Patents

Literature

63results about How to "Save on processing fees" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

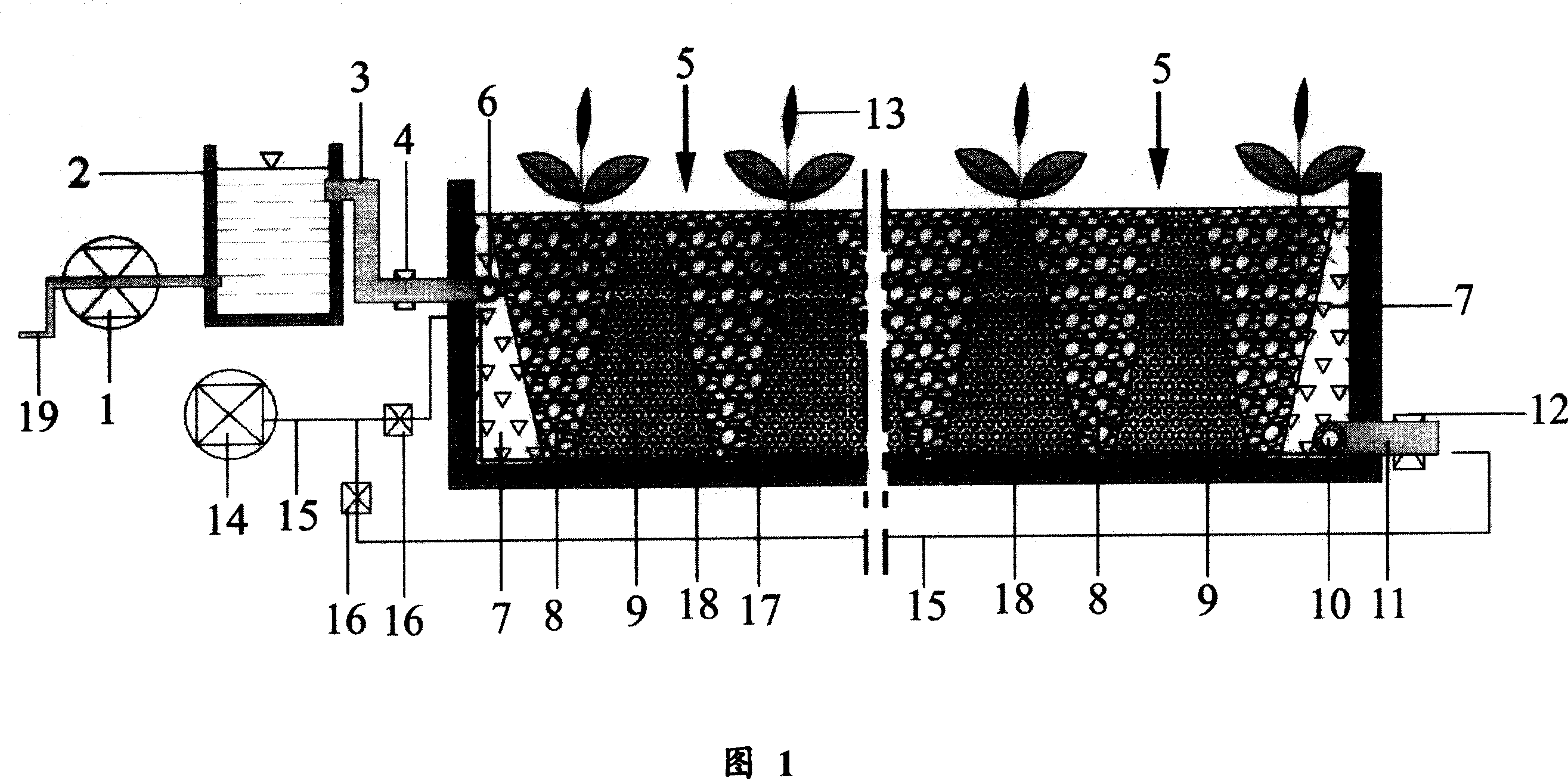

Stirring type undercurrent wetland water body purification apparatus and water body purification method

InactiveCN101007688ARestoring self-cleaning functionReduce resistanceTreatment using aerobic processesSustainable biological treatmentVegetationPurification methods

The invention discloses a self-purification device of disturbing typed artificial hidden flow marshland and purifying method, which is characterized by the following: displaying cube-boxing type; filling packing matrix into pool; planting vegetation on the upper surface of packing matrix; equipping cloth water pipe; incoming water pipe on the two sides of marshland purifying pool; making upper of water level balancing tank higher than marshland purifying pool; penetrating aerated pipe on the bottom of marshland purifying pool; aerating into marshland purifying pool with aeration machine; discharging assembling water from exhaust pipe. The invention possess short time limit for a project and low operation cost.

Owner:TIANJIN WATER CONSERVANCY INST

Energy-saving insulating brick

InactiveCN101172831AExcellent heat absorption and heat preservation effectImprove insulation effectSolid waste managementBrickPortland cement

The invention relates to an energy saving heat preserving brick which solves the technical problems that the prior construction wall has cockamamie energy saving and heat preserving measure constructions, long construction period and high cost. The invention comprises the steps as follows: mixing and stirring the raw materials, extruding for shaping and maintaining. The weight ratio of the raw materials is that: 230 to 320 parts of portland cement, 35 to 20 parts of swelling perlite, 430 to 610 parts of general sand, 70 to 15 parts of cinder, 6 to 3 parts of straw, 4 to 2 parts of plant ash, 1.6 to 2 parts of felted wool fibre, and 97 to 135 parts of water. The invention has good energy saving and heat preserving capacities and good compression resisting intensity.

Owner:江苏康顺鼎上节能保温科技股份有限公司

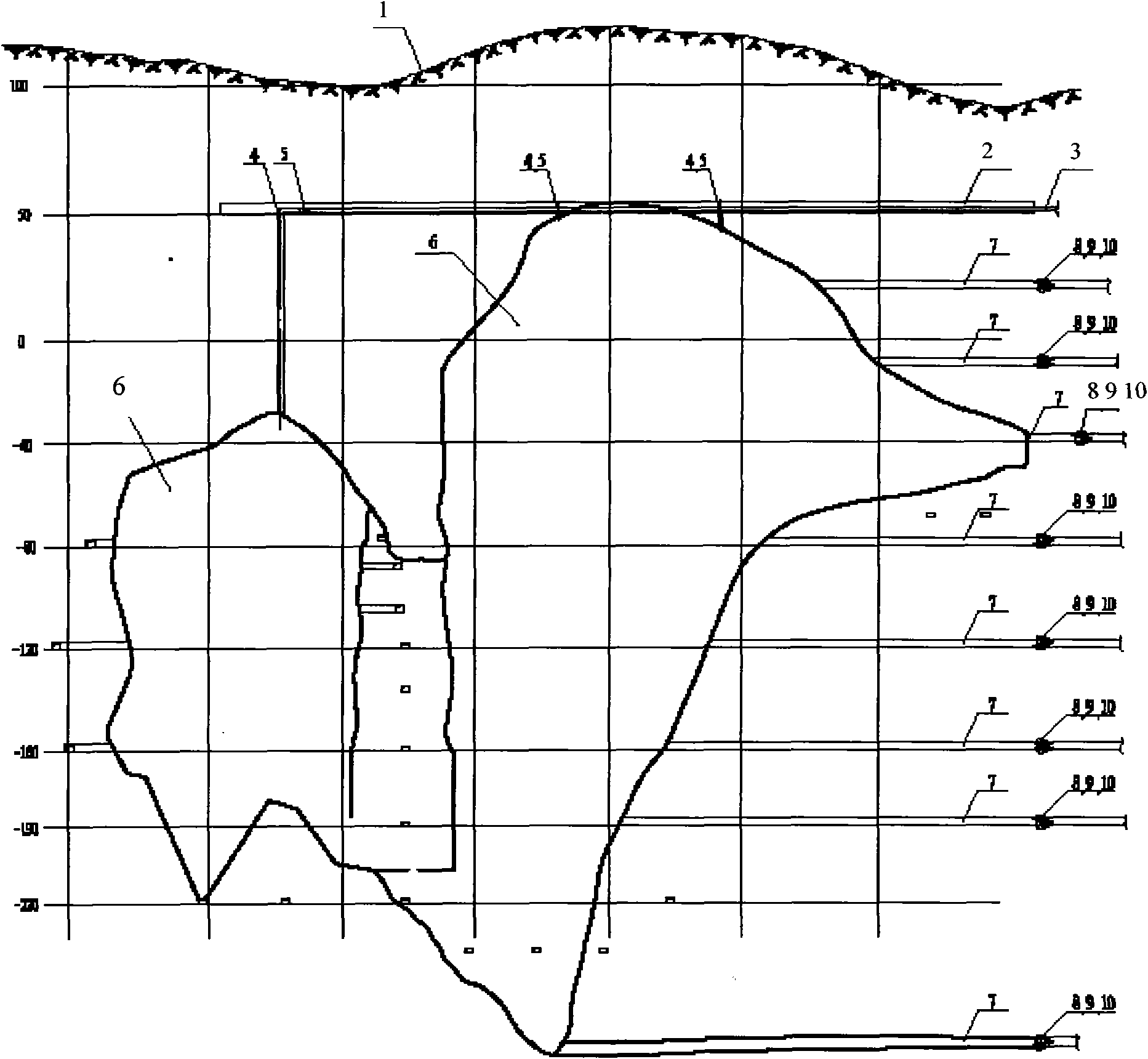

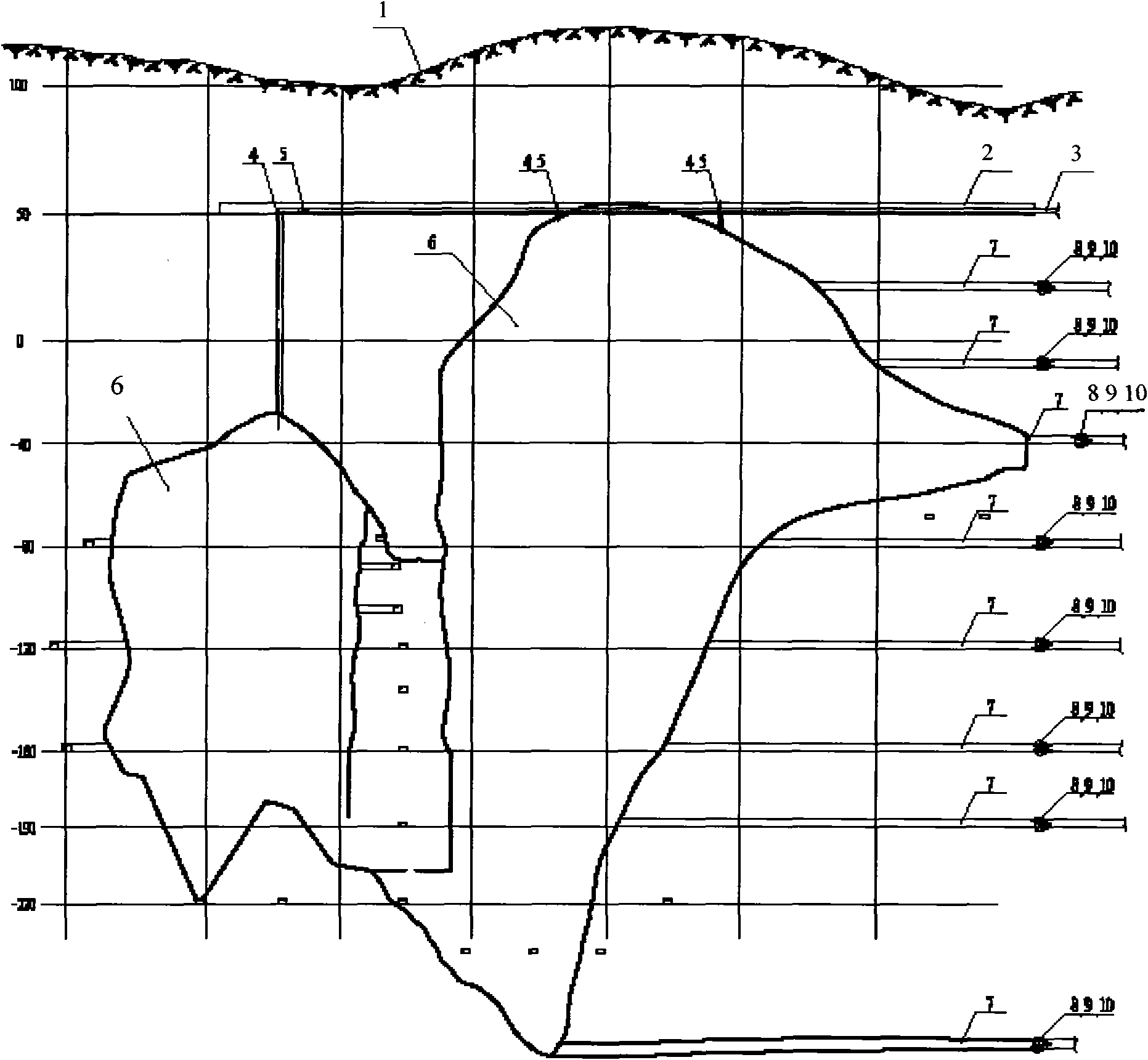

Full tailing filling method in large goafs

InactiveCN101892862AEliminate potential safety hazardsGuarantee normal productionMaterial fill-upDrainageLand acquisitionMining engineering

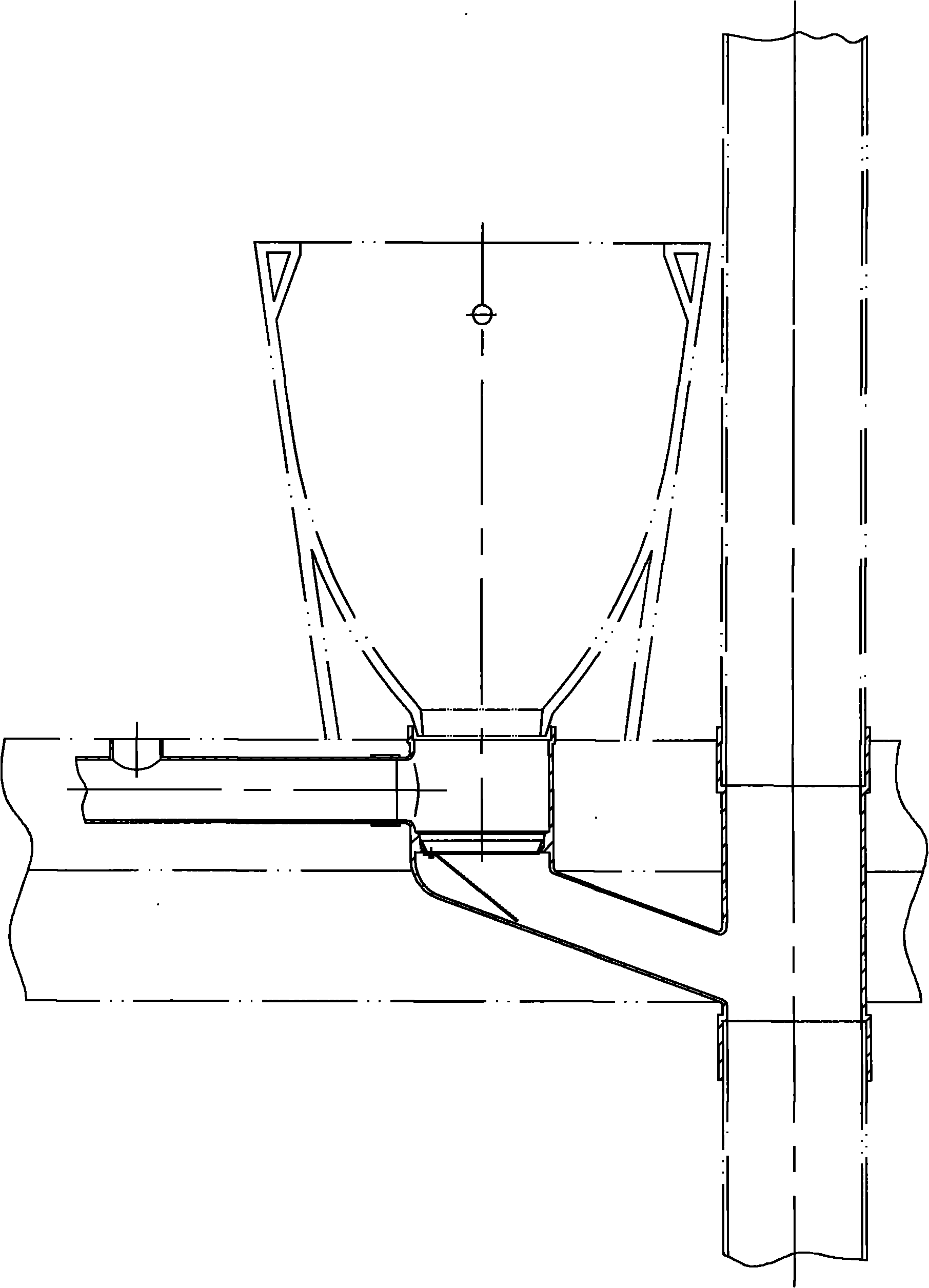

The invention discloses a full tailing filling method in large goafs, which is realized by the technical scheme with the following steps: dividing the combination of relatively independent and adjacent single or a plurality of goafs (6) into a filling unit; building a sealed wall (8) on a tunnel (7) at the periphery of the goafs (6) of the filling unit, arranging a drain pipe (9) in the wall body of the sealed wall (8), and arranging an ore pulp valve (10) on the drain pipe (9); laying a tailing conveying main pipe (3) above the filling unit through an adit (2) above the goafs (6); connecting each upper opening of the filling unit to one or a plurality of hydraulic sand filling pipes (4) through the tailing conveying main pipe (3); and discharging sand at high levels, discharging water in different middle sections, and filling alternately. In the invention, full tailings are used for filling the existing goafs, thereby eliminating the potential safety hazards of the goafs, ensuring the normal production of large deep well mines, saving the treatment cost, the tailing stockpiling and land acquisition cost and the drainage cost of the goafs, realizing the purpose of less-waste and no-waste exploitation, and taking an demonstration effect on constructing ecological mines.

