Patents

Literature

235 results about "Activated Coal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Activated charcoal is a fine black powder made from bone char, coconut shells, peat, petroleum coke, coal, olive pits or sawdust. The charcoal is "activated" by processing it at very high temperatures.

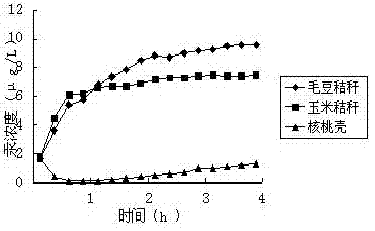

Biomass activated carbon, preparation method thereof and application thereof in flue gas mercury removal

InactiveCN102515162AReduce manufacturing costReduce pollutionCarbon compoundsDispersed particle separationCarbonizationNitrogen gas

The invention discloses biomass activated carbon, a preparation method thereof and the application thereof in flue gas mercury removal. Ordinary crop straws serve as raw materials, the biomass raw materials are impregnated by activator, i.e. zinc chloride aqueous solution with the concentration being 20 percent to 50 percent for 20 hours to 30 hours; after the impregnated biomass raw materials are carbonized for 1.5 hours to 3 hours at 400DEG C to 700DEG C under the protection of nitrogen and are taken out and naturally cooled, the carbonized biomass raw materials are washed by 5 percent to 15 percent of hydrochloric acid, rinsed by distilled water to neutral and filtered by neutral filter paper, dried and ground in an oven, and finally the biomass activated carbon is finally obtained. According to the biomass activated carbon, the ordinary crop straws serve as the raw materials, not only waste can be changed into valuable, but also the production cost is low. Simultaneously, because the biomass activated carbon can absorb methylene blue and mercury, the biomass activated carbon can be used in the demercuration of coal-fired flue gas, and can mitigate the environmental pollution.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Method for preparing P type molecular sieve by using coal ash as raw material

InactiveCN104291349AInhibition of dissolutionCause dissolutionCrystalline aluminosilicate zeolitesMolecular sieveSodium aluminate

The invention relates to a method for preparing a P type molecular sieve by using coal ash as a raw material. The method for preparing the P type molecular sieve by using coal ash as the raw material comprises the following steps: I, pre-treating and activating coal ash; II, preparing sodium silicate and sodium metaaluminate by using activated coal ash; and III, synthesizing the P type molecular sieve: firstly, uniformly mixing a sodium silicate solution with a sodium salt, then, dropwise adding the sodium metaaluminate solution into the mixed liquid, and finally, adding an organic steric hindering agent and a proper amount of deionized water to form a reaction mixture, wherein the molar ratios of the reaction mixture are as follows: SiO2 / Al2O3=0.4-1.8, M / Al2O3=1-5, Na2O / Al2O3=2-4 and H2O / SiO2=20-150 and the organic spatial steric hindering agent is at least one of ethanol amine, diethanol amine and triethanol amine; packing the mixed materials in a polytetrafluoroethylene container, stirring, then putting in a stainless steel reaction kettle, and carrying out hydro-thermal synthesis for 2-8 hours; and taking out products in the reaction kettle, carrying out centrifugal separation and washing by deionized water, and drying to obtain the P type molecular sieve. The method provided by the invention is short in synthetic cost, short in crystallization time and high in yield of the P type molecular sieve.

Owner:NORTHEAST GASOLINEEUM UNIV

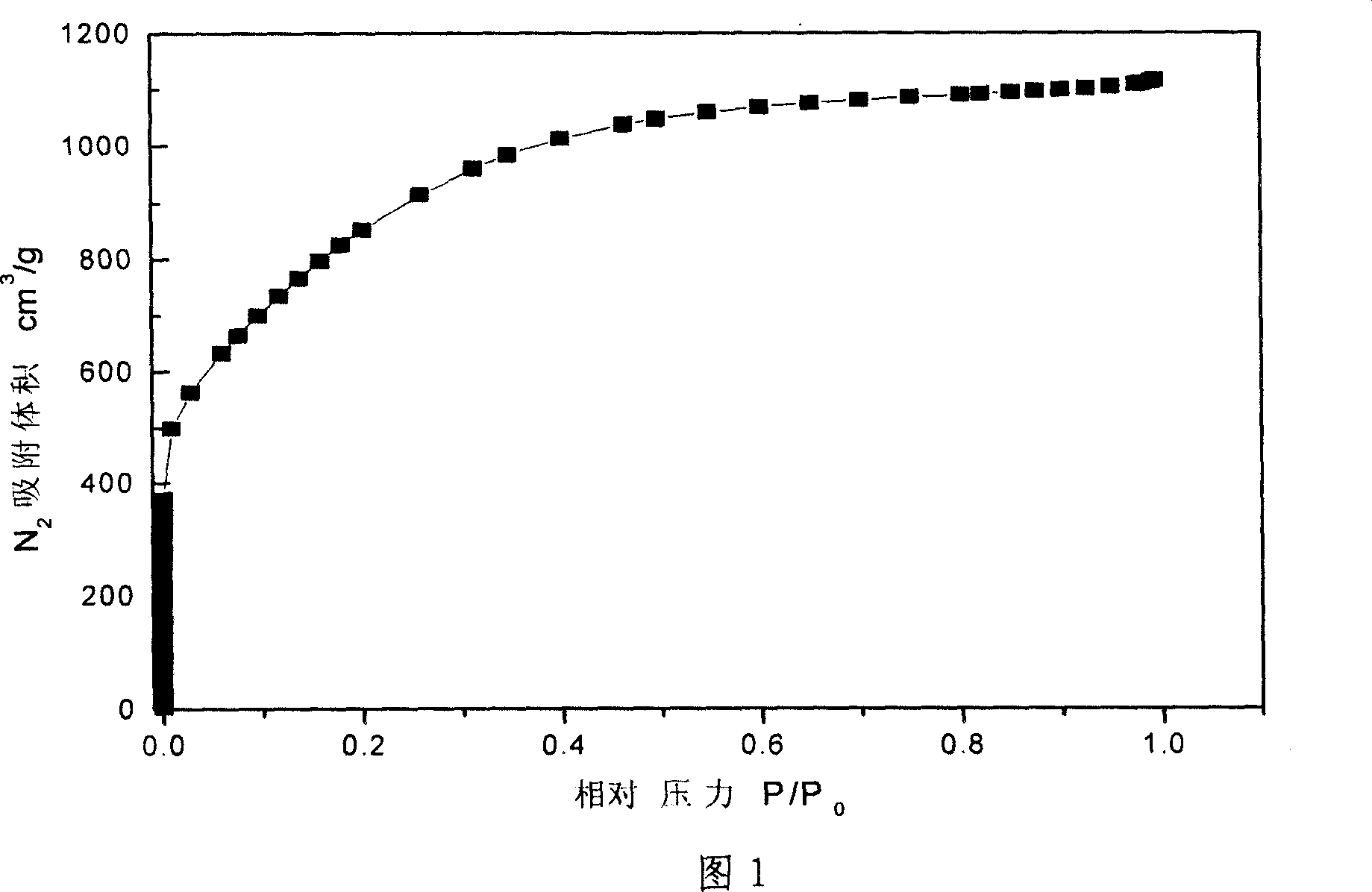

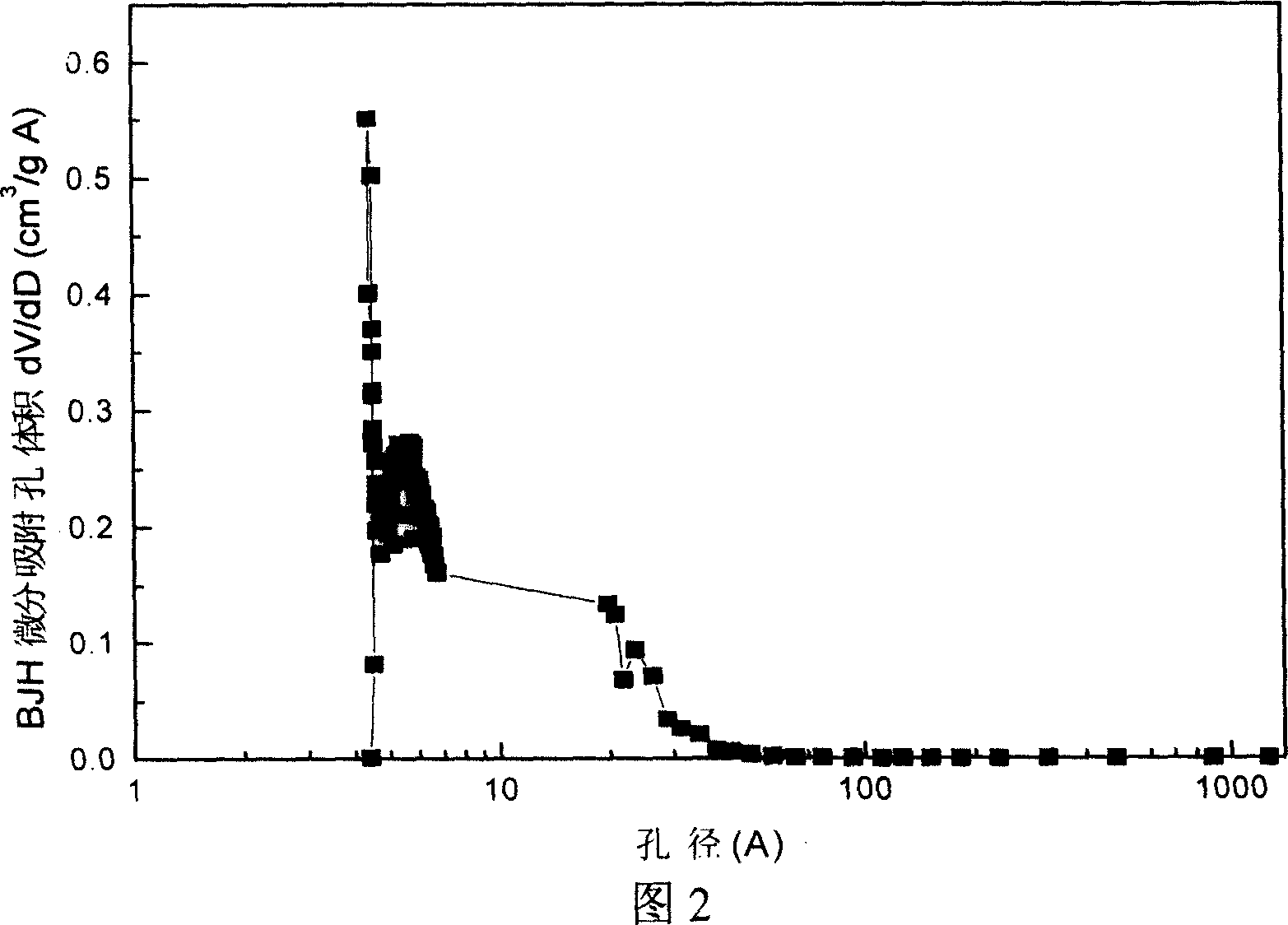

Preparation method of high specific surface area coal mass active carbon

The present invention discloses a preparation method of coal active carbon with high specific area. Said method includes the following steps: pulverizing the coal carbonization material into 24-40 meshes, fully and uniformly mixing the pulverized coal carbonization material with KOH according to the ratio of 1:1-7, placing them into a tubular reactor, then activating at 600-880 deg.C for 2-5 h under the protection of nitrogen gas, cooling to 20-30 deg.C, recovering by-product metal potassium before discharge of material and storing it in kerosene; firstly, using distilled water to wash the residual activated material, recovering residual KOH, repeatedly acid-washing and caustic washing, then using distilled water to wash until the pH value is 6-7, drying at 100-150 deg.C for 10-15 h so as to obtain the coal active carbon.

Owner:SOUTH CHINA UNIV OF TECH

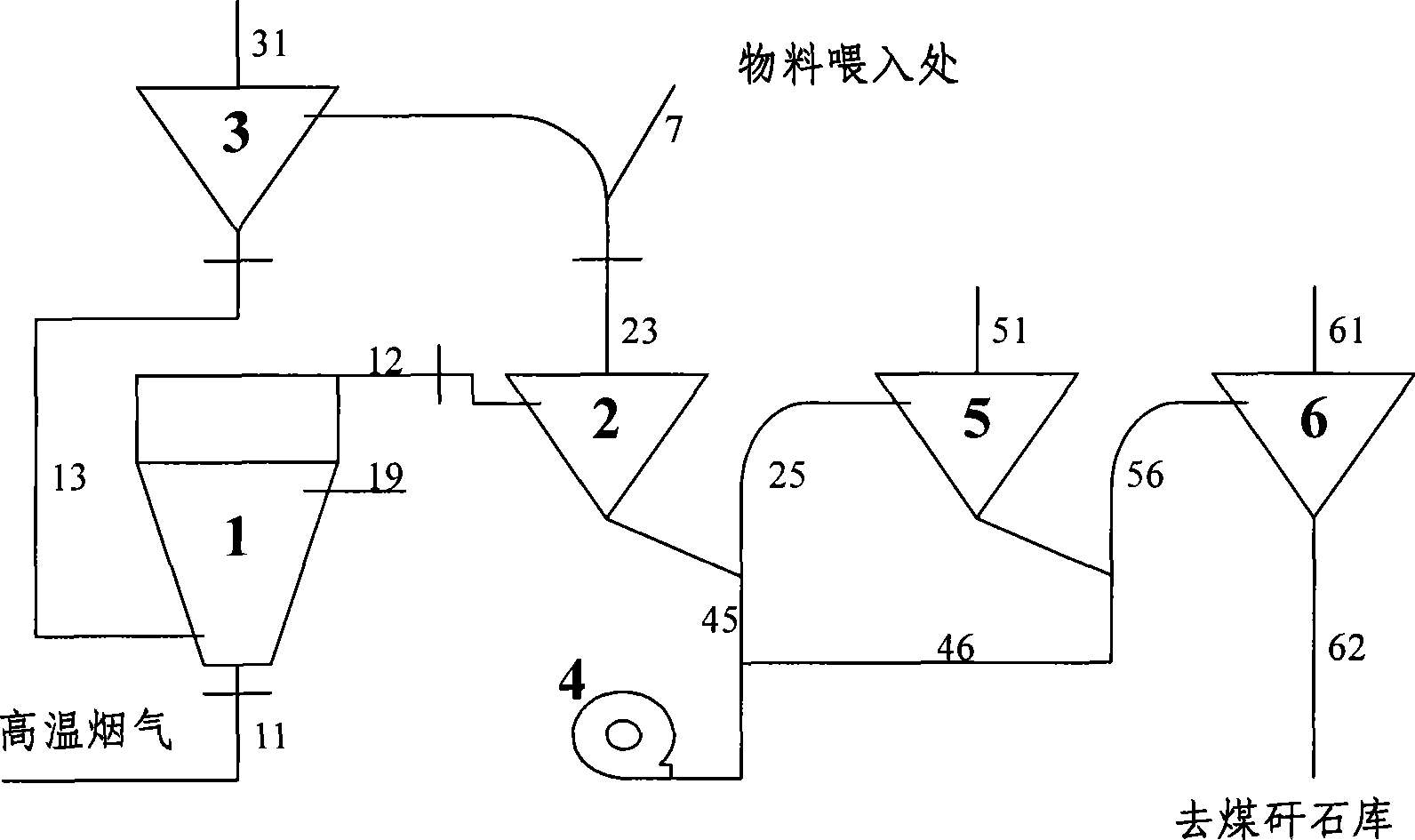

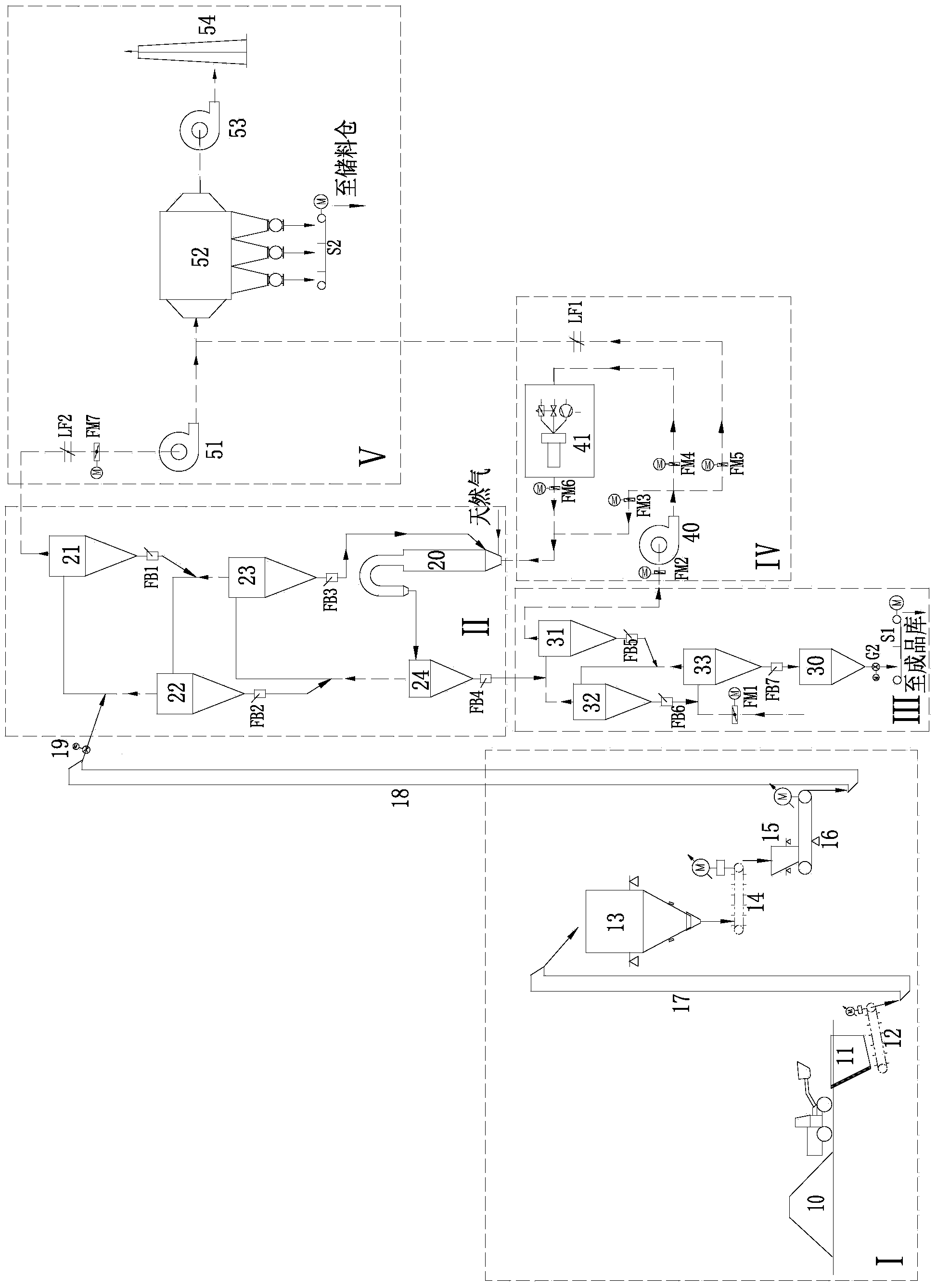

Method and system for preparing active coal gangue

The invention relates to a method and a system for preparing activated coal gangue, and belongs to the field of the cement industry. A coal gangue material is calcined in a heat source, and then the activated coal gangue is obtained by cooling and discharging the calcined coal gangue material by a multistage cyclone, wherein the heat source is high-temperature flue gas continuously discharged during cement production, then the high-temperature airflow is introduced into a calcination furnace to make the preheated coal gangue material calcined in a powder suspension state. The method makes full use of the stable heat source to quickly preheat and calcine the coal gangue and fully decompose limestone at the same time to achieve the aim of increasing calcium activity, forms the high pozzolanicity coal gangue with stable heat source supply, low cost, high production efficiency of the activated coal gangue and high utilization rate of the heat source, can remarkably improves pozzolanicity of the coal gangue, and provide a novel solving means for comprehensive utilization of industrial waste residue.

