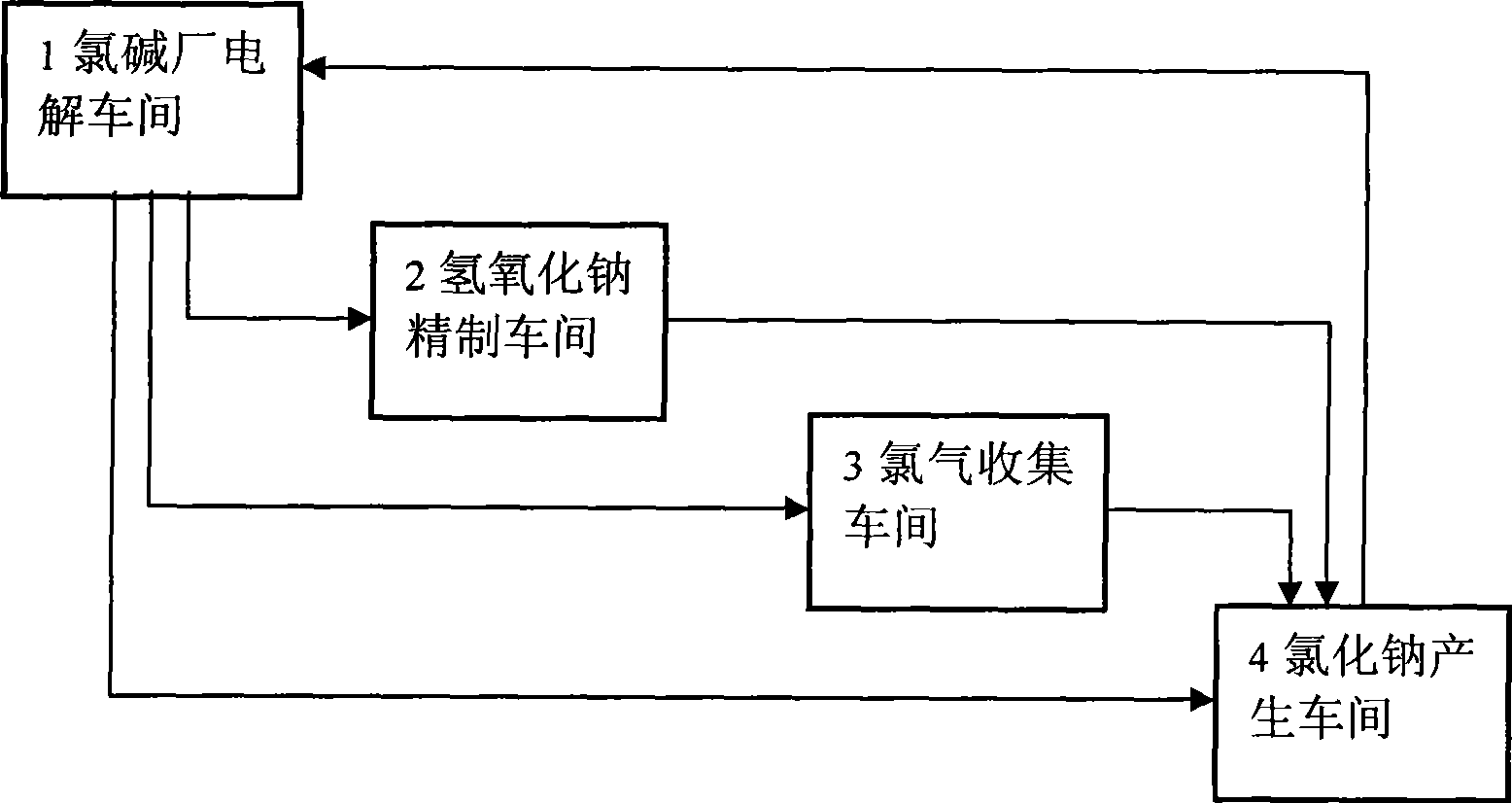

Material circulation system formed by waste carbide mud residue and alkali-chloride industry

A technology of chlor-alkali industry and circulation system, applied in the field of material circulation system, can solve problems such as large land, polluted environment, occupation, etc., and achieve the effect of improving deep processing ability, improving economic benefit and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

