Magnetic biomimetic catalyst and preparation method and application method thereof

A catalyst and magnetic technology, applied in the field of magnetic imitation enzyme catalyst and its preparation, can solve the problems of difficult catalyst recovery, limited degradation effect, large amount of iron sludge, etc., to solve the problem of catalyst separation, rich oxygen-containing functional groups, fixed carbon content high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

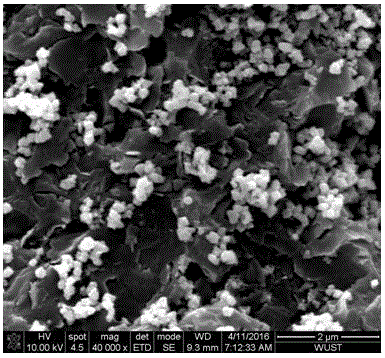

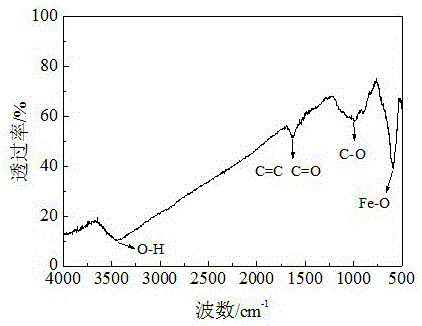

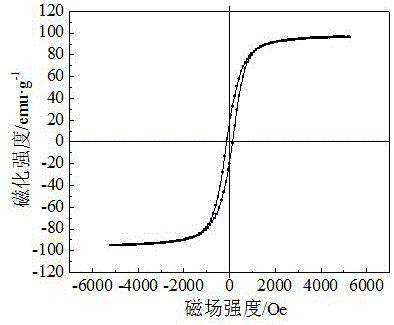

[0038] A magnetic enzyme imitation catalyst and its preparation method and application method. The specific steps of the preparation method described in this embodiment are:

[0039] Step 1. According to the mass ratio of coal-based carbon: KOH solution of 1: (10-20), mix evenly to obtain the mixture; then add the mixture into the quartz reactor, and vacuum at 105°C. Dry in a drying box for 1 to 2 hours to obtain pre-activated coal-based carbon.

[0040] Step 2. Place the pre-activated coal-based carbon in a microwave generator and bubbling with nitrogen for 10-15 minutes; then turn on the microwave generator, activate it at 300-400°C for 2-3 minutes, and cool to 60-90°C , Get activated coal-based carbon.

[0041] Step 3. According to the mass ratio of the activated coal-based carbon: deoxygenated and deionized water of 1: (50~70), mix the activated coal-based carbon and the deionized and deionized water uniformly at 60~100r / min Stir for 10-20min under conditions and stand for 5-1...

Embodiment 2

[0050] A magnetic enzyme imitation catalyst and its preparation method and application method. The specific steps of the preparation method described in this embodiment are:

[0051] Step 1. According to the mass ratio of coal-based carbon: KOH solution of 1: (20~30), mix evenly to obtain the mixture; then add the mixture into the quartz reactor, and vacuum at 105°C Dry in a drying box for 1 to 2 hours to obtain pre-activated coal-based carbon.

[0052] Step 2. Place the pre-activated coal-based carbon in a microwave generator and bubbling nitrogen for 10-15 minutes; then turn on the microwave generator, activate it at 400-500°C for 3-4 minutes, and cool to 60-90°C , Get activated coal-based carbon.

[0053] Step 3. According to the mass ratio of activated coal-based carbon: deoxygenated and deionized water of 1: (60~80), mix the activated coal-based carbon and deionized water evenly at 60-100r / min Stir for 10-20min under conditions and stand for 5-10min to obtain the upper KOH re...

Embodiment 3

[0062] A magnetic enzyme imitation catalyst and its preparation method and application method. The specific steps of the preparation method described in this embodiment are:

[0063] Step 1. According to the mass ratio of coal-based carbon: KOH solution of 1: (30-40), mix evenly to obtain the mixture; then add the mixture into the quartz reactor, and vacuum at 105°C Dry in a drying box for 1 to 2 hours to obtain pre-activated coal-based carbon.

[0064] Step 2. Place the pre-activated coal-based carbon in a microwave generator and bubbling nitrogen for 10-15 minutes; then turn on the microwave generator, activate it at 500-600°C for 4-5 minutes, and cool to 60-90°C , Get activated coal-based carbon.

[0065] Step 3. According to the mass ratio of the activated coal-based carbon: deoxygenated and deionized water of 1: (70~90), mix the activated coal-based carbon and the deionized and deionized water uniformly at 60~100r / min Stir for 10-20min under conditions and stand for 5-10min t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com