Owner:CHINA BUILDING MATERIALS ACAD

Method for realizing separation of aluminium, iron and calcium by activating coal gasification ash

ActiveCN103305686AEfficient separationHigh reactivityProcess efficiency improvementReaction temperatureMaceral

The invention relates to the technical field of a chemical process and discloses a method for realizing separation of aluminium, iron and calcium by activating coal gasification ash. The method comprises the following steps of: the first step, drying the coal gasification ash; the second step: calcining the dried coal gasification ash at a temperature in the range from 700 to 1100 DEG C for 15-75 minutes and then quenching the coal gasification ash to obtain an activated material; and the third step: carrying out a reaction on the activated material and a hydrochloric acid solution or a sulfuric acid solution at a temperature in the range from 60 to 100 DEG C for 30-120 minutes. The method is characterized in that no any auxiliary needs to be added, the mineral composition in the coal gasification ash can be changed at a low temperature, the reaction activity is effectively improved and the leaching reaction time is shortened, so that effectively separation of aluminium, iron and calcium is realized; besides, the heat value of carbon residue in the coal gasification ash can be utilized.

Owner:EAST CHINA UNIV OF SCI & TECH

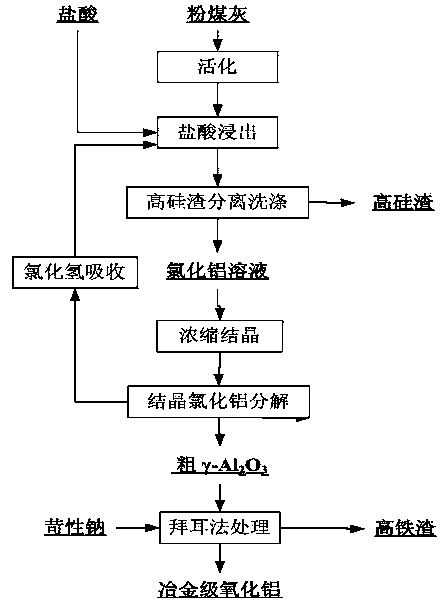

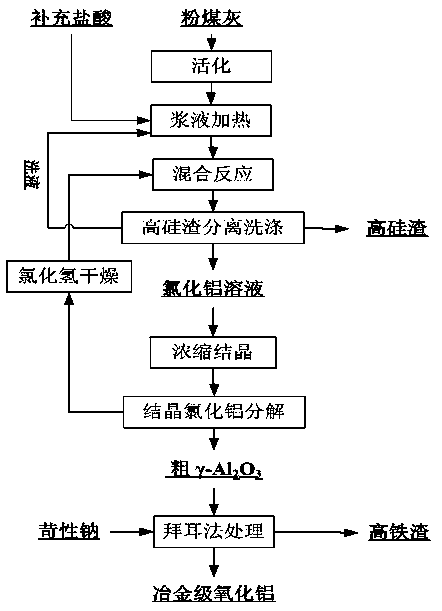

Method for preparing aluminum oxide through treatment of coal ashes with hydrochloric acid

ActiveCN103663511AEffective leachingAchieve cycleAluminium oxides/hydroxidesAluminium chlorideSteelmaking

The invention discloses a method for producing aluminum oxide through treatment and utilization of industrial solid wastes and particularly relates to a method for preparing aluminum oxide through treatment of coal ashes with hydrochloric acid. The method comprises the following steps: activating coal ashes; mixing the activated coal ashes with 15%-36% hydrochloric acid, wherein a molar ratio of HCl in the hydrochloric acid to aluminum oxide and iron oxide in the coal ashes is 4-9; feeding mixed serous fluid into a reactor, heating to 90 DEG C-230 DEG C, wherein reaction time is 1 hour-8 hours; carrying out solid-liquid separation after reacting and cooling to obtain aluminum chloride liquid and high-silicon residue, and evaporating, concentrating or drying to obtain crystallized aluminum chloride; decomposing the crystallize aluminum chloride to obtain crude gamma-Al2O3 and a hydrogen chloride gas; and preparing metallurgical-level aluminum oxide by gamma-Al2O3 through a Bayer process, wherein the residue is high-iron residue and can be used as a steelmaking material. According to the method, any auxiliary agent is not added, so that aluminum oxide in the coal ashes can be effectively leached out, and the leaching rate of the aluminum oxide can reach over 85%.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

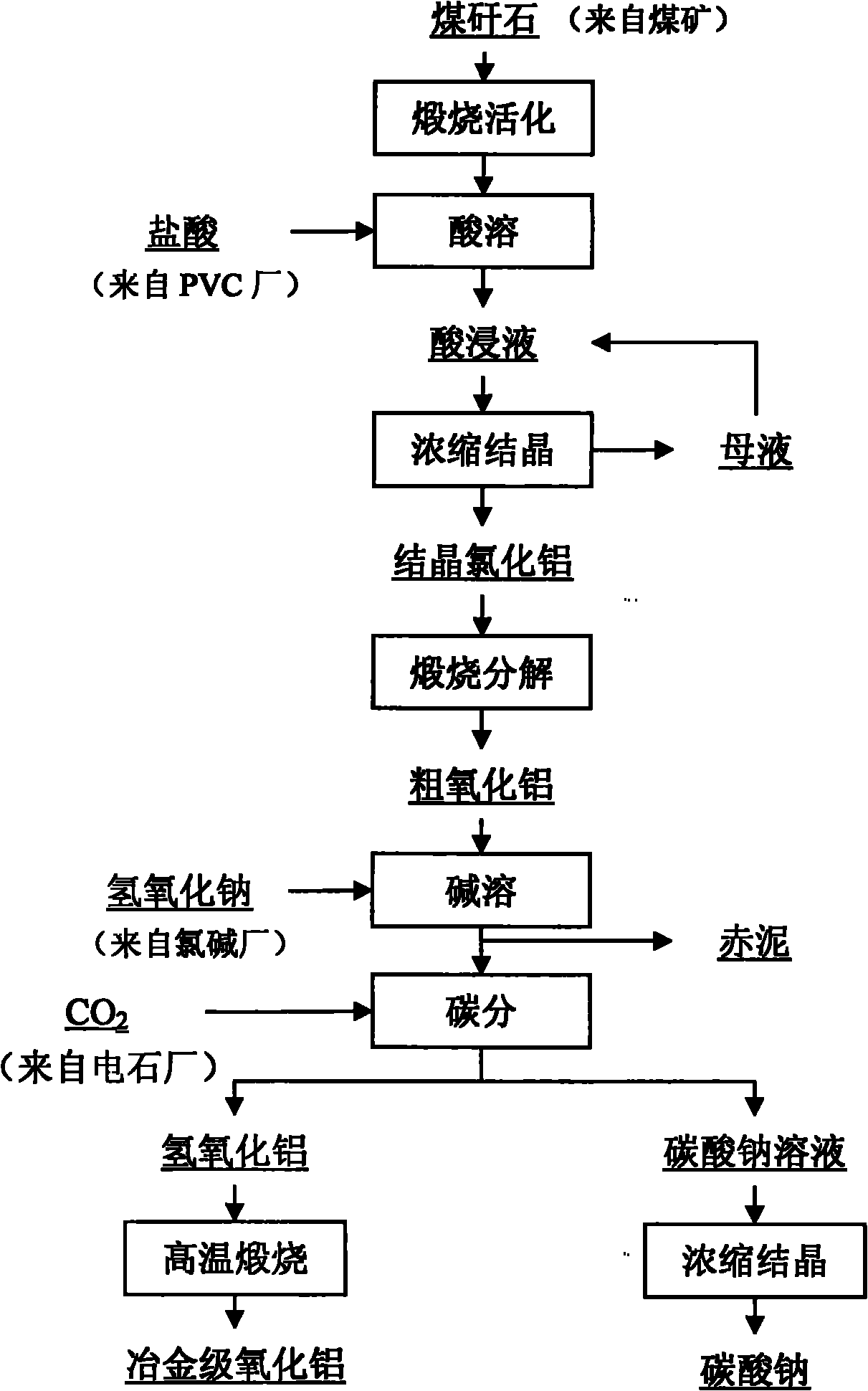

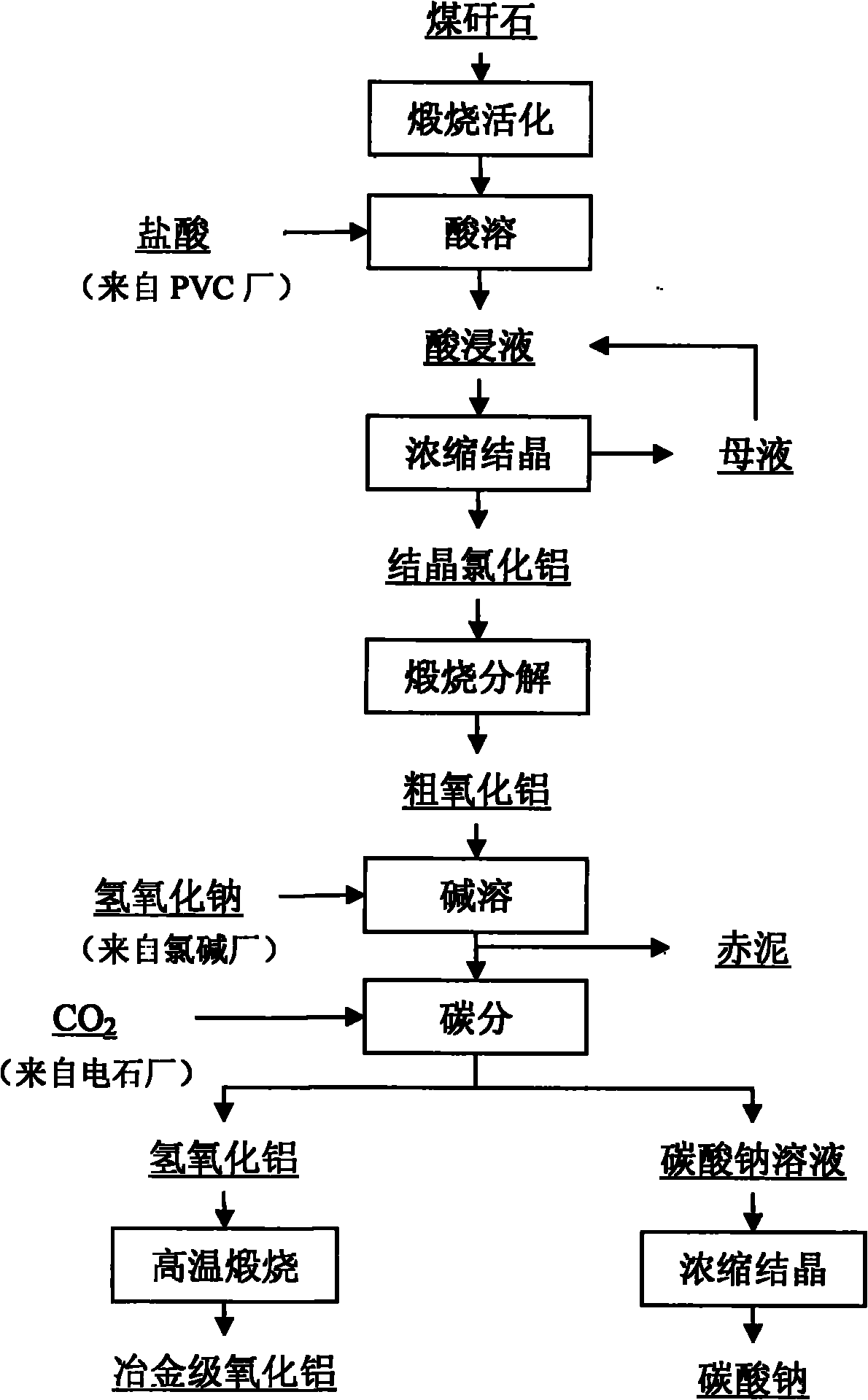

Method for co-producing aluminum oxide and sodium carbonate from coal gangue

InactiveCN101850998AHigh extraction rateReduce manufacturing costAluminium oxide/hydroxide preparationCarbonate preparationResource utilizationAluminium hydroxide

The invention relates to a method for co-producing aluminum oxide and sodium carbonate from coal gangue. The method comprises the following steps of: calcining and activating the coal gangue and dissolving the calcined and activated coal gangue in acid to prepare an aluminum chloride acid extract; concentrating and crystallizing the acid extract to prepare crystalline aluminum chloride; calcining and decomposing the crystalline aluminum chloride to prepare crude aluminum oxide; dissolving the crude aluminum oxide in alkali to prepare sodium metaaluminate; performing solid-liquid separation on iron and titanium insoluble substances and other impurities and washing the product to obtain solution of sodium metaaluminate; adding an aluminum hydroxide seed crystal into the solution of sodium metaaluminate to prepare aluminum hydroxide deposit and solution of sodium carbonate; performing solid-liquid separation to obtain an aluminum hydroxide crystal and solution of sodium carbonate; concentrating and crystallizing the aluminum hydroxide crystal and the solution of sodium carbonate to obtain sodium carbonate; and calcining the aluminum hydroxide to prepare metallurgical-grade aluminum oxide. In a production process, sodium hydroxide from a chlorine industry, hydrochloric acid which is a byproduct of a PVC industry and carbon dioxide discharged from a calcium carbide plant in a production place of the coal gangue are fully utilized, so that industry pollution is reduced, a useful product is obtained and comprehensive resource utilization is realized. The method has the advantages of simple production technology, easily-controlled production process, high aluminum oxide extraction ratio, low production cost and stable product quality.

Owner:CHANGCHUN CHAOWEI NEW MATERIALS TECH

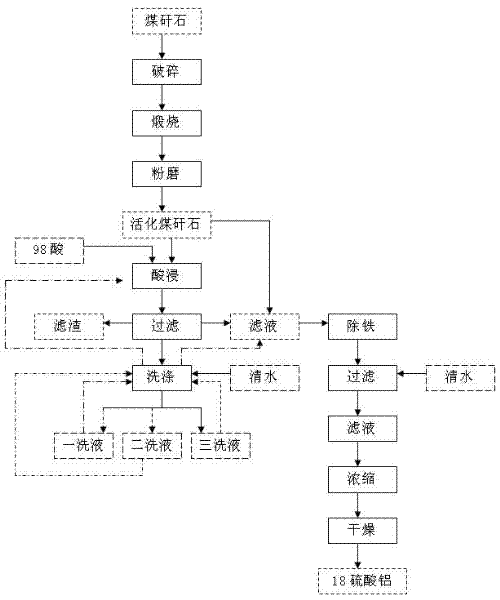

Method for producing low iron aluminum sulfate by utilization of coal gangue

InactiveCN102311136AGood slag activityUnderburn noneWaste processingSolid waste disposalSlagAluminum sulphate

The invention relates to a method for producing low iron aluminum sulfate by the utilization of coal gangue and belongs to the technical field of coal solid waste resource utilization. The method provided by the invention comprises the following steps of: carrying out calcination activation on coal gangue at the temperature of 785-850 DEG C, adjusting the pH of an aluminum sulfate solution by directly using the activated coal gangue, oxidizing divalent iron ions into trivalent ions, removing iron precipitate and a few gel in the aluminum sulfate solution by the utilization of the adsorption property of the coal gangue, producing low iron aluminum sulfate, recycling the removed iron slag, and terminating the recycling operation when the removed iron slag amount is greater than 120% of the acid-leach residue amount or the mass ratio of aluminium to iron in an iron-removing liquid is less than 160. The temperature of the calcinated coal gangue satisfies the operation condition for the boiling of a circulating fluidized bed. No addition of an auxiliary agent helps heat recovery. The activity of the coal gangue cinder is good, the grinding requirement is not high and the energy consumption is low. Hydrogen peroxide or ozone, air and variable valence element-containing hypervalent compounds KMnO4, MnO2 oxidizing agents are adopted to remove iron with less loss of aluminium. The ratio of Al2O3 to Fe in the product is greater than 160 and the quality of the product is high. The acid leaching reaction is carried out at normal pressure. And the production is easy to operate at low cost.

