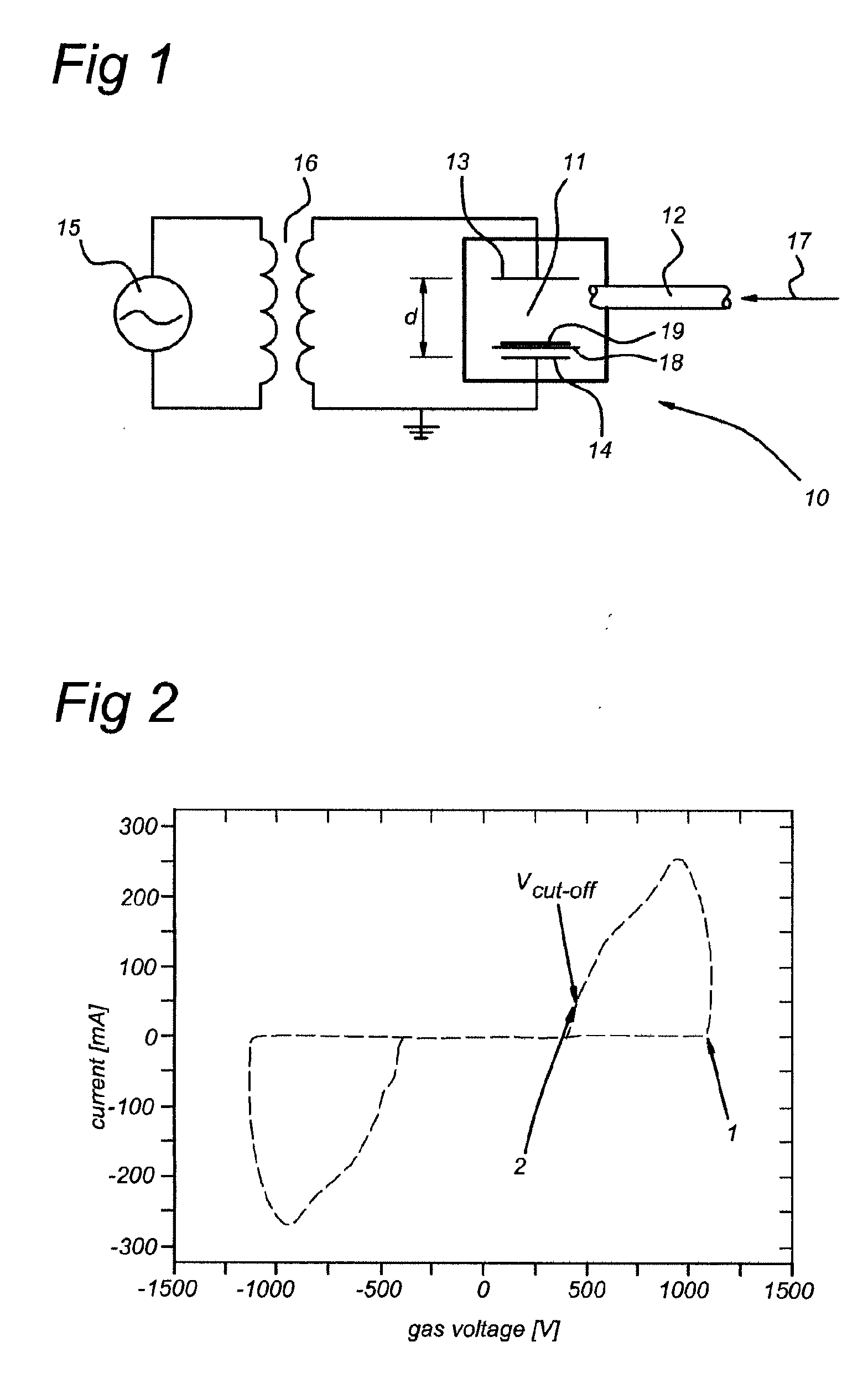

Method and device for treating surfaces using a glow discharge plasma

InactiveUS6919107B2Invention can be simpleSimple methodElectric discharge tubesEnergy based chemical/physical/physico-chemical processesAmbient pressureGlow discharge plasma

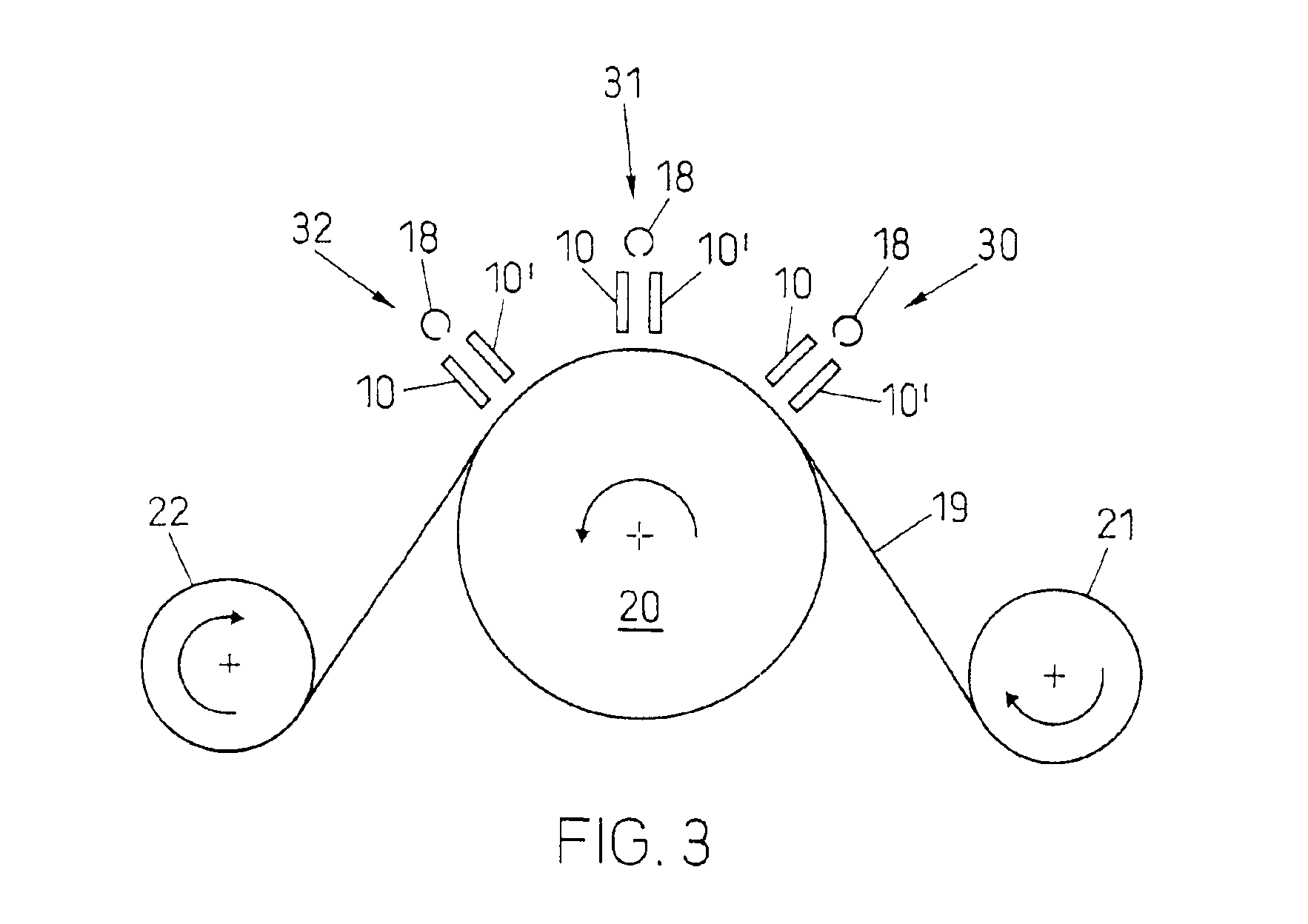

In a process for treating a surface with the aid of a glow discharge plasma sustained in a gas of substantially ambient pressure between two electrodes (10, 10′) unwanted effects of plasma filaments occurring in such a plasma are prevented by positioning the surface (17) to be treated in an edge region (14′) of the plasma. The surface is placed on one side of a plasma space (14) defined by the electrode faces (11, 11′) beyond a pair of aligned edges (13, 13′) of the electrode faces (11, 11′), at a distance of a few millimeters from these edges (13, 13′), and facing these edges (13, 13′). The treatment gas or treatment gas mixture is fed to the plasma space (14) from a second side opposite the edge region (14′) in which the surface (17) to be treated is positioned. During treatment, a substrate (16) whose one surface (17) is to be treated is either stationary or is advanced in a direction substantially perpendicular to the electrode faces (11, 11′).

Owner:TETRA LAVAL HLDG & FINANCE SA

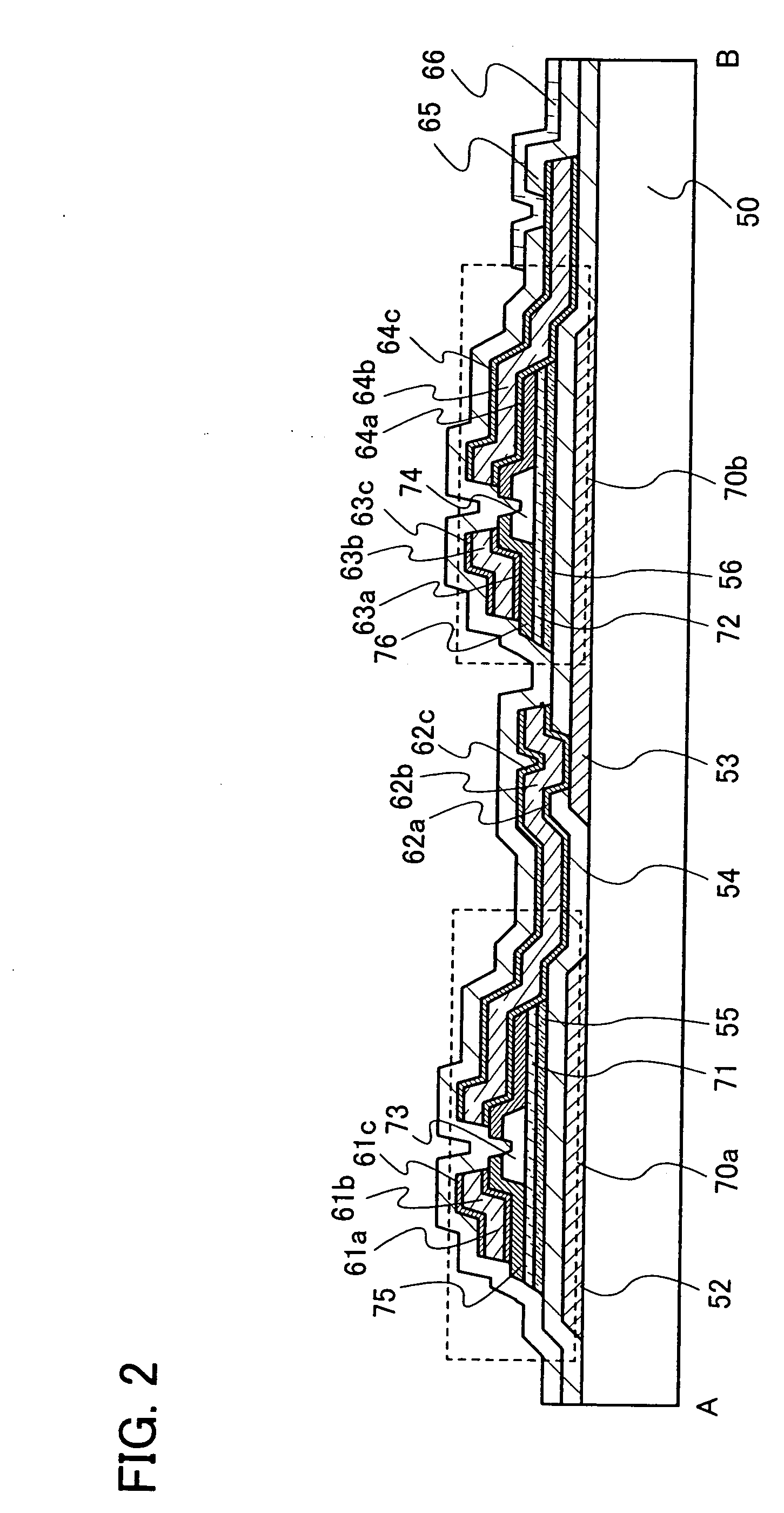

Manufacturing method of semiconductor device

InactiveUS7833845B2Low costIncrease in sizeSolid-state devicesSemiconductor/solid-state device manufacturingHigh frequency powerEngineering

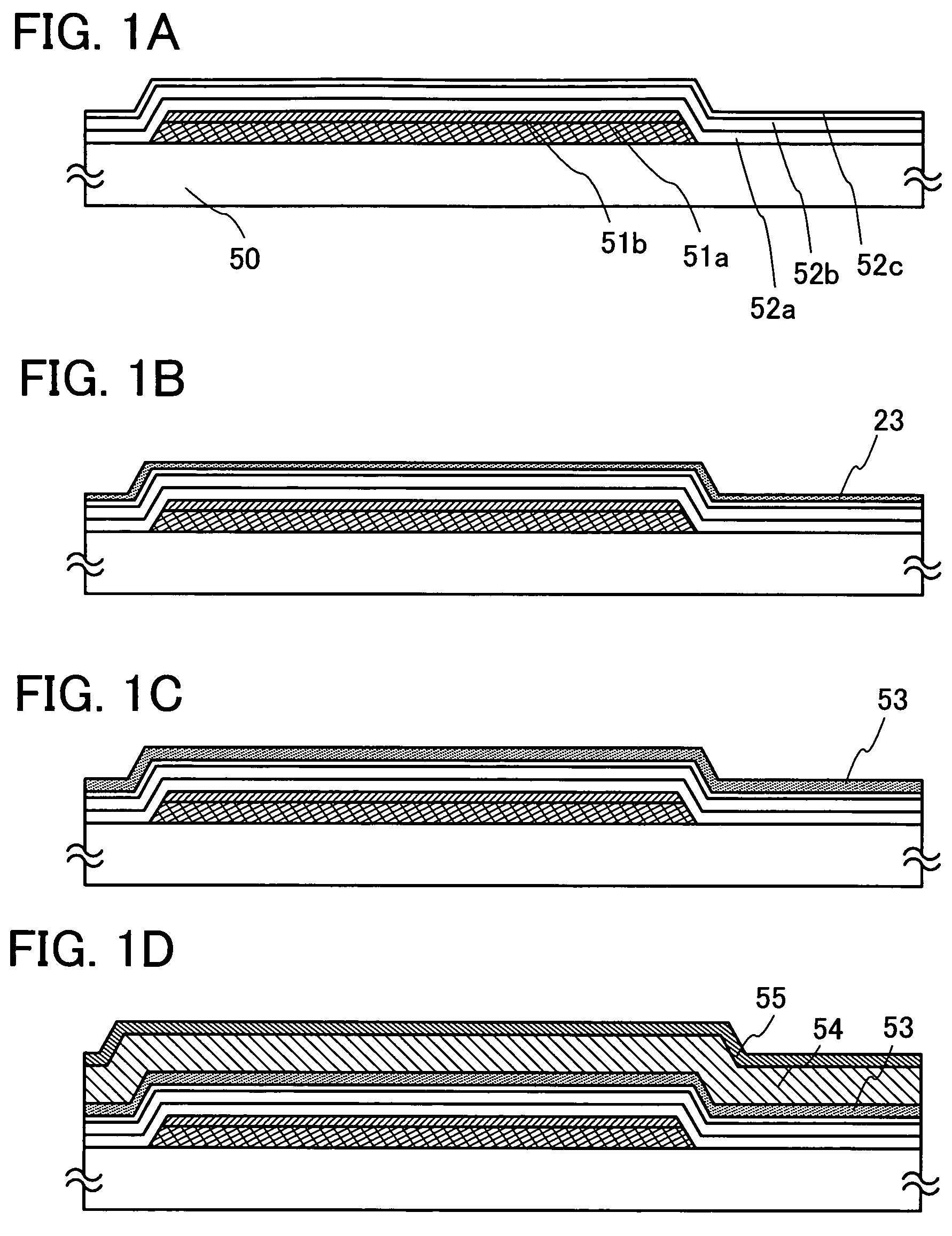

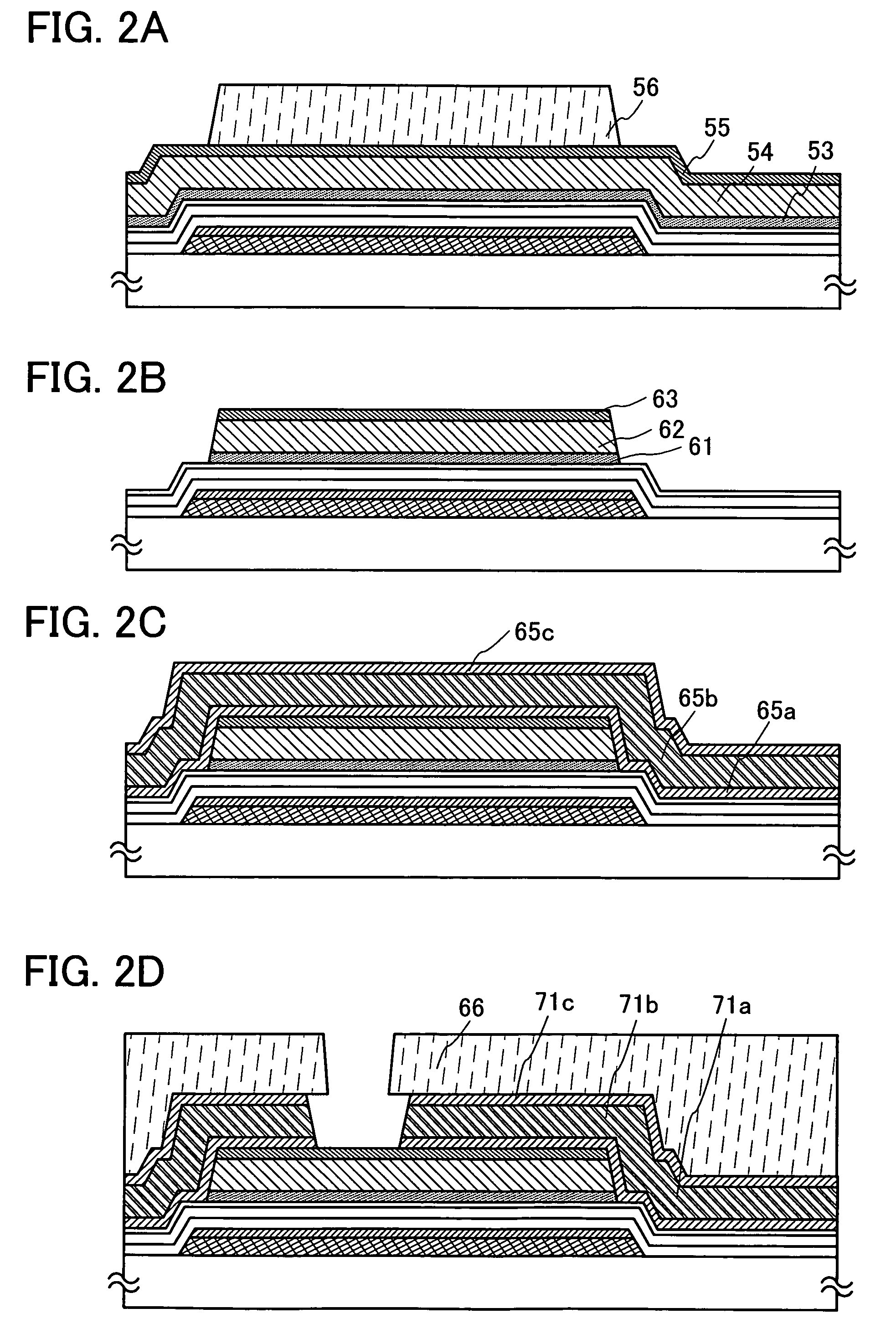

An object is to provide a manufacturing method of a microcrystalline semiconductor film with favorable quality over a large-area substrate. After forming a gate insulating film over a gate electrode, in order to improve quality of a microcrystalline semiconductor film formed in an initial stage, glow discharge plasma is generated by supplying high-frequency powers with different frequencies, and a lower part of the film near an interface with the gate insulating film is formed under a first film formation condition, which is low in film formation rate but results in a good quality film. Thereafter, an upper part of the film is deposited under a second film formation condition with higher film formation rate, and further, a buffer layer is stacked on the microcrystalline semiconductor film.

