Preparation method of high specific surface area coal mass active carbon

A technology of coal-based activated carbon and high specific surface area, which is applied in the field of activated carbon preparation in the chemical industry, which can solve the problems of lack of market competitiveness, incomplete post-processing, and high product prices, and achieve low cost, low ash content, and cost savings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Mix 100g of coal-based carbonized material crushed to 20-40 mesh and activator at a ratio of 1:4, add appropriate amount of water to infiltrate, place in a tubular reactor, and then pretreat at 400°C for 0.5h under nitrogen protection, and then Activate at 900°C for 2.5h, then continue to cool to room temperature in a nitrogen atmosphere, and the reactor is operated in a continuous rotation state during the whole process.

[0023] How to recover the by-product potassium metal before discharging and store it in kerosene.

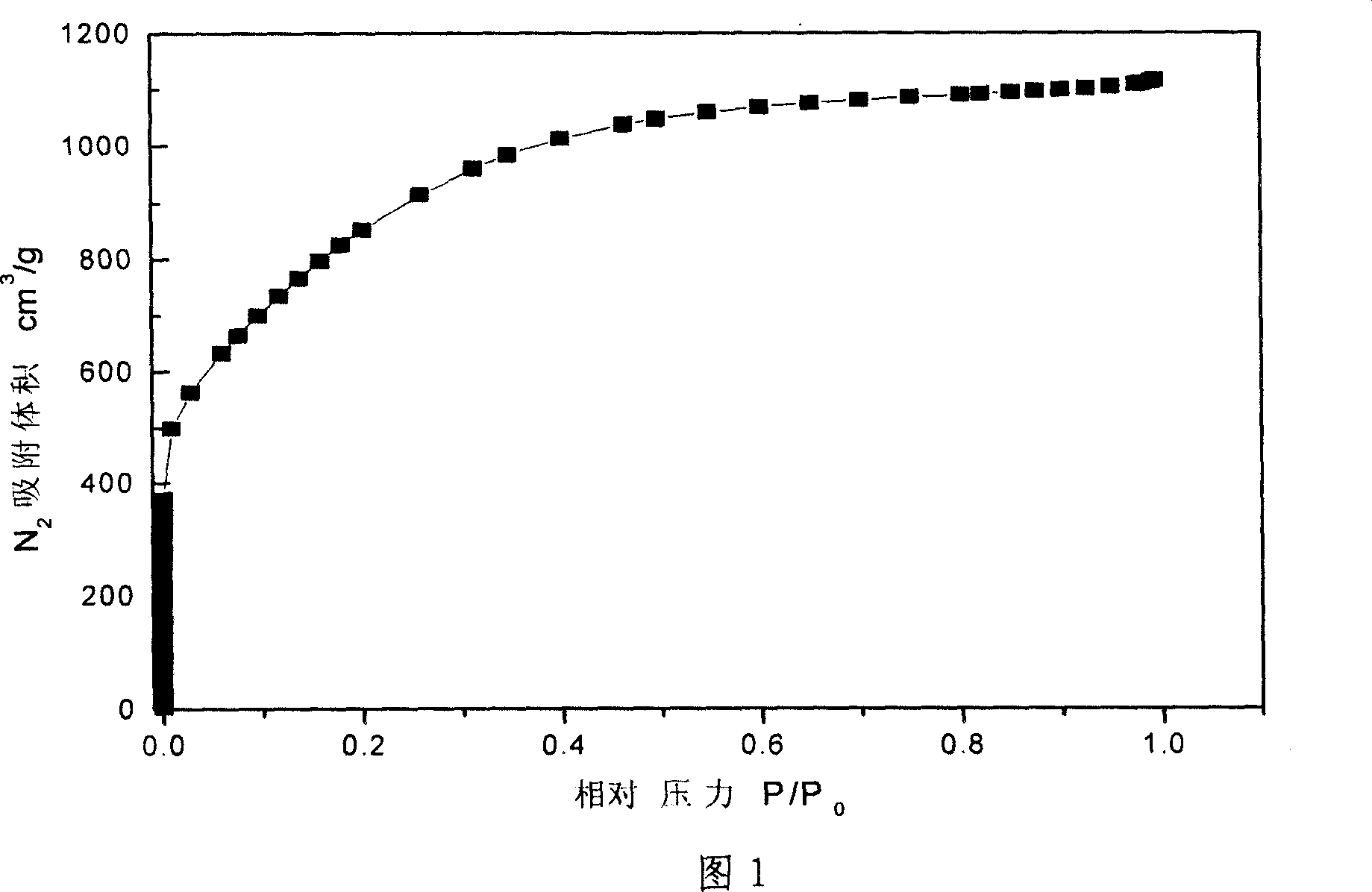

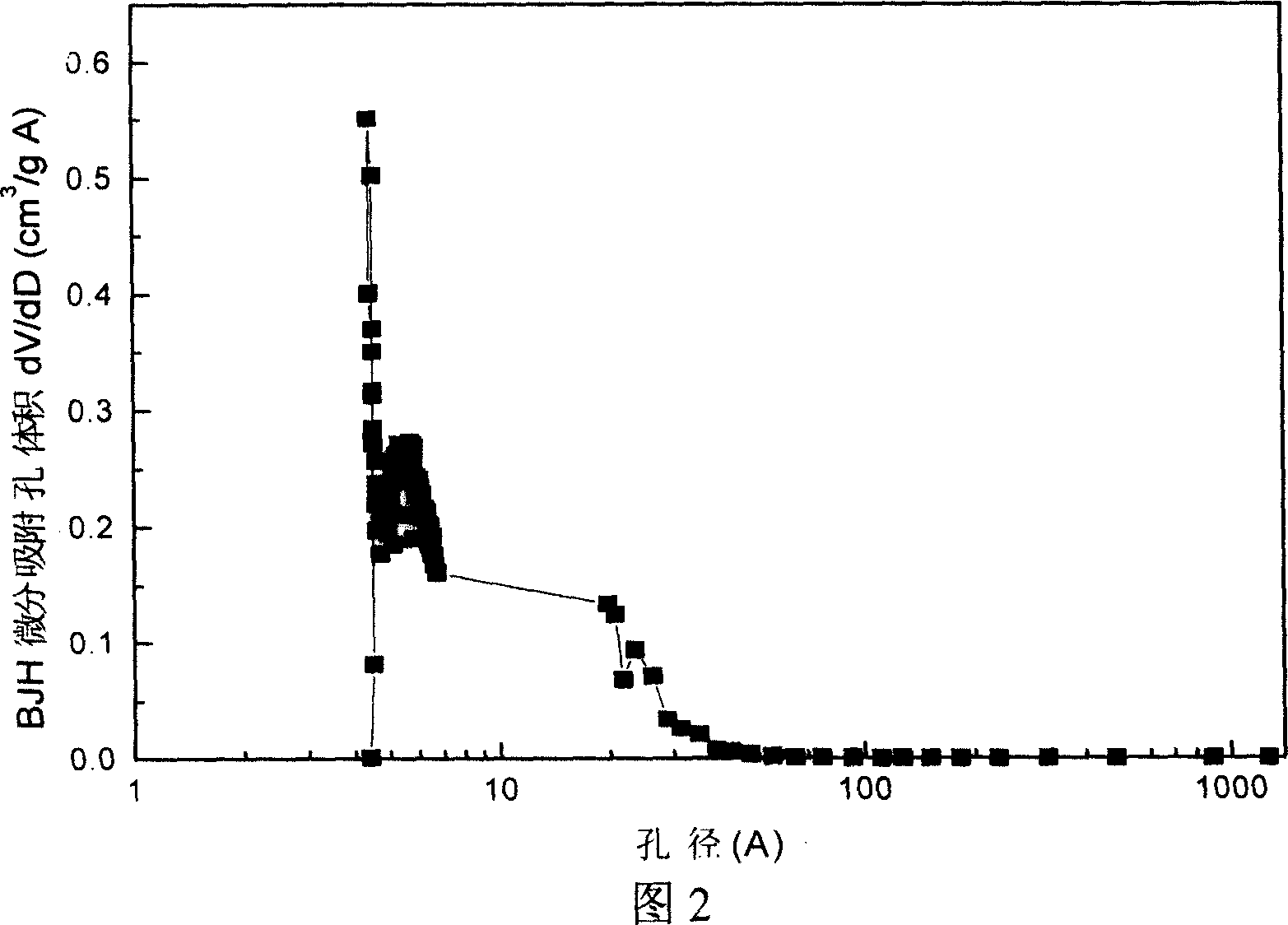

[0024] The activating material is first washed with distilled water, and the residual activator KOH is recovered through waste liquid recovery, and then repeatedly pickled with HCl and alkaline washed with NaOH for 3 times each, and then washed with a large amount of water until the pH value is 6-7, and then heated at 120 ° C. Dry for 12h. After testing, the iodine adsorption value of the activated carbon product was 2657mg / g, the yield was 55%, and t...

example 2

[0026] Mix 100g of coal-based carbonized material pulverized to 20-40 mesh and activator according to the ratio of 1:4, add an appropriate amount of water to infiltrate, place it in a tubular reactor, and then put it under nitrogen (V N2 ==400cm 3 / min) under the protection of 350 ° C for 2 