Patents

Literature

50results about How to "Solve the problem of raw materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production of non-directional cold-rolling silicon steel disc

InactiveCN1982483ASolve the problem of raw materialsReduce rolling forceTemperature control deviceHeat treatment process controlAcid washingPre treatment

Production of non-orientated cold-rolling silicon steel sheet is carried out hot milling, conventionally treating, acid washing, primary cold rolling, intermediate annealing, secondary cold rolling and product annealing. It costs low and has better quality, and it can decrease rolling force and has less harmful elements. It can be used to produce medium and small electric motor.

Owner:上海申群物资有限公司

New techn of utilizing crushed cotton stalk in cultivating edible fungi

The new technology of utilizing crushed cotton stalk in cultivating edible fungi includes crushing cotton stalk into filament, utilizing the filament as main material for the edible fungus culture medium, and spraying Gufengling bacterial liquid in proper amount. The edible fungus culture medium has the composition of cotton stalk 75-90 wt%, supplementary material 10-25 wt% and Gufengling bacterial liquid 0.01-0.05 wt%. The edible fungus culture medium of the present invention has the features of easy-to-obtain material, rich nutrients, low cost, high edible fungus yield, etc.

Owner:符振强

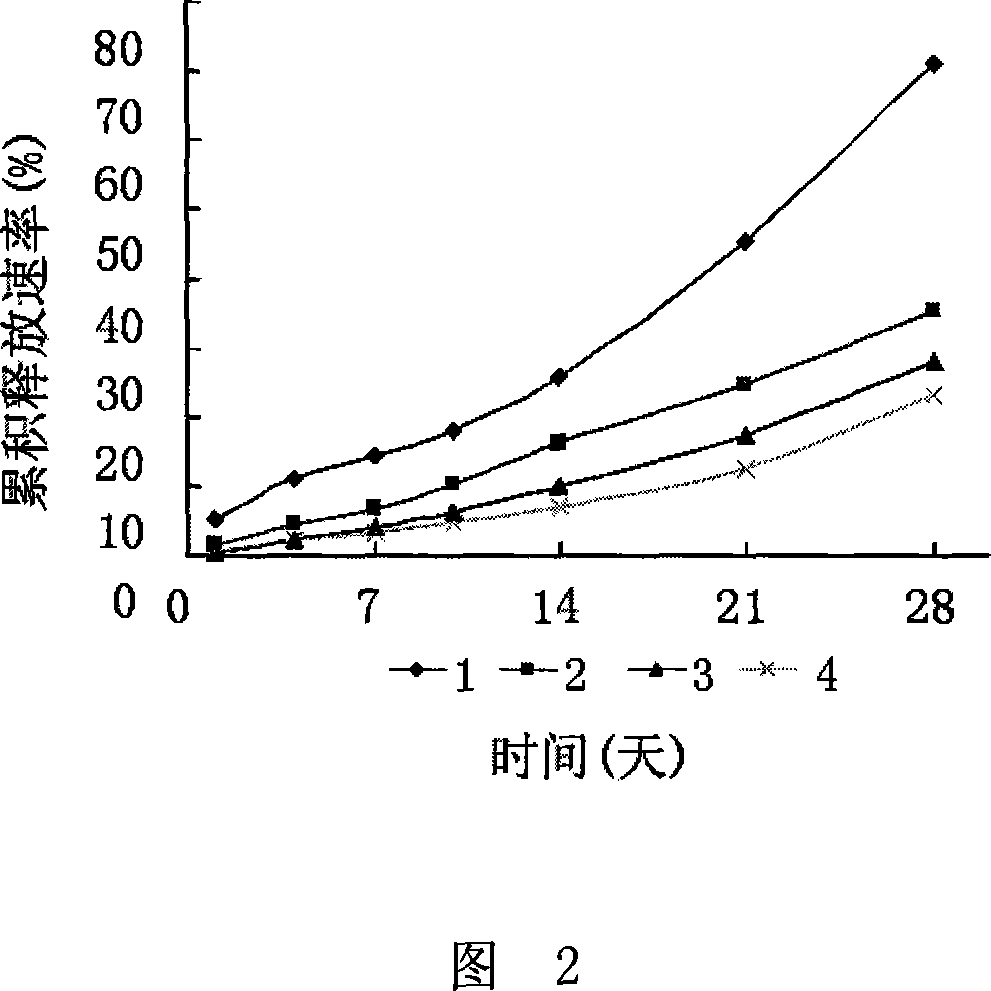

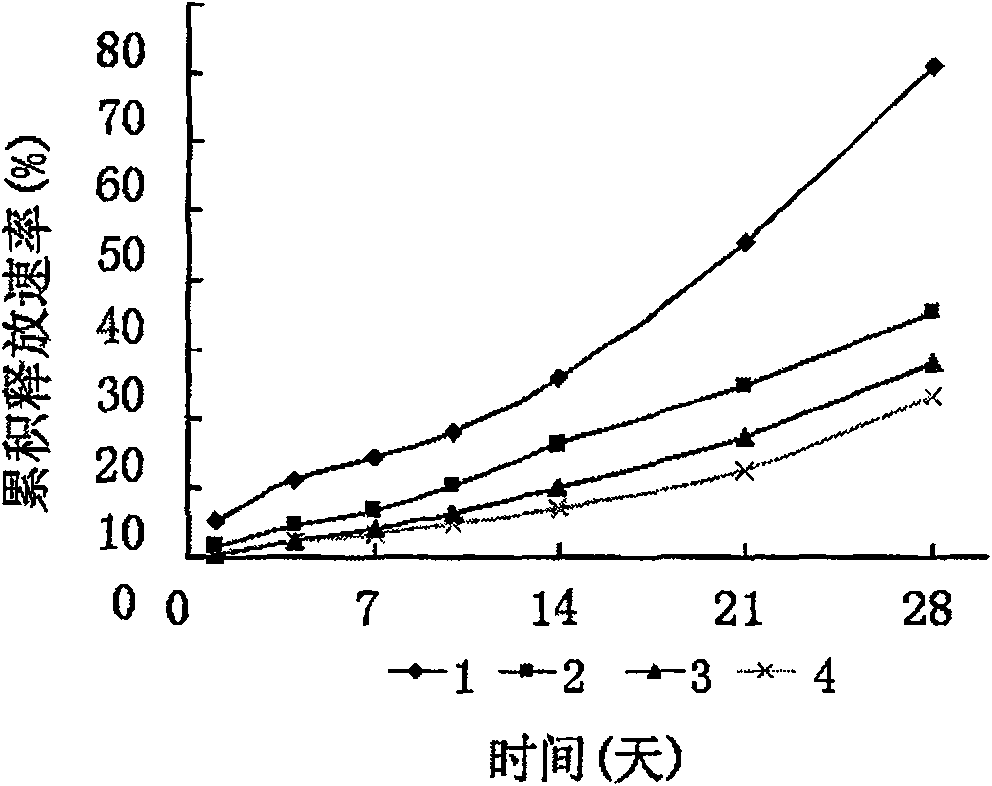

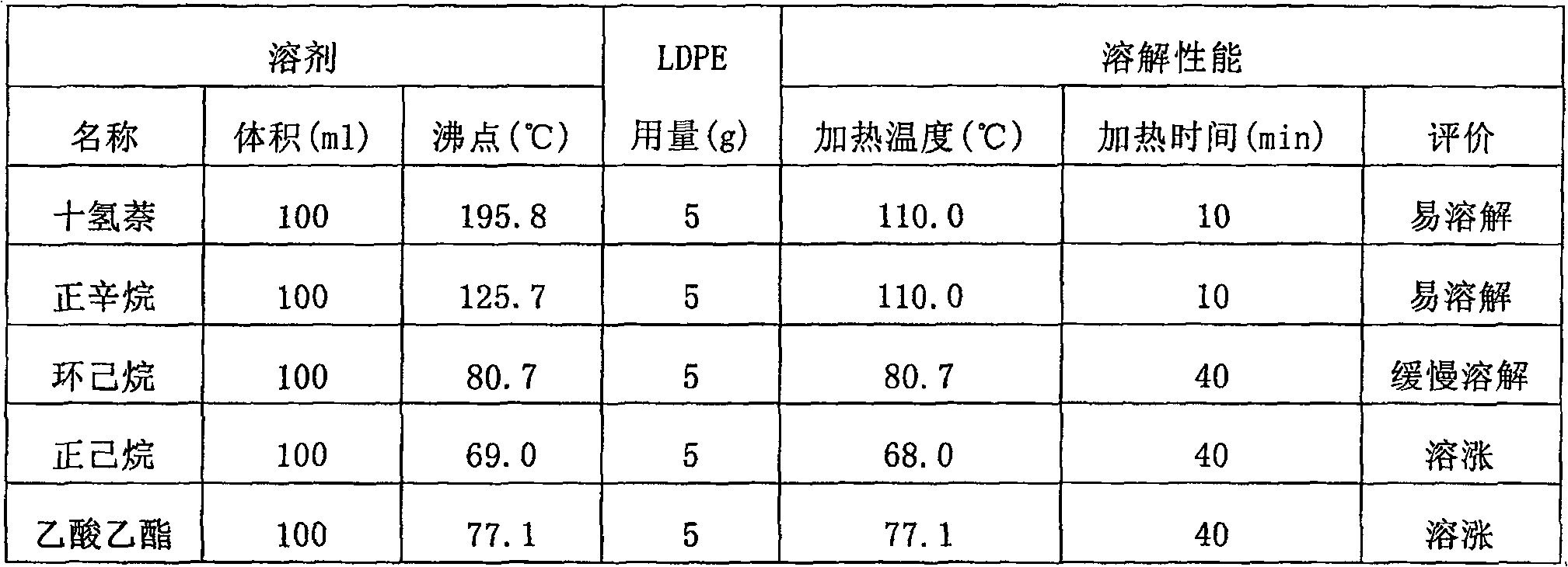

Controlled fertilizer of polymer capsule, production method, and dedicated capsule material

InactiveCN101050148ANo toxicityPromote safe productionFertiliser formsGranulation by powder suspensionLow-density polyethyleneLinear low-density polyethylene

This invention discloses a polymer-coated controlled-release fertilizer, its production method and its specific coating material. The coating material comprises: branched low-density polyethylene with an average molecular weight of 20000-30000, and linear low-density polyethylene with an average molecular weight of 20000-30000 at a weight ratio of 1 :( 0.33-1). The polymer-coated controlled-release fertilizer is composed of water-soluble fertilizer and the coating material defined in claims 1-4. The water-soluble fertilizer is coated with the coating material. The polymer-coated controlled-release fertilizer has good controlled-release performance and safe processing, and can be used on lawns, flowers, vegetables, and economic crops.

Owner:CHINA AGRI UNIV

2-methyl-3-methoxybenzoyl chloride synthesizing process

InactiveCN109384667AImprove separabilitySolve the problem of raw materialsOrganic compound preparationCarboxylic acid esters preparationO-XyleneSynthesis methods

The invention discloses a 2-methyl-3-methoxybenzoyl chloride synthesizing process. According to the present invention, low-cost o-xylene is used as a starting raw material, the product is synthesizedby using a conventional synthesis method comprising nitrification, esterification, reduction, diazotization, methylation, acyl chlorination and other steps, and the total yield is controlled at more than 65%; the esterification of the intermediate product improves the separation degree of the intermediate; the reaction solvent is added in the diazotization step, such that the process parameters are relatively easy to control, and the purity of the intermediate in the diazotization step is more than 96% so as to provide the guarantee for the quality of the subsequent product; and with the synthesis process, the product quality is stable and reliable, and the cost is low.