Owner:HUAWEI METAL MINERAL RESOURCE EFFICIENT RECYCLING UTILIZATION NAT ENG RES CENT CO LTD

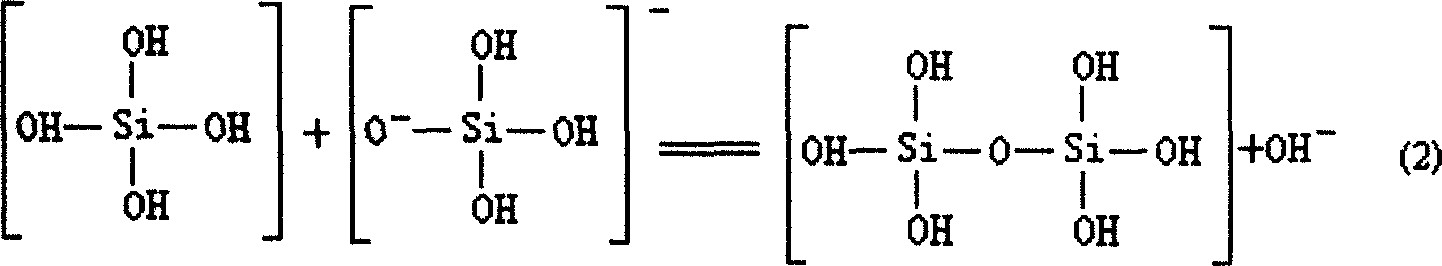

Preparation method of active glass powder mixture material

The invention discloses a preparation method of an active glass powder mixture material and belongs to the field of building materials. In the invention, active glass powder in the grade of 50 [mu]m is used for replacing cement in a concrete mixture material, and with proper additives, concrete satisfying corresponding standard is prepared by means of material blending of the active glass powder with other sand, pebble and water reducing agents according to a reasonable ratio. The method can consume domestic waste glass at large quantity with the addition amount being 1:(3-7), so that performances of concrete are improved, thereby turning the waste glass into useful resources. The method can save cost and protect environment. Strength of the prepared concrete can satisfy national standard completely and satisfy the requirement in C15-C40 grades. The concrete is excellent in durability. The preparation method is simple, is low in cost, allows large-scale production at various regions and different weather conditions, and is greatly improved in operability and reduced in enterprise cost.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

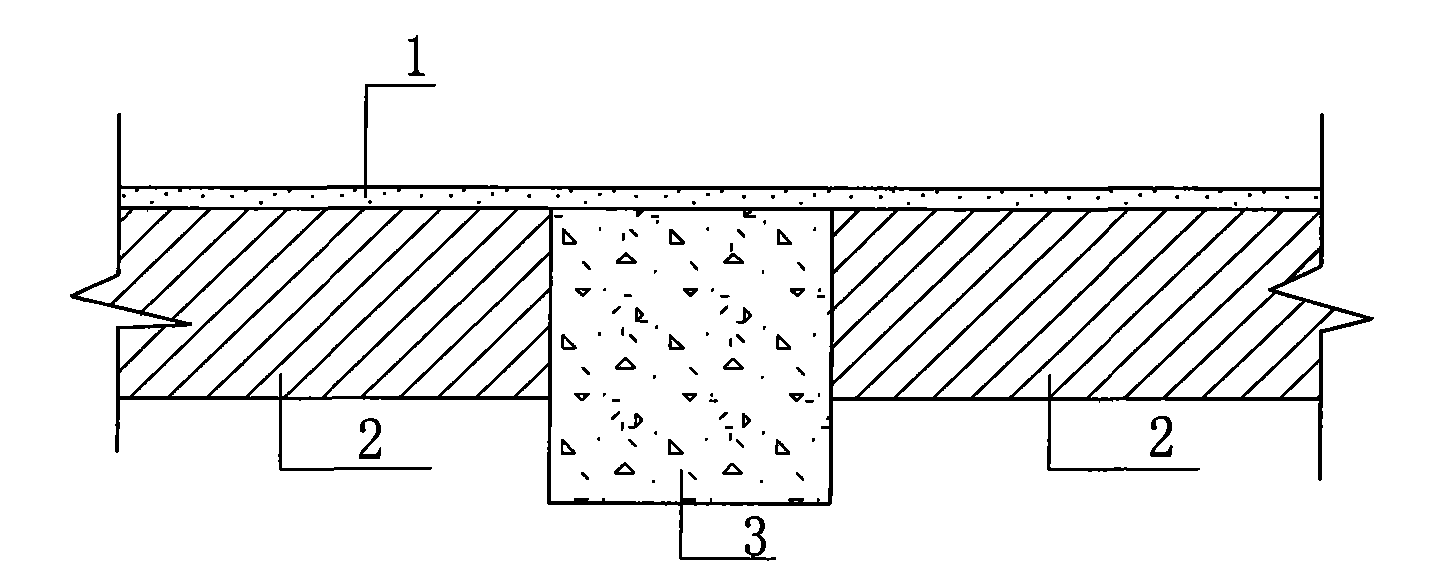

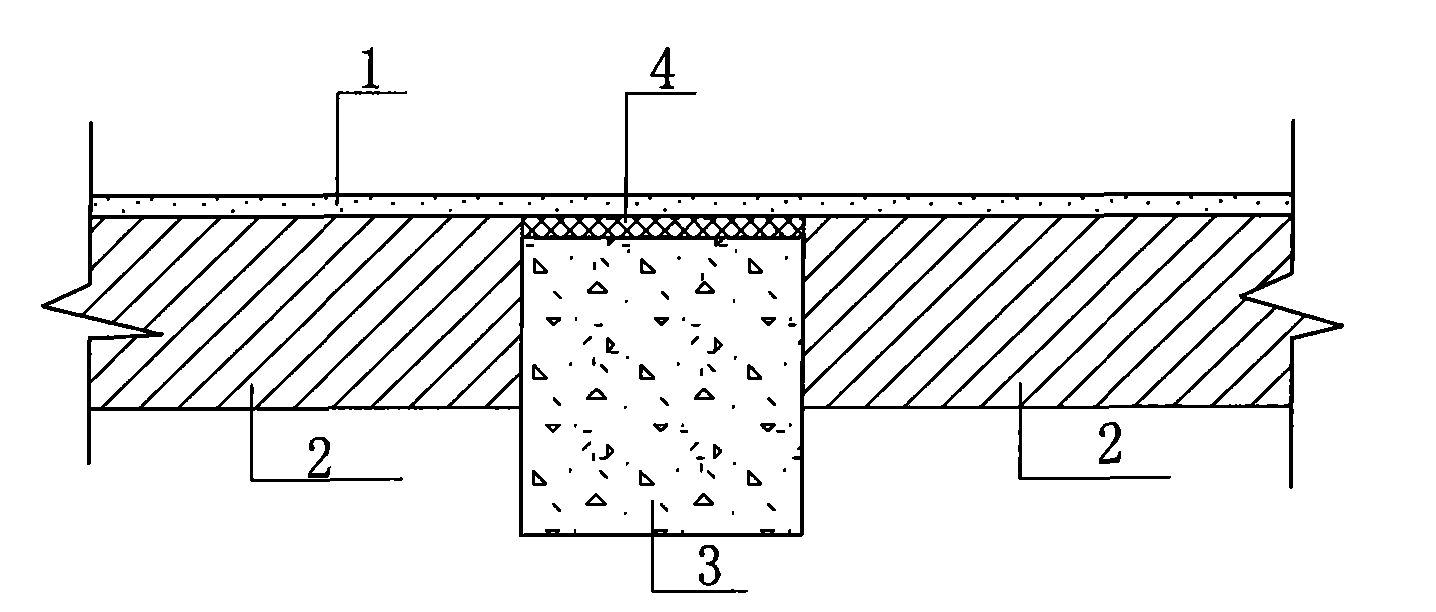

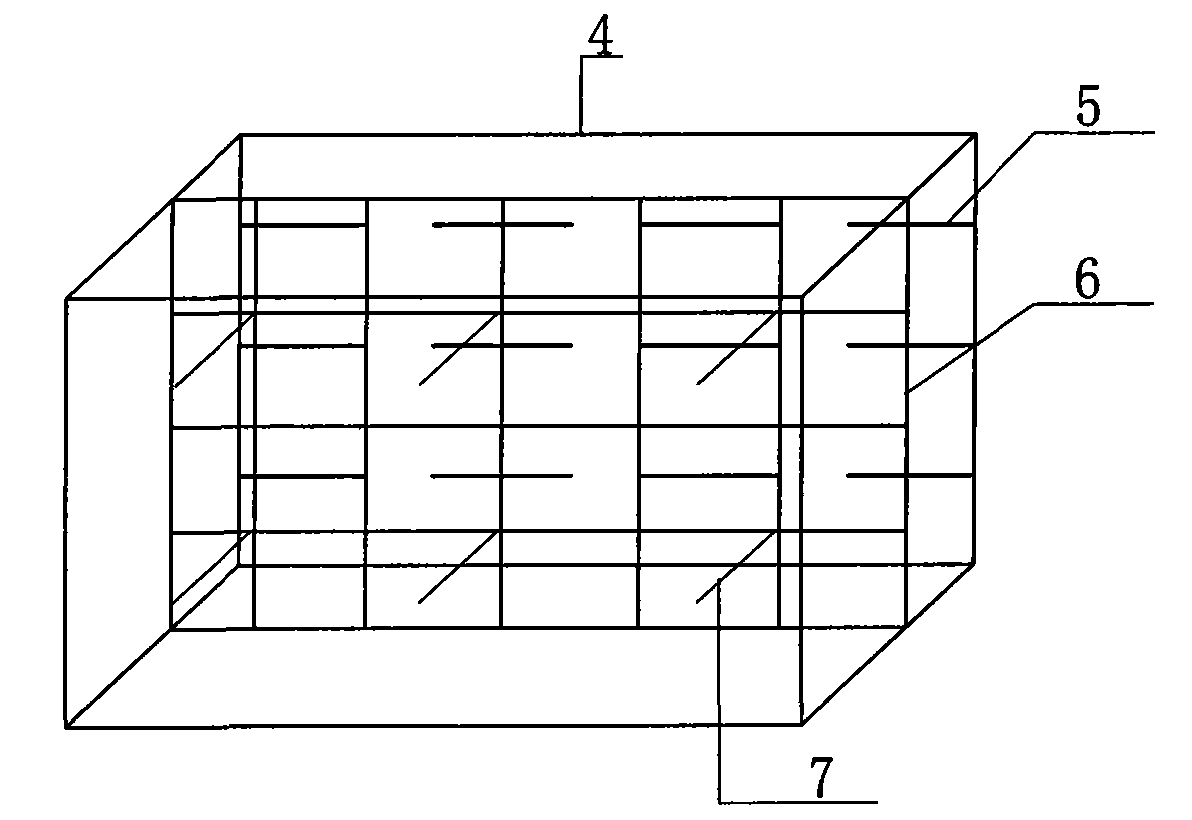

Insulation board of concrete exterior wall

InactiveCN101597940AImprove insulation effectHigh mechanical strengthSolid waste managementCeramic shaping apparatusBreaking strengthFiber

The invention relates to an insulation board of a concrete exterior wall, in particular to the insulation board of the concrete exterior wall at a heat bridge part, which is used in match with the exterior wall body constructed by energy-saving insulation building blocks. The invention is prepared by the following steps: raw materials are mixed, molded by extrusion to obtain the insulation board molding product which is subjected to steam curing and drying to obtain the insulation board molding product of the concrete exterior wall; the invention is characterized in that: before the invention is molded by extrusion, steel mesh is put into the raw materials followed by being molded by extrusion to be the insulation board molding product; the raw materials comprise the following components according to weight percentage: 235-242 parts of silicate cement, 65-67 parts of expanded perlite, 43-45 parts of ceramsite, 80-83 parts of slag, 4-2 parts of plant ash, 1.5-2 parts of wool felt fiber, 0.5-1.0 parts of cloth fiber, 0.5-1.0 parts of bamboo fiber and 94-96 parts of water. The invention has good insulation property, can effectively reduce the heat bridge effect of the exterior wall constructed by energy-saving insulation building blocks, has high breaking strength and can have the same service life with the exterior wall constructed by insulation blocks.