Owner:KUNMING UNIV OF SCI & TECH

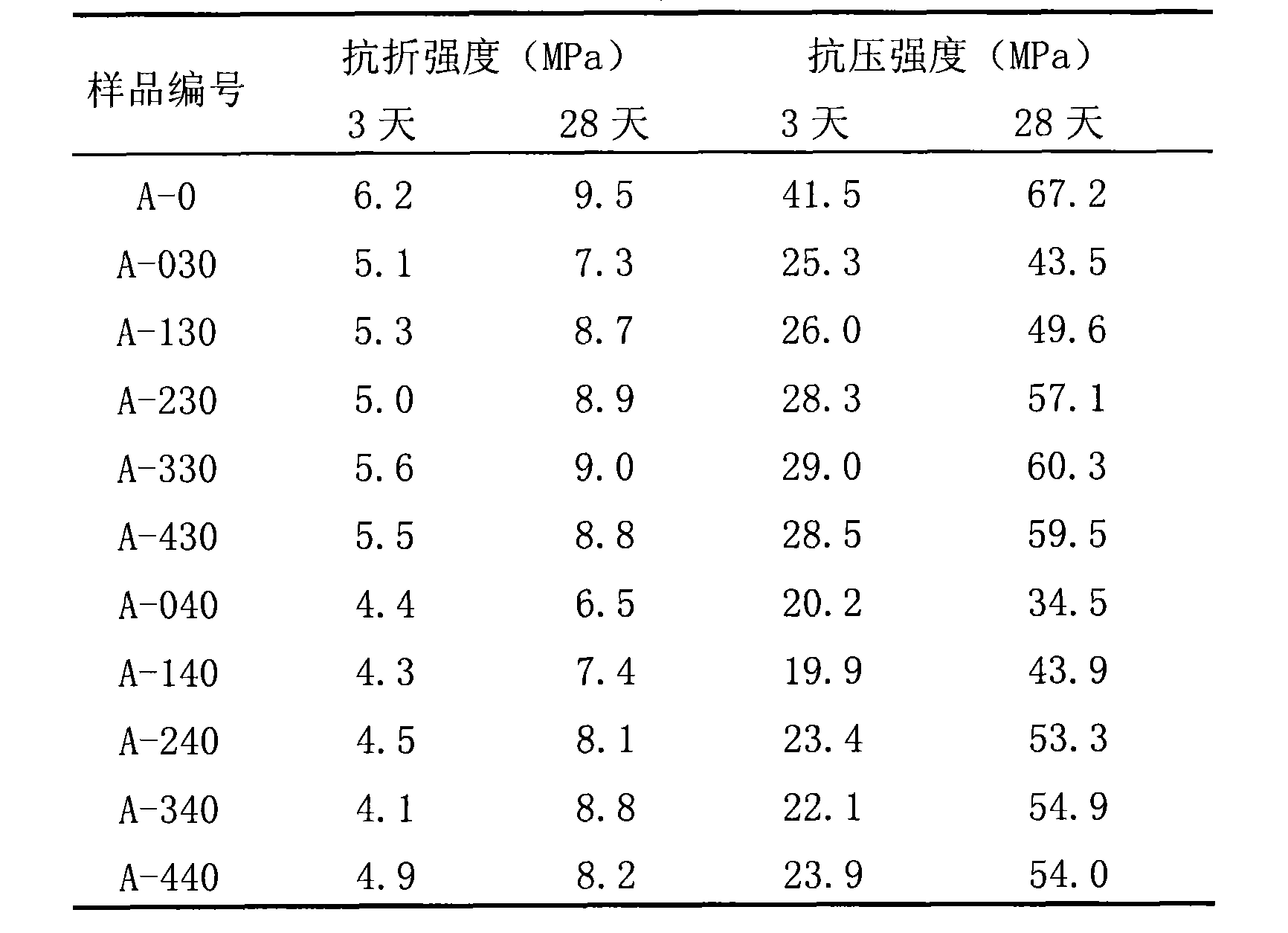

High strength concrete adopting desulfurized gypsum as activator, and preparation method thereof

InactiveCN102452814AHigh strengthIncreased durabilitySolid waste managementHigh strength concreteSucrose

The invention relates to high strength concrete adopting desulfurized gypsum as an activator, and a preparation method thereof. The high strength concrete comprises cement, fly ash, slag powder, activated coal gangue, metakaolin, desulfurized gypsum, slaked lime, sucrose ester, machine-made sand, crushed stone, a polycarboxylate superplasticizer and water according to a formula. According to the present invention, the utilization ratio of various industrial wastes by the concrete can be effectively improved, the use amount of the cement is low, and the penetration resistance, the carbonization resistance and the C1-penetration resistance of the concrete are easily improved; the significant advantages of low cost, high greening degree, carbon discharge reducing and the like are provided. The high strength concrete of the present invention is applicable for constructions of pillars of various buildings, piers and box girders of viaducts, and piers and main towers of sea-crossing bridges, and is further suitable for constructions of high strength filling piles, steel pipe concrete pillars (arches), steel-concrete combination structures, and the like.

Owner:SHANGHAI URBAN CONSTR MATERIAL CO LTD

Method for preparing reactive powder concrete for construction member by utilizing coal gangue

ActiveCN103086662AComprehensive utilization of protectionLow costSolid waste managementNatural resourceBiological activation

The invention provides a method for preparing a reactive powder concrete for construction member by utilizing coal gangue. The method is characterized by comprising steps of: activating industrial solid waste coal gangue through mechanical activation, thermal activation and chemical activator; preparing the reactive powder concrete by using the activated coal gangue powder to substitute a quartz powder, part of cement and silica fume; and preparing a 200 grade reactive powder concrete under normal pressure, and hot water curing condition below 100 DEG C. Solid waste coal gangue is used to substitute a natural resource, so as to reduce raw material cost of the reactive powder concrete; therefore, the invention is of great significance in environmental protection, comprehensive utilization of solid waste and promotion on sustainable development.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

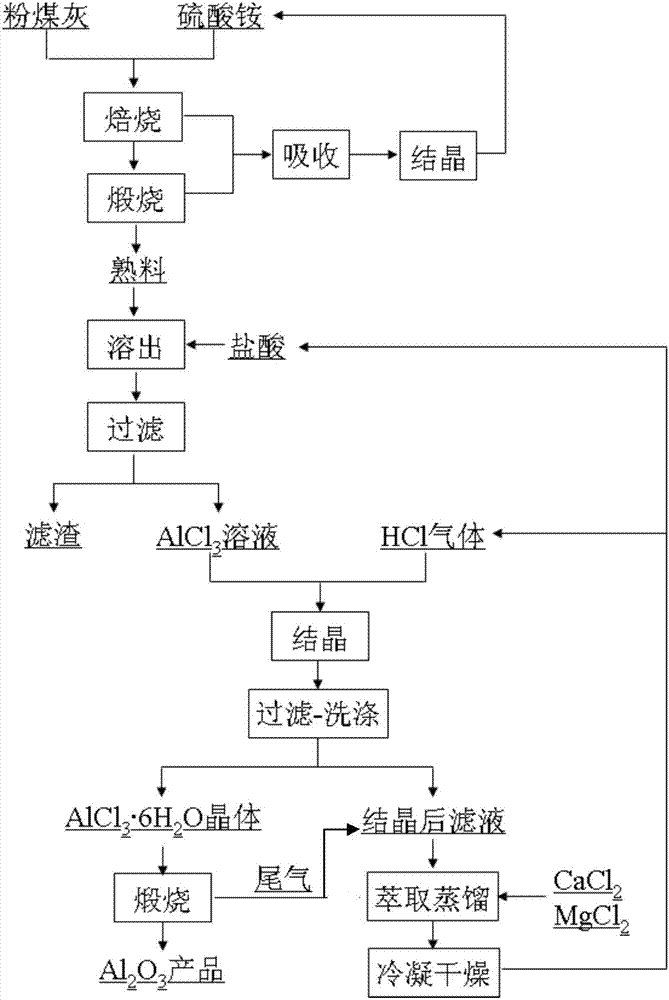

Process method for extracting aluminum oxide in coal ash of pulverized coal furnace by using acid method

InactiveCN106966415ARealize direct recyclingEasy roasting operationAluminium oxides/hydroxidesExtractive distillationBiological activation

The invention relates to a process method for extracting aluminum oxide in coal ash of a pulverized coal furnace by using an acid method. The process method comprises the following steps; adding ammonium sulfate into the coal ash of the pulverized coal furnace for activating, and performing the high-temperature calcination to obtain activated coal ash clinker, adding hydrochloric acid, heating and dissolving out, to obtain aluminum chloride digesting liquor; pumping hydrogen chloride gas into the digesting liquor for crystallizing, performing the solid-liquid separation and washing to obtain high-purity aluminum chloride hexahydrate crystal and waste acid solution, calcining the crystal to generate metallurgy-level aluminum oxide; adding inorganic salt chloride, such as calcium chloride or magnesium chloride, into the waste acid, heating, extractive-distilling and recycling the hydrochloric acid and the hydrogen chloride gas for the dissolving out and crystallization working procedures, performing the absorption-crystallization to tail gas generated in the roasting-calcining activation to generate ammonium sulfate, and realizing the cyclic utilization of materials, wherein the obtained solid residue with abundant silicon dioxide can be used for generating white carbon black or the materials for building. The process method is capable of realizing the reduced recycling of the coal ash of the pulverized coal furnace, and realizing the full cyclic utilization of the materials. The purity of the obtained aluminum oxide product is the first level, the quality of the metallurgy-level aluminum oxide is standard, and the extraction efficiency is up to 84.6%-90.4%.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

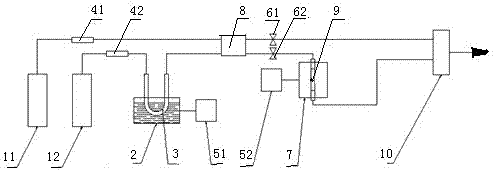

Gas, solid and liquid integrated combustion system

The invention relates to a gas, solid and liquid integrated combustion system, and belongs to the technical field of the environment. The system is composed of a waste gas collection system, a granulation system, a feeding system, a rotating furnace, a combustion furnace, a waste heat boiler, a heat exchanger, a rapid quenching tower, a smoke dry type washing system, a cloth bag dust removal device, a spray tower, a reheater and a chimney. Coal, solid waste and liquid waste are evenly mixed according to the mass ratio (1-12):(2-30):(1-16) in the granulation system for granulation; after collected waste gas is preheated, part of the waste gas enters the rotating furnace, and the other part of the waste gas enters the combustion furnace to be processed through high temperature combustion; high temperature tail gas of the combustion furnace enters the rapid quenching tower, the dry type washing system, the cloth bag dust removal device and the spray tower after heat energy recovery, and is sent to the chimney by a draught fan after the tail gas is cooled and fly ash, dioxin and acid gas are removed, so that emission reaching the standard is completed. Liquid waste produced in the running process of the system is recycled in the granulation system, solid waste such as activated carbon is fed into the rotating furnace to be combusted, and therefore harmless treatment is achieved while running cost of the system is reduced.

Owner:JIANGSU ANQIER WASTE GAS PURIFICATION

Residual oil hydrogenation catalyst as well as preparation method and application thereof

ActiveCN103861595AHigh activityAvoid inactivationCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsComponent LoadActive component

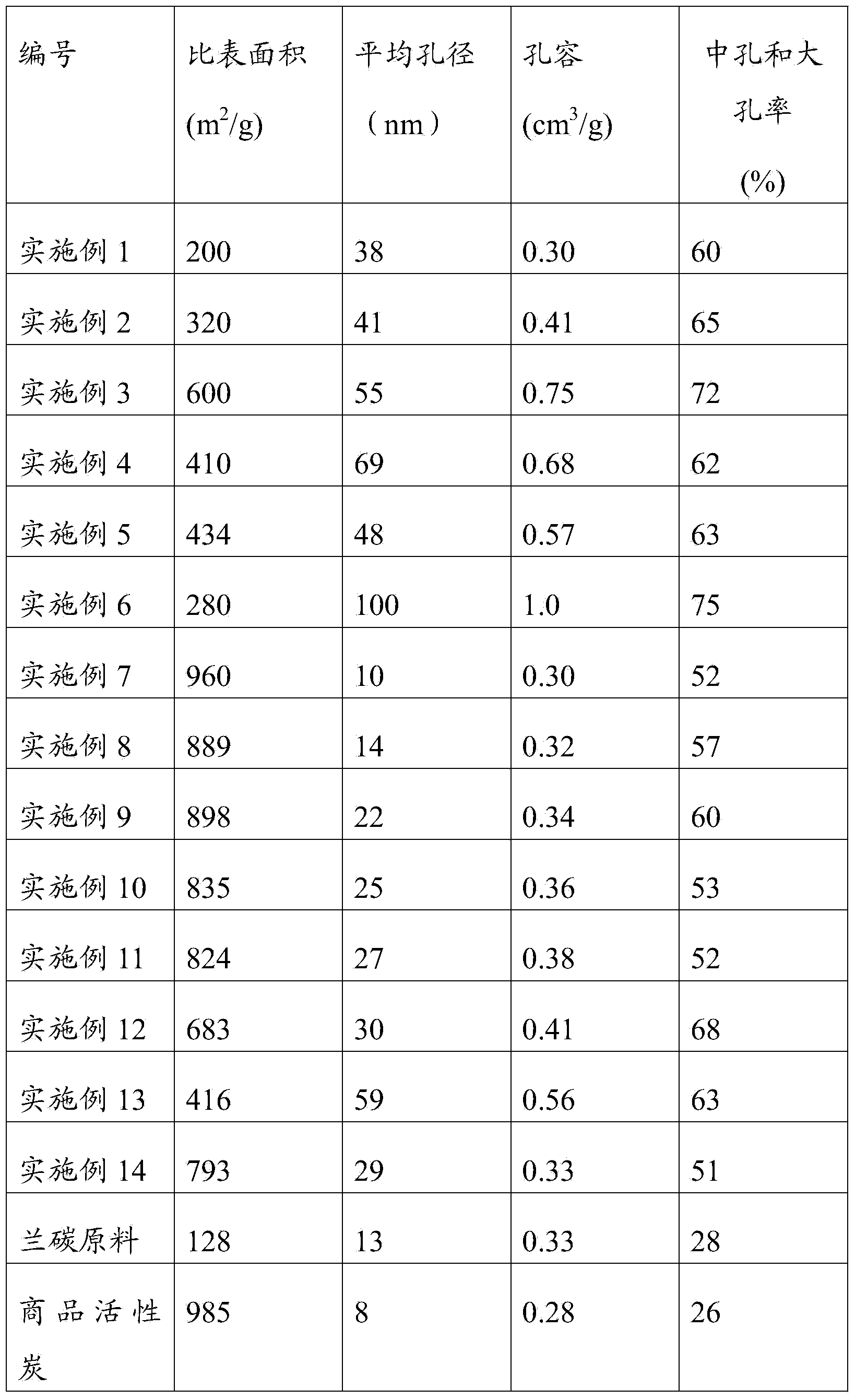

The invention discloses a residual oil hydrogenation catalyst, comprising a carrier and an active metal component loaded on the carrier, wherein the carrier is a graphited reaming coal material; the specific surface area of the graphited reaming coal material is 200-960m<2> / g, the mean pore size is 10-100nm, the pore volume is 0.3-1.0cm<3> / g, the active metal component comprises one or more of VIII metallic oxides and VIB metal oxides, and the graphited reaming coal material is graphited reaming activated coal or graphited reaming semicoke. The invention also discloses a preparation method of the residual oil hydrogenation catalyst. Firstly, a carbon raw material is graphited and chambered to obtain the required carrier, and then the active component is soaked into the vector to obtain the residual oil hydrogenation catalyst.