Owner:JIANGSU YONGAN CHEM CO LTD

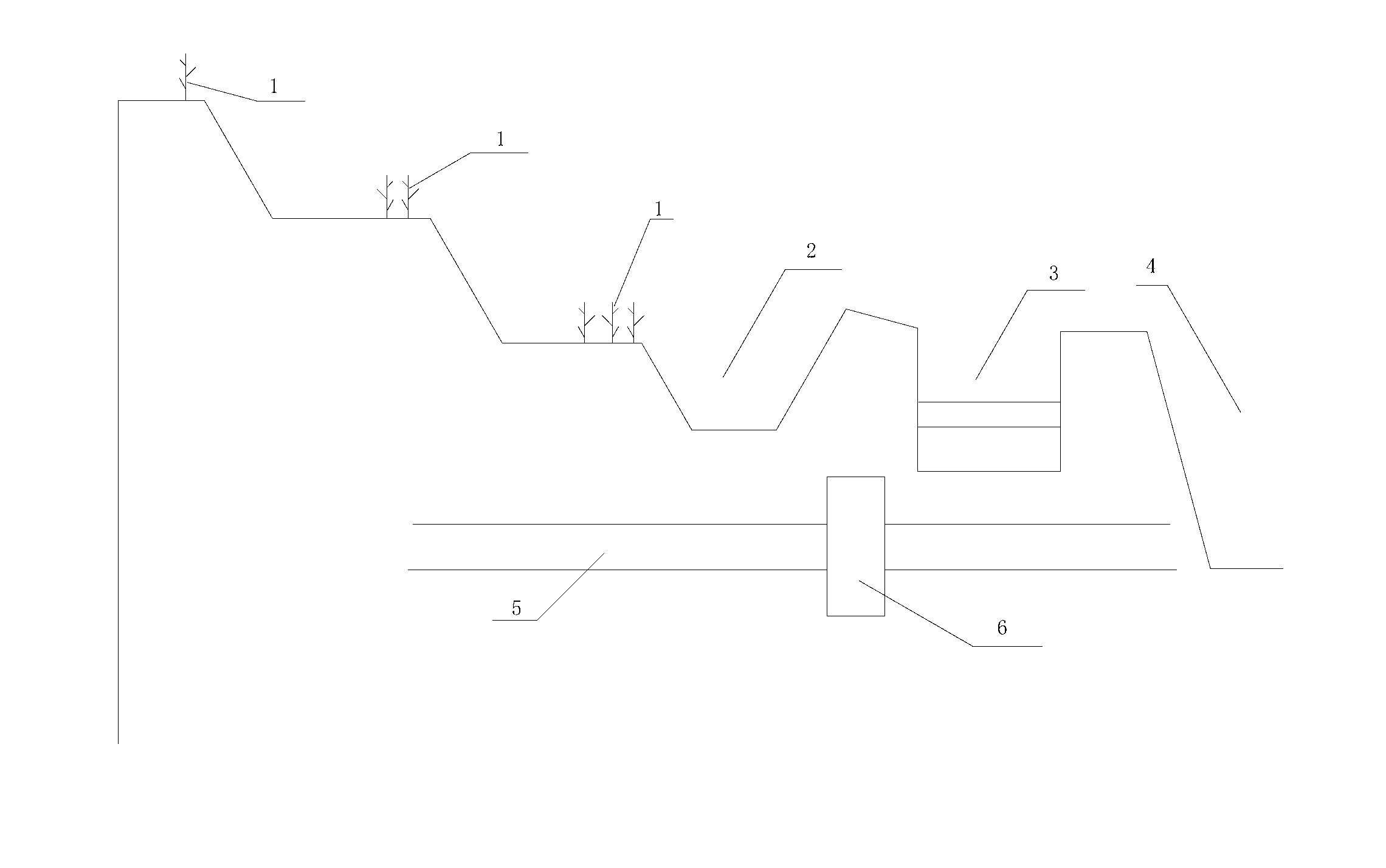

Control system and technology of agricultural non-point source pollution based on hedgerows and multilayer percolation ponds

InactiveCN103073151AAvoid pollutionSolve the problem of raw materialsMultistage water/sewage treatmentBiological water/sewage treatmentSurface waterNutrients substances

The invention discloses a control system of agricultural non-point source pollution based on hedgerows and multilayer percolation ponds. The control system comprises hedgerows, grass ditches, multilayer percolation ponds and denitrification walls, wherein the hedgerows are planted along terrace edges on a sloping field and used for wind prevention and sand fixation and water and soil erosion prevention; the grass ditches are excavated along lower edges of the sloping field and are further used for sediment precipitation and reserved water reuse; the multilayer percolation ponds are arranged between natural water areas and the grass ditches and in parallel with the grass ditches and used for absorbing phosphorus and nitrogen in water overflowing from the grass ditches; and the denitrification walls are arranged outside the natural water areas and on convergence paths of shallow surface water and used for denitrificating nitrate nitrogen in the shallow surface water into nitrogen. According to the control system and a technology of agricultural non-point source pollution based on hedgerows and multilayer percolation ponds, technologies of the hedgerows, grass ditches, multilayer percolation ponds and denitrification walls are combined, and simultaneously, a same surface runoff of non-point source pollution is processed differently in different periods in an actual application process, so that processing loads can be reduced, and nutrient substances and water resources can be recycled.

Owner:TSINGHUA UNIV

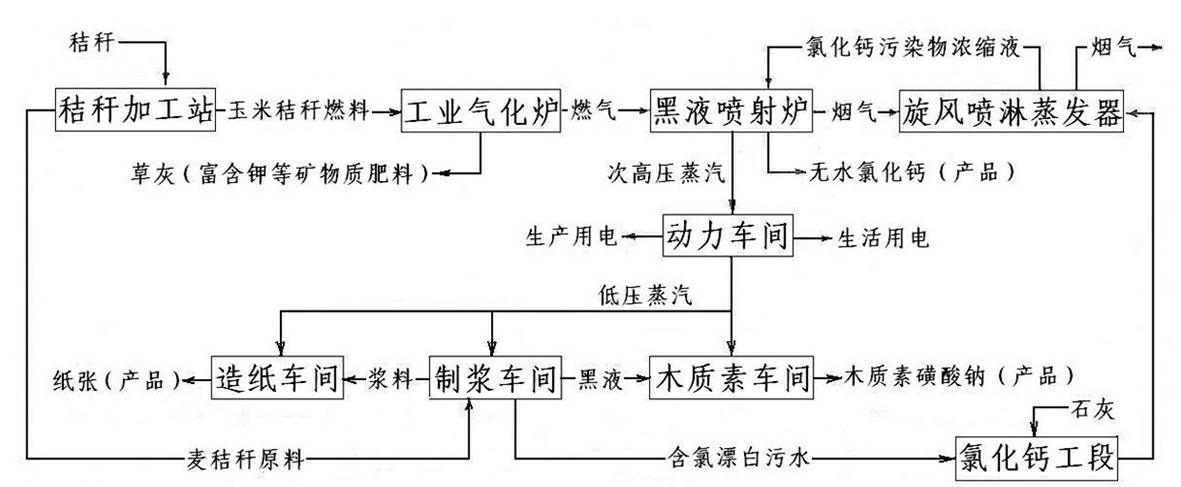

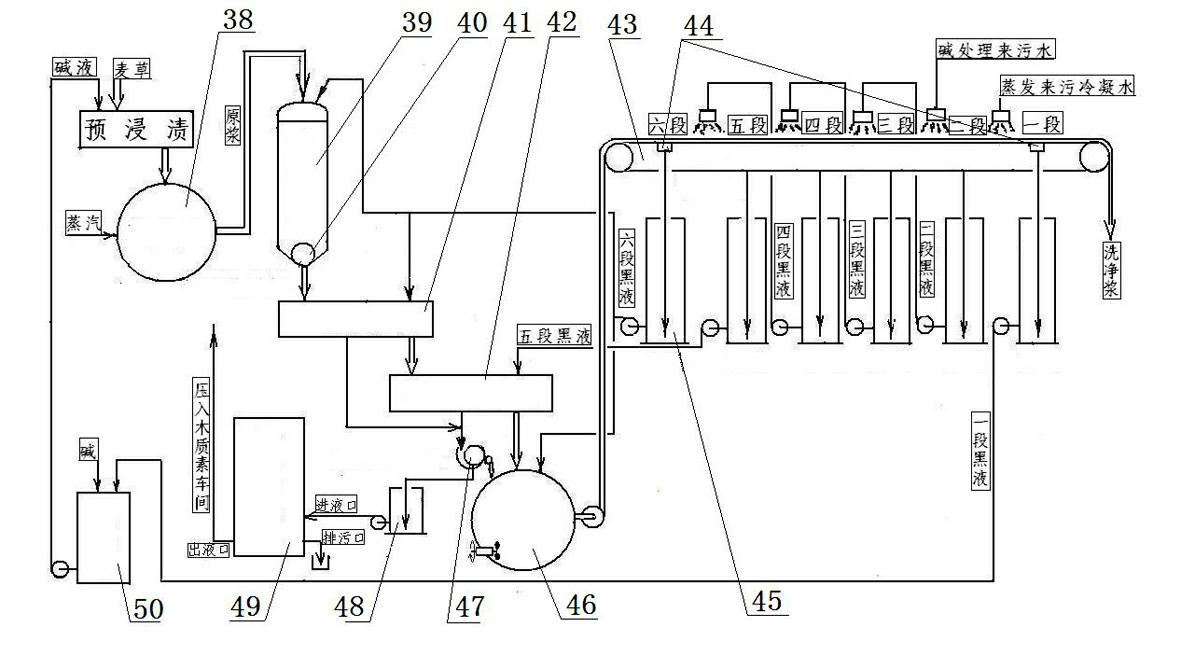

Low-carbon papermaking method

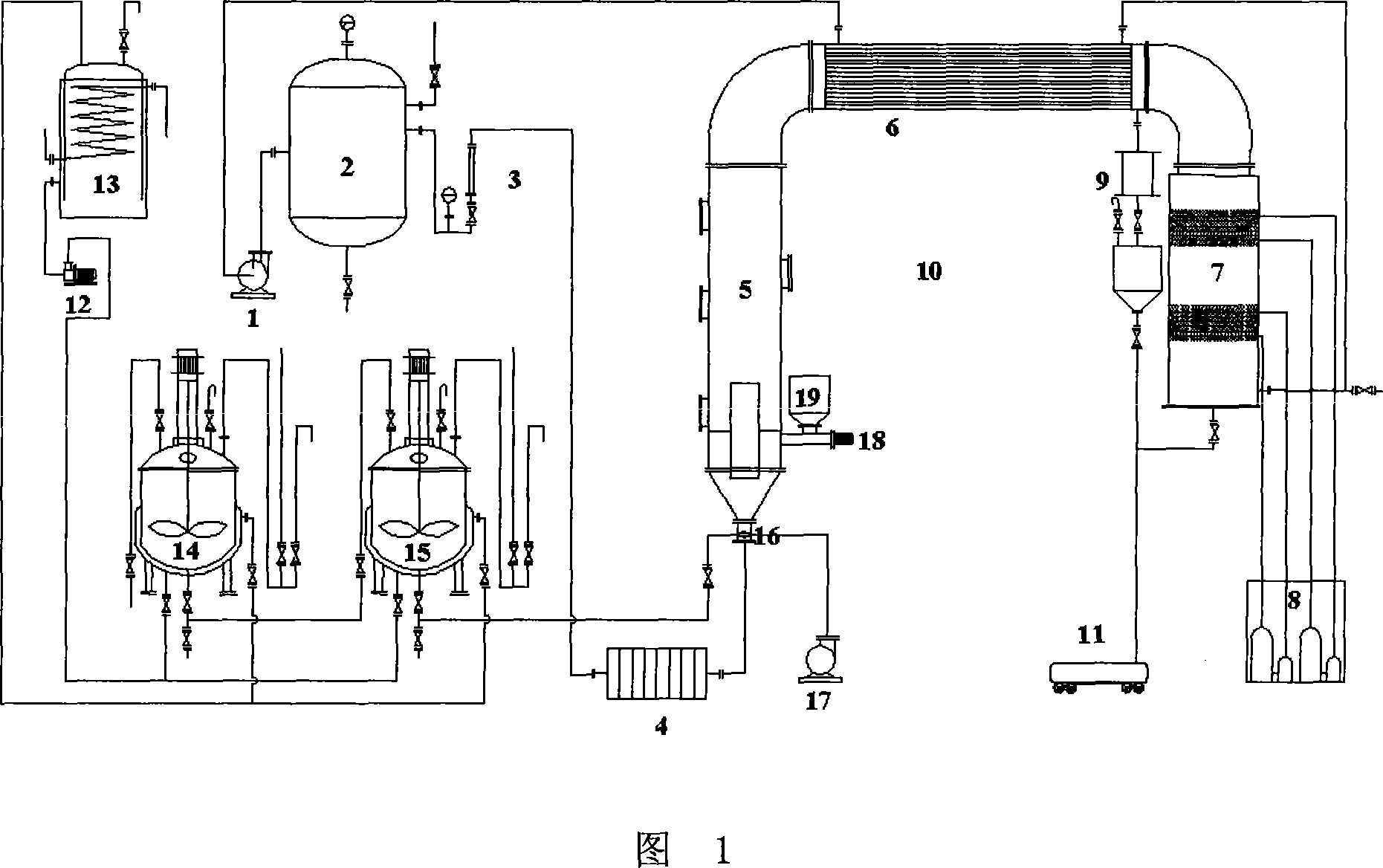

InactiveCN102677530AAchieving zero emissionsSolve the problem of raw materialsWashing/displacing pulp-treating liquorsRegeneration of alkali lyePapermakingHigh pressure