Owner:无锡市康顺节能材料科技有限公司

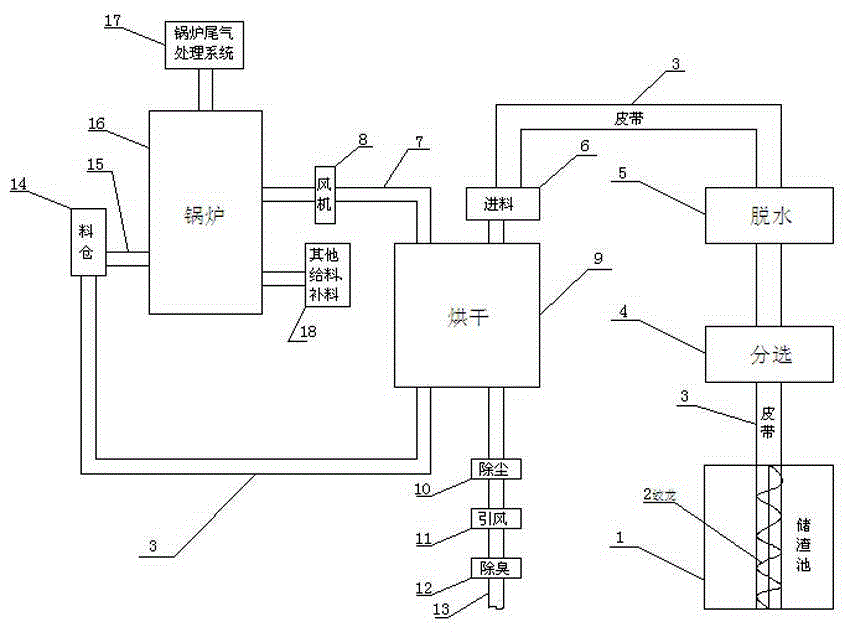

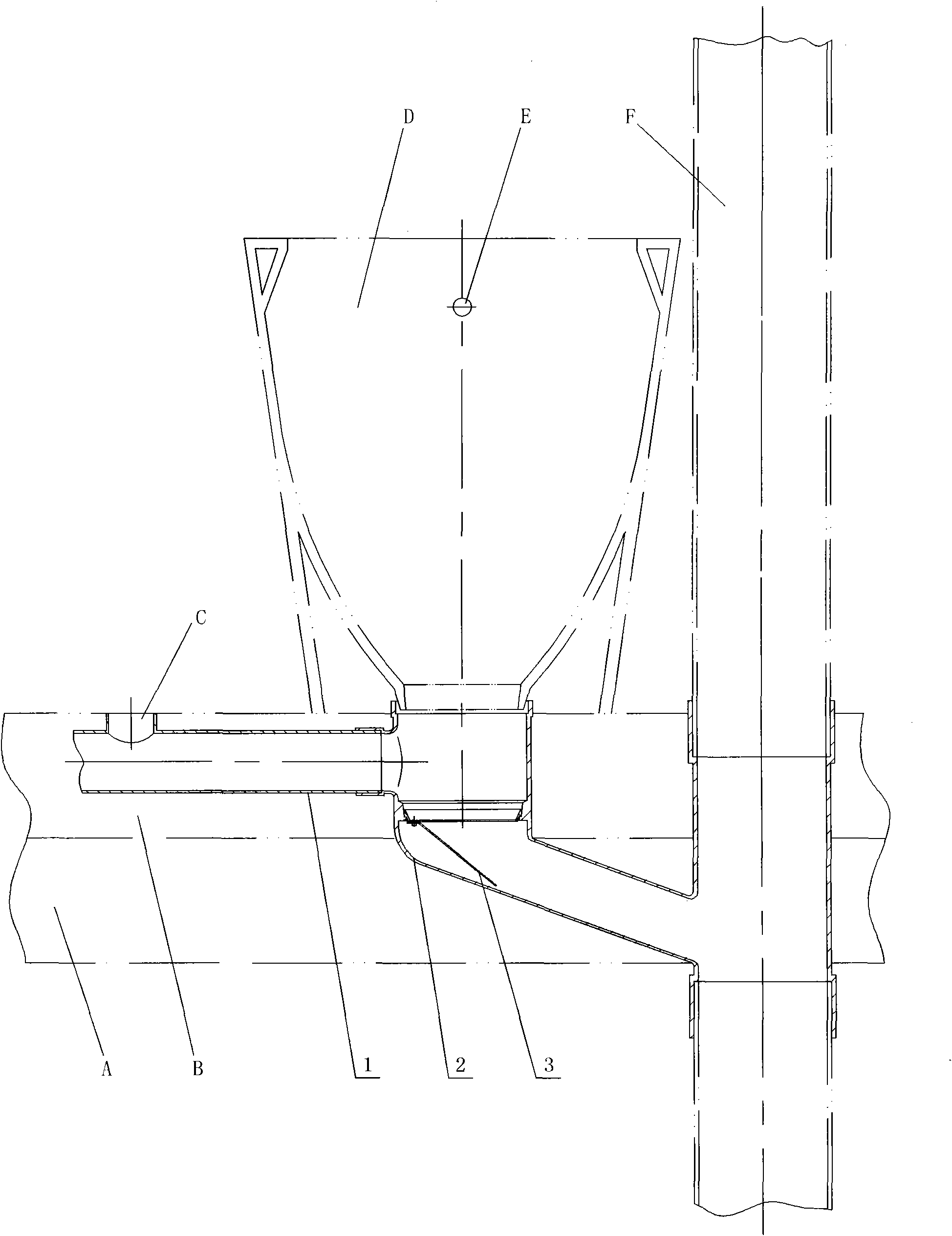

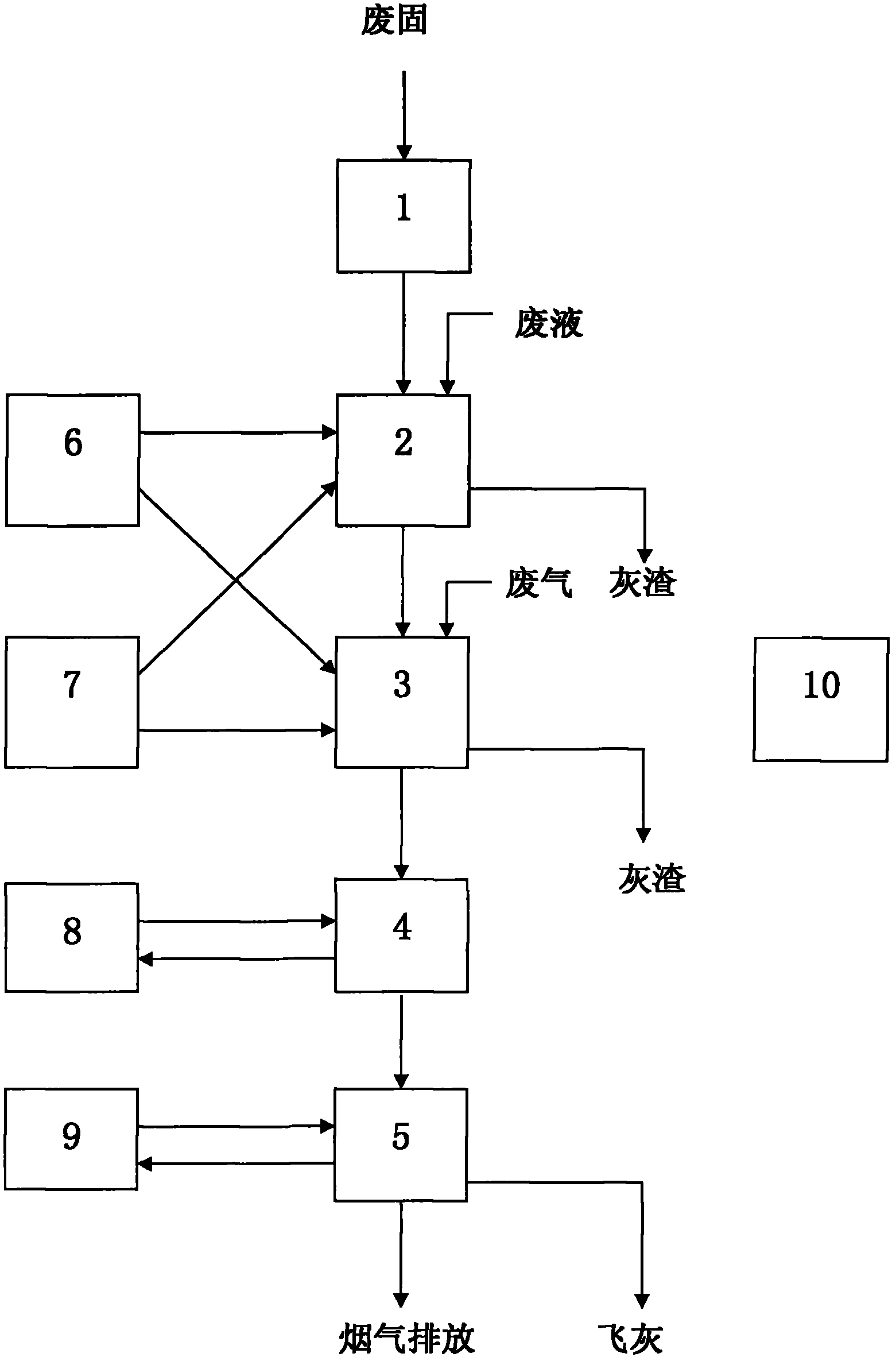

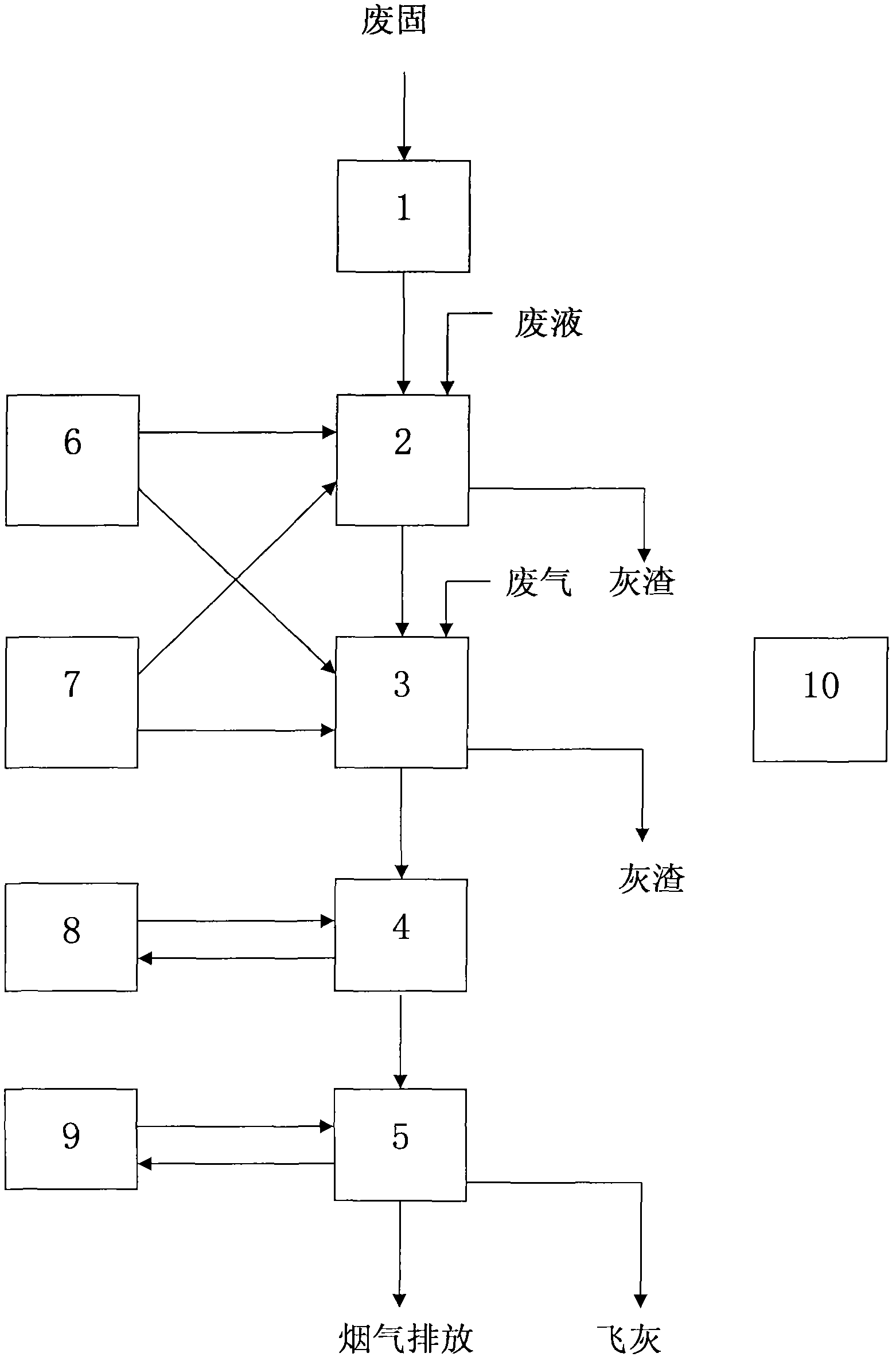

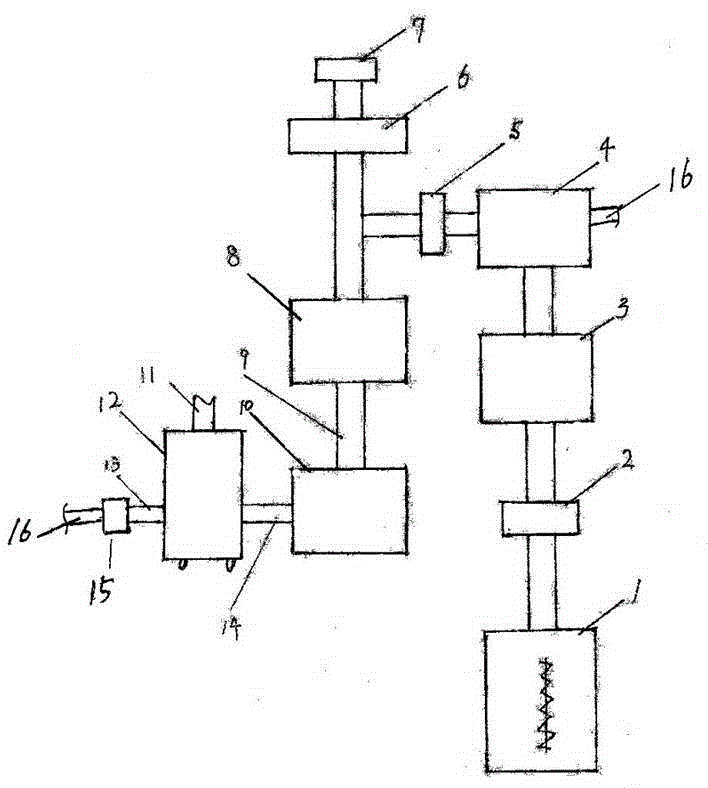

Medicine leached residue or food residue boiler combustion treatment system

InactiveCN104990090ASave on processing feesEasy to useIncinerator apparatusEcological environmentCombustion chamber

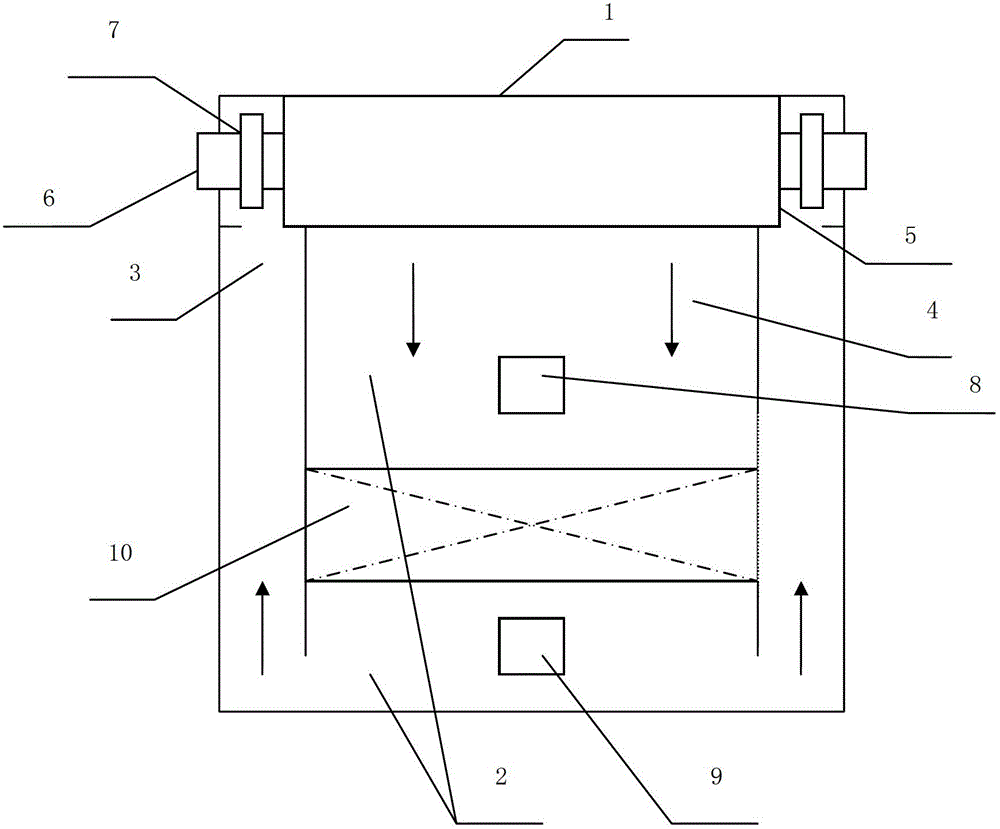

The invention relates to a medicine leached residue or food residue boiler combustion treatment system. The medicine leached residue or food residue boiler combustion treatment system includes a residue storage tank, a dewatering machine, a drying machine and a boiler; the residue storage tank is installed at the inlet of the system; a spiral conveyer is installed in the residue storage tank; waste is transported to a sorting machine through the belt of the spiral conveyer, and then passes through the squeezing dewatering machine, and enters the drying machine so as to be dried; dried materials are sent to the boiler through a belt and a feeding device so as to be combusted; the top of the drying machine is provided with a feeder and an air inlet; the air inlet is connected with one end of a smoke pipe; and the other end of the smoke pipe is communicated with the combustion chamber of the boiler, so that part of high-temperature hot smoke in the combustion chamber of the boiler can be led to the drying machine so as to be adopted as a heat source for drying the materials. With the system adopted, wet waste can be dried and combusted, and heat energy generated in the combustion of the waste can be utilized to provide a heat source for the drying machine and the boiler, and therefore, the system is convenient to use, and waste treatment fees can be decreased, and the occupation of farmland can be avoided, and pollution to the environment can be avoided, and ecological environment protection and people's health can be benefitted. The medicine leached residue or food residue boiler combustion treatment system is suitable for being applied to traditional Chinese medicine or food production enterprises.

Owner:周伟初

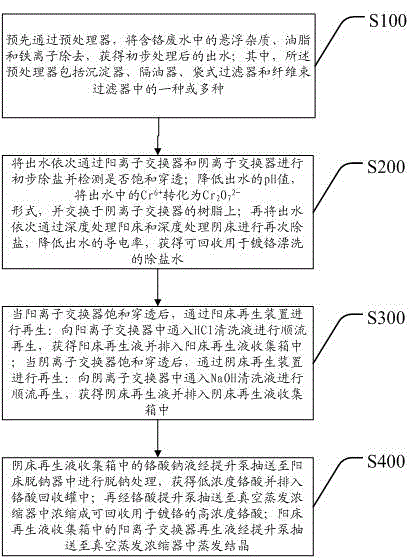

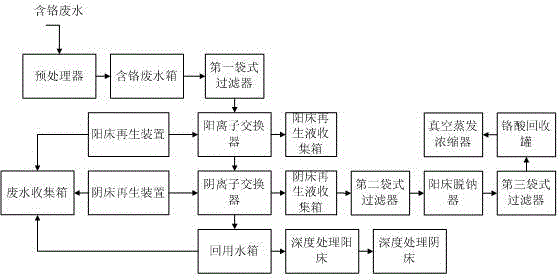

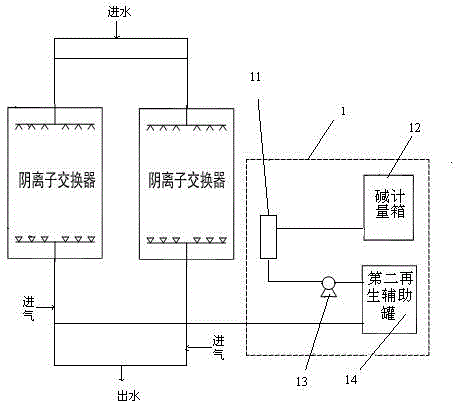

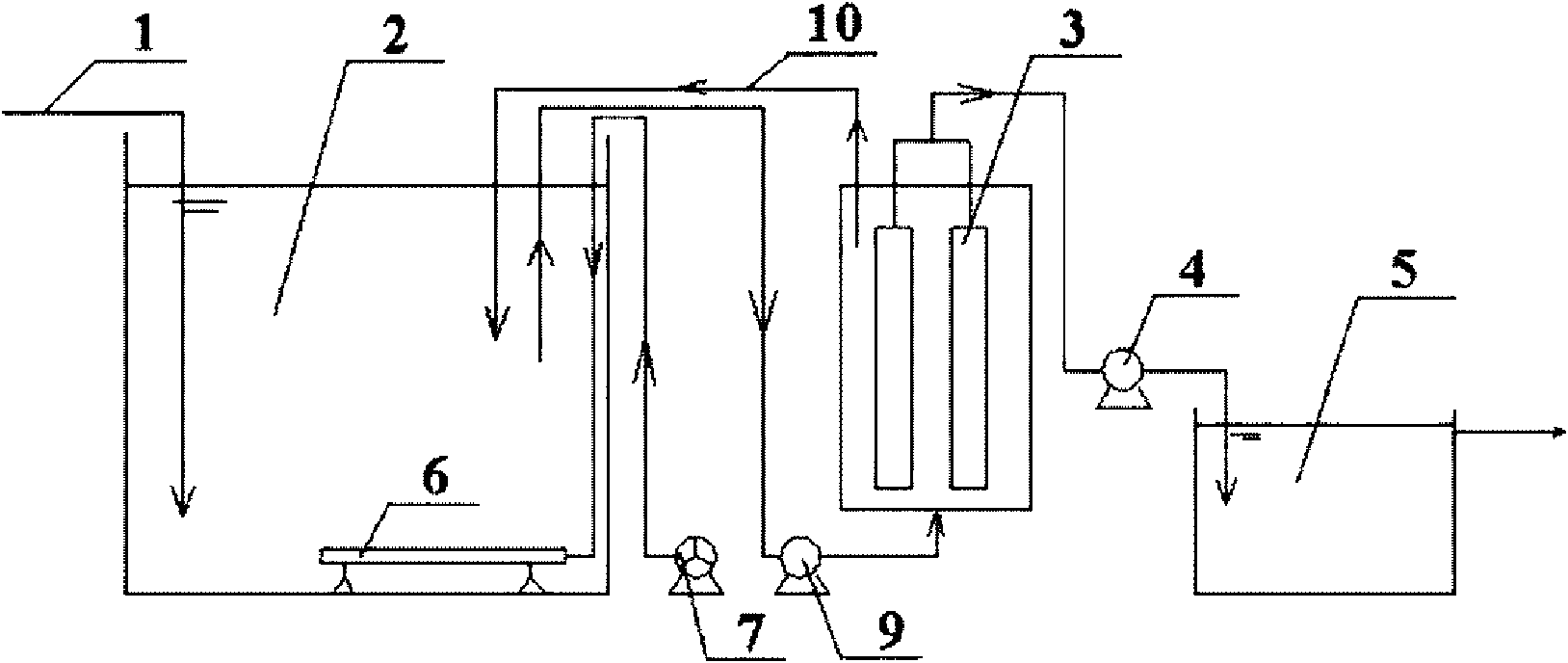

Electroplating chromium-containing wastewater treatment method and device

ActiveCN104909508ARealize closed loop recyclingReduce dosageGeneral water supply conservationWater contaminantsHigh concentrationImpurity

