Preparation method of platinum/vertical graphene composite material electrocatalyst

A technology of vertically oriented and composite materials, which is applied in the field of electrocatalyst preparation of vertically oriented graphene-supported platinum nanoparticle composite materials, can solve problems such as complex process, and achieve the effects of increasing deposition amount, improving catalytic performance, and improving purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

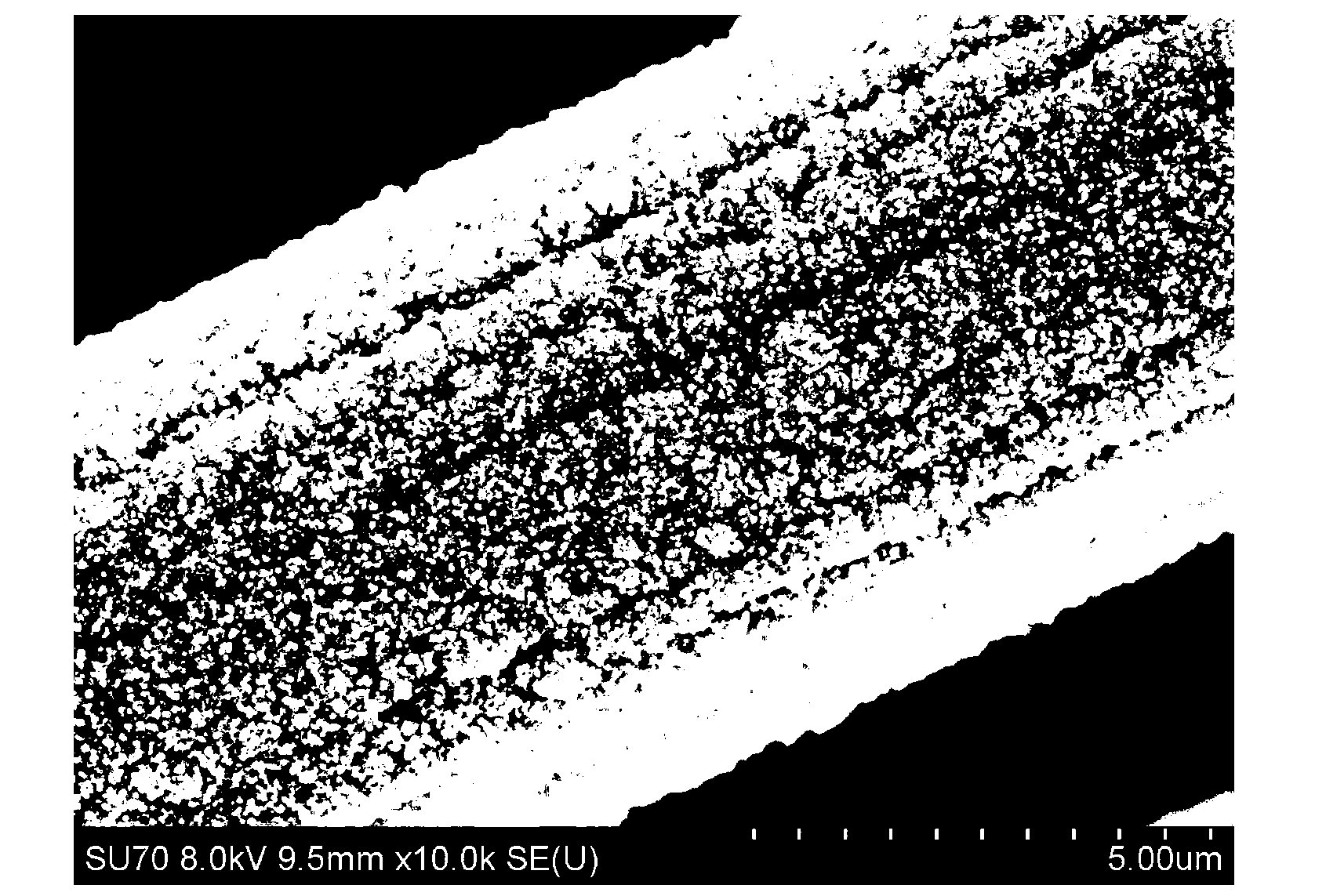

[0031] Arrange the substrate and the needle electrode in the quartz tube, the needle electrode is arranged along the axis of the quartz tube and perpendicular to the substrate, the distance between the substrate and the needle electrode is 10 mm, the substrate is grounded, the needle electrode is connected to 10000 V DC high voltage, and the outside of the quartz tube Wrap the heating wire, the air outlet is open. The inlet of the quartz tube is fed with hydrogen gas, the electric heating is turned on, and the substrate is heated to 700 o c. Keep the electric heating, turn off the hydrogen, feed methane, argon and water vapor from the inlet of the quartz tube, turn on the DC high voltage, generate a local enhanced electric field on the large curvature surface of the needle electrode, and form a normal pressure between the substrate and the needle electrode The glow discharge plasma makes methane and water vapor ionized and decomposed under the action of plasma high-energy ele...