Owner:SEMICON ENERGY LAB CO LTD

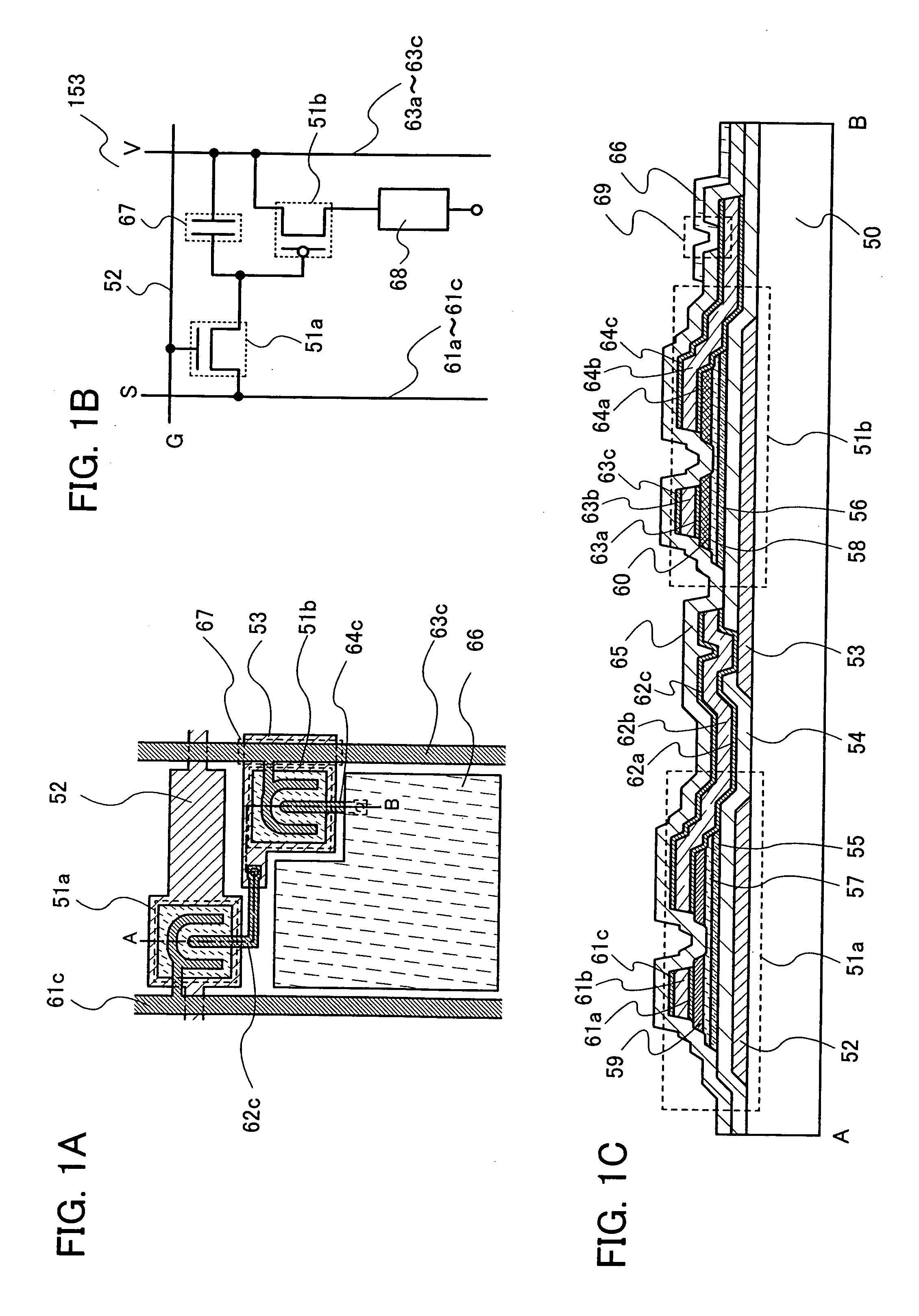

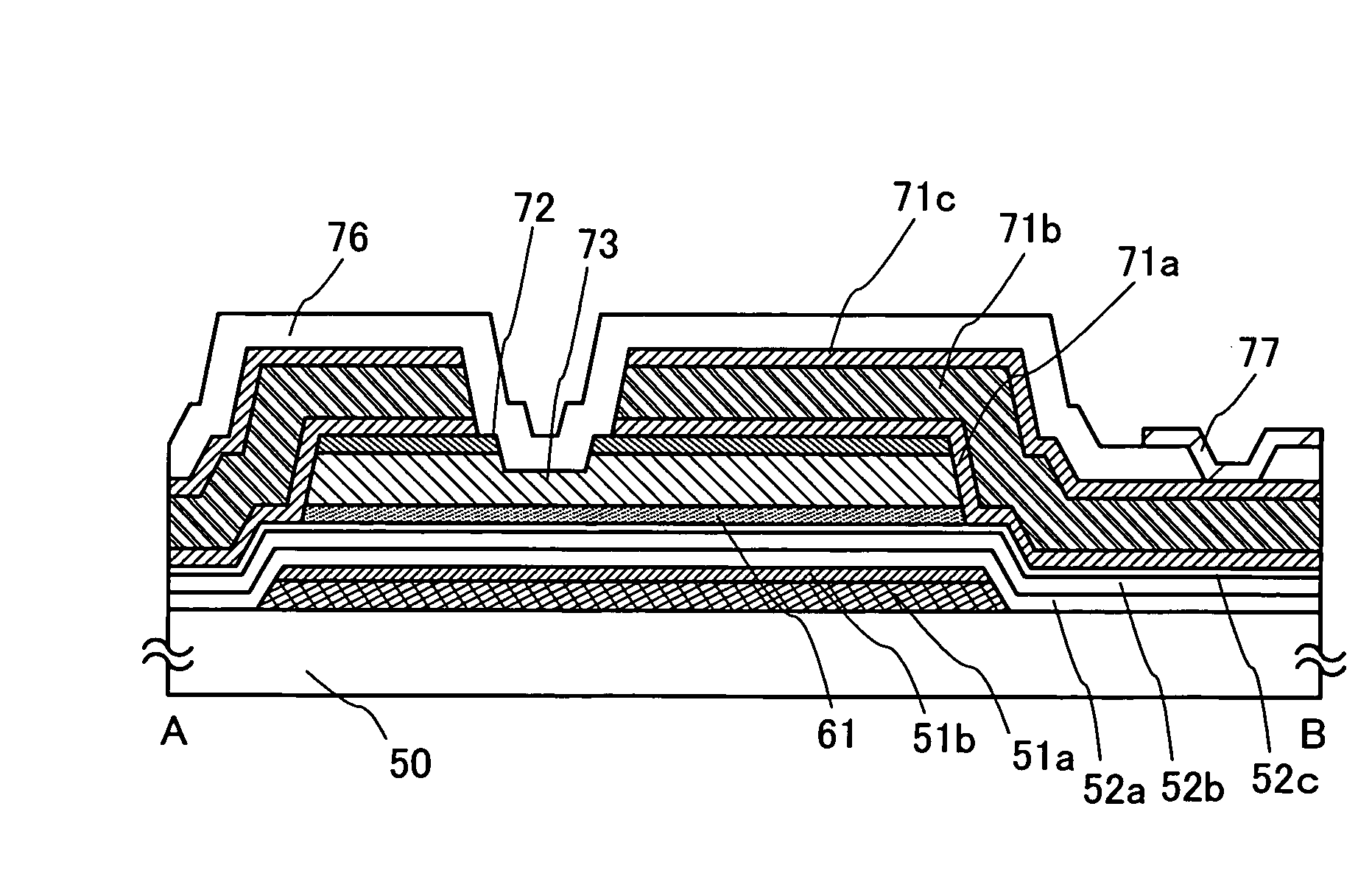

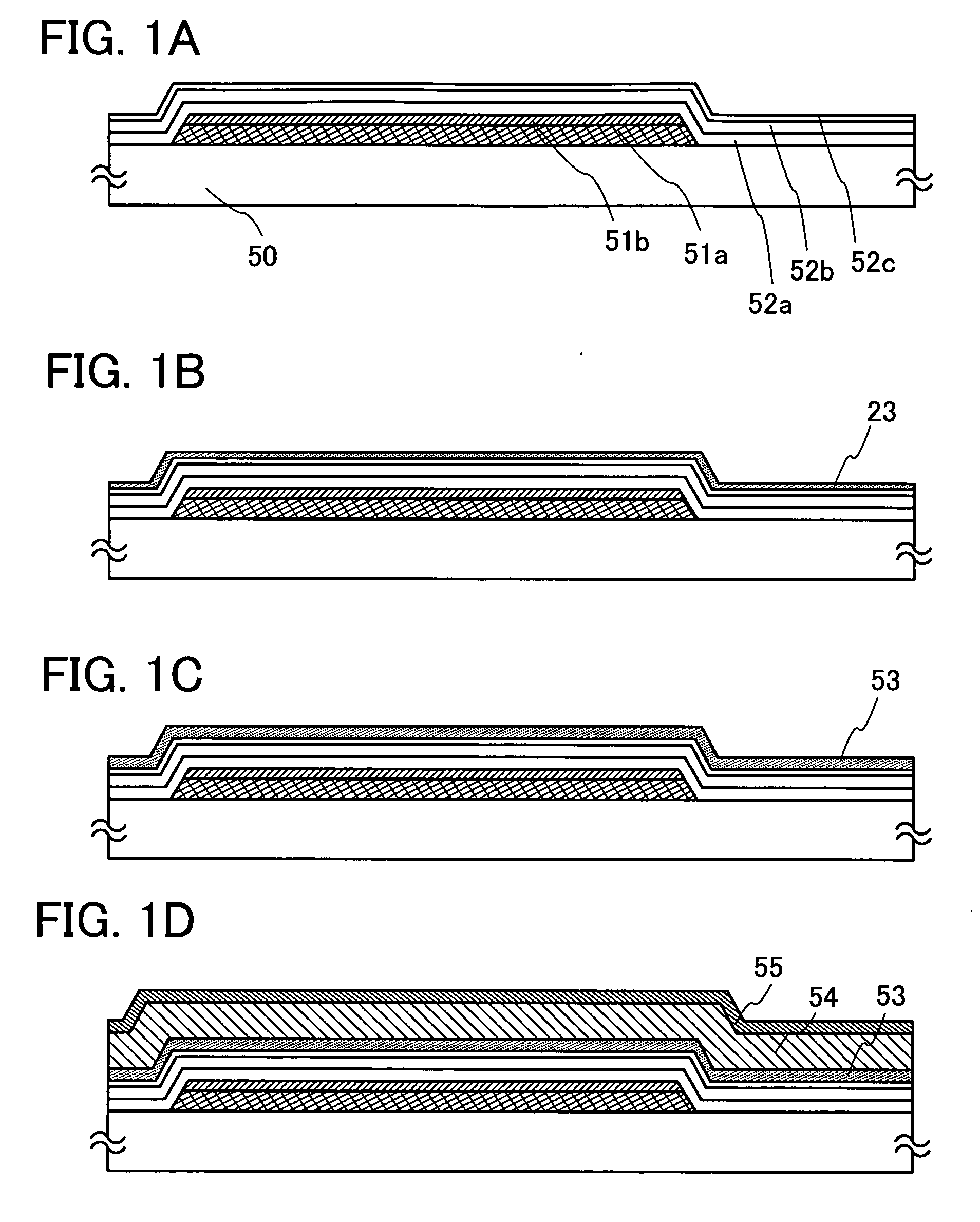

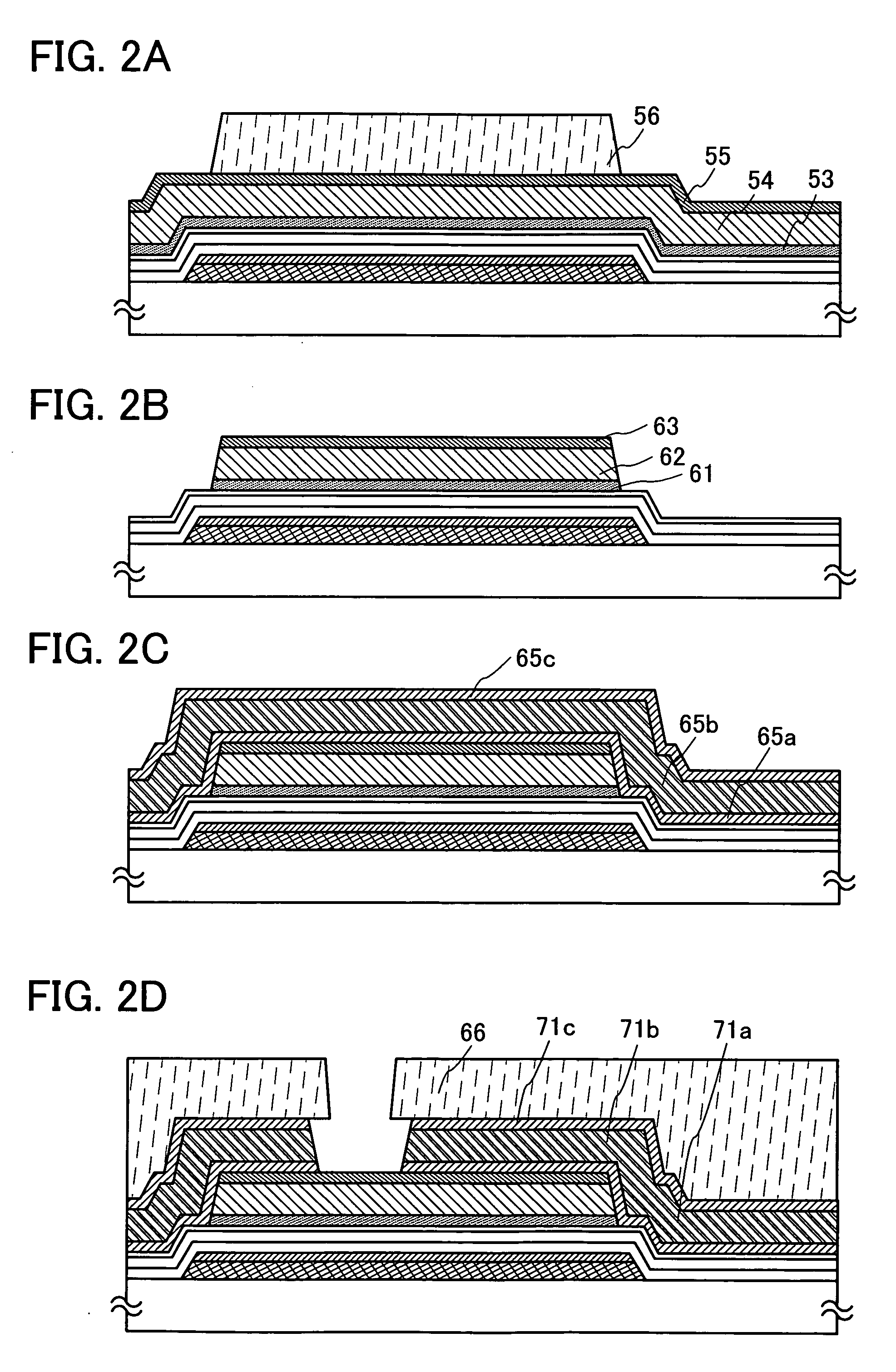

Method for manufacturing display device

InactiveUS20090047775A1Improve uniformityImprove featuresSolid-state devicesSemiconductor/solid-state device manufacturingHigh frequency powerDisplay device

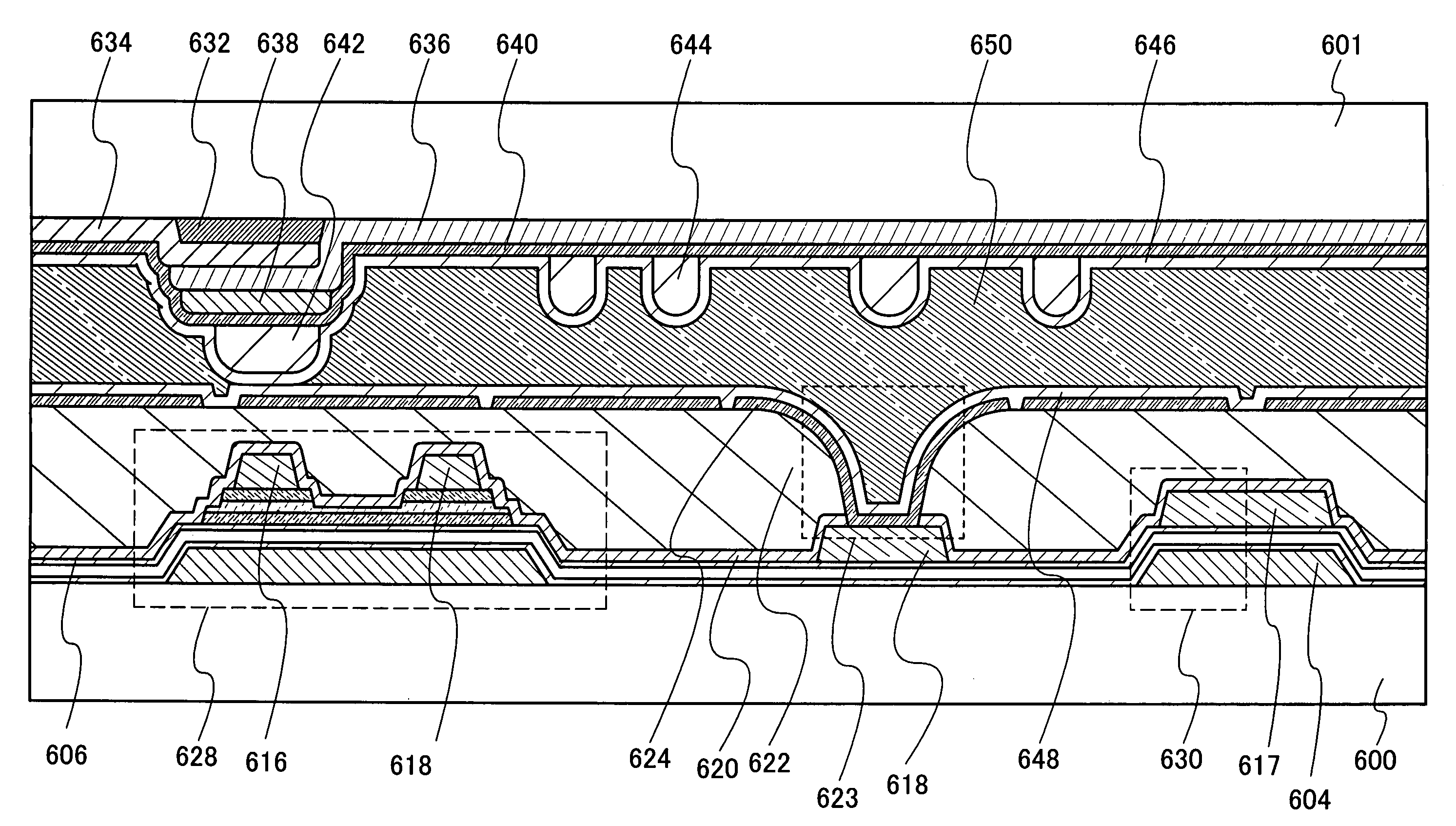

The present invention relates to a method for manufacturing a display device including a p-channel thin film transistor and an n-channel thin film transistor having a microcrystalline semiconductor film each of which are an inverted-staggered type, and relates to a method for formation of an insulating film and a semiconductor film which are included in the thin film transistor. Two or more kinds of high-frequency powers having different frequencies are supplied to an electrode for generating glow discharge plasma in a reaction chamber. High-frequency powers having different frequencies are supplied to generate glow discharge plasma, so that a thin film of a semiconductor or an insulator is formed. High-frequency powers having different frequencies (different wavelength) are superimposed and applied to the electrode of a plasma CVD apparatus, so that densification and uniformity of plasma for preventing the effect of surface standing wave of plasma can be realized.

Owner:SEMICON ENERGY LAB CO LTD

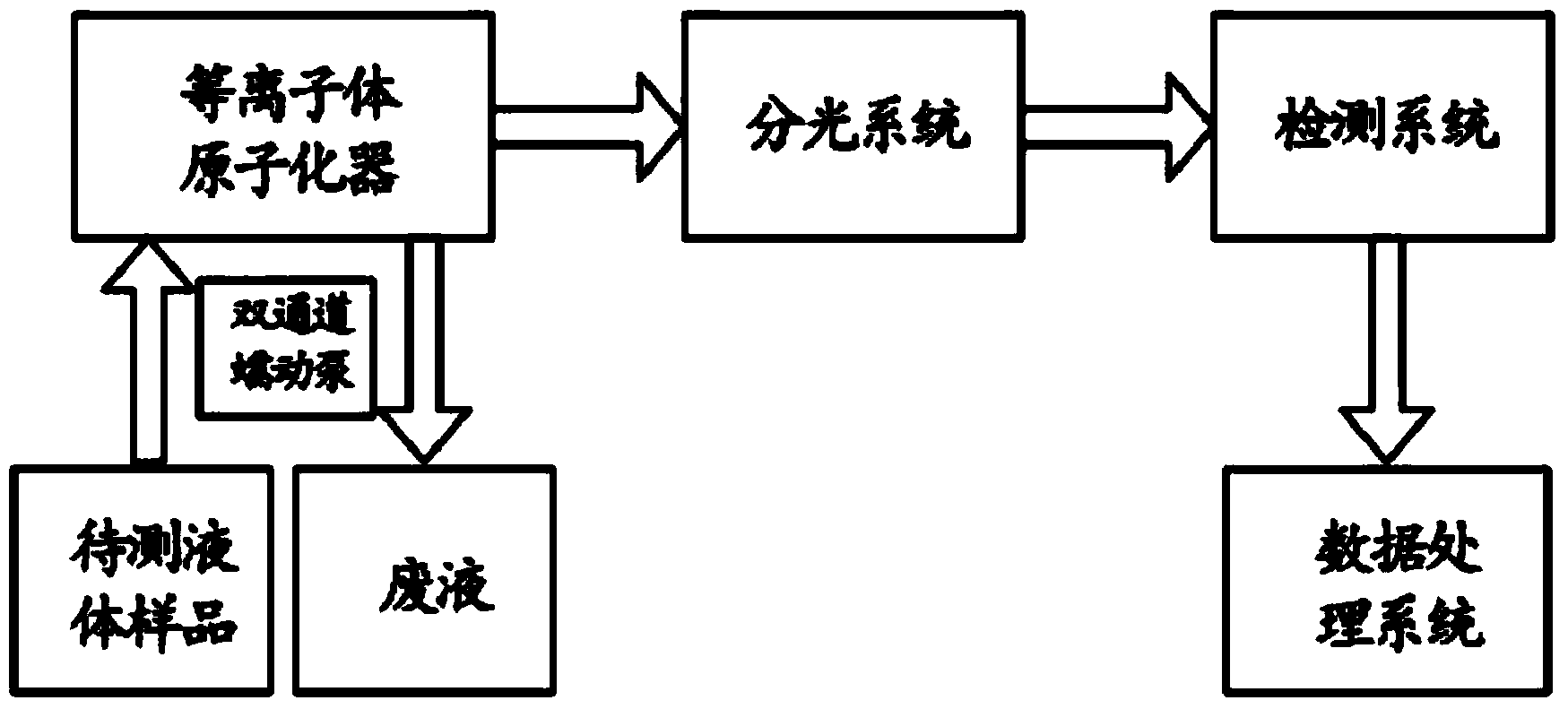

Portable element spectrometer for online detecting liquid sample

ActiveCN103969244AConvenient teaching workFacilitate research workAnalysis by electrical excitationHigh pressureGlow discharge plasma

The invention discloses a portable element spectrometer for online detecting a liquid sample. The portable element spectrometer comprises a sample introduction and discharging system, a plasma atomization device and a spectrum measuring system, wherein the plasma atomization device comprises a metal anode which is connected with a positive electrode of a high-voltage power supply, an auxiliary graphite electrode which is connected with a negative electrode of the high-voltage power supply, a liquid collection pool and a sample feeding pipe; the sample feeding pipe vertically runs through the waste liquid collection pool and the auxiliary graphite electrode and is arranged right below the metal anode; to-be-detected liquid containing metal elements overflows from the top end of the sample feeding pipe to be communicated with the auxiliary graphite electrode; high voltage is applied between the metal anode and the auxiliary graphite electrode to generate glow discharge plasma. The metal element spectrometer has the characteristics that the online real-time detection can be realized, the detection sensitivity is high, the power consumption is low, and the like.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

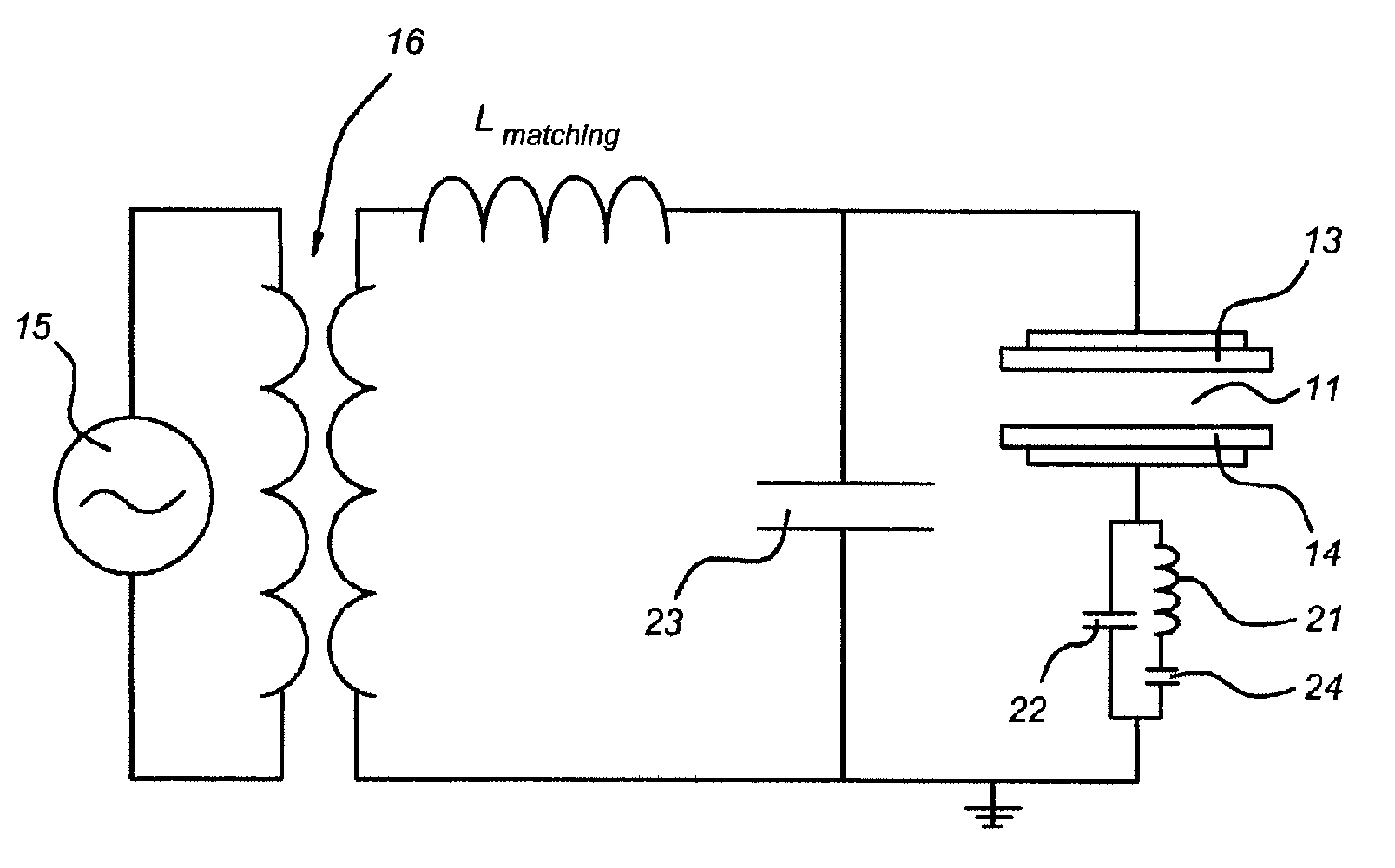

Method and Arrangement for Generating and Controlling a Discharge Plasma

InactiveUS20080317974A1Improve controllabilityLower ratioElectric discharge tubesElectric arc lampsVolumetric Mass DensityLocal current

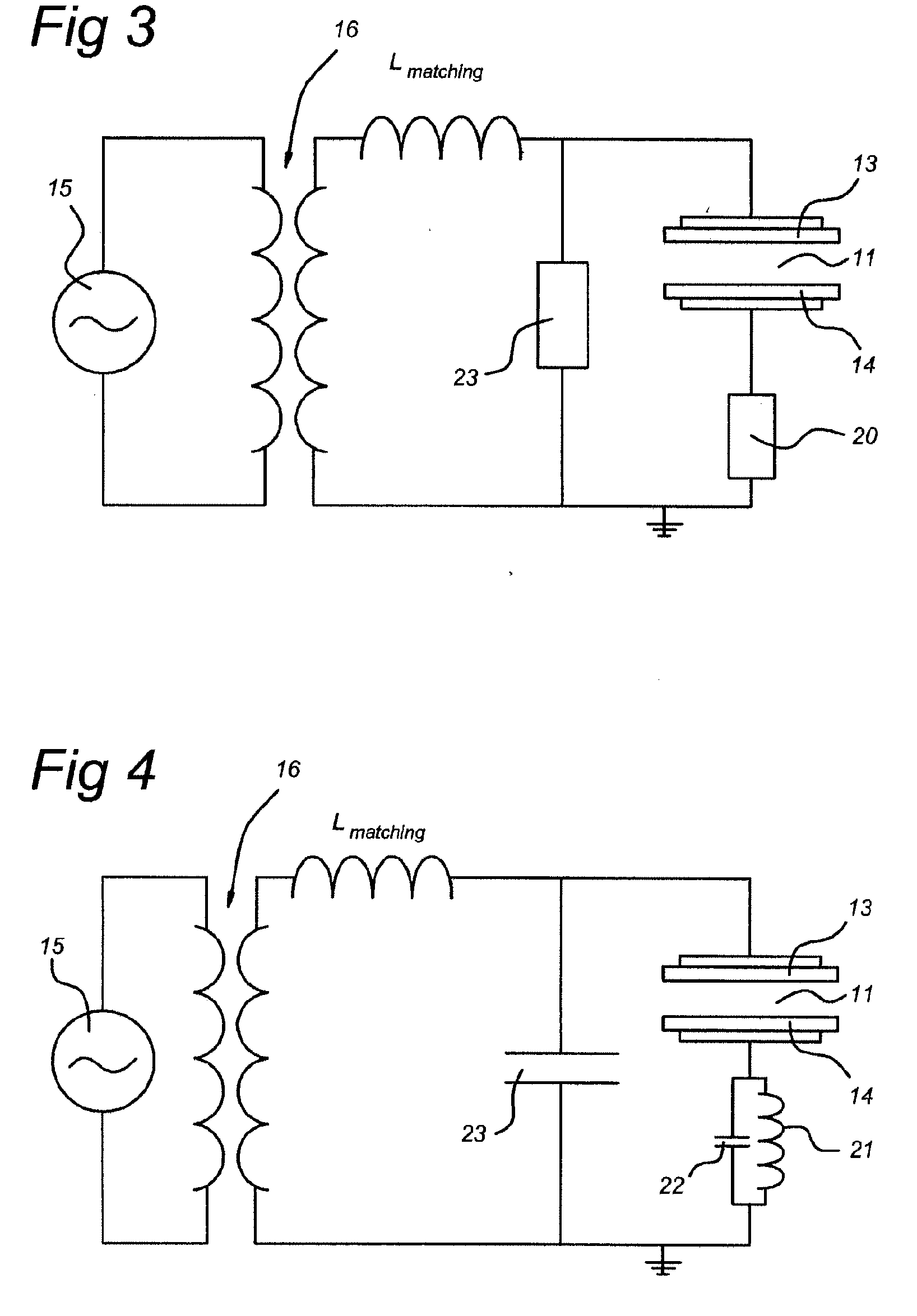

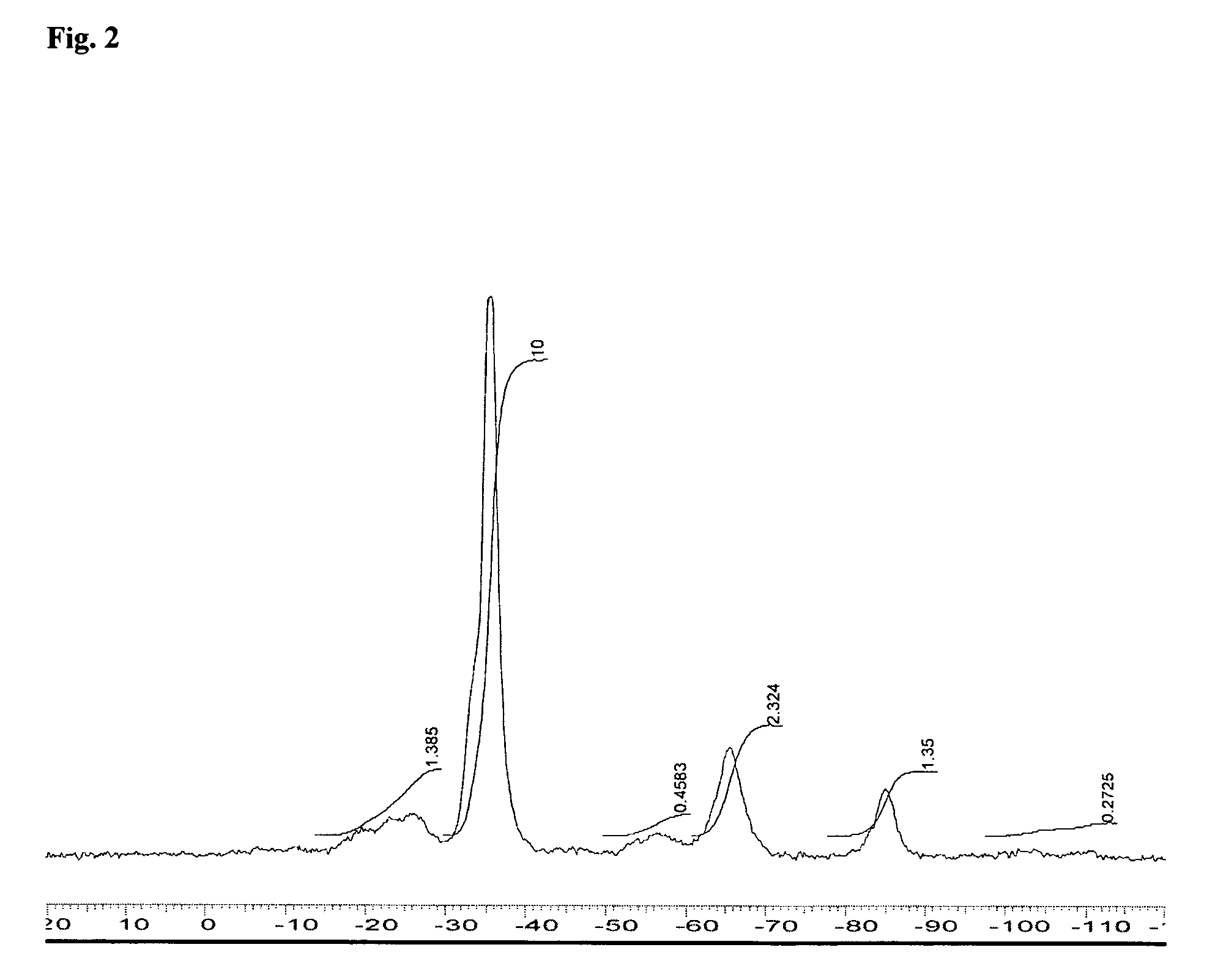

Method and arrangement for controlling a discharge plasma in a discharge space (11) having at least two spaced electrodes (13, 14). A gas or gas mixture is introduced in the discharge space (11), and a power supply (15) for energizing the electrodes (13, 14) is provided for applying an AC plasma energizing voltage to the electrodes (13, 14). At least one current pulse is generated and causes a plasma current and a displacement current. Means for controlling the plasma are provided and arranged to apply a displacement current rate of change for controlling local current density variations associated with a plasma variety having a low ratio of dynamic to static resistance, such as filamentary discharges. By damping such fast variations using a pulse forming circuit (20), a uniform glow discharge plasma is obtained.

