Electrodialysis and chromatography combined process for preparing xylose

A combined process and electrodialysis technology, which is applied in the field of combined electrodialysis and chromatography, can solve the problems of large amount of running sugar, waste of resources, environmental pollution, etc., and achieve the effect of increasing removal rate, reducing environmental protection pressure, and reducing COD content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

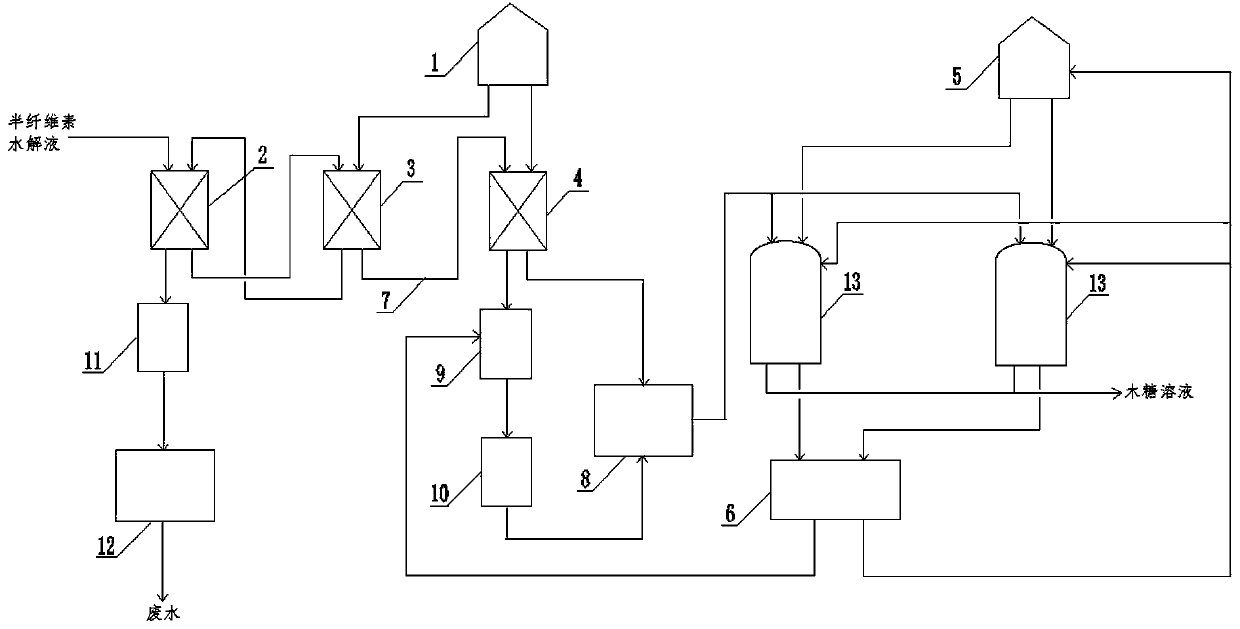

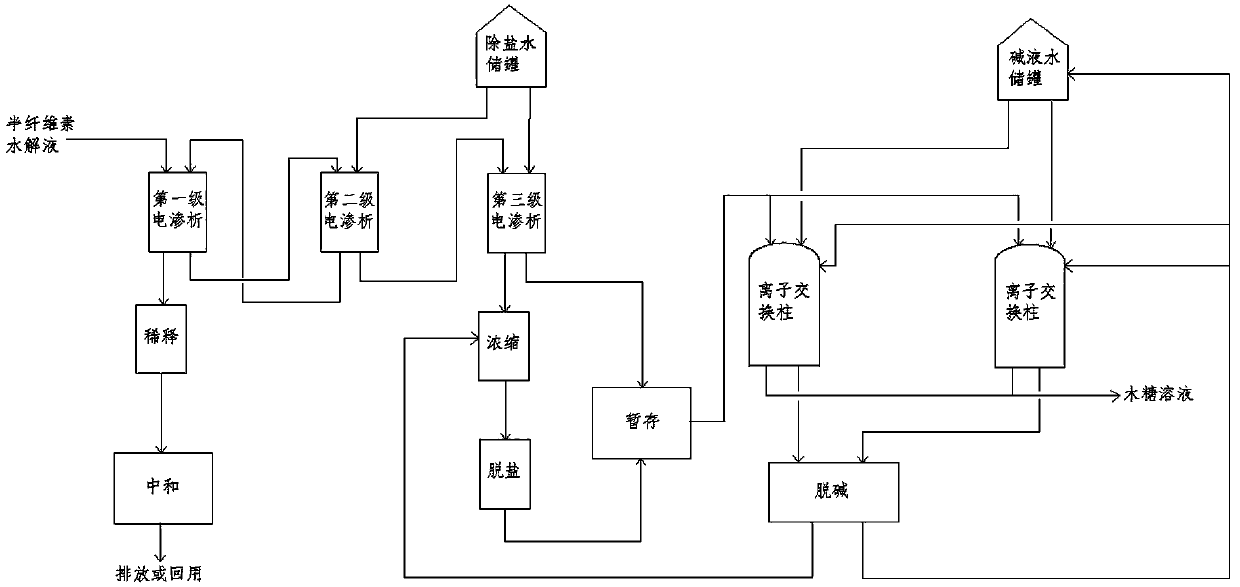

[0073] A combined electrodialysis and chromatography process for preparing xylose, comprising the steps of:

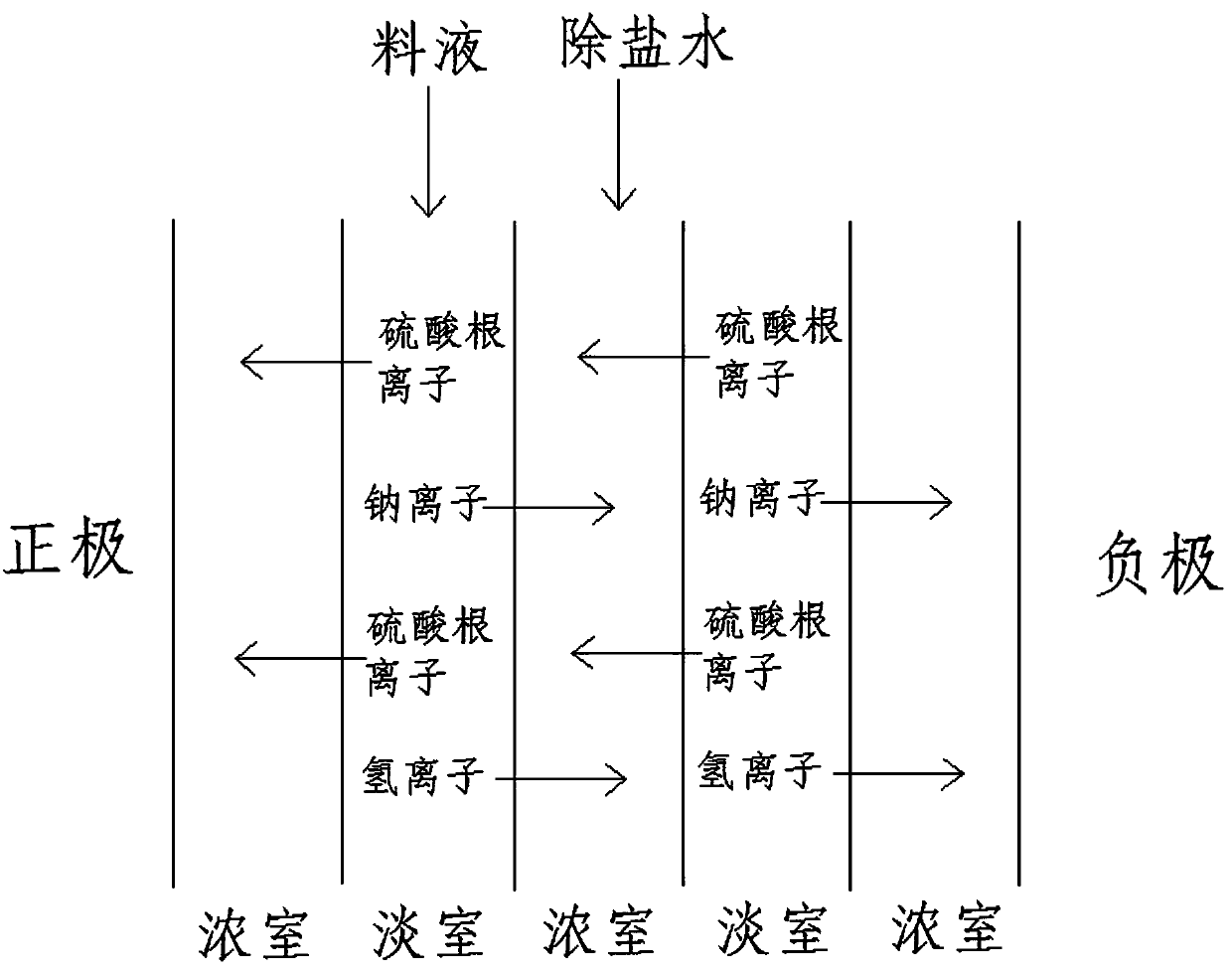

[0074] 1) First-stage electrodialysis: pass the hemicellulose hydrolyzate into the first-stage electrodialysis system, and pass through the second-stage high-salt solution (when the electrodialysis system is used for the first time, pass through demineralized water. When electrodialysis During the normal operation of the system, that is, the second-stage electrodialysis system produces the second-stage high-salt liquid, stop feeding desalted water, and switch to the second-stage high-salt liquid), and through the action of the electrodialysis membrane, the first-stage high-sugar liquid is obtained liquid and the first high-salt liquid;

[0075] 2) Second-level electrodialysis: the first-level high-sugar solution obtained in step 1) is passed into the second-level electrodialysis system, and desalted water is passed through, and the second-level high-sugar solution is o...

Embodiment 2

[0082] On the basis of embodiment 1, further:

[0083] The hemicellulose hydrolyzate refers to the hemicellulose hydrolyzate obtained by hydrolyzing hemicellulose raw materials with sulfuric acid and performing pretreatments such as filtration, decolorization and ultrafiltration by using existing mature technologies. Wherein, in the hemicellulose hydrolyzate, the xylose content is 70-90 g / L, the sodium sulfate content is 20-22 g / L, and the sulfuric acid content is 20-25 g / L.