The invention belongs to the field of papermaking and particularly relates to a low-carbon papermaking method which aims to solve the problems about raw materials, environments and energy sources in the development of papermaking industries in China. The low-carbon papermaking method specifically comprises the following steps of: in order to realize low-carbon papermaking, comprehensively taking crop straws as an energy source to produce secondary high-pressure steam to generate power and taking the crop straws as raw materials to make paper pulp and separate the paper pulp, pollutant black liquid and bleaching effluent; and making various paper through the paper pulp, preparing sodium ligninsulfonate from the pollutant black liquid, and preparing anhydrous calcium chloride from chlorine-containing bleaching sewage. The low-carbon papermaking method disclosed by the invention has the advantages of realizing low-carbon papermaking ecological industry, circular economy, and CP (cleaner production) zero emission by virtue of the comprehensive utilization of the straws, and solves the problems about the raw materials, the environment and the energy sources in the development of the papermaking industries.

Owner:王性仁

Middle-manganese high-silicon low-fluorine smelting type welding flux

ActiveCN101434018ASolve the problem of raw materialsReduce wasteWelding/cutting media/materialsSoldering mediaManganesePetrochemical

The invention discloses a medium-manganese high-silica low-fluorine smelting soldering flux, which belongs to the field of welding in the mechanical industry. The medium-manganese high-silica low-fluorine smelting soldering flux comprises the following effective compositions in portion by weight: 21 to 26 portions of MnO, 36 to 40 portions of SiO2, 4 to 8 portions of CaF2, 15 to 21 portions of CaO, 3 to 5 portions of TiO2, 3 to 5 portions of MgO, less than or equal to 8 portions of Al2O3, and less than or equal to 1.8 portions of FeO. The medium-manganese high-silica low-fluorine smelting soldering flux has the characteristics that poor manganese ore (namely low-grade manganese ore) can be utilized for production, the cost is low, the application scope is wide, various quality and technical indexes of the medium-manganese high-silica low-fluorine smelting soldering flux can meet the pertinent regulations of F4A2-H08A in the GB / T 5293-1999, and so on and the medium-manganese high-silica low-fluorine smelting soldering flux can be widely applied to union melt welding, semiautomatic welding, electroslag pressure welding, copper welding, pressure welding of vertical reinforcements and so on. in the process of equipment manufacturing in the fields of machine manufacturing, the petrochemical industry, coal metallurgy, mines, buildings, electric power, the military industry, aerospace, marine engineering, and so on.

Owner:永州市兴发电熔科技有限公司

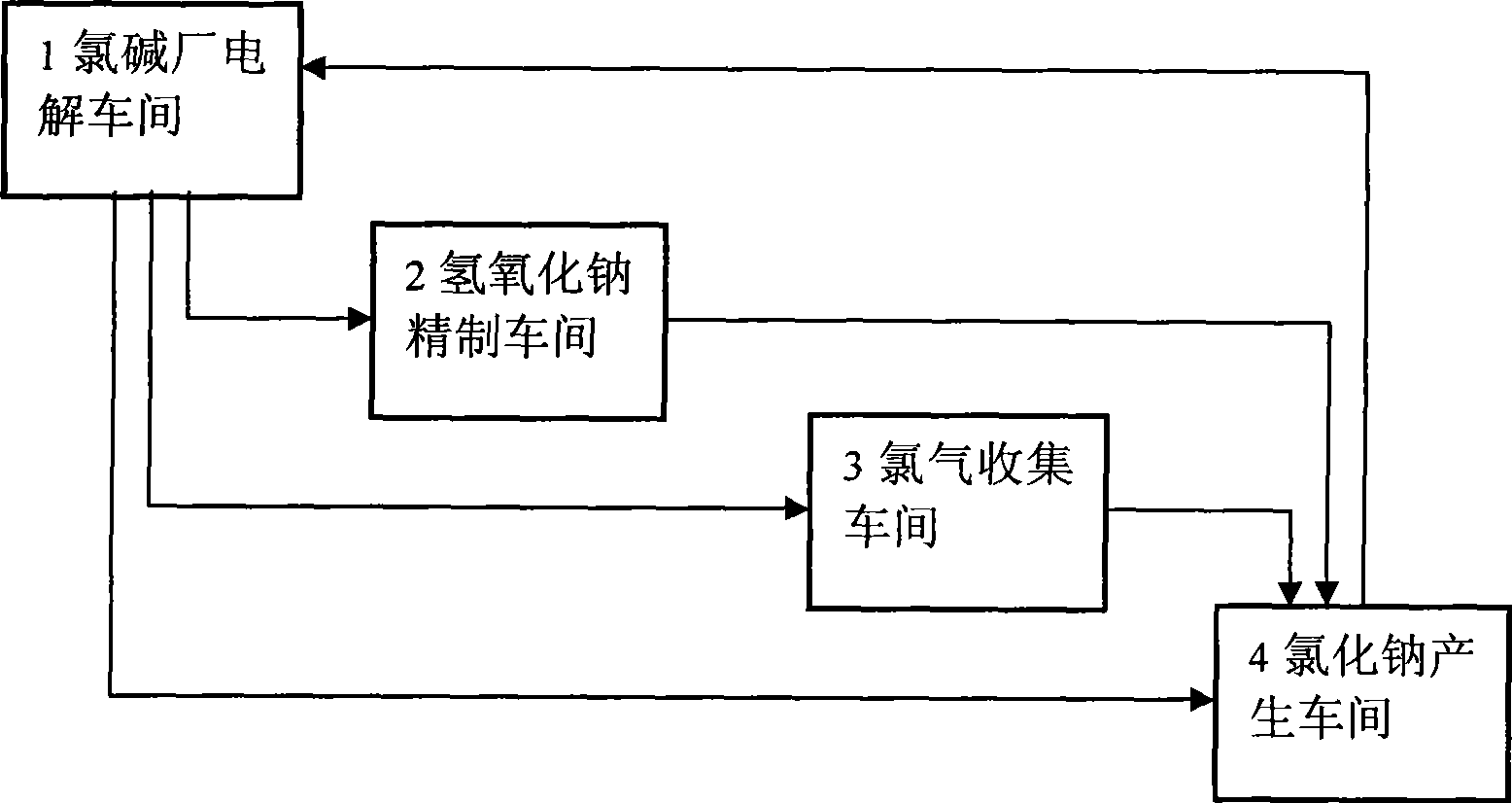

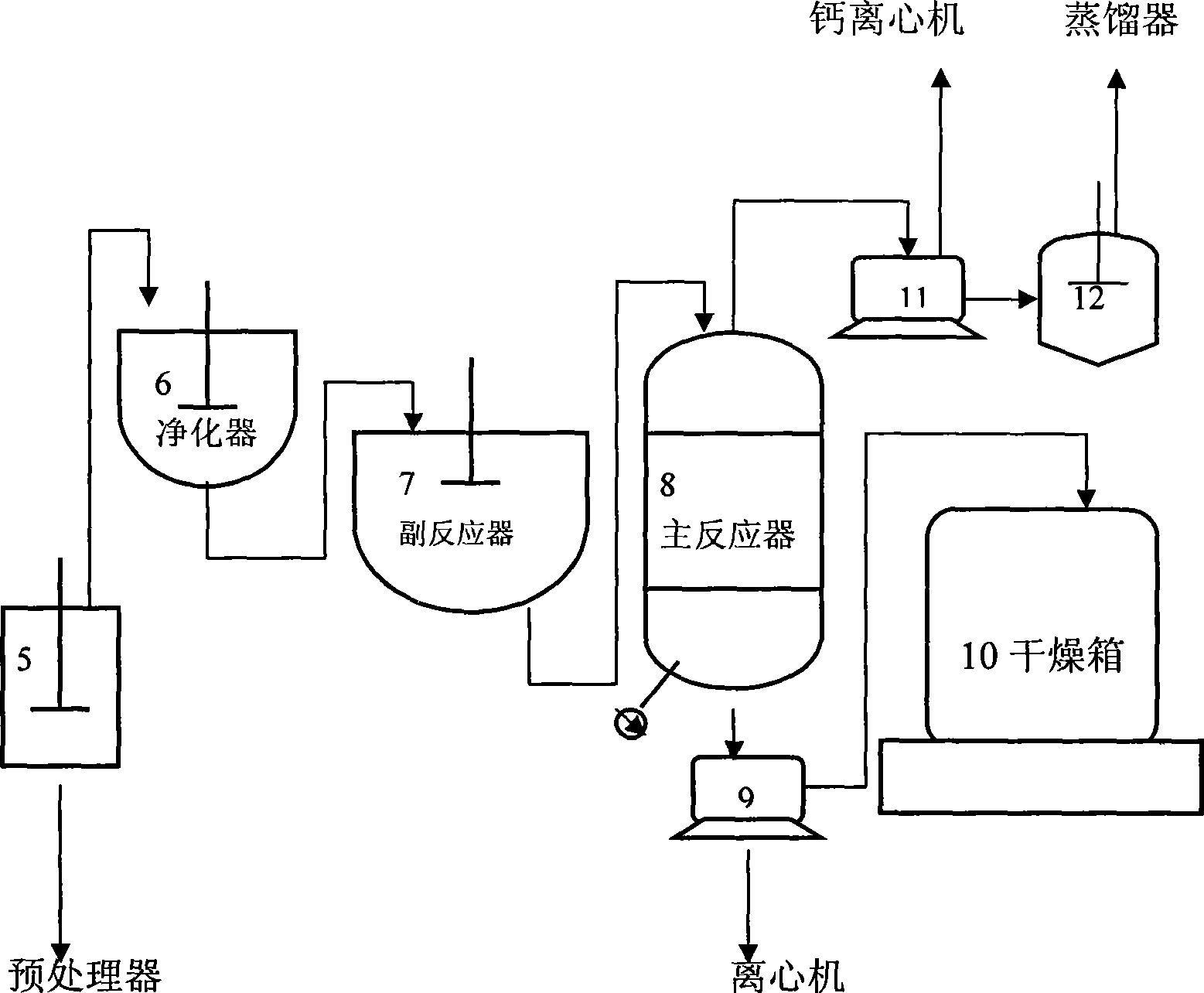

Material circulation system formed by waste carbide mud residue and alkali-chloride industry

InactiveCN101456026ASolve disposal problemsSolve the problem of raw materialsElectrolysis componentsSolid waste disposalElectrolysisCalcium Chloride Hexahydrate

The invention discloses a material circulating system formed by waste acetylene sludge and the chlor-alkali industry. The system comprises: pretreated waste acetylene sludge is reacted with hydrochloric acid, the reaction product is filtered to obtain a calcium chloride solution; the filtrate is reacted with sodium hydroxide generated by electrolysis of a chlor-alkali factory to generate high-purity calvital; the calvital is chloridized, centrifugated, dried and crushed to prepare bleaching powder; and filter cakes are reacted with the hydrochloric acid to generate active carbon. The calcium chloride generated in the reaction can be prepared into calcium chloride dihydrate and anhydrous calcium chloride; and sodium chloride after treatment can be taken as a raw material for electrolysis. The material circulating system effectively solves the problem of treating the waste acetylene sludge and raw material problem in the chlor-alkali industry, embodies recycling economy; and byproducts of the bleaching powder and the active carbon and calcium chloride dihydrate products improve deep processing capacity of an enterprise.