Owner:FUJIFILM MFG EURO

Tungsten-titanium co-doped diamond coating material and preparation technique thereof

InactiveCN101787520AOvercoming the problem of increased coefficient of frictionSolve the brittleness problemVacuum evaporation coatingSputtering coatingDlc coatingGas phase

The invention discloses a tungsten-titanium co-doped diamond (DLC) coating material and a preparation technique thereof, which are characterized by: firstly, removing a pollution layer on the surface of a workpiece by ultrasonic cleaning, and performing argon-ion etching cleaning on the surface of the workpiece by glow discharge to obtain an atomic-scale clean surface; secondly, preparing a gradient transition layer by a reactive magnetron sputtering sedimentation method; and finally, preparing a preparing a DLC coating on the transition layer by magnetron sputtering and glow discharge plasma chemical vapor deposition method, wherein the synthesized DLC coating contains carbon element, tungsten element, titanium element and the like; the tungsten content is 2 to 5 percent; and the titanium content is 0.1 to 2.0 percent. The tungsten-titanium co-doped diamond (DLC) coating material is excellent in membrane / base binding force and low in friction coefficient and wear rate.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

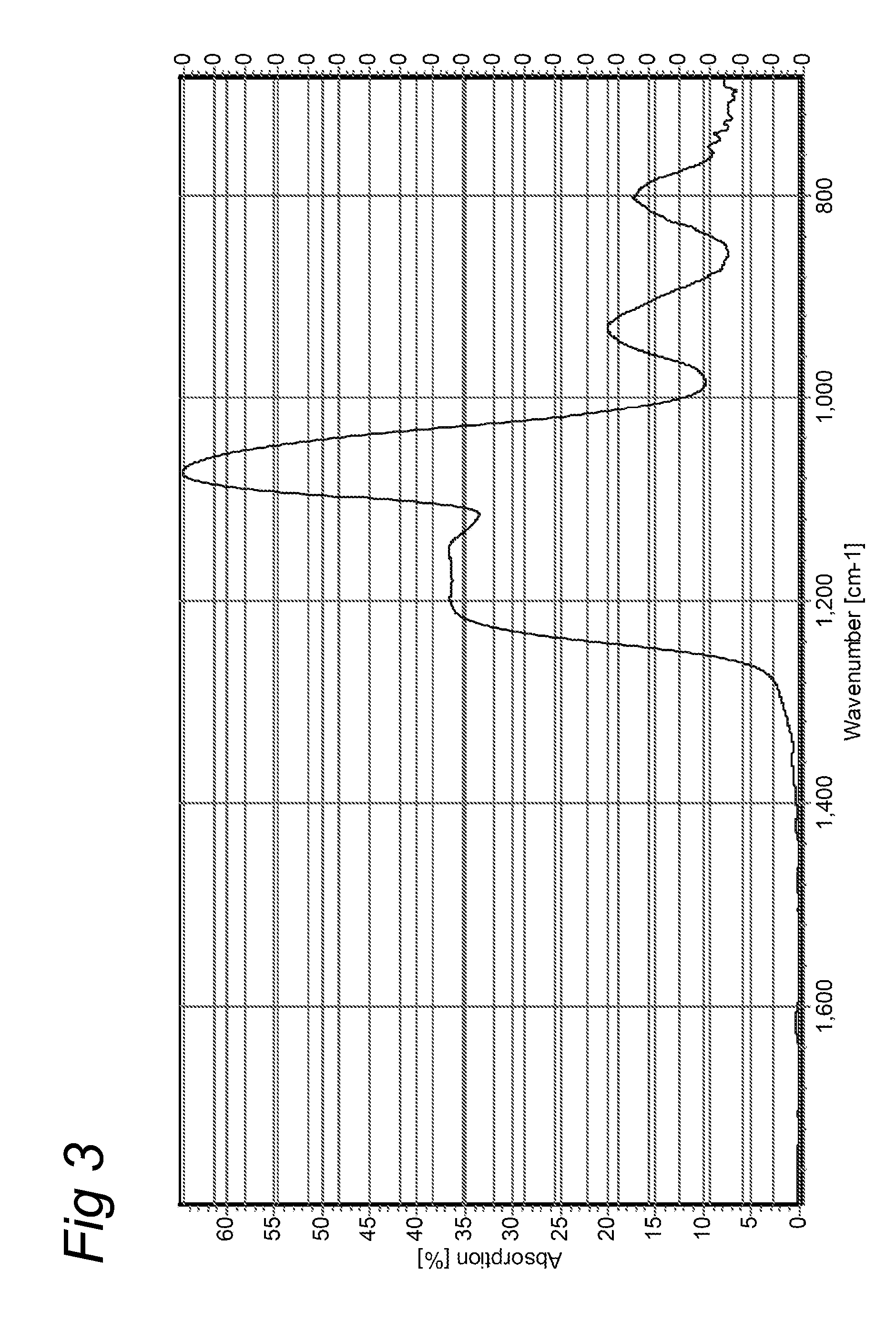

Titania coatings by cvd at atmospheric pressure

InactiveUS20060141290A1Semiconductor/solid-state device manufacturingNatural mineral layered productsAtmospheric pressureGlow discharge plasma

A method for deposition of titania, and titania-containing, thin films by CVD, using an atmospheric pressure glow discharge plasma as a major source of reaction, which leads to film properties, and film growth rates, normally only achievable (by atmospheric pressure CVD) with significantly higher substrate temperatures.

Owner:SAINT-GOBAIN GLASS FRANCE

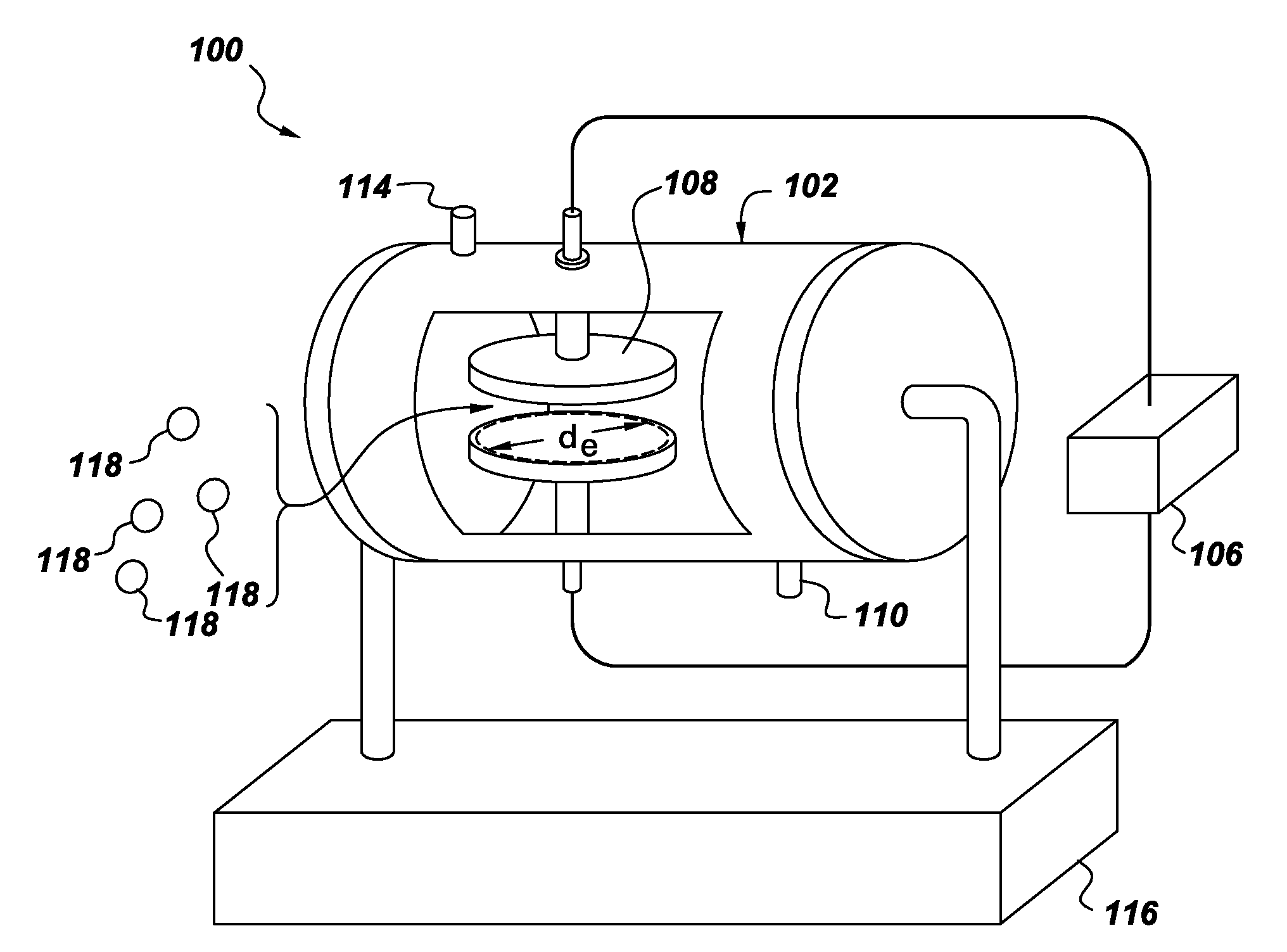

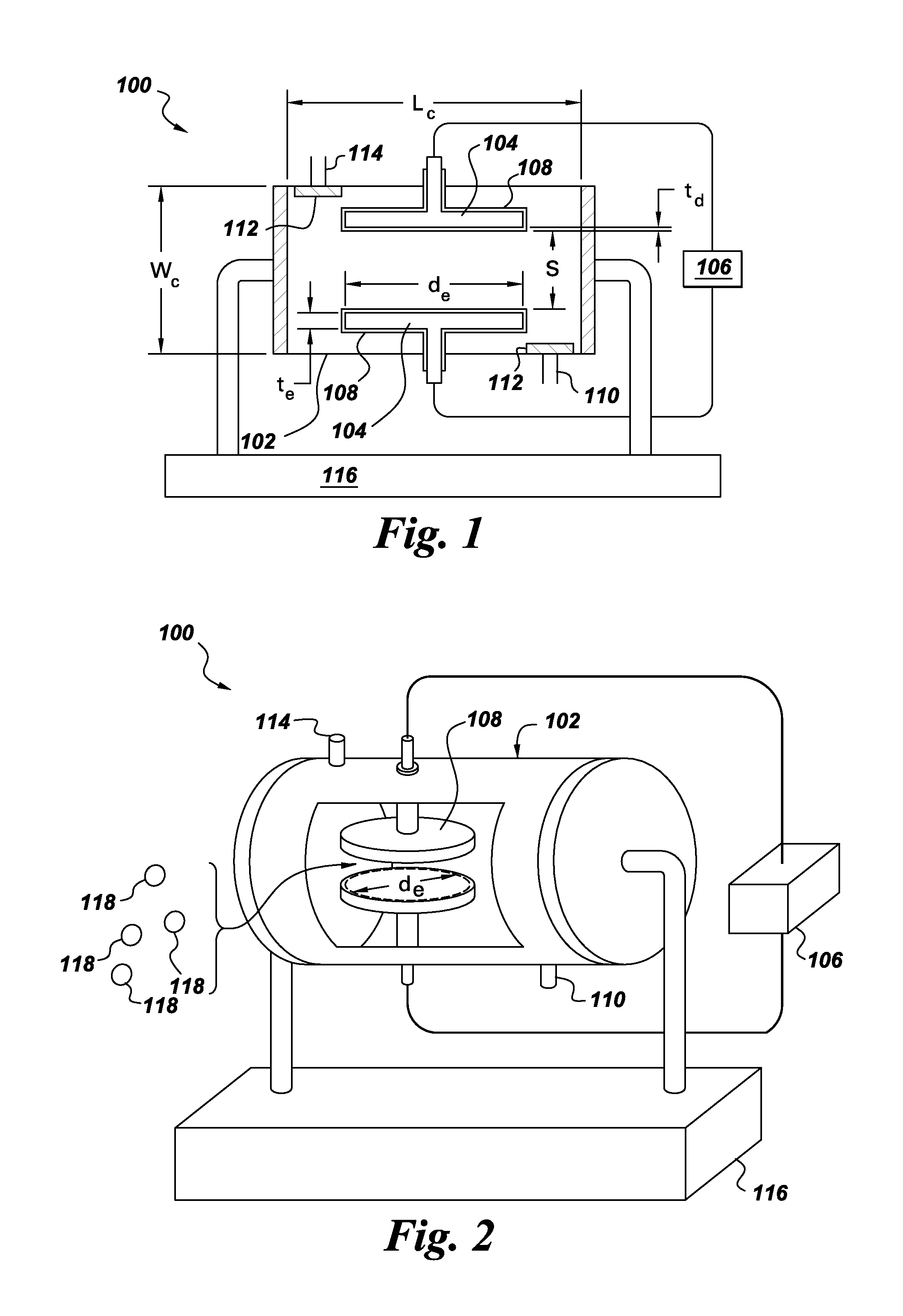

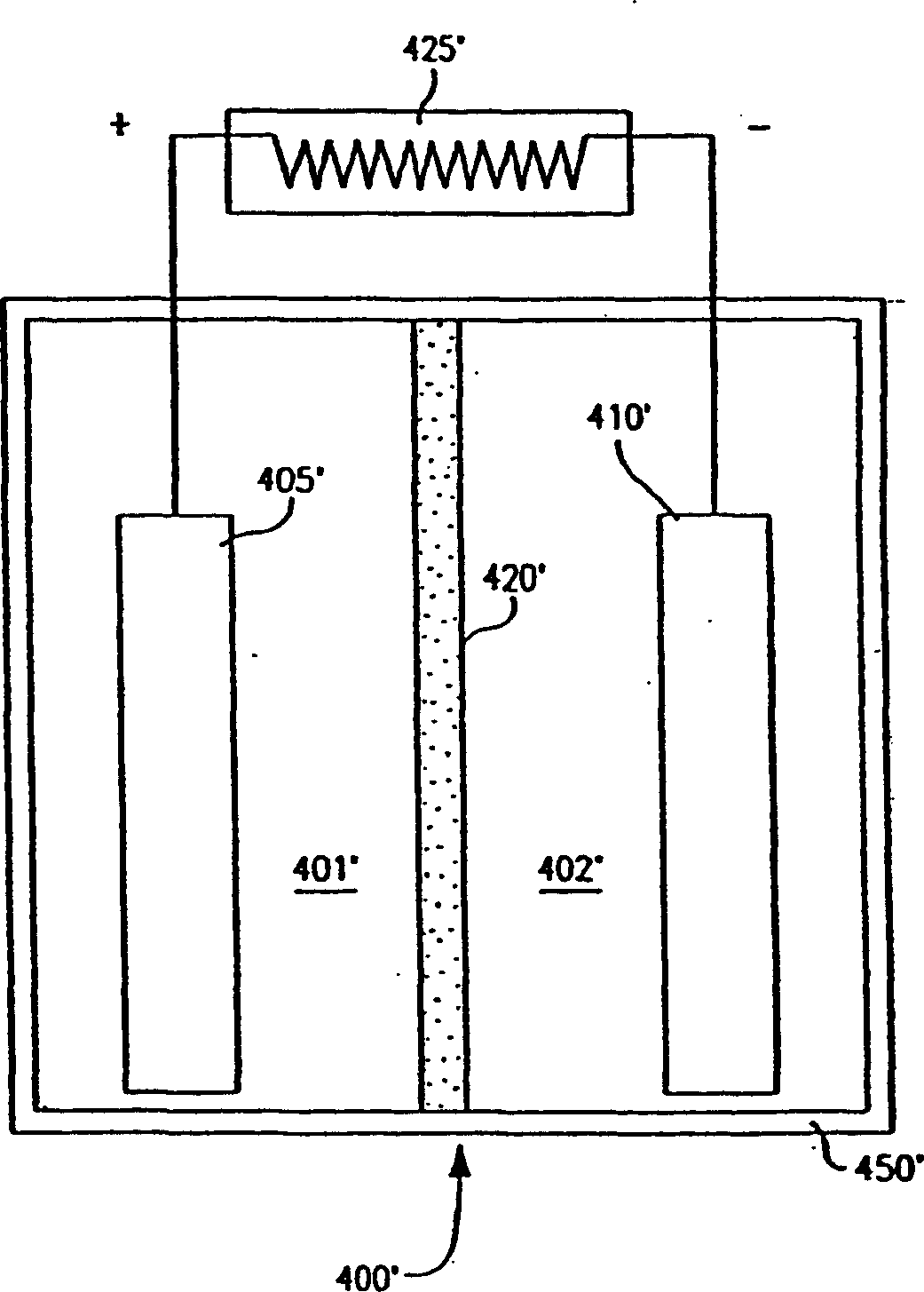

Discharge plasma reactor

InactiveUS20090297409A1Improve adhesionImprove efficiencyEnergy based chemical/physical/physico-chemical processesPlasma techniqueHigh pressureAtmospheric pressure

The present invention is generally directed to a single or dual dielectric barrier discharge reactor for generating flow discharge plasmas at atmospheric pressure or higher pressures. In particular, the present invention relates to a providing stable, energy efficient, glow discharge plasmas having a controlled discharge gap.

Owner:EON LABS

Gel and powder making

A method of forming a gel and / or powder of a metallic oxide, metalloid oxide and / or a mixed oxide or resin thereof from one or more respective organometallic liquid precursor(s) and / or organometalloid liquid precursor(s) by oxidatively treating said liquid in a non-thermal equilibrium plasma discharge and / or an ionised gas stream resulting therefrom and collecting the resulting product. The non-thermal equilibrium plasma is preferably atmospheric plasma glow discharge, continuous low pressure glow discharge plasma, low pressure pulse plasma or direct barrier discharge. The metallic oxides this invention particularly relates to are those in columns 3a and 4a of the periodic table namely, aluminium, gallium, indium, tin and lead and the transition metals. The metalloids may be selected from boron, silicon, germanium, arsenic, antimony and tellurium. Preferred metalloid oxide products made according to the process of the present invention are in particular oxides of silicon including silicone resins and the like, boron, antimony and germanium.

Owner:DOW CORNING IRELAND

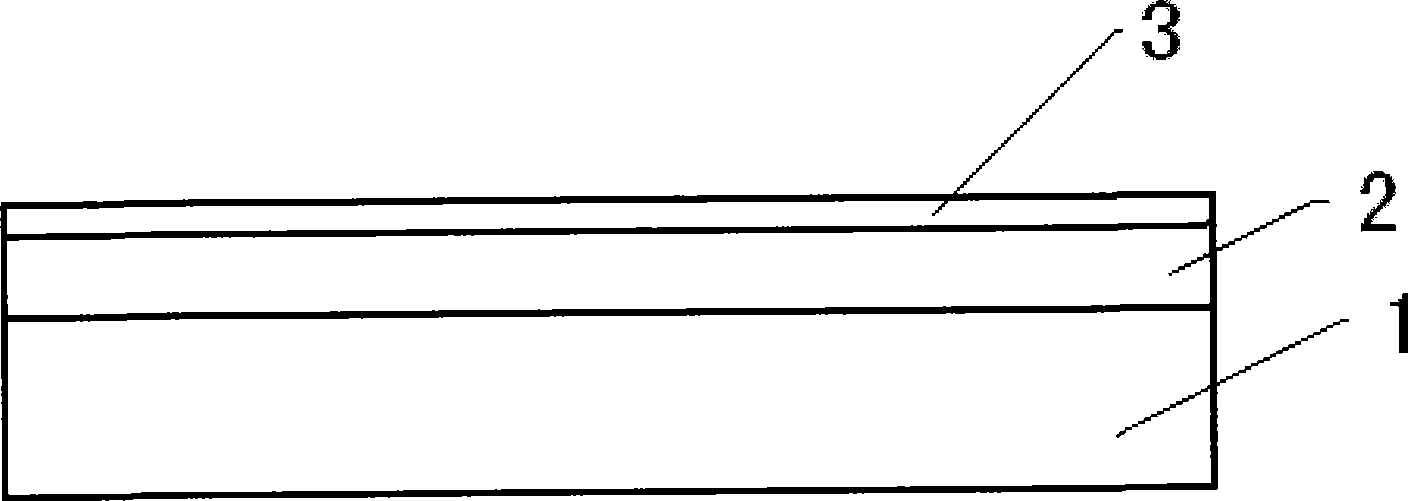

CVD diamond layer overlapped diamond composite sheet for drilling and its production method

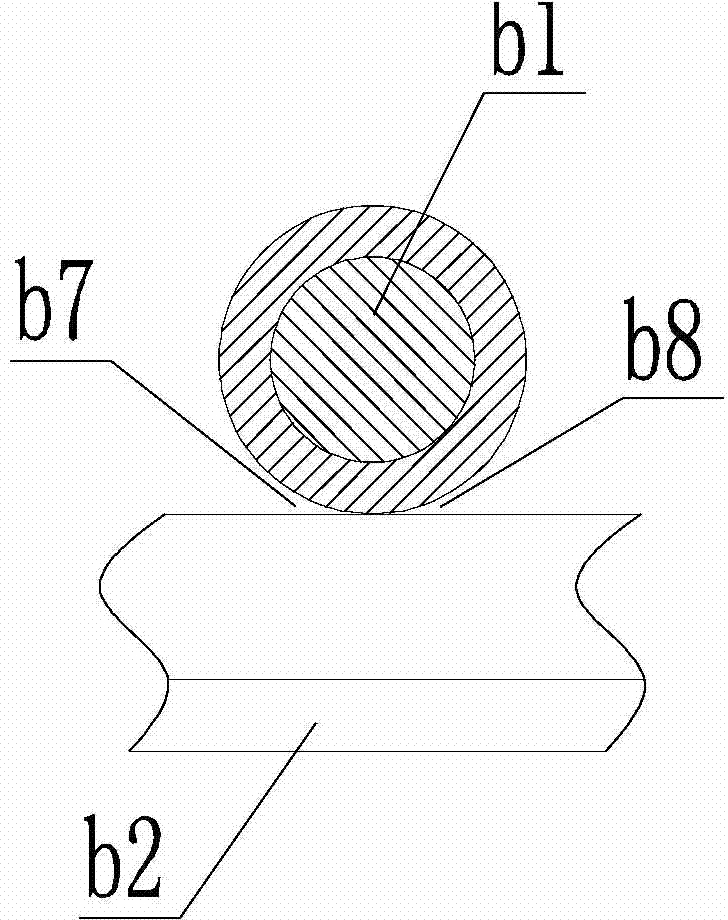

InactiveCN101476445AExtended service lifeImprove temperature resistanceDrill bitsChemical vapor deposition coatingGas phaseChemical vapor deposition

The invention relates to a diamond compact for drilling to cover a CVD diamond coating and a preparing method thereof. The novel diamond compact is prepared from a new material by depositing a layer of diamond film on the surface of the prior diamond compact through chemical vapor deposition methods. The preparing method is disclosed as figure 1, a CVD diamond film 3 with the thickness of between 0. 01 and 2 mm is deposited and covered on the PCD surface 2 of a PDC sheet. The method for preparing the diamond compact adopts the vapor deposition methods of a microwave plasma method, a direct current glow-discharged plasma method, a plasma injection method, a heat wire method, an arc discharge method, a multiple laser beam assistance decomposition method, and the like. Carbon-containing gas or carbon-containing liquid is decomposed, and a CVD diamond film with the thickness of bwteen 0.01 and 2mm is deposited on the PCD surface which is treated. The obtained new material greatly improves the temperature resistance and the wearability of the prior diamond compact, thereby the service life of a drill bit made of the new material is prolonged greatly. The diamond compact can be widely used in drilling industry, construction industry and machining operation industry.