h, and then activated at 850 ° C for 1 h, and then continued to cool to room temperature in a nitrogen atmosphere, and the reactor was intermittently rotated during the whole process. The by-product potassium metal is recovered before discharging and stored in kerosene. The activating material is washed with water first, and the activator is recovered by recycling the waste liquid, and then repeatedly pickled with HCl and washed with NaOH alkali twice, and then washed with a large amount of water until the pH value is 6-7, and then dried at 100°C for 10 hours. The iodine adsorption value of the activated carbon product obtained by this method is 2560mg / g, the yield is 55%, and the specific...

example 3

[0028] Mix 100g of coal-based carbonized material pulverized to 20-40 mesh and activator according to the ratio of 1:3.5, add an appropriate amount of water to infiltrate, place it in a tubular reactor, and then put it under nitrogen (V N2 =200cm 3 / min) under the protection of 450 ° C for 1 h, then activated at 600 ° C for 4 h, and then continued to cool to room temperature in a nitrogen atmosphere, and the reactor was operated continuously during the whole process. The by-product potassium metal is recovered before discharging and stored in kerosene. The activating material is first washed with water, and the activator is recovered by recycling the waste liquid, and then repeatedly washed with oxalic acid and NaOH alkali for 4 times, and then washed with a large amount of water until the pH value is 6-7, and then dried at 150°C for 14 hours. The iodine adsorption value of the activated carbon product obtained by this method is 2500mg / g, the yield is 58%, and the specific su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine adsorption value | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com