Owner:BEIJING HUASHI UNITED ENERGY TECH & DEV +1

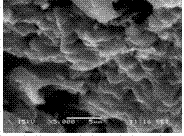

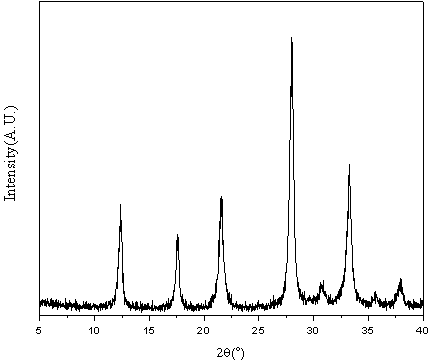

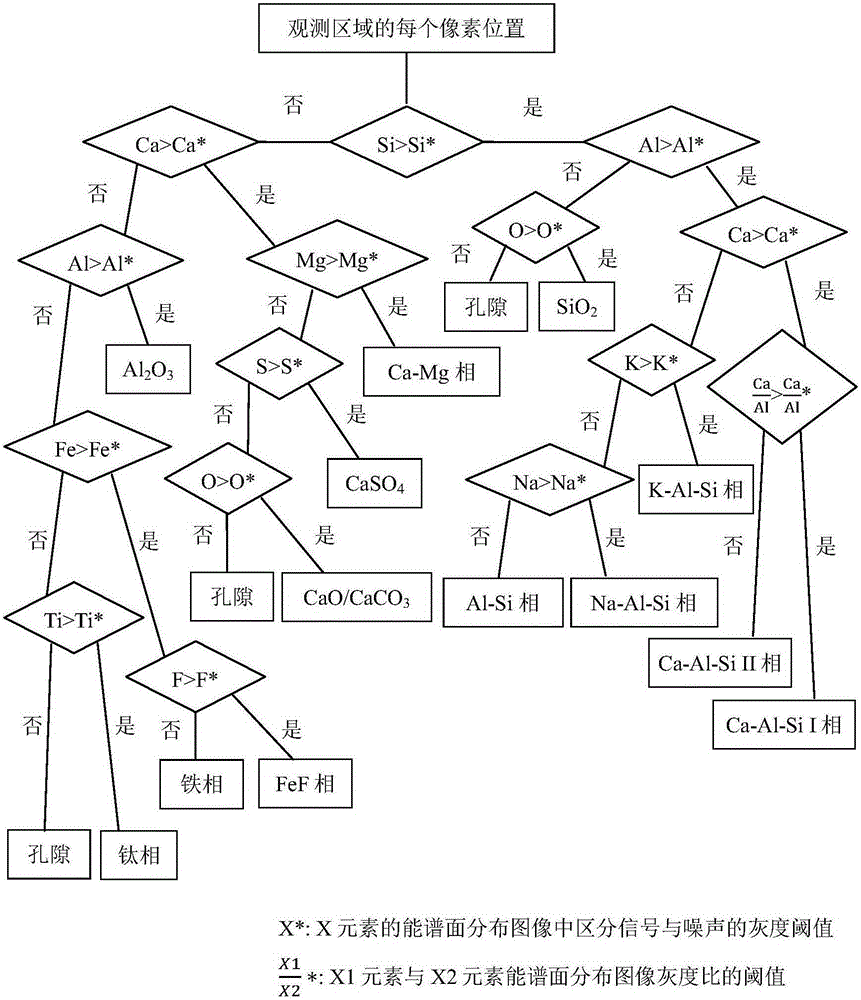

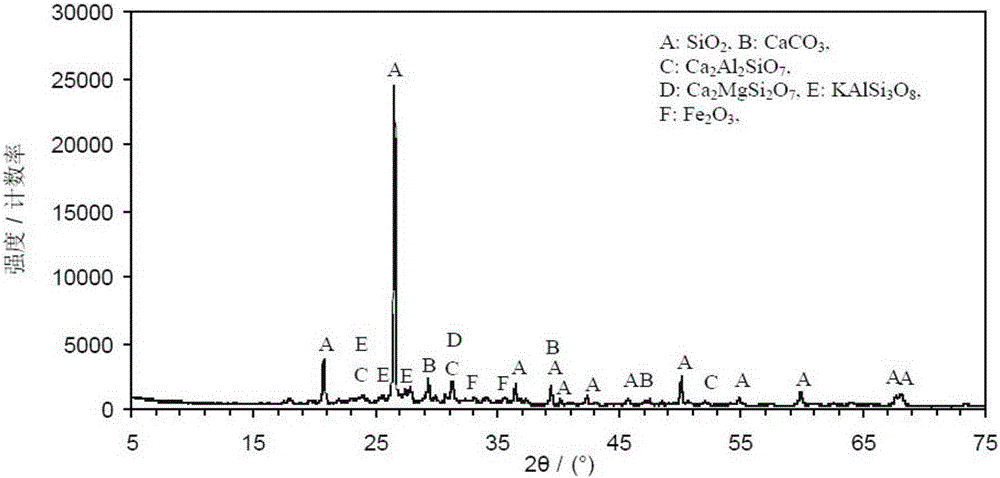

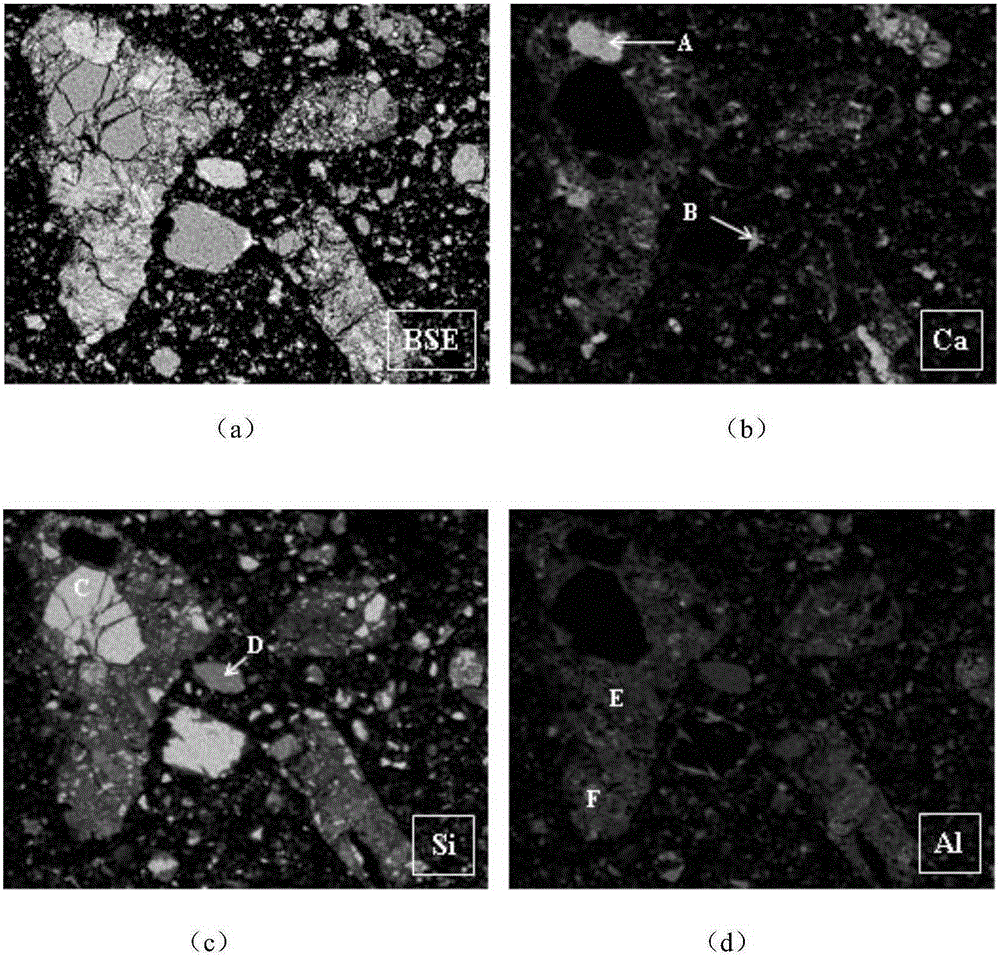

Coal gangue phase analysis method based on energy dispersion X-ray spectrum

ActiveCN105181717AThe spatial distribution is clearly presentedPredictive reactivityMaterial analysis using wave/particle radiationFluorescenceX-ray

The invention relates to a coal gangue phase analysis method based on an energy dispersion X-ray spectrum. The method includes the specific steps of firstly, analyzing the chemical composition of coal gangue through chemical analysis or X-ray spectrofluorimetry; secondly, analyzing the mineral composition of coal gangue through X-ray diffraction; thirdly, determining types of elements where energy spectrum face distribution images need to be collected; fourthly, shooting backscattered electron images and element energy spectrum face distribution images of coal gangue, and analyzing and observing composition of main phases through energy spectrum points; fifthly, designing a phase analysis method, comprehensively processing the energy spectrum distribution images of all the elements in the same area, removing noise in the analysis result, and obtaining split phase pseudocolor images and the phase analysis result of coal gangue. The phase analysis method can be used for type analysis, volume percentage content calculation and space distribution observation in coal gangue and activated coal gangue. The method is effective for both the crystalline state phase and the amorphous state phase, and is sensitive to the low-content phase.

Owner:TONGJI UNIV

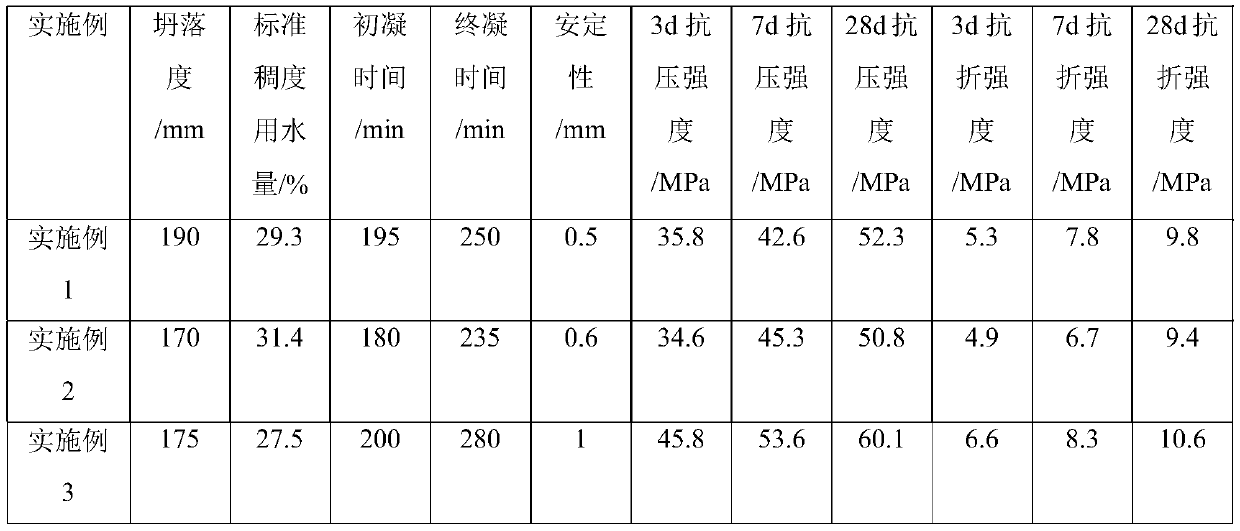

Pit backfill material, preparation method thereof and application method thereof

The invention discloses a pit backfill material and an application method thereof. The pit backfill material comprises cement, calcined activated coal gangue, steel slag powder, lime hydrate powder, phosphogypsum, an expanding agent, glass quartz sand tailings, machine-made sand, a water reducer, and modified starch ether. The material can be constructed through pumping only by adding water with 35-90% of the total weight on a building site and stirring according to requirements. The pit backfill material which is prepared from a large amount of industrial solid wastes in the invention and allows workability, water retention, fluidity and self-compaction fallibility to be good, compressive strength to be high, bonding strength and sulphate erosion resistance to satisfy relevant requirements, and slight dilatability to be possessed has the advantages of simple production technology, convenient application, waste utilization, energy saving, consumption reduction, low carbon, and good market prospect.

Owner:GUANGDONG REDWALL NEW MATERIALS

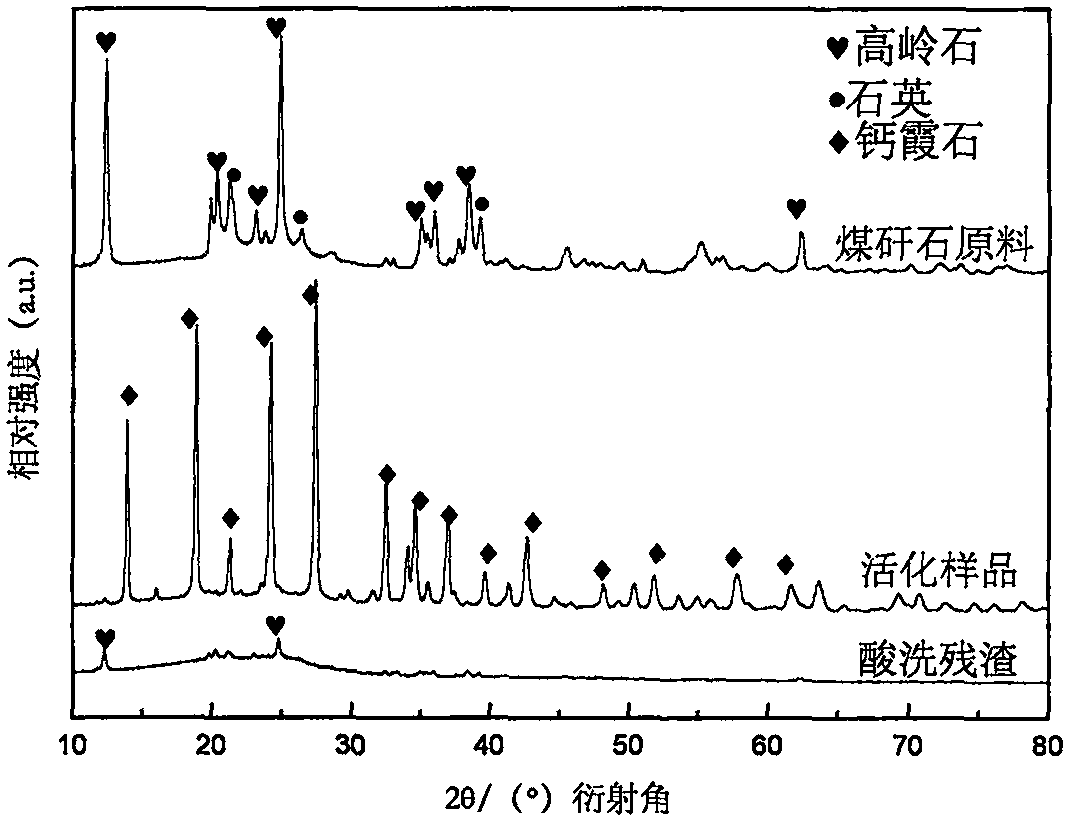

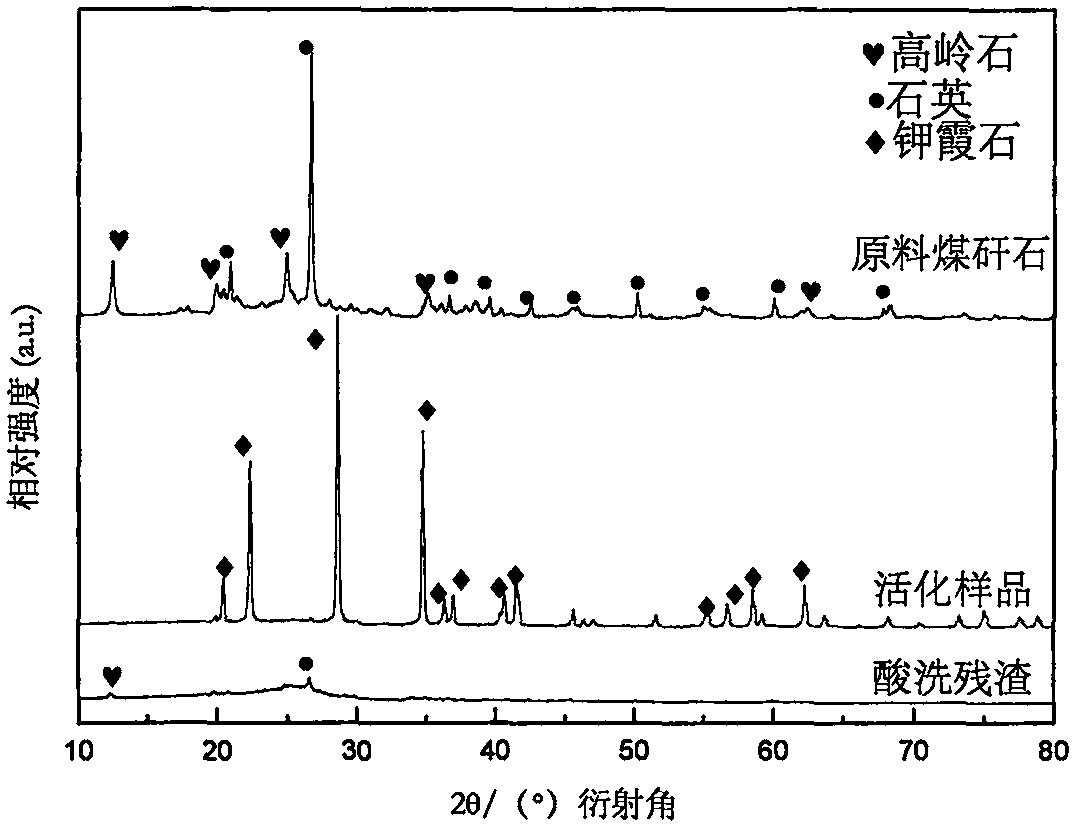

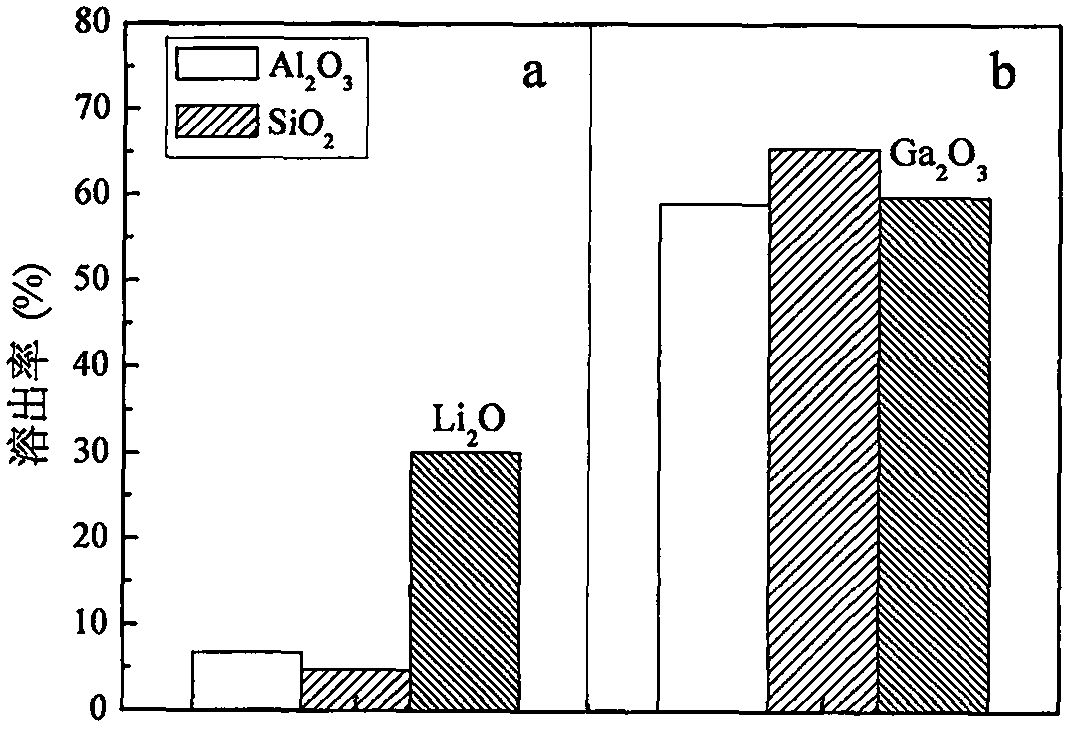

Supercritical (or subcritical) activation method for coal gangue and application of supercritical (or subcritical) activation method

ActiveCN109234527AImprove the activation effectReduce the temperatureSilicaProcess efficiency improvementActivation methodReaction temperature

The invention relates to a subcritical or supercritical activation method for coal gangue. According to the method, alkali as an auxiliary is added to the coal gangue and the coal gangue is subjectedto an activating reaction under the subcritical or supercritical condition, and an activated coal gangue sample can be obtained. The invention further relates to a comprehensive utilization method ofthe coal gangue. According to the comprehensive utilization method, the activated coal gangue sample obtained by subcritical or supercritical activation is subjected to a contact reaction with acid, by means of acid leaching, not only can an aluminum oxide product and a white carbon black product be obtained, but also lithium and gallium which are enriched in the coal gangue can be extracted, final filter residues are used for preparing raw materials of cement, and one zero-pollution and zero-emission way of coal gangue waste recovery is really obtained. The methods have the advantages as follows: coal gangue can be activated at the low temperature of about 400 DEG C, few operation steps are required, reaction temperature is low, reaction time is short, no secondary pollution is produced in the whole process, and the novel environment-friendly coal gangue activation method and the way of coal gangue waste recovery are obtained.