The invention discloses an electroplating chromium-containing wastewater treatment method and device. The treatment method comprises the following steps: (A) pre-removing impurities in chromium-containing wastewater by virtue of a pretreatment device, so as to acquire primarily treated effluent; (B) sequentially carrying out primary desalination on effluent by virtue of a cation exchanger and an anion exchanger, carrying out secondary desalination on effluent by virtue of an advanced treatment cation bed and an advanced treatment anion bed again, so as to obtain desalted water which can be recycled for chromium plating rinsing; (C) regenerating by virtue of a cation bed regeneration device when the cation exchanger is saturated and penetrated, and regenerating by virtue of an anion bed regeneration device when the anion exchanger is saturated and penetrated; and (D) carrying out sodium removal on anion bed regenerated liquid, and concentrating to form recyclable high-concentration chromic acid or carrying out evaporative crystallization. According to the electroplating chromium-containing wastewater treatment method, by virtue of a two-stage cation-anion bed system, the environmental pollution of hexavalent chromium is eliminated, and meanwhile, high-quality desalted water can be obtained and can be applied to production, so that the consumption of tap water and desalted water is saved, and the good economic benefit is achieved.

Owner:GUANGDONG XINTAILONG ENVIRONMENTAL PROTECTION GRP CO LTD

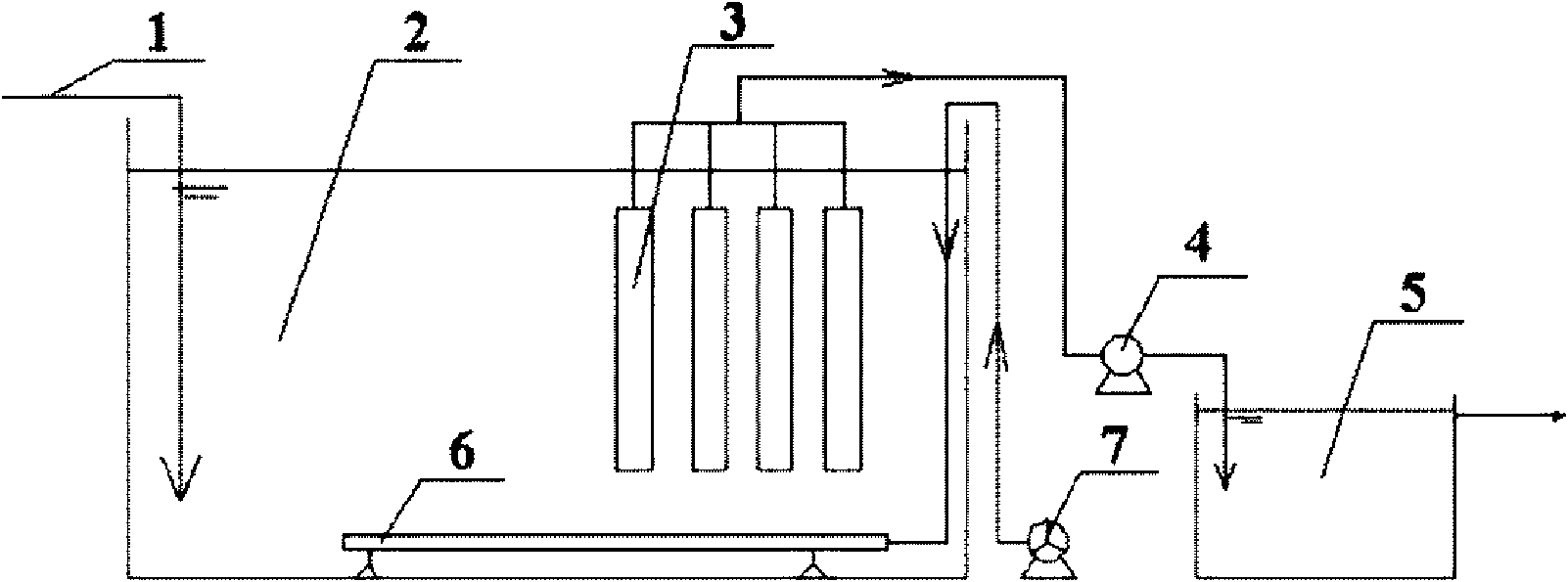

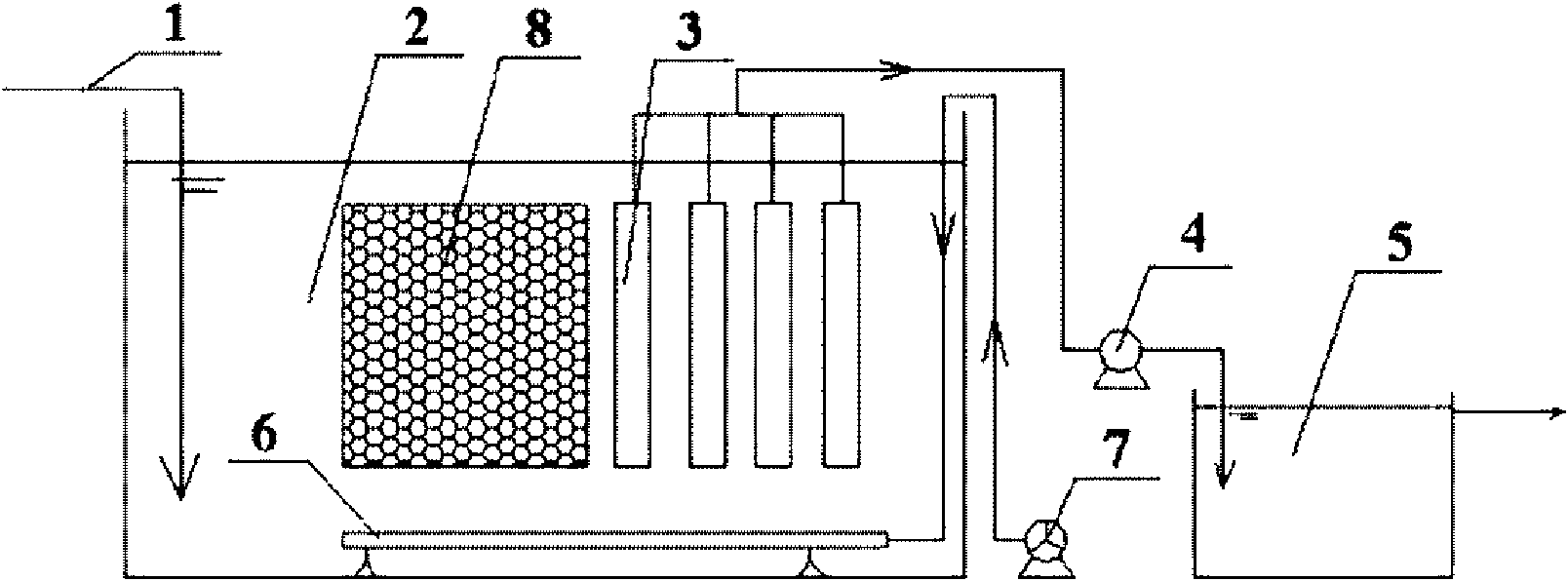

High efficient complex enzyme sewage treatment process and high efficient complex enzyme sewage treatment device

InactiveCN101624253AReduce the decrease in membrane fluxImprove removal efficiencyWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentChemistryPollutant

The invention relates to a high efficient complex enzyme sewage treatment process which is carried out according to the following steps: (1) massive grains such as suspended substances in sewage are removed through a grid, and then the sewage enters a regulating reservoir; (2) the sewage in the regulating reservoir enters a high efficient complex enzyme catalyzing-membrane bioreactor device; (3) the sewage passes through a membrane module of the high efficient complex enzyme catalyzing-membrane bioreactor device, and clear water penetrates through the membrane module and flows out; (4) a concentrated solution which cannot penetrates through the membrane module enters a biological processing part again so as to be further catalyzed and deteriorated; and (5) the steps are repeated till the processed water reaches the reuse water discharging standard. The invention also relates to a high efficient complex enzyme sewage treatment device. The process and the device makes up the detects of the current MBR process, such as membrane pollution, high expense, and the like, and can rapidly deteriorate pollutants, rapidly and high efficiently purify the sewage, achieve good treatment effect and greatly lower the running cost for sewage treatment.

Owner:福州晨翔环保工程有限公司

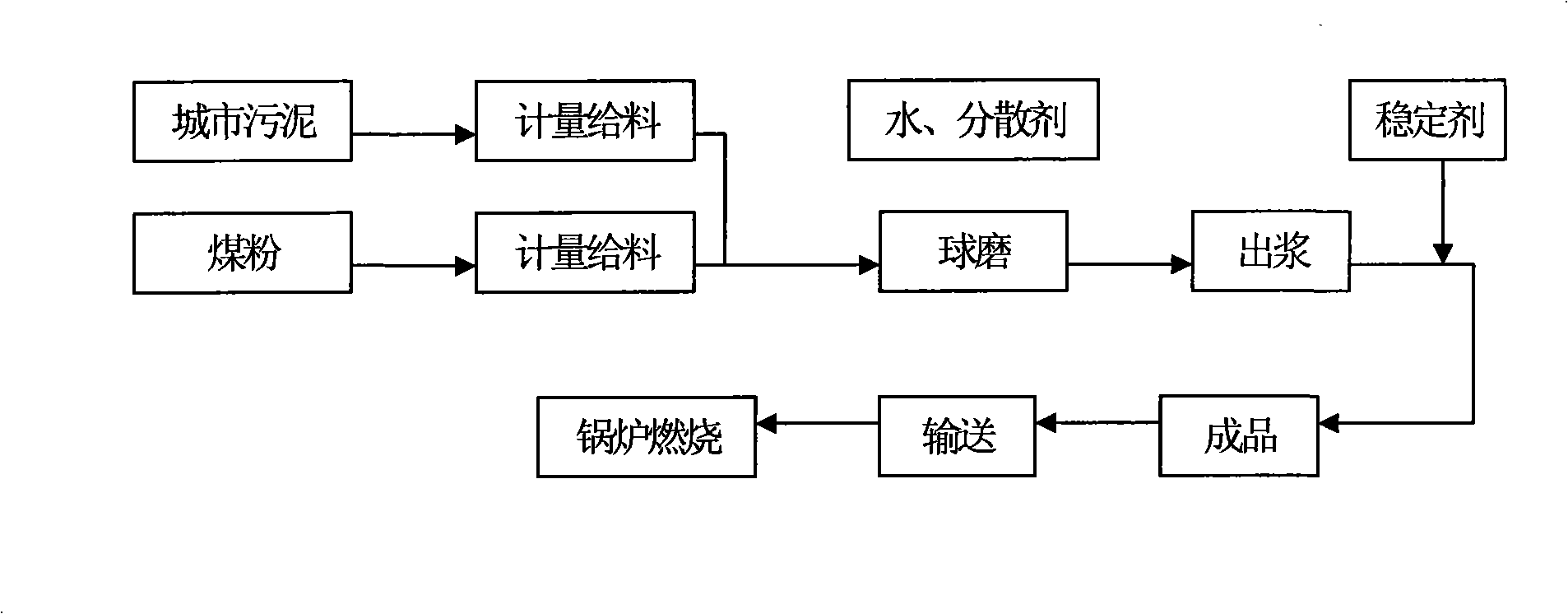

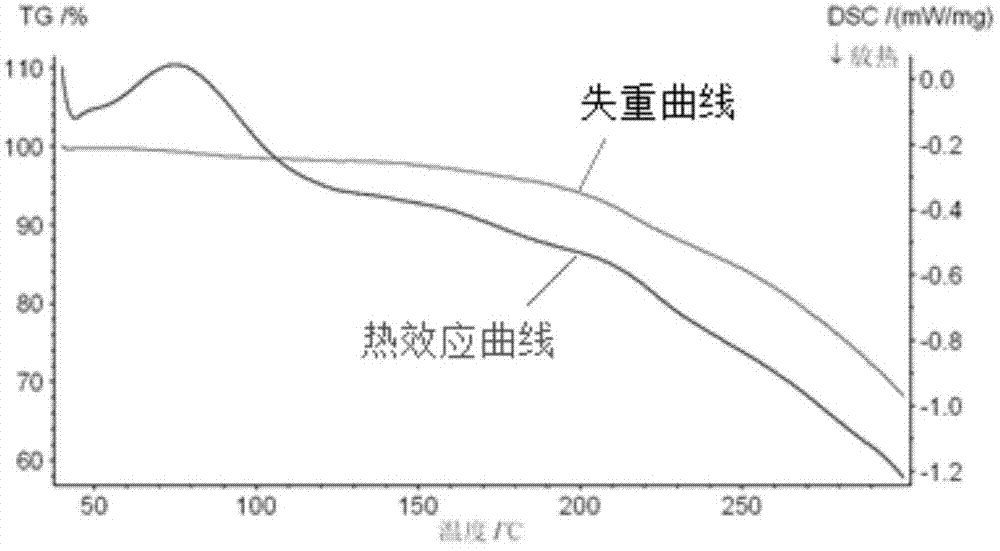

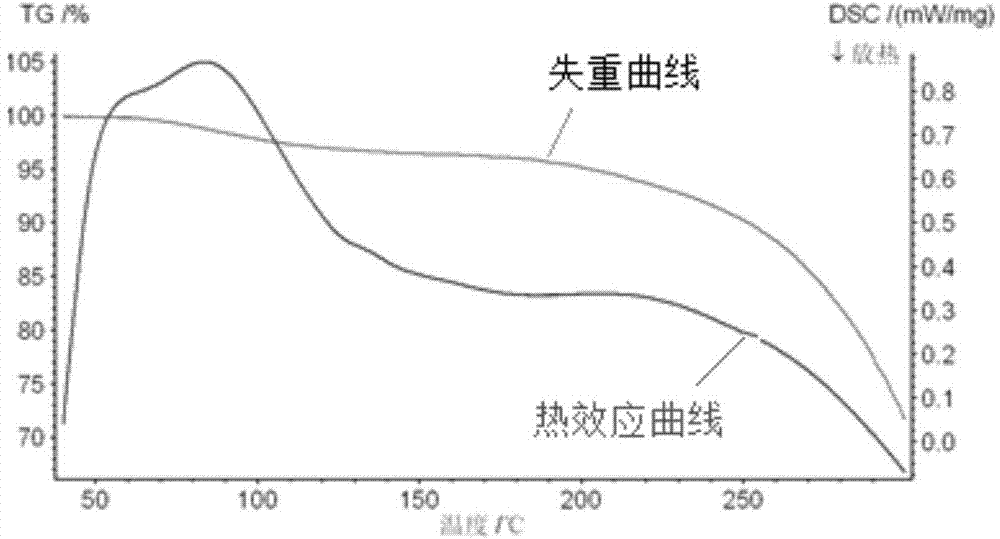

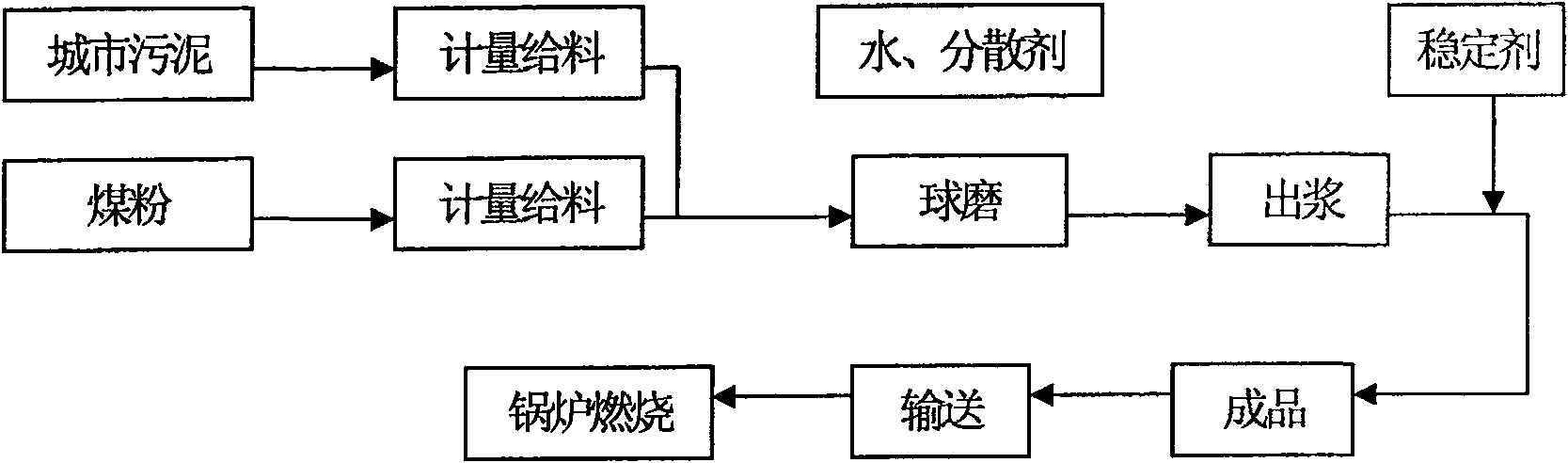

City sewage sludge reclamation processing and utilization method

InactiveCN101270878ASave on processing feesSuitable for industrial productionIncinerator apparatusLump/pulverulent fuel preparationWater contentCoal water