[0084] The ion-exchange column used in step 5) refers to an ion-exchange column including an outlet conductivity>0.5ms / cm or an outlet pH<3.

Embodiment 3

[0086] On the basis of embodiment 2, further:

[0087] Further, in step 1) in the first-stage electrodialysis system, the feed flow rate of the hemicellulose hydrolyzate is 40m 3 / h, the feed flow rate of the second high-salt liquid is 15m 3 / h; the voltage is 150V, the current is 100A, and the temperature is 40°C; the first-stage high-salt liquid discharge flow rate is 15m 3 / h, the discharge flow rate of the first high-sugar liquid is 40m 3 / h;

[0088] In the second-stage electrodialysis system in step 2), the feed flow rate of the first-stage high-sugar liquid is 40m 3 / h, desalted water feed flow rate is 15m 3 / h; the voltage is 150V, the current is 100A, and the temperature is 40°C; the discharge flow rate of the second-stage high-salt liquid is 15m 3 / h, the output flow rate of the second stage high sugar liquid is 40m 3 / h;

[0089] In the third-stage electrodialysis system in step 3), the feed flow rate of the second-stage high-sugar liquid is 40m 3 / h, desalt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific rotation | aaaaa | aaaaa |

| refraction | aaaaa | aaaaa |

| refraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com