Owner:陈继锋

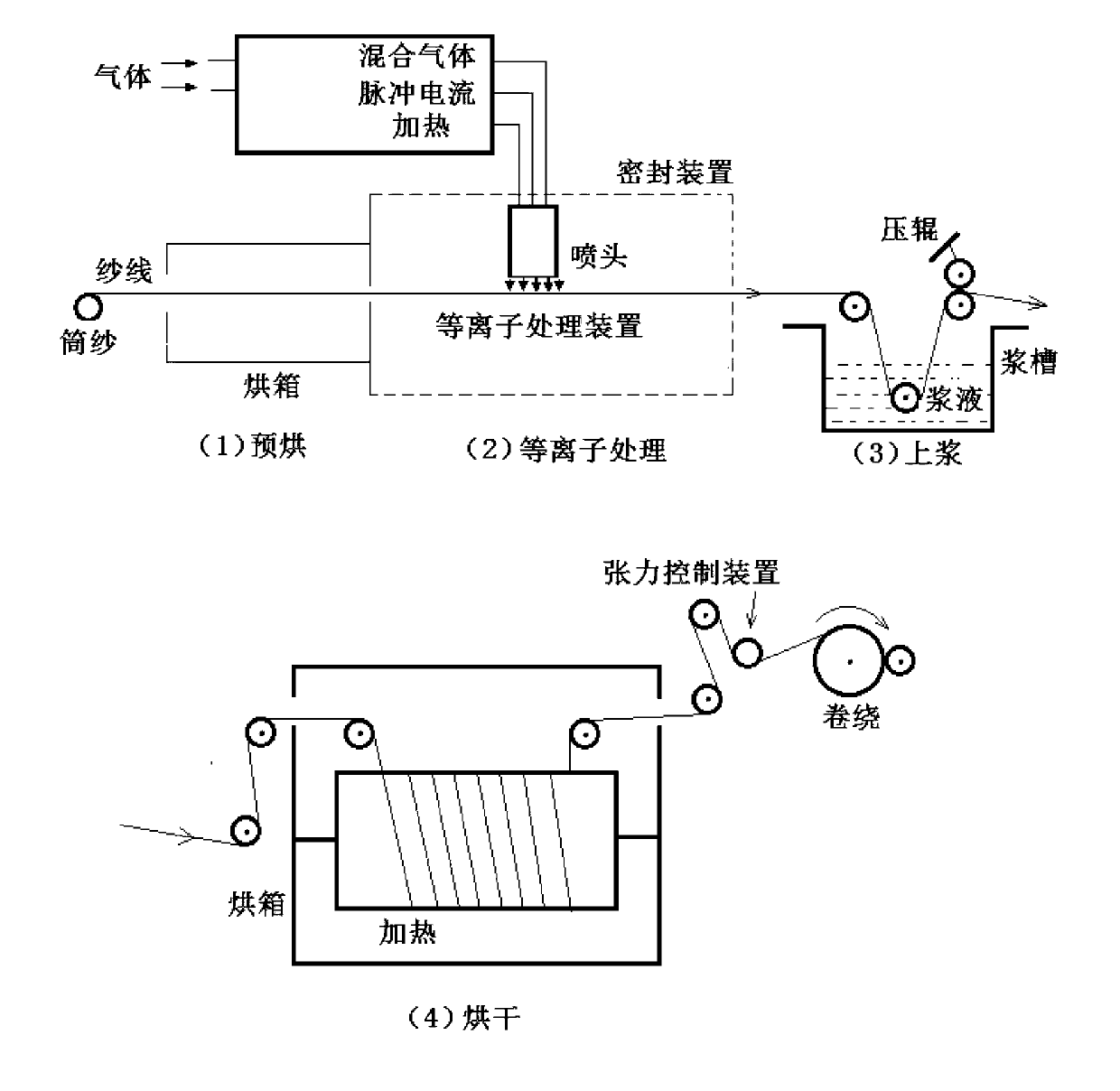

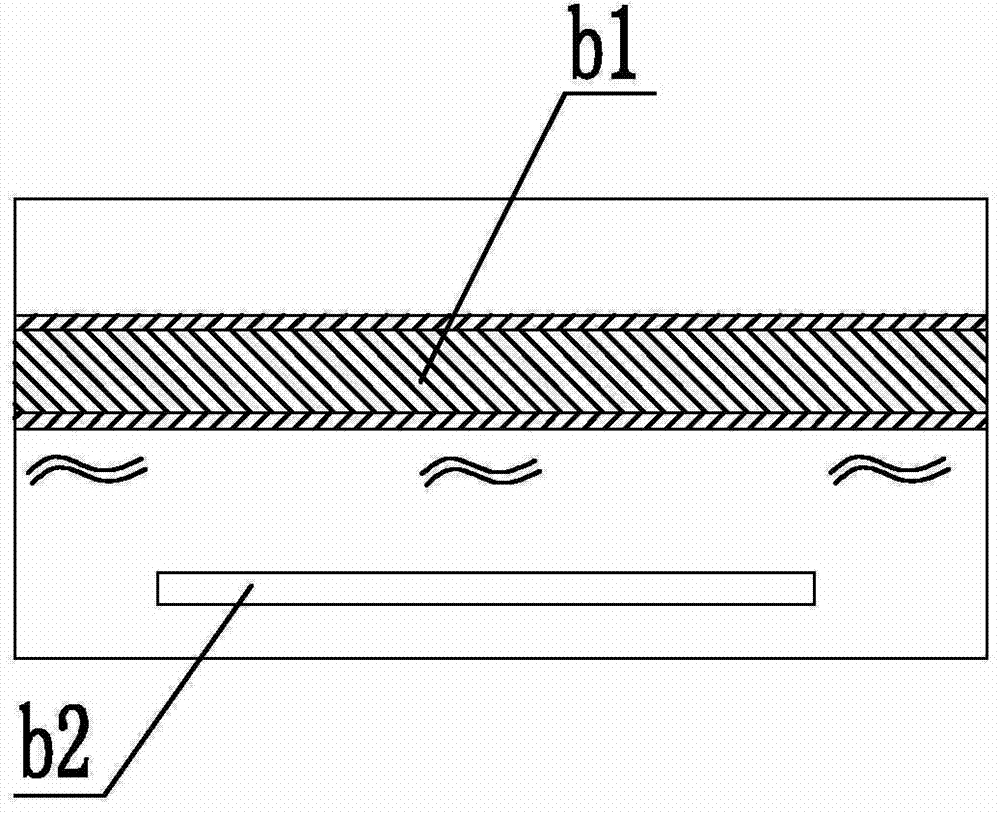

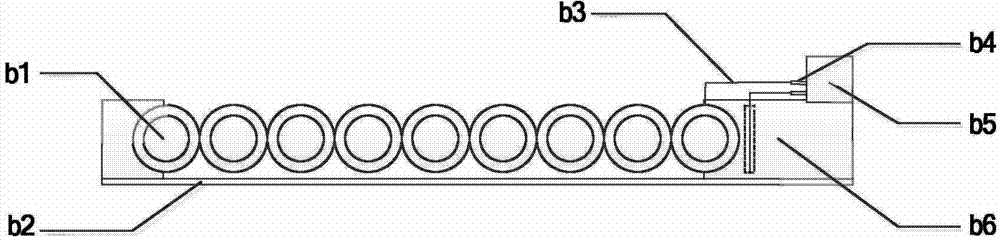

Ecological and environment-friendly high-count cotton yarn sizing method

InactiveCN103132311ANo pollution in the processWide variety of sourcesPhysical treatmentVegetal fibresYarnEngineering

The invention relates to an ecological and environment-friendly high-count cotton yarn sizing method comprising the steps that: high-count yarn is pre-baked by using a pre-baking device, and is treated by using a normal-pressure plasma processing device; the yarn is directly delivered into a sizing tank, and is sized by using an ecological and environment-friendly pulp. The yarn is bake-dried by using a baking oven, and is coiled, such that sizing is finished. The pre-baking device is closely connected with the plasma processing device. The plasma adopted by the normal-pressure plasma processing device is atmospheric pressure glow discharge plasma. The method provided by the invention has the advantages of simple method, low cost of equipment investment and operation, and suitability for popularization. The normal-pressure plasma yarn pre-processing technology adopted by the invention is a dry processing method which is green and environment-friendly. The method causes no pollution and has substantial effect. The invention adopts the ecological pulp with wide material source and low cost. The pulp can be degraded naturally, and causes no pollution to the environment. The method provided by the invention is suitable to be used in sizing high-count cotton yarn with a specification higher than 60 British counts. The sizing quality satisfies the requirement by modern high-speed weaving.

Owner:DONGHUA UNIV

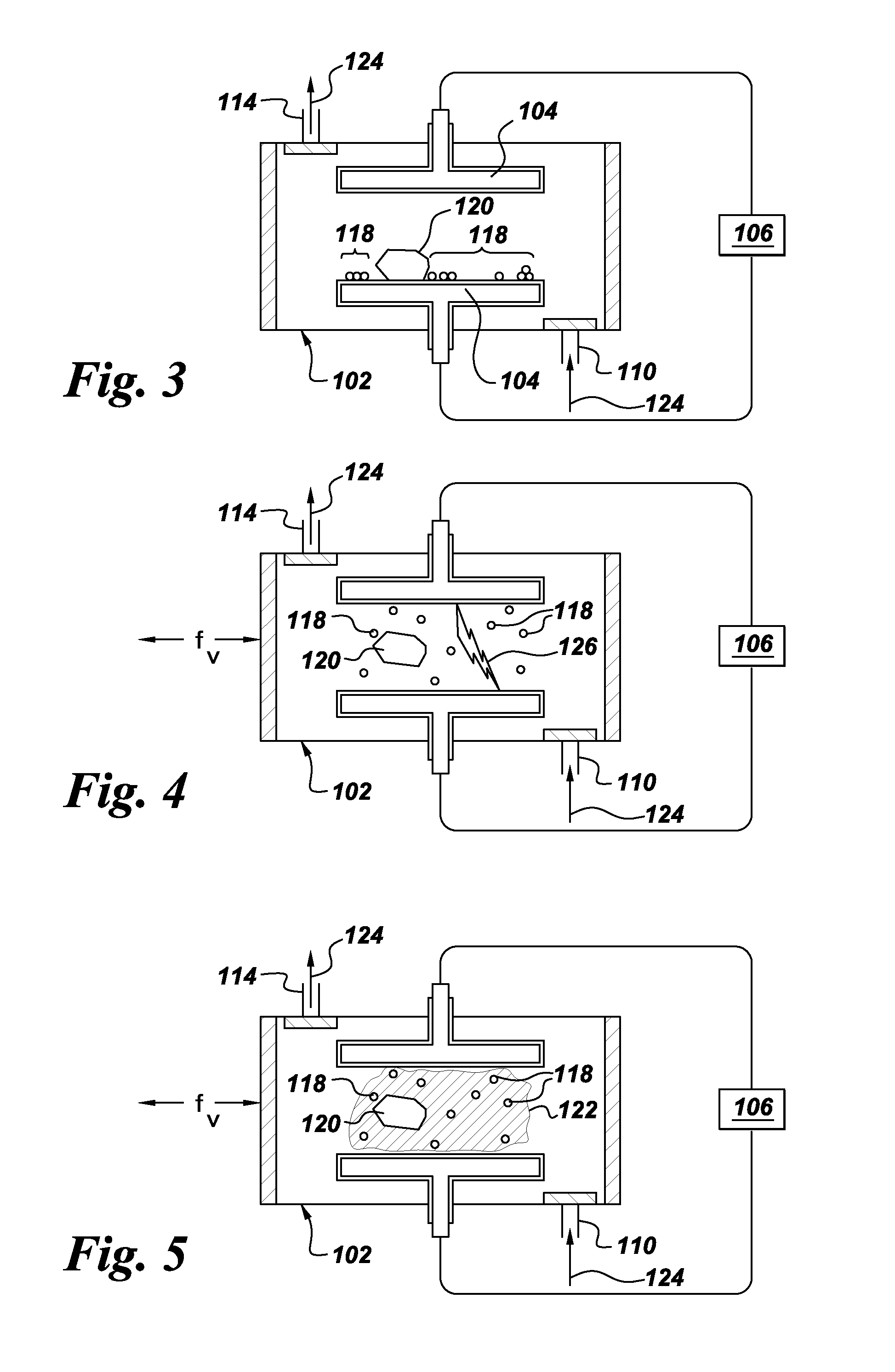

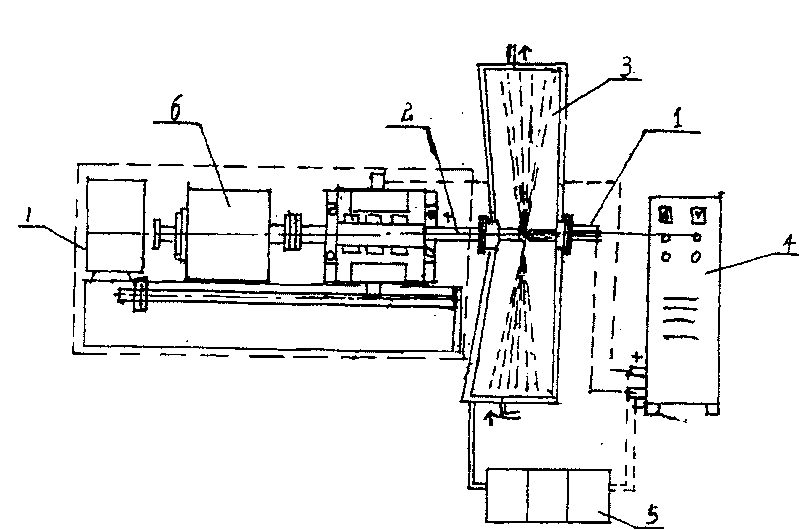

Apparatus and method for producing plasma during milling for processing of material compositions

InactiveUS20110297532A1Energy based chemical/physical/physico-chemical processesPlasma techniqueEngineeringAtmospheric pressure

Owner:GENERAL ELECTRIC CO

Manufacturing method of semiconductor device

InactiveUS20090047761A1Increase display contrastQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingHigh frequency powerGlow discharge plasma

An object is to provide a manufacturing method of a microcrystalline semiconductor film with favorable quality over a large-area substrate. After forming a gate insulating film over a gate electrode, in order to improve quality of a microcrystalline semiconductor film formed in an initial stage, glow discharge plasma is generated by supplying high-frequency powers with different frequencies, and a lower part of the film near an interface with the gate insulating film is formed under a first film formation condition, which is low in film formation rate but results in a good quality film. Thereafter, an upper part of the film is deposited under a second film formation condition with higher film formation rate, and further, a buffer layer is stacked on the microcrystalline semiconductor film.

Owner:SEMICON ENERGY LAB CO LTD

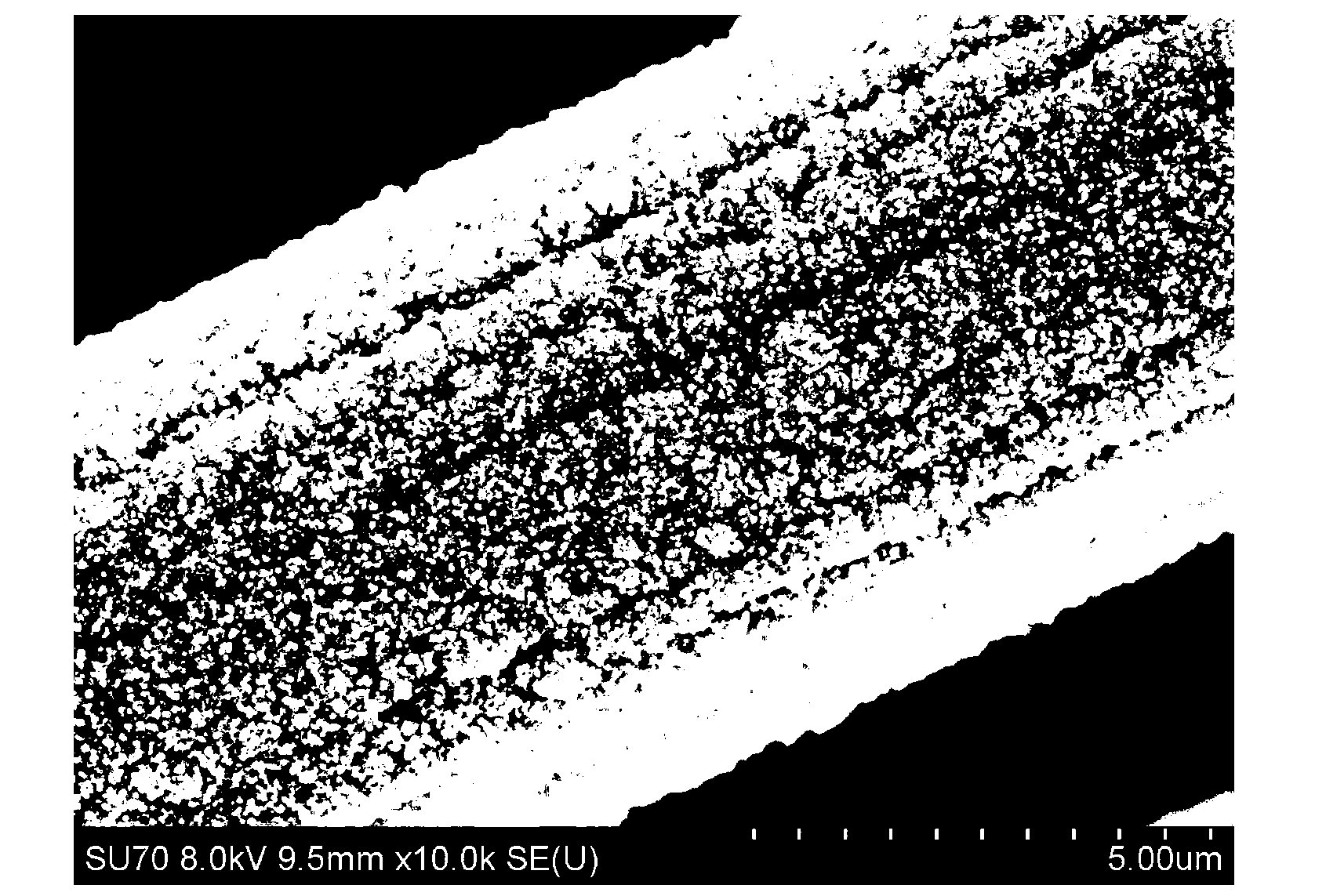

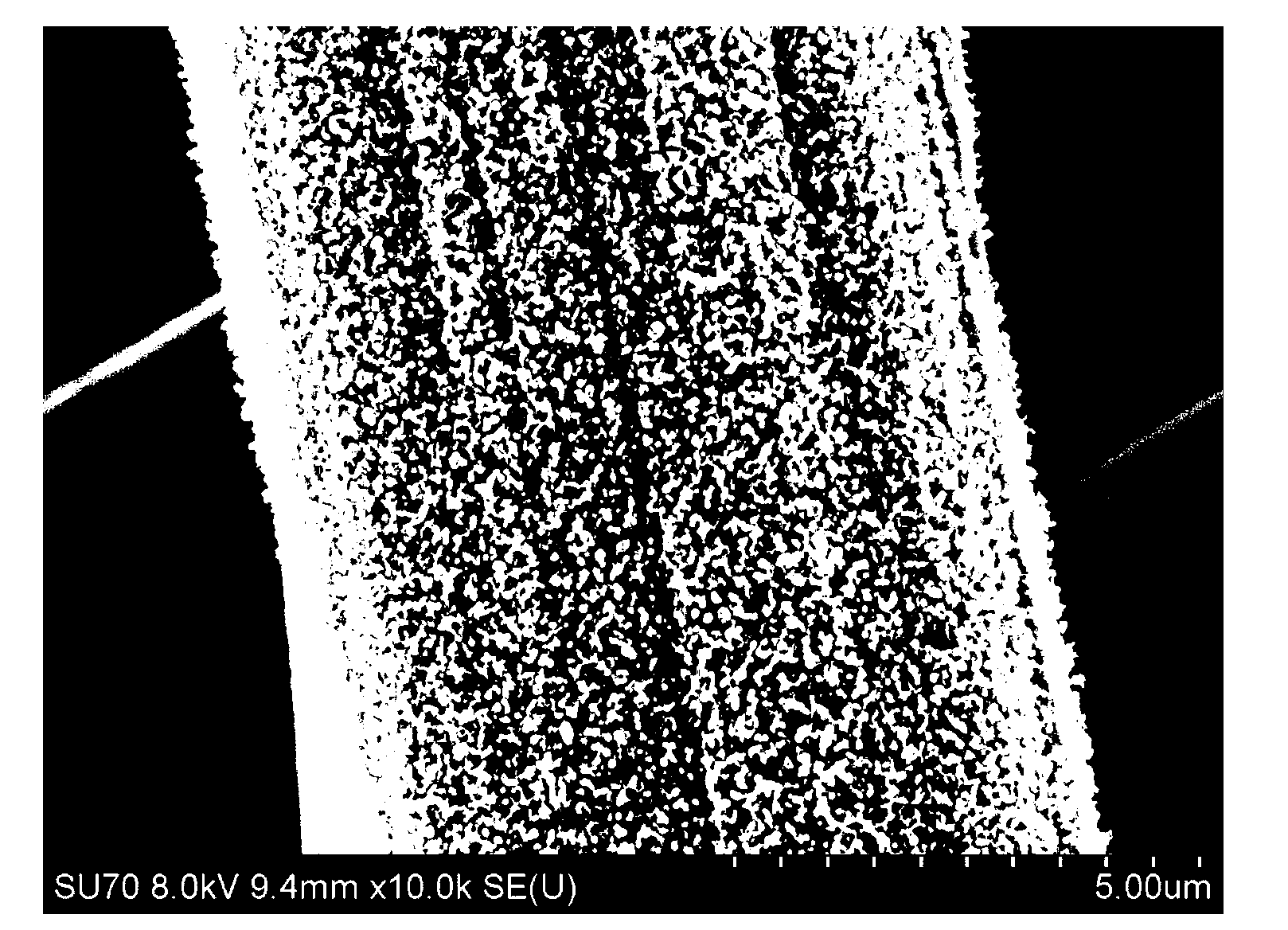

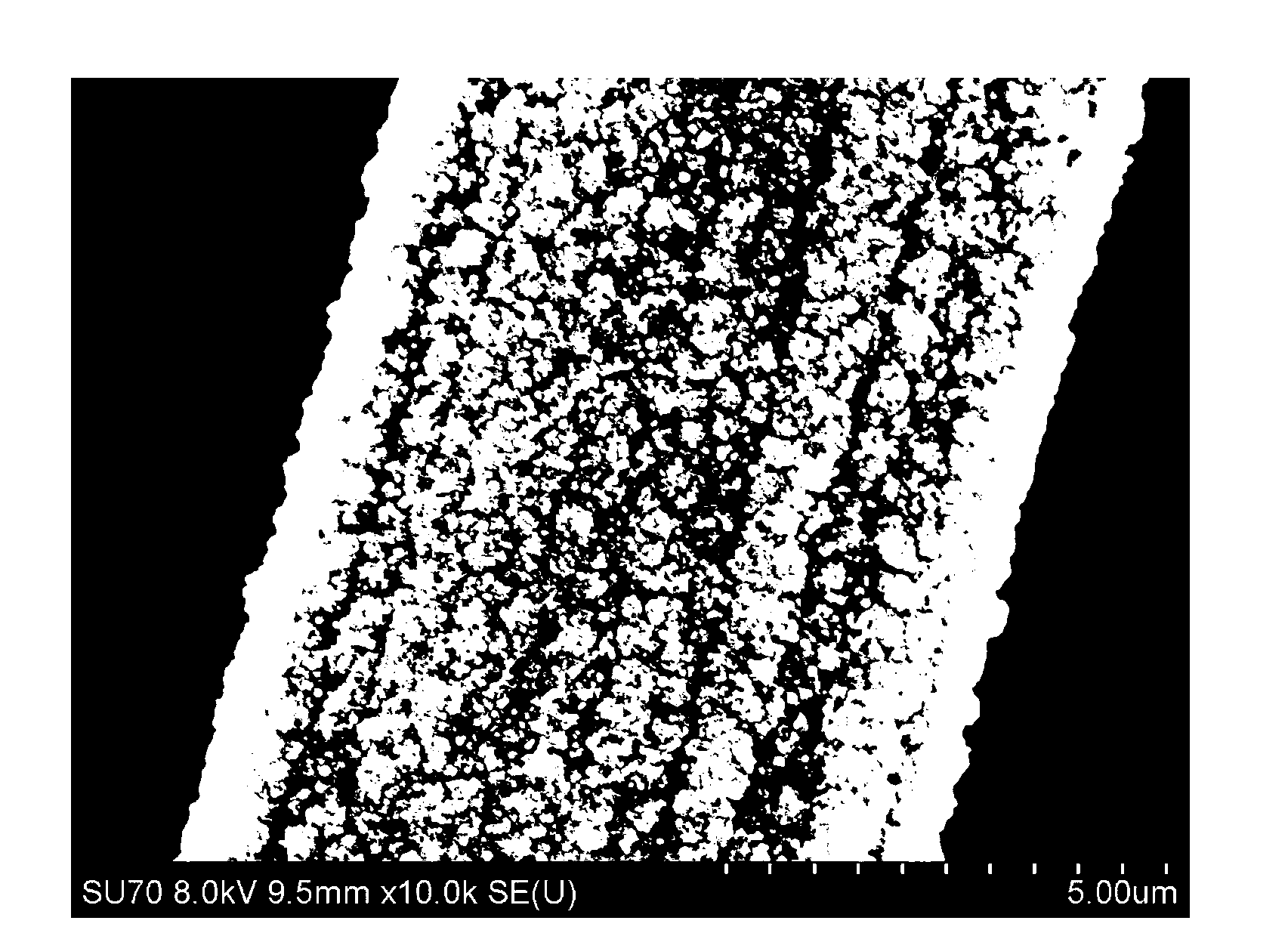

Preparation method of platinum/vertical graphene composite material electrocatalyst

InactiveCN103007926AObvious reunion phenomenonIncrease depositionCell electrodesCatalyst activation/preparationNano catalystGas phase

The invention discloses a preparation method of a platinum / vertical graphene composite material electrocatalyst. The preparation method comprises the following steps: growing a vertical graphene nano sheet through constant voltage direct-current normal glow discharge plasma enhanced chemical vapor deposition; depositing platinum nano grains on the surface of the vertical graphene nano sheet through a electrochemical deposition method in a mode that the vertical graphene nano sheet is used as a carrier; and drying so as to obtain the vertical graphene composite material electrocatalyst. The vertical graphene composite material electrocatalyst prepared by using the plasma enhanced chemical vapor deposition method has no conspicuous graphene agglomeration phenomenon, the distance is controllable, the superficial area can be effectively utilized, and the deposition quantity of a nano catalyst of the carrier in unit volume is increased.