Owner:TAIYUAN UNIV OF TECH

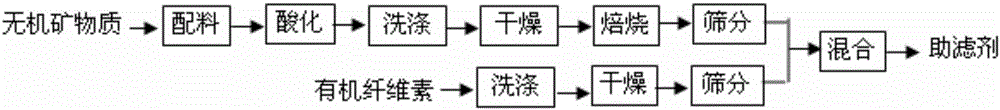

Lubricating oil composite filter aid and preparation method thereof

InactiveCN106669622AReduce manufacturing costFast filteringOther chemical processesLubricant compositionCelluloseSodium Bentonite

The invention discloses a lubricating oil composite filter aid and a preparation method thereof. The composite filter aid is prepared through the steps of preparing materials, acidizing, washing, drying, roasting, sieving and mixing. The composite filter aid is prepared from materials of inorganic mineral substances and organic cellulose, wherein the mass percent of the mineral substances is 50 to 90%, and the mineral substances are chosen from at least two of activated clay, kieselguhr, bentonite, activated carbon, perlite, zeolite, attapulgite, sepiolite, vermiculite, activated aluminum oxide, coal ash, steel slag micropowder and superfine slag powder; the proportion of the organic cellulose is 10 to 50%, and the organic cellulose is chosen from one or more of saw powder, wood bit, bagasse, bran, paper pulp, rice hull, bamboo residue, straw shred residue and lignocellulose. The lubricating oil composite filter aid has the advantages of convenience in use, quick filtering speed and good cleaned oil quality, capability of serving as a filtering agent in a lubricating oil clay refining period and suitablity for adsorbing and filtering technologies of other petroleum products, and the cost is low.

Owner:SHANGHAI INST OF TECH

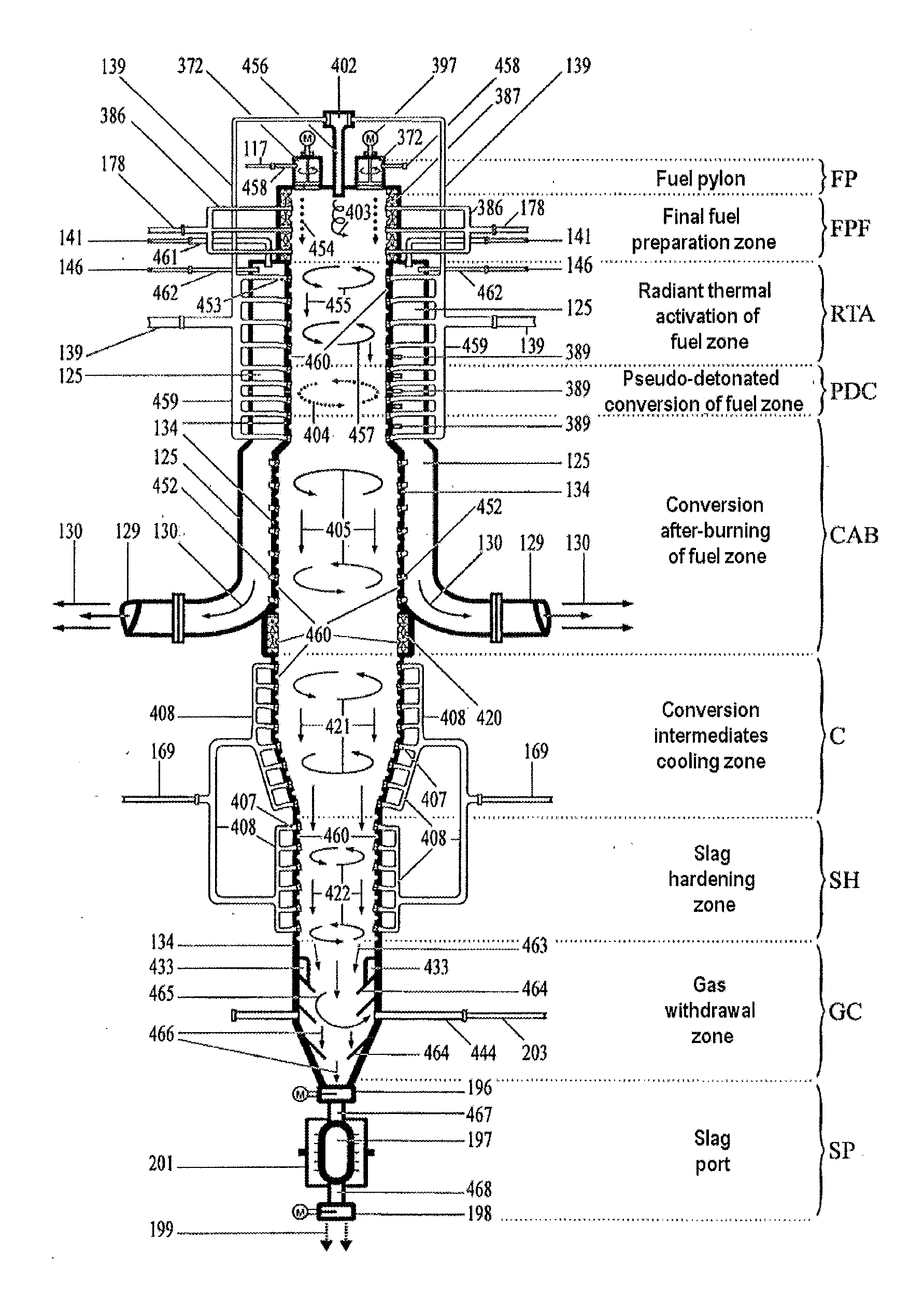

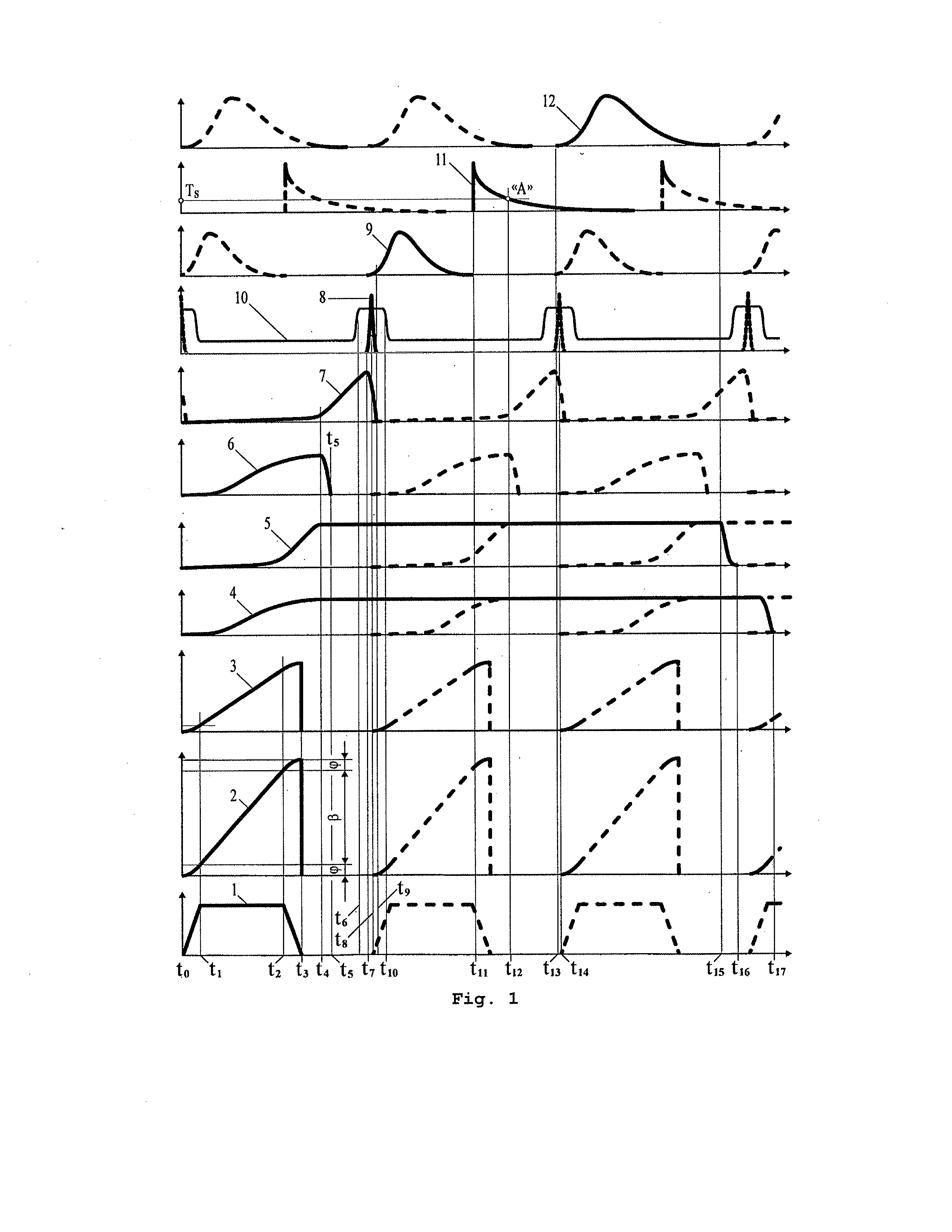

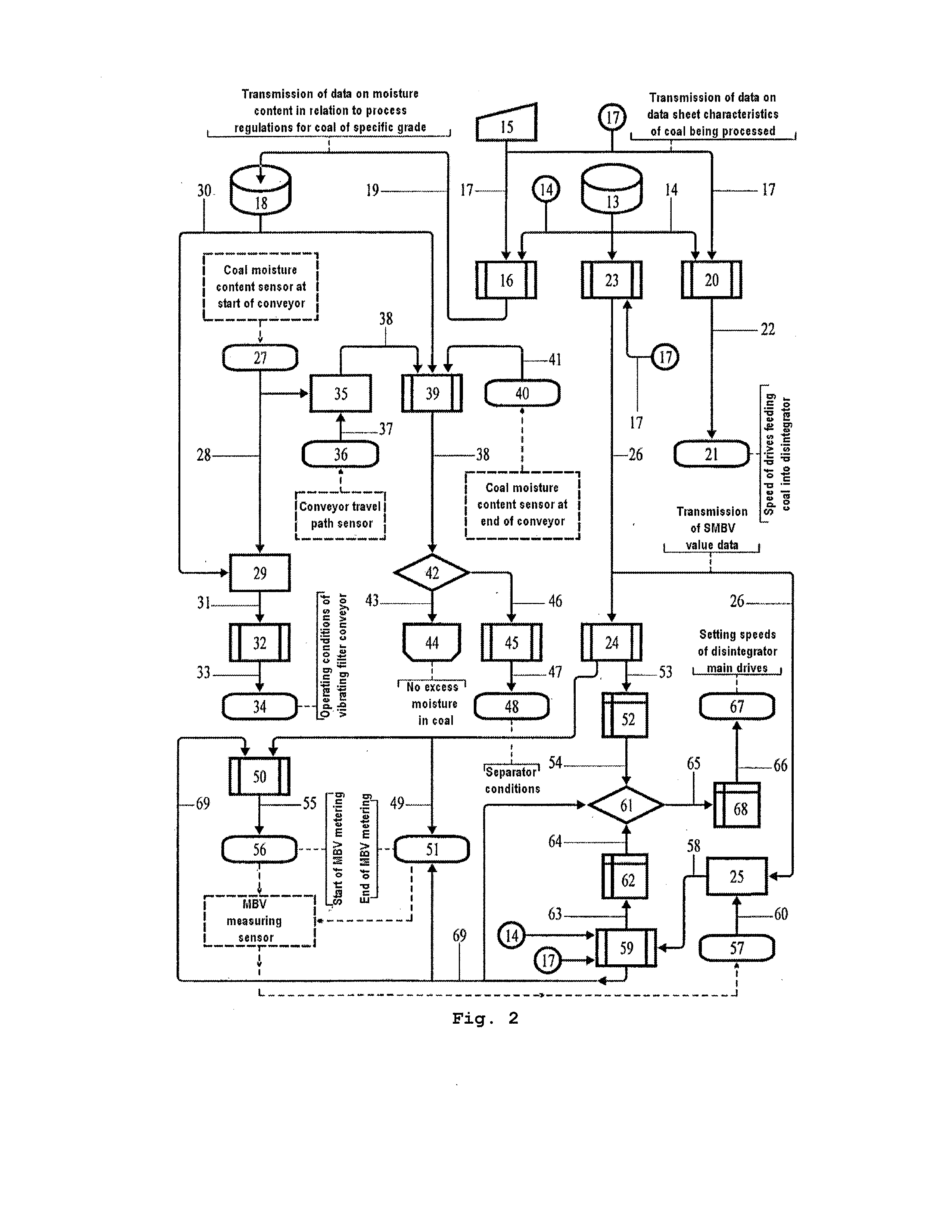

Method for the pseudo-detonated gasification of coal slurry in a combined cycle

InactiveUS20130167441A1High radiation transparencyImprove productivityGasification processes detailsLiquid carbonaceous fuelsThermal energyPower engineering

The invention relates to the field of power engineering and, more specifically, to systems for generating electricity based on the use of solid fuel, primarily brown and black coal. In the coal gasification method, a gasifier is fed with a uniform activated coal water fuel, the droplets of which are of equal size and the coal particles in said droplets having a similar granulometric composition. The fuel droplets are introduced intermittently in separate doses of fuel with a certain amount of motion being imparted thereto. The milling of the coal for the activated coal water fuel preparation method is adjusted adaptively according to the criterion of the actual amount of volatile substances given off by the coal, and the coal is thoroughly classified according to its granulometric composition. The invention provides for more extensive recovery of thermal energy from coal and more efficient electricity generation.

Owner:ASTRA INTERECOTECH

Method for preparing aluminum oxide by using hydrochloric acid treatment coal ash

ActiveCN103663510AGuaranteed concentration of hydrochloric acidAvoid Corrosion HazardsSolid waste disposalAluminium oxides/hydroxidesAluminium chlorideSlag

The invention discloses a method for preparing aluminum oxide by using hydrochloric acid treatment coal ash. The method comprises the steps: activating coal ash; mixing the activated coal ash with hydrochloric acid with the concentration of 5-10 percent; feeding mixed slurries into a heat exchanger to be heated to be between 90 and 200 DEG C; feeding the heated slurries into a reactor; adding hydrogen chloride gas into the reactor and reacting for 1-8 hours; separating solid from the liquid after reaction is finished and the temperature is reduced to obtain aluminum chloride and ferric chloride solution and high silicon slag; evaporating and condensing or drying to obtain crystallized aluminum chloride and ferric chloride; heating and decomposing the crystallized aluminum chloride to obtain coarse gamma-Al2O3 containing a large number of impurities and hydrogen chloride gas; and treating coarse gamma-Al2O3 by using the Bayer process to prepare metallurgical-level aluminum oxide, wherein residual slag is high iron slag and can be used an iron-making raw material. According to the method, the problem of severe corrosion of the equipment can be avoided, aluminum oxide in the coal ash is effectively leached, and the produced aluminum oxide can meet the industrial requirement of electrolytic aluminum.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Coal gasification slag all-component pervious concrete

InactiveCN112125589AQuick responsePromote growthSolid waste managementCement productionMining engineeringSlag

The invention discloses coal gasification slag all-component pervious concrete. Ground coal gasification slag is taken as a silicon-aluminum raw material to prepare a coal gasification slag geopolymerwith good mechanical properties as a cementing material; and screened coal gasification slag is used as aggregate to prepare the pervious concrete which have adaptive mechanical properties and waterpermeability and has good wear resistance and water purification performance. The aggregate and the silicon-aluminum raw material used in the invention are both the coal gasification slag, so that theindustrial solid waste coal gasification slag is fully utilized, and the purpose of resource utilization is achieved. Meanwhile, the coal gasification slag contains a certain amount of activated carbon, so that the adsorption performance of the pervious concrete can be improved, and the pervious concrete which has adaptive mechanical properties and water permeability and has good wear resistanceand water purification performance is obtained.