The invention discloses a method for the resourceful treatment and utilization of the municipal sludge. The invention is that the municipal sludge with 75 percent to 85 percent water content with the coal powder is grinded by a wet ball mill to obtain the mixing granules which accord with the gradation requirements; and the coarse product of the sludge coal water slurry is produced through the addition of the water and dispersant agent according to the technical proportion; the stabilizer is added after 10 minutes standing of the slurry; and the finished product of the sludge coal water slurry is produced, which is in accordance with the GB / T18855-2002 Coal Water Slurry Technical Condition; the finished product of the sludge coal water slurry is transported to the coal water slurry boiler, which is burned as the fuel for the treatment and utilization of the municipal sludge. The slurry production technique is simple, which suits for the industrialized mass production; the product is suitable for the common coal water slurry boiler, which replaces part of the using coal and using water of the coal water slurry while effectively utilizing the heat value of the sludge. The invention can save the coal resource and the water resource, which is an economical and mature on the technology method for the resourceful treatment and utilization of the municipal sludge.

Owner:ZHEJIANG UNIV

Method for preparing sulphur black dye and sodium thiosulfate from sulphur dye waste water

InactiveCN101633495ASolve processing problemsAchieve governanceThiosulfates/dithionites/polythionitesMultistage water/sewage treatmentWastewaterSulphur dye

The invention relates to a method for preparing sulphur black dye and sodium thiosulfate from sulphur dye waste water, which comprises the following steps: heating sulphur dye waste water, then mixing the sulphur dye waste water with 2,4-dinitrochlorobenzol, adjusting the PH value of the mixed solution with alkali, and carrying hydrolysis reaction; mixing and stirring the sulphur dye waste water, the sodium thiosulfate and sulfur, and heating the mixture for carrying out polysulfide reaction; mixing the mixed solution of the hydrolysis reaction and the mixed solution of polysulfide reaction for sulfofication reaction, and after the reaction is finished, introducing air for oxidation reaction to obtain mixed mother solution; filtering the mixed mother solution to obtain sulphur black dye grains, and drying, grinding and blending the sulphur black dye grains to obtain commercial sulphur black dye grains; and condensing, decoloring, crystallizing, drying and screening the filtered mixed mother solution to obtain the sodium thiosulfate. The method can effectively treat sulphur dye waste water, not only solve the problem of sewage treatment, but also save large amount of clean water.

Owner:蔡瑞琳 +1

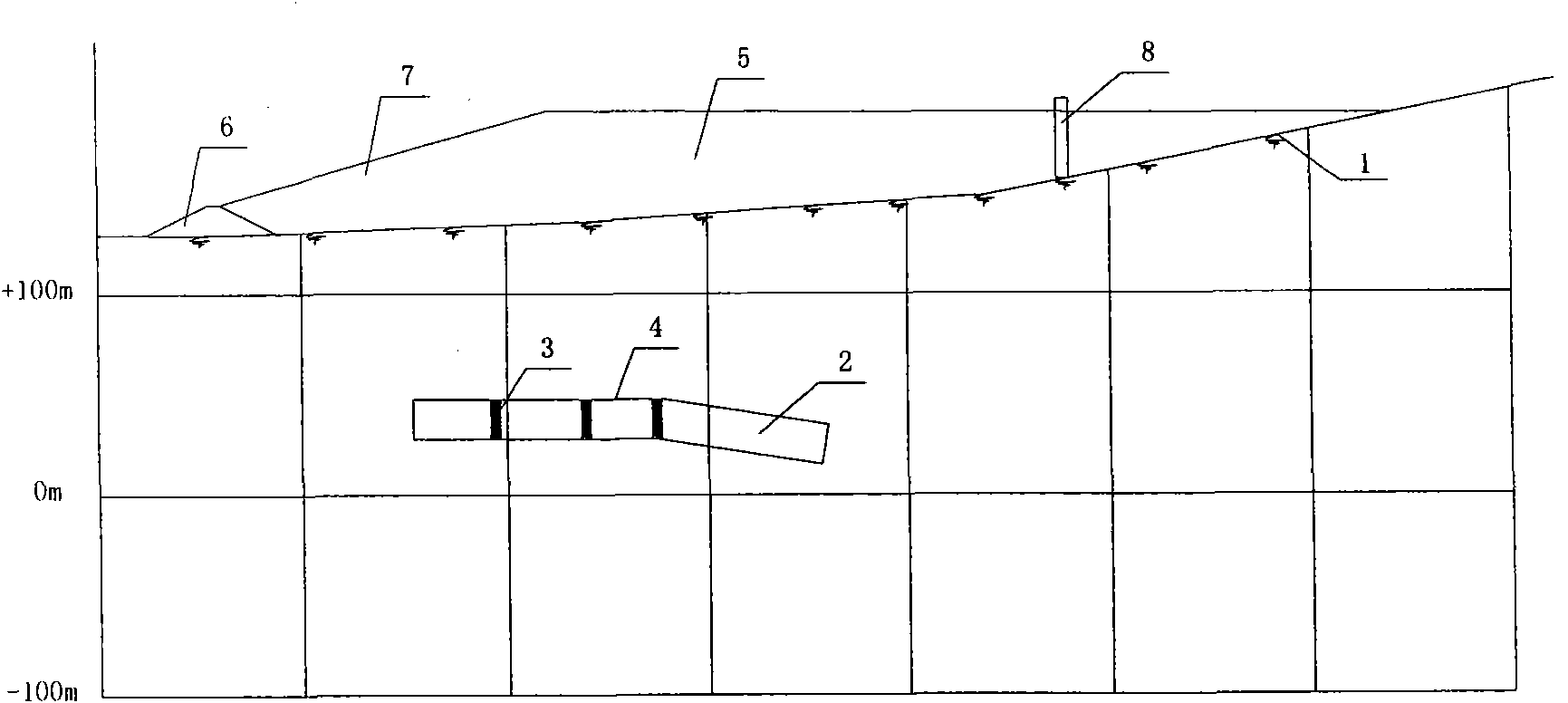

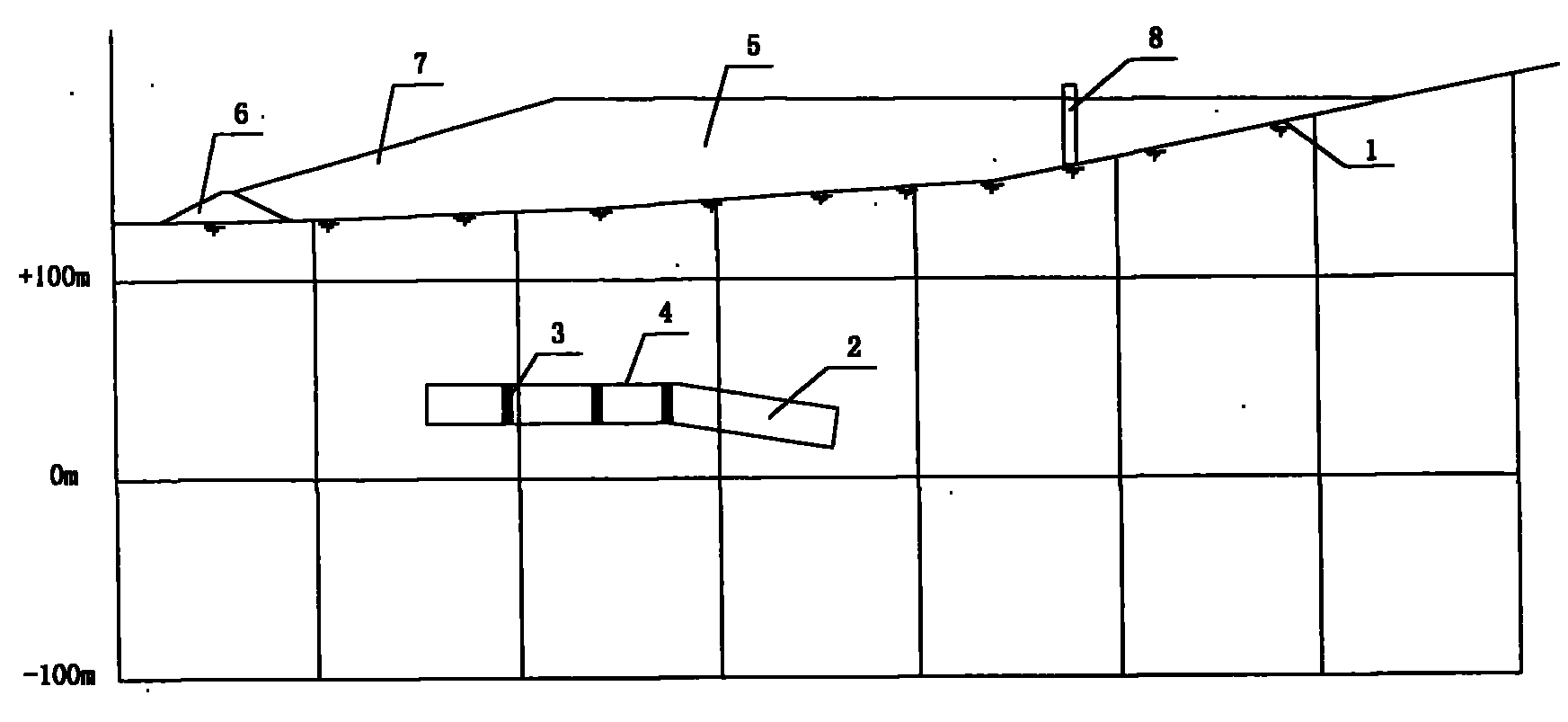

Method for directly building tailing ponds without filling positions above goaf

InactiveCN101974909AEliminate potential safety hazardsGuarantee normal productionEmbankmentsTunnelsWater dischargeElement analysis

The invention discloses a method for directly building tailing ponds without filling positions above a goaf. Through the research on the goaf (2) and the rock mechanic experiments on a jamb (3), roof rocks (4) are regulated and cut into crossed irregular post bodies in blocks for carrying out stability analysis, the elastic plastic finite element analysis is carried out on the goaf (2) under the loading of the tailing ponds (5), the tailing ponds (5) are built under the condition without processing the goaf (2), and the tailing ponds (5) mainly comprise initial dams (6), tail sand piling dams (7) and water discharge systems (8). According to the invention, the tailing ponds are directly built above unfilled goaf, thus the potential safety hazard of directly building the goaf above the oversized goaf can be eliminated, the normal production of a large-scale deep well mine can be ensured, and the goaf processing cost, the tail sand piling and storage long-distance conveying cost and the operation cost can also be saved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