Owner:南通宙亚电子科技有限公司

Lactic acid bacterium fermented chopped chili processing method

InactiveCN105410783AReduce transportationEasy to transportFood ingredient functionsLactic acid bacteriumFlavor

The present invention discloses a lactic acid bacterium fermented chopped chili processing method, including the following specific steps: selecting and grinding, high temperature soaking and sterilizing, pool loading, lactic acid bacterium fermenting agent adding, fermenting and pickling, and salt adding and storing. The dried chilies are used as raw materials and fermented by artificially inoculating lactic acid fermentation liquid, and the obtained product has a special flavor, aroma and health-care function of fermented chili products. The processing method can improve product quality stability and chili product nutritional value, at the same time solve the raw material problem in annual production of pickles, and save the fermentation time compared to the traditional fermentation. However, the method uses dried red chilies as raw materials and the materials are readily available and suitable for industrial production of the raw material preservation requirements, and the raw material quality can be well controlled. In the processing of the chopped chilies, only about 10%-11% of edible salt is added, which saves energy and lower production costs.

Owner:HUNAN XIANGCHUQING FOOD CO LTD

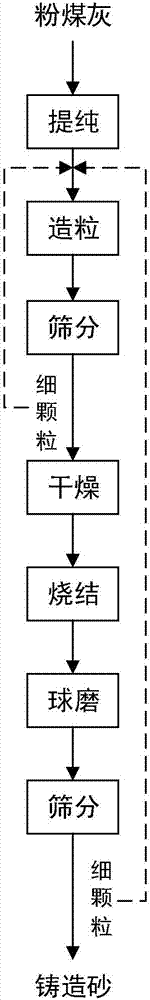

Method for producing precise foundry sand from high-aluminum coal ash

ActiveCN107199310AHigh refractorinessImprove liquidityFoundry mouldsMould handling/dressing devicesFoundryAcid washing

The invention provides a method for producing precise foundry sand from high-aluminum coal ash. The method comprises the following steps of: purifying high-aluminum coal ash, pelletizing, drying, roasting and post-treating the purified high-aluminum coal ash to obtain the precise foundry sand, wherein the step of purifying the precise foundry sand adopts an acid activation-alkali desilicication-diluted acid washing process. The precise foundry sand obtained by the method has the advantages of good mobility, high refractoriness, high strength, a low thermal expansion coefficient, good sand sticking resistance, solves the raw material problem in a production process of the precise foundry sand, successfully treats industrial solid waste, achieves the purpose of changing waste into things of value, and has a good economic and social value.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

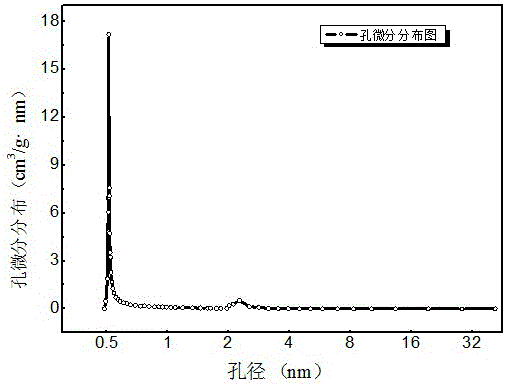

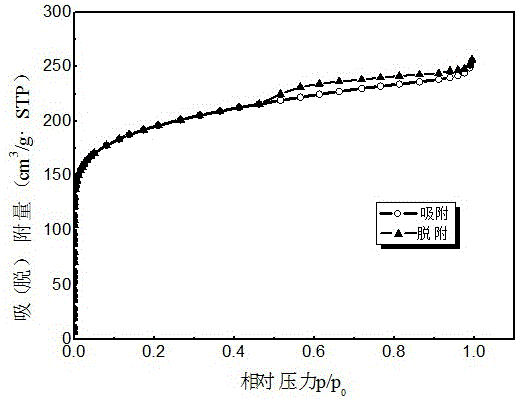

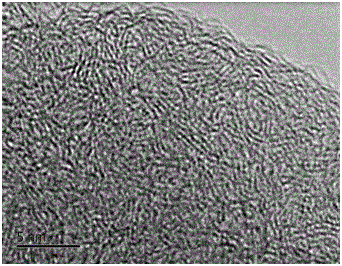

Uniform ultra-microporous activated carbon for gas separation and preparation method of uniform ultra-microporous activated carbon

InactiveCN106517189AReduce dosageReduce corrosionHydrogen separation by selective and reversible uptakeCarbon compoundsActivation methodMass ratio

The invention relates to uniform ultra-microporous activated carbon for gas separation and a preparation method of the uniform ultra-microporous activated carbon. According to the technical scheme of the preparation method, mixing semi-coke with KOH in a mass ratio being 1: (0.01-0.2), adding water and an activating aid to impregnate the mixture for 1-36 h; increasing the temperature to 800-950 DEG C in a programmed manner under N2 protection, controlling thermal decomposition, and introducing water for activation of part of steam for 0.5h-1.5h; finally, washing the mixture with acid and water until the mixture is neutral to obtain the uniform ultra-microporous activated carbon. The pore size is distributed centrally between 0.45 and 0.55 nm, the pores belong to ultra-micropores and have microporosity of 70% or more, and the adsorption capacity of hydrogen is 77cm<3> / g or higher. The semi-coke is taken as a raw material, low in price and low in energy consumption and needs not to be carbonized; an activation method integrates KOH impregnation pretreatment and activation of part of steam, little KOH is consumed, and the activation method has the characteristics of being low in cost and pollution, helpful for reducing corrosion of equipment and the like. The activated carbon prepared with the method has the characteristics of uniform pore size distribution, extremely rich ultra-microporous structure and the like, and can be used in gas separation fields such as pressure swing adsorption hydrogen making or hydrogen storage and the like.

Owner:WUHAN UNIV OF SCI & TECH

Floating and enriching method of low-grade manganese dioxide ore

The invention relates to a floating and enriching method of a low-grade manganese dioxide ore. The method is characterized by comprising the following steps of: grinding an original ore, wherein the passing rate of 200 meshes is 98 percent; adding water to regulate the concentration of ore pulp to 10-30 percent and the pH value to be between 5 and 7; then adding an inhibitor containing oxalic acid, citric acid and dextrin according to a certain proportion and stirring the inhibitor to have a sufficient contact with ore grains; adding a collecting agent consisting of alkyl sulfate and fatty acid to the regulated ore pulp and then selecting a proper process flow according to a manganese grade range in the original ore; and finally, filtering floated tailings through multiple stages of fine selecting and scavenging to obtain manganese-enriched tailings the manganese grade of which is more than 32 percent. The method can be used for floating ores the manganese dioxide grade of which is 5-14 percent, and the low-grade manganese dioxide ores are effectively utilized to produce high-grade manganese ore powder, thus the raw material problems of domestic numerous electrolytic manganese production enterprises are solved.

Owner:HUAYUAN QIANGHUA MINING

Cultivating method for wild bletilla striata variety

InactiveCN105052492AImprove sustainabilitySolve the problem of raw materialsPlant cultivationCultivating equipmentsBletilla striataSeedling

The invention discloses a cultivating method for a wild bletilla striata variety. A mountaintop with the elevation of 2000 m-2860 m is selected, the frost-free season of the mountaintop is as long as 220 days, the first-frost season of the mountaintop is after the end of October, and the annual average air temperature is 12-16 DEG C; a shade house is built to serve as the cultivation land; wild bletilla striata on a mountain with similar conditions is selected as the seed; pseudobulbs of the wild bletilla striata variety are primarily propagated to obtain the bletilla striata seed, the pseudobulbs meeting the requirement are selected and secondarily propagated, and the bletilla striata seed suitable for large-area cultivation and plantation is obtained. Thus, the bletilla striata produced in this way keeps the medical effect of the wild bletilla striata, a basic method and bletilla striata seedlings are provided for cultivation in a larger area, and the problem of deficient resources of the wild bletilla striata is solved.

Owner:XUANWEI MEIRUI AGRI DEV CO LTD

Cultivation material composition for producing agaricus bisporus by using hybridized Pennisetum alopecuroides

InactiveCN102417414AFavorable to the development of artificial cultivationExpand production scaleFertilizer mixturesAgaricusCaladium

The invention discloses a cultivation material composition for producing agaricus bisporus by using hybridized Pennisetum alopecuroides, comprising 70-90 weight portions of hybridized Pennisetum alopecuroides, 10-20 weight portions of dry cow dung, 1.0-1.5 weight portions of calcium superphosphate, 0.5-1.0 weight portions of urea, 0.40-0.60 weight portions of ammonium hydrogen carbonate, 1.5-2.0 weight portions of lime, and 2.0-3.0 weight portions of gypsum. According to the invention, straw or wheat straw, maize straw can be most or all replaced by the hybridized Pennisetum alopecuroides to cultivate agaricus bisporus; the advantages of high yield, good quality and easy obtainment of raw materials are achieved; the invention is beneficial to solve the raw material problem in regions where has less resource of straw and cow dung; the invention can open up a new approach for the developing direction of the hybridized Pennisetum alopecuroides in a Pig-Methane-Forage system of large-scale farms; the energy waste is reduced, the environmental pollution is mitigated, and novel culture mediums can be provided for culturing agaricus bisporus. The invention opens up a feasible shortcut for benefiting the development of artificial cultivation of agaricus bisporus and enlarging production scale.