Owner:WUHAN UNIV OF TECH

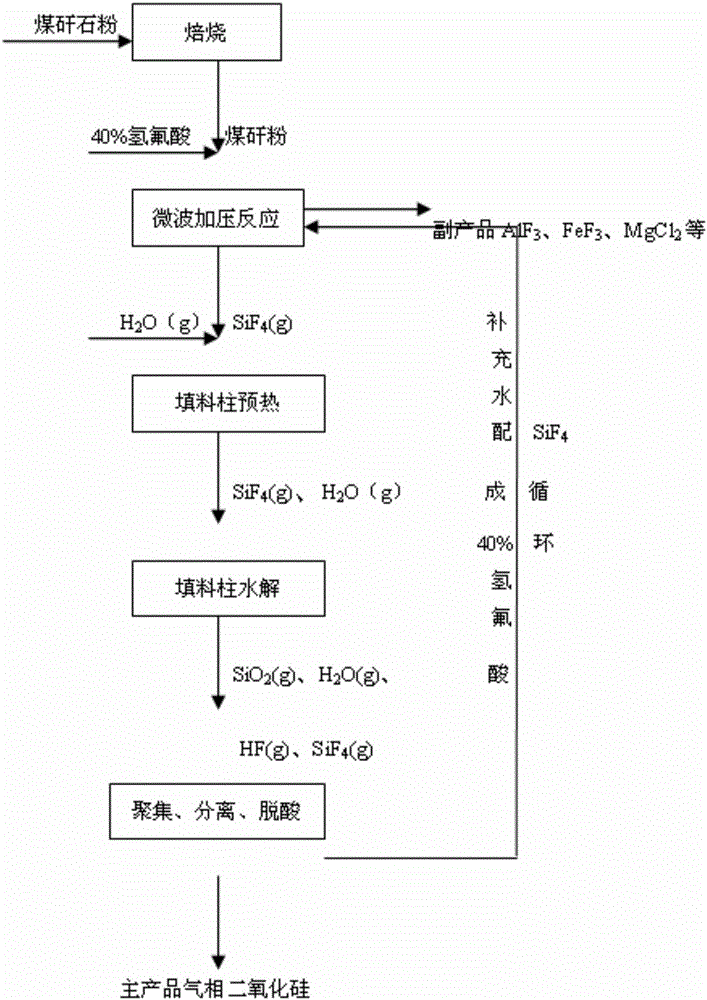

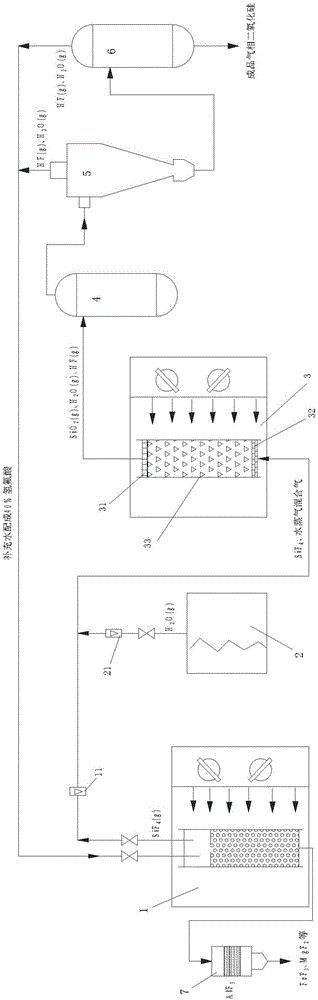

Method and apparatus for preparing fumed silica from coal gangue

The invention discloses a method and an apparatus for preparing fumed silica from coal gangue. The method comprises: performing pressurized reaction, in microwave fields, on activated coal gangue powder and hydrofluoric acid, converging the generated silicon tetrafluoride gas with water vapor to obtain a mixture and introducing the mixture into a micorwave-absorbing agent packed column under microwave irradiation, and performing high-temperature pyrohydrolysis reaction on the mixture to generate gas silicon dioxide and hydrogen fluoride; performing shock chilling, gathering, separating, acid-removing and purging on the generated gas silicon dioxide and hydrogen fluoride as well as unreacted water vapor to prepare a fumed silica product; separating the hydrogen fluoride gas and the water vapor from a cyclone separator and the top of an acid removing furnace, and adding the water to prepare hydrofluoric acid for recycling, wherein the fumed silica product can be used as a thickening agent, a rubber reinforcing agent and a washing assistant agent, and the like; by-products are aluminum fluoride, iron fluoride and magnesium fluoride and the like; the microwave-absorbing agent in the present invention can significantly improve the direct hydrolysis efficiency of silicon tetrafluoride; the pressurized microwave reaction can significantly increase the reaction rate and conversion rate of silicon dioxide and hydrofluoric acid; and the microwave-absorbing agent is recycled and easy to regenerate, and has a high utilization rate, a simple process and low preparation cost.

Owner:LIUPANSHUI NORMAL UNIV

Load type flyash solid base catalyst for producing biological diesel oil and method of producing the same

InactiveCN101130163AHigh activityReduce work costsBiofuelsLiquid hydrocarbon mixture productionAlkaline earth metalBiodiesel

The invention discloses a solid alkaline catalyst of loaded coal ash to make biological diesel, which comprises the following parts: coal ash + alkaline metal hydroxide, coal ash + alkaline earth metal hydroxide, coal ash + alkaline metal salt, coal ash + alkaline earth metal salt, coal ash + alkaline metal hydroxide + alkaline metal salt, coal ash + alkaline metal hydroxide + alkaline metal salt and alkaline metal in the composite system, wherein the total weight of alkaline metal hydroxide, alkaline earth metal hydroxide, alkaline metal salt, alkaline metal salt and alkaline metal is 10-40%; the total weight of coal ash is 60-90%; the catalyst can accelerate the ester exchange reaction effectively under mild reacting condition. The invention has simple technique, low cost to immerse the activated coal ash carrier in the alkaline or salt solution or suspension, which is sintered after aging and adding drying solvent in the mafu stove to generate polymer powder to be grinded and sieved to prepare.

Owner:NORTHWEST A & F UNIV

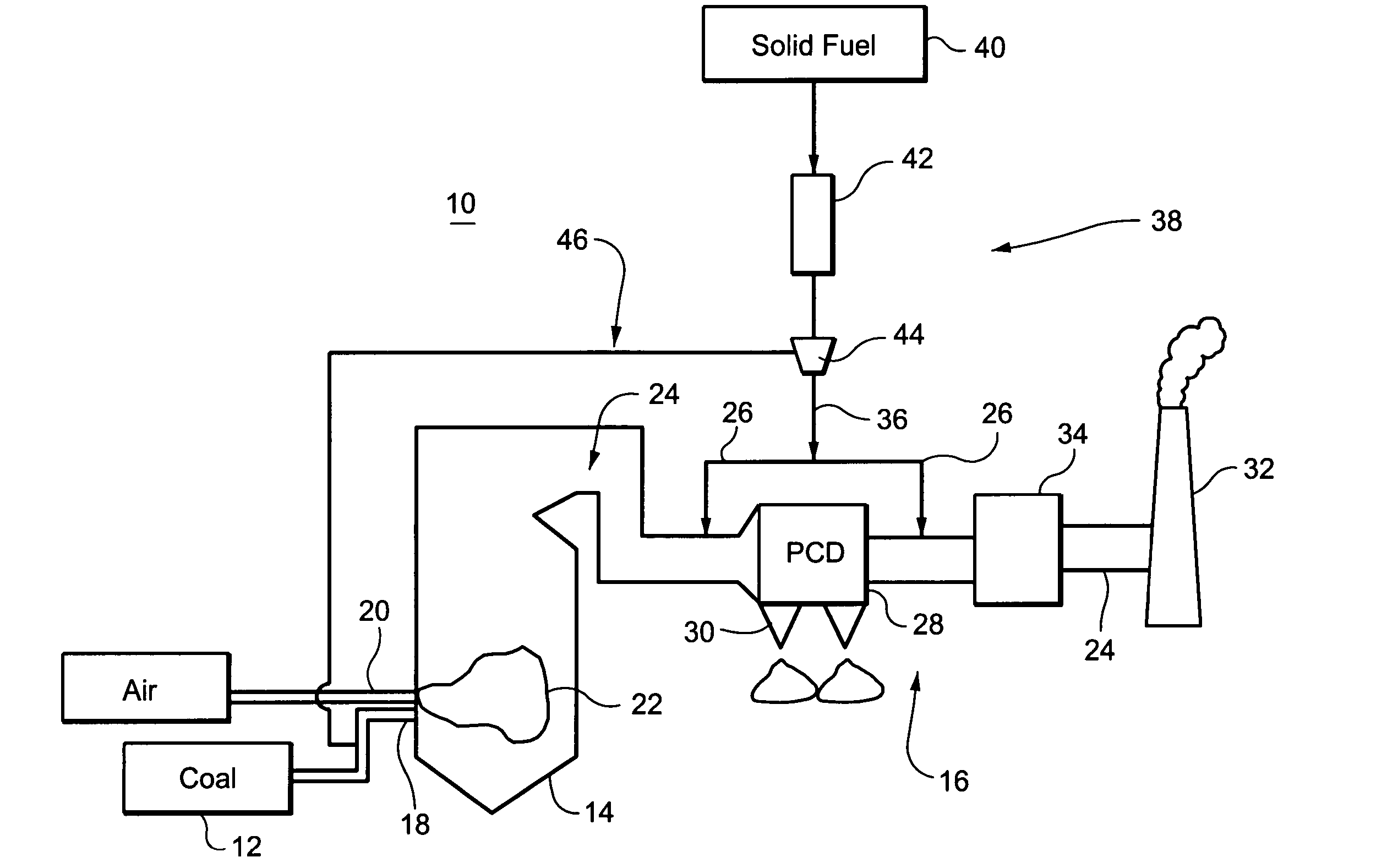

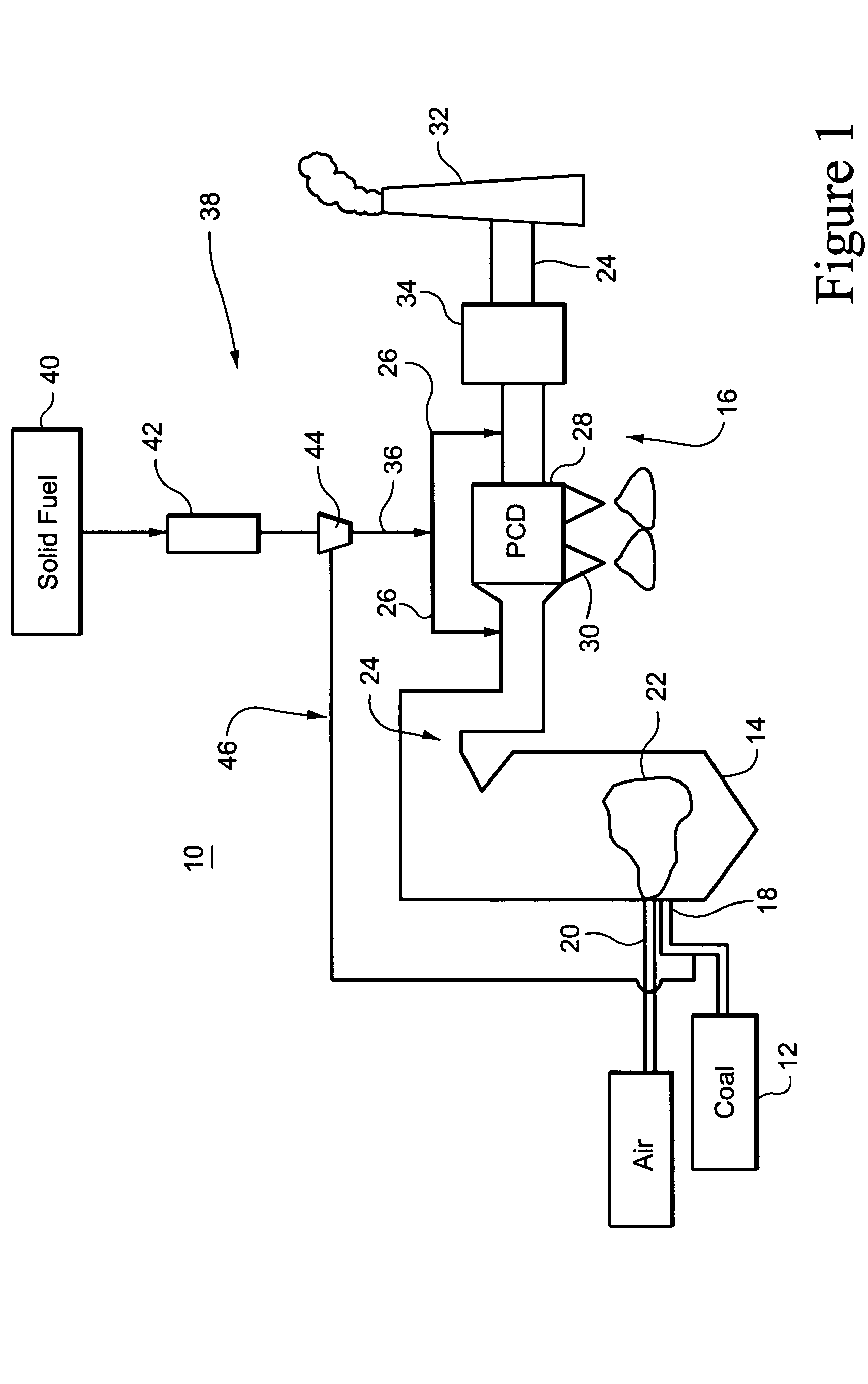

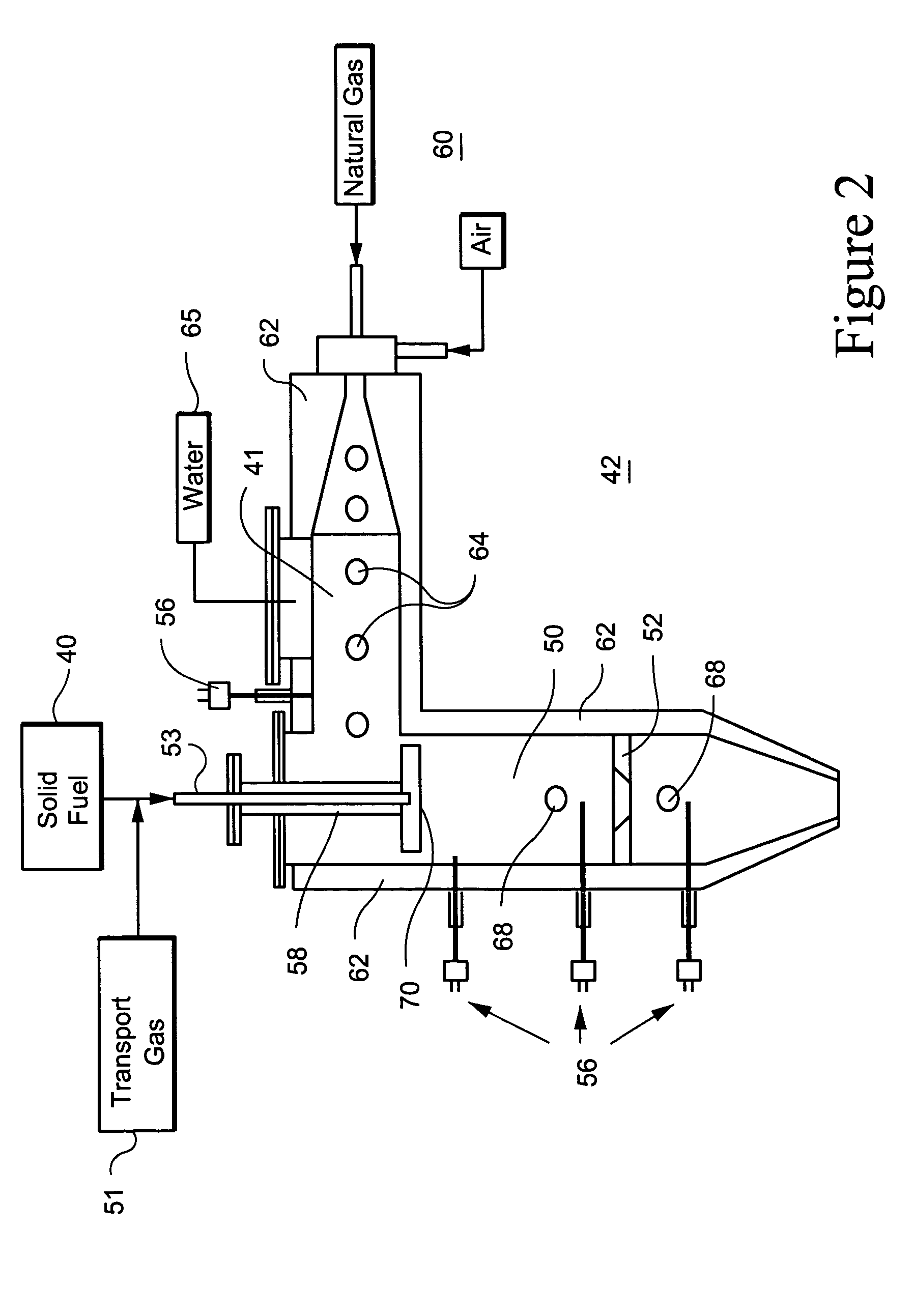

Method and apparatus for utilization of partially gasified coal for mercury removal

A method for capturing mercury in a flue gas formed by solid fuel combustion including: combusting coal, wherein mercury released during combustion is entrained in flue gas generated by the combustion; generating a thermally activated carbon-containing sorbent by partially gasifying a solid fuel in a gasifier local to the combustion of solid fuel; injecting the gasified gas products into the combustion of coal; injecting the thermally activated sorbent in the flue gas, and collecting the injected sorbent in a waste treatment system.