Embodiment 2

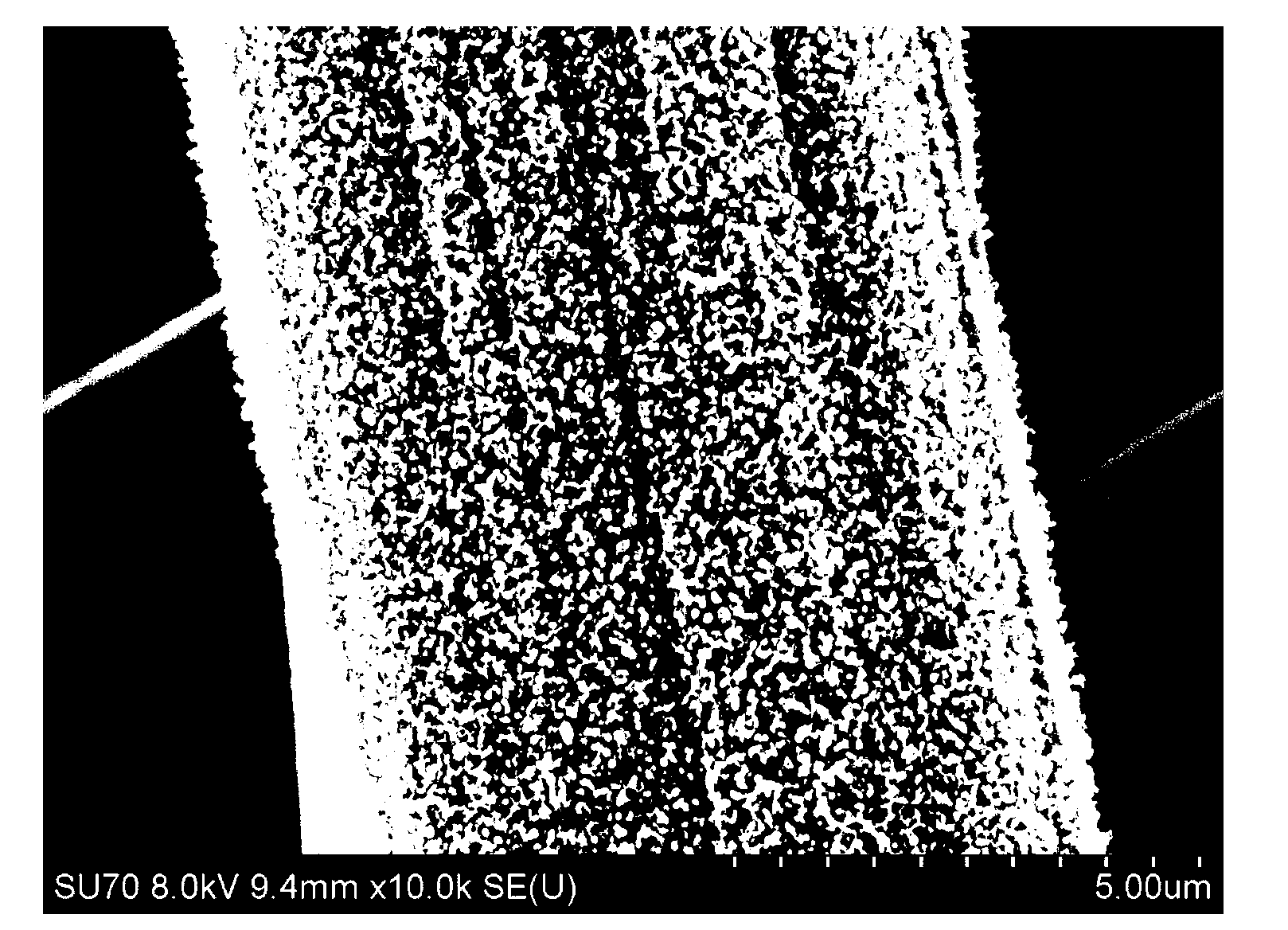

[0033] Repeat Example 1, the difference is only: the distance between the substrate and the needle-shaped electrodes is 5 mm, and the heating temperature of the substrate is 1000 o C, a constant voltage of -0.2 V was applied for 1 s. The scanning electron microscope image of the resulting platinum / vertically oriented graphene composite electrocatalyst is shown in figure 2 shown.