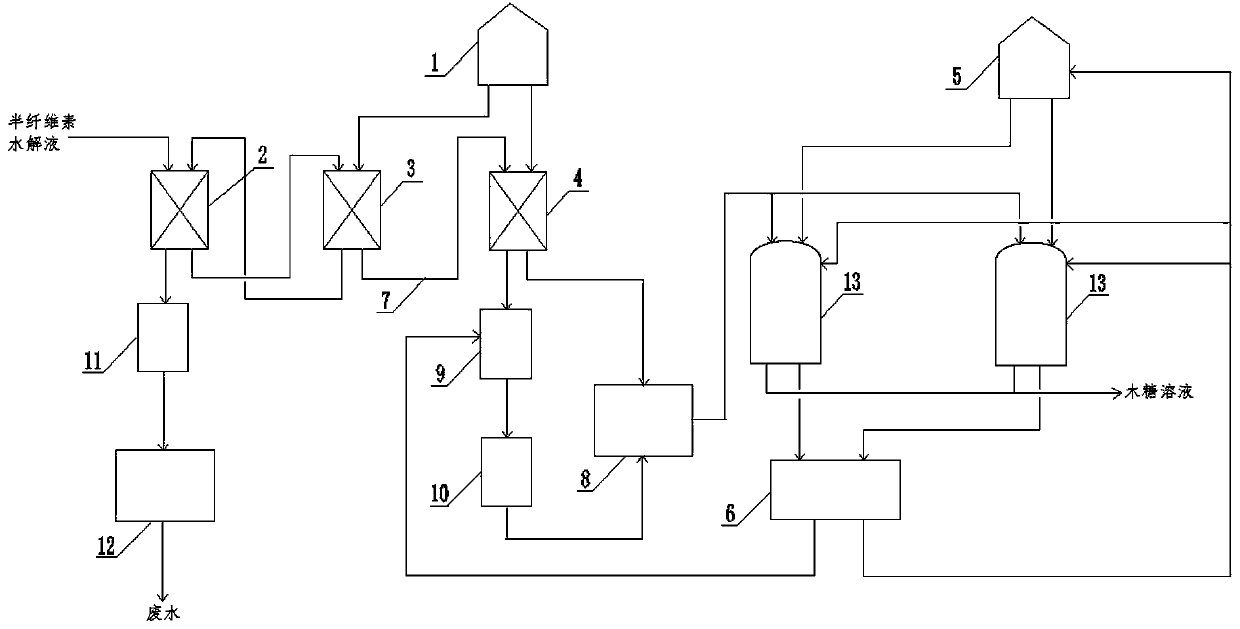

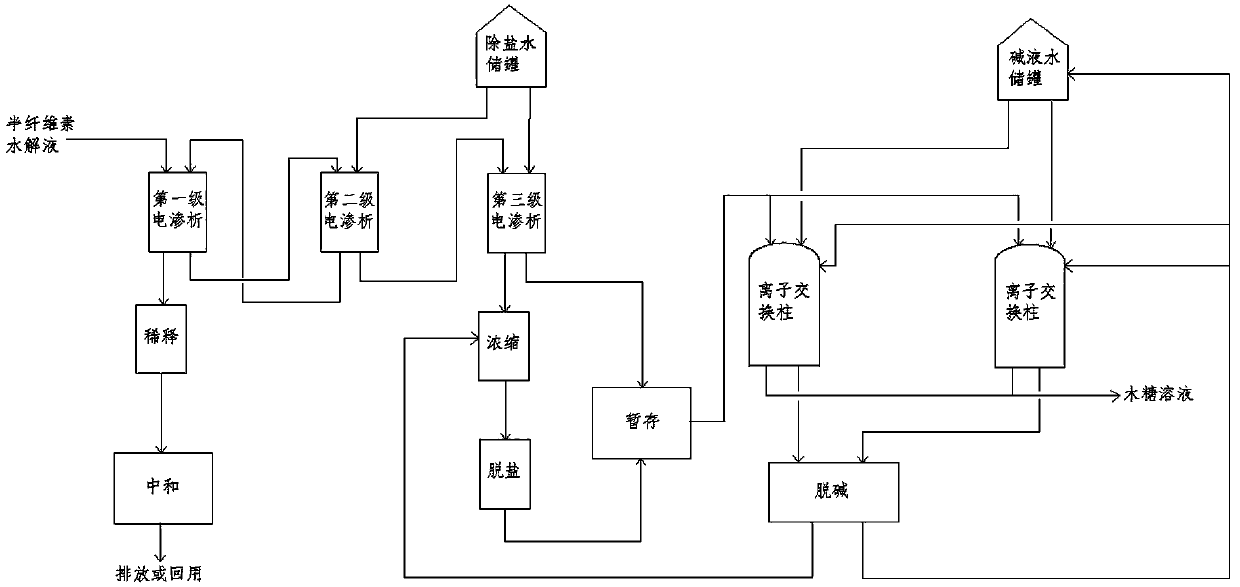

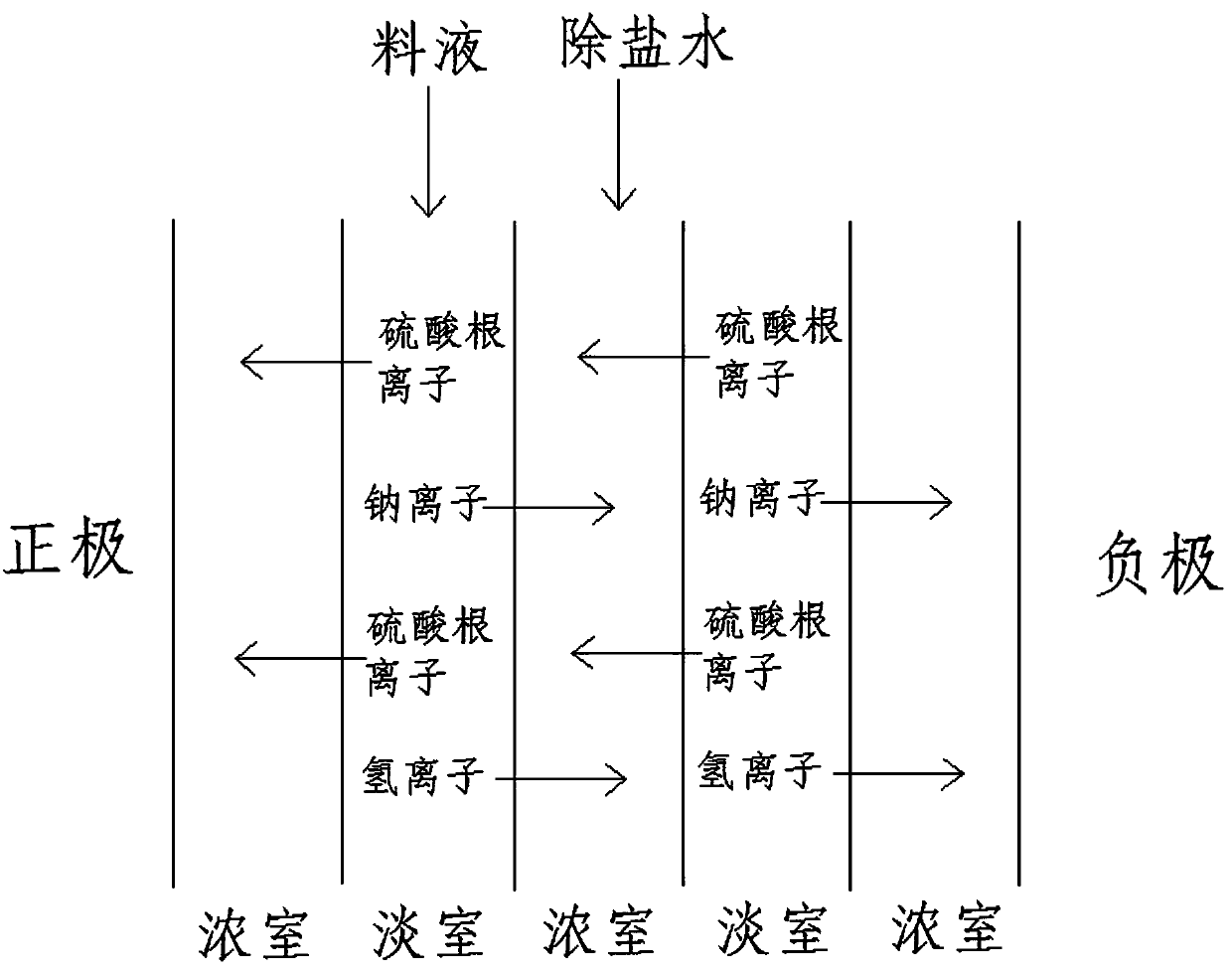

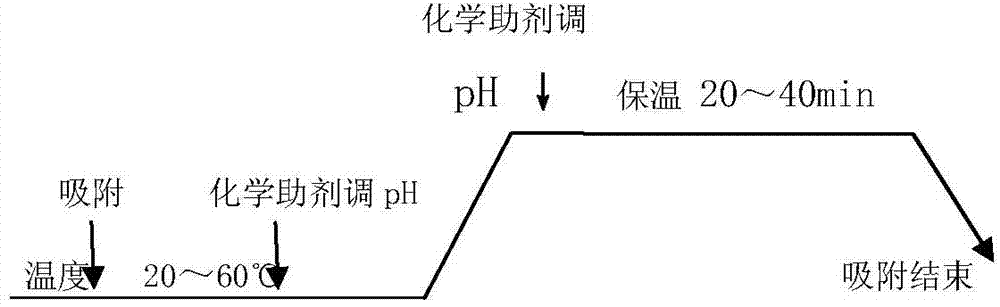

Electrodialysis and chromatography combined process for preparing xylose

The invention discloses an electrodialysis and chromatography combined process for preparing xylose, and belongs to the technical field of xylose production. The process comprises: carrying out three-stage electrodialysis on hemicellulose hydrolysate to finally obtain a first-stage high-salt solution, a third-stage high-salt solution and a third-stage high-sugar solution; concentrating and desalting the third-stage high-salt solution, and making the concentrated and desalted third-stage high-salt solution and the third-stage high-sugar solution co-enter an ion exchange column chromatography process; and regenerating the ion exchange column to obtain a regenerated solution (containing alkali and sugar), carrying out dealkalization on the regenerated solution to obtain an alkali liquid and asugar liquid, recycling the alkali liquid in regeneration of the ion exchange column, concentrating and desalting the sugar liquid and the third-stage high-salt liquid, and carrying out chromatography again. According to the present invention, with the process, the removal rate of the impurities in a xylose solution is increased so as to improve the quality of the product, the third-stage high-salt solution and the regenerated solution are recycled so as to reduce the sugar loss and improve the economic benefits, and on the premise of improving of the quality of the xylose solution and the production efficiency, the COD content in sewage is reduced so as to reduce the environmental protection pressure.

Owner:四川雅华生物有限公司 +1

Production method of refined cotton

InactiveCN102321926AAvoid charringImprove qualityFibre treatment to obtain bast fibreAcid waterCarbonization

The invention belongs to the technical field of refined cotton production, and particularly relates to a production method of refined cotton; the invention can not only improve the quality of refined cotton products, but also reduce water and steam consumption, and can reduce acid water discharge. The method particularly comprises the following steps of: 1) boiling of cotton linter; 2) washing, wherein nitrocellulose acidic waste water is used for washing, and washing is performed till the pH of the cotton material is 6.5-7.5; 3) bleaching, wherein a sodium hypochlorite solution is used for bleaching; 4) acidification, wherein nitrocellulose acidic waste water is added during acidification to control the pH to be 1-5; 5) cold washing, wherein cold washing is performed with water. The nitrocellulose acidic waste water has a total acidity of 5-15 g / l, and comprises the following main components by weight: 0.003%-0.023% of sulfuric acid, 0.006%-0.018% of nitric acid, and the balance of water and impurities. The beneficial effect of the invention is that nitrocellulose acid water needing to be discharged is used to substitute concentrated sulfuric acid during the refined cotton production process, which avoids the carbonization of refined cotton by concentrated sulfuric acid, improves the quality of refined cotton, reduces water and consumption, reduces the discharge of nitrocellulose acid water, and saves the cost for nitrocellulose acid water treatment.

Owner:SICHUAN NITROCELLULOSE CORP

Method for recovering soybean protein from soybean whey waste water

InactiveCN108191950AImprove efficiencyReduce pollutionPeptide preparation methodsWater/sewage treatment by neutralisationSocial benefitsWastewater

The invention relates to a method for recovering soybean protein from soybean whey waste water. The method comprises the following steps: (1) adjusting the pH of the soybean whey waste water to be alkaline and then concentrating; and (2) adjusting the protein concentration of the legumelin concentrated liquid concentrated in the step (1) to 12 to 16 percent and spray-drying to obtain he soybean protein powder. The method provided by the invention can guarantee safe discharge of the waste water, can realize complete utilization of resources and has important economic effect and social benefit.

Owner:LINYI YUWANG VEGETABLE PROTEIN

Method for treating printing and dyeing wastewater by adopting abandoned straw

InactiveCN103896357AReduce in quantityReduce contentOther chemical processesWaste water treatment from textile industryChemical substanceTreatment costs

The invention discloses a method for treating printing and dyeing wastewater by adopting abandoned straw. Firstly a polysaccharide compound is adopted for treating the abandoned straw, and the abandoned straw is chemically modified; then the modified abandoned straw is adopted for adsorbing the printing and dyeing wastewater. According to the method for treating the printing and dyeing wastewater by adopting the abandoned straw, a new printing and dyeing wastewater treatment technology is designed by utilizing the abandoned straw, so that dye molecules in wastewater are quickly attached to the abandoned straw under the adsorption action, and quantity of abandoned dye in dyeing wastewater and content of chemical substances in the dyeing wastewater are obviously reduced. By adopting the method for treating the printing and dyeing wastewater, wastewater treatment cost is greatly reduced and for printing and dyeing mills.

Owner:XI'AN POLYTECHNIC UNIVERSITY

City sewage sludge reclamation processing and utilization method

InactiveCN100580317CSave on processing feesSuitable for industrial productionIncinerator apparatusLump/pulverulent fuel preparationCoal waterSludge

Owner:ZHEJIANG UNIV

Water-saving indoor drainage system

InactiveCN101881039AFlexible and convenient layoutMeet the wishes of individual arrangementFlushing devicesDomestic plumbingWater savingWater leakage

The invention provides a water-saving indoor drainage system which is composed of a toilet horizontal branch pipe, a kitchen horizontal branch pipe, a balcony horizontal branch pipe, a sewage discharger, an odor-proof valve and the like. The height of a pouring board is slightly lowered and a cushion layer is thickened to lay the toilet horizontal branch pipe, the kitchen horizontal branch pipe, the balcony horizontal branch pipe, the sewage discharger, the odor-proof valve and the like into the same floor layer so as not to pass through the floor to enter other households. The indoor drainage system provided by the invention has the advantages of automatically-utilized waste water, water conservation, energy conservation, emission reduction, less expenditure, no odor and floor drainage while relieving nature, no stench returned from an sanitary appliance joint and a closestool, no blockage of the closestool, no blockage and water leakage and easy dredging of a pipe, less loss of room height and good appearance. The water-saving indoor drainage system is applicable to water drainage and conservation transformation of buildings such as houses, hotels, wards and the like, and the system meets the need of the water-saving society.

Owner:王方

Supplementary cooling device and supplementary cooling method of air-cooling power generator

InactiveCN102751817AImprove cooling effectHigh overload performanceCooling/ventillation arrangementStator coilCooling power

The invention discloses a supplementary cooling device and a supplementary cooling method of an air-cooling power generator, which are capable of enabling the air-cooling power generator to generate power with full load at high-temperature weather. The device comprises an air-cooling power generator, a cool air production device, a cool air passage, an air blower and a power generator air inlet temperature-humidity gauge, wherein the cool air production device is installed outside an air-cooling power generator air chamber, one end of the cool air passage is communicated with an air outlet of the cool air production device, the other end of the cool air passage is communicated with an air compensation port, the air blower is installed inside the cool air passage to be close to the air compensation port, the power generator air inlet temperature-humidity gauge is installed on an air inlet passage of the power generator to be close to a rotor, and an overhauling hole is provided with a hot air exhaustion door which can be opened and closed. Due to the adoption of the device, cool air produced by the cool air production device can be blown by the air blower into the air inlet passage of the power generator through the cool air passage via the air compensation port, so that the air inlet temperature can be reduced, the heat of a power generator stator coil can be adequately radiated, and the power generator can be operated at a full load at the high-temperature weather.

Owner:DYNAGREEN ENVIRONMENTAL PROTECTION GROUP

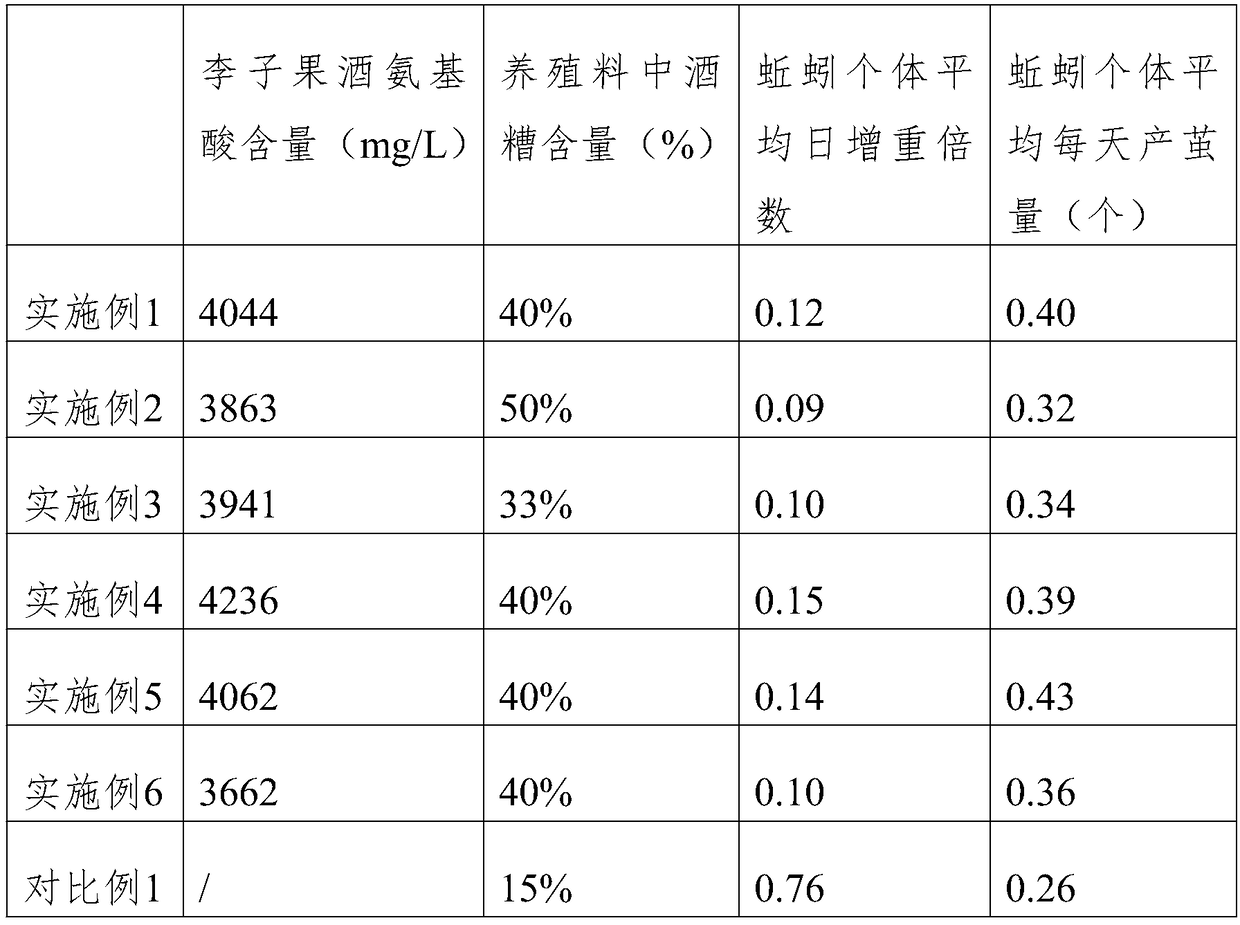

Method for preparing plum fruit wine and recycling fermentation waste residue

The invention belongs to the field of food processing, and relates to a method for preparing plum fruit wine and recycling fermentation waste residue. The fruit wine brewing process comprises the steps as follows: preparing fresh fruit, sorting, cleaning, crushing, disinfecting, squeezing juice, performing enzymatic hydrolysis, canning, fermenting, decanting, filtering, aging, mixing, sterilizing,filtering and obtaining a finished product; furthermore, the waste residue obtained by fermenting plums to prepare the fruit wine is a main component for preparing an earthworm breeding base materialused for breeding earthworms. The method disclosed by the invention overcomes the defects that the fruit wine produced with the traditional brewing method is long-lasting, time-consuming and easy tobe polluted, or defects caused by direct soaking. By adopting the method, a fruit wine drink which is simple in process, natural, green, healthy, rich in nutrition and mellow in flavor, and meets thedemands of widespread customers is obtained. Moreover, the fruit wine fermentation waste residue is taken as the main material for breeding the earthworms, which turns wastes into treasures, thereby avoiding the discharging of the fruit wine fermentation waste residue, reducing the waste treatment expense and fulfilling the purpose of recycling the wastes.

Owner:ZUNYI NORMAL COLLEGE

Hazardous waste harmless incineration system with low energy consumption

InactiveCN102519047ASave on processing feesInhibit NOX productionIndirect carbon-dioxide mitigationIncinerator apparatusPyrolysisOxygen enrichment

The invention discloses a hazardous waste harmless incineration system with low energy consumption. The system adopts a plurality of latest energy-saving combustion technologies and energy-saving consumption reduction measures, optimizes on the whole, and well solves the energy-saving consumption reduction problem of the hazardous waste harmless incineration system. A unique gasification inner container of a solid and liquid waste gasification incineration unit ensures that hazardous solid and liquid wastes are pyrolyzed and gasified under the low-temperature oxygen debt condition; and the novel heat accumulation incineration manner of a gas waste incineration unit ensures that pyrolysis gas and hazardous gas waste are cleaned thoroughly and incinerated for discharge within the controlling index of national standard. The special system structure uses the high temperature heat generated in cleaning and incineration for pyrolysis and gasification, thereby facilitating energy conservation; the system also can select an oxygen enrichment combustor equipped with oxygen enrichment combustion-supporting wind supply equipment, so as to effectively increase the incineration temperature and reduce the combustion-supporting air amount; a waste heat recovering unit further can provide hot wind combustion support for incineration; therefore, the measures can effectively reduce the auxiliary fuel consumption, lower the energy consumption, and reduce the cost for treating hazardous wastes, and further the popularization and the application of the system are facilitated.