Owner:AGRI ECOLOGY INST FUJIAN ACADEMY OF AGRI SCI +2

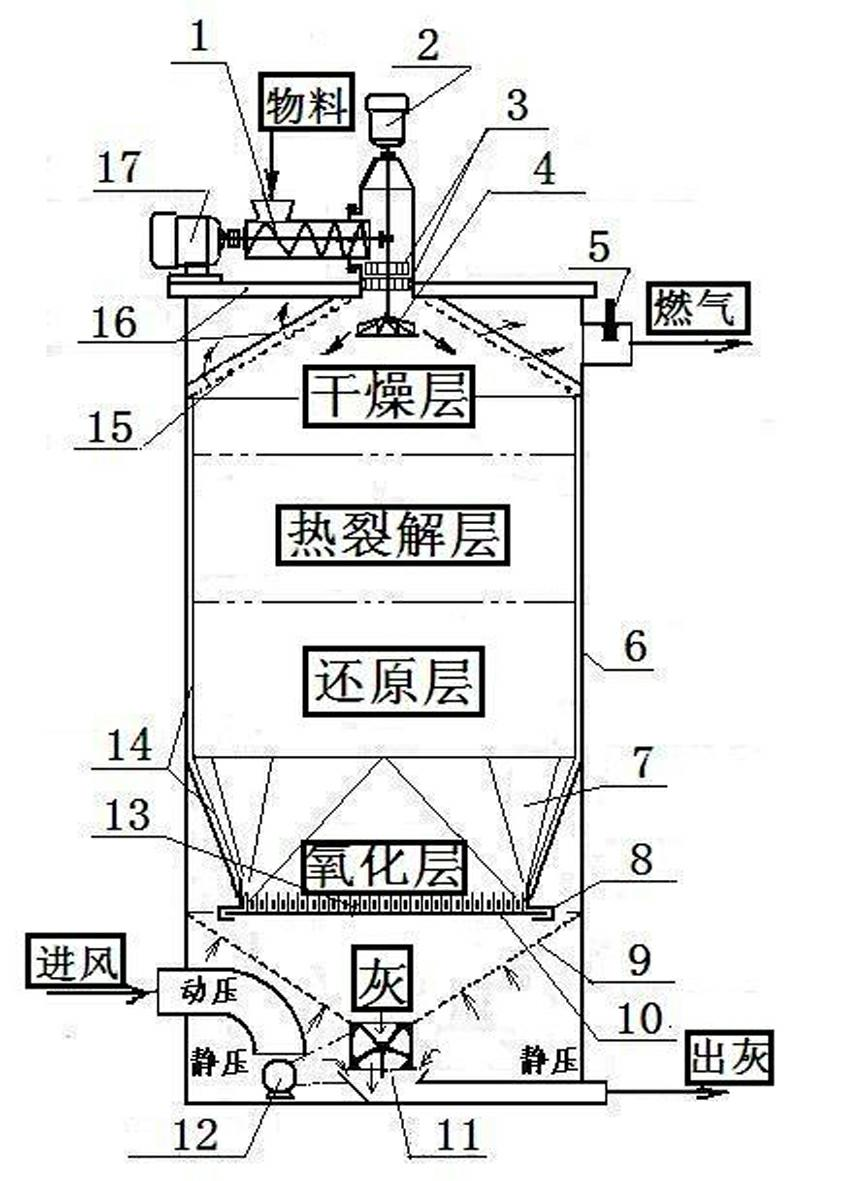

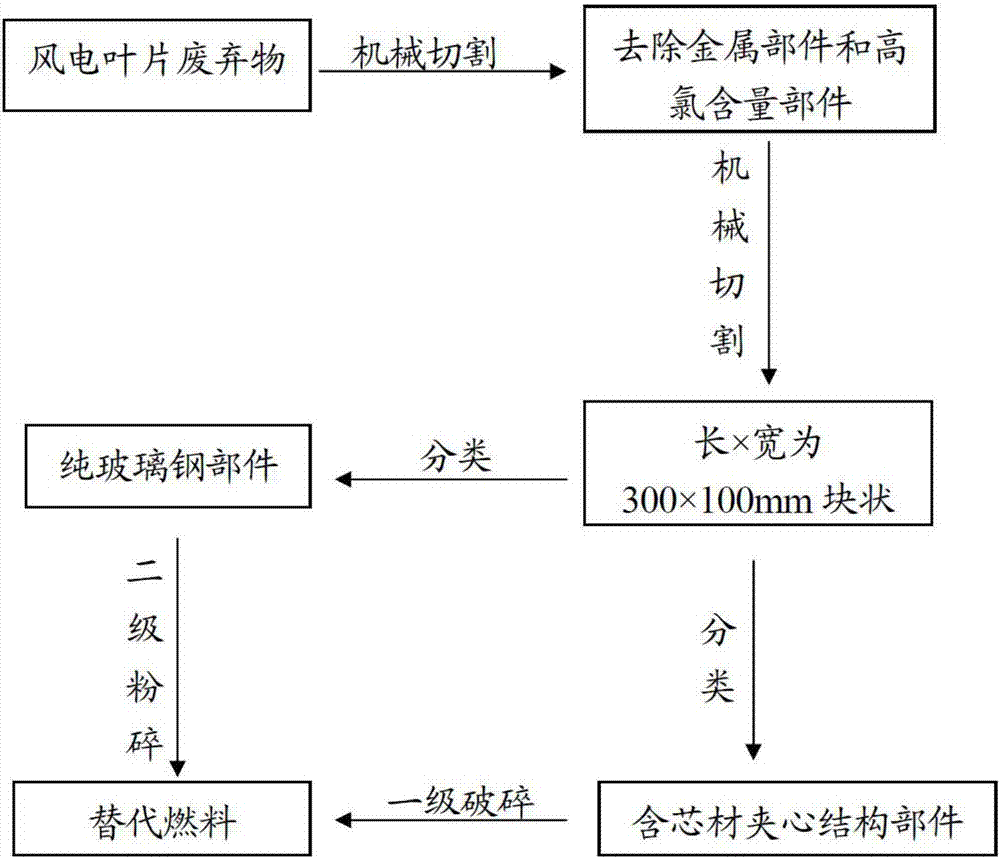

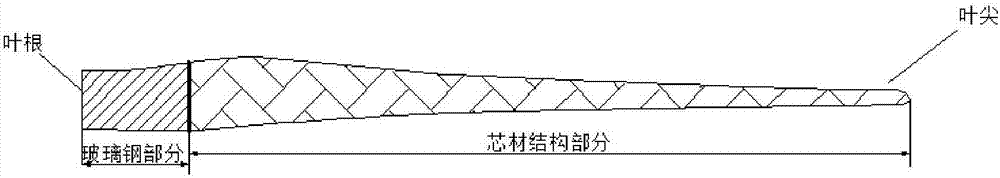

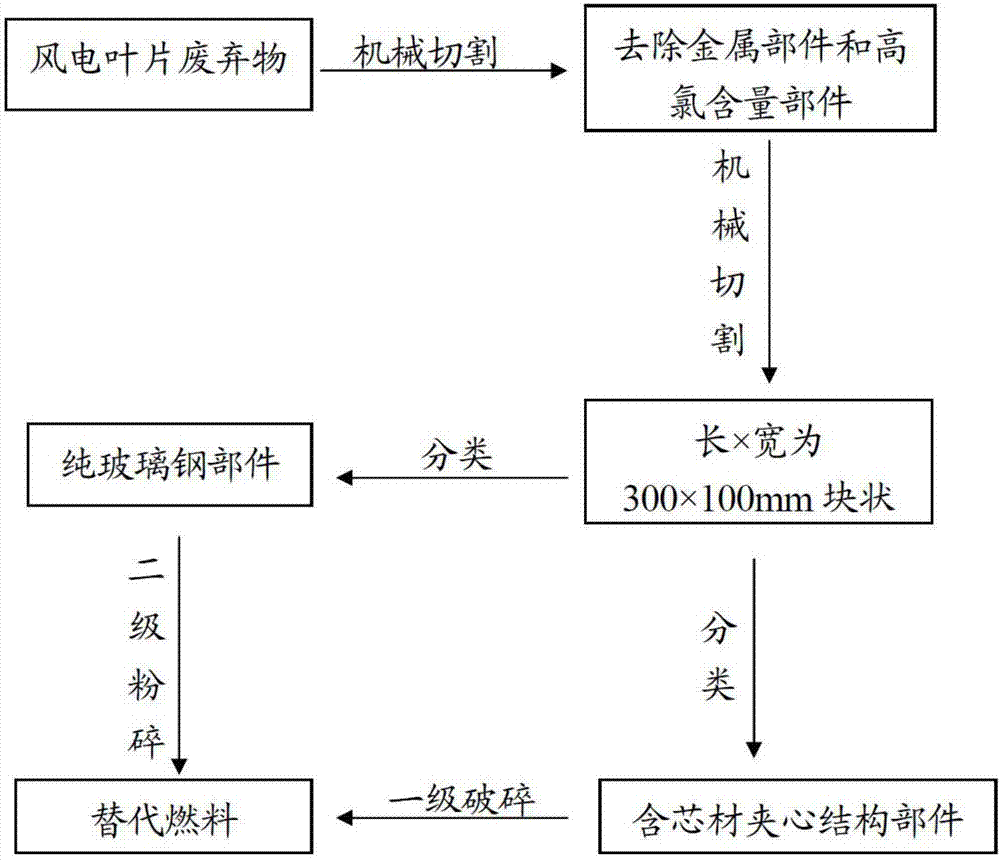

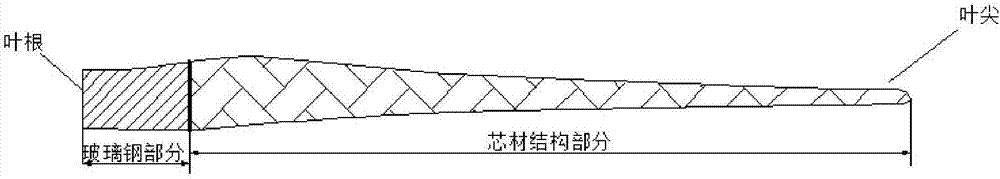

Method for absorbing wind turbine blade wastes in cement kiln

InactiveCN107305010AConsumptionReduce wearIncinerator apparatusCombined combustion mitigationAlternative fuelsHigh energy

The invention provides a method for absorbing wind turbine blade wastes in a cement kiln. The method comprises the following steps: separating metal parts and high-chlorine content parts in the wind turbine blade wastes, and segmenting the remaining wind turbine blade wastes as massive wastes; grinding the massive wastes into particles so as to obtain ground materials; and taking the ground materials as alternative fuel of the cement kiln, and combusting the fuel in a cement kiln decomposing furnace. The method disclosed by the invention is simple, practical, less in initial investment and subsequent maintenance cost, environment-friendly and harmless, belongs to a circular economy manner, accords with the treatment policy of 'reduction, recycling and harmlessness' of municipal wastes, can thoroughly implement and carry out the national policy of cooperatively treating non-medical wastes and industrial wastes in the cement kiln, solves the thermosetting material waste disposal difficulty problem troubling the society for a long time, provides alternative fuel and raw materials for the high-energy-consumption cement industry and has wide application prospects.

Owner:SINOMATECH WIND POWER BLADE

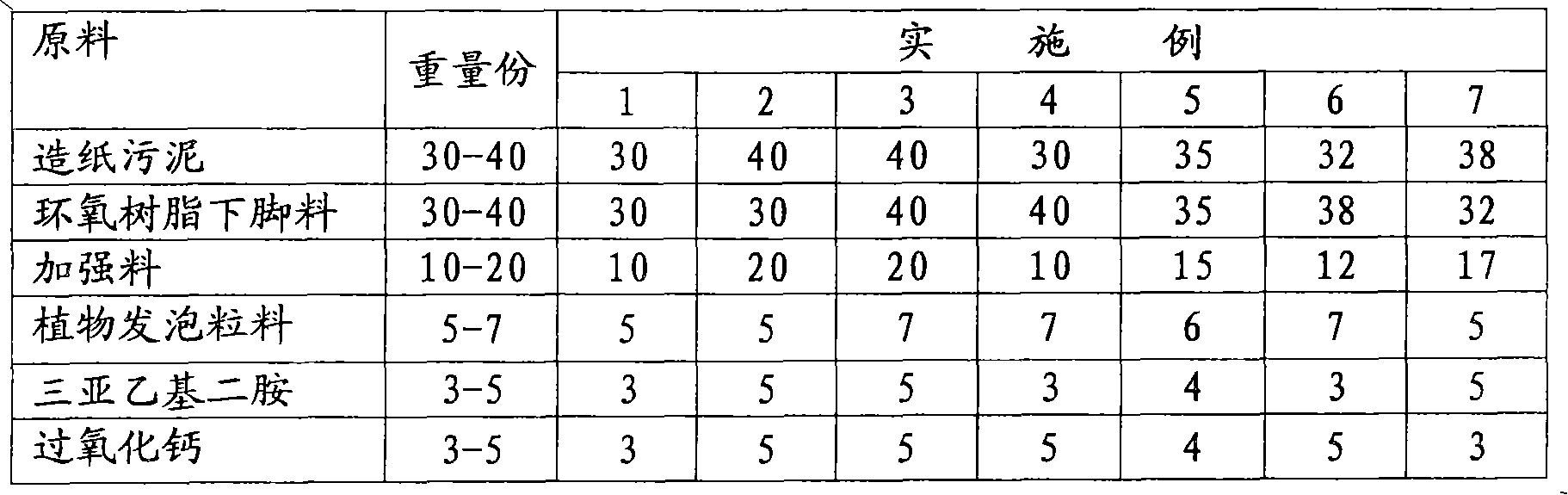

Production method of paper mill sludge landscape ornamental material

InactiveCN101575199ASolve the problem of raw materialsProduct quality is lightSolid waste managementEpoxyPaper mill