Embodiment 3

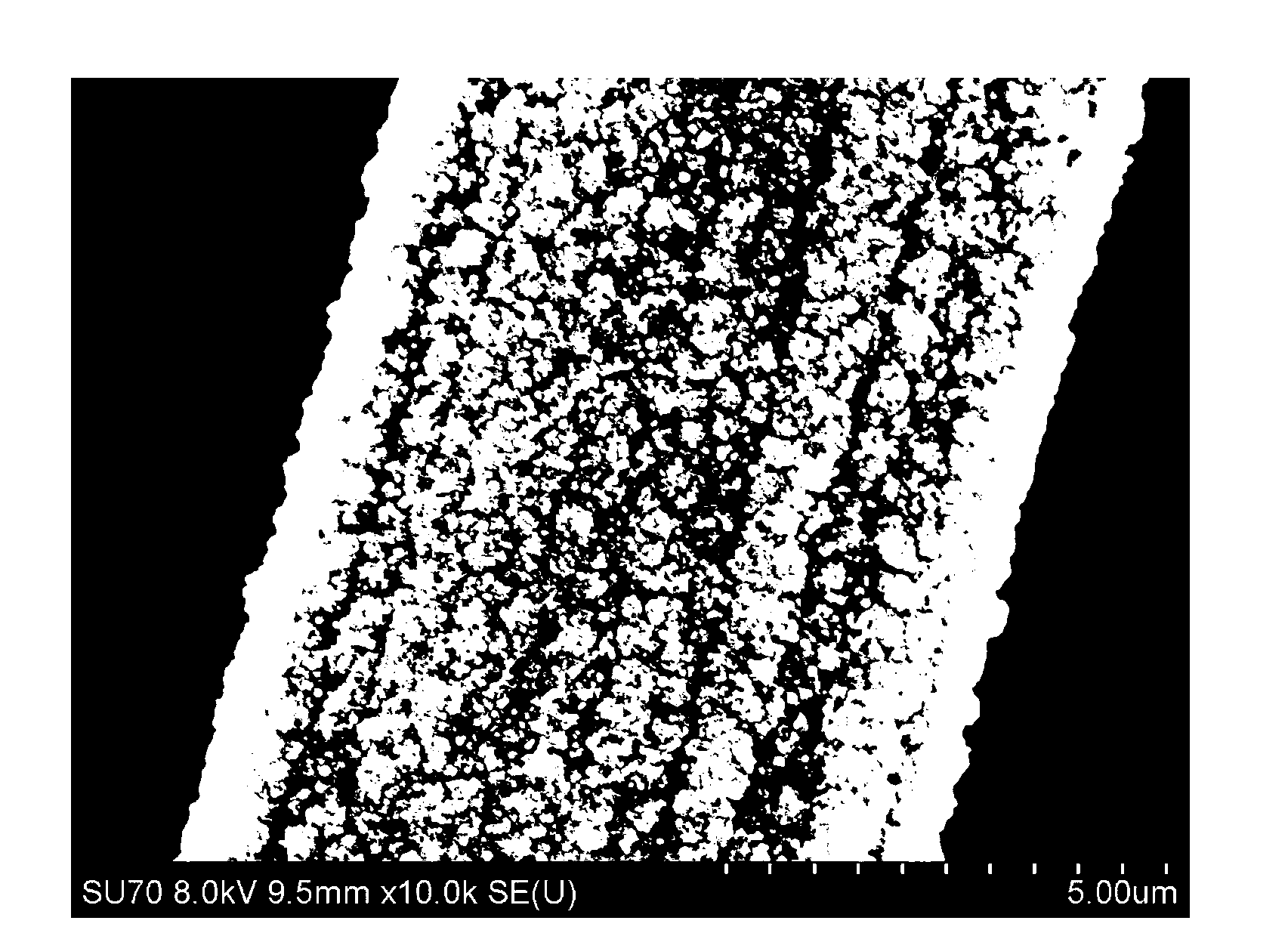

[0035] Repeat Example 1, the difference is only: the distance between the substrate and the needle electrode is 8 mm, and the substrate heating temperature is 900 o C, a constant voltage of -0.1 V was applied for 20 s. The scanning electron microscope image of the resulting platinum / vertically oriented graphene composite electrocatalyst is shown in image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com