Owner:GENERAL ELECTRIC CO

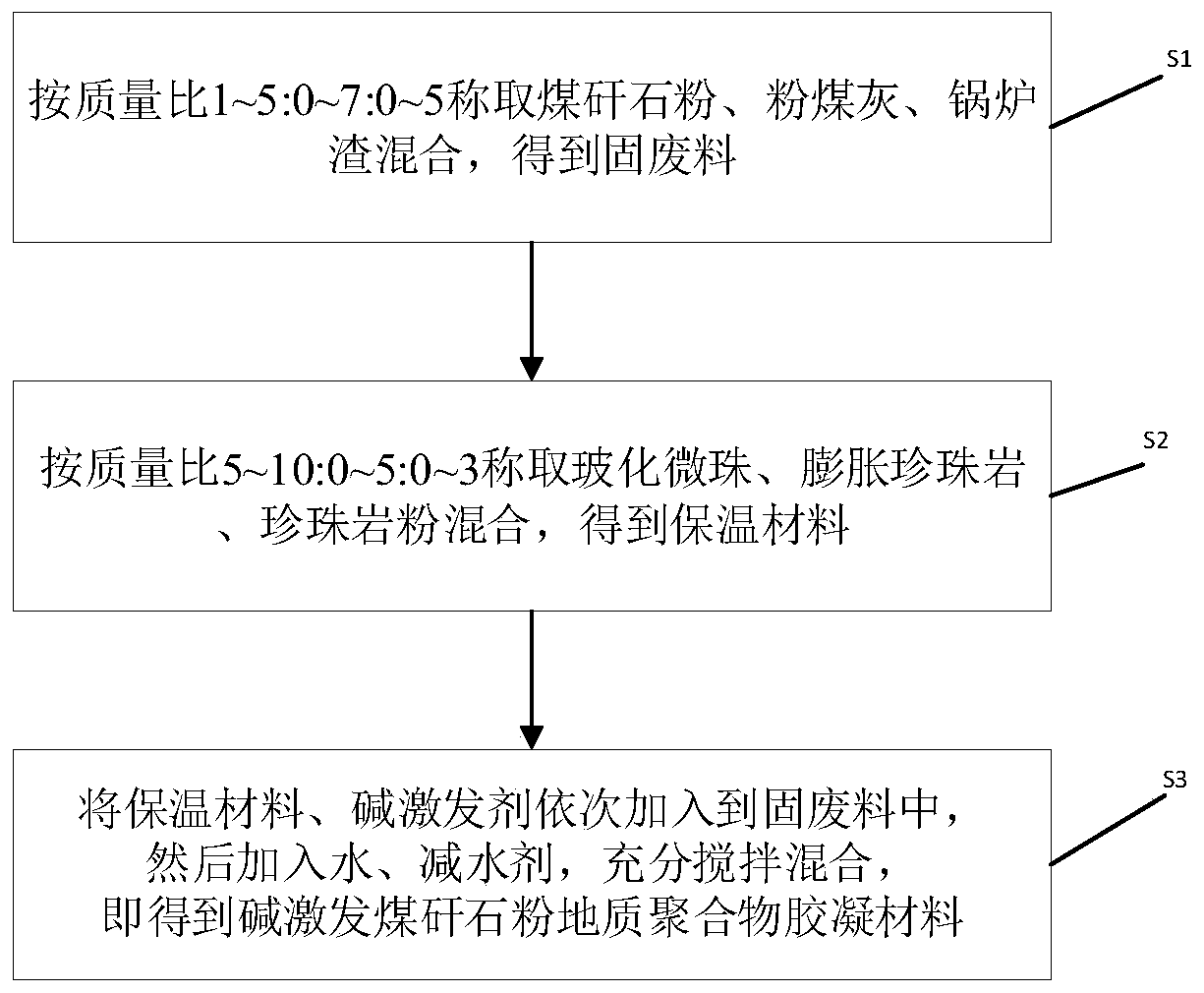

Alkali-activated coal gangue powder geopolymer cementing material and preparation method thereof

ActiveCN111187033AReduce pollutionEffective absorptionCement productionFixation/solidifcation sludge treatmentThermal insulationWater reducer

The invention provides an alkali-activated coal gangue powder geopolymer cementing material, which is prepared by mixing solid waste, a thermal insulation material, an alkali activator, a water reducing agent and water, wherein a mass ratio of the thermal insulation material to the solid waste is (0.3-0.6):1, a mass ratio of the alkali activator to the solid waste is (0.06-0.08):1, a mass ratio ofthe water reducing agent to the solid waste is (0.007-0.01):1, a mass ratio of the water to the solid waste is (0.3-0.6):1, the solid waste is composed of coal gangue powder, fly ash and boiler slagaccording to a mass ratio of (1-5):(0-7):(0-5), and the thermal insulation material is composed of vitrified micro-beads, expanded perlite and perlite powder according to a mass ratio of (5-10):(0-5):(0-3). The invention also provides a preparation method of the alkali-activated coal gangue powder geopolymer cementing material.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for activating coal gangue and/or coal ash by using red mud

ActiveCN103420406AReduce consumptionImplement co-processingSilicaSolid waste disposalRed mudCo-processing

The invention discloses a method for activating coal gangue and / or coal ash by using red mud. The method comprises the following steps: mixing coal gangue and / or coal ash with a certain amount of red mud and Na2CO3; sintering at 600-1000 DEG C to obtain sintered clinker with high reactivity; reacting the sintered clinker and a hydrochloric acid solution with the mass concentration of 15-25% at 80-120 DEG C to extract alumina, wherein in the mixture, the dissolution rate of the alumina can be more than 90%. By the method, the consumption of activating additive alkali can be reduced, co-processing of the red mud and the coal gangue and / or coal ash can be achieved, and a foundation for following use of the coal gangue and / or coal ash is laid.

Owner:SHANXI UNIV

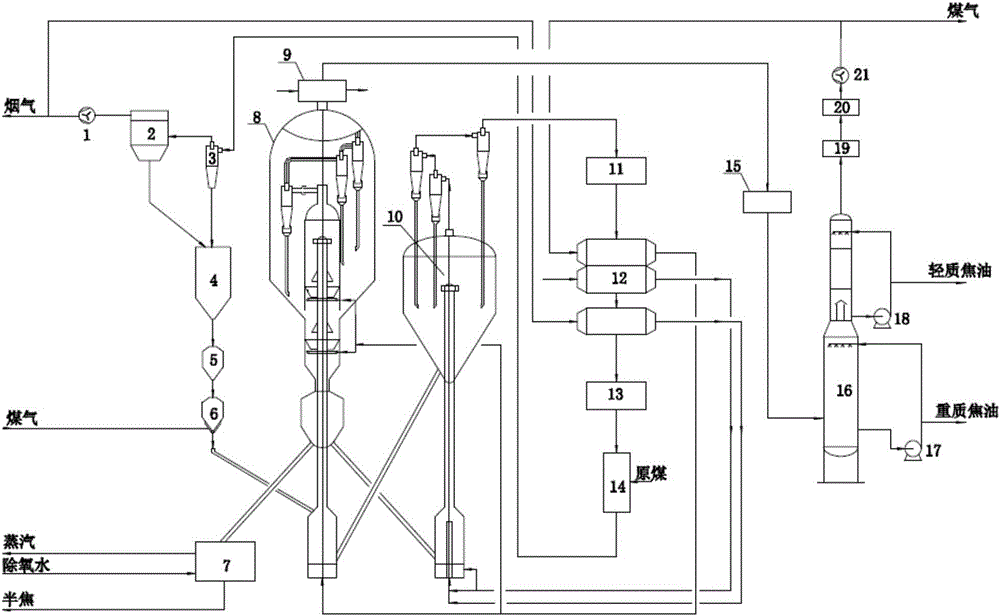

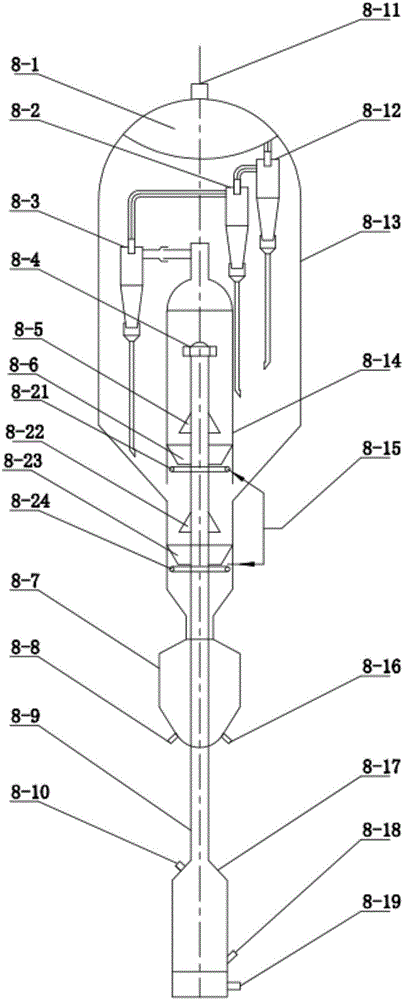

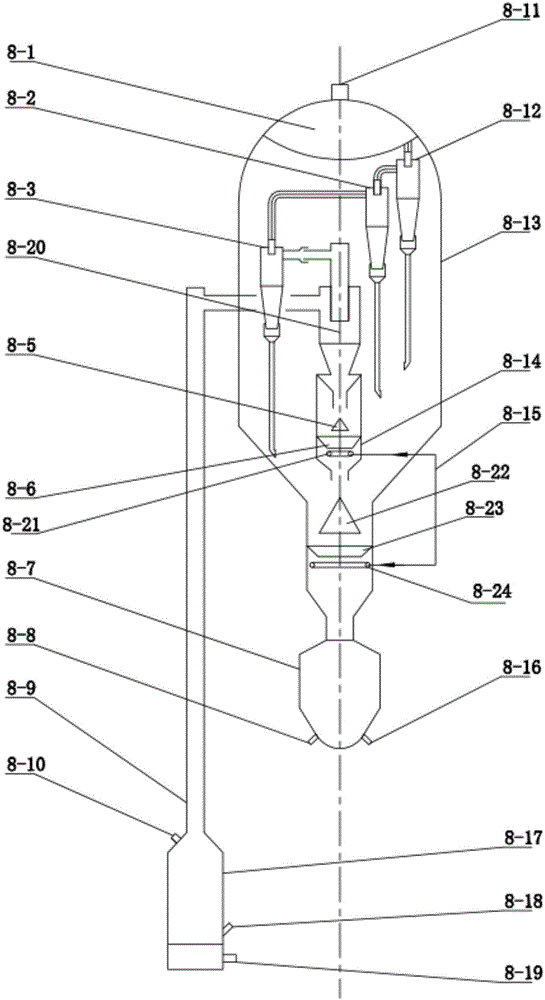

System and method for preparing coal tar, gas and semi-coke by activating coal gas and flash pyrolysing coal with solid heat carrier

ActiveCN106753491AHigh yieldShort stayDirect heating destructive distillationSpecial form destructive distillationHeat carrierHigh energy

The invention relates to a system and method for preparing coal tar, gas and semi-coke by activating coal gas and flash pyrolysing coal with a solid heat carrier. The system comprises a raw coal primary processing apparatus, a pyrolytic reaction separator, a semi-coke heating separator, a recycling apparatus, a coak tar recovering apparatus and a semi-coke cooling apparatus; a part of semi-coke powder discharged from the pyrolytic reaction separator enters the semi-coke heating separator, high-temperature smoke discharged from the semi-coke heating separator enters the recycling apparatus, the coal tar recovering apparatus produces coal tar and coal gas, and the semi-coke cooling apparatus produces semi-coke. In the existing coal tar preparation method, the coal pyrolytic optimization of the coal is not good, so that the existing coat tar preparation method has the technical problems of low oil yield, high investment and high energy consumption. The system for preparing the coal tar, gas and semi-coke by activating the coal gas and flash pyrolysing the coal with the solid heat carrier is rapid in pyrolysis, rapid in output and rapid in cooling.

Owner:陕西凯德利能源科技有限公司

Concrete reinforced water-retaining internal curing material and preparation method thereof

The invention discloses a concrete reinforced water-retaining internal curing material and a preparation method thereof. The method comprises the following steps: respectively weighing the following components in parts by weight: 10 parts of acrylic acid, 4 parts of acrylamide, 3 parts of ground zeolite powder, 2 parts of activated coal gangue powder, 0.005 part of N,N-methylene bisacrylamide and 0.1 part of potassium persulfate, adding the components into a container, uniformly stirring, dropwise adding a NaOH solution, uniformly stirring until the neutralization degree is 60 percent, reacting for 10 hours, and drying, thereby obtaining a solid cross-linking agent; weighing the solid cross-linking agent, coal ash beads, silica colloidal particles, phosphorus gypsum, natural alunite, magnesium oxide and calcium oxide according to the weight ratio of 82:5:4:3:3:2:1, adding the mixture into a ball mill, and grinding, thereby obtaining the concrete reinforced water-retaining internal curing material. The concrete reinforced water-retaining internal curing material disclosed by the invention is excellent in water retention capacity, pores reserved by water release inside concrete filled with the traditional internal curing material can be canceled, the compaction rate and strength of the concrete are guaranteed, the later maintenance cost is greatly reduced, the self-shrinkage within 28 days is reduced by 50-80 percent compared with that of common concrete, and the compressive strength is improved by 5-10 percent.