The invention discloses a production method of paper mill sludge landscape ornamental material, which is characterized by comprising the following raw materials according to parts by weight: 30 to 40 parts of paper mill sludge, 30 to 40 parts of epoxy resin leftover, 10 to 20 parts of reinforcing material, 5 to 7 of plant foaming granules, 3 to 5 of triethylenediamine and 3 to 5 parts of calcium peroxide. The production method comprises the following five steps of: first, preparing material; second, mixing; third, moulding and heat pressing; fourth, stacking and curing; and fifth, surface treatment. The prepared plank material is particularly applicable to be used as a flower bed boarding of the landscape area, is beautiful and elegant, and has low cost and water resistance and appropriate strength. The landscape ornamental plate is produced by the method, thus making waste profitable, not only solving the environmental problem, but also solving the problem of material for producing the artificial board; and the plank material has lighter weight and low energy dissipation in production.

Owner:潘金瓶

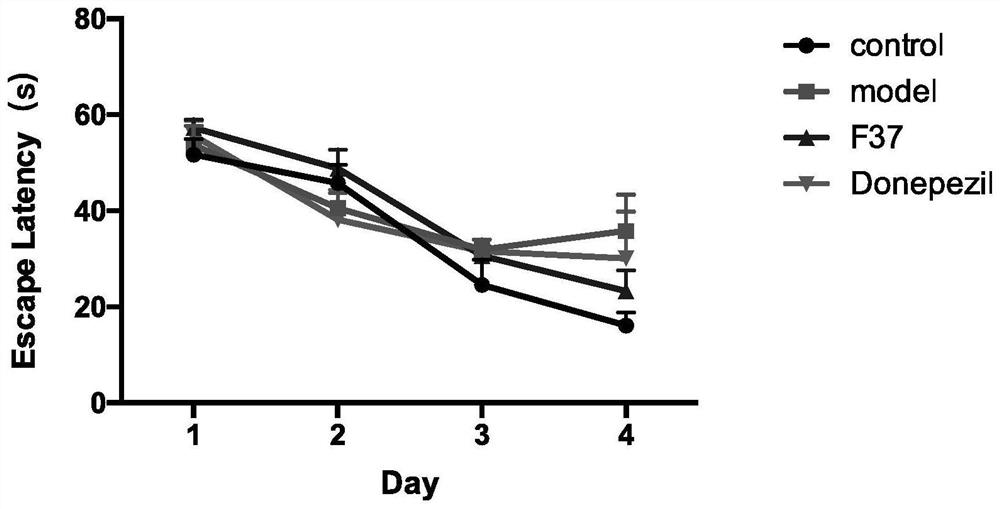

Steroid sapogenin derivative as well as preparation method and application thereof

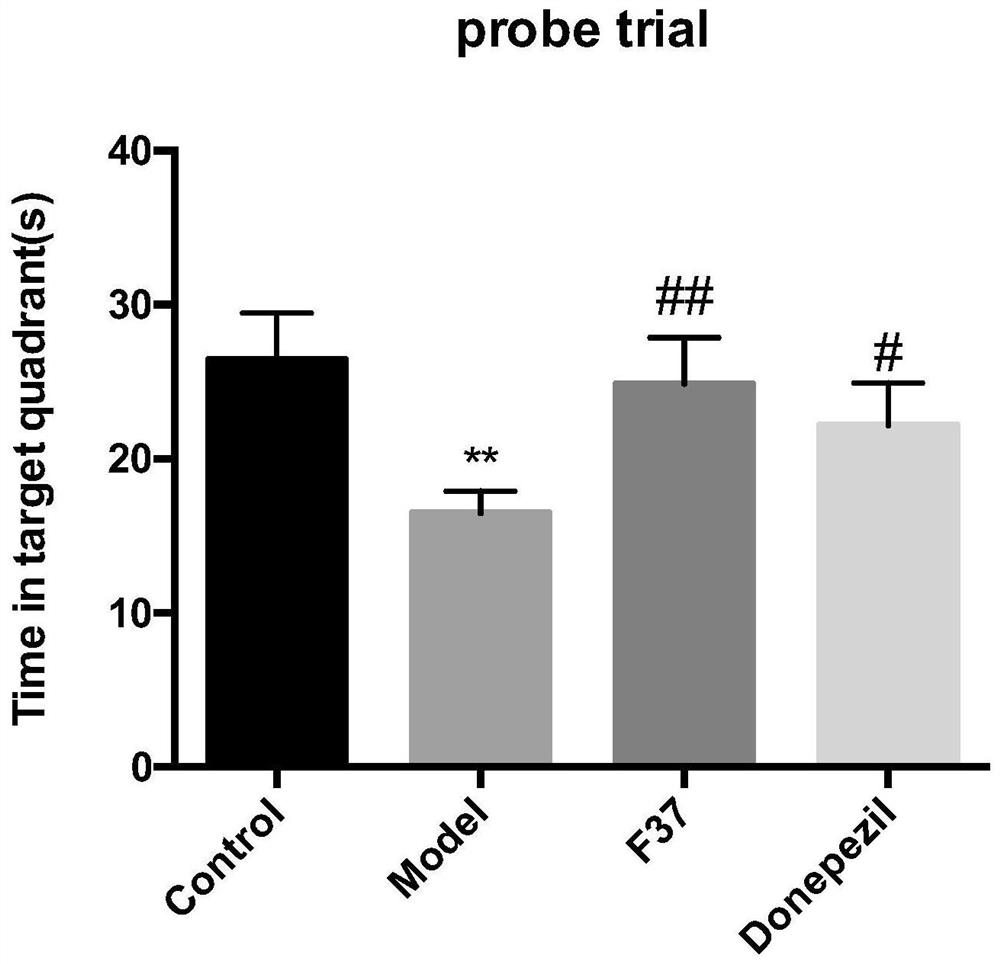

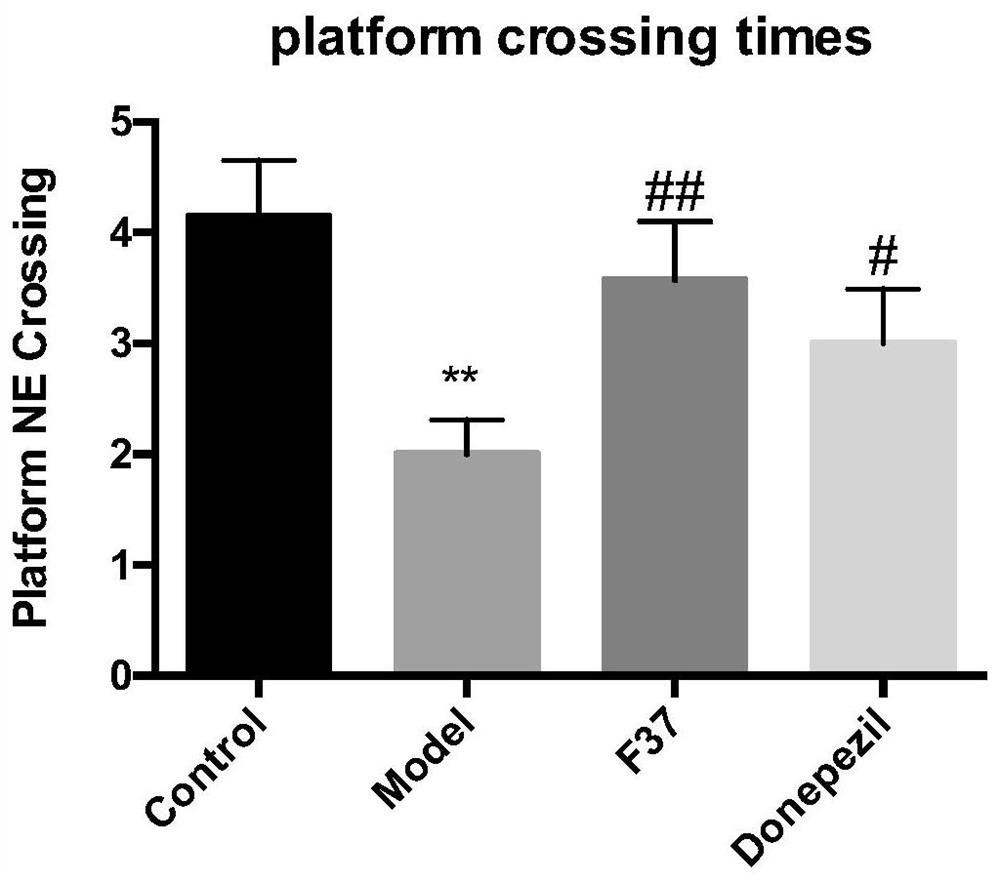

ActiveCN111825740AImprove protectionHas acetylcholinesterase inhibitory effectOrganic active ingredientsNervous disorderDiseasePharmaceutical Substances

The invention discloses a steroid sapogenin derivative represented by general formula (1), and a pharmaceutically acceptable salt and a pharmaceutical composition thereof. The steroid sapogenin derivative disclosed by the invention has a protective effect on neurons, and also has anti-inflammatory and antioxidant effects and an acetylcholin esterase inhibition effect, so that the steroid sapogeninderivative can be used for treating cholinesterase inhibition, oxidative stress and inflammation-related diseases.

Owner:EAST CHINA UNIV OF SCI & TECH

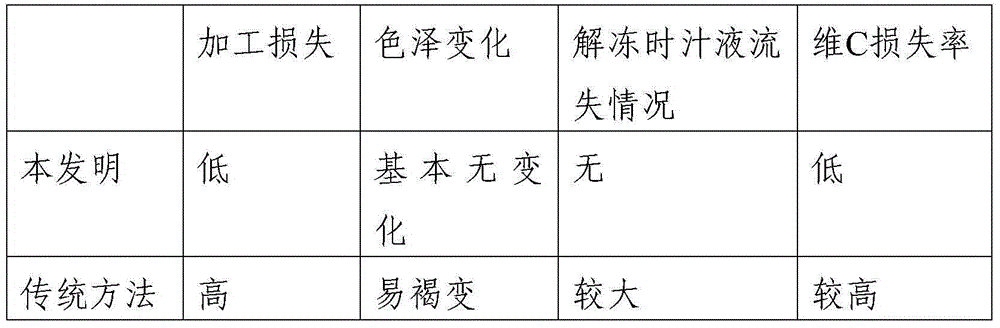

Frozen original pulp of purple Chinese yam and preparation method thereof

ActiveCN105231145ASolve the problem of raw materialsNo churnFood freezingFood ingredientsBULK ACTIVE INGREDIENTActive ingredient

The present invention relates to a freezing method for original pulp of purple Chinese yam. The preparation steps are as follows: subjecting the pre-processed purple yam to cold beating, color protecting, filling, quick freezing and freeze preservation in turn. The present invention provides a method of freezing and freeze-preserving the original pulp of purple Chinese yam, according to the method, thawed Chinese yam pulp can be prepared into purple Chinese yam powder by spray drying or be prepared into purple Chinese yam beverages, or can be directly used as raw materials for food processing, so that the problems of purple Chinese yam annual preservation and raw materials for processing are effectively solved. During the processing procedure, high temperature steps are avoid so as to effectively preserve active ingredients, and low temperature freeze preservation can effectively extend the shelf life of Chinese yam pulp and facilitate processing after thawing.