Owner:ZHEJIANG UNIV

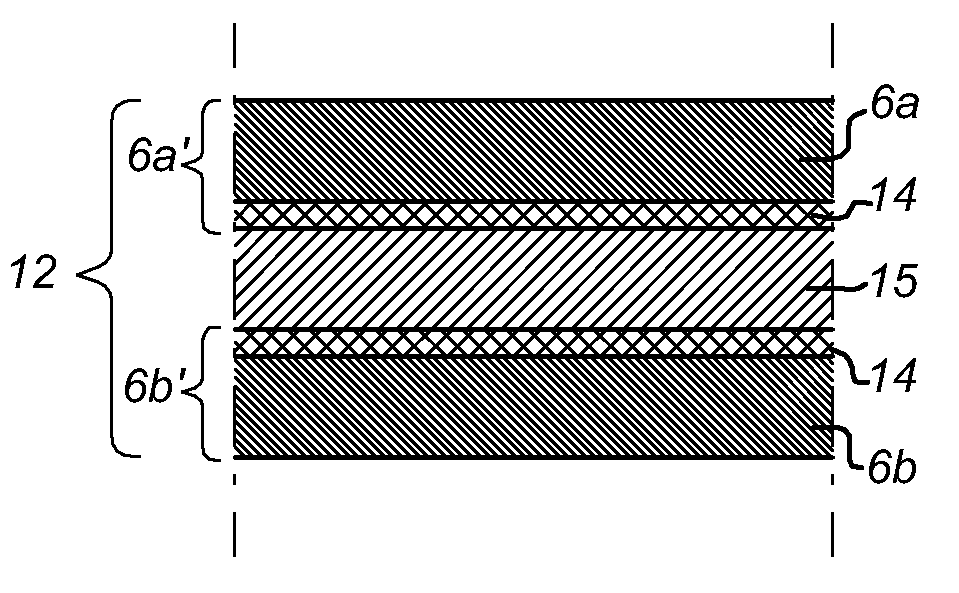

Method for manufacturing a multi-layer stack structure with improved wvtr barrier property

InactiveUS20110049491A1Effective and efficient and cheap processImprove barrier propertiesLamination ancillary operationsSolid-state devicesEngineeringAtmospheric pressure

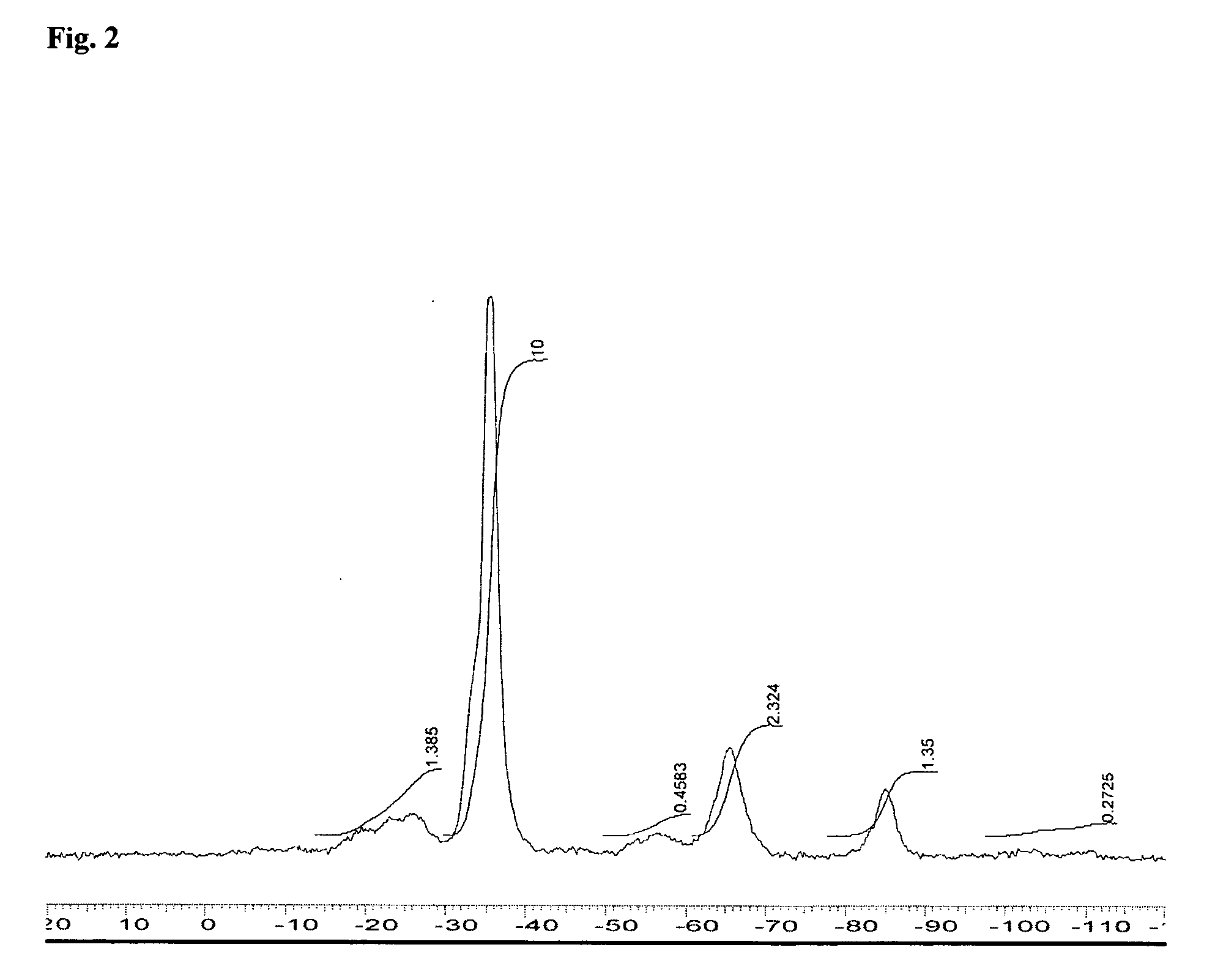

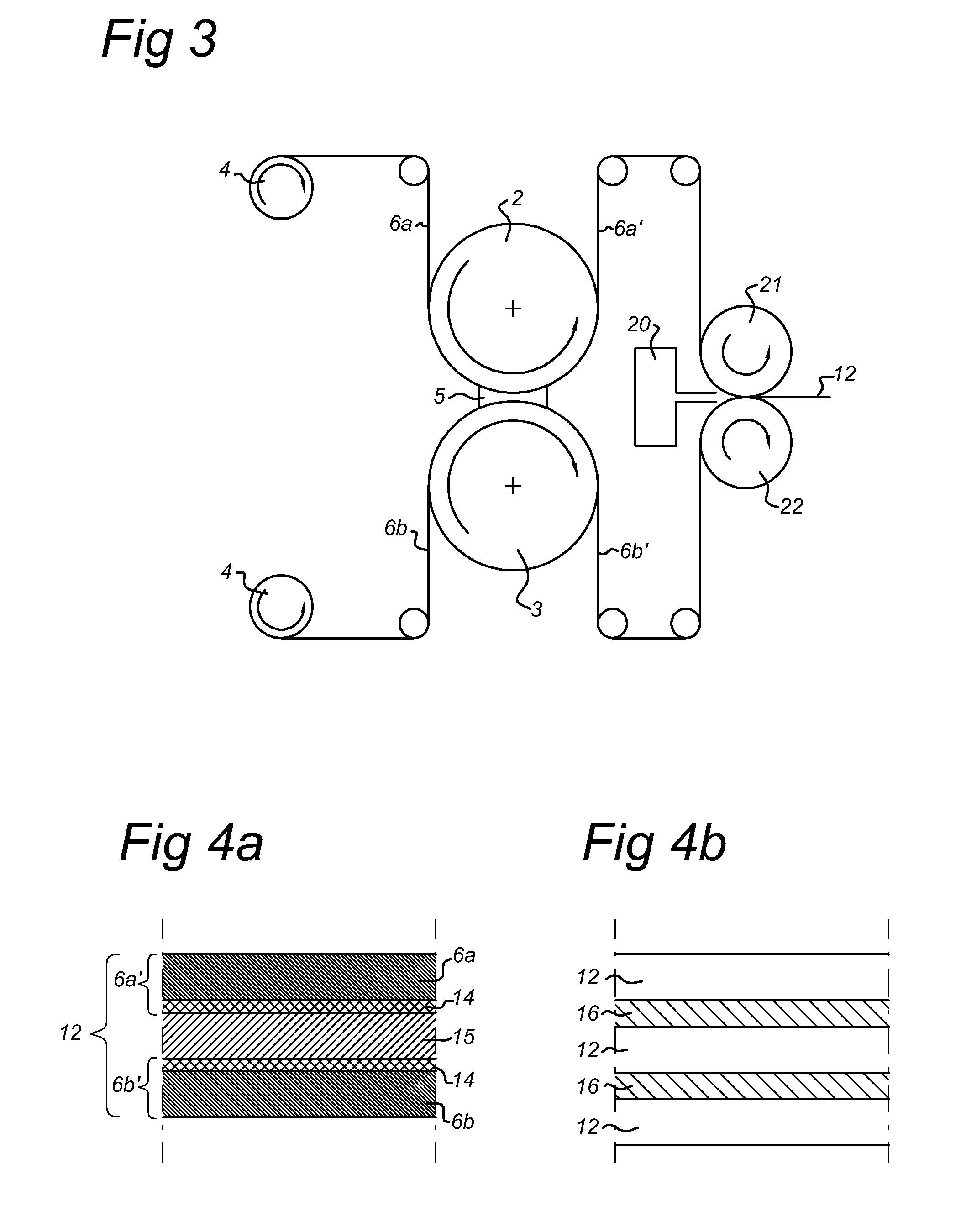

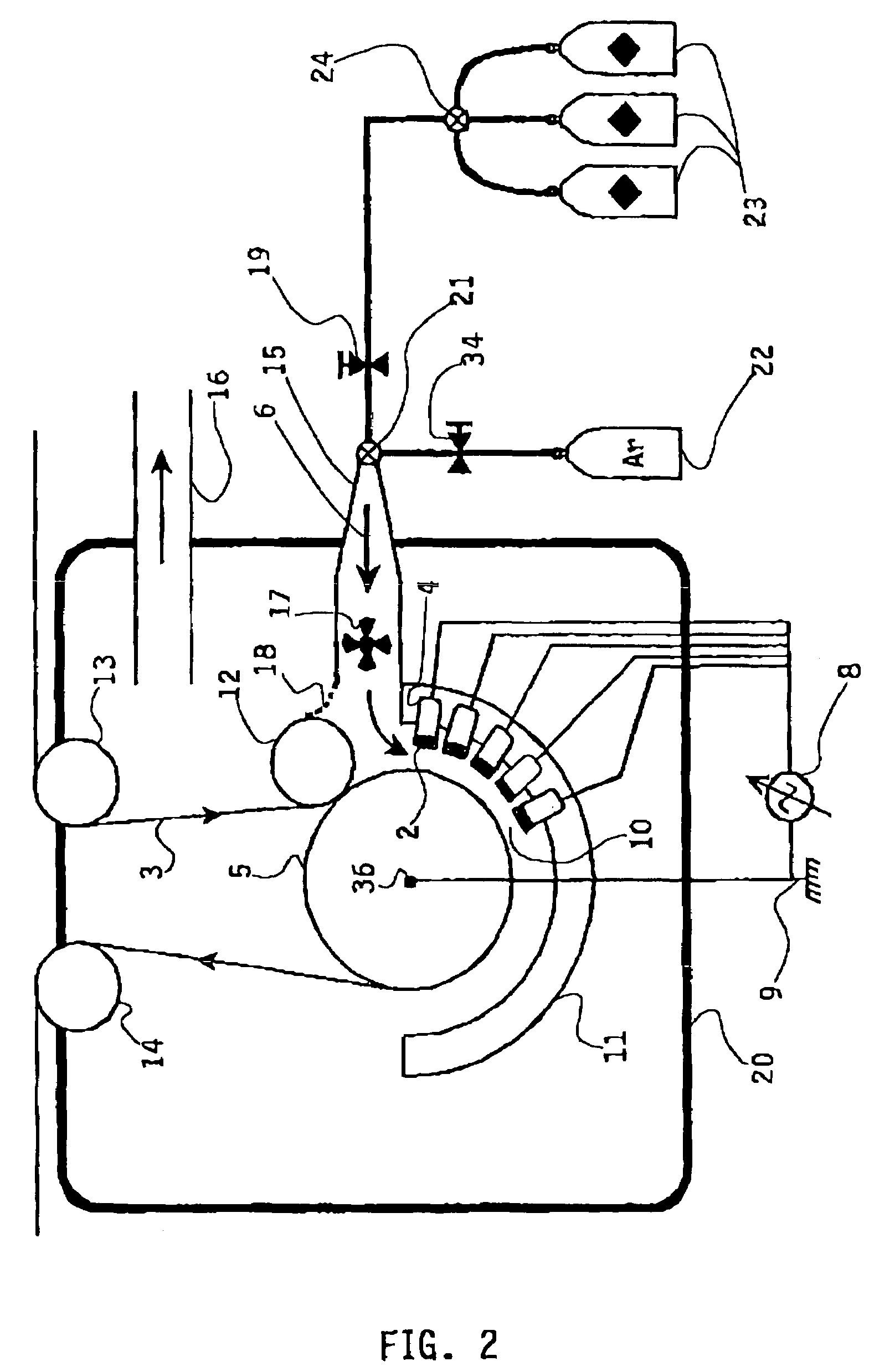

A method and apparatus for manufacturing a multi-layer stack structure (12), the structure (12) comprising in order: a substrate (6a) a barrier layer (14) an adhesive layer (15) a barrier layer (14) a substrate (6b). The method comprises: a) providing two substrates (6a, 6b) in a single treatment space (5), the treatment space (5) comprising at least two electrodes (2, 3) for generating an atmospheric pressure glow discharge plasma in the treatment space (5); b) treating the facing surfaces of the two substrates (6a, 6b) simultaneously in the single treatment space (5); c) laminating the two treated substrates (6a, 6b) with an adhesive layer (15) in between the facing surfaces to obtain the multi-layer stack structure (12).

Owner:FUJIFILM MFG EURO

Gel and powder making

A method of forming a gel and / or powder of a metallic oxide, metalloid oxide and / or a mixed oxide or resin thereof from one or more respective organometallic liquid precursor(s) and / or organometalloid liquid precursor(s) by oxidatively treating said liquid in a non-thermal equilibrium plasma discharge and / or an ionised gas stream resulting therefrom and collecting the resulting product. The non-thermal equilibrium plasma is preferably atmospheric plasma glow discharge, continuous low pressure glow discharge plasma, low pressure pulse plasma or direct barrier discharge. The metallic oxides this invention particularly relates to are those in columns 3a and 4a of the periodic table namely, aluminium, gallium, indium, tin and lead and the transition metals. The metalloids may be selected from boron, silicon, germanium, arsenic, antimony and tellurium. Preferred metalloid oxide products made according to the process of the present invention are in particular oxides of silicon including silicone resins and the like, boron, antimony and germanium.

Owner:DOW CORNING IRELAND

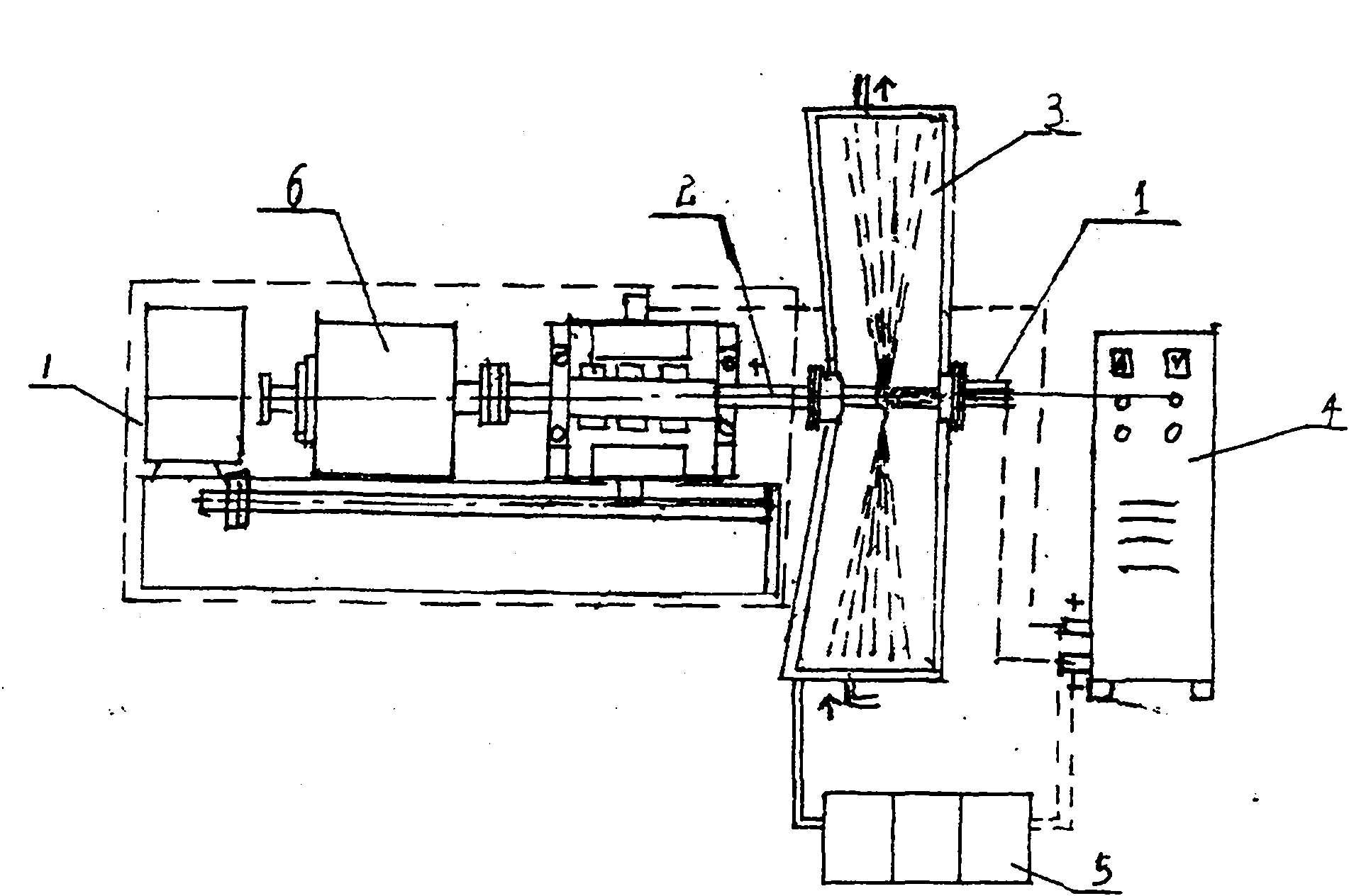

Methods for preparing titanium alloy TC4 prill by plasma auxiliary rotation electrode

The invention relates to a method for preparing a titanium alloy TC4 spherical powder by a plasma auxiliary rotation-electrode centrifugal process, comprising the following steps of: generating a glow discharge plasma arc between consumption type electrodes manufactured by a plasma auxiliary electrode and a rotational cylindrical titanium alloy TC4 in a closed container protected by inert gas, wherein a section of the titanium alloy TC4 electrode, which is close to the plasma arc, forms droplets due to high temperature generated by the plasma arc; throwing the droplets by centrifugal force; air-cooling and curing the titanium alloy TC4 droplets into a spherical shape in the inert atmosphere environment of the closed container; and obtaining a titanium alloy TC4 prill. The method can obtain the titanium alloy TC4 prill which has average sphere diameters between 0.08 mm and 1.8 mm and better monodispersity by changing technological parameters; in addition, the prepared powder prill has good sphericity, lower malformed particle proportion and controllable sphere diameter and can be used in the field of laser three-dimensional forming and for preparing special components of aerospace planes.