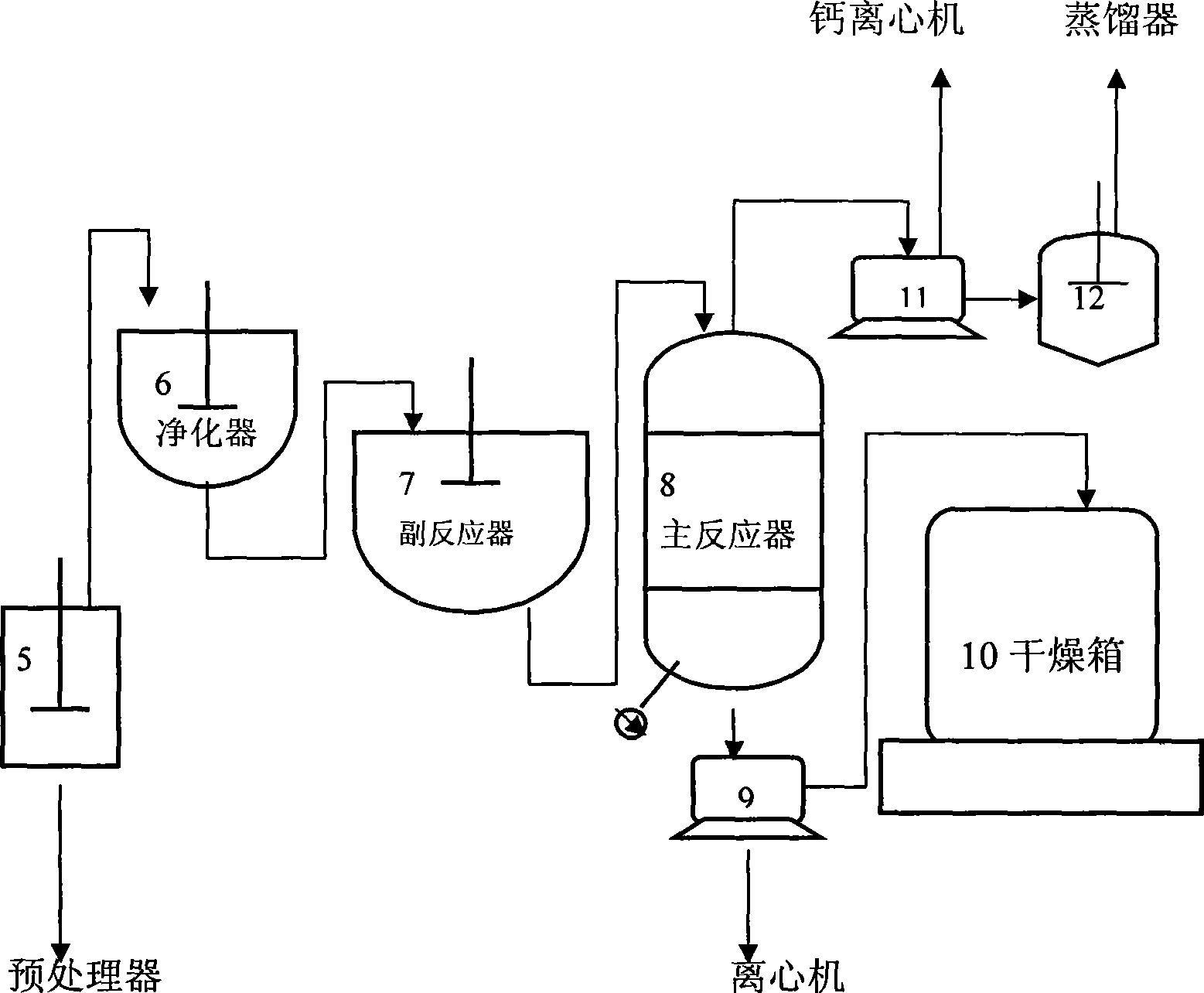

[0032] 100kg of calcium carbide slag (calcium hydroxide content is 85%; dry material) and 300kg of water are injected into the preprocessor 5 with a stirring device and stirred to form a uniform emulsion, and naturally settle for 30s to form suspended calcium hydroxide emulsion Calcium hydroxide emulsion and hydrochloric acid are injected into the purifier 6 according to the quality of pure substance 1:0.8, and stirred for 10 minutes to make the substance completely react. After the reaction solution is filtered, calcium chloride filtrate and filter cake are formed; calcium chloride filtrate The sodium hydroxide generated by electrolysis is injected into the secondary reactor 7 according to the pure substance quality 1:0.6 and stirred to generate high-purity calcium hydroxide and relatively pure sodium chloride solution containing 93.28kg of solute, and the sodium chloride solution is refined by soda ash and hydrochloric acid Afterwards, it is sent to the electrolysis workshop ...

Embodiment 2

[0034] The process flow is as in Example 1, 100kg of calcium carbide slag (calcium hydroxide content is 85%; dry material) and 600kg of water, natural sedimentation for 50s, calcium hydroxide emulsion and hydrochloric acid according to the pure substance quality 1:1.2, stirred for 10 minutes , the calcium chloride filtrate and the sodium hydroxide that electrolysis generates are by pure substance quality 1:1.1, make comparatively pure sodium chloride solution containing solute 134.39kg, high-purity calcium hydroxide and chlorine gas pure substance quality 1:1.1, complete bleaching 87.44kg of fine powder finished product, filter cake is reacted with the hydrochloric acid solution of concentration 10%, both obtained 6kg of high-quality activated carbon products, made 52.98kg calcium chloride dihydrate.

Embodiment 3

[0036] The process flow is as in Example 1, 100kg of calcium carbide slag (calcium hydroxide content is 85%; dry material) and 200kg of water, natural sedimentation for 20s, calcium hydroxide emulsion and hydrochloric acid according to the pure substance quality 1:0.6, stirred for 10 minutes , the calcium chloride filtrate and the sodium hydroxide generated by electrolysis press the pure substance quality 1:0.4 to obtain a relatively pure sodium chloride solution containing 46.64kg of solute, high-purity calcium hydroxide and chlorine gas pure substance quality 1:0.4, and the bleaching process is completed. 16.87kg of fine powder finished product, filter cake reacts with the hydrochloric acid solution of concentration 10%, both obtains 6kg of high-quality activated carbon products, makes 10.22kg calcium chloride dihydrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com