Activated carbon with high specific surface area and preparation method of activated carbon

A high specific surface area, activated carbon technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of large energy input, uneven activation effect, low yield, etc., and achieve high degree of aromatization and low carbon content High, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

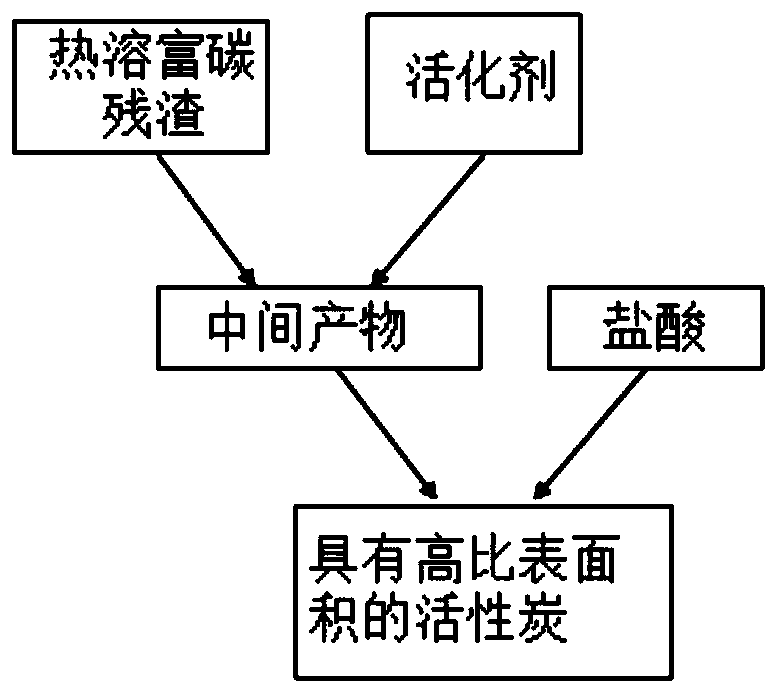

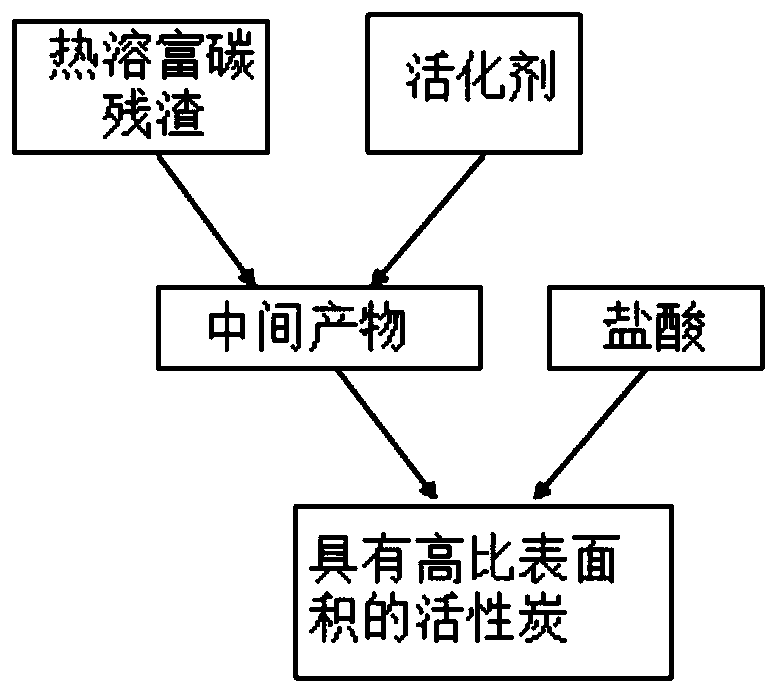

[0021] Such as figure 1 Shown, the invention provides a kind of preparation method with the gac of high specific surface area, and this preparation method comprises the steps:

[0022] (a) Mix hot soluble carbon-rich residue and activator (such as sodium hydroxide, potassium hydroxide, sodium bicarbonate, potassium bicarbonate, ferric chloride, zinc chloride, phosphoric acid or sulfuric acid) at a ratio of 2:1 to 1:6 The mass ratio is fully mixed, placed in the reactor, heated and kept for 30min to 150min, and then cooled to room temperature to obtain the intermediate product. The entire heating, keeping and cooling process is carried out under an inert atmosphere such as a nitrogen atmosphere;

[0023] (b) After the intermediate product is pickled with hydrochloric acid with a concentration of 0.5mol / L to 6mol / L, it is washed with deionized water until neutral, and finally dried to obtain the activated carbon with a high specific surface area, wherein Hydrochloric acid pickl...

Embodiment 1

[0030] (a) Grind and mix the above-mentioned thermally soluble carbon-rich residue with sodium hydroxide at a mass ratio of 2:1, then place it in a reactor, raise the temperature from room temperature to 700°C at a heating rate of 5°C / min, and keep it warm Cool to room temperature after 30min to obtain intermediate product;

[0031] (b) After the intermediate product was pickled with hydrochloric acid with a concentration of 1 mol / L, it was washed with deionized water until neutral, and finally dried to obtain the activated carbon with a high specific surface area, which was designated as C-1.

[0032] Through the BET characterization of the C-1, its specific surface area is 987.4m 2 / g, the total pore volume is 0.4984cm 3 / g, the average pore diameter reaches 0.9165nm.

Embodiment 2

[0034] (a) Grind and mix the above-mentioned thermally soluble carbon-rich residue with sodium hydroxide at a mass ratio of 1:2, then place it in a reactor, raise the temperature from room temperature to 900°C at a rate of 10°C / min, and keep it warm Cool to room temperature after 60min to obtain intermediate product;

[0035] (b) After the intermediate product was pickled with hydrochloric acid with a concentration of 1 mol / L, it was washed with deionized water until neutral, and finally dried to obtain the activated carbon with a high specific surface area, which was designated as C-2.

[0036] By BET characterization of the C-2, its specific surface area is 713.4m 2 / g, the total pore volume is 1.3584cm 3 / g, the average pore diameter reaches 1.1753nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com