Residual oil hydrogenation catalyst as well as preparation method and application thereof

A residue hydrogenation and catalyst technology, applied in the field of coal chemical industry, can solve the problems of easy blockage of microporous structure and easy coking of catalysts, so as to improve the metal removal rate, improve the conversion rate of residue oil and liquid yield, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

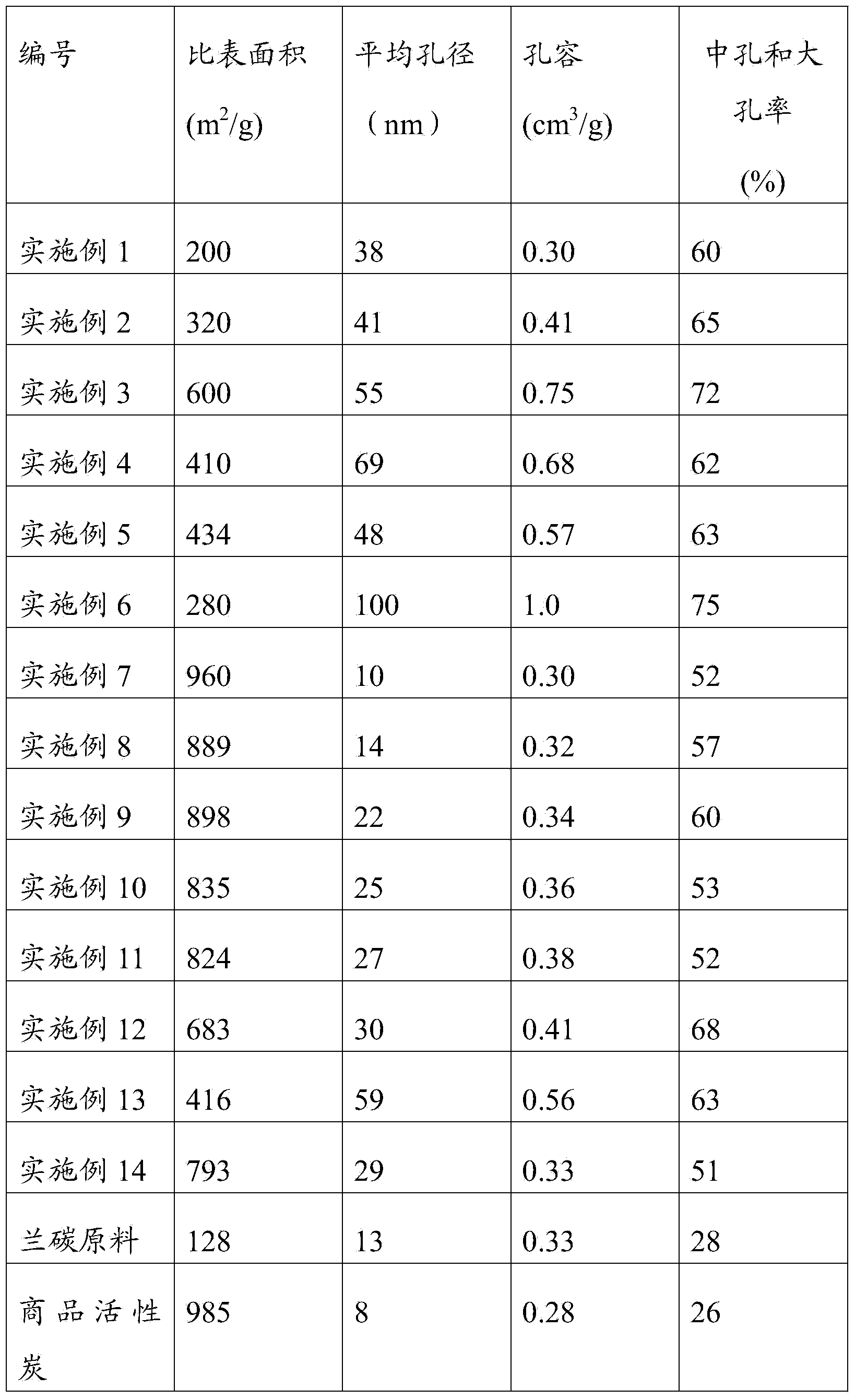

Examples

Embodiment 1

[0031] (1) Crush the blue carbon raw material, pass through a 280-mesh sieve, dry at 120°C to remove water, place it in a high-temperature furnace, and treat it at 1500°C for 8.0 hours under the protection of an inert gas, and take it out when the temperature drops to room temperature;

[0032] (2) After dry mixing the graphitized carbon material and KOH pore expander at a mass ratio of 1:2, place it in a tube furnace with a mixed atmosphere of oxygen and nitrogen (volume ratio 1:9) , carry out hole expansion treatment at 500°C for 0.5h;

[0033] (3) After acid washing and water washing, the reamed sample was centrifuged and dried at 100°C for 3 hours to obtain the graphitized pore reamed blue carbon carrier;

[0034] (4) Weigh 150g FeSO 4 ·7H 2 O is used as the precursor of the active component, and it is impregnated onto 100 g of the above-mentioned graphitized pore-expanding blue carbon by the equal volume impregnation method. After the impregnation, it is dried at 120°C ...

Embodiment 2

[0037] (1) Crush the blue carbon raw material, pass through a 280-mesh sieve, dry at 120°C to remove water, place it in a high-temperature furnace, and treat it at 1500°C for 3.0 hours under the protection of an inert gas, and take it out when the temperature drops to room temperature;

[0038] (2) Combine the graphitized carbon material with Na 2 CO 3 After the pore-enlarging agent is dry-mixed evenly with a mass ratio of 1:4, it is placed in a tube furnace with a mixed atmosphere of oxygen and helium (volume ratio 1:9), and the pore-enlarging treatment is performed at 700°C for 6 hours;

[0039] (3) After acid washing and water washing, the reamed sample was centrifuged and dried at 100°C for 3 hours to obtain the graphitized pore reamed blue carbon carrier;

[0040] (4) Weigh 118g FeSO 4 ·7H 2 O and 0.9g (NH 4 ) 6 Mo 7 o24 4H 2 O is used as the precursor of the active component, and it is impregnated onto 100 g of the above-mentioned graphitized pore-expanding blue c...

Embodiment 3

[0043] (1) Crush the blue carbon raw material, pass through a 280-mesh sieve, dry at 120°C to remove water, place it in a high-temperature furnace, and treat it at 1700°C for 6.0 hours under the protection of an inert gas, and take it out when the temperature drops to room temperature;

[0044] (2) Combine graphitized carbon material with K 2 CO 3 After the pore-enlarging agent is dry-mixed uniformly with a mass ratio of 1:6, it is placed in a tube furnace with a mixed atmosphere of oxygen and nitrogen (volume ratio 1:9), and the pore-enlarging treatment is performed at 800°C for 12 hours;

[0045] (3) After acid washing and water washing, the reamed sample was centrifuged and dried at 100°C for 3 hours to obtain the graphitized pore reamed blue carbon carrier;

[0046] (4) Weigh 123g ammonium ferrous sulfate ((NH 4 ) 2 SO 4 ·FeSO 4 ·6H 2 O) and 3.2g (NH 4 ) 6 MO 7 o 24 4H 2 O is used as the precursor of the active component, and it is impregnated onto 100 g of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com