Biomass activated carbon, preparation method thereof and application thereof in flue gas mercury removal

A technology of activated carbon and biomass, applied in the fields of biomass utilization and pollutant removal, can solve the problems of low yield, complicated steps, strict preparation conditions, etc., and achieve the effects of low production cost, simple production equipment and easy production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

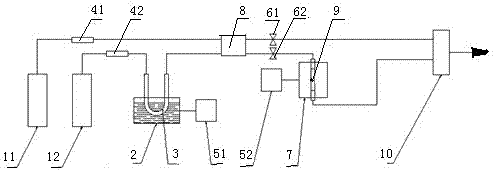

Method used

Image

Examples

Embodiment 1

[0050] With the peanut shell of Tanghe County, Henan Province as raw material, a kind of biomass activated carbon of the present invention is prepared, comprising the following steps:

[0051] (1) Pretreatment of biomass raw materials

[0052] Wash the peanut shells with clean water and dry them in an oven; after drying, transfer the raw materials to a mortar for grinding and pass through a 60-mesh sieve;

[0053] (2) Activation of biomass raw materials

[0054] Immersing the pretreated biomass raw material peanut shells in the step (1) with an activator zinc chloride solution for 20h-30h;

[0055] The concentration of the zinc chloride aqueous solution used is 20%; 30%; 40%; 50%;

[0056] (3) Carbonization of biomass raw materials

[0057] The impregnated biomass raw material obtained in step (2) is placed in a nitrogen-protected environment, and the temperature is controlled to be 400°C; 500°C; 600°C; 700°C; the time is 1.5h; 2h; 2.5h; 3h, Carry out carbonization, ta...

Embodiment 2

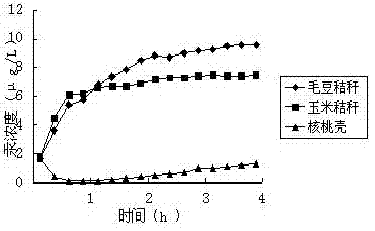

[0059] Taking the walnut shell of Tanghe County, Henan Province as raw material, a kind of biomass activated carbon of the present invention is prepared, comprising the steps:

[0060] (1) Pretreatment of biomass raw materials

[0061] Wash the walnut shells with clean water and dry them in an oven; after drying, transfer the raw materials to a mortar for grinding and pass through a 60-mesh sieve;

[0062] (2) Activation of biomass raw materials

[0063] Immersing the pretreated biomass walnut shells in step (1) with an activator zinc chloride solution for 20 to 30 hours;

[0064] The concentration of the zinc chloride aqueous solution used is 20%; 30%; 40%; 50%;

[0065] (3) Carbonization of biomass raw materials

[0066] Carbonize the impregnated biomass raw material obtained in step (2) under a nitrogen-protected environment at controlled temperatures of 600°C; 700°C; 400°C; 500°C for 2h; 1.5h; 3h; 2.5h , take out the carbonized biomass raw material, after natural c...

Embodiment 3

[0068] Using corn stalks in Nanqiao Town, Fengxian District, Shanghai as a raw material, preparing a kind of biomass activated carbon of the present invention comprises the following steps:

[0069] (1) Pretreatment of biomass raw materials

[0070] Wash the corn stalks with clean water and dry them in an oven; after drying, transfer the raw materials to a mortar for grinding and pass through a 60-mesh sieve;

[0071] (2) Activation of biomass raw materials

[0072] Immersing the pretreated biomass raw material corn stalks in step (1) with an activator zinc chloride solution for 20 to 30 hours;

[0073] The concentration of the zinc chloride aqueous solution used is 20%; 30%; 40%; 50%;

[0074] (3) Carbonization of biomass raw materials

[0075] The impregnated biomass raw material obtained in step (2) is placed in a nitrogen-protected environment, and the temperature is controlled to be 700°C; 600°C; 500°C; 400°C; and the time is 2.5h; 3h; 1.5h; 2h, Carry out carboniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com