Owner:张建利

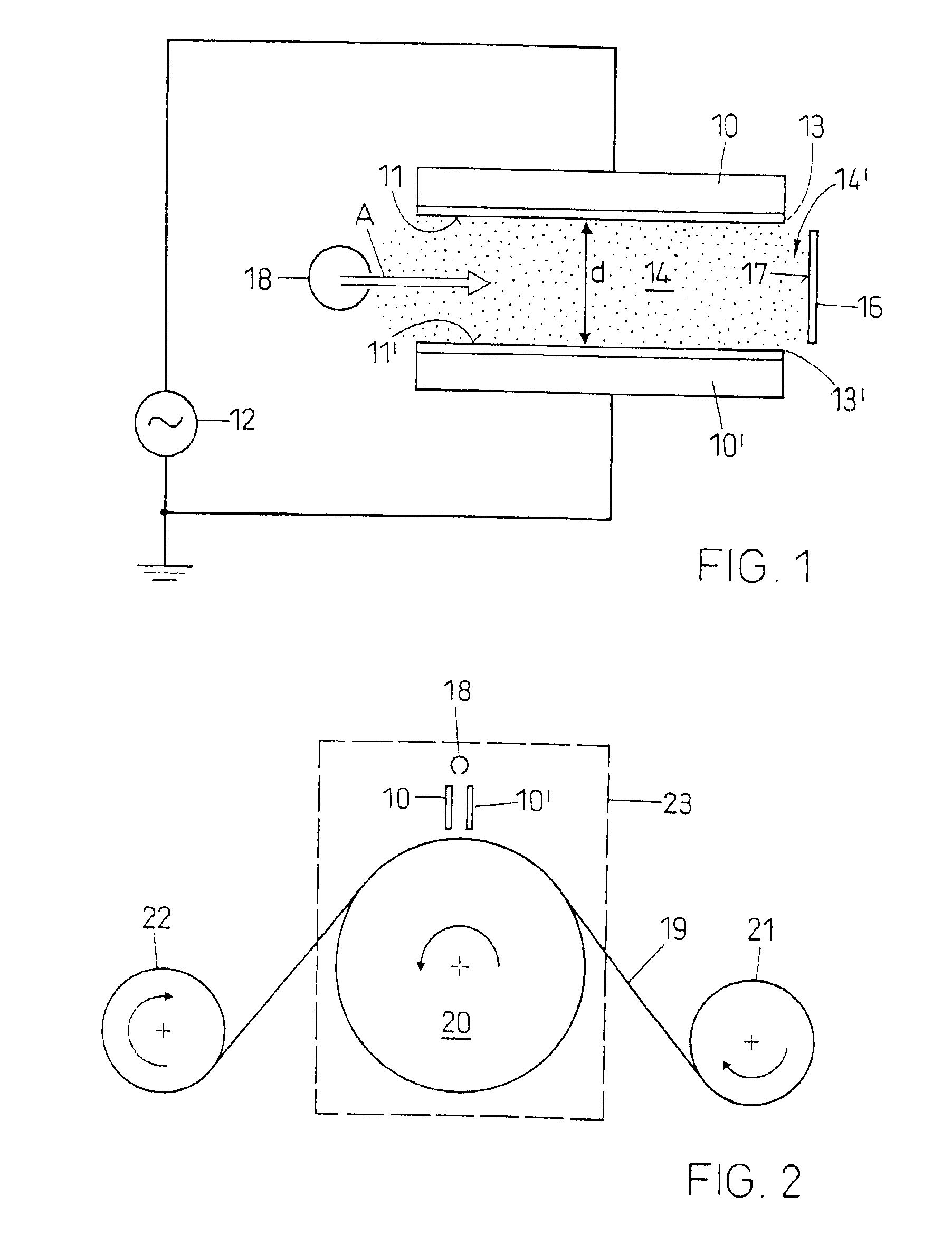

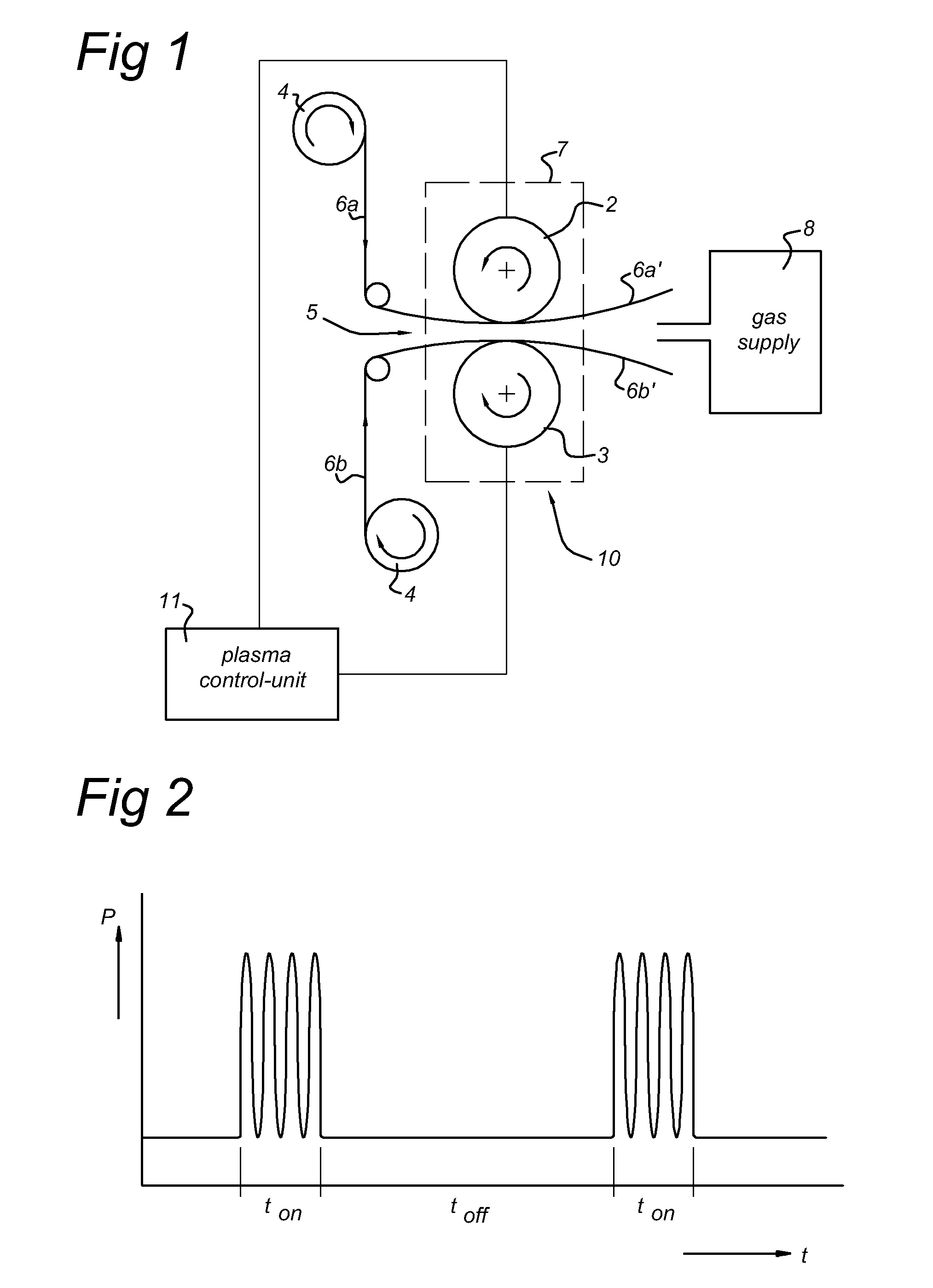

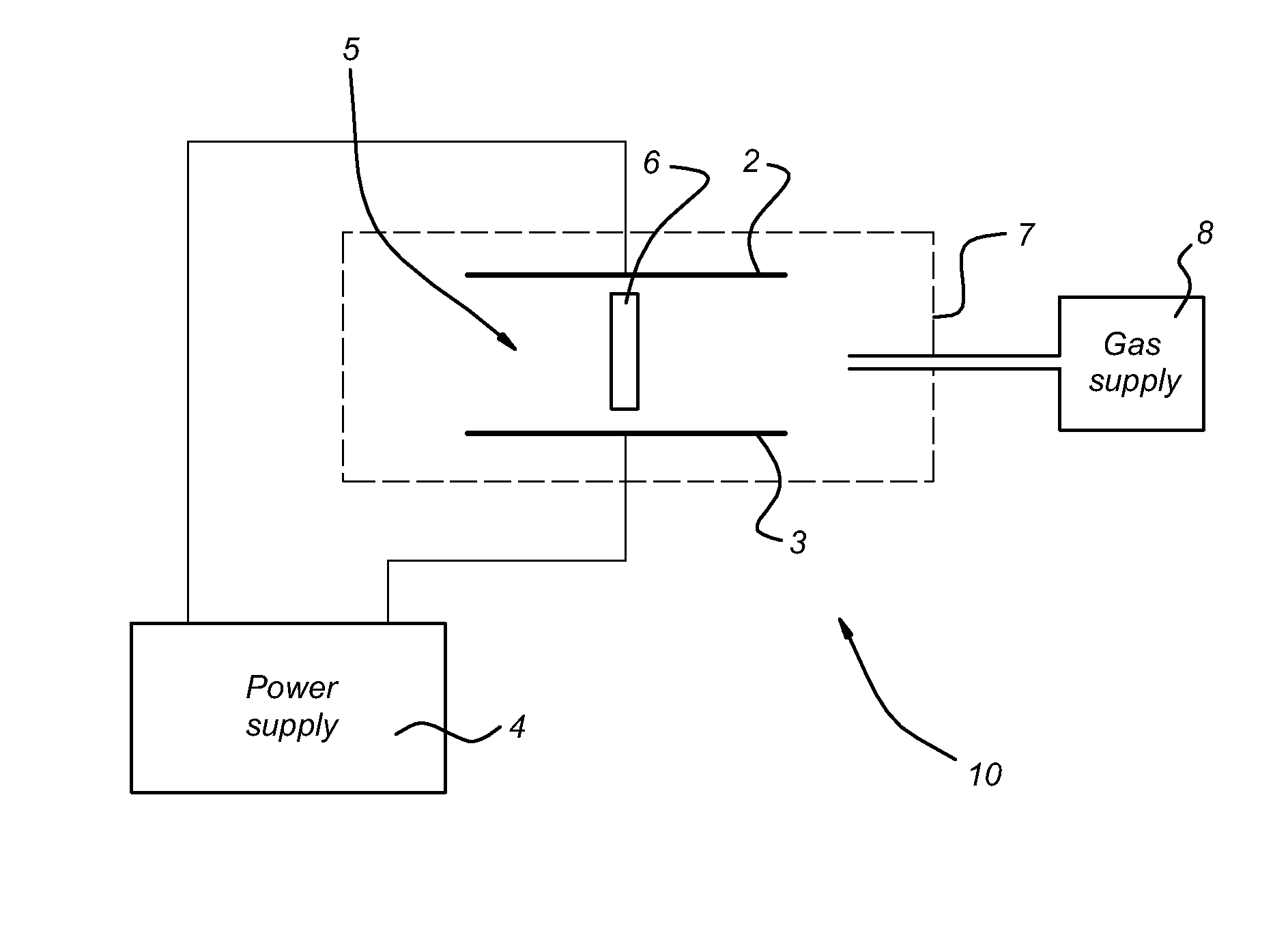

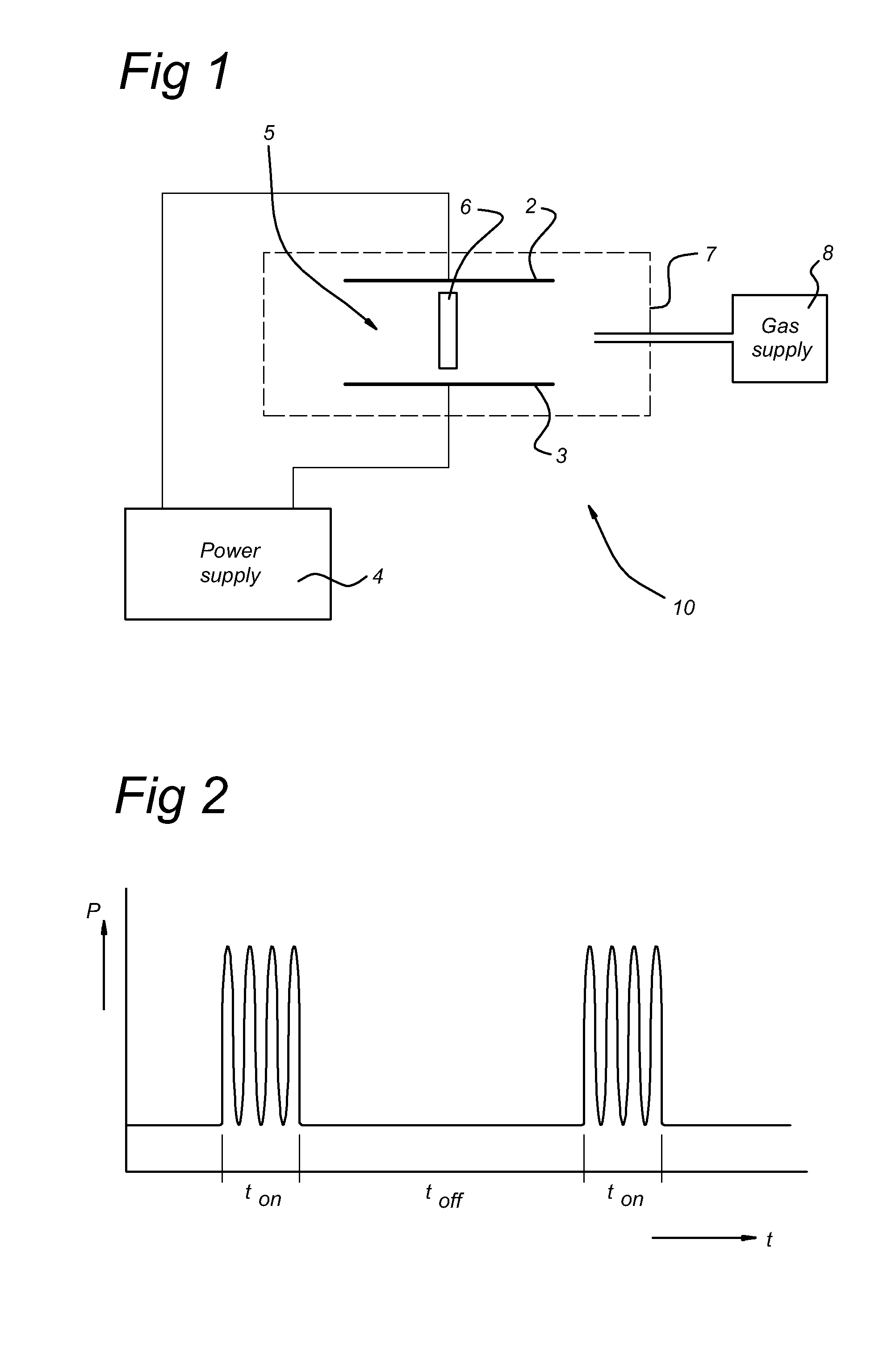

Method and apparatus for deposition using pulsed atmospheric pressure glow discharge

InactiveUS20090238997A1Quality improvementLow efficiencyChemical vapor deposition coatingPlasma techniqueNitrogen gasGlow discharge plasma

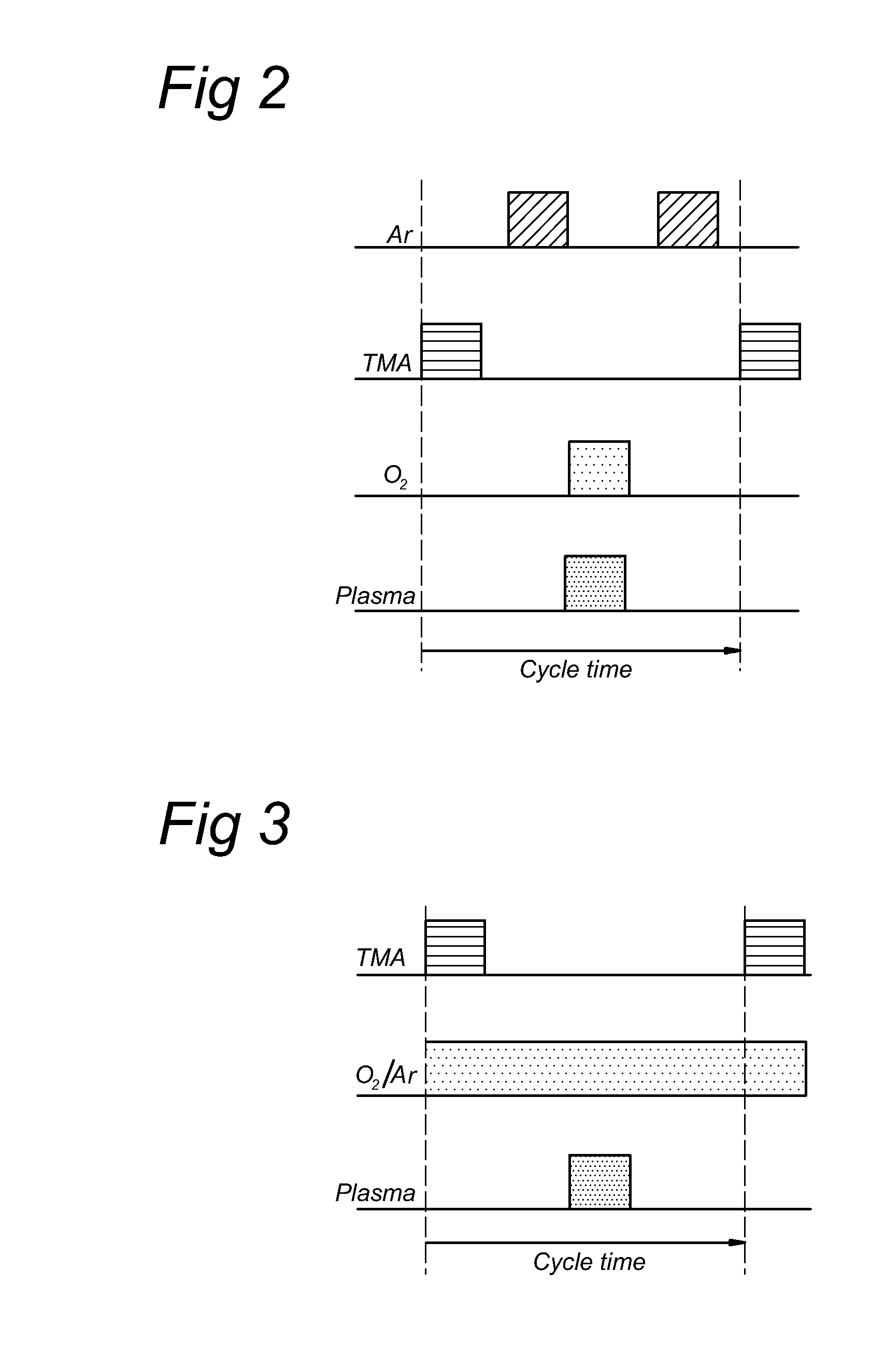

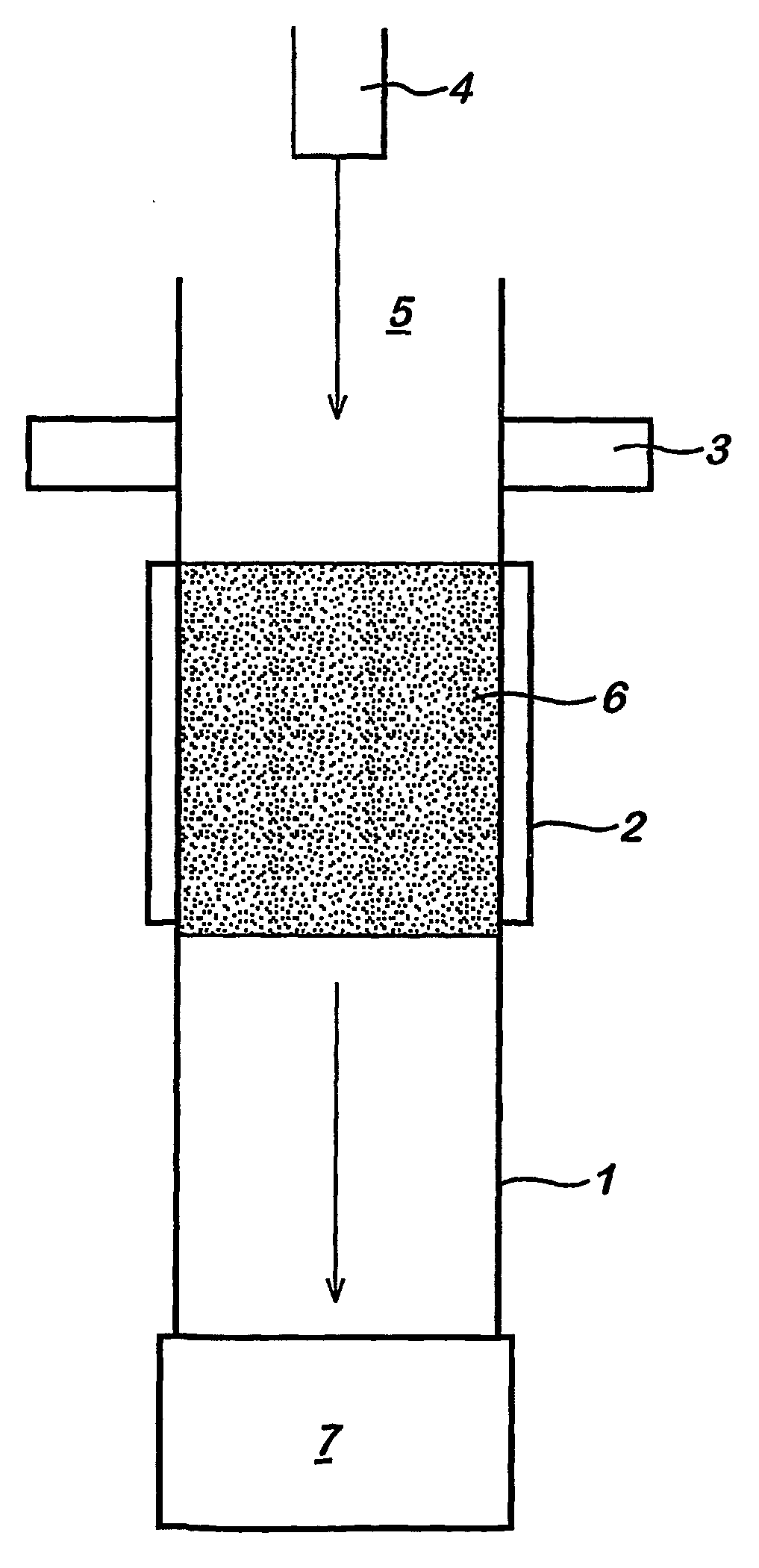

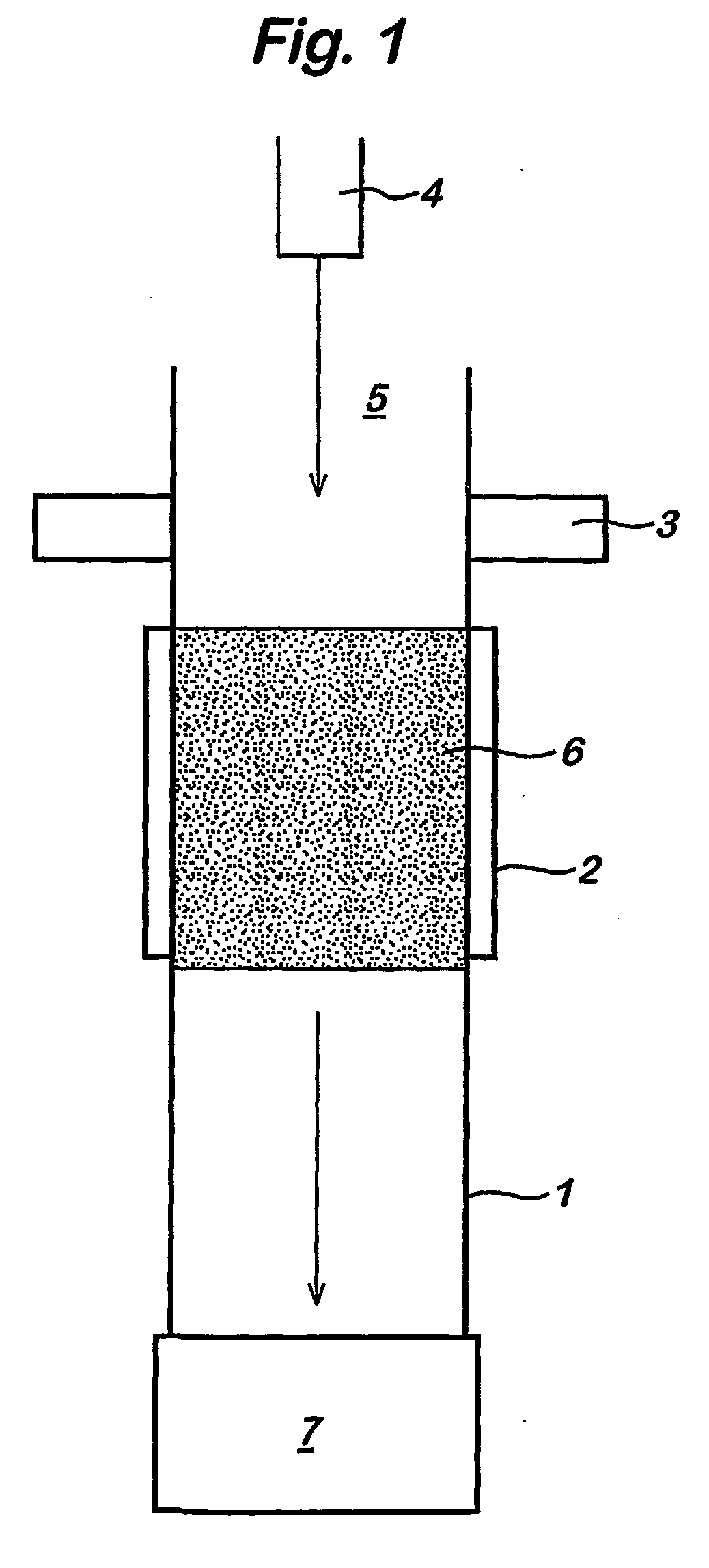

Method and apparatus for deposition of a chemical compound or element using an atmospheric pressure glow discharge plasma in a treatment space (5) comprising two electrodes (2, 3) connected to a power supply (4) for providing electrical power during an on-time (ton), the treatment space is filled with a gas composition of an active and an inert gas mixture, including a precursor of the chemical compound or element to be deposited. Dust formation is prevented by using Nitrogen in the gas composition, applying short pulses and using a predetermined residence time of the gas composition in the treatment space. Best results are obtained when using a stabilized plasma.

Owner:FUJIFILM MFG EURO

Plasma Booster for Plasma Treatment Installation

ActiveUS20130040072A1Increase plasma densityGood dissociation and excitationElectric discharge tubesVacuum evaporation coatingCharge carrierPlasma coating