Owner:朱海生

Sludge dewatering method for waste paper deinking technology

InactiveCN1978785AEasy to handleSave on processing feesPulp liquor regenerationPaper recyclingPollutantScrew press

The invention relates to a new sludge dewatering method used in waste paper de-inking technology. It includes the following steps: diluting sludge, storing in sludge storage pool, entering gravitational bed, auger delivery, screw press, sludge discharging; adding cationic polyacrylamide in entering gravitational bed; separating and water discharging in gravitational bed and screw press. Its feature is adding 600-800mg / L concentrated sulfuric acid in sludge storage pool which can increase gravitational bed processing effect, reduce 95% suspended matter in filtrate, cut down dissolubility CODcr1100mg / L, thereby omit air floatation and chemicals to make the filtrate discharge directly, make sludge self draining concentration reach 18-20% that one times higher than original method after processing by gravitational bed, reduce pollutant handing cost, has considerable annual economic benefit.

Owner:SHANDONG HUATAI PAPER

Method for treating solid waste slags in production process of ceramic tiles

InactiveCN109180148AEmission reductionAvoid deformationCeramic materials productionClaywaresSocial benefitsBrick

The invention discloses a method for treating solid waste slags in the production process of ceramic tiles. The method comprises the following steps: mixing the solid waste slag produced in the production process of ceramic tiles with powder to be taken as the green brick material, and performing ball milling, pulping, powder injection, moulding, biscuit firing, glazing, glaze firing and edge polishing to obtain the finished products of the ceramic tiles; the solid waste slag accounts for 14-60% of the total weight of the green brick material, and the powder accounts for 40-86% of the total weight of the green brick material; the solid waste slag is formed by waste mud, waste green bricks, polishing waste slag, edging waste slag, scraped waste slag and finely-edging waste slag; the powderis prepared from kaolin, white mud, tea mountain sand, talc and feldspar. The method disclosed by the invention has the beneficial effects that the ceramic tiles are prepared by utilizing the solid waste slag in the production process of the ceramic tiles, and processes of low-temperature biscuit firing and high-temperature glaze firing are adopted; secondary pollution caused by landfill of the waste slag is reduced, the problem of difficulty in treatment of the solid waste slag in manufacturers of the ceramic tiles is solved, the production cost is saved and the economic benefit and the social benefit are good.

Owner:广西亚欧瓷业有限公司

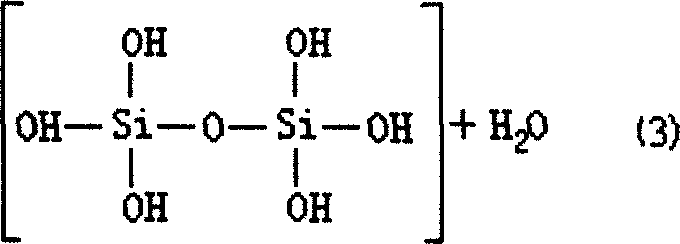

Novel dyeing process for blended knitting yarn

The present invention provides a novel dyeing process for blended knitting yarns, which adopts a novel assistant PS liquid; leaves out formic acid, acetic acid, anhydrous sodium sulphate, a leveling agent, ammonium sulfate, an osmotic agent and a dispersant; simplifies production process; and stabilizes dyeing process. The novel dyeing process has the advantages that only the novel assistant agent PS liquid is used when dyeing by using a wool reactive weak acid dye and a cationic dye; dyeing defects in the process of high count yarn hank dyeing is not easy to generate, which improves the degree of dyeing and saves the dye; the stable dyeing-accelerating property can increase the improvement of color fastness; the dyeing time is shortened, which can save massive energy and increase labor productivity; a softening treatment for dyeing water is not necessary and tap water can be used for dyeing directly, and the water treatment cost is reduced because of no dyeing defects and seasonal aberration; and the assistant agent cost is reduced greatly.

Owner:TIANJIN TEXTILE ENG RES INST

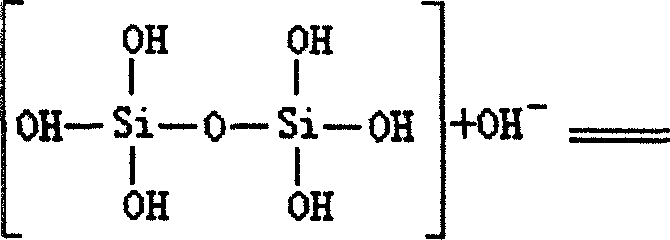

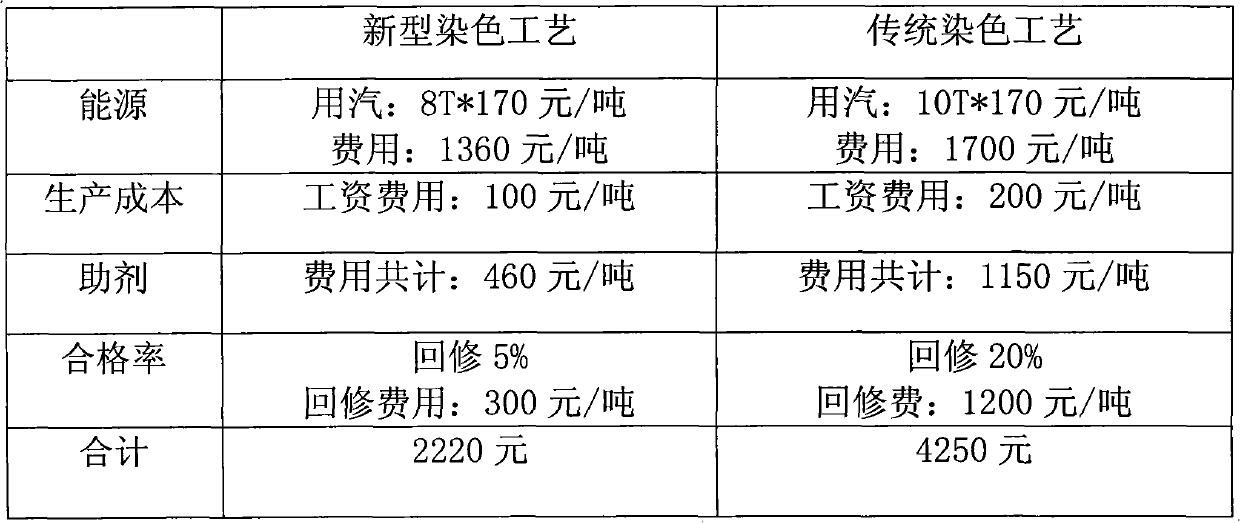

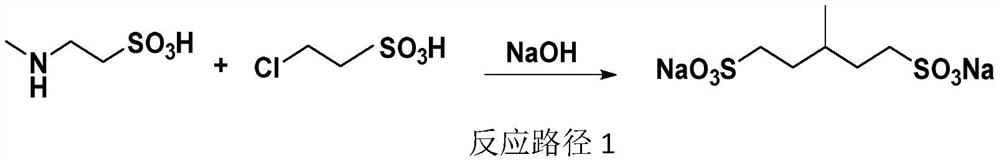

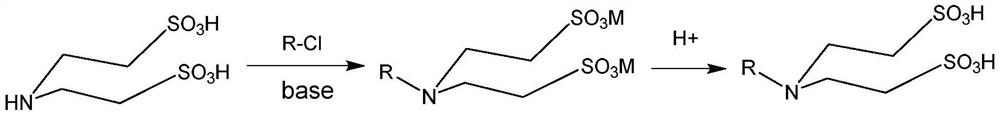

Production method of N, N-bis (2-sulfonic acid ethyl)-1-alkylamine

PendingCN112778169ALow costSimple structureSulfonic acids salts preparationSulfonic acid preparationSide productActive agent

The invention relates to a production method of N, N-bis (2-sulfonic acid ethyl)-1-alkylamine, wherein N, N-bis (2-sulfonic acid ethyl)-1-alkylamine is a core raw material for synthesizing a surfactant N, N-bis (2-sulfonic acid ethyl)-1-alkylamine disodium salt. The invention mainly solves the problem of finding a simple, convenient and environment-friendly synthesis method. The method comprises the following steps: reacting a by-product N, N-bis (2-sulfonic acid ethyl) amine generated in a taurine production process with 1-chloralkane under an alkaline condition to directly obtain N, N-bis (2-sulfonic acid ethyl)-1-alkylamine disodium salt, and acidifying to obtain N, N-bis (2-sulfonic acid ethyl)-1-alkylamine. According to the method, the raw material N, N-bis (2-sulfonic acid ethyl)-amine is a by-product caused by the problems of condition control and the like in the production process of taurine, and is convenient and easy to obtain, the reaction condition is mild, and the method is suitable for industrial production.

Owner:HUBEI GRAND LIFE SCI & TECH CO LTD

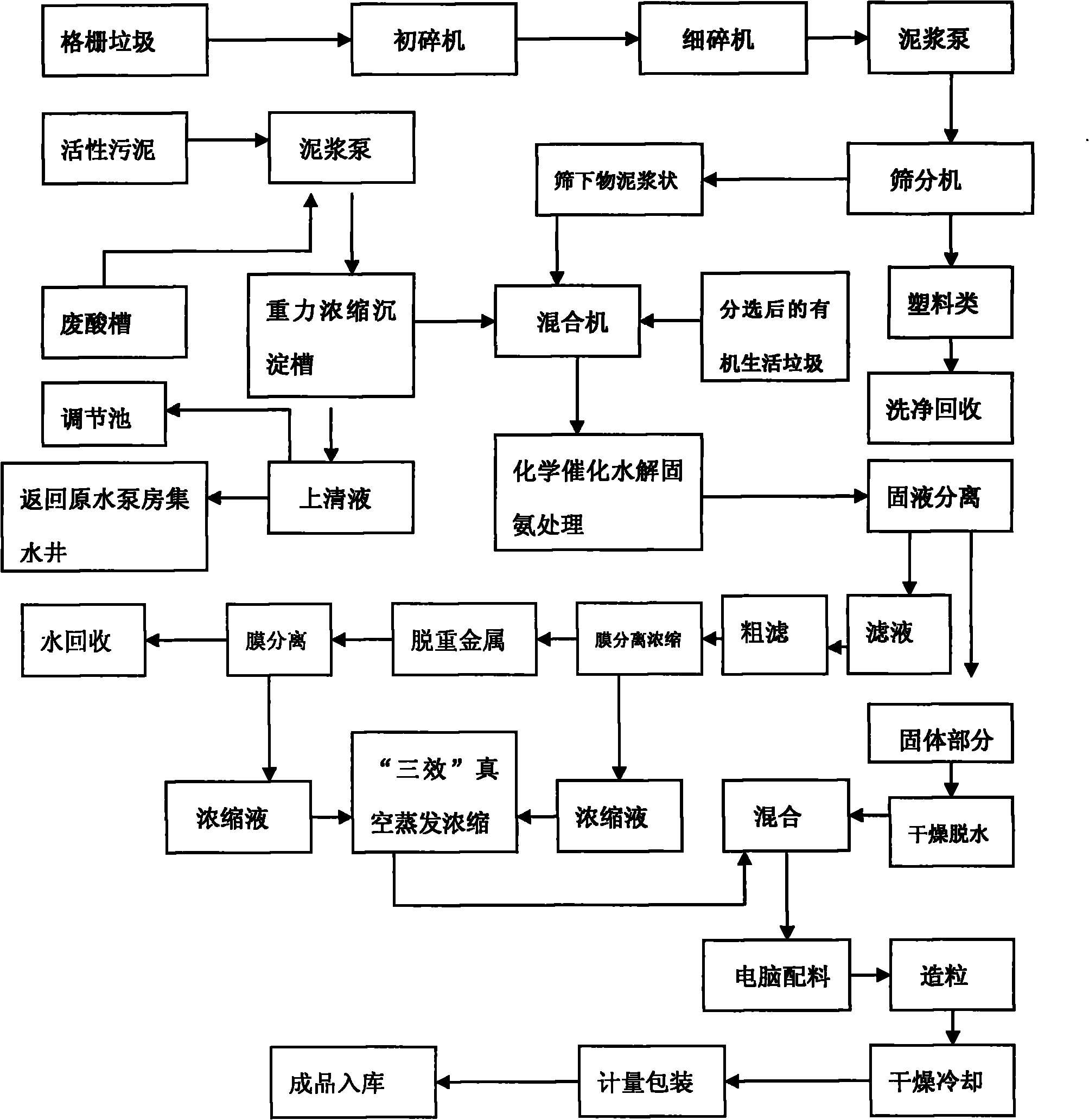

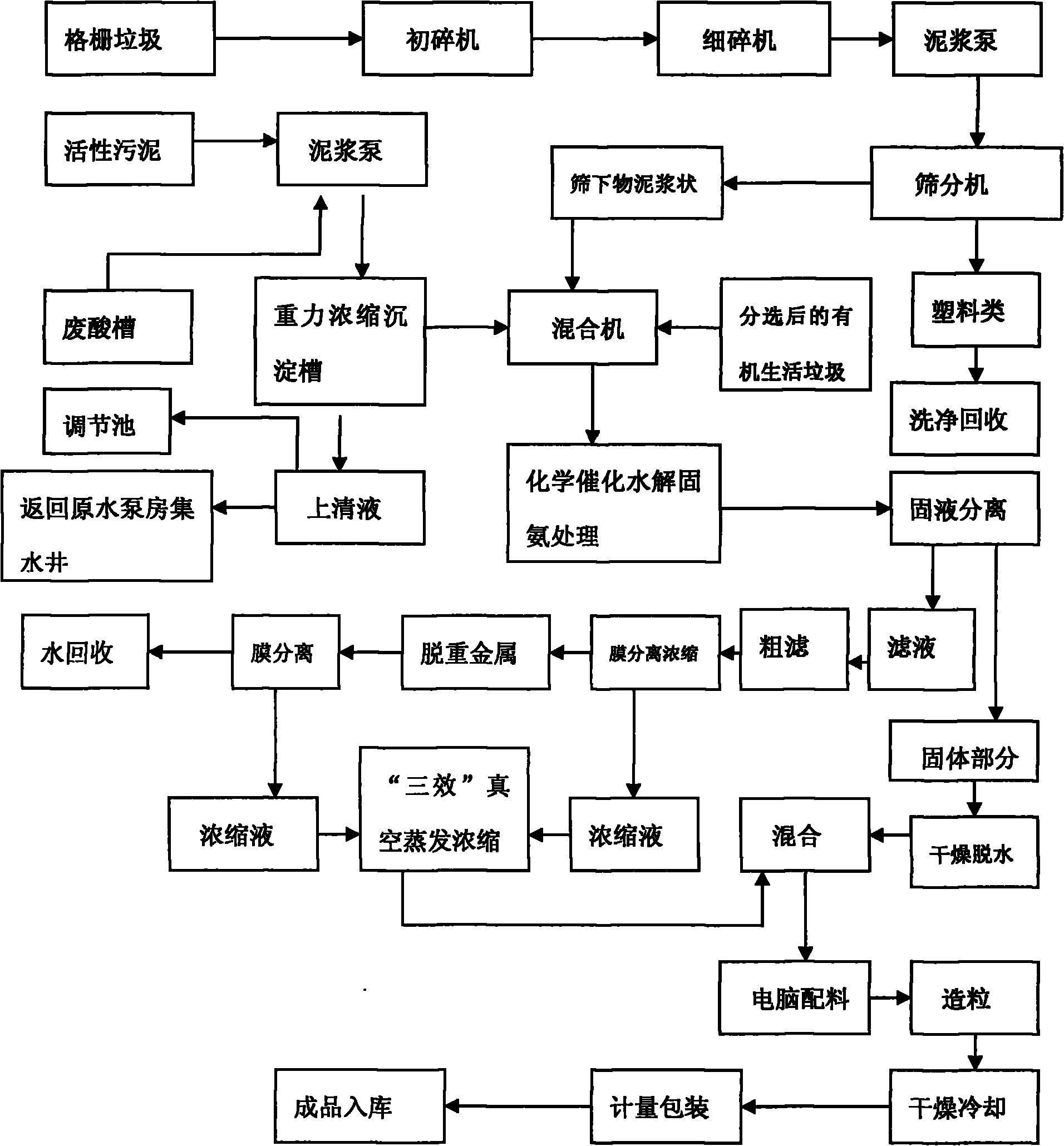

Method for comprehensively treating grating garbage and activated sludge in sewage plant

InactiveCN101863689ASave on processing feesLow costSludge treatment by de-watering/drying/thickeningClimate change adaptationActivated sludgeGrating

The invention provides a method for comprehensively treating grating garbage and activated sludge in a sewage plant. The pretreated grating garbage and concentrated activated sludge are mixed and the mixture and sorted organic domestic garbage are subjected to chemical catalytic hydrolysis and ammonia-fixing treatment to form an organic energy fertilizer by the prior art. The method has the advantages that: 1, the grating garbage does not need conveying outside through payment to be treated, so that the processing fee of the grating garbage is saved; 2, the activated sludge is treated by waste acid and subjected to gravity concentration, and two-step concentration (gravity settling and flocculation concentration by adding polyacrylamide) in the prior art is changed into one-step concentration, so that the equipment and material cost is saved, and the process is simple and quick and has significance for environmental protection by using the waste acid; and 3, the concentrated activatedsludge and the pretreated grating garbage are directly mixed and subjected to chemical catalytic hydrolysis, so that the dehydration process is saved, the repeated process is avoided, the floor area is reduced and the equipment investment is saved.