Owner:CHANGAN UNIV

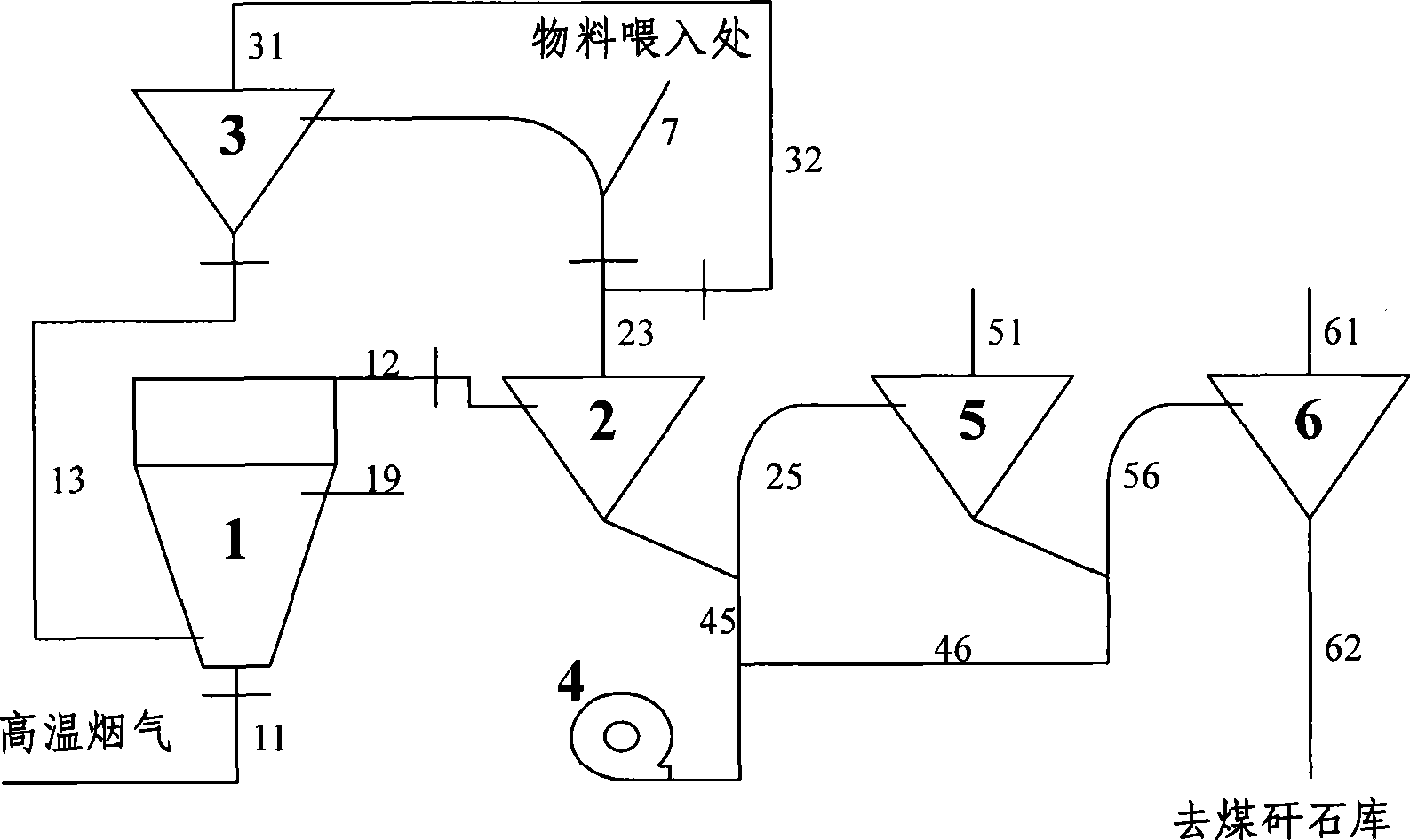

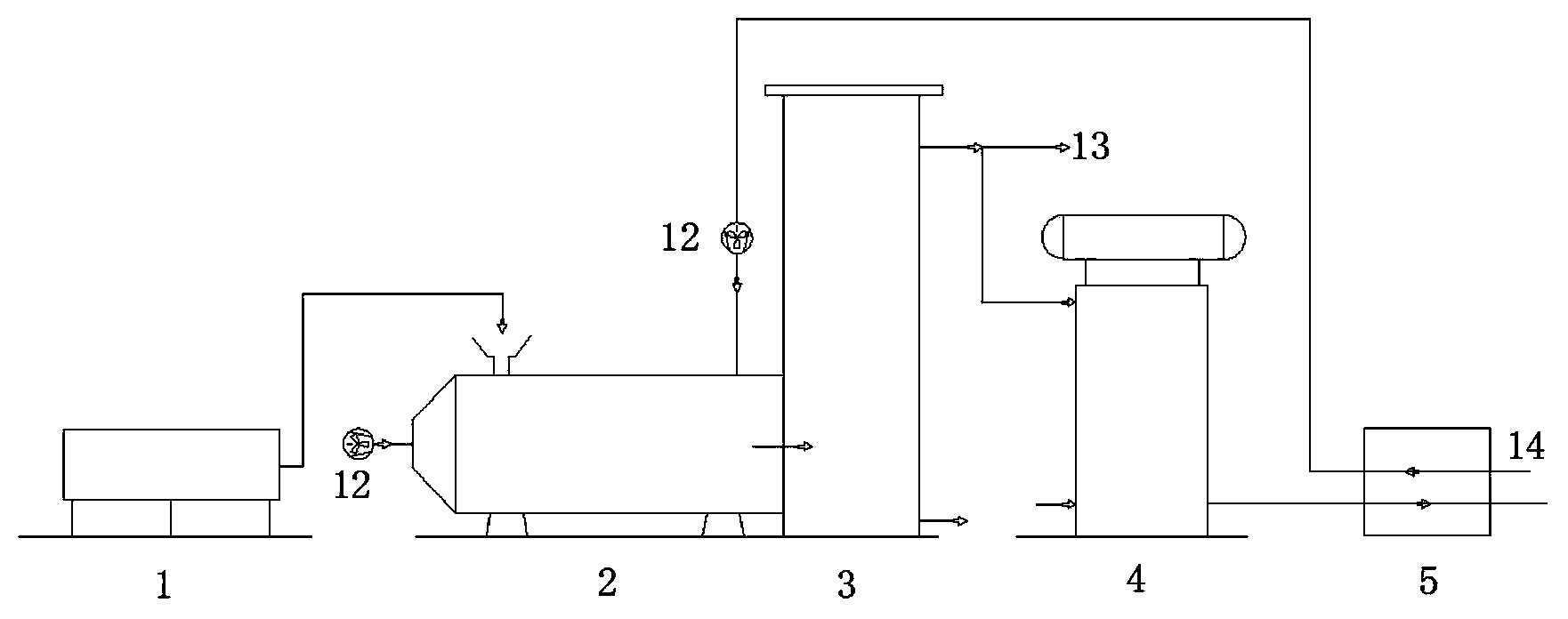

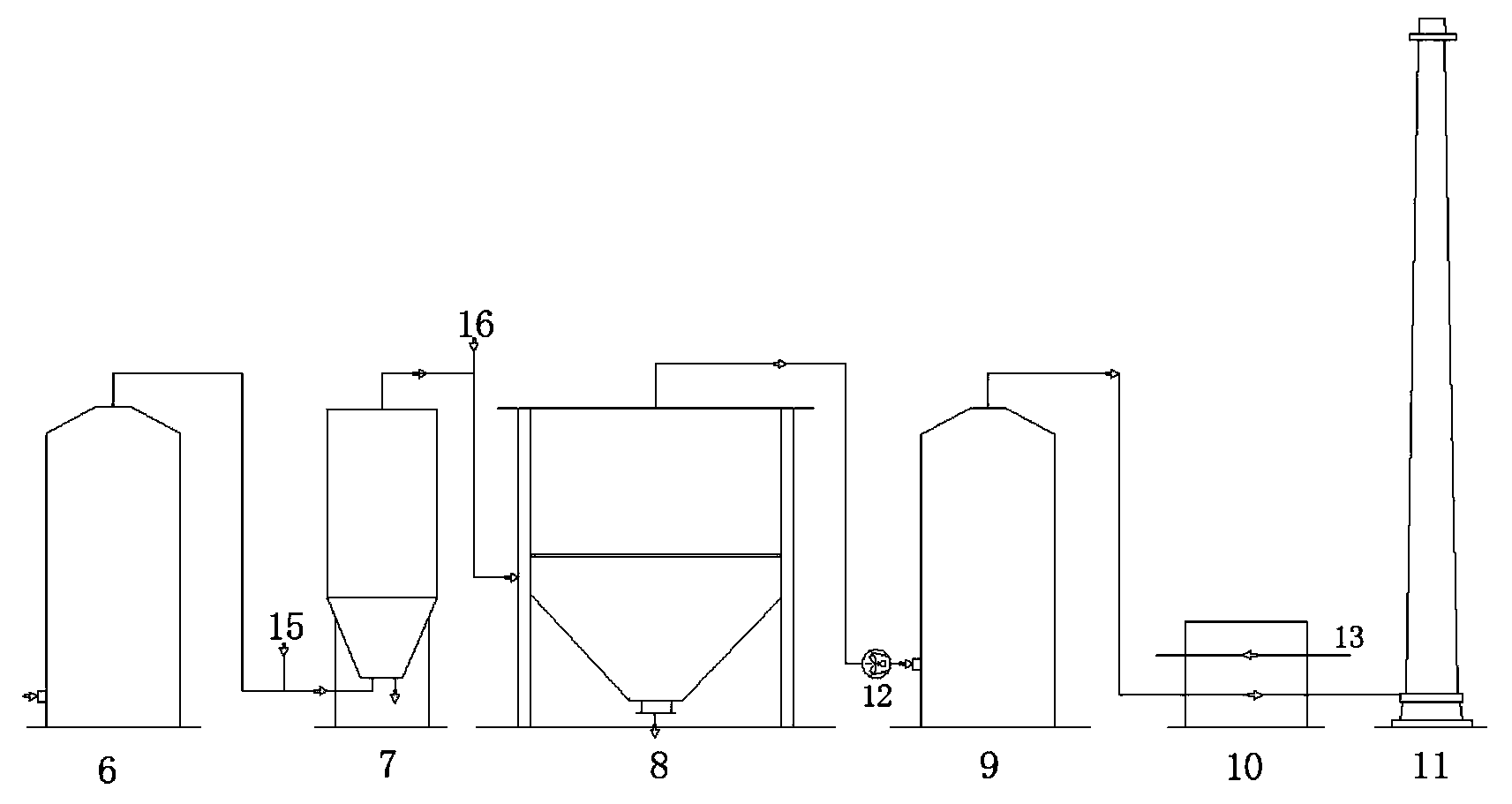

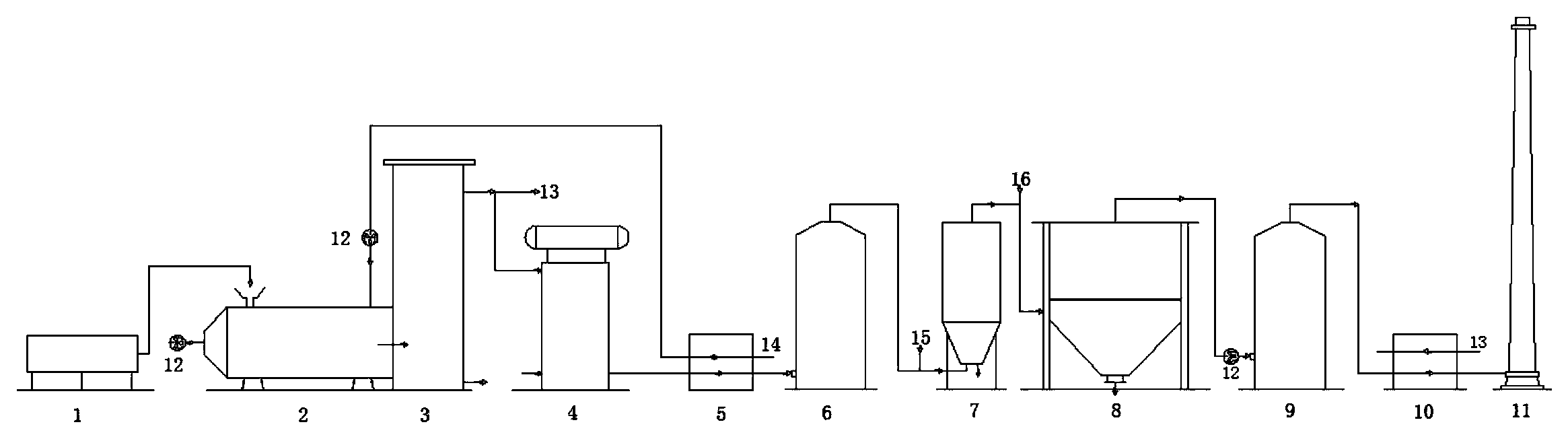

Production system of suspended-state calcined coal gangues

ActiveCN103864325AImprove thermal efficiencyHigh activitySolid waste managementCold airDecomposition

The invention discloses a production system of suspended-state calcined coal gangues. The production system comprises a material preparing and feeding sub system, a preheating and decomposition furnace-calcining sub system, a product cooling and heat-recycling sub system, a hot air preparing and supplying sub system and a system power and waste gas-purifying sub system, wherein the material preparing and feeding sub system is used for quantitatively and stably supplying coal gangue powder to a pre-heater; the preheating and decomposition furnace-calcining sub system is used for preheating materials to a set temperature under a suspended state, and decomposing and sintering the materials in a decomposition furnace; the product cooling and heat recycling sub system is used for sucking in cold air to cool the sintered materials under the suspended state to obtain low-temperature activated coal gangues; the hot air preparing and supplying sub system is used for ventilating hot air to the hot air furnace for burning pulverized coal or fluidized block coal, and providing hot air to the decomposition furnace of the preheating and decomposition furnace-calcining sub system, wherein the hot air is from the product cooling and heat-recycling sub system; and the system power and waste gas purifying sub system is used for providing gas flow power to the preheating and decomposition furnace-calcining sub system, purifying all waste gas of the preheating and decomposition furnace-calcining sub system and excessive gas emitted by the hot air preparing and supplying sub system. The production system disclosed by the invention can massively, efficiently, continuously and stably produce and process high-activity cinerite coal gangues.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for preparing flocculant aluminum polychlorid by utilizing coal ash

ActiveCN107628632AChange shapeEfficient removalAluminium chloridesWater/sewage treatment by flocculation/precipitationMicrowaveAluminium chlorohydrate

The invention belongs to the technical field of flocculant production and specifically relates to a method for preparing flocculant aluminum polychlorid by utilizing coal ash. The method for preparingflocculant aluminum polychlorid by utilizing coal ash comprises the following steps: grinding and sieving the coal ash and using aqueous alkali for ultrasonically treating; mixing the coal ash treated with alkali, compound sodium additive and water and then activating with microwave, thereby acquiring pre-activated coal ash; calcinating and activating the pre-activated coal ash under high temperature, thereby acquiring the secondary pre-activated coal ash; performing acid leaching and high-temperature high-pressure acid solution on the secondary pre-activated coal ash, and then using calciumaluminate mineral powder for regulating the basicity, thereby acquiring the aluminum polychlorid. The method provided by the invention is simple in operation and low in cost, is suitable for industrial production, utilizes the coal ash as the raw material and is capable of turning waste into wealth, reducing the production cost and avoiding the environmental pollution caused by the waste coal ashsolid.

Owner:唐山中絮工业水处理有限公司

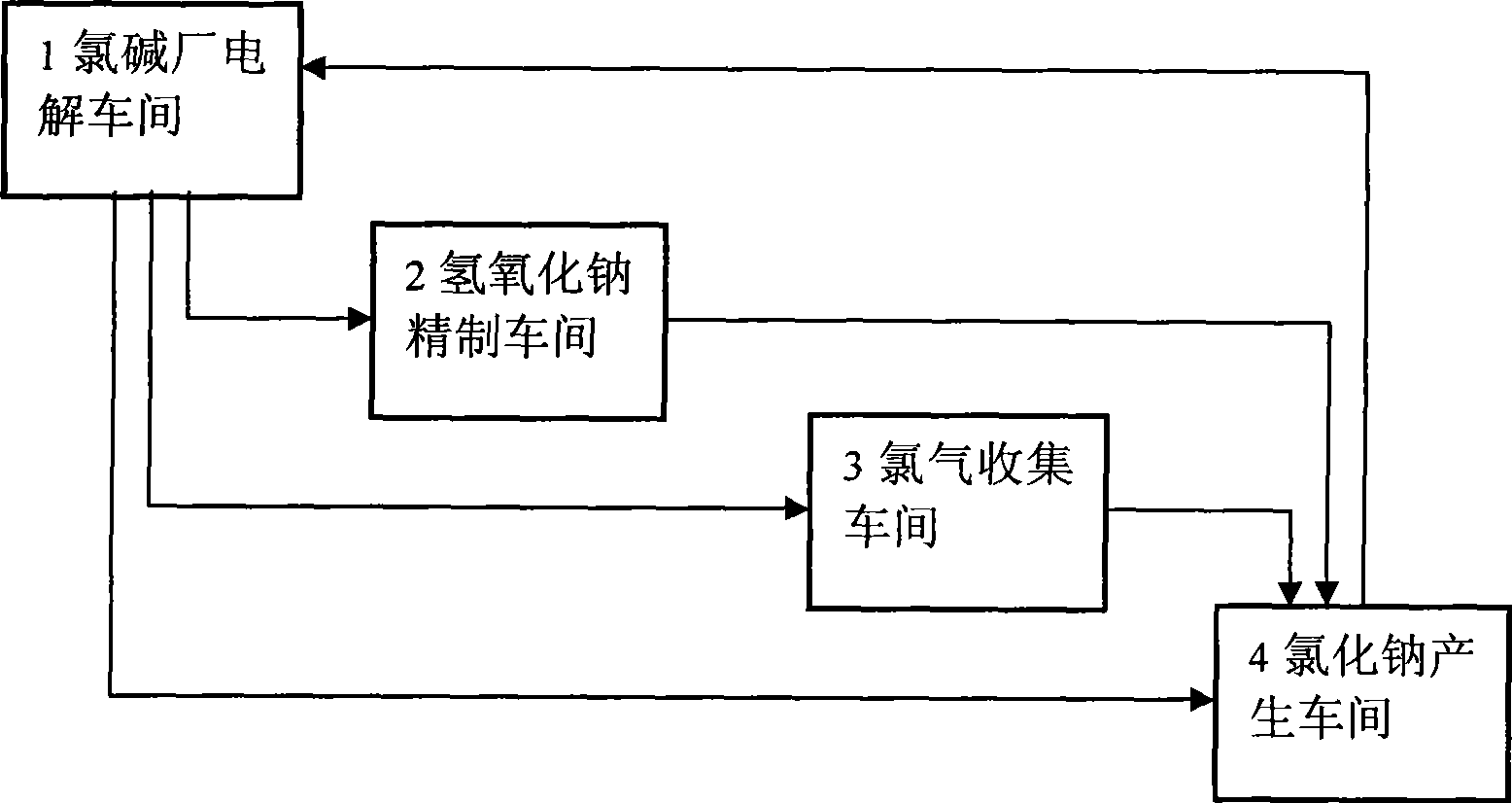

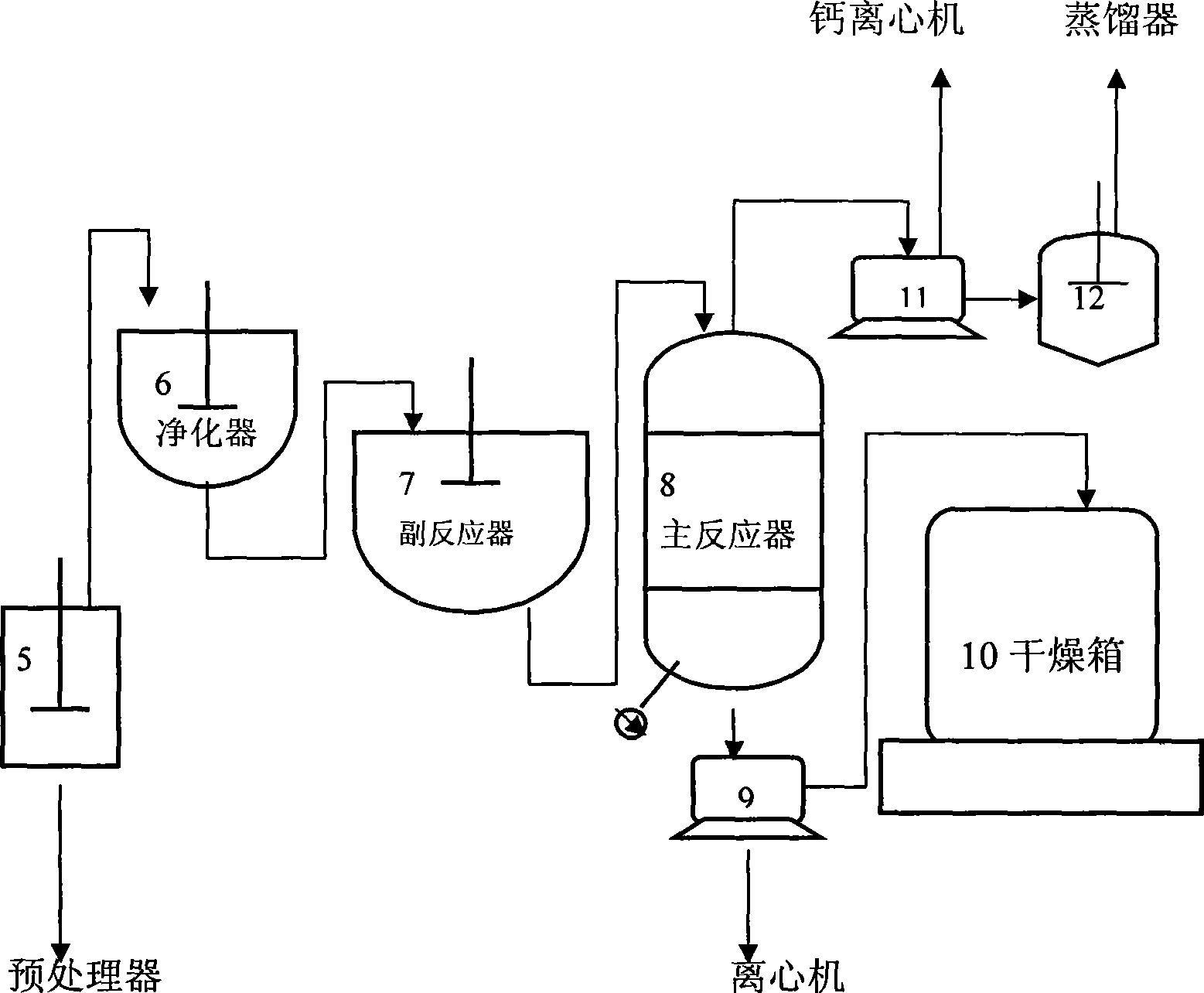

Material circulation system formed by waste carbide mud residue and alkali-chloride industry

InactiveCN101456026ASolve disposal problemsSolve the problem of raw materialsElectrolysis componentsSolid waste disposalElectrolysisCalcium Chloride Hexahydrate

The invention discloses a material circulating system formed by waste acetylene sludge and the chlor-alkali industry. The system comprises: pretreated waste acetylene sludge is reacted with hydrochloric acid, the reaction product is filtered to obtain a calcium chloride solution; the filtrate is reacted with sodium hydroxide generated by electrolysis of a chlor-alkali factory to generate high-purity calvital; the calvital is chloridized, centrifugated, dried and crushed to prepare bleaching powder; and filter cakes are reacted with the hydrochloric acid to generate active carbon. The calcium chloride generated in the reaction can be prepared into calcium chloride dihydrate and anhydrous calcium chloride; and sodium chloride after treatment can be taken as a raw material for electrolysis. The material circulating system effectively solves the problem of treating the waste acetylene sludge and raw material problem in the chlor-alkali industry, embodies recycling economy; and byproducts of the bleaching powder and the active carbon and calcium chloride dihydrate products improve deep processing capacity of an enterprise.

Owner:南通宙亚电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com