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

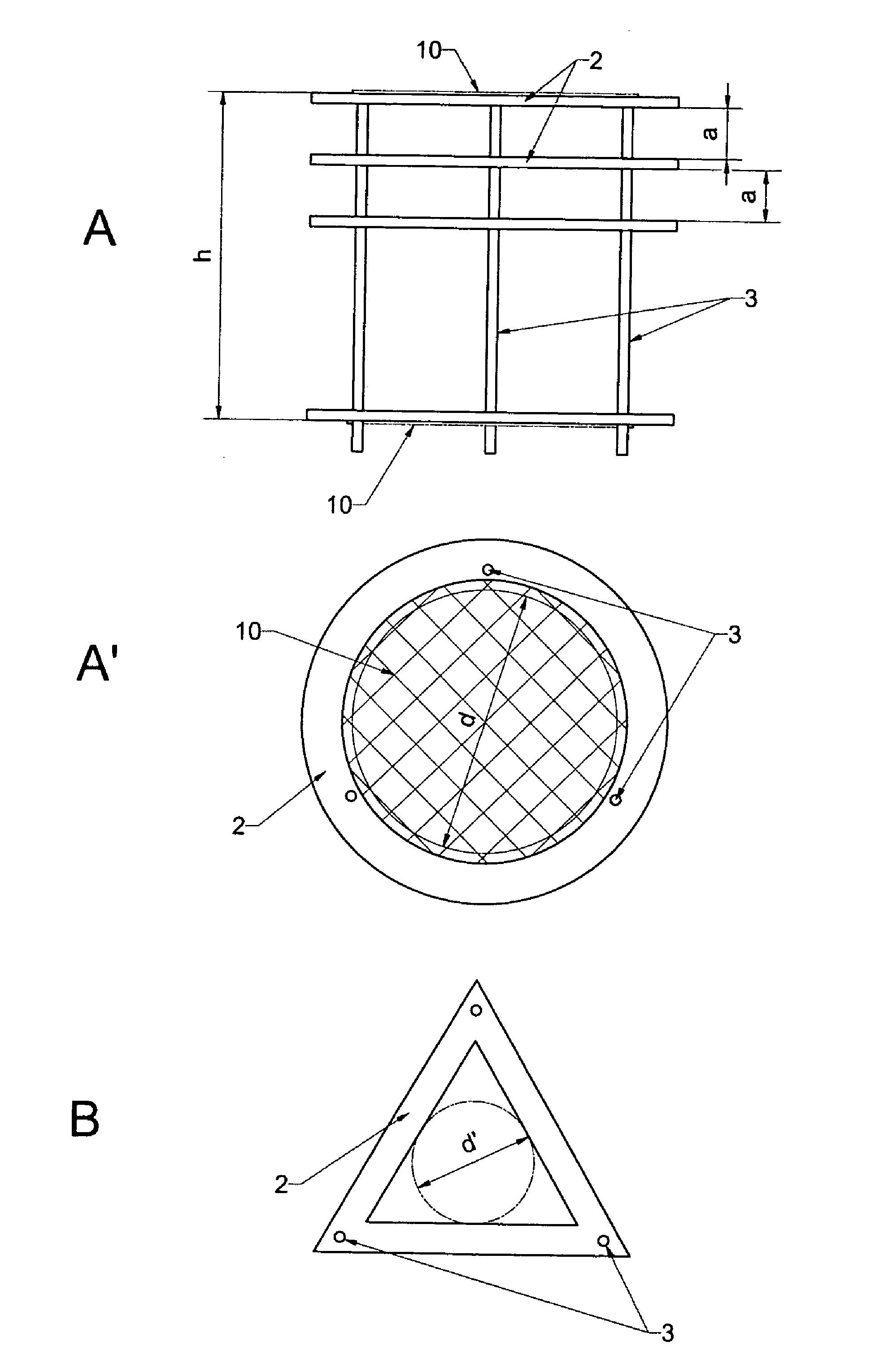

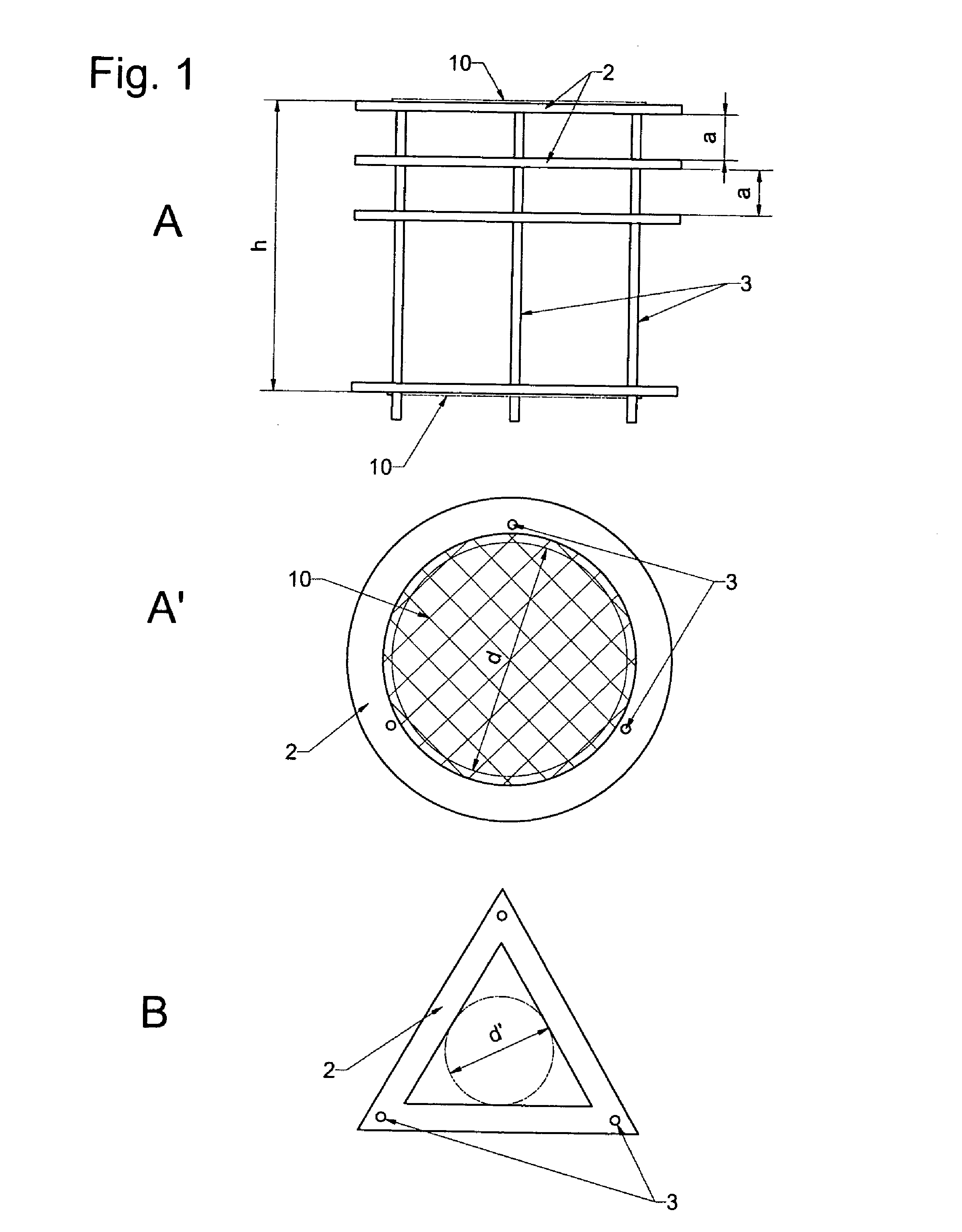

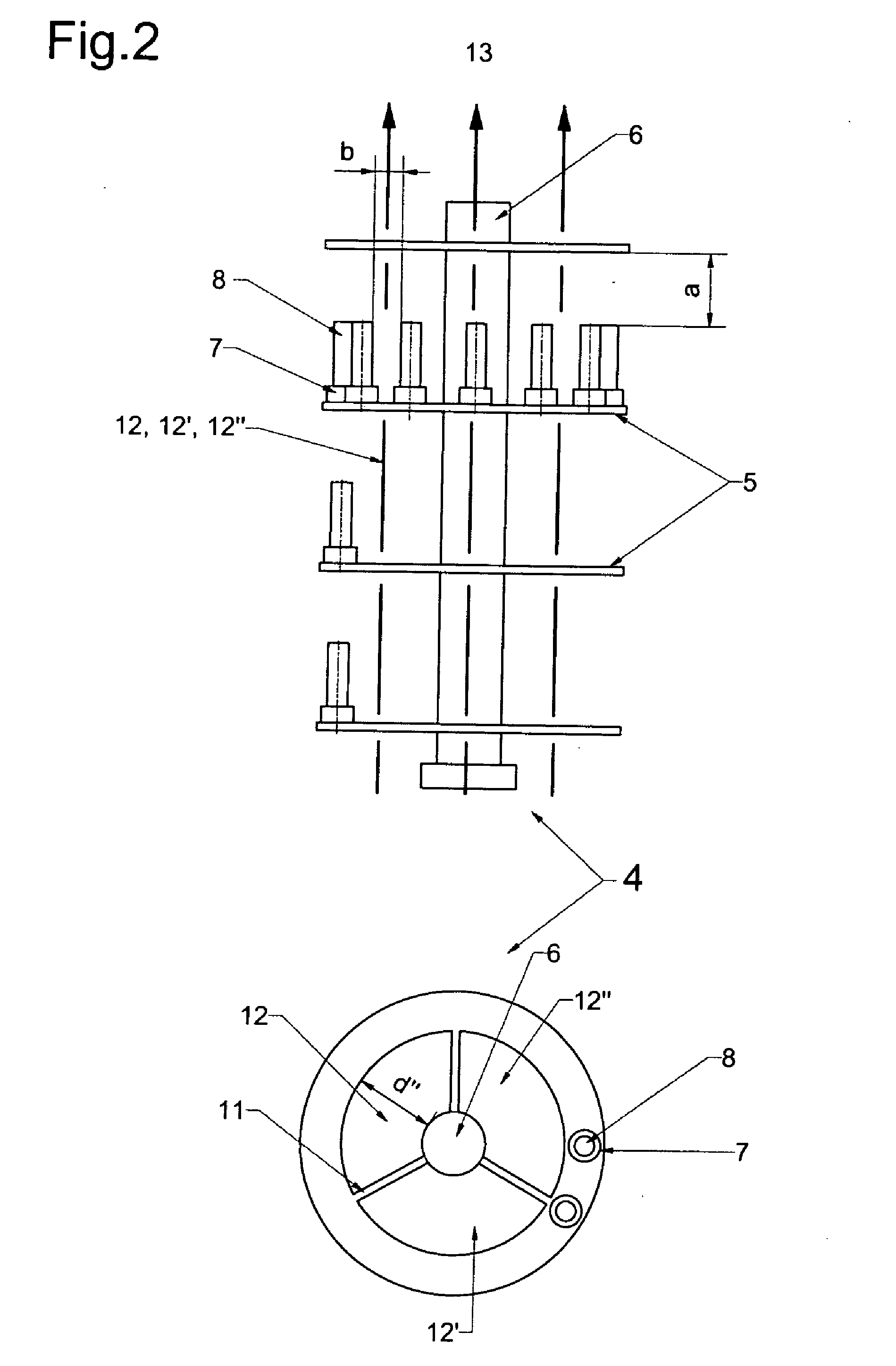

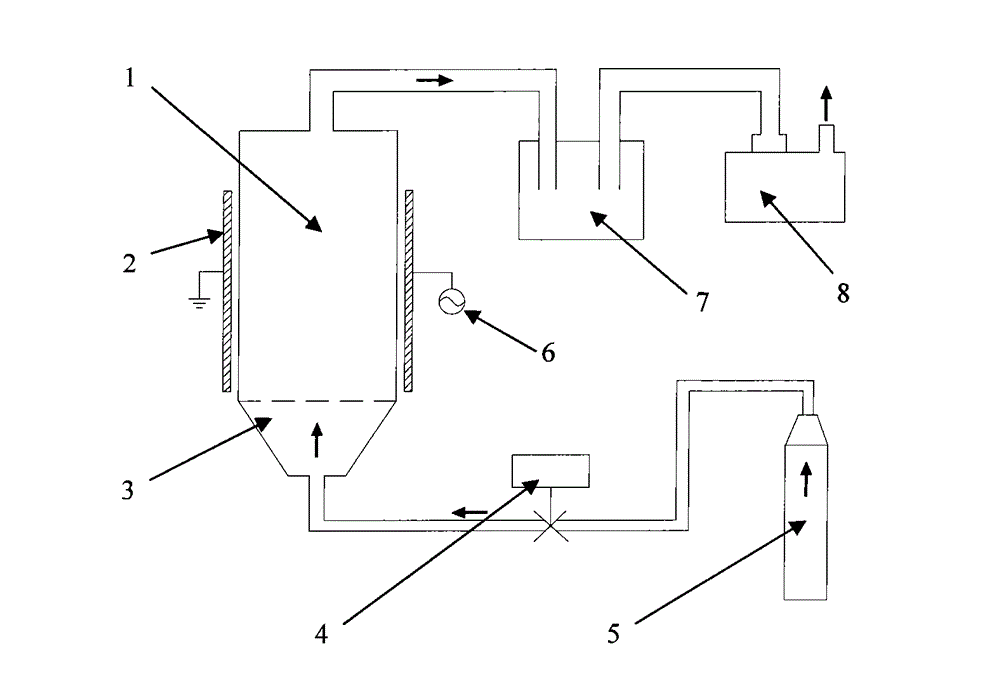

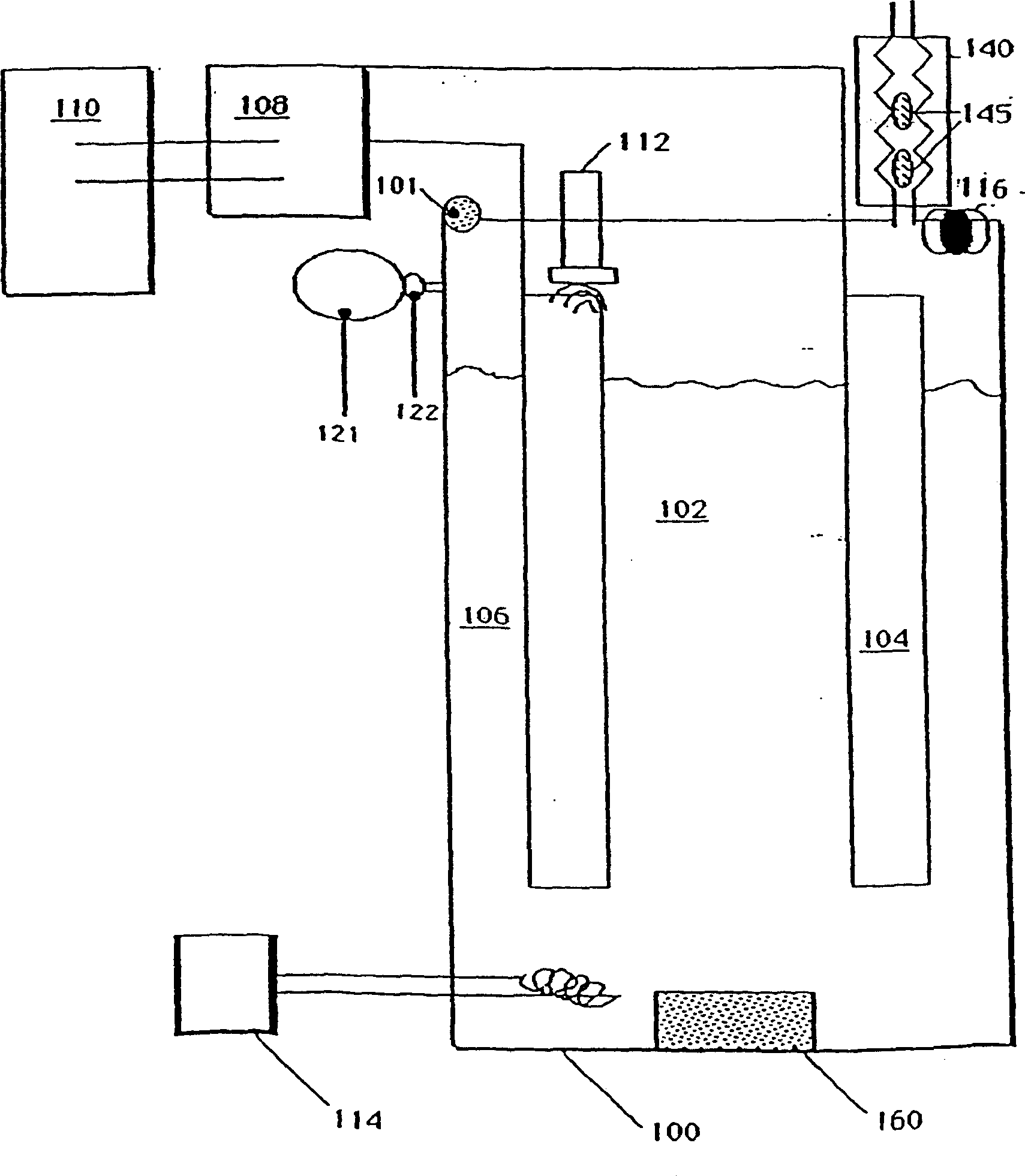

Powder material low temperature plasma surface treatment method and its apparatus

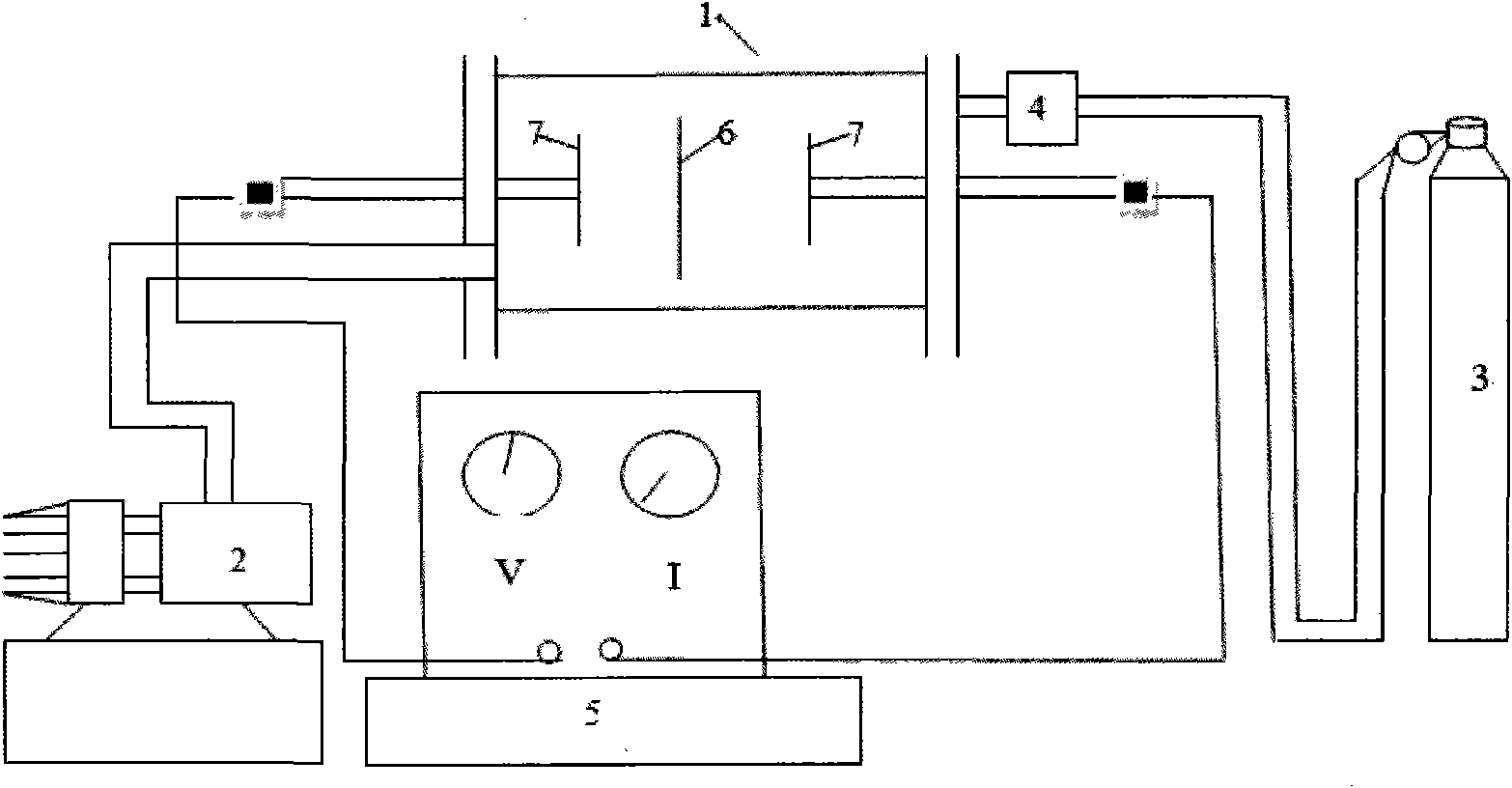

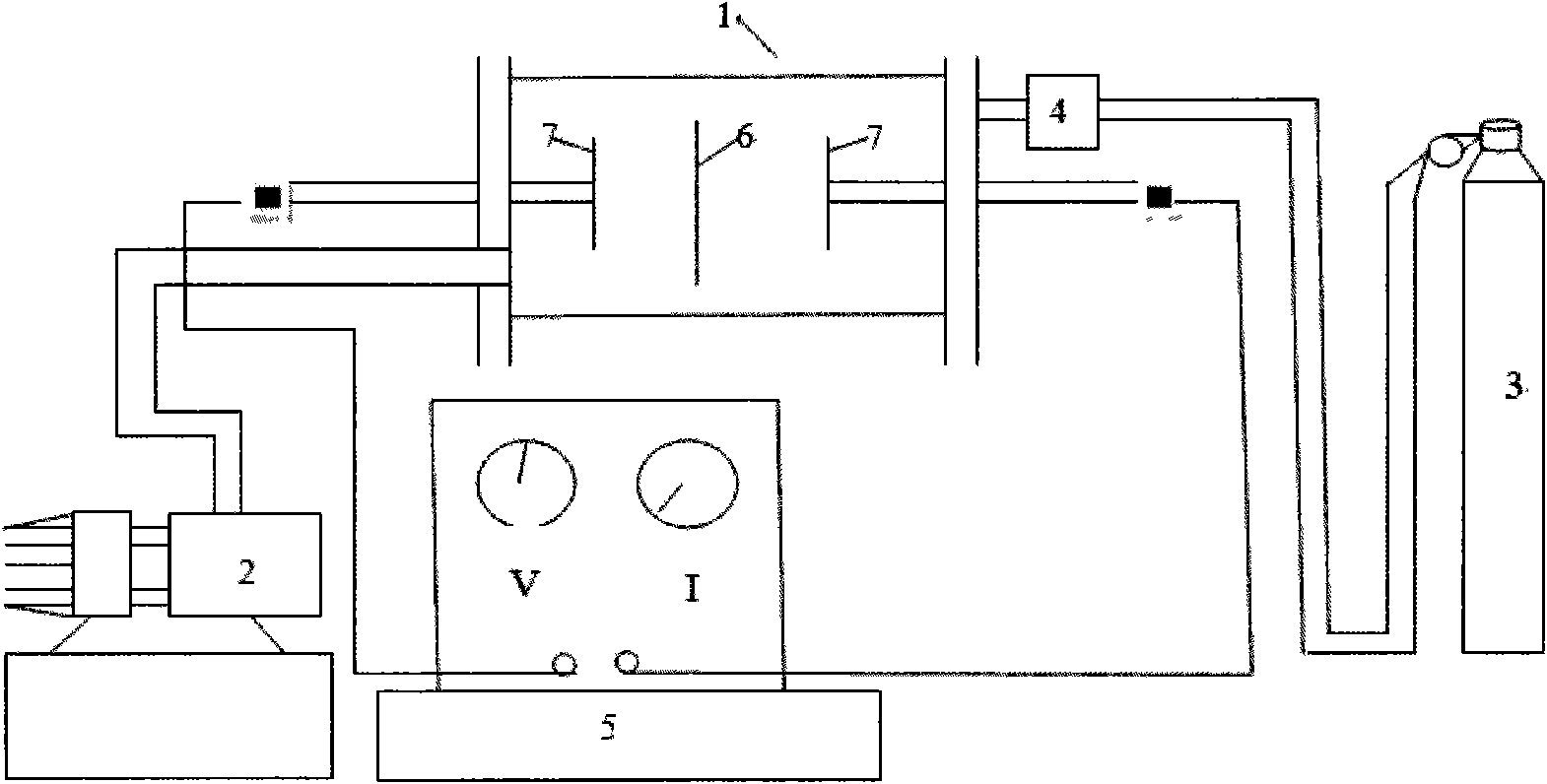

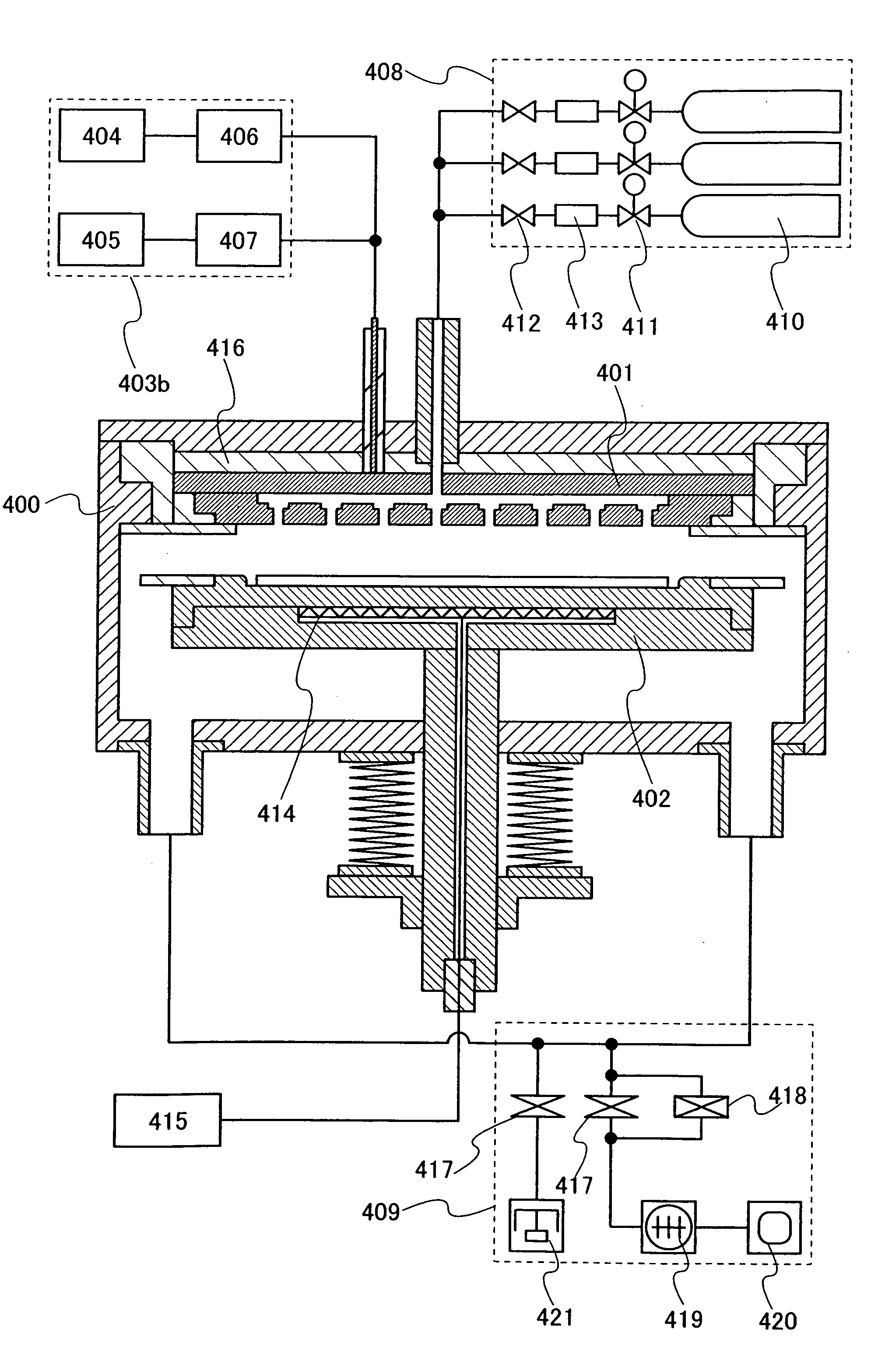

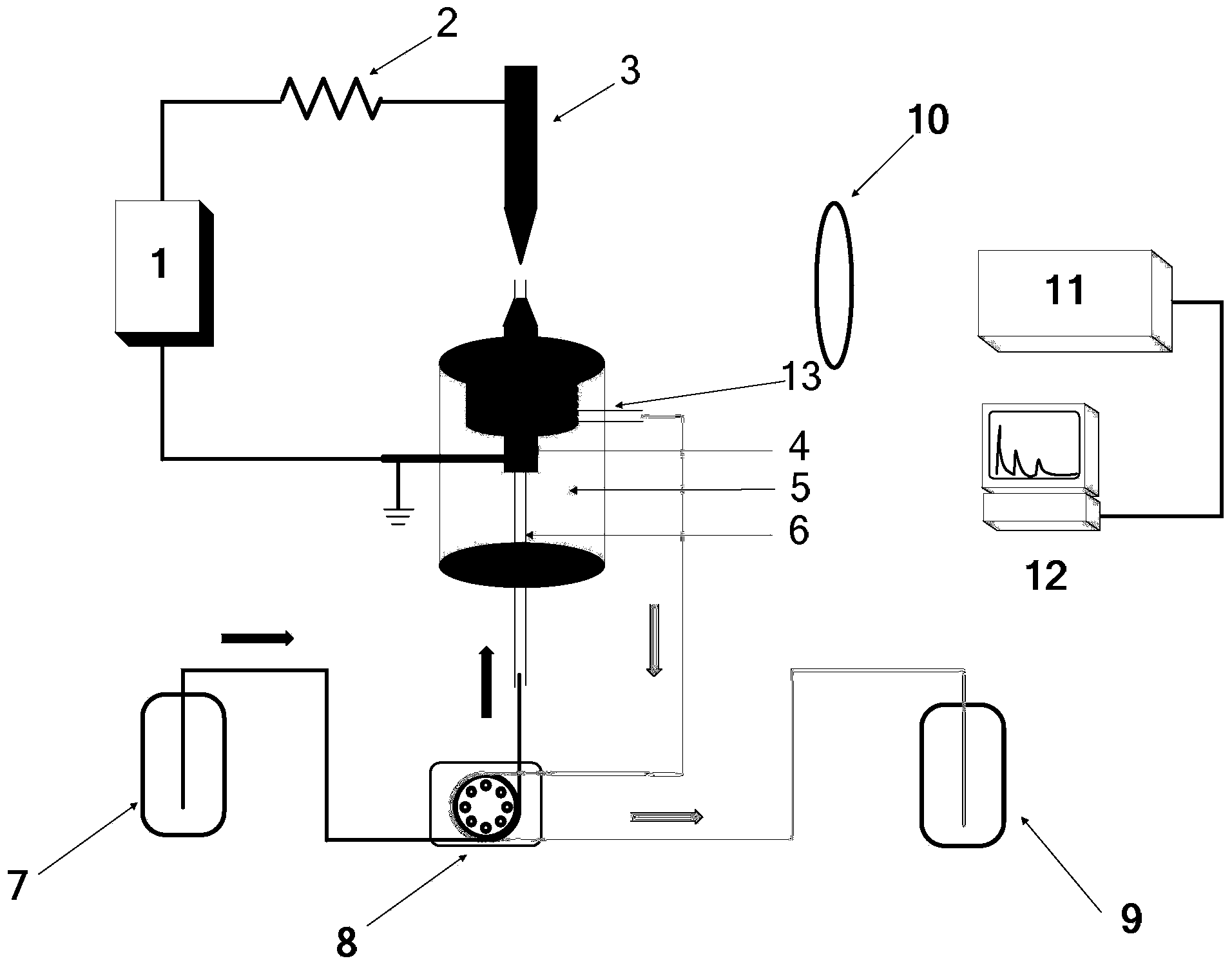

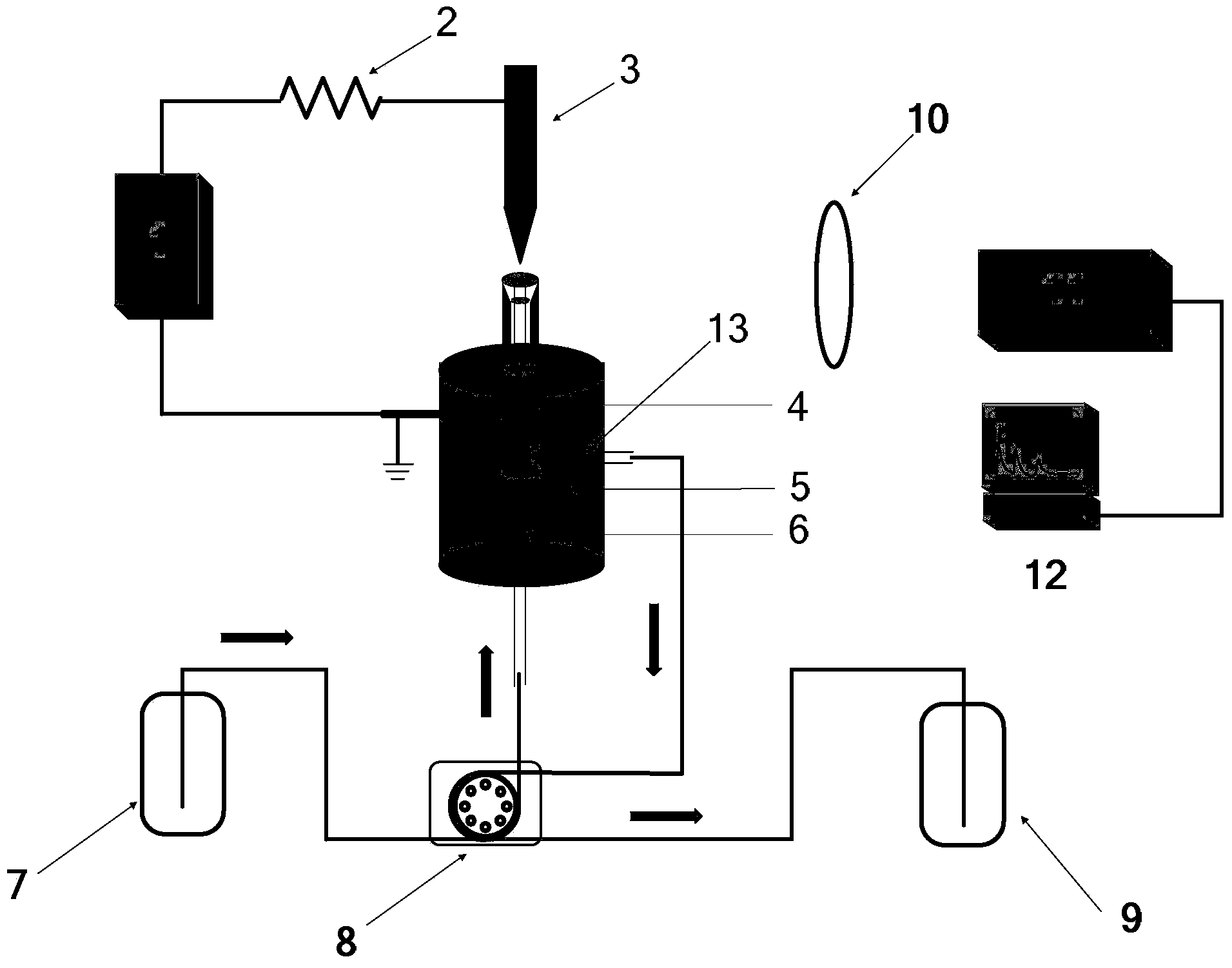

ActiveCN102744020AUniform treatmentImprove processing efficiencyEnergy based chemical/physical/physico-chemical processesParticulatesGas cylinder

The invention provides a powder material low temperature plasma surface treatment method, which comprises the following steps: filling the powder material in a fluidized bed for surface treatment, performing vacuum-pumping in the fluidized bed, the reaction gas is introduced with quantification at the bottom of the fluidized bed, and the glow discharge plasma is generated in the fluidized bed by applying an electric field. A surface treatment apparatus comprises an electrode, the fluidized bed, a flow regulator, a gas cylinder, a plasma power supply generator, a particle filtering trap and a vacuum pump. According to the invention, treatment is carried out on the surface exposed in the plasma atmosphere, full treatment on the separated particulate surface can be realized, the treatment uniformity is good, the treatment efficiency is high and the treatment effect is ideal.

