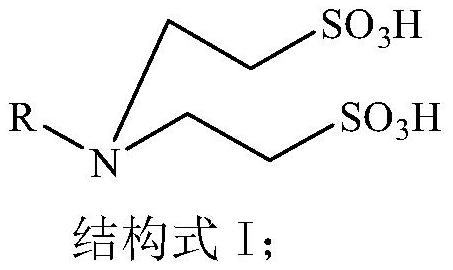

Production method of N, N-bis (2-sulfonic acid ethyl)-1-alkylamine

A technology for the production of ethyl sulfonate, which is applied in the chemical field, can solve problems such as high cost, high sulfur content, and environmental impact, and achieve the effects of reduced by-products, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

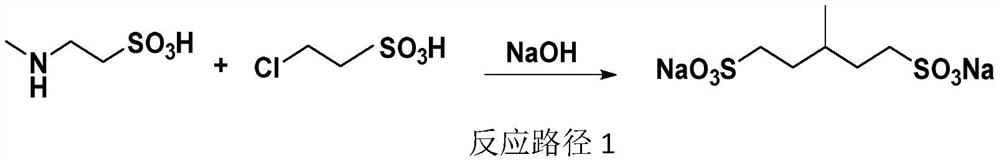

Problems solved by technology

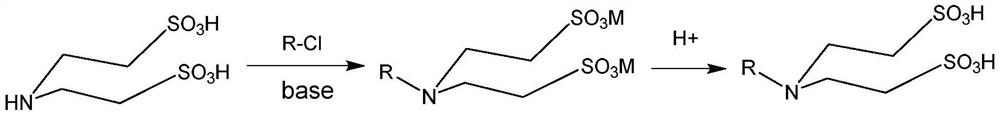

Method used

Image

Examples

Embodiment 1

[0034] Preparation of N,N-bis(2-sulfonic acid ethyl)amine by separation and purification

[0035] In a 5L autoclave, add 296.2g sodium isethionate (2mol), 303.6g 28% ammonia solution (NH 3 About 5mol), 1L of deionized water, react at 260°C for 1 hour, cool to about 80°C, and remove excess ammonia by vacuum distillation. After removing ammonia, the material is acidified by cation exchange membrane to obtain taurine , N, N-bis(2-sulfonic acid ethyl)amine eluent. Heat and concentrate until the content of taurine is about 34%, recrystallize at lower temperature, filter out taurine, and concentrate the remaining primary mother liquor again until the content of taurine is about 34%, recrystallize at lower temperature, filter out taurine , when the remaining about 300mL of the secondary mother liquor was concentrated until cloudy, add 100mL of methanol, place overnight at 0-5°C, filter out the solid, and dry the solid to obtain N,N-bis(2-sulfonic acid ethyl) Amine 27.9 g. The reac...

Embodiment 2

[0037] Preparation of N,N-bis(2-sulfonic acid ethyl)-1-n-octylamine disodium

[0038] In a 500 ml three-necked flask, add 23.3 g of N,N-bis(2-sulfonic acid ethyl)amine (0.1 mol) and 60 mL of deionized water, then add 50 g of acetone and 16.3 g of 1-chloro-n-octane (0.11 mol), simultaneously dropwise add 5N sodium hydroxide aqueous solution, and heat to 25 ℃, and carefully control the pH of the reaction solution in the whole process at the same time between 9~10, the dropping speed is fast at the beginning, as the reaction approaches the end point, The rate of addition slowed down, and the addition was completed in about 1 hour. After the dropwise addition, continue the heat preservation reaction for 2 hours, then cool to obtain a white paste reaction product, put it in the refrigerator overnight, filter, wash the filter cake with acetone, and dry to obtain a white solid N,N-bis(2-sulfonic acid ethyl Base)-1-n-octylamine disodium salt 20 grams (51.5% yield).

Embodiment 3

[0040]Preparation of N,N-bis(2-sulfonic acid ethyl)-1-n-octylamine disodium

[0041] In a 500 ml three-necked flask, add 23.3 g of N,N-bis(2-sulfonic acid ethyl)amine (0.1 mol) and 60 mL of deionized water, then add 50 g of acetone and 16.3 g of 1-chloro-n-octane (0.11 mol), simultaneously dropwise add 5N sodium hydroxide aqueous solution, and heat to 50 ℃, and carefully control the pH of the reaction solution in the whole process at the same time between 9~10, the dropping speed is fast at the beginning, as the reaction approaches the end point, The rate of addition slowed down, and the addition was completed in about 1 hour. After the dropwise addition, continue the heat preservation reaction for 2 hours, then cool to obtain a white paste reaction product, put it in the refrigerator overnight, filter, wash the filter cake with acetone, and dry to obtain a white solid N,N-bis(2-sulfonic acid ethyl Base)-1-n-octylamine disodium salt 33 grams (yield 85%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com