Method for treating printing and dyeing wastewater by adopting abandoned straw

A technology for waste straw and printing and dyeing wastewater is applied in the treatment of printing and dyeing wastewater. The use of waste straw to treat printing and dyeing wastewater can solve the problems of long treatment period, low treatment efficiency and high treatment cost, and reduce the amount of waste dyes and the content of chemical substances. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

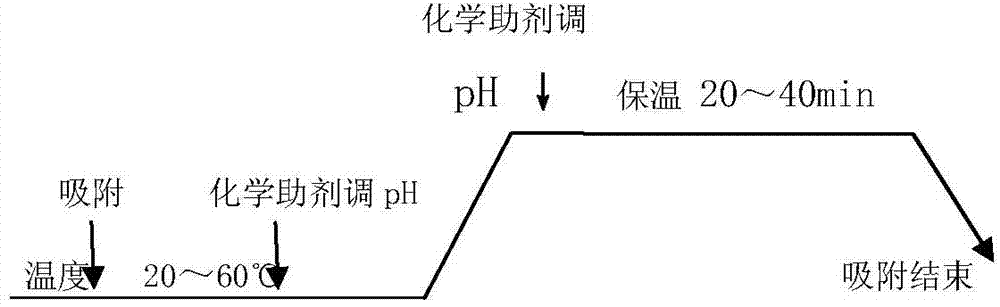

[0034] Step 1: Refer to prescription 1 to take 10g of waste straw, calculate the water consumption as 300ml according to the bath ratio of 30:1, and the amount of polysaccharide compound as 0.03g (the amount of polysaccharide compound is calculated as 0.1% of the water consumption), and then mix the polysaccharide compound with the above amount Prepare a solution with water, adjust the pH value to 8-8.5 (use NaHCO 3 、Na 2 CO 3 Adjustment), and then put the waste straw into the polysaccharide compound solution, control the temperature at 25-35° C., and the time for 30 minutes to obtain the modified waste straw.

[0035] Step 2: Take 5g of modified straw according to prescription 2, use 1% concentration of printing and dyeing wastewater, calculate the amount of printing and dyeing wastewater as 150ml according to the bath ratio of 30:1, and adjust the pH value to 8 (use NaHCO 3 、Na 2 CO 3 adjustment), put the waste straw into the printing and dyeing wastewater, control the t...

Embodiment 2

[0045] Step 1: Refer to prescription 1 to take 10g of waste straw, calculate the water consumption as 300ml according to the bath ratio of 30:1, and the amount of polysaccharide compound as 0.06g (the amount of polysaccharide compound is calculated as 0.2% of the water consumption), and then mix the polysaccharide compound and Prepare a solution with water, and adjust the pH value to 8.0-8.5 (use NaHCO 3 、Na 2 CO 3 Adjustment), and then put the waste straw into the polysaccharide compound solution, control the temperature at 25-35° C., and the time for 30 minutes to obtain the modified waste straw.

[0046] Step 2: Take 5g of modified straw according to prescription 2, use 3% concentration of printing and dyeing wastewater, calculate the amount of printing and dyeing wastewater as 150ml according to the bath ratio of 30:1, and adjust the pH value to 9 (use NaHCO3 、Na 2 CO 3 adjustment), put the waste straw into the printing and dyeing wastewater, control the temperature at ...

Embodiment 3

[0056] Step 1: Refer to prescription 1 to take 10g of waste straw, calculate the water consumption as 300ml according to the bath ratio of 30:1, and the amount of polysaccharide compound as 0.075g (the amount of polysaccharide compound is calculated as 0.25% of the water consumption), and then mix the polysaccharide compound and Prepare a solution with water, adjust the pH value to 8-8.5 (use NaHCO 3 、Na 2 CO 3 Adjustment), and then put the waste straw into the polysaccharide compound solution, control the temperature at 25-35° C., and the time for 30 minutes to obtain the modified waste straw.

[0057] Step 2: Take 5g of modified straw according to prescription 2, use 5% concentration of printing and dyeing wastewater, calculate the amount of printing and dyeing wastewater as 150ml according to the bath ratio of 30:1, and adjust the pH value to 10 (use NaHCO 3 、Na 2 CO 3 Adjustment), put the waste straw into the printing and dyeing wastewater, control the temperature at 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com