Owner:SUZHOU OPS PLASMA TECH

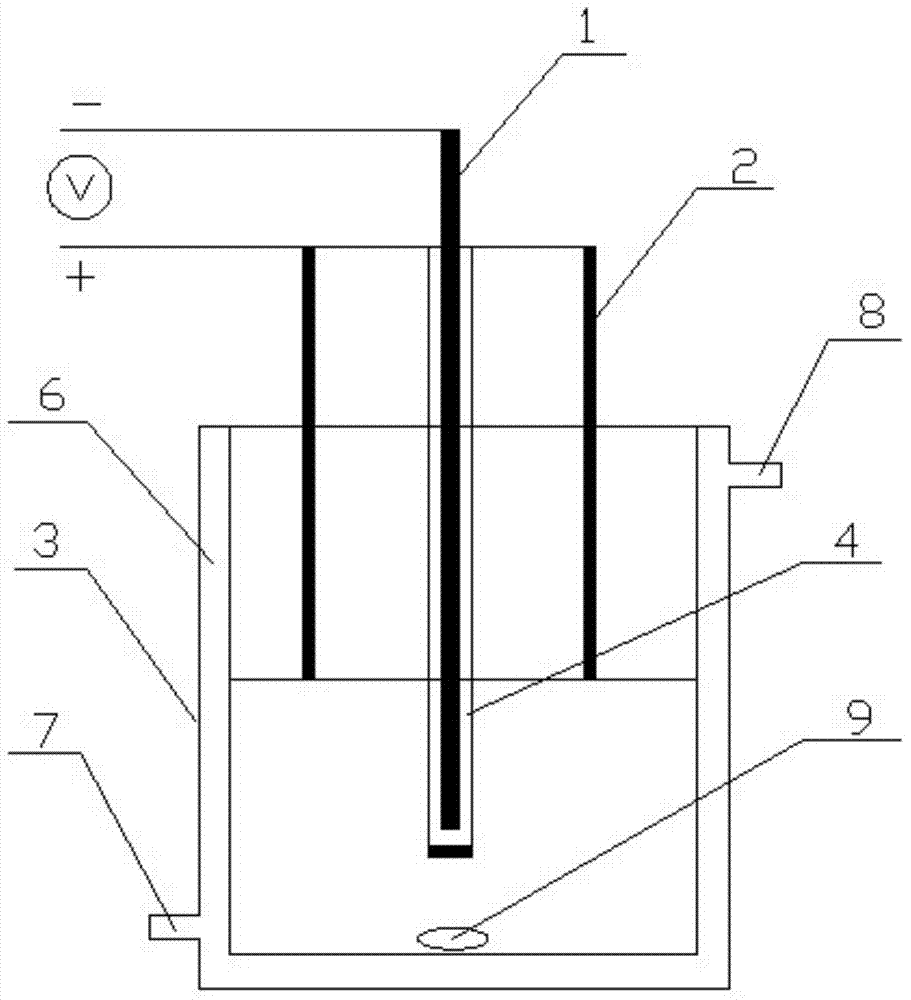

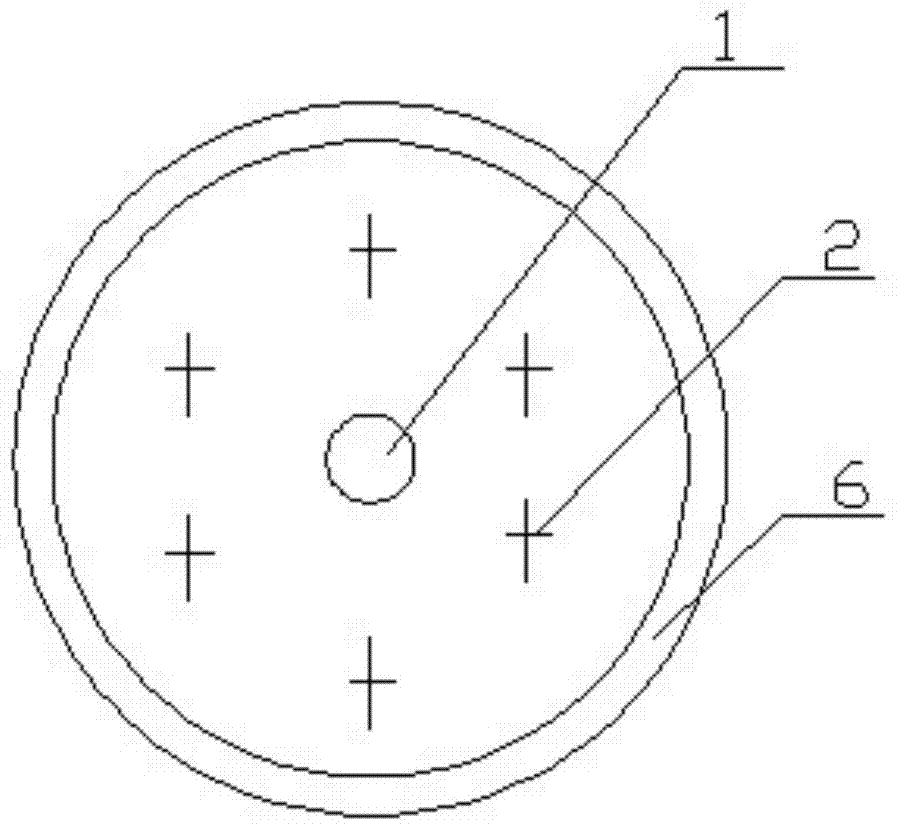

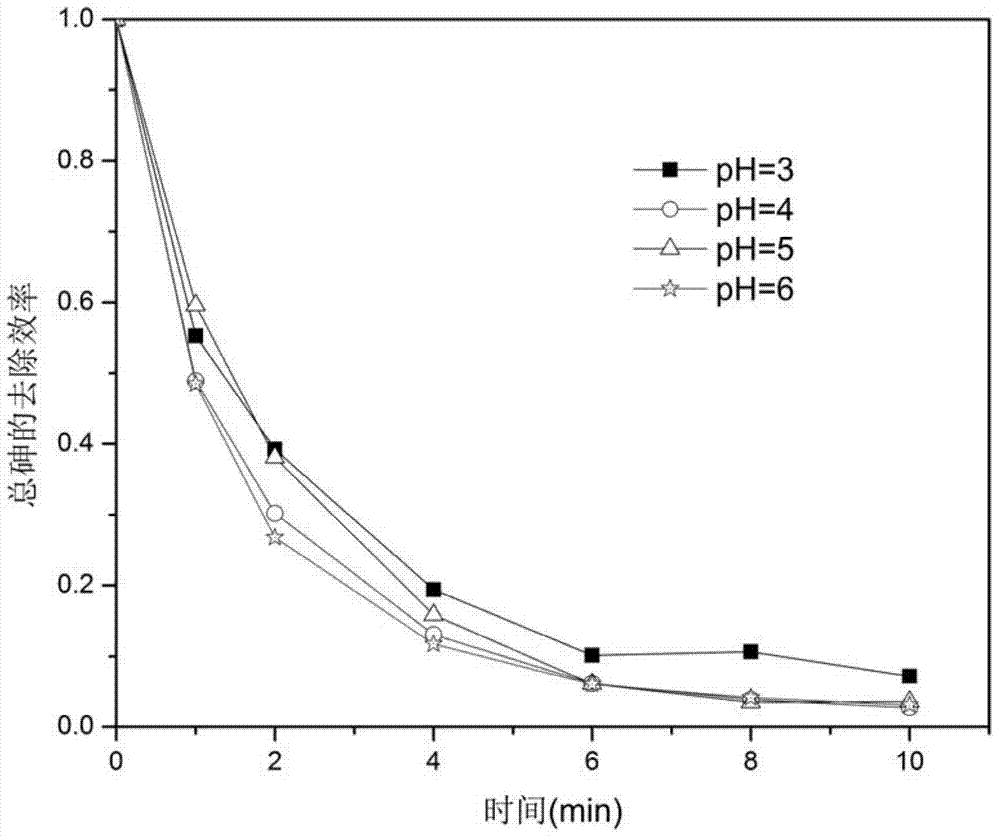

Method and device for high-efficiently and quickly oxidizing and fixing arsenic in wastewater based on glow discharge

ActiveCN103864185APromote generationThe generated active substances such as hydroxyl radicals can effectively strengthen the oxidation of As(III)Water/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by oxidationArsenatePlasma technology

The invention relates to the field of environment wastewater disposal, and particularly relates to a method and a device for high-efficiently and quickly oxidizing and fixing arsenic in wastewater based on glow discharge. According to the method and based on the device, plasma technology is applied to a system for disposing wastewater containing As (III), As (V), Fe (III), and Fe(II) ions from metallurgy, mining and the like, As (III) is converted into less-toxic As (V), and Fe (II) in the solution is oxidized into Fe (III) by using a glow discharge system, and simultaneously the hard-soluble amorphous compound precipitate ferric arsenate can be quickly produced at an appropriate pH and within the range of better arsenic-iron mole ratio in the glow discharge plasma system, thereby achieving the purpose of high-efficiency removal of arsenic.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

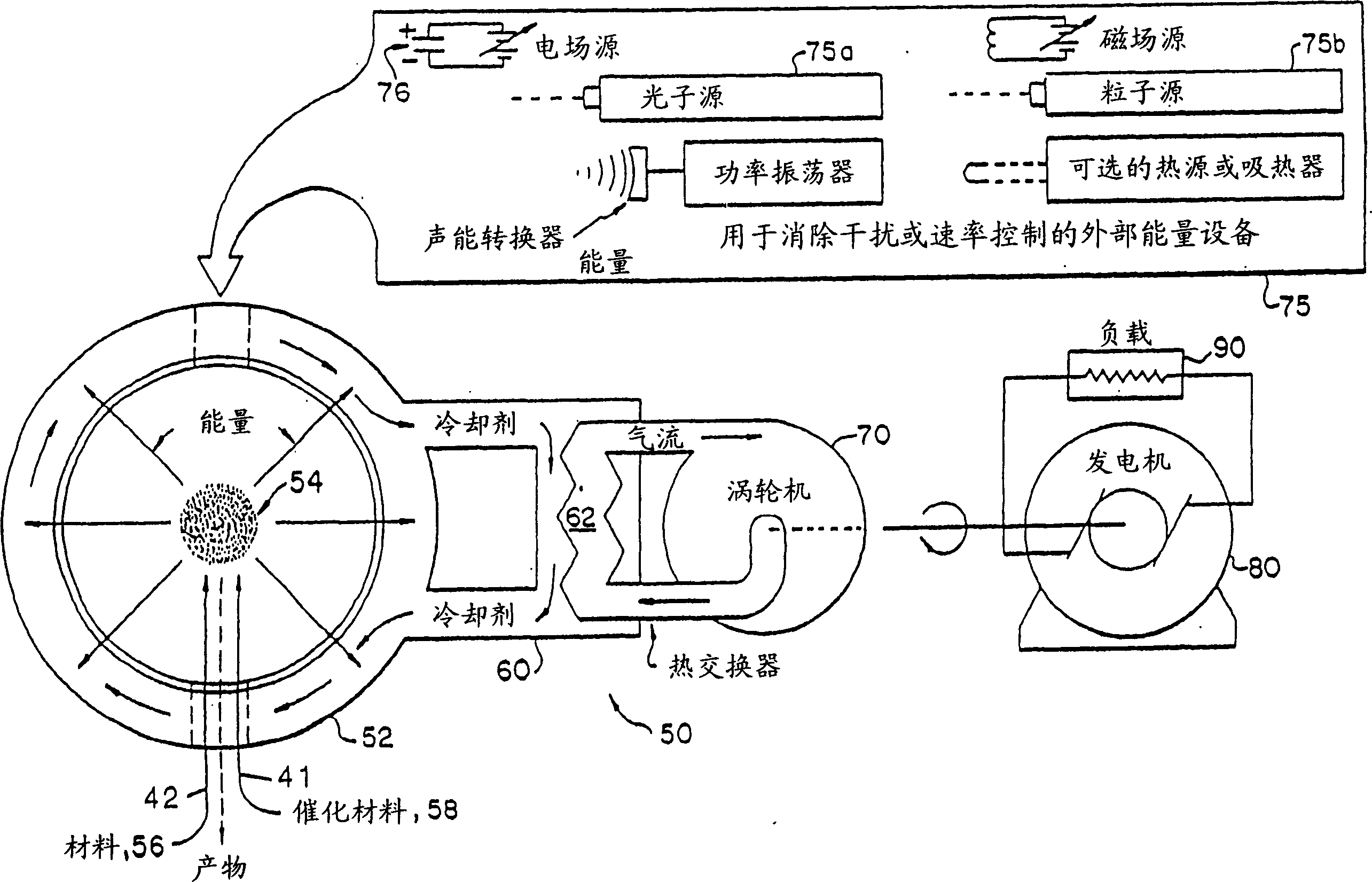

Microwave power cell, chemical reactor and power converter

Provided is a power source and / or power converter. The power source includes a cell 910 for the catalysis of atomic hydrogen to form novel hydrogen species and / or compositions of matter comprisi ng new forms of hydrogen. The reaction can be initiated and / or maintained by a microwave or glow discharge plasma of hydrogen and a source of catalyst. The plasma power may be converted to electricity by a magnetohydrodynamic power converter 913 or a plasmadynamic power converter.

Owner:BRILLIANT LIGHT POWER

Glow discharge plasma water treatment method and device

ActiveCN103754994AEasy to handleImprove processing efficiencyWater/sewage treatment using germicide/oligodynamic-processElectricityWastewater

The invention discloses a glow discharge plasma water treatment method comprising the following steps: after to-be-treated wastewater is subjected to mechanical treatment, water surface electrodes having the same potential are placed on the wastewater surface, the water surface electrodes are each cylindrical in shape, an insulating medium externally wraps the water surface electrodes, and the water surface electrodes are connected to a positive electrode or a negative electrode of a power source; an underwater electrode connected to the positive electrode or the negative electrode of the power source is placed in the wastewater, and is an exposed conductive material; the water surface electrodes are directly contacted with the wastewater, and a gap is formed between the outer surface of each water surface electrode and the water surface; after the power supply is switched on and an initial discharge voltage is reached, glow discharge is generated in the gaps, plasma and active particles are generated, and the wastewater is deep treated by utilizing the plasma and the active particles. The invention also provides a corresponding plasma water treatment device aiming at the plasma water treatment method. The method and the device are suitable for various water treatment, besides, can remove microbes and bacteria in the wastewater, and can remove peculiar smell radiated by the wastewater.

Owner:BEIJING RUIYUDA TECH

Method and arrangement for generating an atmospheric pressure glow discharge plasma (APG)

InactiveUS7491429B2Cost effectiveGood treatment effectElectric discharge tubesPretreated surfacesNitrogenGlow plasma

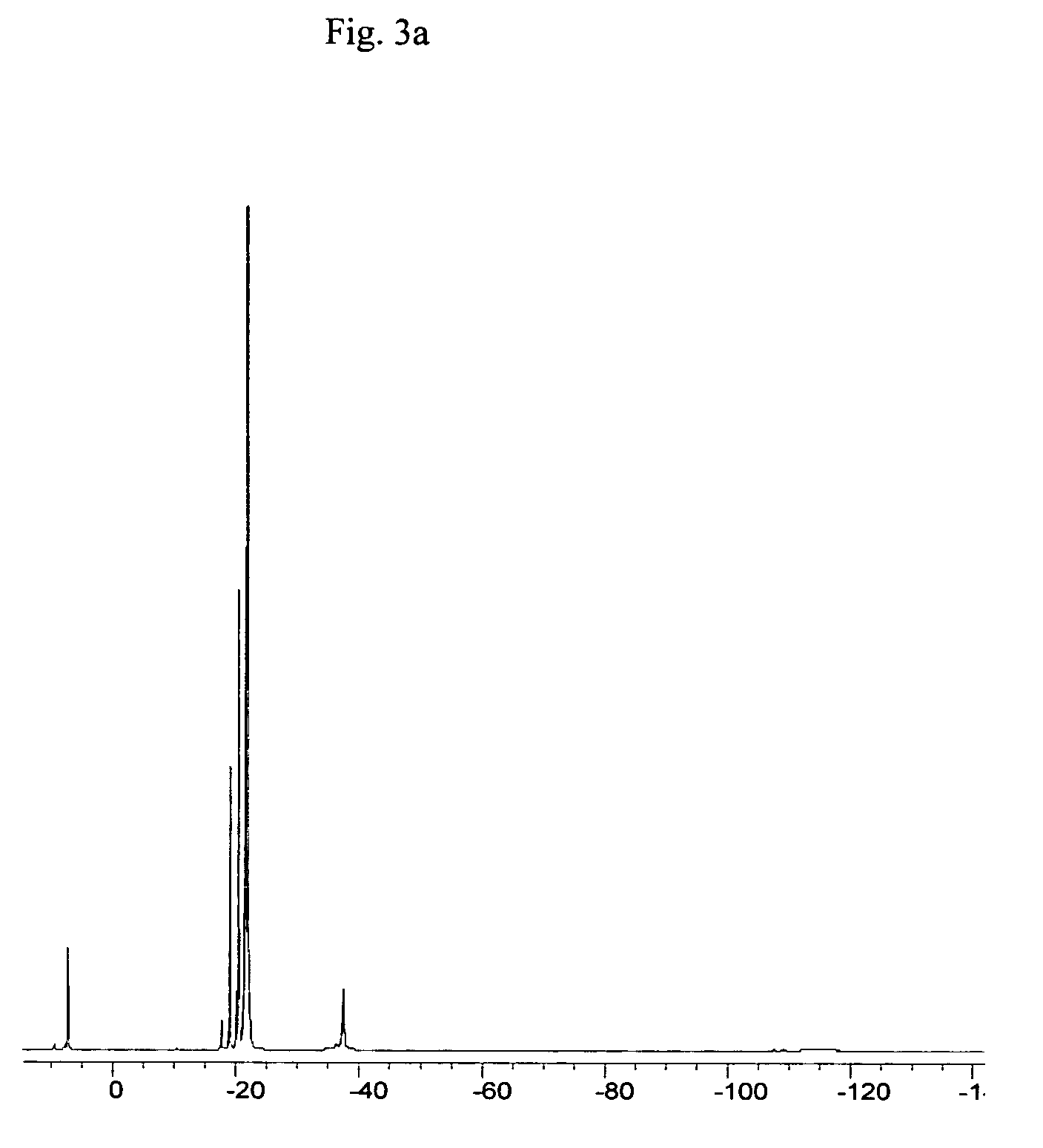

Method and arrangement (1) for generating an atmospheric pressure glow plasma APG (7), where in a plurality of electrodes, (4, 5) are arranged defining a discharge space (10) for forming said plasma (7). The electrodes (4,5) are connected to a power supply (8) providing an AC-voltage having a frequency of at least 50 kHz to the electrodes (4,5). A gaseous substance (6) is provided in said discharge space and comprises t least one of a group of argon, nitrogen and air.

Owner:FUJI PHOTO FILM BV

Method for preparing high temperature alloy GH 4169 metal globule by utilizing auxiliary plasma rotation electrode

The invention relates to a method for preparing high temperature alloy GH 4169 metal globule powder by utilizing a centrifugal process of an auxiliary plasma rotation electrode. Glow discharge plasma arcs are generated between the auxiliary plasma electrode and a consumption-type electrode made of cylindrical rotary high temperature alloy GH 4169 metal in a closed container under the protection of inert gases; one section of the high temperature alloy GH 4169 metal electrode near the plasma arcs is heated to form small drops of liquid via the high temperature generated by the plasma arcs; the small drops of liquid are thrown around through the centrifugal force; then the small drops of liquid of the high temperature alloy GH 4169 metal are air-cooled and solidified to form globules in the inert atmosphere of inert gases in the closed container so as to obtain high temperature alloy GH 4169 metal globules. In the method, the high temperature alloy GH 4169 metal globules with an average sphere diameter of 0.09-1.6mm and better monodispersity can be obtained. The prepared powdered metal globule has good sphericity, lower rate of abnormal particles and controllable sphere diameter. The method can be used for preparing special members of aerospace planes in the field of the laser solid shaping process.

Owner:张建利

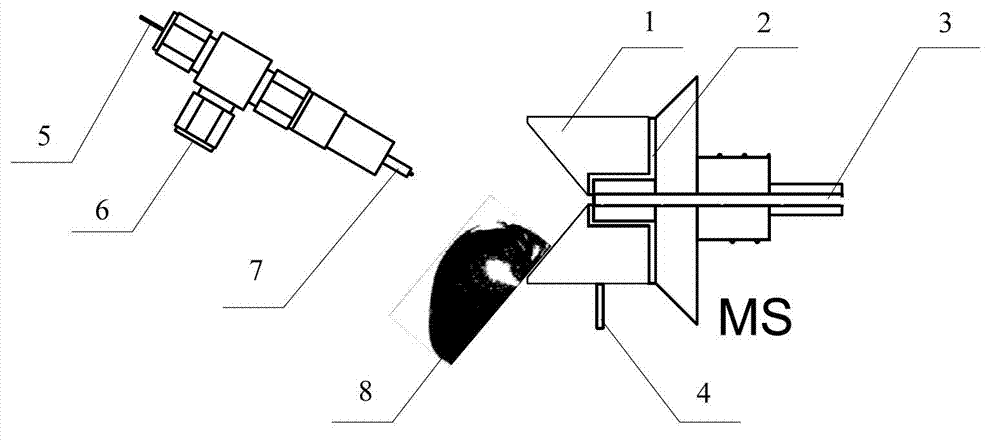

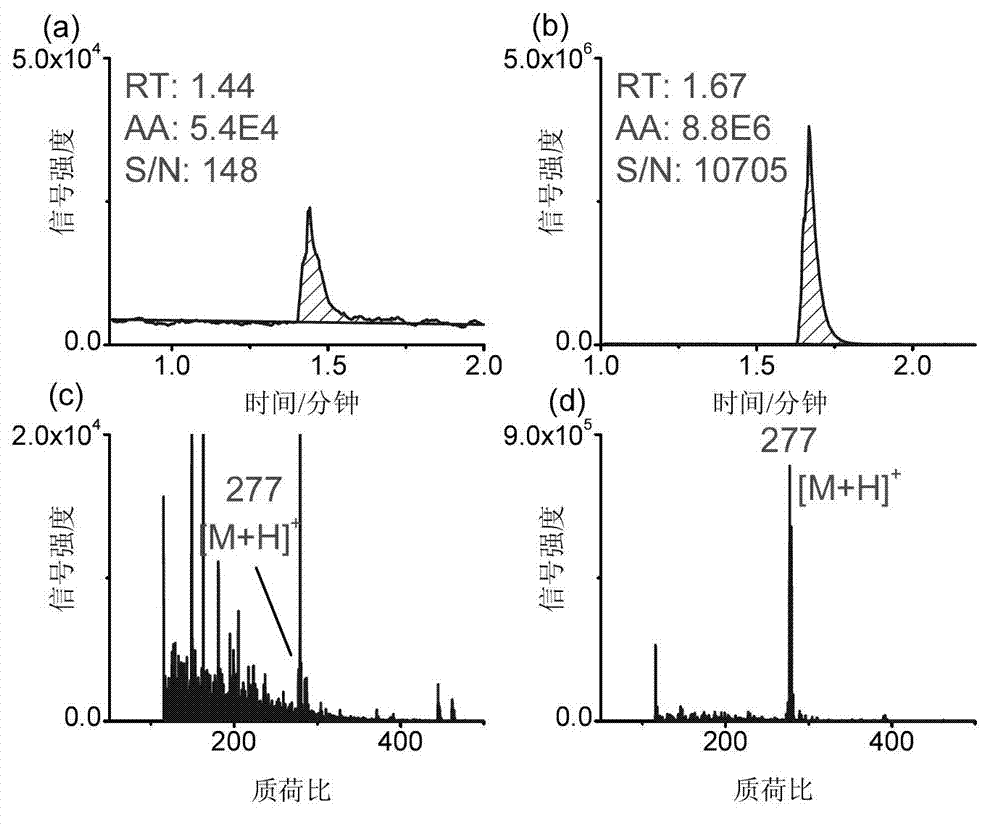

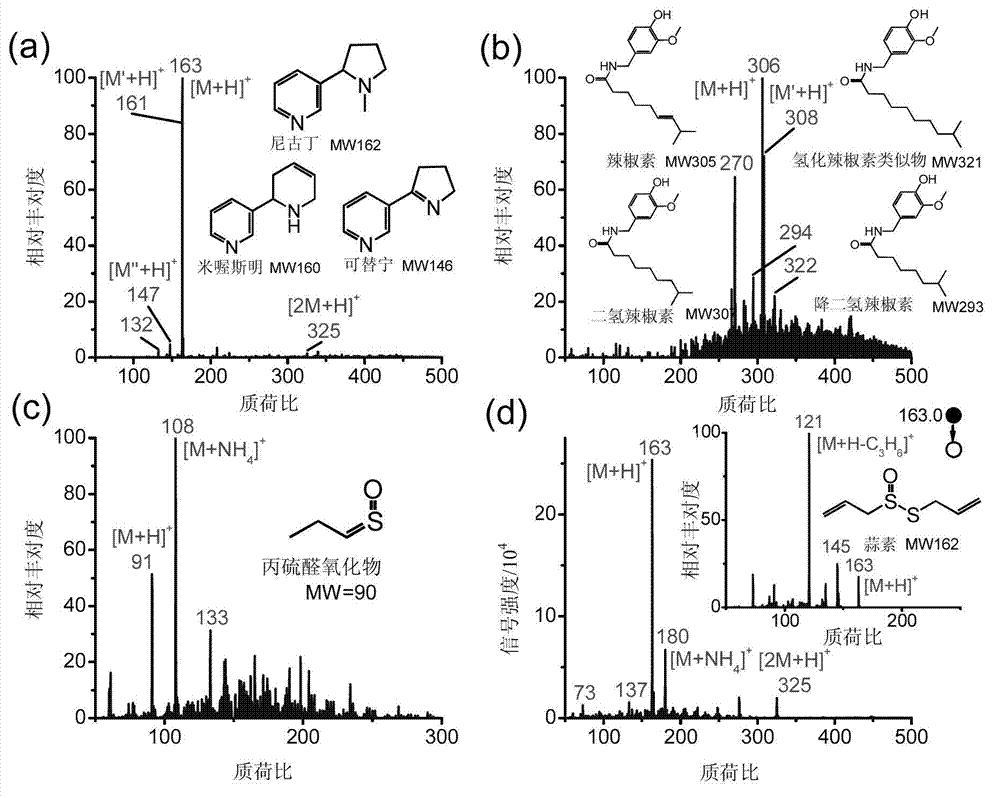

Sensitive glow discharge direct ionization method and device thereof

InactiveCN103094050ASimple structureReduce volumeMaterial analysis by electric/magnetic meansIon sources/gunsMouth shapeIonization

The invention discloses a sensitive glow discharge direct ionization method and the sensitive glow discharge direct ionization device. The device comprises a taper sleeve electrode and a glow discharge plasma generating device which discharges to the taper sleeve electrode. A slot which is used for inserting an ion transport tube of a mass spectrometer in a sleeved mode is arranged inside one end of the taper sleeve electrode, and insulating spacers of the sealing taper sleeve electrode and the ion transport tube are arranged outside of the end port of the taper sleeve electrode. The other end of the taper sleeve electrode is in a horn-mouth-shaped hollow taper shape and is communicated with the ion transport tube. The taper sleeve electrode is provided with a junction pole for connecting the ground. The sensitive glow discharge direct ionization device comprises a closed tubular cavity and pin electrodes penetrating through the tubular cavity. The pin electrodes extend from two ends of the tubular cavity. Slim tubes are arranged at the pin electrodes arranged outside of the tubular cavity in a sleeved mode. The slim tubes and the tubular cavity are in sealing connection. A ring cavity is formed between the slim tubes and the pin electrodes. The ring cavity is communicated with an inner cavity of the tubular cavity. Carrier gas inlets are formed in a side wall of the tubular cavity. End ports of the slim tubes arranged in the pin electrodes in a sleeved mode are carrier gas outlets.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com