Owner:HUNAN AGRICULTURAL UNIV

Production of non-directional cold-rolling silicon steel disc

InactiveCN100478458CSolve the problem of raw materialsReduce rolling forceTemperature control deviceHeat treatment process controlAcid washingPre treatment

Owner:上海申群物资有限公司

Process for producing paper pipe glue from isooctyl ester wastewater

InactiveCN106634732ASolve processing problemsSolve the problem of raw materialsNon-macromolecular adhesive additivesStarch adhesivesChemistryCorn starch

The invention relates to the field of paper pipe glue and particularly relates to a process for producing paper pipe glue from isooctyl ester wastewater. In the process, raw materials include: polyvinyl alcohol, kaolin, corn starch, formaldehyde, hydrochloric acid, sodium hydroxide, a plasticizer, potassium persulfate, ethylene glycol, tap water, and the isooctyl ester wastewater. The formula is reasonable and the process is complete. By using the isooctyl ester wastewater as a raw material for producing the paper pipe glue, a problem of treatment of the isooctyl ester wastewater is solved, and a problem of raw materials of the paper pipe glue is solved, thus saving cost.

Owner:JIANGSU GUOJIAO CHEM TECH

PRM concrete reinforcing agent

The invention relates to the technical field of comprehensive utilization of red mud, gypsum and fly ash, in particular to a PRM concrete reinforcing agent. The PRM concrete reinforcing agent comprises the following components in percentage by weight: 5 to 30 parts of red mud Red mud, 5 to 30 parts of gypsum Gypsum, 10 to 50 parts of fly ash and 10 to 50 parts of mineral powder, and the sum of the weight ratios of all the components is 100. The raw materials are all dried after particles with the diameter being 0.5 cm or above are filtered out, and then the raw materials are fully and uniformly mixed. The PRM concrete reinforcing agent provided by the invention is low in price and high in strength, and solves the problem of industrial solid wastes.

Owner:上海百奥恒新材料有限公司

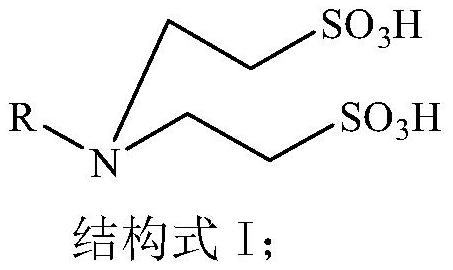

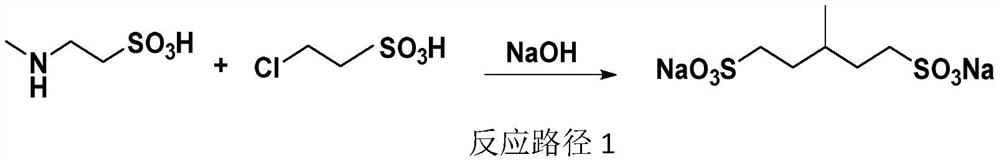

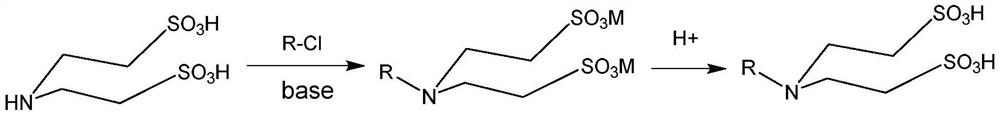

Production method of N, N-bis (2-sulfonic acid ethyl)-1-alkylamine

PendingCN112778169ALow costSimple structureSulfonic acids salts preparationSulfonic acid preparationSide productActive agent

The invention relates to a production method of N, N-bis (2-sulfonic acid ethyl)-1-alkylamine, wherein N, N-bis (2-sulfonic acid ethyl)-1-alkylamine is a core raw material for synthesizing a surfactant N, N-bis (2-sulfonic acid ethyl)-1-alkylamine disodium salt. The invention mainly solves the problem of finding a simple, convenient and environment-friendly synthesis method. The method comprises the following steps: reacting a by-product N, N-bis (2-sulfonic acid ethyl) amine generated in a taurine production process with 1-chloralkane under an alkaline condition to directly obtain N, N-bis (2-sulfonic acid ethyl)-1-alkylamine disodium salt, and acidifying to obtain N, N-bis (2-sulfonic acid ethyl)-1-alkylamine. According to the method, the raw material N, N-bis (2-sulfonic acid ethyl)-amine is a by-product caused by the problems of condition control and the like in the production process of taurine, and is convenient and easy to obtain, the reaction condition is mild, and the method is suitable for industrial production.

Owner:HUBEI GRAND LIFE SCI & TECH CO LTD

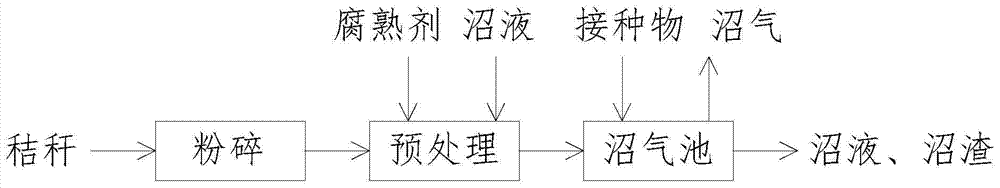

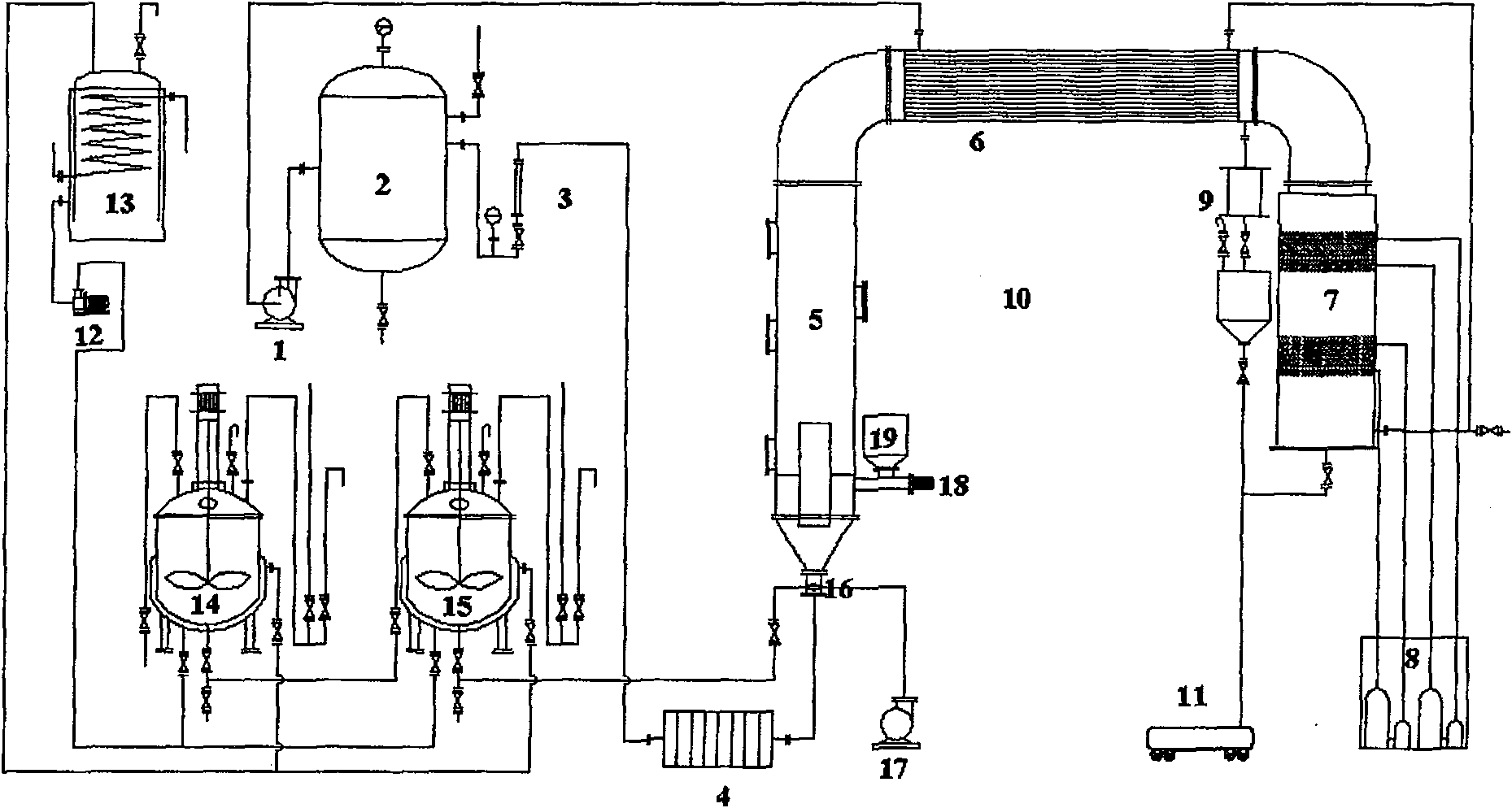

Household pure straw biogas fermentation process

ActiveCN104561112BSolve the problem of raw materialsStable outputWaste based fuelFermentationSlurryPre treatment

Owner:南京市生态环境保护科学研究院

Controlled fertilizer of polymer capsule, production method, and dedicated capsule material

InactiveCN100558682CNo toxicityPromote safe productionFertiliser formsGranulation by powder suspensionLow-density polyethyleneLinear low-density polyethylene

The invention discloses a polymer-coated controlled-release fertilizer, a production method and a special coating material. The coating material of the controlled-release fertilizer comprises branched low-density polyethylene with an average molecular weight between 20,000-30,000 Daltons and linear low-density polyethylene with an average molecular weight between 20,000-30,000 Daltons; The mass fraction ratio of the branched low-density polyethylene and the linear low-density polyethylene is 1:0.33-1. The polymer-coated controlled-release fertilizer is composed of a water-soluble fertilizer and the coating material in claims 1-4; the coating material is coated on the water-soluble fertilizer. The coated fertilizer of the invention has good controlled-release performance, safe and non-toxic processing technology, and can be used for economic crops such as lawns, flowers and vegetables.

Owner:CHINA AGRI UNIV

Preparation method of modified macroporous styrene-divinylbenzene anion exchange resin

InactiveCN110975943AThe reaction process is simpleShort reaction timeOrganic anion exchangersAnion exchanger materialsFormamideDivinylbenzene

The invention discloses a preparation method of modified macroporous styrene-divinylbenzene anion exchange resin. Phthalimido styrene-divinylbenzene resin and sodium hydroxide which are used as raw materials are reacted in the presence of a catalyst and a solvent to obtain the modified macroporous styrene-divinylbenzene anion exchange resin. The amino functional group content of the modified macroporous styrene-divinylbenzene anion exchange resin prepared by the method is 2.4-6.5 mmol / g, and the method has the advantages of simple reaction process, short time, low energy consumption, small environmental pollution and low cost, and is an ideal process for realizing industrial production.