Owner:SHANGHAI MULIANG IND CO LTD

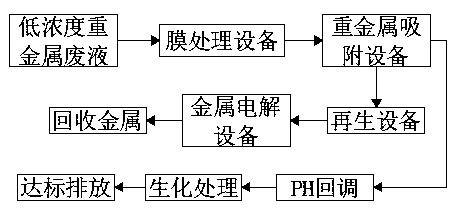

Heavy metal recovery process for treating low-concentration plating heavy metal wastewater

InactiveCN108726790AHeavy metal sludge reductionSavings on waste water treatmentPhotography auxillary processesWater contaminantsIonChemistry

The invention discloses a heavy metal recovery process for treating low-concentration plating heavy metal wastewater. The process comprises the following steps: pumping unpretreated low-concentrationheavy metal wastewater into membrane treatment equipment by a pump, wherein the wastewater contains heavy metal ions, COD (Chemical Oxygen Demand), NH4 and complexes, and the filtering precision of the membrane is 0.01 micron; removing suspended solids, colloid and organic matters, enabling membrane equipment effluent to enter heavy metal adsorption equipment to adsorb copper ions, washing out heavy metal ions by acid regeneration after the adsorbed filter material is saturated, enabling regenerated liquid to enter metal electrolysis equipment to be electrolyzed into sheet metal to be recovered after the ion concentration reaches a certain number, returning the electrolyzed regenerated liquid to recycle, adding a new acid to supplement when the concentration is not enough, regulating the pH value of the adsorption equipment effluent to 7-8, and performing biochemical treatment to remove the heavy metals. According to the wastewater treatment process, since the heavy metals are removedby adopting an adsorption method, the amount of heavy metal sludge is reduced, the sludge treatment cost is saved, and valuable metals in the wastewater are recovered, so that recycling is realized, and the whole wastewater treatment cost is saved.

Owner:广东世来福环保科技有限公司

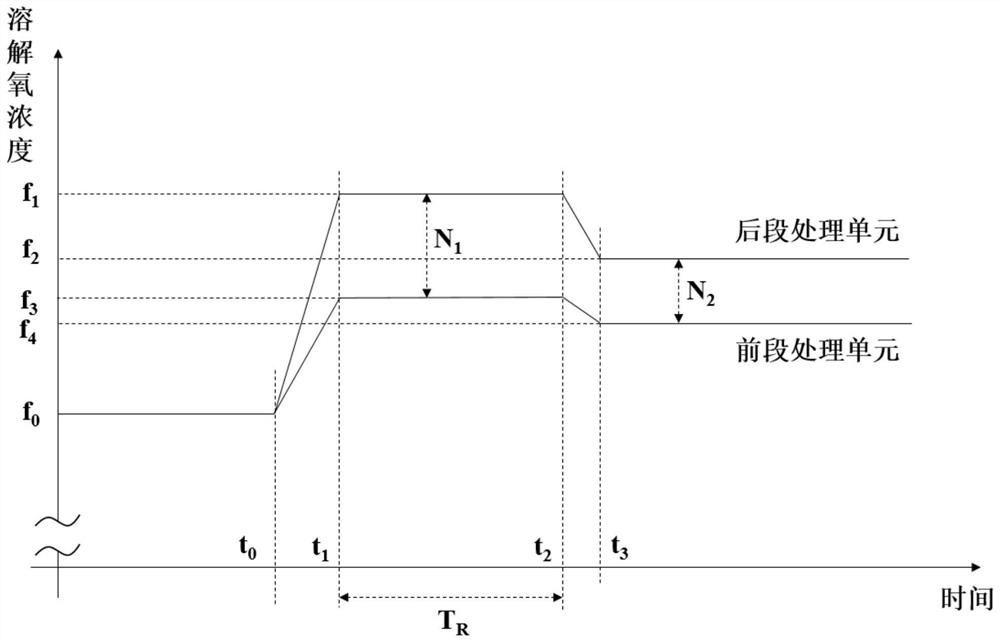

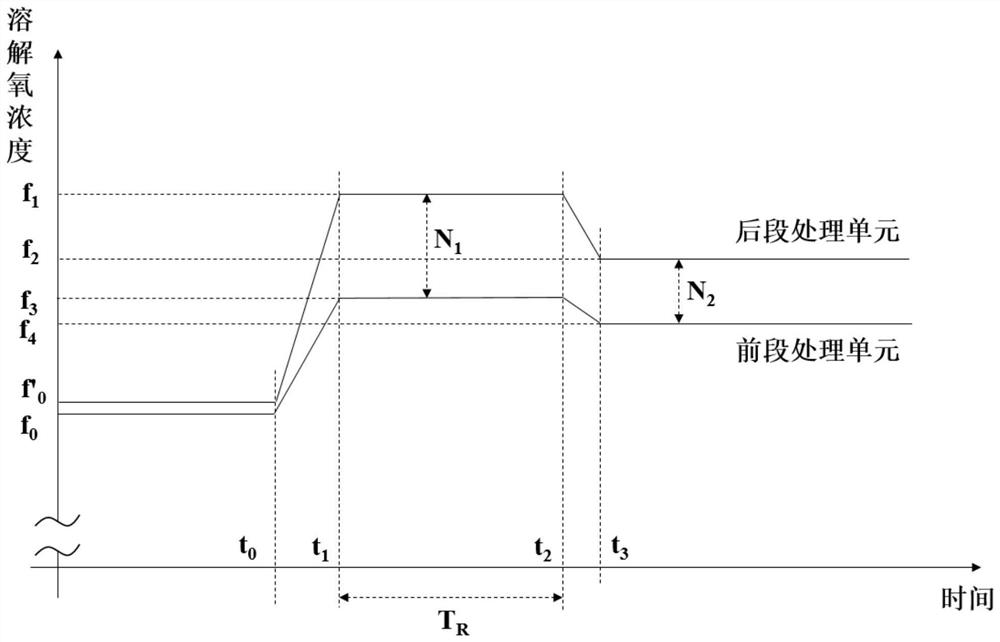

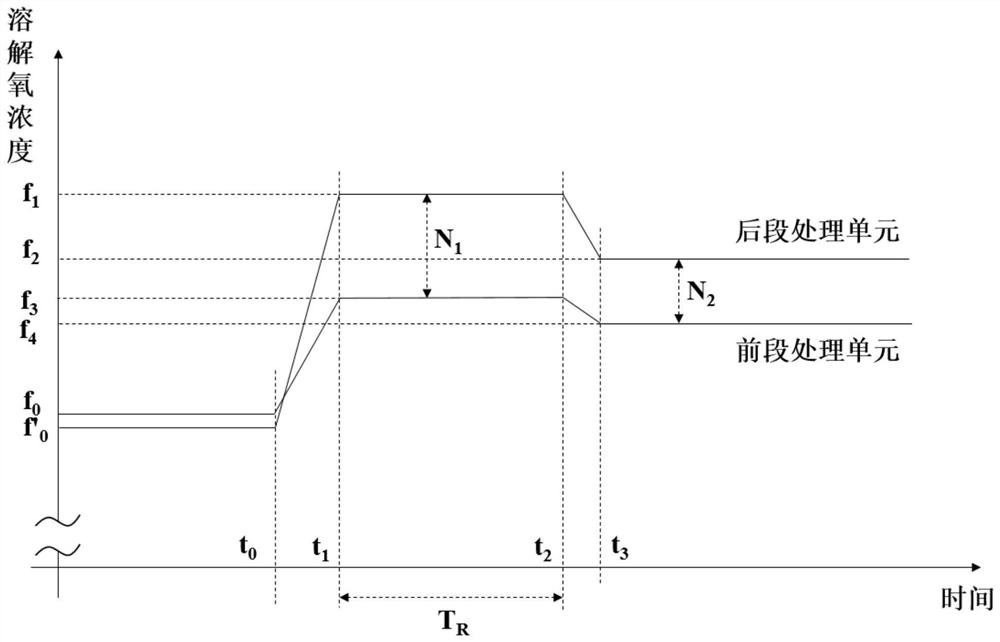

MBBR and oil refining wastewater treatment system

ActiveCN113044969AImprove processing efficiencyImprove impact resistanceWater treatment parameter controlWater treatment compoundsActivated sludgeBiofilm

The invention belongs to the field of wastewater treatment, and particularly relates to an MBBR and an oil refining wastewater treatment system. The invention provides an MBBR. Dissolved oxygen concentrations of different treatment sections are controlled according to a specific DO curve, a bacterial colony structure is adjusted, and a front-section treatment unit is used for carrying out buffer adjustment on wastewater; the microorganisms in the rear-section treatment unit further reduce COD and BOD in the wastewater, so that stable effluent quality is ensured; based on the MBBR, the invention further provides a treatment system. An A+MBBR+O combined process is matched with an efficient microbial preparation to treat the oil refining wastewater. The treatment efficiency and the impact resistance of the system are improved, the stability of the effluent quality is ensured, the impact caused by water quality fluctuation is relieved, the operation stability is improved, meanwhile, the MBBR is used as a process combining a suspension growth activated sludge method and an adhesion growth biological membrane method, the occupied area is small, the system operation cost is further reduced, and the capital construction cost is reduced.

Owner:青岛万慧源环保科技有限公司

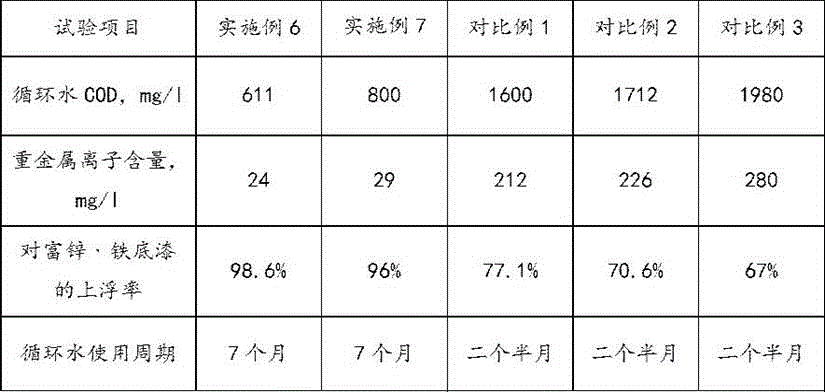

Wet material boiler combustion treatment system with two drying devices

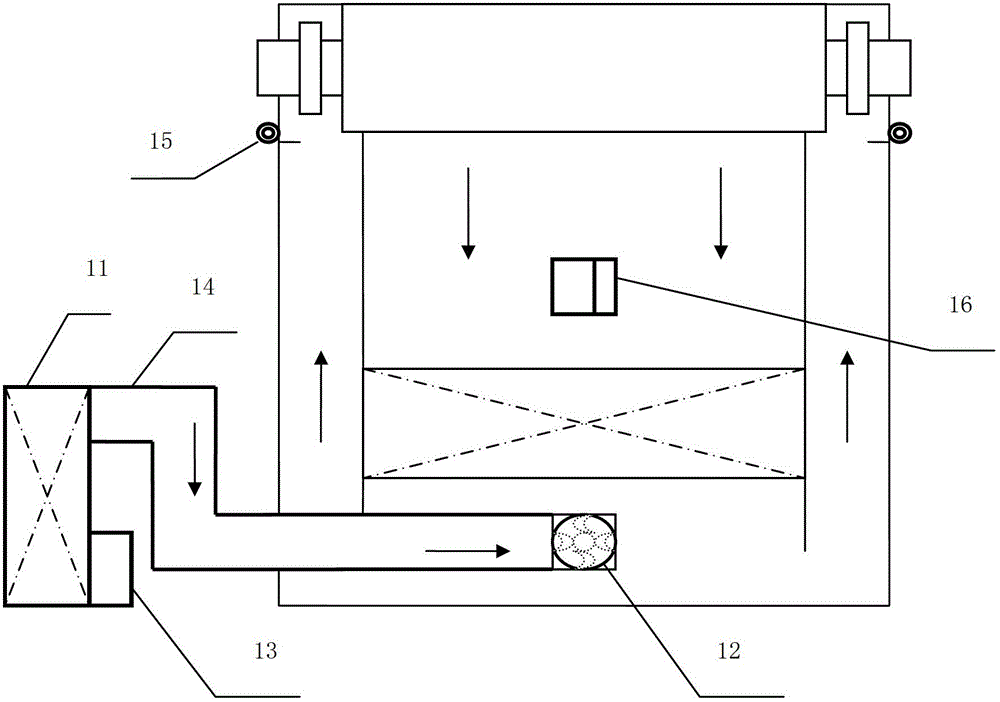

InactiveCN105240860ABurn fullyReduce harmful ingredientsDrying machines with non-progressive movementsIncinerator apparatusDrum dryingProcess engineering

The invention discloses a wet material boiler combustion treatment system with two sets of drying devices and belongs to the technical field of environmental protection. The wet material boiler combustion treatment system comprises two sets of drying devices and a boiler; the two sets of drying devices are composed of an initial drying device and a secondary drying device; the initial drying device is composed of a storage bin, an auger conveying belt, a refiner, a squeezing and draining machine, a rotary drum drying machine and a switching auger, which are sequentially connected through pipelines; the secondary drying device is composed of an air blower, a heat exchanger, an air flow drying machine and a dry material bin, which are sequentially connected through pipelines; and dried materials are conveyed into the boiler through an auger feeding machine to be incinerated. Through adoption of the system disclosed by the invention, wet garbage can be dried and then combusted, and meanwhile, thermal energy generated by garbage combustion provides a heat source for the boiler and the drying machines, so that the use is convenient, the garbage treatment cost is reduced, in addition, farmland occupation and environment pollution are avoided, ecological environment protection and physical health of human are facilitated and the system is suitable for being used by enterprises having wet garbage, especially suitable for being used by traditional Chinese medicine or food production enterprises.

Owner:周伟初

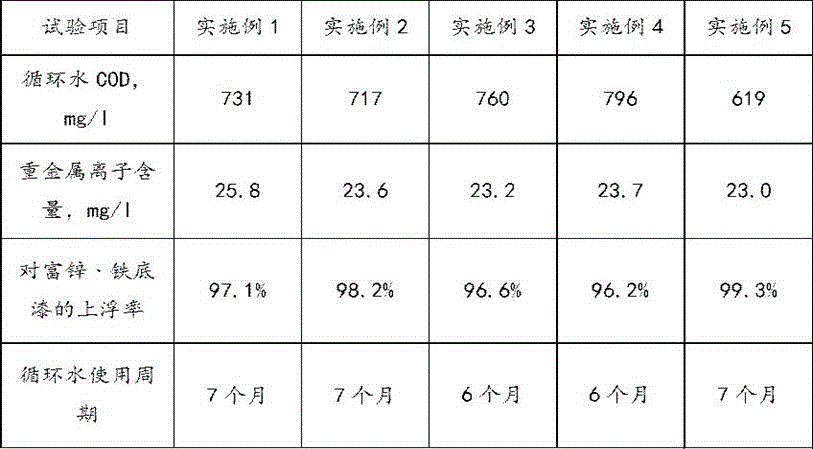

Efficient paint spraying circulation water treatment agent as well as preparation method and use method thereof

ActiveCN106630079AStrong stick breaking abilityGood flocculation and floating effectFatty/oily/floating substances removal devicesPaint waste treatmentEthylenediaminePotassium hydroxide

The invention discloses an efficient paint spraying circulation water treatment agent as well as a preparation method and a use method thereof. The paint spraying circulation water treatment agent is prepared from an agent A, an agent B, an agent C and an agent D, wherein the agent A is prepared by reacting polyacrylic acid and ammonia water; the agent B is composed of amide-based polymer and water at a weight ratio of 1: (100-120); the agent C is prepared by mixing a compound Y with a compound Z at a weight ratio of 1: 1; the compound Y is composed of polyaluminum chloride and disodium ethylenediamine tetraacetate; the compound Z is composed of sodium citrate and sodium pyrophosphate; the agent D is prepared by mixing potassium hydroxide, sorbitan fatty acid ester and water at a weight ratio of 1: (2-3): (1-2); the agent A, the agent B, the agent C and the agent D can be prepared respectively; when in use, the agent A, the agent B, the agent C and the agent D are added in sequence, wherein the weight ratio of the agent A to the agent B to the agent C to the agent D is 5: 5: 1: 1. The paint spraying circulation water treatment agent provided by the invention has strong viscosity breaking capacity and enables the paint to be completely not sticky.

Owner:HUNAN JINYU ENVIRONMENTAL PROTECTION TECH CO LTD

Monosidum glutamate industrial wastewater recycling process and device

ActiveCN103043858ARecycling hasSave waterMultistage water/sewage treatmentFood preparationChemical industryWater saving

The invention discloses a monosidum glutamate industrial wastewater recycling process and a monosidum glutamate industrial wastewater recycling device, and belongs to the field of fermentation. The water from monosidum glutamate industrial equipment is collected to a condensation water storage tank by a primary condensation water collecting pipe and then is sent to a power plant boiler for reuse after passing the water quality inspection without being discharged; the water from monosidum glutamate industrial equipment is collected to a condensation water tank by a secondary condensation water collecting pipe and then is reused for production without being discharged; and the water from monosidum glutamate industrial equipment is collected by a wastewater collecting pipe to be reused for production to cool and supplement water without being discharged. Compared with the prior art, the monosidum glutamate industrial wastewater recycling process and the monosidum glutamate industrial wastewater recycling device have the characteristics of energy conservation, water conservation, environmental friendliness and the like, are applied to fermentation, chemical industry and food, and have a good popularization and application value.

Owner:LINGHUA GROUP INCORPORATED COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com