Owner:JIANGSU XINLU CHEM NEW MATERIAL

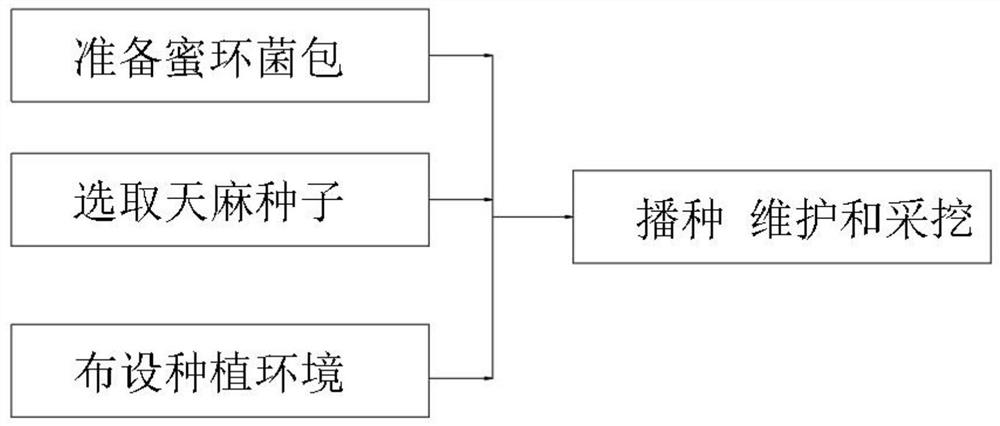

Technology for large-scale cultivation of gastrodia elata through improved armillaria mellea bags

The invention discloses a technology for large-scale cultivation of gastrodia elata through improved armillaria mellea bags, which comprises a preparation stage and a later stage. The preparation stage comprises three steps of preparing armillaria mellea bags, selecting gastrodia elata seeds and laying a planting environment, and the later stage comprises a sowing stage, a maintenance stage and a digging stage. The step of preparing the armillaria mellea bags is carried out before the two steps of selecting gastrodia elata seeds and arranging a planting environment. According to the step of preparing the armillaria mellea bags, A1, the armillaria mellea bag comprises two raw material formulas: 1) 70% of fresh weed tree sawdust, 15% of corn flour, 12% of bran, 1% of bean pulp powder, 1% of sesame cake powder and 1% of gypsum powder; the water content is 65 + / -1%; 2) 50% of pleurotus eryngii and flammulina velutipes wastes which cannot be fermented, 30% of coarse sawdust, 18% of bran or corn flour, 1% of soybean meal powder and 1% of sesame cake powder, and the water content is 65 + / -1%. In the operation process, cost, resources and labor force are saved, the growth cycle of gastrodia elata is shortened, economic benefits are improved, and the problem of contradiction between raw materials and ecology in large-scale cultivation is solved.

Owner:HUBEI UNIV OF CHINESE MEDICINE

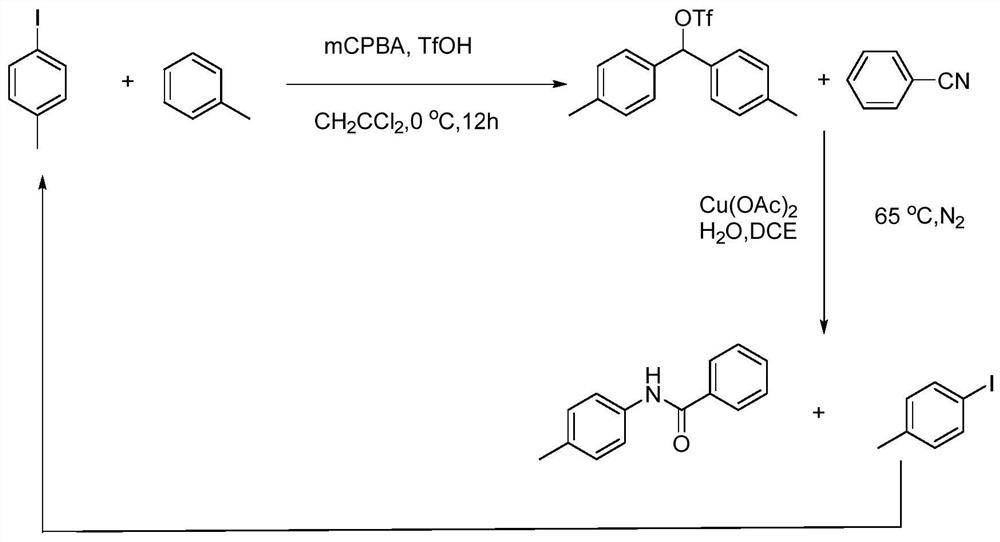

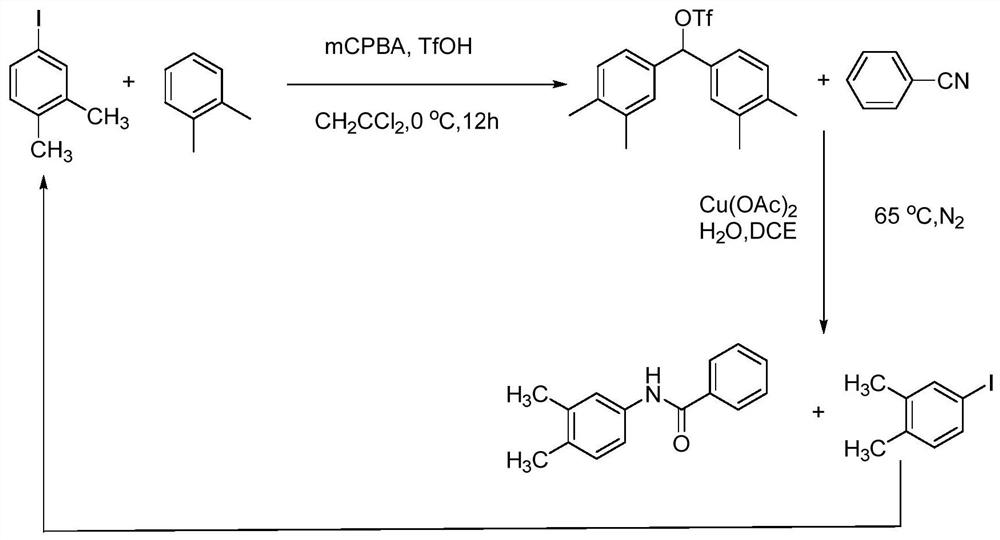

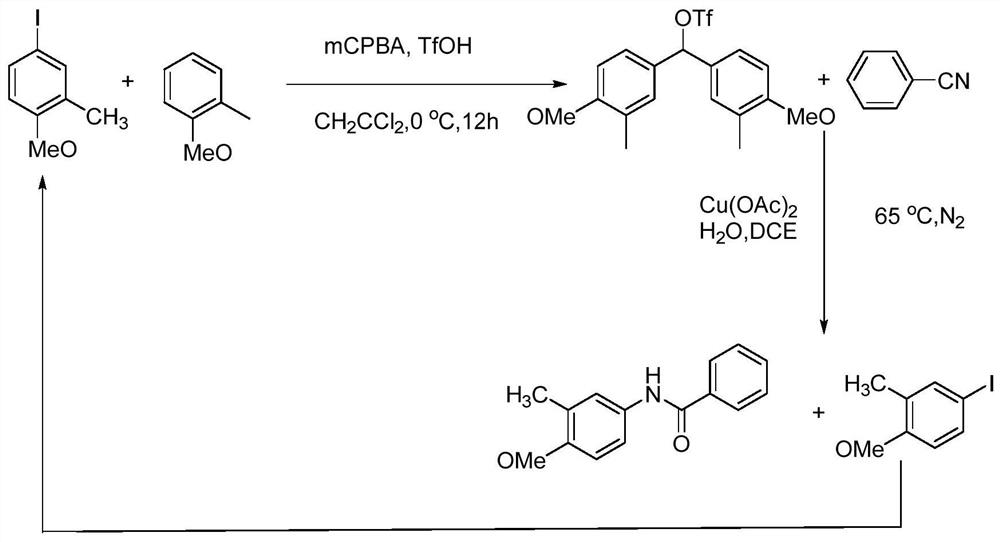

Synthesis method of N-aryl amide with recoverable raw materials

PendingCN113387846ALow priceFew synthetic stepsEther separation/purificationOrganic compound preparationArylCombinatorial chemistry

The invention provides a synthesis method of N-aryl amide with recoverable raw materials, which utilizes the double influence of steric hindrance and electric aromatic hydrocarbon effect on amidation selectivity, so that amidation only occurs at the para-position of an aromatic hydrocarbon electron-rich substituent group, then a single product is prepared accordingly, and the raw material problem of Goldberg reaction and the position selectivity problem of direct C-H bond amidation are solved.

Owner:周旭明

Rock wool produced by using phosphorous slag and preparation method thereof

ActiveCN101786790BImprove fire performanceImprove insulation effectGlass making apparatusChemical industrySlag

The invention discloses a rock wool produced by using phosphorous slag and a preparation method thereof, the rock wool is prepared by phosphorous slag as main raw material and dolomite and bauxite both as auxiliary raw material, wherein the proportions of the raw materials by weight part are calculated as below: 60-85 parts of phosphorous slag, 1-8 parts of dolomite and 10-25 parts of bauxite. Compared with the current method for producing rock wool with natural volcanic rock or volcano metamorphic rock, the method according to the invention realizes the production of the rock wool by using the phosphorous slag as raw material, which not only settles the raw material problem about rock wool heat-preserving material during the production in regions without natural volcanic rock or volcano metamorphic rock, but also widens the comprehensive utilization scope of industrial solid wastes such as the phosphorous slag and the like; adopting the method can effectively utilize the phosphorous slag and other industrial solid wastes to develop novel product with high added value, conforming to the requirements of policies related to cyclic economy as well as energy conservation and pollution reduction, and simultaneously achieving excellent development prospect. The rock wool produced according to the method has the advantages of good fireproof and heat preservation performance, long use time and the like, and is particularly suitable for the use as heat preservation material in the industries such as heat preservation of building energy-saving wall, chemical industry, building material, etc.

Owner:贵州省建筑材料科学研究设计院有限责任公司 +1

Method of consuming wind power blade waste in heat-engine plant

InactiveCN107202324AWide range of applicationsBroad application prospectsIncinerator apparatusCombined combustion mitigationCircular economyCoal

The invention provides a method of consuming wind power blade waste in a heat-engine plant. The method comprises the following steps: metal components and high-chlorine-content components are separated from the wind power blade waste, and the rest of the wind power blade waste is cut into block-shaped waste; the block-shaped waste is pulverized into particles and thus a pulverized material is obtained; and the pulverized material acts as an alternative fuel of the heat-engine plant and is burnt in a boiler of the heat-engine plant. The method is simple and practical, the initial investment and the subsequent maintenance cost are little, the method is environment-friendly and harmless, belongs to a circular economy mode, and corresponds with a treatment policy of "reduction, reclamation and harmlessness" on municipal waste, the problem that the treatment on thermosetting material waste is difficult, which perplexes the society for a long time is solved, the alternative fuel is provided for the heat-engine plant, the usage of coal is reduced and the method has wide application prospects.

Owner:SINOMATECH WIND POWER BLADE

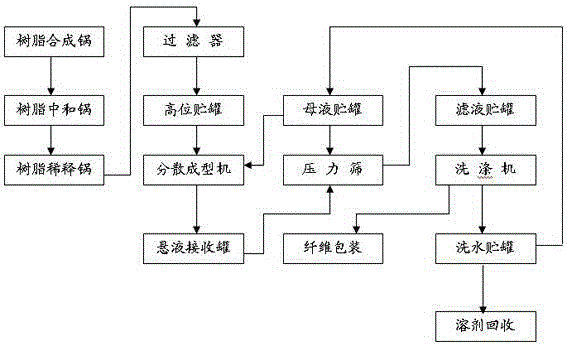

Production method of meta-position aramid paper fibrid

InactiveCN102660795BEasy to shapeGood dispersionSynthetic cellulose/non-cellulose material pulp/paperMonocomponent polyamides artificial filamentChlorideFiber suspension

Owner:SICHUAN YUNTONG CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com